Page 1

(Supersedes PQ435)

PQ435-1

cas

161-562795-001

JUNE, 1994

4

and

Installation, Operation

RENEWAL PARTS IDENTIFICATION

Type CAS-20CM Electric Steam Boiler

(Standard Trim is 100 PSI — 0-90 PSI Operating Pressure Range)

© 2010 Chromalox, Inc.

Model Electric Capacity BHP Rating Voltage Phase Amperes Drawn Contactor

20 kW 2.0 208 1 96 50A, 4 Pole

16/20 kW 1.6/2.0 208/230 3 45/51 60A, 3 Pole

CAS-20CM

20 kW 2.0 240 1 84 50A, 4 Pole

20 kW 2.0 346 3 34 40A, 3 Pole

20 kW 2.0 380 1 53 60A, 2 Pole

20 kW 2.0 480 3 24 30A, 3 Pole

Note: Control circuit 120V

Boiler Serial No. ______________________________________________ Power Circuit Voltage __________________________

Model No. ___________________________________________________ Control Circuit Voltage__________________________

National Board No. ____________________________________________ Amps ___________Phase __________Cy __________

IMPORTANT – This data file contains the National Board Registration Certificate approving your boiler. It must be kept near the boiler at all

times.

Page 2

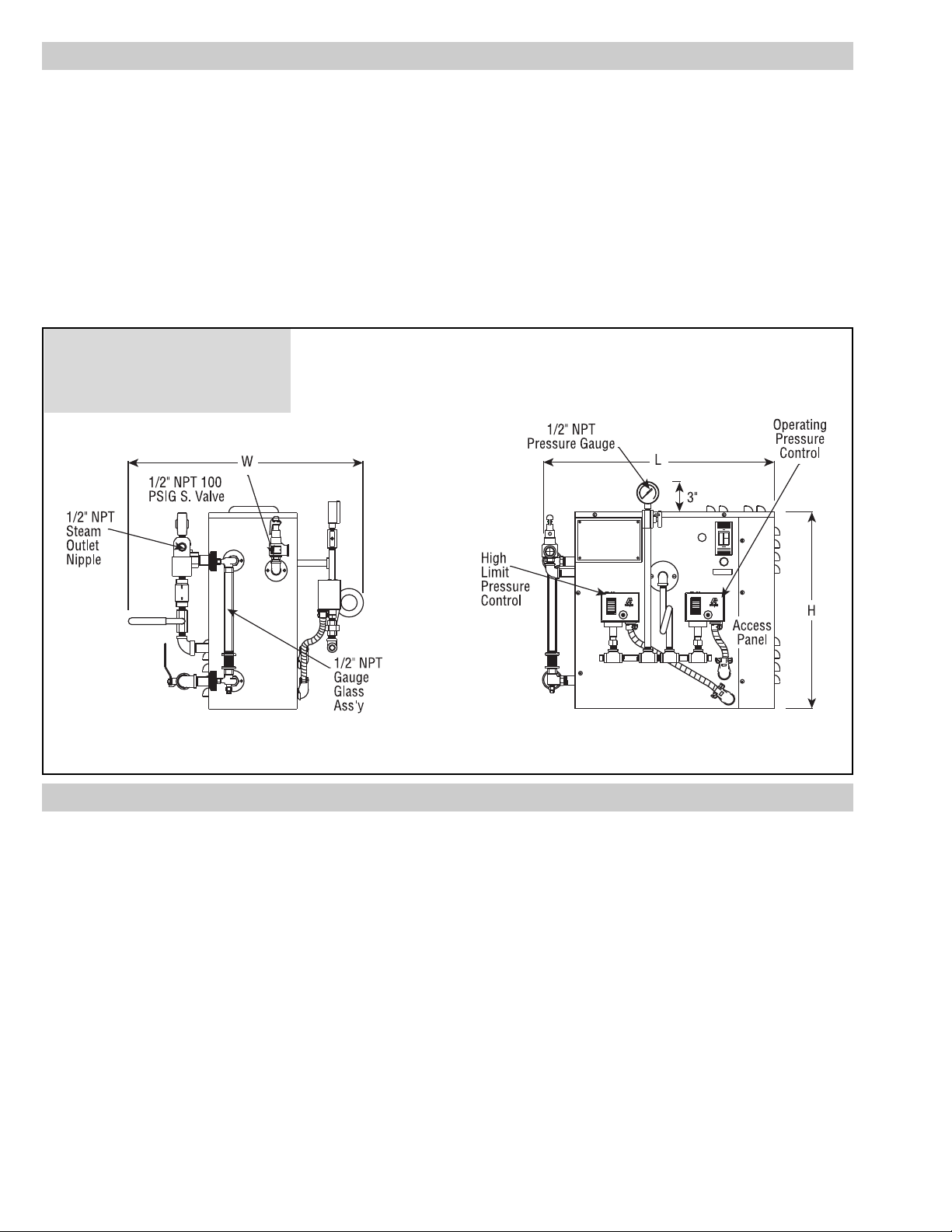

INSTALLATION

WARNING: To avoid electrical shock hazard, boilers

must be suitably grounded to earth.

Note: Chromalox boilers are pre-tested before shipment; no internal piping or wiring is necessary. WARNING: Substitution of

components or modification of wiring without prior consent of

Chromalox voids warranty.

1. Bolt unit securely to level floor or platform.

Note: A minimum distance of 18 inches from wall, other

equipment, etc. must be allowed for removal of the elements.

2. Complete all piping to boiler. Connect water line to tagged fitting on the motor and pump assembly if used, or to tagged fitting on water control feeder.

3. When any type of feed other than a pump feed is used, the

water supply line pressure must be 10 pounds greater than the

boiler operating pressure to assure proper water level in boiler.

Lack of water can cause heater failure. Keep feed water line

valves open at all times.

4. Connect steam line (with outlet valve) to boiler steam outlet.

5. Open all gauge valves and steam outlet valve; keep drain valve

closed.

Note: The safety valve should be provided with a drain line

sized no less than the outlet size of the valve and routed per

local codes.

6. Floor drain to be provided directly below unit.

WIRING

Type CAS

Electric Steam Boiler

WARNING: Hazard of Electrical Shock. Disconnect

all power before working on boiler. Boilers must be

grounded in accordance with the National

Electrical Code (NEC) standards to avoid shock

hazard.

WARNING: Use 90°C copper conductors only.

1. Select proper wire gauge and type for supply conductors in

accordance with the National Electrical Code and local wiring

codes following wiring diagram supplied (See recommendations for disconnect switches and fusing).

Note: Purchaser should use a safety disconnect employing circuit breakers or fuses between the main power source and the

boiler. This overcurrent protection should be installed in addition to any other supplementary fuses or circuit breakers provided as an integral part of the boiler.

2. If a separate control circuit is used, the control circuit should

be connected to the control terminal block and the circuit protected by overcurrent devices in accordance with the National

Electrical Code.

3. Chromalox boilers are solid state devices. Since boilers are

connected to water lines, these devices are susceptible to voltage surges and lightning damage. Industrial type lightning pro-

tectors should be installed per manufacturer’s recommendations at your service entrance.

4. Be sure that all electrical connections are sufficiently tight-

ened. Loose connections will cause overheating and damage to

the electrical wiring.

5. Special instructions for customers supplying their own con-

densate or pump system.

A. Check the voltage of the motor before making the wiring

connection. The motor should always match the voltage of

the control circuit. Standard control circuit voltage is 120

volts ± 10 volts.

B. Internal water feed relay is rated at a maximum of

1

/3 H.P.,

120 volts. Motors rated greater than

1

/3 H.P., or other than

120V, single phase, require the use of a suitable motor starter.

6. After all service connections are made, open feed water supply

valve and energize the boiler. The feed water solenoid will

open, fill the boiler to the proper water level and automatically shut off. The feed solenoid will continuously cycle on and

off as the boiler requires water. If, for any reason, the water

drops below the minimum safe operating level, the boiler’s

electrical circuits, except the feed solenoid will be de-energized automatically. Upon refilling to the proper level, the

boiler will automatically restart.

-2-

Page 3

SOLID STATE FLOATLESS LIQUID LEVEL

CONTROL SYSTEM

This boiler is equipped with a solid state, floatless liquid level

control which operates by sensing the electrical resistance of

water. Note: Control will not work with de-ionized or demineralized water. Two probes are provided. The HI probe activates and

controls the feed water relay. The LOW probe is a safety back-up

probe that turns off the power to the element in the event of low

water. A 12 volt potential is established between each probe and

ground. The presence or absence of water generates a small signal

that is amplified and fed to a SCR. The SCR, in turn, activates a

relay, depending on the function and the water level.

ADJUSTING PRESSURE CONTROLS

Chromalox boilers are supplied with operating and high limit pressure controls. One is used for controlling the operating pressure of

the boiler while the other is used as a high limit control.

MANUAL BLOWDOWN INSTRUCTIONS

Blowdown is an essential part of boiler operation. It is the best

preventive maintenance you can give your boiler and will add

years of life to the unit. Make sure a blowdown schedule is established and followed regularly.

Blowdown will remove accumulated hard water scale and dislodge scale from water heating surface thereby insuring efficient

heating. In extremely hard water areas blowdown is necessary

once a day. In soft water areas, once each week. If water is known

to be corrosive, consult water treating specialists to recommend

water treatment needed to insure corrosion free boiler operation. If

there is a particular problem which applies to your own local water

condition other than mineral content, take this into consideration

in determining what schedule is to be followed.

1. At the end of the working day turn switch to the OFF position

and close water supply valve. De-energize wall mounted safety switch (main power supply).

2. If blowing down into a receptacle, cover receptacle to prevent

splash of scalding water.

3. It is preferable to connect the blowdown valve directly into a

drainage system. If this is done, the boiler can be discharged at

operating pressure. However, check local codes and suitability

of drainage system before connecting.

4. When blowdown is complete and boiler is drained (a) close the

blowdown valve; (b) open water supply valve; (c) put boiler

switch in the ON position; and, (d) close wall mounted safety

switch.

5. When refilling is complete, turn off the boiler switch unless

further operation is desired.

The use of chemical boiler cleaning compounds in these boilers

voids all warranties unless approved by Chromalox, Inc.

-3-

SCHEMATIC WIRING DIAGRAM

OPERATION

HTR

O

Wire Color Code —

B = Black

W = White

R = Red

O = Orange

Y = Yellow

GR = Green

BL = Blue

Page 4

MAINTENANCE

WARNING: Hazard of Electric Shock. Disconnect all

power before working on boiler.

1. A monthly inspection should be made to ensure that all electri-

cal connections are tight.

2. When steam or water leaks are observed, fittings should be

tightened immediately.

3. Every four months, the Solid State Liquid Control probes

should be checked for deposits and cleaned if necessary.

Remove deposits from probe and teflon sleeve. This is accomplished by removing the inspection plate and with the use of a

standard spark plug wrench, removing the probes. Care should

be taken during the removal and reinstallation of the probes so

the porcelain insulator is not damaged.

The feed water probe is mounted in a surge isolator tube. This

isolator tube should be removed and cleaned at the same time

as the probes.

Note: Make sure that probe does not touch the insulator tube,

as grounding will occur. This will cause boiler to run dry.

4. At the same time, remove the heating element and inspect for

scale formation. If scale has begun to form, clean element and

also flush boiler.

TROUBLE SHOOTING HINTS

1. Boiler does not energize when main switch is turned on (noth-

ing happens).

A. Check to see if main power is turned on.

B. Check to see if control circuit voltage is turned on. (ON-

OFF switch has a pilot light)

C. Check power and control circuit fuses or breakers.

D. Check control circuit fuse on boiler.

E. Check all electrical connection for tightness.

2. Boiler power control circuit pilot light is on. Boiler will not fill

or heat.

A. No water in boiler. Check sight glass, it should be

1

/8 to 1/2

full. Check water feed lines, valves, pumps, strainer, etc. for

proper operation.

B. Solid state water feed probe inoperative. Check solid state

liquid controls probes. Water feed solenoid should activate

10 seconds after control circuit is turned on. Clean probe

and isolator tube as required. Make sure probe is straight

and does not touch wall.

C. Water feed relay bad – replace plug-in relay.

D. Solenoid valve bad — replace solenoid valve.

3. Boiler has power and water in sight glass. Boiler will not heat.

A. Bad heating contactor. Check for open coil or frozen contacts.

B. Bad relay on control Board. Replace control board.

C. Burned out element. Replace heating element.

D. Loose power connection. Tighten electrical connections.

4. Boiler floods.

A. Check high water probe and isolator tube for deposits.

B. Check water feed relay for frozen contacts.

C. Check solenoid valve, may be stuck or damaged.

5. Element repeatedly burns out.

A. Low water cutoff probe damaged or shorted to ground.

Remove and check low probe.

B. Boiler not supplied with water. Check water feed lines,

valves and circuits. Check water feed probe.

C. Control board defective. Check operation of board and

component. Replace board if necessary.

6. Control board trouble shooting. Start-up sequence.

The two probe board has the following sequence of operation

when the boiler is initially energized.

A. Turn on control circuit power.

B. Approximately 10 second delay before water feed solenoid

or pump starts.

C. Water rises in boiler and contacts low probe which closes

relay contacts, turning on heater.

D. Water continues to rise to HI probe. Turns off water feed.

Normal Operation Sequence.

1. Water drops below HI probe. After 10 second delay, water feed

energizes refilling boiler.

2. Water reaches HI probe and turns off water feed.

3. Sight glass should be

1

/3 to 1/2 full. Heater contactor will cycle at

operating pressure depending on load. Heater contactor should

not chatter on short cycle. In the event of contactor chatter,

check for low water condition and check for damaged or shorted probes.

Inconsistent water level causing low water cutoff.

1. Test feed solenoid control circuit by energizing control circuit.

Remove cover plate from probes.

2. Check for shorted or failed water feed probes.

3. Check water feed lines, valves and circuits.

INSTRUCTIONS FOR ELEMENT REPLACEMENT

Note: Element failure is usually caused by excessive scale build

up or low water operating conditions. Before replacing element, be

sure boiler tank is clean and free of scale. Check control board,

water feed system and control probes for proper operation.

Failure to perform the above maintenance checks may result in

immediate burn-out of new elements.

1. A monthly inspection of the boilers, boiler installation and

electrical wiring should be made to insure proper operation.

These inspections should include:

A. Electrical connections. Look for overheated or discolored

power terminals. Check and tighten all terminals that may

work loose from expansion and contraction.

B. Check for steam or water leaks and tighten all pipe fittings.

C. Check safety relief valve.

D. Check water feed line, strainers and check valves.

E. Blow down boiler and make sure drain lines are clear.

Read completely before starting work.

1. Disconnect boiler from electric power supply at main safety

switch or fuse panel. Then turn boiler switch to “off” position.

2. On automatic feed units, close valve on incoming water line.

Drain boiler completely of water.

3. Remove wiring compartment end panel to expose heating ele-

ment.

4. Disconnect wire (electric) leads connecting element to main

power system of boiler. Again note wire connections to facilitate re-assembly. Proceed to remove (6)

5

/16-18 bolts from

flange.

5. Thoroughly clean boiler flange of all foreign material. Be cer-

tain no part of old gasket remains on boiler flange.

6. Apply “Slic-Tite” Gasket Compound (or equivalent) to both

surfaces of new gasket supplied with replacement element.

Proceed to install element flange assembly with gasket

between boiler flange and element flange. In doing this, be

careful to align flange holes; element flange is marked “TOP”

so wire connection terminals on top element assembly will be

in line with previously disconnected wire leads to facilitate

easy connections.

7. When all (6) flange bolts are tight, connect all wires to termi-

nals. Make certain wires are clean and bright to assure good

electrical contact and nuts on screws are firmly secured.

Note: Bolts should be tightened to a torque of 22 ft. lbs.

8. Open water valve so water supply can reach boiler feed mech-

anism.

9. Put main safety switch to “ON” position.

10. Turn boiler switch to “ON” position.

11. As boiler automatically refills, observe the new flange assem-

bly for possible leaks. If water is noticed, the bolts must be

retightened. Before doing this, turn the boiler off at the main

fuse safety switch.

12. As boiler is heated to working pressure, check flange assembly

again for leaks.

WARNING: Avoid use of chemical cleaning compounds. Follow maintenance instructions.

-4-

Page 5

-5-

RENEWAL PARTS IDENTIFICATION

HEATING ELEMENTS

Description Part Number

20kW 240V 1PH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-300121-006

20kW 208V 1-3PH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-554735-023

16/20kW 208/230V 3PH . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-554735-024

20kW 346V 1-3PH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-554735-051

20kW 380V 1PH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-554735-042

20kW 480V 3PH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-554735-030

Element Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132-146012-001

Element Bolt (6 Req’d.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345-072565-428

ELECTRICAL COMPONENTS

Description Part Number

Rocker Switch with Pilot (ON/OFF) . . . . . . . . . . . . . . . . . . . . 292-053223-002

Contactor 30A, 3 pole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 072-047913-020

Contactor 40A, 3 pole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 072-047913-012

Contactor 50A, 4 pole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 072-047913-021

Contactor 60A, 2 pole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 072-047913-026

Contactor 60A, 3 pole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 072-047913-016

Fuse Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129-300029-001

Terminal Block, Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303-075444-001

Terminal Block, Power (1 PH only) . . . . . . . . . . . . . . . . . . . . 303-047468-003

Fuse 15A, 250V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128-072576-027

GAUGE GLASS PARTS

Description Part Number

Sight Glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374-121046-021

Sight Glass O-Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132-073284-001

Valve Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344-120970-003

Sight Glass Protector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334-056360-002

Nipple, Conduit 1” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198-300084-004

PRESSURE CONTROLS

Description Part Number

Operating Pressure Control Auto Reset . . . . . . . . . . . . . . . . . 292-300031-001

High Limit Pressure Control – Auto Reset . . . . . . . . . . . . . . . 292-300031-001

VALVES AND GAUGES

Description Part Number

Safety Valve

1

/2”, 100 PSIG . . . . . . . . . . . . . . . . . . . . . . . . . . . 334-300032-004

Check Valve

3

/8” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344-118536-005

Drain Valve

1

/2” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344-121194-006

Solenoid Valve, 120V,

1

/4” NPT . . . . . . . . . . . . . . . . . . . . . . . . 344-121780-012

Strainer

1

/4” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351-118664-003

Pressure Gauge,

1

/4”, 0-160 PSIG . . . . . . . . . . . . . . . . . . . . . 130-118661-001

SOLID STATE LEVEL CONTROL PARTS

Description Part Number

Probe Level Control, 5

3

/8” . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242-300036-010

Probe, Cutoff, 5

7

/8” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242-300036-011

Control Board with Relay (2 probe) . . . . . . . . . . . . . . . . . . . . 323-300033-001

Control Board* (1 probe) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323-300033-011

Control Board* (3 probe) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323-300033-006

Relay for Control Board, Plug-in . . . . . . . . . . . . . . . . . . . . . . 072-300047-001

Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346-300035-001

Probe Isolator (For Level Control) . . . . . . . . . . . . . . . . . . . . . 332-300009-002

*Used on older models.

Page 6

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...