Chromalox Cartridge Heaters Modifications

Cartridge Heaters

Modifications & Options

Modifications & Options

Cartridge heaters can be easily specified to

meet the demands of special applications.

Simply select from a variety of standard options and features to customize the heater to

your specific needs. For customized engineering or alternative options, contact your Chromalox sales representative for fast turnaround

on your specifications.

• LeadwireTypes

• EndSealOptions

• LeadOptions

• MountingOptions

• Built-InThermocouple

Leadwire Types

Operating

Temperature

Description Volts

Mica Fiberglas

Insulation

Fluoropolymer 300V

®

300V Standard

600V

600V

Seal Options

Type Description/Application

Epoxy Epoxy seal available on above

Fluoropolymer

RTV For applications where a mois-

Hermetic Ceramic-to-metal seal is good

MR

SEOT2

leads by voiding end of sheath

and lling with epoxy to provide a

moisture barrier.

A swaged-in seal that provides

additional moisture resistance.

ture barrier is required.

for element temperatures up to

1000°F. Specify heater length

beyond the seal. Metal portion

of the seal overlaps the heater

sheath by 3/16".

Meets UL File

SEOT2.SA 12768

(°F) (°C)

842 450

392 200

Components

End Seal Temperature Limits

Operating

Temperature

Description

Air Set Cement Standard 1000 538

Epoxy Seal 194 90

Fluoropolymer Seal 392 200

RTV Seal 284

Hermetic Seal 1000 538

MR-SEOT2 374 190

End Seal Options

Hermetic Seal

Ceramic-to-metal seal is good for element

temperatures up to 1000°F. Specify heater

lengthbeyondtheseal.Metalportionofthe

seal overlaps the heater sheath by 3/16”. For

washdown conditions.

Hermetic Seal Code 8C

Lead Options

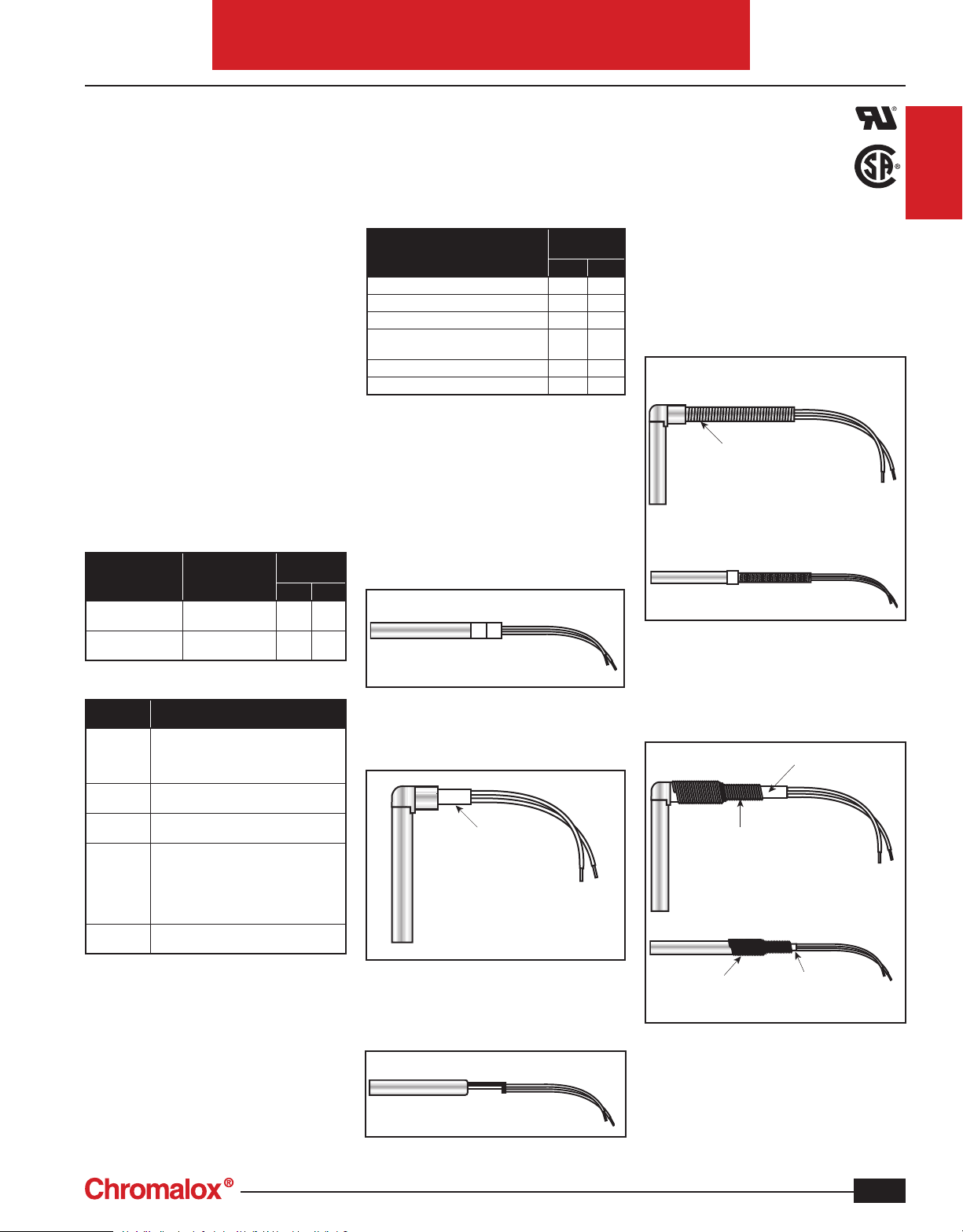

Right Angle Flexible Leads

Heat Shrink Insulation (100°C)

(°F) (°C)

140

392

200

Code 14C

Lead Options (cont’d.)

Flexible Stainless Steel Conduit

Flexible Stainless Steel Conduit provides

leadwire protection from abrasion and sharp

edges, and facilitates easier handling in harsh

environments. Available in both straight and

right angle configurations.

Right Angle

Code 15C - Standard

Code 16C - Moisture Resistant

Flexible Stainless Steel Conduit

for Abrasion Protection

Straight

Code 4C - Standard

Code 5C - Moisture Resistant

Protective Spring

Available in both straight and right angle configurations, the Protective Spring gives strong,

yet flexible leadwire protection from bending,

fatigue and flexing.

Right Angle

Code 18C

Protective Spring

Straight Code 3C

Heat Shrink Insulation

(100°C)

cartridge

Strain Relief

Strain Relief supports leads to reduce bending,

crimping and breakage.

Code 19C

Protective Spring Provides

a Flexible Strain Relief

to Leadwire

Heat Shrink

Insulation

(100°C)

A-95

Components

Cartridge Heaters

Modifications & Options (cont’d.)

Lead Options (cont’d.)

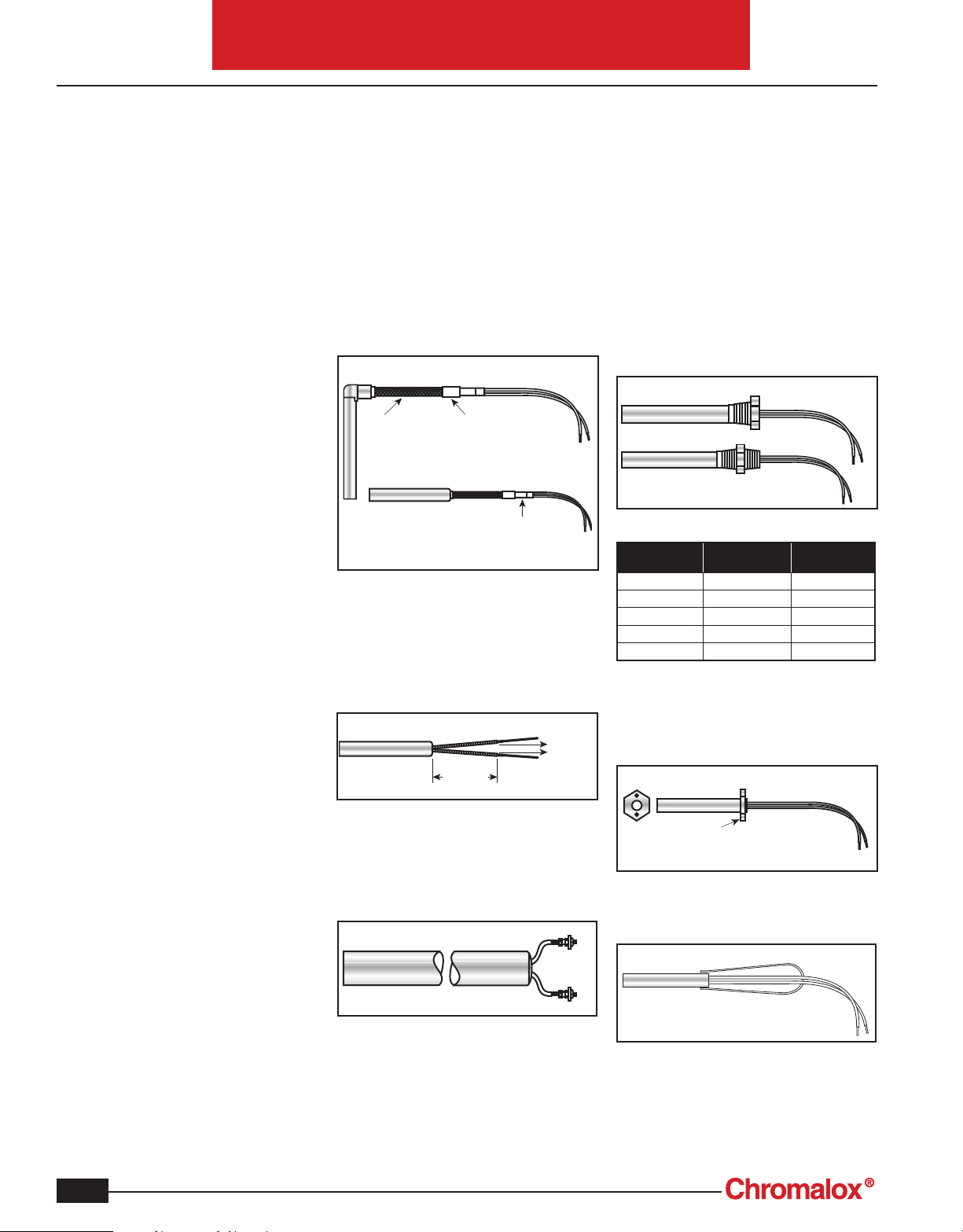

Metal Braid

Stainless Steel metal braid protects leadwire

from abrasion and sharp edges, yet maintains

exibilityandeaseofinstallation.Metalbraid

is available in both straight and right angle

configurations.

Code 17C Right Angle

Heat Shrink

Insulating

Beads

Insulation

(100°C)

Heat Shrink

Insulation

(100°F)

Leadwire

Crimped

to Retain

Insulation

Beads

Metal Braid Protects

Leads from Abrasive

and Sharp Surfaces

Code 13C Straight

Ceramic Beads

Ceramic Bead insulation can be specified to

protect leadwires from high ambient temperatures up to 1200°F (649°C). To order, specify

ceramic beads length and additional lead

length.

Code 12C

Mounting Options

Threaded Fittings

Threaded fittings allow the heater to be easily

installed into a threaded hole for immersion

applications. Available with single or double

threaded fittings. The fitting overlaps the cartridge heater sheath by 1/4". Specify “brass”

or “stainless steel” threaded fitting.

Code 9CS Single End

Code 9CD Double End

Threaded Fitting Sizes

Nom. Heater

Diameter (In.)

1/4 1/8 - 27 7/16

3/8 1/4 - 18 9/16

1/2 3/8 - 18 11/16

5/8 1/2 - 14 7/8

3/4 3/4 - 14 1-1/16

Mounting Flange

The mounting flange option allows for easy

mounting and specific positioning of the

heater within an application.

NPT Size

(In.)

Hex Size

(In.)

Code 10C

A-96

Threaded Post Terminals

Post Terminals provide a strong, secure connection to buss bars or ring/fork connectors.

Available only on 5/8 and 3/4” diameter heaters.

Code 20C

1/8" Thick Stainless

Steel Mounting Flange

Wire Pull

The Wire Pull assists in heater removal.

Code 11C

Loading...

Loading...