Page 1

3 Phase Voltages*

Output

Quantity/Rating

Elec at

of Contactors

No./kW

Rating Cap. Vol. 212˚F Heating

Model (BHP) (kW) (Gals.) (Lbs./Hr.)

208 240 480†

Elements

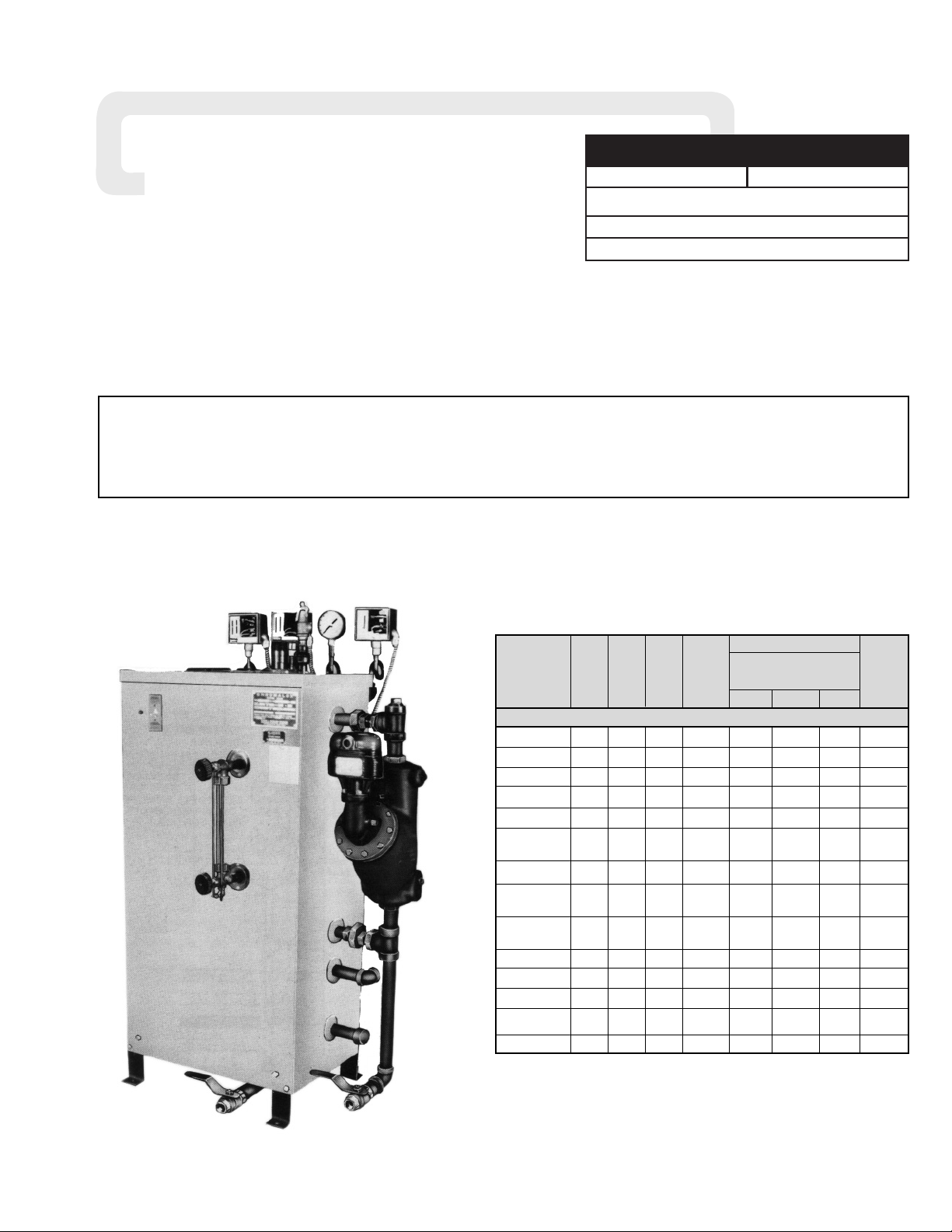

Type CHPES — 20-250 PSIG

CHPES-6A 0.6 6 6 18 30 30 30 1-6

CHPES-9A 0.9 9 6 27 30 30 30 1-9

CHPES-12A 1.22 12 6 36.2 40 30 30 1-12

CHPES-18A 1.73 17 6 51.2 50 50 30 1-17

CHPES-24A 2.45 24 14.3 72.3 2-40 2-30 2-30 2-12

1-40 1-40 1-12

CHPES-30A 2.95 29 14.3 87.4

1-50 1-30

40

1-17

CHPES-36A 3.47 34 14.3 102.5 2-50 2-50 50 2-17

1-40 1-30 1-40 1-12

CHPES-48A 4.69 46 14.3 138.7

2-50 2-50 1-30 2-17

2-50 2-30 2-12

CHPES-60A 5.91 58 14.3 174.8

2-40 2-50

2-40

2-17

CHPES-72A 6.93 68 14.3 205 4-50 4-50 2-50 4-17

CHPES-100A 10.40 102 27.8 307 6-50 6-50 3-50 6-17

CHPES-135A 13.9 136 30.5 410 — 8-50 4-50 8-17

1-30

CHPES-160A 16.1 157.5 30.5 475 — 7-60

3-60

7-22.5

CHPES-180A 18.4 180 30.5 543 — 8-60 4-60 8-22.5

Chromalox

®

DIVISION 4 SECTION

CHPES

SALES

REFERENCE

DATE

SERVICE REFERENCE

Installation, Operation

and

RENEWAL PARTS IDENTIFICATION

PQ436-1

MAY, 1999

(Supersedes PQ436)

161-562802-002

© 2010 Chromalox, Inc.

Type CHPES-6A through CHPES-180A

High Pressure Electric Steam Boiler

Standard Trim is 250 PSI — 0-225 PSI Operating Pressure Range

Boiler Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Power Circuit Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Control Circuit Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

National Board No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Amps . . . . . . . . . . . . . . . Phase . . . . . . . . . . . Cy . . . . . . . . . .

Important — This data file contains the National Board Registration Certificate for your boiler. It must be kept near the boiler at all times.

* Single phase available up to and including 24 kW capacity.

† All boilers must have separate 120V Control Circuit or Transformer.

Boilers under 40 Amps max are not fused.

Page 2

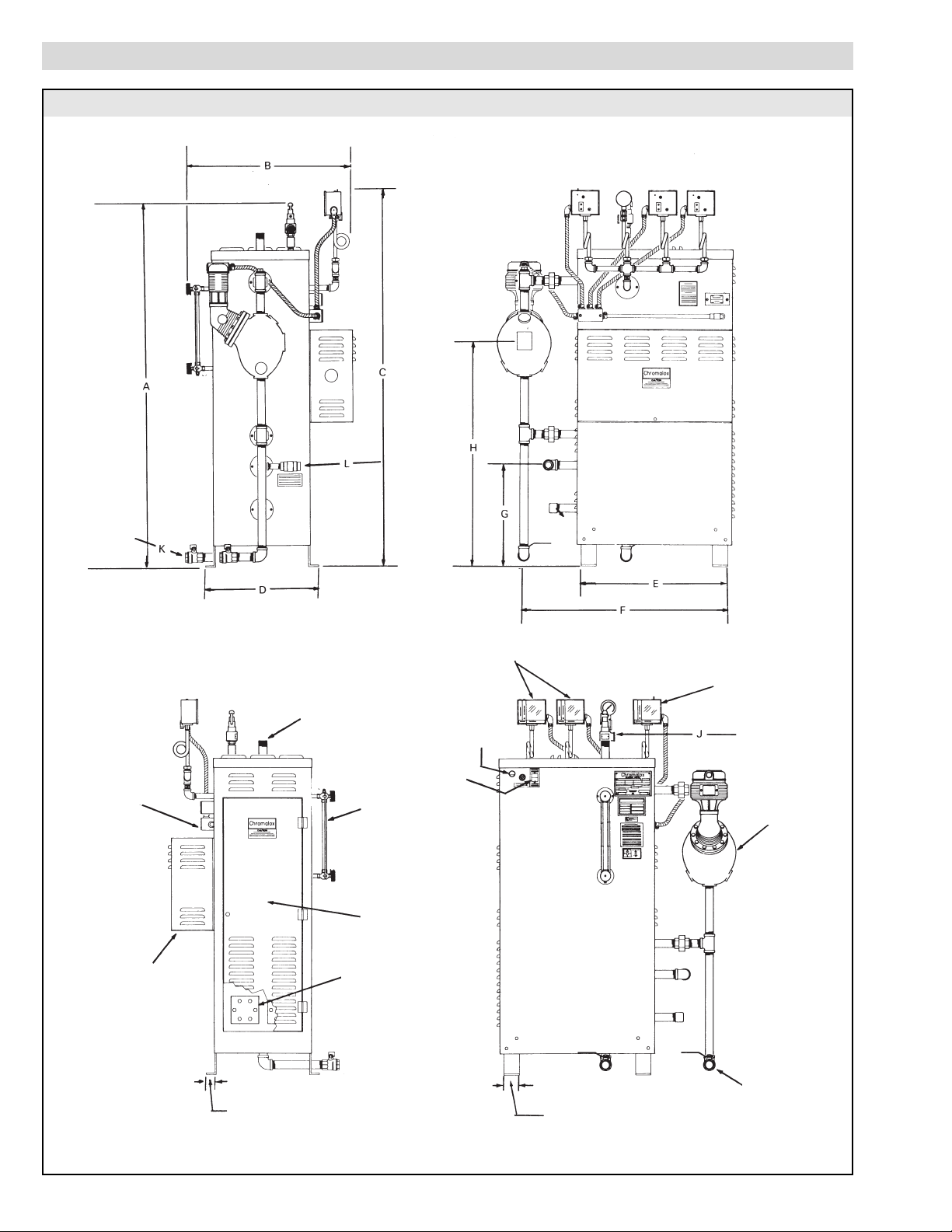

MODEL CHPES-6A through CHPES-180A

DIMENSIONS

Pump Solenoid

Connection

Conduit Box

Control Panel

Standard When

Three (3) or

More Contactors

are Used

7/16" Bolt Hole Typical

Steam Outlet

Sight Glass

Element

Element

Access Door

Operating

Pressure

Controls

Control

Circuit Fuse

Control Circuit

On/Off Switch

with Pilot Light

5/8"

7/16" Bolt Hole Typical

1-1/4"

Drain

Blowdown

Valve

McDonnell & Miller

Low Water Cutoff

Pump Control

Manual Reset

High Limit Control

Safety Valve Outlet

Drain

Blowdown

Valve

Check

Valve

2

Page 3

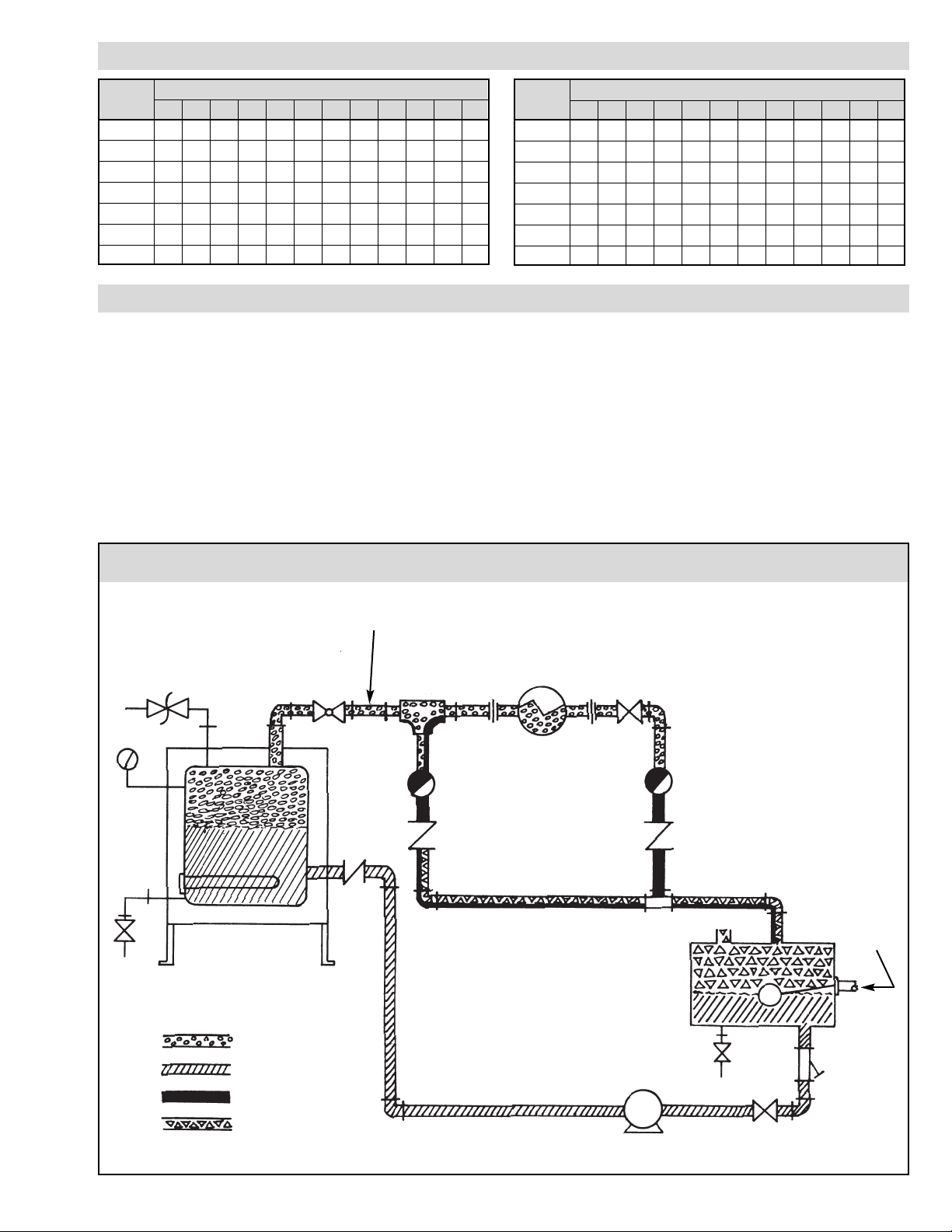

Typical Plumbing Installation of a Steam Boiler with Condensate Return System

Type CHPES — Dimensions (In.)

DIMENSIONS

INSTALLATION

Model A B* C D E F G H I J K L

CHPES-6A 37 22-1/2 30 15-1/4 20 30-1/2 9-1/2 16 1/2 1 1/2 1/2

CHPES-9A 37 22-1/2 30 15-1/4 20 30-1/2 9-1/2 16 1/2 1 1/2 1/2

CHPES-12A 37 22-1/2 30 15-1/4 20 30-1/2 9-1/2 16 1/2 1 1/2 1/2

CHPES-18A 37 22-1/2 30 15-1/4 20 30-1/2 9-1/2 16 1/2 1 1/2 1/2

CHPES-24A 43-1/2 26 46 17-1/2 23 34-1/2 16-1/2 24-1/2 1 1 1 3/4

CHPES-30A 43-1/2 26 46 17-1/2 23 34-1/2 16-1/2 24-1/2 1 1 1 3/4

CHPES-36A 43-1/2 26 46 17-1/2 23 34-1/2 16-1/2 24-1/2 1 1 1 3/4

Type CHPES — Dimensions (In.)

Model A B* C D E F G H I J K L

CHPES-48A 43-1/2 26 46 17-1/2 23 34-1/2 16-1/2 24-1/2 1 1 1 3/4

CHPES-60A 43-1/2 26 46 17-1/2 23 34-1/2 16-1/2 24-1/2 1 1 1 3/4

CHPES-72A 43-1/2 26 46 17-1/2 23 34-1/2 16-1/2 24-1/2 1 1 1 3/4

CHPES-100A 63-1/2 30 55 21 27 36 16-3/4 37-1/2 1-1/2 1-1/4 1 3/4

CHPES-135A 63-1/2 32 55 20-1/2 26 37-1/2 16 37-1/2 2 1-1/4 1 3/4

CHPES-160A 63-1/2 32 55 20-1/2 26 37-1/2 16 37-1/2 2 1-1/4 1 3/4

CHPES-180A 63-1/2 32 55 20-1/2 26 37-1/2 16 37-1/2 2 1-1/4 1 3/4

WARNING: To avoid electrical shock hazard, boilers

must be suitably grounded to earth.

1. The boiler should be mounted on a solid level foundation. Note:

When installing boiler, allow sufficient room (21” minimum) to

facilitate removal of elements if and when necessary.

2. WARNING: A minimum distance of 18” between boil-

er and any combustible material must be maintained.

3. Complete all piping to boiler. Connect water line to tagged fitting

on the motor and pump assembly, if used, or to tagged fitting on

water control feeder.

4. When any type of feed other than a pump feed is used — the existing water supply must be 10 pounds greater than the boiler operating pressure to assure water supply maintains proper water level in

boiler. Otherwise, lack of water can cause heater failure. Keep feed

water line valves open at all times except during blowdown.

5. All water feed systems are connected to water inlet check valve.

6. Connect steam line (with Globe valve) to boiler steam outlet.

Valve should be placed as close as possible to boiler outlet and

sized per label on boiler.

7. To insure maximum efficiency of supplied kW, all piping from

outlet should be insulated.

8. Drain and relief valve piping should be in accordance with state

and local codes. Floor drain to be provided directly below unit.

9. All electrical wiring should be done by licensed electrician in

accordance with national and local electrical codes.

10. If pump is located less than 30 feet from boiler, a second

check valve is required.

Vacuum

Breaker

Safety

Valve

Drain

Boiler

Check

Valve

Check

Valve

Check

Valve

Globe

Valve

Gate

Valve

Heat

Exchanger

Water/Steam

Separator

Insulated Steam Lines

(Pitch Down 5˚)

Pitch Down 5˚

Vent

Condensate

Return

Drain

Gate

Valve

Strainer

Return

Cold Water

Make-Up

Centrifugal

Turbine Pump

Steam

Water

Condensate

Vapor

(Typical

Load)

Trap

Trap

3

*Add two inches for transformer.

Page 4

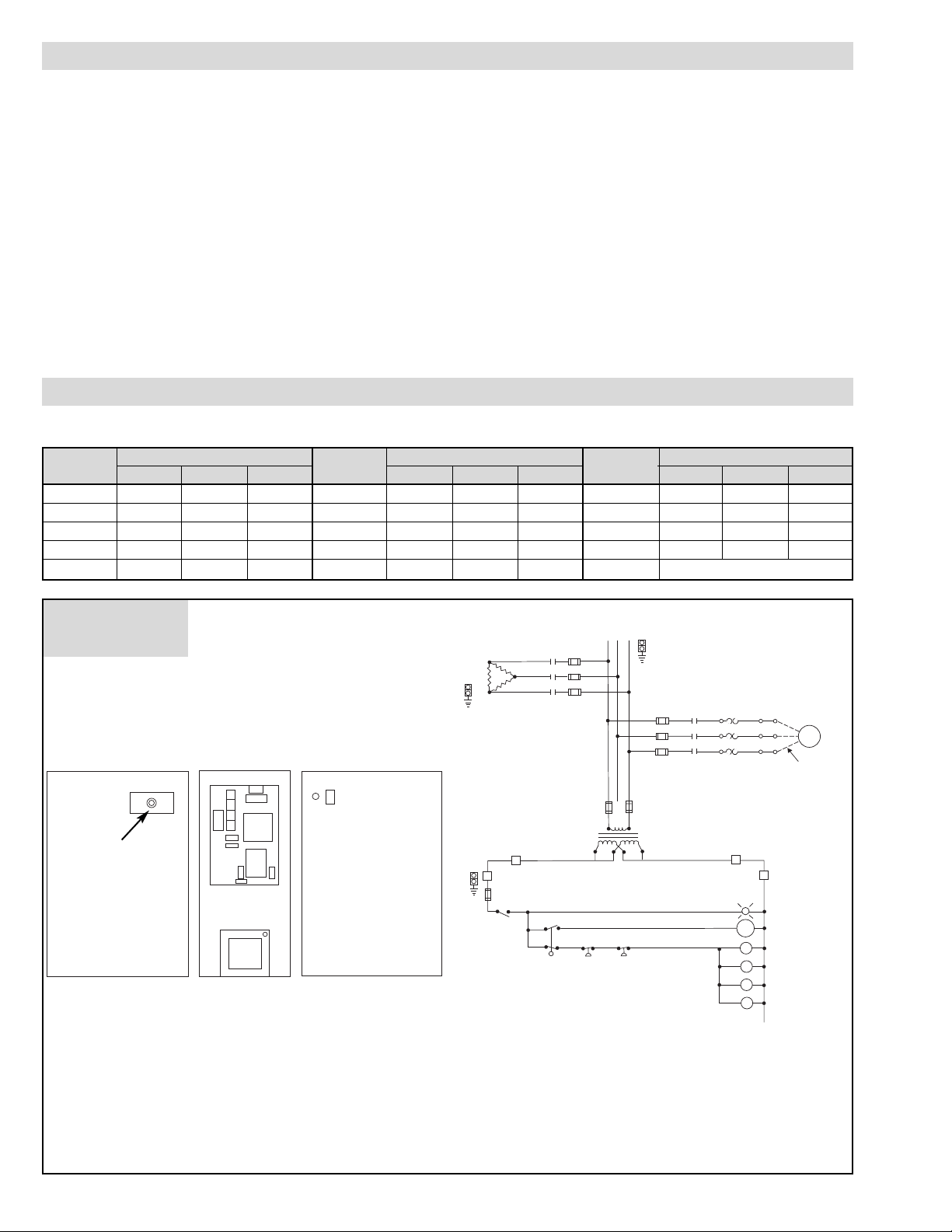

Diagram 1

3 Phase Voltage 3 Phase Voltage 3 Phase Voltage

Boiler 208 240 480 Boiler 208 240 480 Boiler 208 240 480

WIRING

TYPICAL WIRING DIAGRAMS

WARNING: Hazard of Shock. Disconnect all power

before working on boiler. Boilers must be effectively

grounded in accordance with the National Electrical

Code to eliminate shock hazard.

WARNING: Use 90˚copper conductors only.

1. Select proper wire gauge and type for supply conductors in accor-

dance with the National Electrical Code and local wiring codes following wiring diagram supplied (See recommendations for disconnect switches and fusing).

2. The unit is completely wired and pre-tested before shipment. No

internal wiring is required. Check all electrical connections for

tightness and retighten if necessary before energizing.

If a separate control circuit is used, the control circuit should be

connected to the control terminal block, inside access door (not

required with transformer).

3. Safety Switches — WARNING: Purchaser should use a

safety switch employing circuit breakers or fuses

between his main power source and the boiler.

4. Because of their water lines, boilers are susceptible to lightning

damage. Industrial type lightning protectors should be installed per

manufacturer’s recommendations at your service entrance. Check

your contractor or electrical dealer for recommended type for your

system.

5. Be sure all electrical connections are sufficiently tightened.

6. WARNING: Substitution of components or modifica-

tion of wiring system voids the warranty and may

lead to dangerous operating conditions.

7. SPECIAL INSTRUCTIONS FOR CUSTOMERS SUPPLYING THEIR OWN CONDENSATE OR PUMP SYSTEMS.

A. Check the voltage of the motor before making the wiring con-

nection. Some Chromalox boilers are supplied with dual voltage systems. The motor should always match the voltage of the

control circuit.

B. The motor circuit should be wired into the pump control as

shown in wiring diagram (float type pump control). If boiler is

equipped with solid state pump control, refer to wiring diagram

and use terminals 5 and 2.

Use Applicable wiring diagrams based on model number and power voltage.

CHPES-6A 1 1 1 CHPES-30A 2 2 3 CHPES-100A 8 8 9

CHPES-9A 1 1 1 CHPES-36A 2 2 3 CHPES-135A 10 11

CHPES-12A 1 1 1 CHPES-48A 4 4 5 CHPES-160A 12 12

CHPES-18A 1 1 1 CHPES-60A 6 6 7 CHPES-180A 10 10

CHPES-24A 2 2 3 CHPES-72A 6 6 7 Export 14

2PS

BR

Heater

Contactors

Feed Water

Boiler On

3

GND

B

FU9

B

1PB

Off

1

GND

1

GND

1 HTR

C1

FU1

FU2

FU3

FU8

FU7

H1

H2

X1

X3

L3

1L1

1L3

1L2

L2L1

X2

X4

Optional Transformer

1

1

C1

2

2

C4

C3

C2

R

1LT

Y

On

IFS

O

1PS

O

O

W

Feed Water

Electrical

Connection

21

1TB

123

3

GND

1

GND

2

GND

1

HTR

FU9

FU

1PB

Cabinet Exterior Left Side Cabinet Exterior Right Side

Panel Layout

CR

FU4

FU5

FU6

2L1

2L3

2L2

1

Mtr

Customer

Connect

Feed Water

Motor

10L

30L

20L

IT1

IT3

IT2

CR

Wire Color Code

B = Black

BR = Brown

R = Red

O = Orange

Y = Yellow

G = Green

BL = Blue

W = White

* Boilers under 40 Amps total (not fused)

4

Page 5

Diagram 2

TYPICAL WIRING DIAGRAMS

2PS

BR

Heater

Contactors

Feed Water

Boiler On

3

GND

B

FU12

B

1PB

Off

2

GND

1

GND

1 HTR

C1

FU1

FU2

FU3

FU11

FU10

H1

H2

X1

X3

L3

1L1

1L3

1L2

L2L1

X2 X4

Optional Transformer

1

1

C1

2

2

C2

R

1LT

Y

On

IFS

O

1PS

O

O

W

Feed Water

Electrical

Connection

2

1

2TB

2 GND

1

HTR

FU12

1PB

Cabinet Exterior Left Side Cabinet Exterior Right Side

Panel Layout

2

HTR

C1

FU

1 2 3

C2

FU

4 5 6

1TB

1 GND

3

GND

H4

H3

2 HTR

C2

FU4

FU5

FU6

2L1

2L3

2L2

CR

FU7

FU8

FU9

3L1

3L3

3L2

1

Mtr

Customer

Connect

Feed Water

Motor

10L

30L

20L

IT1

IT3

IT2

CR

Wire Color Code

B = Black

BR = Brown

R = Red

O = Orange

Y = Yellow

G = Green

BL = Blue

W = White

Diagram 3

2PS

BR

Heater

Contactor

Feed Water

Boiler On

3

GND

B

FU9

B

1PB

Off

1

GND

1 HTR

C1

FU1

FU2

FU3

FU8FU7

H1

H2

X1

X3

L3

1L1

1L3

1L2

L2L1

X2 X4

Optional Transformer

1

1

C1

2

2

R

1LT

Y

On

IFS

O

1PS

O

O

W

Feed Water

Electrical

Connection

2

1

2TB

2 GND

1

HTR

FU9

1PB

Cabinet Exterior Left Side Cabinet Exterior Right Side

Panel Layout

2

HTR

C1

FU

1 2 3

1 GND

3 GND

H4

H3

2 HTR

2L1

2L3

2L2

2

GND

CR

FU4

FU5

FU6

3L1

3L3

3L2

1

Mtr

Customer

Connect

Feed Water

Motor

10L

30L

20L

IT1

IT3

IT2

CR

Wire Color Code

B = Black

BR = Brown

R = Red

O = Orange

Y = Yellow

G = Green

BL = Blue

W = White

* Boilers under 40 Amps total (not fused)

5

Page 6

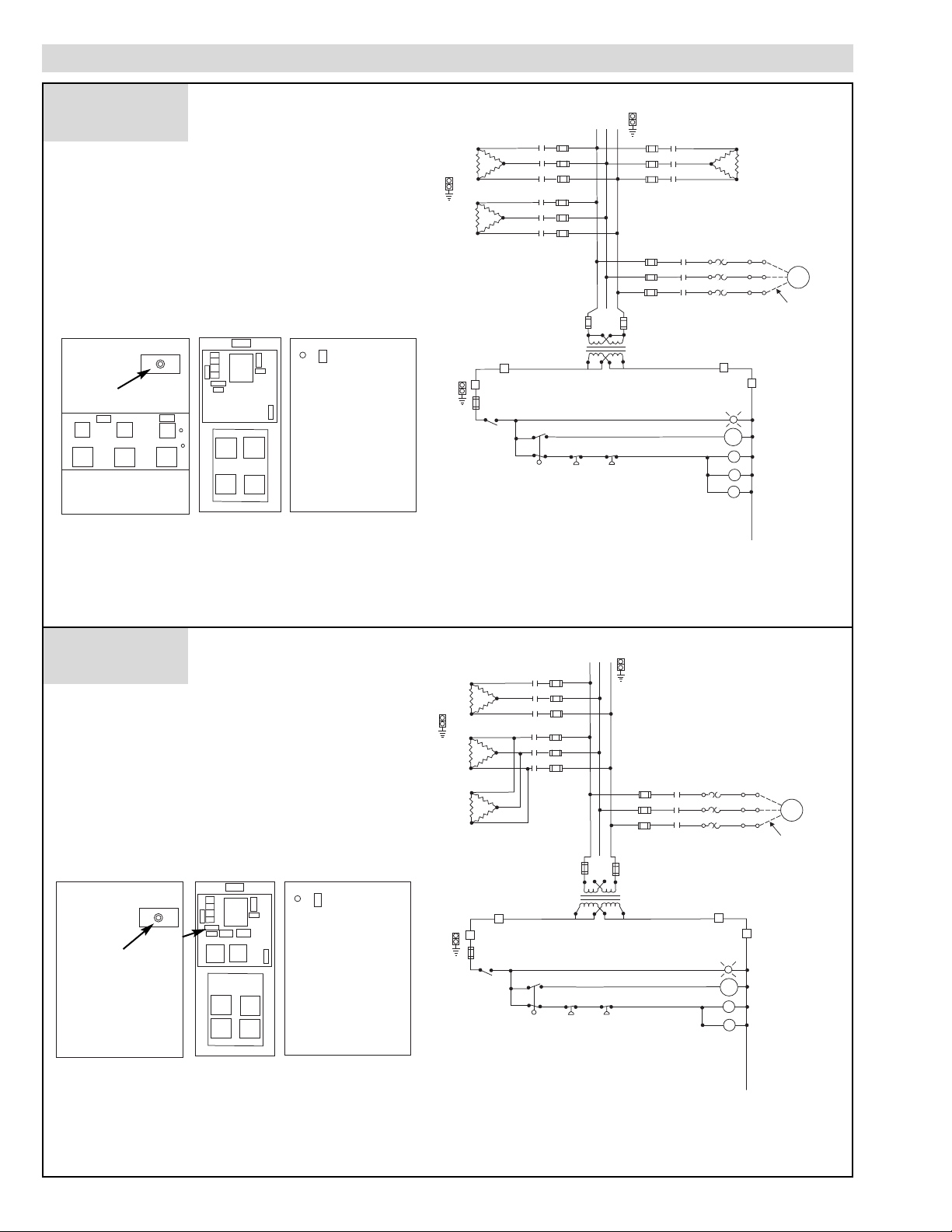

Diagram 4

TYPICAL WIRING DIAGRAMS

2PS

BR

Heater

Contactor

Feed Water

Boiler On

3

GND

B

FU15

B

1PB

Off

2

GND

1

GND

1 HTR

C1

FU1

FU2

FU3

FU14

FU13

H1

H2

X1

X3

L3

1L1

1L3

1L2

L2L1

X2

X4

Optional Transformer

1

1

C1

2

2

C2

R

1LT

Y

On

IFS

O

1PS

O

O

W

Feed Water

Electrical

Connection

2

1

2TB

2 GND

1 GND

2 GND

1

HTR

FU15

1PB

Cabinet Exterior Left Side Cabinet Exterior Right Side

Panel Layout

2

HTR

3

Htr

1TB

3

GND

H4

H3

2 HTR

C2

FU4

FU5

FU6

2L1

2L3

2L2

FU

1 2 3

FU

4 5 6

FU

7 8 9

C1

C3

C2

FU7

FU8

FU9

C3

3L1

1L3

3L2

3 HTR

C3

Heater

Contactor

CR

FU10

FU11

FU12

4L1

4L3

4L2

1

Mtr

Customer

Connect

Feed Water

Motor

10L

30L

20L

IT1

IT3

IT2

CR

Wire Color Code

B = Black

BR = Brown

R = Red

O = Orange

Y = Yellow

G = Green

BL = Blue

W = White

Diagram 5

2PS

BR

Heater

Contactors

Feed Water

Boiler On

3

GND

B

FU12

B

1PB

Off

2

GND

1

GND

1 HTR

C1

FU1

FU2

FU3

FU11

FU10

H1

H2

X1

X3

L3

1L1

1L3

1L2

L2L1

X2

X4

Optional Transformer

1

1

C1

2

2

C2

R

1LT

Y

On

IFS

O

1PS

O

O

W

Feed Water

Electrical

Connection

2

1

2TB

2 GND

1

HTR

FU12

1PB

Cabinet Exterior Left Side Cabinet Exterior Right Side

Panel Layout

2

HTR

C2

FU

4 5 6

1TB

1 GND

3

GND

H4

H3

2 HTR

C2

FU4

FU5

FU6

2L1

2L3

2L2

C1

FU

1 2 3

3

HTR

3 HTR

3L1

3L3

3L2

CR

FU7

FU8

FU9

4L1

4L3

4L2

1

Mtr

Customer

Connect

Feed Water

Motor

10L

30L

20L

IT1

IT3

IT2

CR

Wire Color Code

B = Black

BR = Brown

R = Red

O = Orange

Y = Yellow

G = Green

BL = Blue

W = White

6

Page 7

Diagram 6

TYPICAL WIRING DIAGRAMS

2PS

BR

Heater

Contactors

Feed Water

Boiler On

3

GND

B

FU18

B

1PB

Off

2

GND

1

GND

1 HTR

C1

FU1

FU2

FU3

FU17

FU16

H1

X1

X3

L3

1L1

1L3

1L2

L2L1

X2

X4

Optional Transformer

1

1

C1

2

2

C2

R

1LT

Y

On

IFS

O

1PS

O

O

W

Feed Water

Electrical

Connection

2

1

2TB

1 GND

2 GND

1

HTR

FU18

1PB

Cabinet Exterior Left Side Cabinet Exterior Right Side

Panel Layout

2

HTR

3

Htr

1TB

3

GND

H2

2 HTR

C2

FU4

FU5

FU6

2L1

2L3

2L2

FU

1 2 3

FU

4 5 6

FU

7 8 9

C1

C3

C2

FU7

FU8

FU9

C3

3L1

1L3

3L2

3 HTR

C3

C4

FU

10

11 12

4

Htr

FU10

FU11

FU12

C4

4L1

4L3

4L2

4 HTR

C4

CR

FU13

FU14

FU15

5L1

5L3

5L2

1

Mtr

Customer

Connect

Feed Water

Motor

10L

30L

20L

IT1

IT3

IT2

CR

Wire Color Code

B = Black

BR = Brown

R = Red

O = Orange

Y = Yellow

G = Green

BL = Blue

W = White

Diagram 7

2PS

BR

Heater

Contactors

Feed Water

Boiler On

3

GND

B

FU12

B

1PB

Off

1 HTR

C1

FU1

FU2

FU3

FU11

FU10

H1

H2

X1

X3

L3

1L1

1L3

1L2

L2L1

X2 X4

Optional Transformer

1

1

C1

2

2

R

1LT

Y

On

IFS

O

1PS

O

O

W

Feed Water

Electrical

Connection

2

1

2TB

2 GND

1

HTR

FU12

1PB

Cabinet Exterior Left Side Cabinet Exterior Right Side

Panel Layout

2

HTR

FU

1 2 3

1 GND

3

GND

H4

H3

3 HTR

3L1

3L3

3L2

2

GND

3

HTR

4

HTR

C1

C2

FU

4 5 6

1TB

C2

FU4

FU5

FU6

1

GND

2 HTR

2L1

2L3

2L2

4 HTR

4L1

4L3

4L2

C2

CR

FU7

FU8

FU9

5L1

5L3

5L2

1

Mtr

Customer

Connect

Feed Water

Motor

10L

30L

20L

IT1

IT3

IT2

CR

Wire Color Code

B = Black

BR = Brown

R = Red

O = Orange

Y = Yellow

G = Green

BL = Blue

W = White

7

Page 8

Diagram 8

TYPICAL WIRING DIAGRAMS

FU

1 2 3

FU

4 5 6

FU

7 8 9

C1 C3

C2

C4

FU

10

11 12

C5

FU

13

14 15

C6

FU

16

17 18

5

HTR

4

HTR

3

HTR

6

HTR

2

HTR

1

HTR

1

2

2TB

1TB

3 GND

2

GND

1

GND

FU24

1PB

3

GND

C2

C6

C5

C4

C3

2PS

3PS

1PS

On

Off

FU24

IFS

O

O

O

Y

BR

B

B

1PB

1

1

2

2

W

R

Boiler

On

Feed Water

Heater Contactor

Heater Contactor

Heater Contactor

Heater Contactor

Heater Contactor

Heater Contactor

1LT

Optional Transformer

X1 X4

X2

X3

FU22

FU23

2 HTR

3 HTR

1 HTR

1L1

1L3

1L2

2L1

2L3

2L2

3L1

3L3

3L2

4 HTR

4L1

4L3

4L2

C1

C4

C3

C2

FU1

FU18

FU17

FU16

FU15

FU14

FU13

FU12

FU11

FU10

FU9

FU8

FU7

FU6

FU5

FU4

FU3

FU2

C6

C5

5 HTR

6 HTR

5L1

6L3

6L2

6L1

5L3

5L2

L1

L3

L2

1

GND

2

GND

Cabinet Exterior Left Side Cabinet Exterior Right Side

Panel Layout

Feed Water

Electrical

Connection

CR

FU19

FU20

FU21

7L1

7L3

7L2

1

Mtr

Customer

Connect

Feed Water

Motor

10L

30L

20L

IT1

IT3

IT2

CR

C1

Wire Color Code

B = Black

BR = Brown

R = Red

O = Orange

Y = Yellow

G = Green

BL = Blue

W = White

Diagram 9

FU

1 2 3

FU

4 5 6

FU

7 8 9

C1 C3

C2

5

HTR

4

HTR

3

HTR

6

HTR

2

HTR

1

HTR

1

2

2TB

1TB

3 GND

2

GND

1 GND

FU15

1PB

3

GND

C1

C2

C3

3PS

1PS

On

Off

FU15

IFS

O

O

O

Y

BR

B

B

1PB

1

1

2

2

W

R

Boiler

On

Feed Water

Heater Contactor

Heater Contactor

Heater Contactor

1LT

Optional Transformer

X1

X4X2

X3

C1

C2

FU1

FU9

FU8

FU7

FU6

FU5

FU4

FU3

FU2

C3

5 HTR

6 HTR

5L1

6L3

6L2

6L1

5L3

5L2

1

GND

Cabinet Exterior Left Side Cabinet Exterior Right Side

Panel Layout

Feed Water

Electrical

Connection

2PS

H1

H4

H2

H3

FU13

FU14

2 HTR

3 HTR

1 HTR

1L1

1L3

1L2

2L1

2L3

2L2

3L1

3L3

3L2

4 HTR

4L1

4L3

4L2

2

GND

L1

L2

L3

CR

FU10

FU11

FU12

7L1

7L3

7L2

1

Mtr

Customer

Connect

Feed Water

Motor

10L

30L

20L

IT1

IT3

IT2

CR

Wire Color Code

B = Black

BR = Brown

R = Red

O = Orange

Y = Yellow

G = Green

BL = Blue

W = White

8

Page 9

Diagram 10

TYPICAL WIRING DIAGRAMS

13

14 15

16

17 18

19

20 21

C5 C7

C6

C1

1 2 3C24 5 6C37 8 9

5

HTR

4

HTR

3

HTR

6

HTR

2

HTR

1

HTR

1

2

2TB

1TB

3 GND

2

GND

1

GND

FU30

1PB

3

GND

C1

C2

C6

C3

2PS

3PS

1PS

On

Off

FU30

IFS

O

O

O

Y

BR

B

B

1PB

1

1

2

2

W

R

Boiler

On

Feed Water

Heater Contactor

1LT

Optional Transformer

X1

X4X2

X3

FU28 FU29

2 HTR

3 HTR

1 HTR

1L1

1L3

1L2

2L1

2L3

2L2

3L1

3L3

3L2

4 HTR

4L1

4L3

4L2

C1

C4

C3

C2

FU1

FU18

FU17

FU16

FU15

FU14

FU13

FU12

FU11

FU10

FU9

FU8

FU7

FU6

FU5

FU4

FU3

FU2

C6

C5

5 HTR

6 HTR

5L1

6L3

6L2

6L1

5L3

5L2

L1

L3

L2

1

GND

2

GND

Cabinet Exterior Left Side Cabinet Exterior Right Side

Panel Layout

Feed Water

Electrical

Connection

22

23 24

C4

7

HTR

8

HTR

10

11 12

C8

C8

C4

Heater Contactor

H1 H4

H2

H3

FU24

FU23

FU22

FU21

FU20

FU13

C8

C7

7 HTR

6 HTR

7L1

8L3

8L2

8L1

5L3

7L2

C5

C7

CR

FU25

FU26

FU27

9L1

9L3

9L2

1

Mtr

Customer

Connect

Feed Water

Motor

10L

30L

20L

IT1

IT3

IT2

CR

Wire Color Code

B = Black

BR = Brown

R = Red

O = Orange

Y = Yellow

G = Green

BL = Blue

W = White

Diagram 11

FU

1 2 3

FU

4 5 6

FU

7 8 9

C1 C3

C2

5

HTR

4

HTR

3

HTR

6

HTR

2

HTR

1

HTR

1

2

2TB

1TB

3 GND

2

GND

1 GND

FU18

1PB

3

GND

C1

C2

C3

3PS

1PS

On

Off

FU18

IFS

O

O

O

Y

BR

B

B

1PB

1

1

2

2

W

R

Boiler

On

Feed Water

Heater Contactor

Heater Contactor

1LT

Optional Transformer

X1

X4X2

X3

C1

C2

FU1

FU9

FU8

FU7

FU6

FU5

FU4

FU3

FU2

C3

5 HTR

6 HTR

5L1

6L3

6L2

6L1

5L3

5L2

1

GND

Cabinet Exterior Left Side Cabinet Exterior Right Side

Panel Layout

Feed Water

Electrical

Connection

2PS

H1

H4

H2H3

FU16

FU17

2 HTR

3 HTR

1 HTR

1L1

1L3

1L2

2L1

2L3

2L2

3L1

3L3

3L2

4 HTR

4L1

4L3

4L2

2

GND

L1

L2

L3

FU

10

11 12

C4

7HTR 8

HTR

C4

FU12

FU11

FU10

C4

7 HTR

8 HTR

5L1

8L3

8L2

8L1

5L3

7L2

CR

FU13

FU14

FU15

9L1

9L3

9L2

1

Mtr

Customer

Connect

Feed Water

Motor

10L

30L

20L

IT1

IT3

IT2

CR

Wire Color Code

B = Black

BR = Brown

R = Red

O = Orange

Y = Yellow

G = Green

BL = Blue

W = White

9

Page 10

Diagram 12

TYPICAL WIRING DIAGRAMS

FU

13

14 15

FU

16

17 18

FU

19

20 21

C5 C7

C6

C1

1 2 3C24 5 6C37 8 9

5

HTR

4

HTR

3

HTR

6

HTR

2

HTR

1

HTR

1

2

2TB

1TB

3 GND

2

GND

1

GND

FU27

1PB

3

GND

C1

C2

C5

C3

2PS

3PS

1PS

On

Off

FU27

IFS

O

O

O

Y

BR

B

B

1PB

1

1

2

2

W

R

Boiler

On

Feed Water

Heater Contactor

1LT

Optional Transformer

X1 X4

X2

X3

FU25 FU26

2 HTR

3 HTR

1 HTR

1L1

1L3

1L2

2L1

2L3

2L2

3L1

3L3

3L2

4 HTR

4L1

4L3

4L2

C1

C4

C3

C2

FU1

FU18

FU17

FU16

FU15

FU14

FU13

FU12

FU11

FU10

FU9

FU8

FU7

FU6

FU5

FU4

FU3

FU2

C6

C5

5 HTR

6 HTR

5L1

6L3

6L2

6L1

5L3

5L2

L1

L3

L2

1

GND

2

GND

Cabinet Exterior Left Side Cabinet Exterior Right Side

Panel Layout

Feed Water

Electrical

Connection

C4

7

HTR

FU

10

11 12

C4

Heater Contactor

H1 H4

H2

H3

FU21

FU20

FU19

C7

7 HTR

7L1

5L3

7L2

FU

FU

FU

C7

C6

Heater Contactor

Heater Contactor

Heater Contactor

Heater Contactor

Heater Contactor

CR

FU22

FU23

FU24

8L1

8L3

8L2

1

Mtr

Customer

Connect

Feed Water

Motor

10L

30L

20L

IT1

IT3

IT2

CR

Wire Color Code

B = Black

BR = Brown

R = Red

O = Orange

Y = Yellow

G = Green

BL = Blue

W = White

Diagram 13

FU

1 2 3

FU

4 5 6

FU

7 8 9

C1

C4

C2

5

HTR

4

HTR

3

HTR

6

HTR

2

HTR

1

HTR

1

2

2TB

1TB

3 GND

2

GND

1

GND

FU18

1PB

3

GND

C1

C2

C3

2PS

3PS

1PS

On

Off

FU18

IFS

O

O

O

Y

BR

B

B

1PB

1

1

2

2

W

R

Boiler

On

Feed Water

Heater Contactor

1LT

Optional Transformer

X1 X4

X2

X3

FU16 FU17

2 HTR

3 HTR

1 HTR

1L1

1L3

1L2

2L1

2L3

2L2

3L1

3L3

3L2

4 HTR

4L1

4L3

4L2

C1

C2

FU1

FU9

FU8

FU7

FU6

FU5

FU4

FU3

FU2

C3

5 HTR

6 HTR

5L1

6L3

6L2

6L1

5L3

5L2

L1

L3

L2

1

GND

2

GND

Cabinet Exterior Left Side Cabinet Exterior Right Side

Panel Layout

Feed Water

Electrical

Connection

7

HTR

FU

10

11 12

C4

Heater Contactor

H1

H4

H3

H2

FU12

FU11

FU10

C4

7 HTR

7L1

5L3

7L2

Heater Contactor

Heater Contactor

C3

CR

FU13

FU14

FU15

8L1

8L3

8L2

1

Mtr

Customer

Connect

Feed Water

Motor

10L

30L

20L

IT1

IT3

IT2

CR

Wire Color Code

B = Black

BR = Brown

R = Red

O = Orange

Y = Yellow

G = Green

BL = Blue

W = White

10

Page 11

After proper wiring and piping of boiler system is complete, testing of

controls can start. Before testing controls, it is recommended that

all contactor fusing be removed. This is to prevent possible element

failure under test conditions.

A. OPERATING AND TESTING THE McDONNELL &

MILLER LOW WATER CUTOFF CONTROL.

1. Be sure all valves from incoming water supply are fully open.

Turn boiler switch to “ON” position, pump or solenoid

valve will energize, allowing boiler to fill with water. Proper

water level is automatically reached with level control supplied. Pump or solenoid feed will shut off at proper water level.

Contactor(s) will energize, supplying power voltage to elements.

2. Checking operation of pump switch. (Figure 1) With water

level visible in sight glass, partially open drain valve at bottom

of boiler. If automatic blowdown supplied, push manual blowdown switch until valve open light is on, hold for few seconds.

Water level will fall, allowing float to trip pump switch to

“ON” position. Close drain valve or release manual blowdown

switch.

Pump motor or solenoid valve will energize and water level

will resume to normal level in sight glass.

3. Checking low water cutout switch operation, open drain

valve completely. If automatic blowdown supplied, push in

and hold manual blowdown switch until water level falls

enough to trip cutout switch. Close drain valve or release manual blowdown switch. If low water cutout is automatic reset,

pump or solenoid will return water level to normal. If low

water cutout is manual reset, then manual reset button on

McDonnell & Miller low water cutoff control must be pushed

to complete circuit. Turn off boiler. Reinstall contactor

fuses.

WARNING: Be sure all electrical connections are tight

before energizing boiler. Reset all manual reset controls by pushing reset buttons on: (1) high limit control

located on top of boiler and (2) McDonnell & Miller

located on the side of boiler.

Diagram 14

TYPICAL WIRING DIAGRAMS

3

GND

C1

CR

C2

C3

2PS

1PS

On

Off

FU16

IFS

O

O

Y

BR

B

B

1PB

1

2

W

R

Boiler

On

9.9

Heater Contactor

1LT

2 HTR

1 HTR

1L1

1L3

1L2

2L1

2L3

2L2

C1

C2

FU1

FU9

FU8

FU7

FU6

FU5

FU4

FU3

FU2

C3

3 HTR

3L1

3L3

3L2

L1

L3

L2

1

GND

2

GND

Heater Contactor

FU12

FU11

FU10

C4

4 HTR

4L1

4L3

4L2

Heater Contactor

Heater Contactor

346V 3Ø 50 HZ

220 VAC Single Phase Control Circuit

1

C4

1CR-1

BW

1CR-2

Customer Pump

Connection

FU

1 2 3

FU

4 5 6

FU

7 8 9

C1

C4

C2

3

HTR

2

HTR

1

HTR

4

HTR

1

2

2TB

1TB

3

GND

2

GND

1

GND

FU16

1PB

Cabinet Exterior Left Side Cabinet Exterior Right Side

Panel Layout

Feed Water

Electrical

Connection

FU

10

11 12

C3

1CR

FU13

FU14

FU15

5L1

5L3

5L2

1

Mtr

Customer

Connect

Feed Water

Motor

10L

30L

20L

IT1

IT3

IT2

CR

Wire Color Code

B = Black

BR = Brown

R = Red

O = Orange

Y = Yellow

G = Green

BL = Blue

W = White

11

A

C

D

B

Line

Pump

Low-Water

Cut-Off

Terminals

Alarm

Circuit

Terminals

Pump

Circuit

Terminals

Pump

Switch

Cut-off

and

Alarm

Switch

Adjusting

Screws

Figure 1 — Automatic Reset Low-Water Cutoff Junction Box

PRE-OPERATION CHECK

Page 12

B. ADJUSTING OPERATING PRESSURE CONTROLS

1. Chromalox boilers are supplied with operating and high limit pres-

sure controls. One is used for controlling the operating pressure of

the boiler while the other is used as a high limit control. To determine the difference in the controls, the high limit has a manual reset

lever on top of the case. Also, there is no differential scale present.

2. On all controls, the pressure adjusting screw on the top of the case

sets the desired pressure. Turning the screw counterclockwise

reduces the pressure setting (CUT OUT) (See Figure 2). High limit

control should be set at 10 psig above the operating pressure of the

boiler.

3. The differential adjusting screw on the operating control is set in the

same manner as the pressure adjusting screw. The CUT OUT setting minus the differential setting, equals CUT IN pressure of the

operating control.

To check operation of the controls, close steam outlet valve and adjust

operating pressure control to a low pressure setting. Also, set high limit

control at 10 psig above operating pressure control. Turn on boiler, and

allow pressure to build up. When pressure gauge reading approaches

set point of pressure control, the switch will trip and shut off boiler.

Turn off boiler.

To reset pressure control, bleed off enough pressure in the boiler by

opening steam outlet drain, or blowdown valve to allow the operating

control to reset.

4. HIGH LIMIT PRESSURE CONTROL OPERATION

The high limit is tested in the same manner but with the operating

control set above the pressure setting of the high limit. (Figure 3)

CAUTION: THIS IS FOR TEST PURPOSES ONLY!

When the high limit trips, turn off boiler and reset high limit to

proper setting. The manual reset level must be pushed to resume

operation upon startup.

Scaleplates

Pressure

Adjusting

Screw

Mercury

Switch

Index

Mark

Pointer

Leveling

Indicator

Diaphragm

Assembly

Operating

Lever

Pressure

Setting

Indicator

Differential

Setting

Indicator

Differential

Adjusting Screw

Figure 2 — Pressure Control

Scaleplates

Pressure

Adjusting

Screw

Manual

Reset

Lever

Mercury

Switch

Index

Mark

Pointer

Leveling

Indicator

Diaphragm

Assembly

Operating

Lever

Pressure

Setting

Indicator

Figure 3 — Hi Limit Control

12

OPERATION

OPERATION

RECOMMENDED START-UP PROCEDURES

1. Close globe valve on steam outlet side of boiler. (Customer Supplied)

2. Turn on boiler and allow pressure to build up to operating pressure.

3. Only open globe valve at quarter turns at first, introducing smaller

amounts of steam into process. Avoid opening globe valve all at

once. This will eliminate the possibility of evacuating the boiler of

water caused by the suddenly increased boiling of the water in the

vessel as the pressure is reduced. On boilers where constant pressure is not maintained, globe valve should be kept partially closed.

This will maintain a constant head on the boiler and stabilize any

fluctuation in boiler water level.

Note: For best boiler performance, a 1/4” less steam valve

than size of safety valve should be plumbed as close as practicable to steam outlet. Where 1/2” safety valve is used on boiler, a 1/4” steam valve is recommended.

MANUAL BLOWDOWN INSTRUCTIONS

Blowdown is an essential part of boiler operation. It is the best

preventative maintenance you can give your boiler and will add

years of life to the unit. Make sure a blowdown schedule is established and followed regularly.

In extremely hard water areas, blowdown is necessary once a

day. In soft water areas, once each week. If there is a particular

problem which applies to your own local water condition other

than mineral content, take this into consideration in determining

which schedule is to be followed.

1. At end of the working day, while boiler is still operating, turn

switch to the OFF position and close water supply valve. De-energize wall mounted safety switch.

2. If blowing-down into a receptacle, allow pressure to decrease to

15-20 psi before opening blowdown valve.

3. It is preferable to connect the blowdown valve directly into a

drainage system. If this is done, the boiler can be discharged at

operating pressure.

4. When discharge is complete and boiler is drained — (a) close the

blowdown valve; (b) open water supply valve; (c) put boiler switch

in the ON position; and, (d) close wall mounted safety switch.

5. When refilling is complete, turn off the boiler switch unless further

operation is desirable.

6. If you have been supplied with a Manual Reset Low Water control

as required in some states, the reset button on the control must be

pushed before boiler will begin developing pressure. (Do not push

reset until boiler has filled with water.)

The use of chemical boiler cleaning compounds in these boilers

voids all warranties unless approved by manufacturer. Some compounds will damage copper sheathed heating elements to shorten

useful life.

Page 13

OPERATION

AUTOMATIC BLOWDOWN INSTRUCTIONS

(IF FURNISHED)

The Automatic Blowdown is a device which automatically starts

up your boiler in the morning; shuts it down at night and blows down

(partially drains) the main boiler drain and the low water cut-off column for a predetermined time interval each working day.

The heart of the unit is an electrically operated straight through

type ball valve. It is specially designed to handle dirty, corrosive fluids and particles without requiring cleaning or the use of a strainer.

Both the valve and the boiler are controlled by an electric control

unit which indicates with pilot lights when the drain valve is in the

opened or closed position and when the boiler is ON or OFF. In addition to the automatic control function, the unit has a push button which

momentarily de-energizes the boiler and opens the drain valve regardless of the time of day.

The unit may also be used to blow down boilers which run continuously, day and night.

INITIAL TESTING — Set the switch marked “Programmed

duty/24 Hour duty” located on the panel box to the “ON” position.

On the large timer set the “ON” tab at about 8 AM and the “OFF”

tab at about 8 PM. Set the blowdown cycle dial at “O”.

Turn the large timer by hand until the “ON” tab passes the “TIME

NOW” indicator so the “TIME NOW” arrow indicates 10 AM.

Energize the main feed to the “LINE TERMINALS” of the unit.

The “BOILER ON” pilot light as well as the “VALVE CLOSED”

light should glow.

Hold down the “DRAIN” button for about six seconds. The

“BOILER ON” light should go out immediately as well as the

“VALVE CLOSED” light. It takes about 4 seconds for the drain valve

to open fully at which time the “DRAIN VALVE OPEN” light should

light. As soon as the “DRAIN” button is released the valve begins to

close. When it reaches the closed position, the “VALVE CLOSED”

and the “BOILER ON” should light up again.

Now turn the wheel on the large timer until the “OFF” tab passes

the “TIME NOW” arrow. The “BOILER ON” light should go out and

the valve should begin to open. Once the “VALVE OPEN” light goes

on, the valve should remain open for a few seconds and then automatically close. The “VALVE CLOSED” light should light and the

“BOILER ON” light should remain off.

OPERATION— Set the “BOILER PROGRAMMED DUTY”

switch to “BOILER ON” if the boiler is to be shut down each night.

Set it to “24-HOUR DUTY” if the boiler is to remain on continuously 24-hours per day (except during blowdown).

Set the tabs on the large timer for the ON and OFF times desired

for the boiler, screw in the small black day-skip tabs if is to remain off

during the weekend, etc.

If the boiler is on 24-hour duty, set the OFF tab for the time that is

desired for blowdown. Tzhe ON tab can be ignored, but must remain

on timer.

The small time delay relay controls the time that the drain valve

remains open. The time is controlled by adjusting knob marked

Blowdown cycle. Counterclockwise decreases, clockwise increases

blowdown time. Time must be adjusted by trial.

13

Boiler On

Valve Open

Valve Closed

Programmed Duty

24 Hour Duty

Manual Drain

Valve Actuator

Timer

Automatic Blowdown Control Cabinet

Display View of Automatic Blowdown Control Cabinet

Terminal Block

Support

7 Day Clock

Control

Relay

Time Delay Relay

311

7

2102628

Terminal Block

Component Layout

Support

Replace with

Amp Fuse Only

Manual Drain

24 Hour Duty

Prorammed Duty

Valve Open

Valve Closed

Boiler On

Blowdown Cycle

30's

0's

80's

Cycle

Adjustment

On/Off Switch

Indicator Light

Indicator Light

Switch

PB Switch

Fuse

Valve Closed

Boiler Control

(3)

Boiler On

Ball Valve

Control

(5)

7-Day Timer

(2.3)

Exterior Side

2

w

Clock

3A

1

8

1LT

2LT

3LT

0

Valve Open

Blowdown Valve

Motorized

6

Y

B

2A

1A2B1B

BL

2

3

4

2

34

1

2

1

P

2PB

1PB

1CL

1CL

1TR

PR

1CR

G

3

B

1FU

15A

7

R

B

10

1CR

1TR

1

R

R8

2W

O

R

/

M

O

BL

/

R11

Wiring Diagram for Automatic Blowdown

Page 14

OPTIONAL EQUIPMENT FOR STEAM BOILERS

AUXILIARY LOW WATER CUTOFF

Operation

Operation of this control is accomplished by sensing a minute AC

current flowing between submerged contact probe in the boiler shell.

When this minute AC current is conducted through an external circuit resistance up to 40,000 ohms or less, a signal of sufficient magnitude is present to trigger the SCR and, in turn energize the control

relay.

As the water level in the boiler drops below the level of the probe,

the AC current is broken and the control relay is de-energized. The

control will not energize until sufficient water is present in the boiler.

Specifications

Input Supply — 120 vac/50-60 hz

Detectable Range — 100,000 ohms

Probe Voltage — 24 Vac

Probe Current — 10 milliamps

Control Relay — Single pole double throw

WARNING: Control will not work with de-ionized or

demineralized water.

PROPORTIONING PRESSURE CONTROL FOR

SEQUENCER AND SCR CONTROLS

Typical Operation

Pressure variations cause the bellows to expand or contract.

Linkage between the bellows and the potentiometer wiper causes the

wiper to move across the windings on the potentiometer. This varies

the resistance between R and B, and between R and W, causing an

unbalance in the circuit connected to the controller.

A proportioning pressure control is used to regulate a motor driven

or solid state sequencer. The controller potentiometer, the feedback

potentiometer in the motor and a balancing relay in the motor form an

electric bridge circuit. As long as the pressure of the controlled medium remains at the set point of the controller, the circuit is balanced;

i.e., equal currents flow through both sides of the balancing relay and

the relay contacts are open. When the circuit is balanced, the motor

does not run.

If the pressure of the controlled medium rises, the wiper in the controller moves toward W. This unbalances the circuit so a larger current

flows through one side of the balancing relay. The “close” contacts in

the relay make, causing the motor to drive toward its closed position. As

the motor runs, the wiper on the feedback potentiometer moves in a

direction to balance the circuit. When the circuit is again in balance, the

balancing relay contacts open and the motor stops.

Similarly if the pressure of the controlled medium falls, the wiper on

the controller potentiometer moves toward B, and the “open” contacts

in the balancing relay make. The motor drives towards its open position

until circuit balance is achieved.

The slightest change in the pressure of the controlled medium will

cause a change in the number of elements energized to compensate for

it, thus keeping the pressure constant. This process is called modulation.

PROPORTIONAL PRESSURE CONTROL ONLY SUPPLIED

WITH SEQUENCER

Main Setting — Turn the adjustment screw until the indicator is

opposite the low point of the desired throttling range. That is, if the pressure is to be held at a minimum of 50 psi, set the indicator at 50 psi. The

pressure will them be maintained between 50 psi and a higher pressure

equal to the 50 psi plus the throttling range.

THROTTLING RANGE SETTING L91B

After setting the indicator for the minimum pressure, turn the throttling range adjustment screw until the throttling range indicator points to

the desired throttling range on the scale. This scale is graduated from

“min” to “F”. The value of each division varies with the scale range of

the instrument.

PRESSURE VALUE EACH

SCALE RATING DIVISION ON SCALE

0-15 psi 2.2 psi

20-300 psi 16.4 psi

Pressure scale rating will vary depending on pressure control supplied.

CHECKOUT

After the controller has been installed, wired, and set, it should be

tested with the system in operation. First allow the system to stabilize.

Then observe the operation of the controller while raising and lowering

its set point. Pressure should increase when the set point is raised and

decrease when the set point is lowered. Use accurate pressure testing

equipment when checking out the controller. Do not rely on inexpensive

gauges. The controllers are carefully calibrated at the factory.

If the motor or actuator runs the proper direction when the set point

is adjusted, it can be assumed that the controller is operating properly. If

it runs in the wrong direction, reverse the B and W wires. Observe the

action of the motor to see if it stabilizes. If the motor is moving constantly, widen the proportioning range a little at a time, until the system

is stable.

14

Adjusting Screw

Differential Adjusting Screw

R

W

B

3

3

2

2

2

2

6

6

2

2

1

1

LWCO Probe

Aux. Low

Water Cutoff

O

O

O

R

H

C

1PS

C1

NO

L1 L2

1PS

BL

W

Y

2PS

BL

Auto

Blow

Down

System

BR

C1

W

W

Heater

Contactor

Feed Water

(Solenoid Pump)

R

1LT

W

Boiler On

2

GND

3

GND

1

GND

B

FU3

B

1PB On

Off

X1

X3

X2 X4

1 HTR

C1

Fuses Supplied

on Boilers Rated

Over 40 Amps.

FU

FU

FU

FU2

FU1

H1 H2H3 H4

480V/120V

1.5 KVA

480V

3

60 HZ

L1 L3

L2

Typical Wiring for

Auxiliary Low Water Cutoff

Electronic Resistance Sensing

Amplifier for Auxiliary

Low Water Cutoff

(L91B) Proportioning Pressure Control used with Sequencer Control

Page 15

OPTIONAL EQUIPMENT FOR STEAM BOILERS

IF A CONTROLLER SEEMS TO OPERATE IMPROPERLY

If the controller is suspected of operating improperly, it may be

further checked as follows:

1. Leave the controller installed where it is, but disconnect all power

to the boiler.

2. Loosen the cover screw below the main scaleplate and remove the

cover.

3. Disconnect the wires from the controller.

4. Connect an ohmmeter between controller terminals B and W to

measure the resistance of the potentiometer in the controller. The

ohmmeter should read about 135 ohms on an L91B.

5. Connect the ohmmeter between controller terminals W and R and

raise the set point of the controller above the actual pressure being

measured. The ohmmeter should read the full value of the potentiometer measured in step 4 (135 ohms for an L91B).

6. Slowly lower the set point of the controller while observing the

ohmmeter reading. The resistance should drop to zero at some set

point below the actual pressure.

7. An approximation of the proportioning range can be made by

observing the change in set point required for a resistance change

from zero to full value.

8. When the controller is operating properly, reconnect the wires,

replace the cover, tighten the cover screw, and reset the controller

to the desired value.

9. Reconnect power to the controlled motor.

BOILER SEQUENCER (5 STEP) MOTOR DRIVEN

RECYCLE FEATURE

The step control is designed to drop out all contactors when control circuit is interrupted. On resumption of power, the camshaft

rotates to the counterclockwise (ccw) limit, opening all the load

switches. The recycle relay then energizes, pulling in the load contact, and finally the camshaft rotates clockwise (cw) to the position

called for by the pressure controller energizing, in sequence, the

required load stages.

TESTING OPERATION OF SEQUENCER

1. With boiler off, remove wiring from pressure control on

sequencer low voltage terminal board.

2. Turn on boiler to supply the voltage to the sequencer. Short ter-

minal R and B for counterclockwise rotation and terminal R and

W for clockwise rotation.

3. If sequencer operates under this test procedure, but when rewired

to pressure controller and does not function, check pressure control. Note that wiring is W-B and B-W-R-R between sequencer

and pressure controller

BOILER SEQUENCE — SOLID STATE

Solid State Progressive Sequencer

The solid state progressive sequencer provides accurate electronic control of multi-stage loads of the type used in Chromalox

steam boilers. It features progressive sequencing (first on-first off)

which equalizes the operating time of each load. This control gives

visual indication of each energized stage by means of integral solid

state light emitting diodes. In the event of power interruption, all

heating elements are immediately de-energized for safety. When

power resumes, the control will restage the loads one at a time.

The solid state sequencer operates on 120V AC/60 Hz and each

output is relay switched with a load rating of 125 VA at 120V AC.

The input to the sequencer is a 0-135 OHM potentiometer supplied on the operating pressure control. The sequencer has a sensitivity control which is adjustable from min. to max. This sensitivity

control defines the amount of resistance (pressure) deviation

allowed before adding or subtracting a load. Potentiometer resistance should decrease with increasing pressure. Connections are

made to red and white terminals of proportional pressure control.

See Wiring Diagram 337-300164-452 for Boiler With Solid State

Sequencer.

Main Scale

Adjusting

Screw

Proportioning Range

Adjusting Screw

R

W

B

Main Scale

Setting

Indicator

Set Point

Increase

R

W

B

Ohmmeter

Increases to

135 Ohms

Terminals are not Labeled, but Screw-Heads are

Color Coded Red (R), White (W) and Blue (B).

15

Solid State Sequencer

Sequencer (5-Step)

Page 16

HIGH PRESSURE FEED

High pressure makeup water pumps are used when water pressure

does not exceed boiler pressure by more than 10 psi and when condensate water is not returned to the boiler. Note: Consult factory or

sales office for motor/pump sizing for appropriate water feed system.

Installation

WARNING: Hazard of Electric Shock. Water feed system

must be effectively grounded in accordance with the

National Electrical Codes to eliminate shock hazard.

1. Locate feed on level floor or platform.

2. Connect water line to tagged fitting on feed.

3. Connect piping from discharge to water inlet check valve on boil-

er with minimum of 90˚ bends or other restrictions.

4. All electrical wiring should be done by licensed electricians in

accordance with local and national electrical codes. Refer to boiler instruction for manual wiring diagram.

5. If pump is located less than 30 feet from boiler, a second check

valve is required.

WATER FEED SYSTEMS

Automatic High Pressure Water Feed Pump/Motor Assembly

OPTIONAL EQUIPMENT FOR STEAM BOILERS

16

Pipe

Dimensions (In.)

Assembly Pressure Size

Model HP Range (NPT) A B C D E F

ES-38020 3/4 0-200 1/2 16-1/4 3 7-3/16 4-7/8 6-1/2 6-1/8

Pressure

Control

5 Step

Control

Sequencer

Auto

Blowdown

System

Heater Contactor

Heater Contactor

Heater Contactor

Heater Contactor

Feed Water

Solenoid Valve

Boiler

On

Optional Transformer

480/120V

480V 3Ø 60 HZ

CR

W

1

Mtr

Customer

Connect

Feed Water

Motor

10L

30L

20L

IT1

IT3

IT2

CR

L1 L3

L2

Pump Motor Dimensions

Typical wiring for boilers equipped with Auto Blowdown System and/or Solid State Sequencer

Wire Color Code

B = Black

BR = Brown

R = Red

O = Orange

Y = Yellow

G = Green

BL = Blue

W = White

Page 17

30 Gal.

Condensate

Return System

WATER FEED SYSTEMS

CONDENSATE RETURN SYSTEMS

Chromalox condensate return systems are used wherever condensed

steam can be collected for reuse in the boiler. Significant energy can be

saved by returning condensate to the boiler. The condensed water is free

from corroding minerals and carries a substantial amount of heat which

does not have to be replenished.

IMPORTANT: Vacuum breaker is required whenever using a condensate return system.

Installation — Wiring

A. Check the voltage of the motor before making the wiring connection.

Some Chromalox boilers are supplied with dual voltage systems. The

motor should always match the voltage of the control circuit.

B. The motor circuit should be wired into the pump control located on

the boiler. See boiler instruction sheet for wiring diagram.

C. All electrical wiring should be done by licensed electrician.

D. Be sure to use the proper wire. Electrical wiring to boiler

should be in accordance with National Electrical Code or local

wiring code following wiring diagram supplied.

Plumbing

A. Connect water line to tagged fitting on the motor and pump assem-

bly control feeder.

B. Interconnecting piping between boiler and condensate return system

should be installed with a minimum of 90˚ bends or other restrictions.

17

MAINTENANCE

WARNING: Hazard of Shock. Disconnect all power

before working on boiler.

Chromalox Electric Steam Boilers are designed for years of trouble-free

performance. To establish a good preventative maintenance program,

we suggest the building maintenance man or engineer familiarize himself with these simple rules:

1. The use of specific boiler cleaning compounds cannot be rec-

ommended. We do recommend that a reputable firm of water treat-

ment engineers be consulted regarding conditioning boiler water.

Proper selection must be made of a compound to prevent damage to

copper sheath heating elements.

2. The sight glass should be checked daily to ensure the boiler has ade-

quate water.

3. A monthly inspection should be made of internal wiring. All elec-

trical connections should be checked for tightness.

A check for water or steam leaks should also be made and any loose

fittings immediately tightened.

4. If boiler is equipped with Solid State Auxiliary Low Water Cutoff,

every four months the probe should be checked for deposits and

cleaned, if necessary. This is accomplished by removing inspection

plate, removing the probe (with a standard sparkplug wrench) clean-

ing and replacing.

Note: The system will not operate if the boiler is using distilled,

demineralized or deionized water. At the same time, one of the bot-

tom heating elements should be removed. If scale has begun to form,

all elements should be cleaned and boiler drained and flushed.

5. IMPORTANT: The Manufacturers’ Data Report enclosed

within the instruction sheet is very important and must be put in a

safe place. You may be called upon to produce it by a state agency.

INSTRUCTIONS FOR ELEMENT REPLACEMENT

WARNING: Before installing your new elements, be sure

the McDonnell-Miller low-water cut-off is operating

perfectly and the float chamber and lower equalizer

column are completely clear of sludge or other foreign

matter.

Failure to do this may cause the immediate burnout of the new ele-

ments.

All elements are thoroughly checked before shipment. The manufacturer cannot be responsible for burnouts caused by a faulty low-water

cut-off.

The lower equalizer column can best be examined by breaking the

unions on either side and then visually and manually examining the piping with your fingers or probes to see if it is clear and clean.

Boiler

1" Steam Equalizing Pipe

Pump and Low

Water Control

Normal Boiler

Water Level

Cutoff Level

is Arrow Mark

Blowdown

Valve

1" Water Equalizing Pipe

1-1/2"

Condensate Storage Tank Pump Discharge Condensate

Model For Boiler Model Max. Pressure (psig) Capacity (Gals.) Pump (Hp) Motor (Volts/Phase) Conn. (NPT) Ref. Conn. (NPT) L H W

HPCS-

3003 All CHPES 250 30 3 240 / 480 1 1-1/4 2 36 42-3/16 24

1-1/4” NPT Vent

Return Inlet

Make-Up Valve

Inlet

1-1/4” NPT

3” NPT Discharge

1” NPT

Drain

L

H

W

Dimensions (In.)

Page 18

18

MAINTENANCE

RENEWAL PARTS IDENTIFICATION

Drain Blowdown Valve

Drain Blowdown Valve

Water Level Sight Glass

On/Off Switch and

Pilot Light

Steam Outlet

Operating Pressure Control

Range 10-300 Psi

Safety Valve

Manual Reset High

Limit Control

Pressure Gauge, 0-600 Psi

McDonnell & Miller #194

Low Water Cutoff/Pump

Check Valve/Water Inlet

(not shown)

READ COMPLETELY BEFORE STARTING WORK

1. Disconnect boiler from electric power supply at main safety

switch or fuse panel. Then, turn boiler switch to “off” position.

2. On automatic feed units, close valve on incoming water line. Drain

boiler completely of water.

3. Open boiler door to expose heating element.

4. Disconnect wire (electric) leads connecting element to main power

system of boiler. Again note wire connections to facilitate

reassembly. Proceed to remove (6) 5/16-18 bolts from flange.

5. Thoroughly clean boiler flange of all foreign material. Be certain

no part of old gasket remains on boiler flange.

6. Apply “Slic-Tite” Gasket Compound or equal to both surfaces of

new gasket with supplied replacement element. Proceed to install

element flange assembly with gasket between boiler flange and

element flange. In doing this, be careful to align flange holes so

wire connection terminals on element assembly are in line with

previously disconnected wire leads to facilitate easy connections.

7. When all (6) flange bolts are tight, connect all wires to terminals.

Make certain wires are clean and bright to assure good electrical

contact and nuts on screws are firmly secured.

WARNING: Avoid use of chemical cleaning compounds. Follow maintenance instructions.

8. Open water valve so water supply can reach boiler feed mecha-

nism.

9. Put main safety switch to “on” position.

10. Turn boiler to “on” position.

11. As boiler automatically refills, observe the new flange assemble

for possible leaks. If water is noticed, to bolts must be retightened.

Before doing this, turn the boiler off at the main fuse safety switch.

12. As boiler is heated to working pressure, check flange assembly

again for leaks.

WARNING: Avoid the use of chemical cleaning compounds. Follow maintenance instructions

Page 19

Part Description Part Number

1/4” Ball Valve (Pressure Gauge) . . . . . . . . . . . . . . . . . . . . . . . . 344-121194-007

Blowdown Valve 1” CHPES-24A

through 180A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344-121194-042

Pressure Gauge 3-1/2” 0-600 psi CHPES-100A

through 180A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130-118661-012

Fusible Contactors

30 amp with 35-60 amp 600V block . . . . . . . . . . . . . . . . . . . . . 072-122686-003

40 amp with 35-60 amp 600V block . . . . . . . . . . . . . . . . . . . . . 072-122686-006

50 amp with 35-60 amp 600V block . . . . . . . . . . . . . . . . . . . . . 072-122686-009

Non Fusible Contactors

60 amp without fuse block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 072-047913-016

50 amp without fuse block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 072-047913-019

40 amp without fuse block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 072-047913-012

30 amp without fuse block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 072-047913-020

35 amp 600V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128-123459-012

40 amp 600V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128-123459-013

45 amp 600V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128-123459-014

50 amp 600V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128-123459-015

60 amp 600V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128-123459-016

Fuse Block 35-60 amp 60 amp 600V . . . . . . . . . . . . . . . . . . . . 129-047445-002

Power Terminal Blocks

3 Pole 115 amp 1 line circuit 1 load circuits . . . . . . . . . . . . . . . 303-071809-032

3 Pole 175 amp 1 line circuit 4 load circuits . . . . . . . . . . . . . . . 303-071809-012

3 Pole 335 amp 1 line circuit 4 load circuits . . . . . . . . . . . . . . . 303-071809-014

3 Pole 335 amp 1 line circuit 8 load circuits . . . . . . . . . . . . . . . 303-071809-016

SINGLE PHASE

12kW 208V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-554735-004

12kW 480V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-554735-009

17kW 208V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-554735-006

17kW 480V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-554735-011

THREE PHASE

12kW 208V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-554735-003

12kW 240V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-554735-001

12kW 346V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-554735-012

12kW 380V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-554735-017

12kW 480V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-554735-008

17kW 208V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-554735-005

17kW 240V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-554735-002

17kW 346V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-554735-013

17kW 380V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-554735-018

17kW 480V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-554735-010

22.5kW 240V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-554735-021

22.5kW 480V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-554735-022

22.5kW 550V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-554735-019

Check Valve 1/2” CHPES-6A through 18A . . . . . . . . . . . . . . . . . 344-114590-013

Check Valve 3/4” CHPES-24A through 180A . . . . . . . . . . . . . . . 344-114590-014

Gauge Glass Assemble Valves

(O-ring gaskets included) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344-120970-004

Protector Rods (2 Required) CHPES-6A

through 18A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242-121047-008

Protector Rods (2 required) CHPES-24A

through 180A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242-121047-001

O-ring gaskets (2 required) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132-073284-003

Sight Glass Tubing, 7” CHPES-6A

through 18A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374-121046-006

Sight Glass Tubing, 9” CHPES-24A through 72A . . . . . . . . . . . 374-121046-038

Sight Glass Tubing, 11” CHPES-100A through 180A . . . . . . . . 374-121046-015

250 psig 1/2” CHPES-6A through 180A . . . . . . . . . . . . . . . . . . . 344-300032-006

19

RENEWAL PARTS IDENTIFICATION

VALVES & GAUGES

HEATING ELEMENTS — SPECIFY VOLTAGE

Part Description Part Number

Operating Pressure Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 429-300038-009

Hi-Limit Control (Manual Reset) 15 psi . . . . . . . . . . . . . . . . . . . 429-300038-008

Proportional Pressure Control . . . . . . . . . . . . . . . . . . . . . . . . . . 429-300039-004

5-Step Motor-Driven Sequencer . . . . . . . . . . . . . . . . . . . . . . . . 323-121505-001

10-Step Motor-Driven Sequencer . . . . . . . . . . . . . . . . . . . . . . . 323-121505-002

6-Step Solid State Sequencer . . . . . . . . . . . . . . . . . . . . . . . . . . 323-300107-015

10-Step Solid State Sequencer . . . . . . . . . . . . . . . . . . . . . . . . . 323-300107-015

Siphon Tube for Pressure Controls . . . . . . . . . . . . . . . . . . . . . . 215-300026-002

MM-94 Control Complete (Auto Reset) . . . . . . . . . . . . . . . . . . . 292-300065-007

MM-94M Control Complete (Manual Reset) . . . . . . . . . . . . . . . 292-300065-008

1KVA 208V Primary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315-300088-020

1KVA 240/480V Primary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315-300088-021

1-1/2 KVA 208V Primary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315-300088-025

1-1/2 KVA 240/480V Primary . . . . . . . . . . . . . . . . . . . . . . . . . . . 315-300088-026

Motor and Pump used in ES-38020 HP . . . . . . . . . . . . . . . . . . . 226-300177-009

Pump only used in ES-38020 HP . . . . . . . . . . . . . . . . . . . . . . . . 226-300173-011

Motor and Pump used in ES-38020 HP . . . . . . . . . . . . . . . . . . . 193-121843-020

Strainer used in ES-38020 HP . . . . . . . . . . . . . . . . . . . . . . . . . . 351-118664-001

V-Band Mount used in ES-38020 HP . . . . . . . . . . . . . . . . . . . . . 355-300174-001

Solenoid Valve used in ES-38020 HP . . . . . . . . . . . . . . . . . . . . 344-121780-002

Hose Assembly 18” Long used in EES-38020 HP . . . . . . . . . . . . . 349-300181-002

Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128-121133-053

Overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359-122688-031

Condensate Return System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296-300222-026

Pump/Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Contact Factory

Probe Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346-300035-001

Aux Low Water Cut-off Board with Relay . . . . . . . . . . . . . . . . . . 323-300033-016

Aux Low Water Cut-off Board Without Relay . . . . . . . . . . . . . . . 323-300033-017

Relay for Aux Low Cut-off Board . . . . . . . . . . . . . . . . . . . . . . . . 072-300047-003

Probe 7-15/16” CHPES 6A through 18A . . . . . . . . . . . . . . . . . . 242-300036-019

Probe 9-1/2” CHPES 24A through 72A . . . . . . . . . . . . . . . . . . . 242-300036-002

Probe 10-15/16” CHPES-100A through CHPES-180A . . . . . . . . 242-300036-017

ON-OFF Switch with Pilot Light . . . . . . . . . . . . . . . . . . . . . . . . . 292-053223-002

Control Circuit Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128-072576-027

Control Circuit Terminal Block 4 Pole 250V 20AMP . . . . . . . . . 303-075443-003

Control Circuit Fuse Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129-300029-001

Blank Flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121-300199-001

Element Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132-146012-001

Stainless Steel Bolts (6 required) for Element . . . . . . . . . . . . . . 345-072565-428

Vacuum Breaker Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344-300149-003

Motorized Valve 1/2” CHPES-6A through CHPES-18A . . . . . . . . 344-300089-009

Motorized Valve 1” CHPES-24A through CHPES-180A . . . . . . . 344-300089-010

Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292-300101-002

Relay SPST No. 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 072-300072-002

Relay Interval Delay .6-60 Sec. 3 . . . . . . . . . . . . . . . . . . . . . . . . 072-300148-001

Switch Momentary Contact DPDT 4 . . . . . . . . . . . . . . . . . . . . . . 292-300146-001

Switch Rocker SPDT 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272-300147-001

Pilot Light Red 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213-300145-001

Terminal Block 4 Pole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303-075444-003

Terminal Block 5 Pole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303-075444-004

Fuse Block 30A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129-024494-001

Fuse 15A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128-121133-072

CONTACTORS

POWER FUSES AND TERMINAL BLOCKS

GAUGE GLASS ASSEMBLIES, CHECK VALVES & SIGHT GLASSES

SAFETY VALVE

PRESSURE CONTROLS & SEQUENCES

COLD WATER INJECTION PUMPS (0-100 PSIG)

CONDENSATE RETURN SYSTEMS

CONTROL VOLTAGE TRANSFORMERS (120V SECONDARY)

LOW WATER CUTOFF & PUMP CONTROLS

AUX LOW WATER CUT-OFF (OPTIONAL EQUIPMENT)

MISCELLANEOUS PARTS

AUTO BLOWDOWN PARTS

Page 20

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...