Page 1

Hardware Instruction Manual

C4

4-Channel SCR Power Controller

with Independent PID Control

PK544

0037-75573

April 2018

i

Page 2

Table of Contents

Important Safeguards ............................................................................................................. 1

1. Initial Instructions .............................................................................................................. 2

1.1 General Description ................................................................................................................................. 2

1.2 Features ................................................................................................................................................... 2

1.3 Product Inspection .................................................................................................................................. 2

2. Dimensions & Weights ...................................................................................................... 3

3. Installation - Mounting ...................................................................................................... 4

4. Installation - Wiring ........................................................................................................... 5

5. Emission, Immunity and Safety Standards ..................................................................... 6

6. Controller Overview .......................................................................................................... 7

6.1 Layout ................................................................................................................................................... 7

6.2 Cooling Fan ............................................................................................................................................. 8

6.3 Inserting a New Field Bus Interface Card ................................................................................................ 8

7. Connections and Indication ............................................................................................. 9

7.1 Power Connections ................................................................................................................................. 9

7.2 Power Wiring Considerations .................................................................................................................. 9

7.3 Input & Output Connections .................................................................................................................. 10

7.4 LED Logic .............................................................................................................................................. 10

7.5 Rotary Switches .................................................................................................................................... 11

7.6 Connector Detail .................................................................................................................................... 11

7.6.1 Connector J1/J1a ......................................................................................................................... 11

7.6.2 Connector J2 ................................................................................................................................ 14

7.6.3 Connector J3 ................................................................................................................................ 15

7.6.4 Connector J4 ................................................................................................................................ 16

7.7 DIP-Switch Configuration ...................................................................................................................... 17

7.8 Serial Communication Ports .................................................................................................................. 18

7.8.1 Port1 (Standard Local Bus) ..........................................................................................................18

7.8.2 Port2 (Optional Fieldbus) .............................................................................................................. 19

7.8.3 Connection Example: Communication Port ................................................................................. 25

8. Load Connection Examples ........................................................................................... 29

8.1 4 Single Phase Loads, 3- Phase Line with Neutral ............................................................................... 31

8.1 4 Single Phase Loads, 3- Phase Line without Neutral .......................................................................... 31

8.3 Two 3-Phase Loads, Closed Delta ........................................................................................................32

8.4 Two 3-Phase Loads, Star (Wye) without Neutral ................................................................................... 32

8.5 One 3-phase Load Active, One 3-Phase Load Inactive, Wye without Neutral ...................................... 33

8.6 One 3-Phase Load, Inside Delta ............................................................................................................ 33

9. Inductive and Transformer Coupled Load Guidelines ................................................. 34

10. Communications Port (Modbus RTU/RS485) ............................................................... 34

11. Autobaud Function .......................................................................................................... 35

11.1 Autobaud Port 1 Sequence ................................................................................................................... 35

11.2 11.2 Autonode Sequence for Fieldbus Use ........................................................................................... 35

12. Specifications .................................................................................................................. 36

13. Ordering Information ....................................................................................................... 40

14. Configuration and Programming ................................................................................... 41

15. Accessories ..................................................................................................................... 41

ii

Page 3

Important Safeguards

HIGH VOLTAGE (up to 480 VAC) is used in the

operation of this equipment; DEATH ON CONTACT may result if personnel fail to observe

safety precautions.

Learn the areas containing high-voltage connections when installing or operating this

equipment.

Be careful not to contact high-voltage connections when installing or operating this equipment.

Before working inside the equipment, turn

power off and ground all points of high potential before touching them.

The owner/installer must provide all necessary

safety and protection devices and follow all

current electrical wiring standards and regulations. Failure to do so may compromise the

integrity of the controller and/or cause product

failure resulting in a safety risk to operational

and service personnel.

This controller utilizes a heat sink which is designed to cool the unit during operation. Under no circumstance should air flow around the

controller be compromised in any way. Failure

to do so may result in the overheating of the

controller, product failure, product temperatures and even fire.

During continuous operation, the heat sink can

reach very high temperatures, and keeps a

high temperature even after the unit is turned

off due to its high thermal inertia.

Higher voltages may be present. DO NOT work

on the power section without first cutting out

electrical power to the panel. Failure to do so

may cause serious injury or death.

ELECTRIC SHOCK HAZARD: Any installation involving control equipment must be performed

by a qualified person and must be effectively grounded in accordance with the National

Electrical Code to eliminate shock hazard.

1

Page 4

1. Initial Instructions

1.1 General Description

The C4 is an extremely compact advanced SCR power

controller that provides a unique combination of performance, reliability, and flexibility. The C4 multiple

zone SCR power controller manages both single phase

and 3-phase industrial heating load applications. Load

management options include: Up to 4 independently

controlled single phase loads or one 3-phase/3-leg

load (with or without an additional single phase load) or

up to two 3-phase/2-Leg loads.

Standard features: Output choices range from 30 kW

to 80 kW per unit or from 16 to 40 Amps per zone at

480 Vac (for higher amperages the C4X can be used);

Four universal main process inputs, two digital inputs,

two configurable alarm outputs, Mod-bus RTU/RS485

digital communications, DIN Rail or panel mountable.

Optional features: One or four Current Transformers (input), four analog inputs, integral fuse holder (30

kW & 60 kW only), four configurable outputs, modular

Fieldbus Communication protocols including Modbus

RTU, Modbus TCP, Ethernet IP, EtherCAT, CANopen,

DeviceNet, Profibus, and Profinet. This new Chromalox

controller is the ideal PID and power control solution

for applications demanding high performance, continuous service, preventative maintenance information,

and increasing need for process data and information

for quality and process improvement analysis. Industry

markets such as, but not limited to:

• Packaging

• Plastics Processing; Extrusion; Thermforming; Injection Molding, Welding & Joining

• Semiconductor

• Material Finishing; Paint Booths;

• Textile

• Multiple zoned furnaces; Tunnel Ovens

• Food Processing

1.2 Features

• 30, 60, 80kW controller size capacity (refer to C4X

for higher amperages)

• Solid state relay control

• One or four current transformers

• Fuses-holder (option)

• 4 universal main inputs

• 4 heat/cool independent PID

• 4 main output internally wired to the SSR

• 4 auxiliary analog inputs (option)

• 4 configurable output (option): relay / logic / analog/

TRIAC

• 2 configurable relay alarm output

• 2 digital inputs

• Standard digital communication: Modbus RTU/

RS485

• Optional Fieldbus communication: Profibus DP,

CANopen, DeviceNet, Modbus RTU, Ethernet Modbus TCP, Ethernet IP, EtherCAT, ProfiNET

• DIN rail mounting

• Integrated heat sink and fan

• cULus, CE

1.3 Product Inspection

Immediately after unpacking the unit and prior to installing, check the order code and the other data on

the label attached to the outside of the container and

write them down. If troubleshooting is necessary, you

will need to provide this data to a Chromalox customer

service representative.

Upon removing package, ensure that there is no physical damage to the controller during shipment, and that

the package also contains the “Configuration and Programming” manual.

If there are signs of damage or if any parts are missing,

notify your Chromalox representative immediately.

Read through all installation sections in detail within

this document before installing the C4 on any piece of

equipment or in a control panel enclosure. Spacing requirements must be honored for proper operation and

safety.

2

Page 5

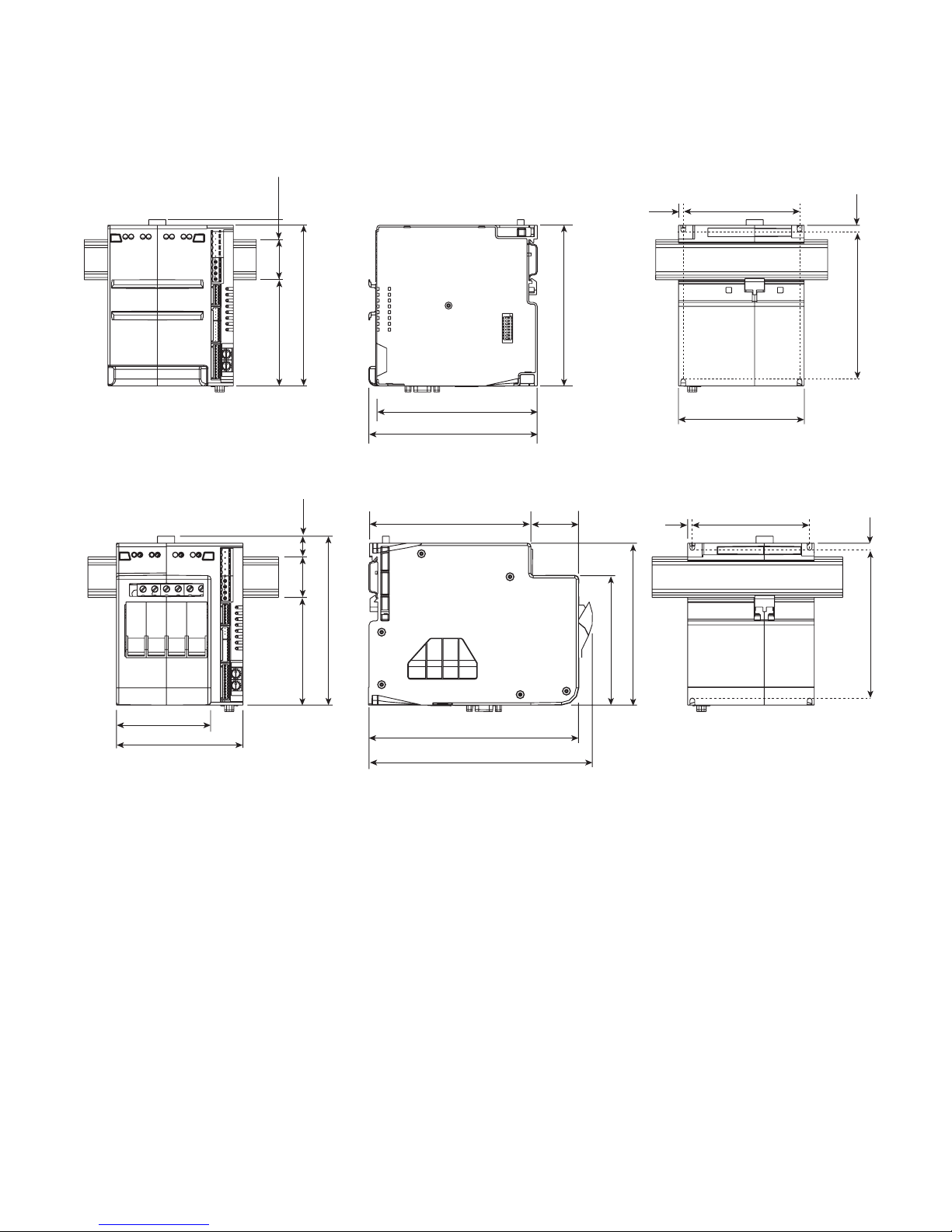

2. Dimensions and Weights

(155)

Models without Fuse Holder

3.85

(92.5)

0.75

(19.6)

1.4

(35)

0.75

(19.5)

5.5

(140)

1.4

(35)

5.75

(147)

5.75

(147)

(140)

5.5

(140)

5.5

1.55

(42)

5.5

(140)

4.4

(111.5)

5.5

(140)

0.16

(4)

0.16

(4)

4

(101.5)

4.3

(109.5)

4

(101.5)

0.16

(4)

5.2

(132)

0.16

(4)

5.2

(132)

3.25

(52

)

4.3

(109.5)

3.65

(92.5)

7.7

7.2

(182)

3

Page 6

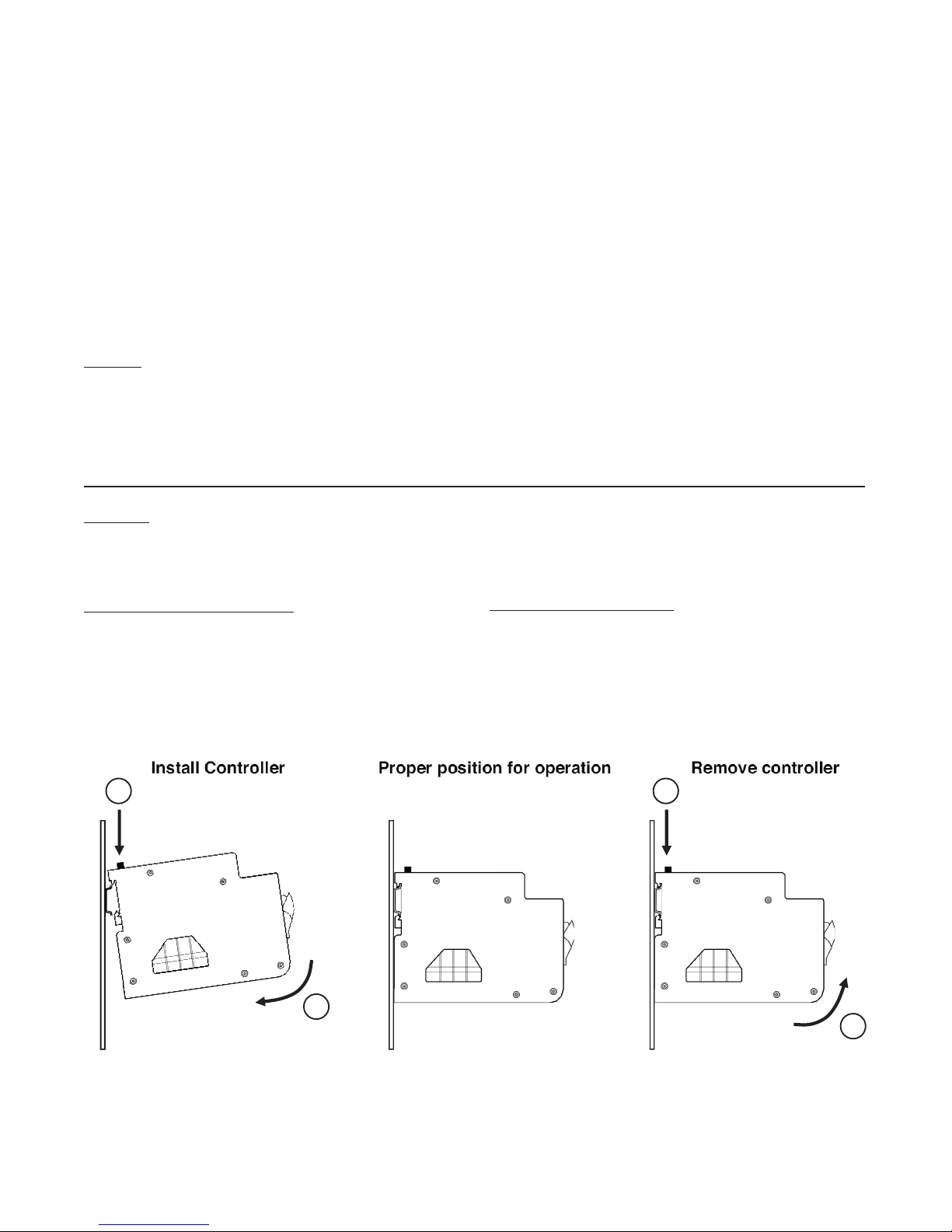

3. Installation

ROTATE

To ensure proper performance, maximum safety and

reliability, it is essential to install the unit correctly. This

includes proper mounting, spacing, hardware and wiring. See below:

• Maximum surrounding air temperature is 40°C in

“Open Type Equipment” which is suitable for use in

pollution degree 2. For temperature >40°C refer to

the Derating Curves.

• Install the unit vertically (max 10° inclination from

vertical axis).

Spacing

To ensure maximum reliability, the device must be correctly installed in the panel in such a way as to obtain

adequate heat exchange between the heat sink and

the surrounding air under conditions of natural convec-

Mounting

C4 Models to be installed on a DIN Rail . Rear panel

dimensions are on previous page.

tion. Under no circumstance shall any component, including cable channels, compromise minimum thermal

spacing dimensions. Air must be able to flow vertically

on the heat sink without any obstacles.

Solid state devices dissipate heat which may impact

installation room temperature. Exchange with external

air or an air conditioner may be necessary to transfer

heat outside the panel.

• Minimum vertical distance between unit and panel

wall: 3.9” (100 mm)

• Minimum horizontal distance between unit and panel wall: 0.8” (20 mm)

• Minimum horizontal distance between adjacent

power control units: 0.4” (10 mm)

To install C4 onto a DIN Rail:

1. Depress DIN mounting spring. u

2. Position controller on the DIN Rail at a slight angle.

3. Lower controller on to DIN Rail. v

4. Release the mounting spring.

1

PRESS

2

ROTATE

To remove from DIN Rail:

1. Depress DIN mounting spring. u

2. Rotate bottom of controller off of the DIN Rail. v

3. Remove from DIN Rail.

1

PRESS

2

4

Page 7

4. Installation – Wiring

This section covers the C4 wiring installation instructions for the power supply, inputs, outputs and interfaces.

CAREFULLY READ THE FOLLOWING WARNINGS

BEFORE INSTALLING THE INSTRUMENT!

Failure to obey these warnings could create

electrical safety and electromagnetic compatibility problems, as well as void the warranty

and cause personal injury or death.

Electrical Power Supply

• The controller DOES NOT have an On/Off switch.

The user must install a switch or isolator that conforms to all codes and electrical safety requirements

(CE mark) to cut off the power supply upstream of

the controller. The switch must be installed in the

immediate vicinity of the controller and with-in

reach of the operator. A single switch can be used

for multiple devices.

• The earth connection must be made with a specific

lead.

• If the product is used in applications with risk of

harm to persons or damage to machines or materials, it MUST be equipped with auxiliary alarm

device(s). It is advisable to provide the ability to

check for tripped alarms during regular operation.

DO NOT install the product in rooms with hazardous (inflammable or explosive) atmosphere; it may

be connected to elements that operate in such atmosphere only by means of appropriate interfaces

that conform to current safety standards..

Notes on Electrical Safety and Electromagnetic

Compatibility

CE MARKING: EMC (electromagnetic compatibility)

conformity in compliance with Directive 2004/108/

CE and following modifications. Series C4 control-

lers are mainly intended for industrial use, installed on

panels or control panels of production process machines or systems. For purposes of electromagnetic

compatibility, the most restrictive generic standards

have been adopted, as shown on the tables.

LV (low voltage) conformity Directive 2006/95/CE.

EMC compliance has been verified with respect to the

information in Tables 1 and 2.

Recommended Installation for purposes of EMC

Instrument power supply

• The power supply for the electronic instrumentation

on the panels must always come directly from a cut/

off device with fuse for the instrument part.

• Electronic instrumentation and electromechanical

power devices such as relays, contactors, solenoids,

etc., MUST ALWAYS be powered by separate lines.

• When the power supply line of electronic instruments is heavily disturbed by switching of SCR power groups or by motors, you should use an isolation

transformer only for the controllers, grounding its

sheathing.

• It is important for the system to be well grounded.

Voltage between neutral and ground must not be > 1

V and resistance must be < 6Ω (Ohms).

• If the grid voltage is highly unstable, use a voltage

stabilizer.

• In proximity of high frequency generators or arc

welders, use adequate grid filters.

• The power supply lines must be separate from instrument input and output lines.

• Supply from Class II or from limited energy sources.

Input and output connections

Before connecting or disconnecting any connection, always check that the power and control cables are isolated from voltage. Appropriate devices must be provided:

fuses or automatic switches to protect power lines.

•

Connected outside circuits must be doubly isolated.

• To connect analog or linear inputs, strain gauges,

TC, RTD, etc., you have to:

• physically separate the input cables from those

of the power supply, outputs, and power connections.

• use braided and shielded cables, with sheath-

ing grounded at a single point.

• To connect the control outputs and alarm outputs

(contactors, solenoids, motors, fans, etc.), install

RC (series of capacitors and resistors) groups parallel to inductive loads that work in AC.

(Note: all condensers must conform to VDE stan-

dards (class X2) and support voltage of at least

220Vac. Resistances must be at least 2W).

• Install a 1N4007 diode parallel to the coil of inductive loads that work in DC.

Installation Notes

Use the extra rapid fuse indicated in Table 15.1 later

in this manual, according to the wiring schematic examples and controller rating. Additionally, the applications with solid state units require a safety automatic

switch to disengage the load power line during certain

alarm events.

5

Page 8

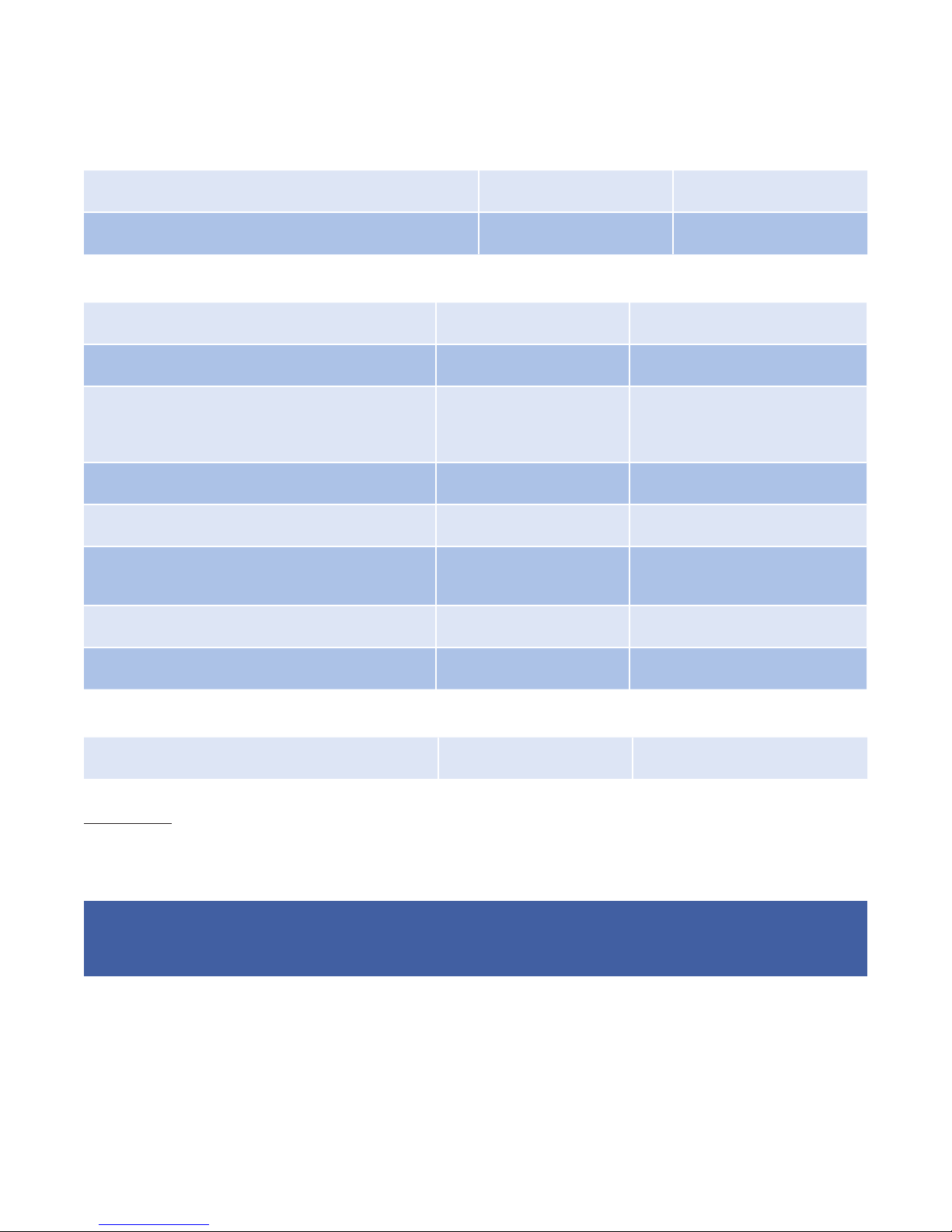

5. Emission, Immunity and Safety Standards

Table 1: EMC Emission

AC semiconductor motor controllers and conductors

for non-motor loads

Emission enclosure compliant in firing mode single

cycle and phase angle if external filter fitted

Table 2: EMC Immunity

Generic standards, immunity standard for

industrial environments

ESD immunity EN 61000-4-2

RF interference immunity

Conducted disturbance immunity

Burst immunity EN 61000-4-4

Surge immunity EN 61000-4-4/5

EN 60947-4-3

EN 60947-4-3

EN 60947-4-3 CISPR-11

EN 55011

4 kV contact discharge

8 kV air discharge

10 V/m amplitude modulated

80 MHz-1 GHz

10 V/m amplitude modulated

1.4 GHz-2 GHz

10 V/m amplitude modulated

0.15 MHz-80 MHz

2 kV power line

2 kV I/O signal line

PPower line-line 1 kV (level 2)

Power line-earth 2kV (level 3)

Signal line-earth 1kV (level 2)

Class A

Group 2

Magnetic fields immunity EN 61000-4-8 100 A/m (level 5)

Voltage dips, short interruptions and voltage

immunity tests

Table 3: LVD Safety

Safety requirements for electrical equipment for

measurement, control and laboratory use

ATTENTION

This product has been designed for class A equipment. Use of the product in domestic environments may cause

radio interference, in which case the user may be required to employ additional noise mitigation methods.

Per UL, the SCCR (Short Circuit Current Rating) is 100kA for models: C4 - XXXXX - 0 - XX Suitable for use on

a circuit capable of delivering not more than 100RMS kA symmetrical, 480VAC when protected only by listed

cartridge fuses manufactured by BUSSMAN type DFJ200 non renewable (JDDZ) 200A class J current limiting

fuses.

The CE declaration of conformity is available on request.

EN 61000-4-11 100%U, 70%U, 40%U,

EN 61010-1

UL 508

6

Page 9

6. Controller Overview

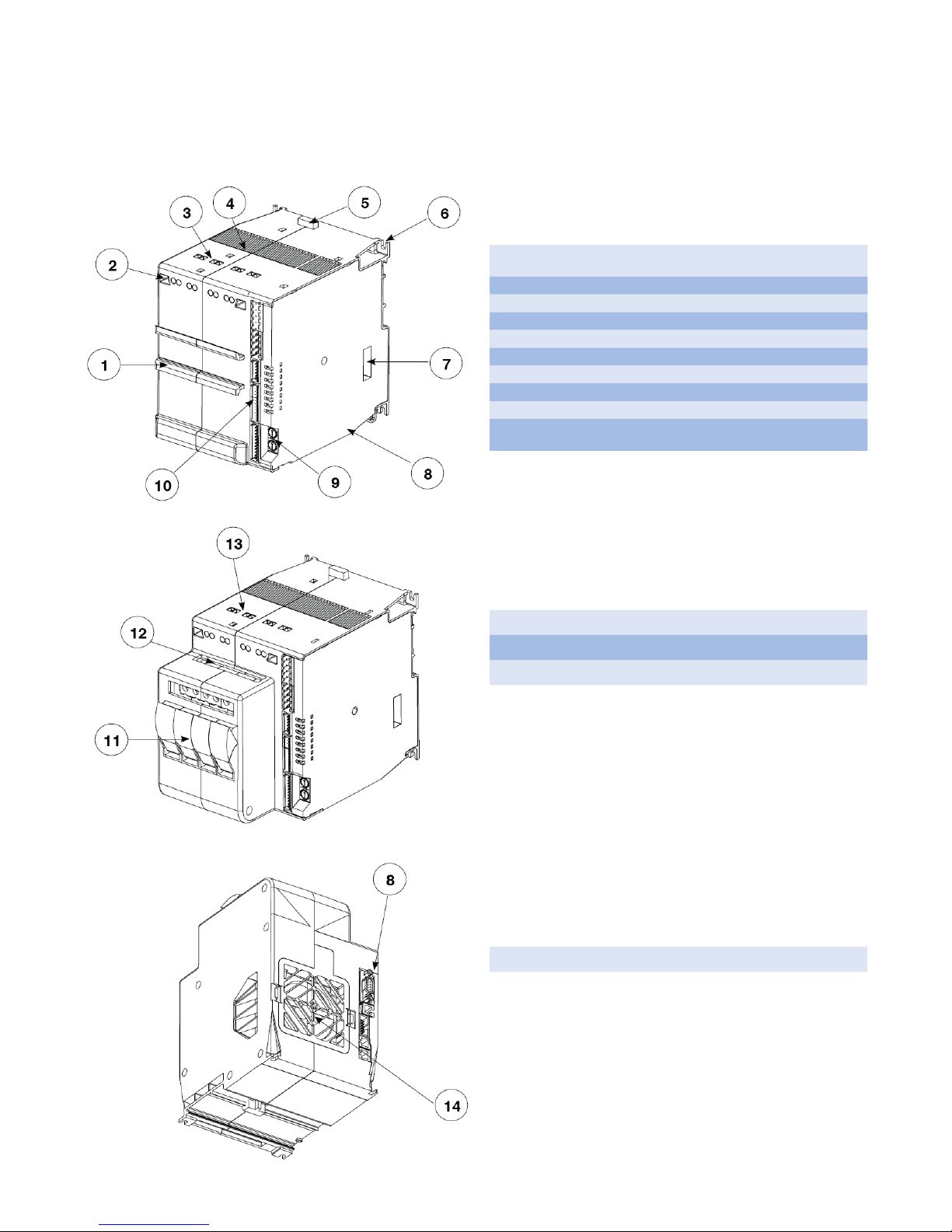

6.1 Layout

Front DIN rail mount for the C4-OP programming module.

1.

This mount is only present on models without fuse holders.

2. Screwdriver access to power connection screws.

3. Power supply connection terminals

4. Heat sink ventilation screen: DO NOT OBSTRUCT

5. Spring clamp release for rear DIN rail.

6. Fastening slots for additional mounting security.

7. DIP switches for controller function / load configuration.

8. Communication ports (Port1, Port2).

9. Rotary switches for setting node address or number

Input signal & low voltage power supply terminals

10.

(J1, J2, J3, J4)

11. Fuse holders. (Only available on 30KW and 60KW models).

12. Terminals for fuse holder connection (F1, F2, F3, F4/N)

13. Terminals for load power connection (U1, U2, U3, U4)

14. Air intake / fan protection screen: DO NOT OBSTRUCT

7

Page 10

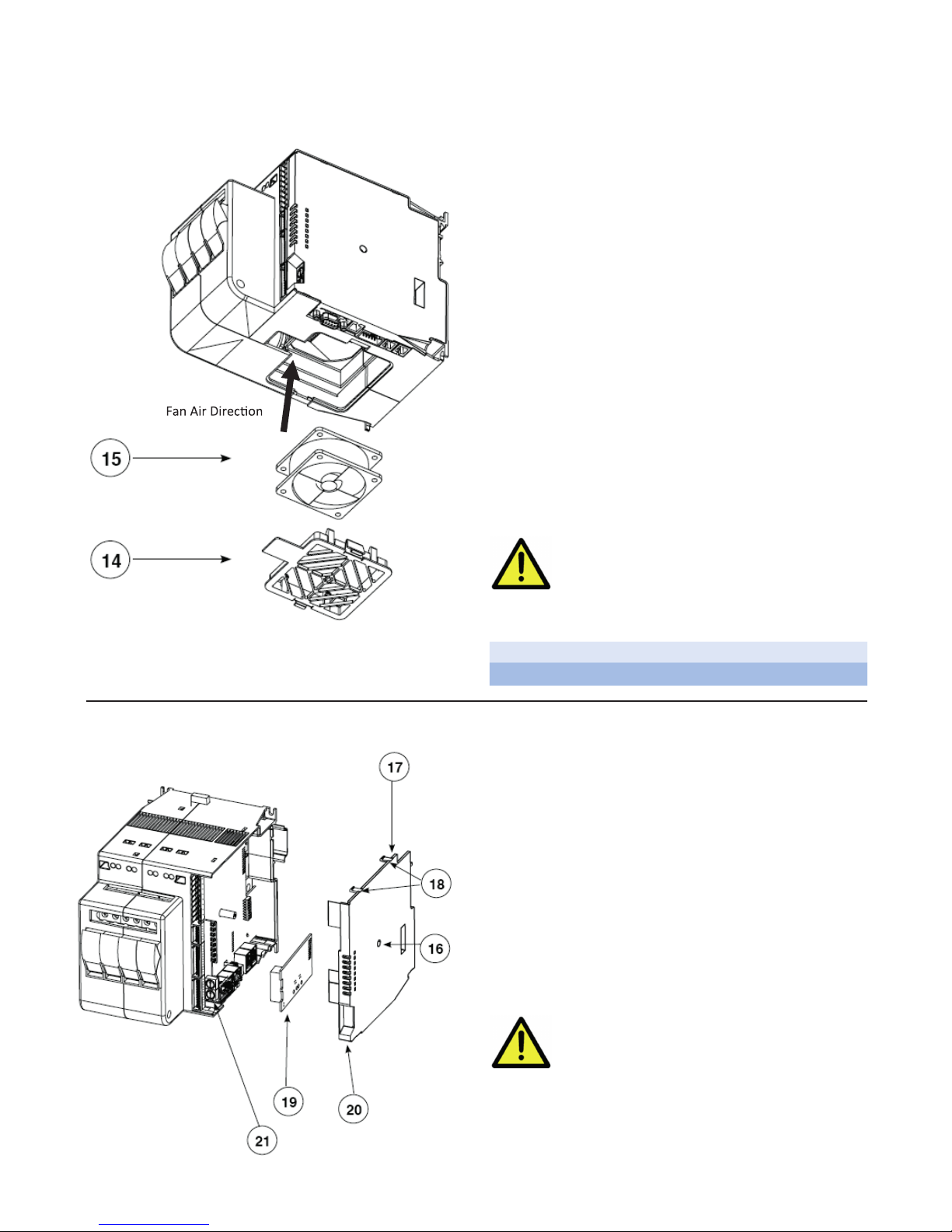

6.2 Cooling Fan

PERIODIC CLEANING

Every 6-12 months (depending on the dust level of

the installation) blow a compressed air jet downward

through the upper rectangular cooling grilles (on the

side opposite the fan). This will clean the internal heat

dissipater and the cooling fan.

IN CASE OF OVERHEAT ALARM

If periodic cleaning does not eliminate the problem, do

as follows:

a. Remove the fan support grille by detaching the two

support tabs

b. Disconnect the fan connector from the board

c. Check the condition of the fan

d. Clean or replace the fan

NOTE: Ensure that the air flow arrow on the fan is

pointing towards the heat sink e Insert the connector into the board

f. Insert the fan support grille until it attaches

g. Power up the device and check fan rotation when at

least one load is on

6.3 Inserting a New Field Bus Interface Card

Before and during the inspection/

maintenance, cut power to the fan

controller and verify that the system

is isolated for operator safety.

14 Support Grill

15 Fan

To insert a communication module, the Field Bus

Interface Board compartment must be accessed.

Follow these steps:

1. Remove the Fieldbus compartment cover screw

(16)

2. With a flat screwdriver, gently apply pressure at (18)

3. Remove compartment cover (17)

4. Insert Fieldbus card (19) into the proper connector

(21)

5. Remove applicable communication port tab (20) on

cover (17)

6. Carefully replace compartment cover (17)

7. Tighten compartment cover screw (16)

Before attempting board replacement,

ensure that power to the controller

has been cut and verify that the

system is isolated for operator safety.

8

Page 11

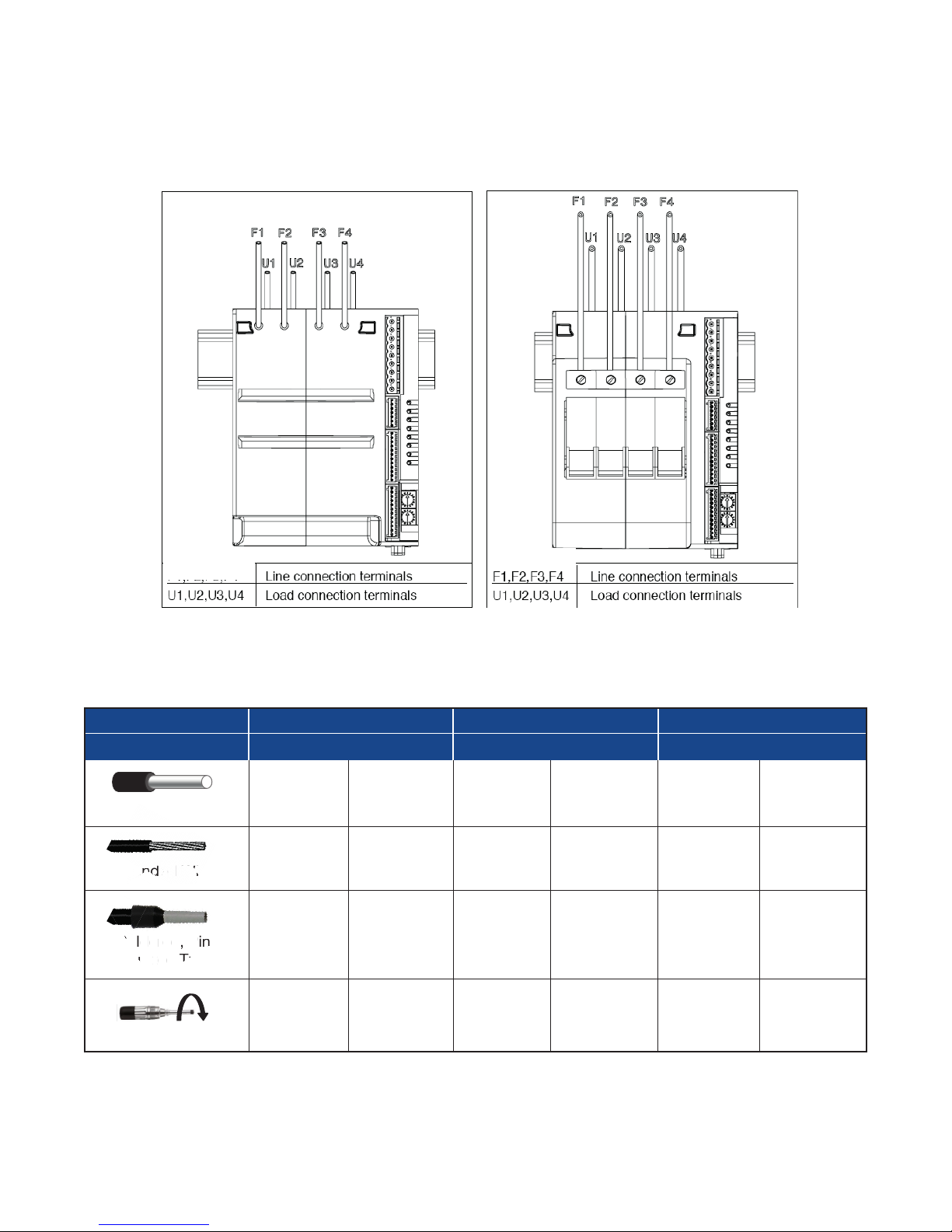

7. Connections and Indication

Model without fuse holder Model with fuse holder

So

li

Solid Wire

d

d

Solid Wire

Stranded Wire

d

d

Solid Wire

Stranded Wire

Soldered, Pin

Insulated Tube

Torque Force

d

d

7.1 Power Connections

F1,F2,F3,F4/

7.2 Power Wiring Considerations

Model 30kW 60kW 80kW

Max Current 16 Amps 30 Amps 40 Amps

Solid Wire

Stranded Wire

Soldered, Pin

Insulated Tube

0.2 - 6mm2 24 - 10 AWG 0.2 - 6mm2 24 - 10 AWG 0.5 - 16mm2 20 - 6 AWG

0.2 - 4mm2 24 - 10 AWG 0.2 - 4mm2 24 - 10 AWG 0.5 - 10mm2 20 - 7 AWG

0.25 - 4mm2 23 - 10 AWG 0.25 - 4mm2 23 - 10 AWG 0.5 - 10mm2 20 - 7 AWG

0.5 - 0.6Nm 0.5 - 0.6 Nm 1.2 - 1.5Nm

/N

4.4 - 5.3

In-lb

4.4 - 5.3

In-Lb

10.6 - 13.3

In-Lb

9

Page 12

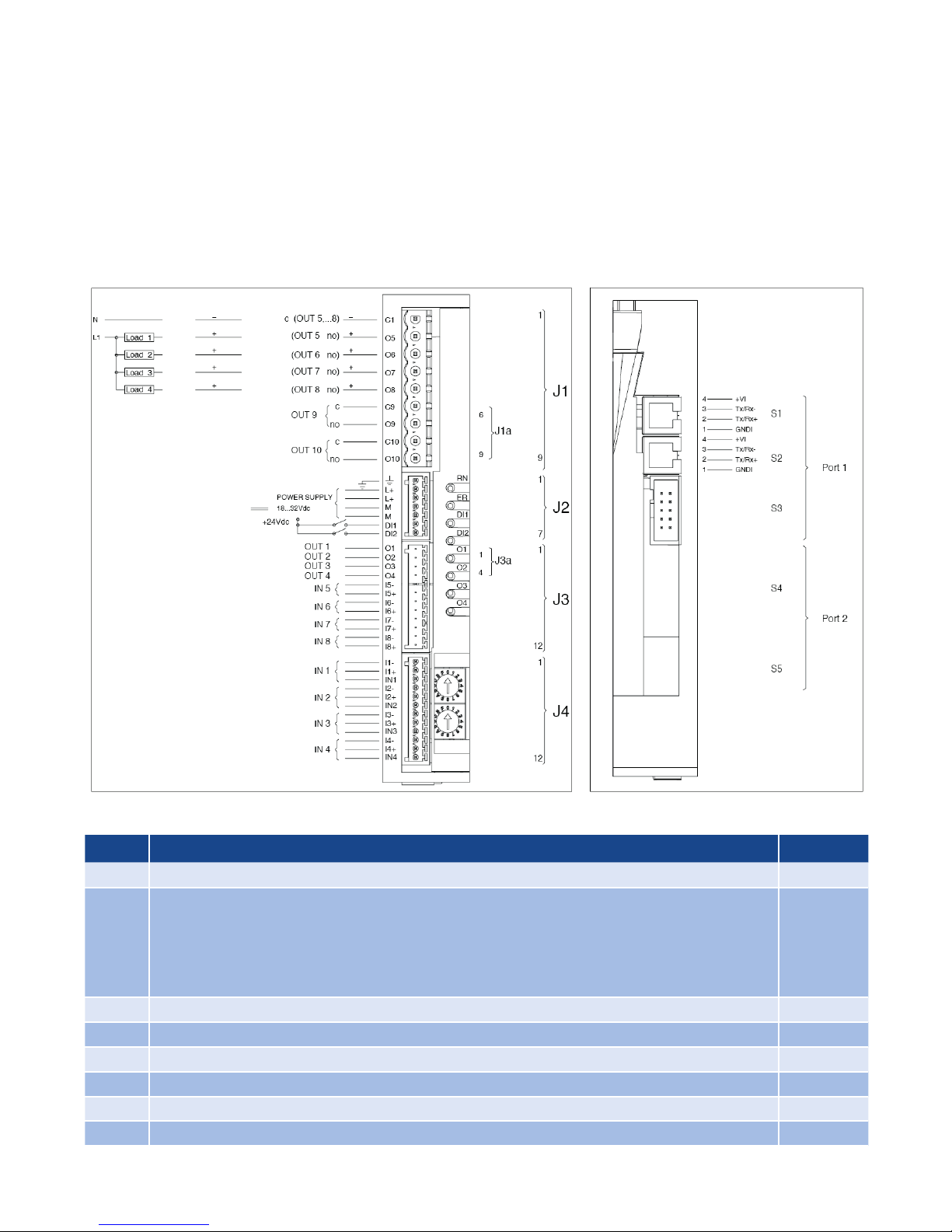

7.3 Input & Output Connections

• Use adequately compensated cable for thermocouple inputs. Maintain polarity by avoiding junctions

on the cables.

• If using a grounded thermocouple, the connection

must be at a single point.

• For RTD inputs, use copper extension cables and

avoid junctions on the cables. Resistance must not

exceed 20 Ohm.

TRIAC Logic/Analog Relay

• For 2-wire RTDs, make the connection indicated instead of the third wire.

• Refer to the applicable Connectors Detail starting in

section 7.6

7.4 LED Logic

LED Description Color

RN RUN - Flashes during regular operation Green

ERROR (Fault Condition) - Illuminates when a fault is present

Lo = Process Variable value < Lo.S

ER

HI = Process Variable value > Hi.S

Sbr = Sensor interrupted or input values over maximum limits

Err = RTD third wire interrupted for Pt100 or input values below minimum

ER = (red) flashing: Alarm temperature OVER_HEAT (STATUS.STRUMENTO 4 bit 1)

DI1 State of digital input 1: DI1 Yellow

DI2 State of digital input 2: DI2 Yellow

O1 State of output 1: O1 Yellow

O2 State of output 2: O2 Yellow

O3 State of output 3: O3 Yellow

O4 State of output 4: O4 Yellow

Red

10

Page 13

7.5 Rotary Switches

0

Switch Drescription

0

1

F

2

E

3

D

4

C

5

B

A

9

8

0

1

F

E

D

C

B

A

9

8

X1

6

7

2

3

4

5

6

7

X1

Defines Address of Controller Module

Available address: 00...99

7.6 Connector Detail

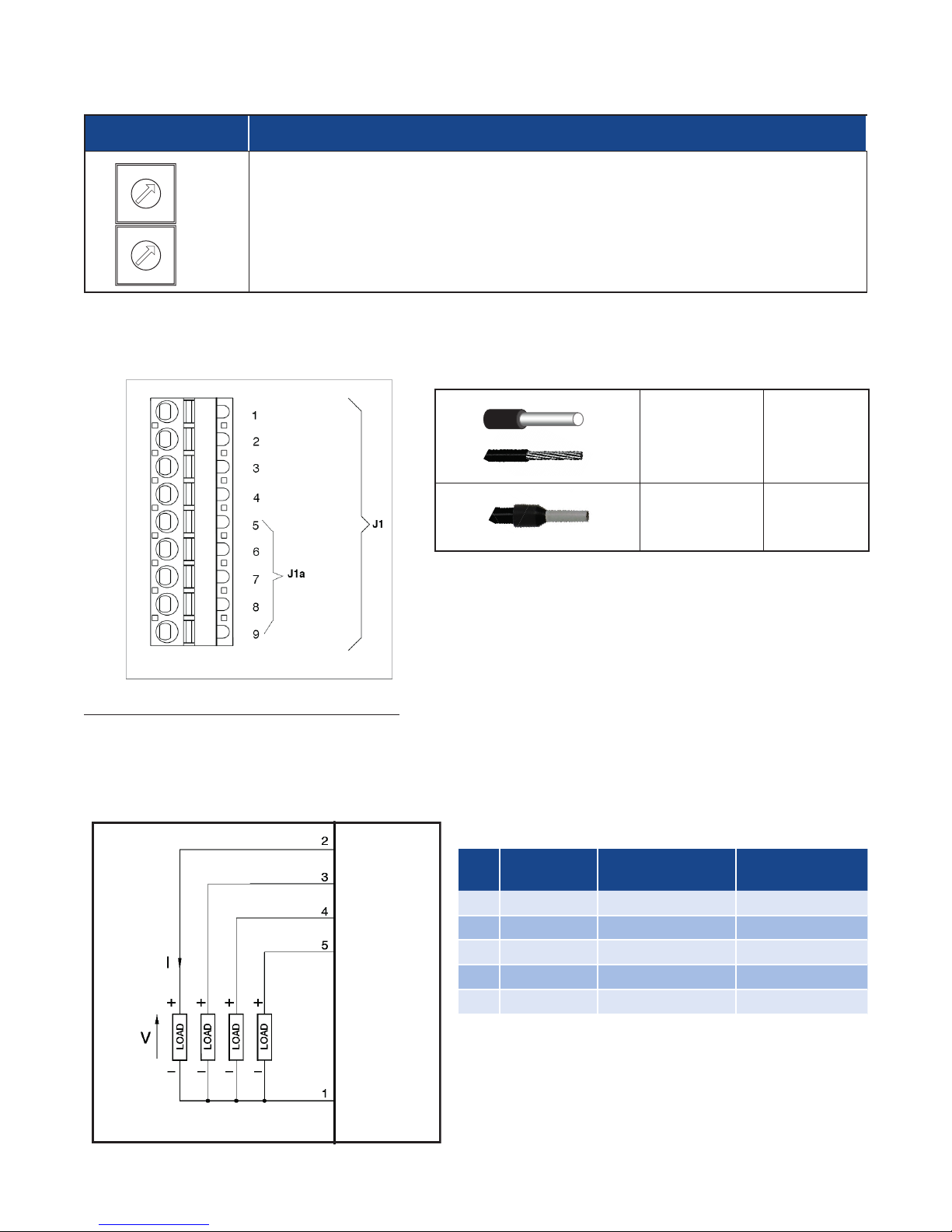

7.6.1 Connector J1 / J1a (Note: If Auxiliary Outputs O5 - O8, are present, connector J1a becomes J1.)

0.2 - 2.5mm2 24-14 AWG

0.25 - 2.5mm2 23-14 AWG

Outputs 5 - 8: Logic or Analog Output Type

Logic outputs: 18 - 36Vdc, max 20mA

Analog outputs: Voltage (default): 0 - 10V, 2 - 10V, max 25mA or Current: 0 - 20mA, 4 - 20mA, max 500Ω

Wiring Schematic for Outputs 5 - 8, both Logic & Analog Outputs

O5

PIN Legend

Polarity

O6

O7

PIN Name Description

1 Com O5-O8 Outputs Common ( – )

(Logic or Analog)

2 O5 Output 5 ( + )

O8

3 O6 Output 6 ( + )

4 O7 Output 7 ( + )

5 O8 Output 8 ( + )

Com O5-O8

11

Page 14

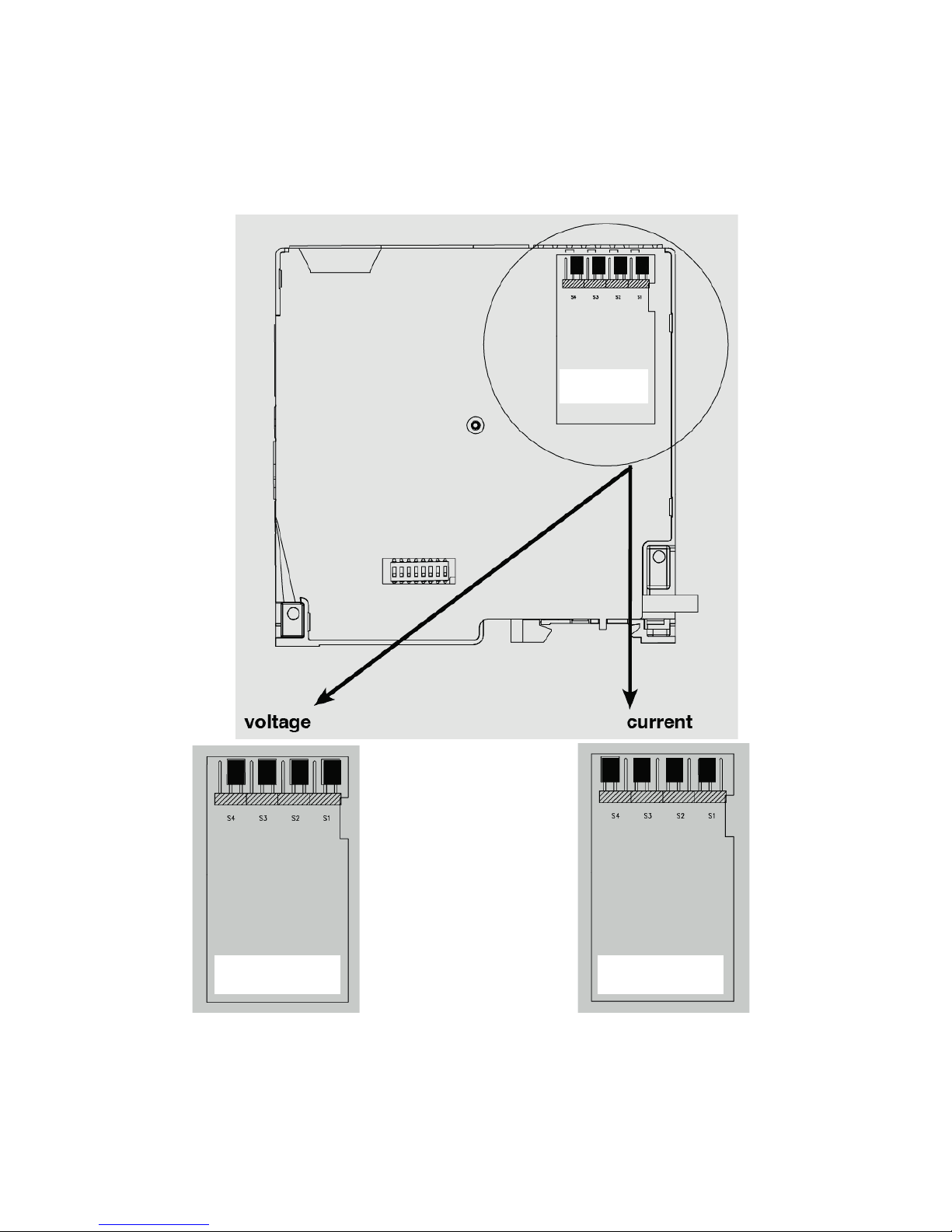

When the optional Auxiliary Output type “A” (Analog) is selected, one must choose whether the output is Voltagebased (default) or Current-based. This selection is carried out via proper jumper placement on the board as follows:

C4

Output Card

C4

Output Card

12

C4

Output Card

Page 15

Outputs 5 - 8: TRIAC Type

Com O5-O8

O5

O6

O7

O8

TRIAC outputs: Voltage: 24...230Vac, max 1A

Wiring Schematic for Outputs 5 - 8, TRIAC Outputs

Com O5-O8

O5

O6

O7

O8

PIN Legend

PIN Name Description

1

Com O5-O8 Outputs Common

2

3

4

O5 Output 5

O6 Output 6

O7 Output 7

5

Outputs 5 - 8: Relay Type

Outputs Out 5 - Out 8, Relay outputs: Ir = 3A max, NO (normally open)

V = 250V/30 Vdc cosw = 1; I = 12A max

Wiring Schematic for Outputs 5 - 8, Relay Outputs

Com O5-O8

O5

O6

O7

O8

PIN Name Description

1

Com O5-O8 Outputs Common

2

3

4

O8 Output 8

PIN Legend

O5 Output 5

O6 Output 6

O7 Output 7

13

5

O8 Output 8

Page 16

Outputs 9, 10: Relay Type

Outputs Out 9, Out 10, Relay outputs: 5A max

V = 250V/30Vdc cosw = 1; I = 5A max

Wiring Schematic for Outputs 9 & 10, Relay Outputs

PIN Name Description

1

2

3

4

7.6.2 Connector J2 (Power Supply, Digital Input 1 & Digital Input 2)

PIN Legend

Com O9 Output Common O9

O9 Output O9

Com O10 Output Common O10

O10 Output O10

Wiring Schematic for J2 - Power Supply, Digital Inputs

0.14 - 0.5mm2 28-20AWG

0.25 - 0.5mm2 23-20AWG

PIN Legend

PIN Name Description

1

2

3

4

5

6

L+

L+

M-

M-

DI1 Digital Input 1

Ground

Power Supply

18 - 32 Vdc

14

7

DI2 Digital Input 2

Page 17

7.6.3 Connector J3 (Auxiliary Inputs)

Wiring Schematic for J3 - Auxiliary Inputs

0.14 - 0.5mm2 28-20 AWG

0.25 - 0.5mm2 23-20 AWG

PIN Legend

PIN Name Description

1

2

3

4

5

6

7

8

9

10

11

12

- No Connection

- No Connection

- No Connection

- No Connection

15+ Auxiliary Input 5

I5- Auxiliary Input 5

I6+ Auxiliary Input 6

I6- Auxiliary Input 6

I7+ Auxiliary Input 7

17- Auxiliary Input 7

I8- Auxiliary Input 8

18+ Auxiliary Input 8

15

Page 18

7.6.4 Connector J4 (Inputs 1 - 4)

Inputs 1 - 4

0.14 - 0.5mm2 28-20 AWG

0.25 - 0.5mm2 23-20 AWG

PIN Legend

PIN

1

2

60mV/Tc

Linear Input

I1- I1- I1-

I1+ I1+

3

4

5

I2- I2- I2-

I2+ I2+

6

7

8

I3- II3- 13-

I3+ I3+

9

10

11

I4- I4- I4-

I4+ I4+

12

1V/20mA

Linear Input

IN1+ IN1

IN2+ IN2

IN3+ IN3

IN4+ IN4

Pt100

Input

16

Page 19

7.7 Dip-Switch Configuration

Dip

Switch

1

2

3

4

Dip Switch Legend

Function Description

Load Connection See Load Configuration Table Below.

No Function

5

6

7

8

Frequency ON: 60 Hz OFF: 50 Hz

Factory Default ON: Resets Controller to Factory Settings

Simulation ON: Simulation Mode

RS485

Communications

Load Configuration Table

Dip Switch

1 2 3

OFF

ON

OFF

ON

OFF

OFF OFF 4 independent zones (4 single-phase loads)

OFF OFF

Zone 1: 3-phase load, star (wye) connection, with

neutral

ON OFF Zone 1: 3-phase load, open delta connection

ON OFF

OFF ON

Zone 1 & 3: Two 3-phase loads, star (wye)

connection, without neutral

Zone 1 & 3: Two 3-phase loads, closed delta

connection

ON: When the device is the ONLY RS-485

device or when it is the LAST RS-485 device

Load Connection Type

ON

OFF

ON

OFF ON No Function

ON ON No Function

ON ON No Function

17

Page 20

7.8 Serial Communication Ports

Modbus RTU/RS485 Serial Interface

e C4-OP Section

7.8.1 Port1 (Standard Local Bus): Connectors S1, S2, S3

1 9 2 F

1 9 0 F

0 1

Connector S3 accepts the C4-OP local

interface terminal. See th

for more detail.

Connector S1/S2

RJ10 4-4 Pin Pin Name Description Note

Cable Type: Flat telephone cable for pin 4-4 conductor 28 AWG

1 GND1 (**) -

2 Tx/Rx+ Data reception/transmission (A+)

3 Tx/Rx- Data reception/transmission (B-)

4 +V Reserved -

(*) Enable #8 DIP Switch on

last device on Modbus RS485

line

(**) Connect the GND signal to

Modbus devices with a line

distance > 300 ft. (100 m)

18

Page 21

7.8.2 Port2 (Optional Fieldbus): Connectors S4, S5

le RJ10 Connector

le RJ10 Connector

A. Modbus RTU/RS485, Modbus RTU/RS485

Connector S4/S5

RJ10 4-4 Pin Pin Name Description Note

1 GND1 (**) -

2 Tx/Rx+ Data reception/transmission (A+)

(*) Enable Fieldbus DIP Switch

on last device on Modbus

RS485 line

(**) Connect the GND signal to

3 Tx/Rx- Data reception/transmission (B-)

Modbus devices with a line

distance > 300 ft (100 m)

4 +V Reserved -

Cable Type: Flat telephone cable for pin 4-4 conductor 28 AWG

S5 Fema

S4 Fema

End of line Modbus

Termination Dip Switch*

19

Page 22

B. Modbus RTU/RS485, Profibus DP Interface

le RJ10 Connector

Green LED

S5 Female DB9 Connector

Connector S4

RJ10 4-4 Pin Pin Name Description Note

1 GND1 (**) -

2 Rx/Tx+ Data reception/transmission (A+)

(**) Connect the GND signal to

Modbus devices with a line

distance > 300 ft. (100 m)

3 Rx/Tx- Data reception/transmission (B-)

4 +V Reserved -

Cable Type: Flat telephone cable for pin 4-4 conductor 28 AWG

S4 Fema

Yellow LED

Red LED

Connector S5

D-Sub 9 Pins Male Pin Name Description Note

1 Shield EMC Production

Connect the terminal resistances as shown in the figure.

2 M24V Output Voltage - 24V

3 RxD/TxD-P Data reception/transmission

4 n.c. n.c.

5 DGND Data Ground

6 VP Positive Power Supply +5V

7 P24V Output Voltage +24V

8 RxD/TxD-N Data Reception/Transmission

9 n.c. n.c.

Cable Type: Shielded 1 pair 22 AWG conforming to PROFIBUS.

20

Page 23

C. Modbus RTU/RS485, CANopen Interface

le RJ10 Connector

Green LED

Connector S4

RJ10 4-4 Pin Pin Name Description Note

1 GND1 (**) -

2 Rx/Tx+ Data reception/transmission (A+)

(**) Connect the GND signal

among Modbus devices with a

line distance > 300 ft. (100 m)

S5 Male DB9 Connector

S4 Fema

Red LED

3 Rx/Tx- Data reception/transmission (B-)

4 +V Reserved -

Cable Type: Flat telephone cable for pin 4-4 conductor 28 AWG

Connector S5

D-Sub 9 Pins

Female Pin Name Description Note

1 - Reserved Connect the terminal resis-

2 CAN_L CAN_L bus line (domination low)

3 CAN_GND CAN Ground

4 - Reserved

5 (CAN_SHLD) Optional CAN Shield

6 (GND) Optional Ground

7 CAN_H

CAN_H bus line (domination High)

8 - Reserved

Optional CAN external positive sup-

9 (CAN_V+)

ply (dedicated for supply of trans-

ceiver and optocouplers, if galvanic

isolation of the bus node applies)

tances as shown in the figure.

Cable Type: Shielded 2 pairs 22/24 AWG conforming to CANopen.

21

Page 24

D. Modbus RTU/RS485, DeviceNet Interface

Connector S4

RJ10 4-4 Pin Pin Name Description Note

1 GND1 (**) -

2 Rx/Tx+ Data reception/transmission (A+)

(**) Connect the GND signal to

Modbus devices with a line

distance > 300 ft. (100 m)

S5 Male Connector

S4 Female RJ10 Connector

Red LED

Green LED

3 Rx/Tx- Data reception/transmission (B-)

4 +V Reserved -

Cable Type: Flat telephone cable for pin 4-4 conductor 28 AWG

Connector S5

D-Sub 9 Pins Male Pin Name Description Note

Connect a 120Ω / 1/4W resis-

1 V- Negative Power Supply

tance between the “CAN_L”

and “CAN_H” signals at each

end of the DeviceNet network.

2 CAN_L Low Signal

3 SHIELD Shield

4 CAN_H High Signal

5 V+ Positive Power Supply

Cable Type: Shielded 1 pair 22 AWG conforming to PROFIBUS.

22

Page 25

E. Modbus RTU/RS485, Modbus TCP/Ethernet Interface

Green LED

S5 Female RJ45 Connector

Connector S4

RJ10 4-4 Pin Pin Name Description Note

1 GND1 (**) -

2 Rx/Tx+ Data reception/transmission (A+)

(**) Connect the GND signal

among Modbus devices with a

line distance > 300 ft. (100 m)

3 Rx/Tx- Data reception/transmission (B-)

4 +V Reserved -

Cable Type: Flat telephone cable for pin 4-4 conductor 28 AWG

S4 Female RJ10 Connector

Yellow LED

Connector S5

RJ45 Pin Name Description Note

1 TX+ Data + Transmission

2 TX- Data - Transmission

3 RX+ Data + Reception

4 n.c.

5 n.c.

6 RX- Data - Reception

7 n.c.

8 n.c.

Cable Type: Use standard category 6 cable according to TIA/EIA-568A.

23

Page 26

Modbus RTU/RS485, Ethernet IP Interface or Modbus RTU/RS485, EtherCAT Interface or

Modbus RTU/RS485, ProfiNET Interface

LED Logic - Ethernet IP Fieldbus Module

H1

LED GREEN Module State

H2

LED RED Module State

H7

LED RED Network State

H8

LED GREEN Network State

LED Bicolor GREEN (H1)

H4

RED (H2)

LED Bicolor GREEN (H8)

H6

RED (H7)

J1

Connector Port ETH0

J3

Connector Port ETH1

J2

Connector Serial Modbus

LED Logic - EtherCAT Fieldbus Module

H1

LED GREEN Link/Activity Port ETH0

H2

LED RED Run Run

H7

LED RED Run Run

H8

LED GREEN Link/Activity Port ETH1

LED Bicolor GREEN (H1)

H4

RED (H2)

LED Bicolor GREEN (H8)

H6

RED (H7)

J1

Connector Port ETH0 (IN)

J3

Connector Port ETH1 (OUT)

J2

Connector Serial Modbus

LED Logic - ProfiNet Fieldbus Module

H1

LED GREEN Link Port ETH0

H2

LED RED Signal Port ETH0

H7

LED RED Activity Port ETH1

H8

LED GREEN Link Port ETH1

LED Bicolor GREEN (H1)

H4

RED (H2)

LED Bicolor GREEN (H8)

H6

RED (H7)

J1

Connector Port ETH0

J3

Connector Port ETH1

J2

Connector Serial Modbus

Port ETH0

Port ETH1

Port ETH

Port ETH

Connector J2 RJ10 4-4 Pin

Pin Name Description Note

1 GND1 (**) -

+V

Data reception/

transmission

(A+)

Data reception/

transmission

(B-)

-

2 Tx/Rx+

3 Tx/Rx-

4

Reserved

Cable Type: Flat telephone cable for pin 4-4 conductor 28 AWG

Connector J1 and J3 RJ45

Pin Name Description Note

1 TX+ Data Transmission +

2 TX- Data Transmission -

3 RX+ Data Reception +

4 n.c.

5 n.c.

6 RX- Data Reception -

7 n.c.

8 n.c.

Cable Type: Use standard category 5 cable according to TIA/

EIA-568B

(**) It is

adviseable to

also connect

the GND signal between

Modbus

devices with a

line distance

> 300 ft.

(100 m)

24

Page 27

7.8.3 Connection Example: Communication Ports

A. Supervisory PC/PLC with multiple C4 Modules, with C4-OP.

May need to use Autobaud to synchronize communications.

B. HMI Connection via Modbus RTU (RS-485) to four C4 Modules

May need to use Autobaud function to synchronize communications.

C. SCADA System with fieldbus interface, Single Master Setup

May need to use AutoNode Sequence to set communications.

25

Page 28

D. C4 with Multiple Master Communications Ports

This configuration will allow two masters to simultaneously operate. This will allow the fieldbus to operate, while

allowing the 2nd port to be used for local information, verification of process, or for configuration tool C-PWR

software to be utilized.

Use Autonode to set communications.

C4 or C4-IR Fieldbus Network

Purple: Fieldbus Network wiring to Master Unit.

SW7 must be set to “off” on all units.

Blue: Fieldbus Network Slave Unit connection via RS-485.

Green: 2nd Master Communications Port for local master or configuration

using C-PWR Software

26

Page 29

E. C4 with a Single Master Communication Port

Use Autonode Sequence for configuration. See section 12.2

C4 or C4-IR Fieldbus Network

Purple: Fieldbus Network wiring to Master Unit.

SW7 must be set to “off” on all units.

Blue: Fieldbus Network Slave Unit connection via RS-485.

C-PWR Configuration Tool can be used via RS-485 ports only. Fieldbus connection must be broken to utilize configuration.

Single Master systems can be expanded to two master systems in field.

27

Page 30

F. Multiple Fieldbus Connections

C4 or C4-IR Fieldbus Network

Purple: Fieldbus Network wiring to Master Unit. SW7 must be set to “off” on

all units.

28

Page 31

8. Load Connection Example

3Ø Delta 3Ø Wye (Star)

The following wiring diagrams and electrical equations are provided as a reference for this manual. The three phase

equations shown can be applied to any balanced Delta or Wye (star) circuit. The terms used in the equations are

identified below:

Vl = Line Voltage Wt = Total Watts

Vp = Phase Voltage R1 = R2 = R3 = Element Resistance

Il = Line Current (Amps) Wc = Wattage per Circuit (Equal Circuits)

Ip = Phase Current (Amps) Rc = Circuit Resistance in Ohms Measured Phase to Phase

2

2

÷ R1)

2

The model C4 has specific dipswitch settings

for the various load configurations. Incorrectly setting with a mismatch load configuration

could result in unpredicted results. Please refer to section 7.7 or the Load Connection examples for these proper dipswitch settings.

2

2

÷ R

1

2

29

Page 32

Open Delta & Wye

3Ø Open Delta

3Ø Open Wye (Star)

of an element in a

Three phase heating circuits are most efficient when operated under balanced conditions. If it is necessary to operate an unbalanced load, the equations below can be used to calculate the circuit values for open three phase Delta

or Wye circuits. The terms used in the equations are identified below:

Note:

The loss of a phase or failure of an element in a

three (3) element Delta circuit will reduce the

wattage output by 33%

2

÷ R1)

Note:

The loss of a phase or failure

three (3) element Wye circuit will reduce the

wattage output by 50%. Heating elements are

basically in series on single phase power.

30

Page 33

8.1 4 Single-Phase Loads, 3-phase line with neutral

N

L1

L2

L3

The model C4 has specific dipswitch settings

for the various load configurations. Incorrectly

setting with a mismatched load configuration

could result in unpredicted results. Please refer to section 7.6 or the Load Connection examples for these proper dipswitch settings.

Dip Switch

OFF OFF OFF

Load Connection Type1 2 3

4 independent zones

(4 single phase loads)

Physical Wiring Diagram

L1

L2

L3

N

LOAD 1

F1 U1 F2 U2 F3 U3 F4/N U4

LOAD 2

LOAD 3

LOAD 4

8.2 4 Single-Phase Loads, 3-phase line without neutral

L1

L2

L3

F1

U1

LOAD 1

LOAD 2

F2

U2

LOAD 3

U3

F3

F4

U4

LOAD 4

LOAD 1

F1 U1 F2 U2 F3 U3 F4/N U4

LOAD 2

Dip Switch

Load Connection Type1 2 3

OFF OFF OFF

4 independent zones

(4 single phase loads)

LOAD 3

LOAD 4

31

Page 34

U1

F1

L1

L2

L3

8.3 Two 3-Phase Loads, Closed Delta

L1

L2

L3

U1

F1

L1

L2

L3

F2

U2

LOAD 1

LOAD 3

LOAD 2

LOAD 1

LOAD 2

LOAD 3

F1 U1 F2 U2 F3 U3 F4/N U4

LOAD 3A

LOAD 1A

LOAD 2A

Dip Switch

Load Connection Type1 2 3

OFF OFF ON

Zone 1 & 3: Two 3-phase loads,

closed delta connection

8.4 Two 3-phase loads, star (wye) without neutral

L1

L2

L3

F3

F4

F2

U3

U4

U2

LOAD 2A

LOAD 2

LOAD 1A

LOAD 3A

LOAD 1

LOAD 3

LOAD 3

LOAD 1

F1 U1 F2 U2 F3 U3 F4/N U4

LOAD 2

Dip Switch

Load Connection Type1 2 3

Zone 1 & 3: Two 3-phase loads,

ON ON OFF

star (wye) connection, without

neutral

LOAD 3A

LOAD 2A

LOAD 1A

F3

F4

U3

U4

LOAD 1A

LOAD 2A

LOAD 3A

32

Page 35

8.5 One 3-phase load active, One 3-phase load inactive, Wye without neutral

L3

L1

L2

L3

Dip Switch

Load Connection Type1 2 3

ON OFF ON

Zone 1: 3-phase load, star (wye)

connection, with neutral

8.6 One 3-phase load, inside delta

LOAD 1

U1 F1 U2 F2 U3 F3 U4 F4

LOAD 2

LOAD 3

Dip Switch

Load Connection Type1 2 3

OFF ON OFF

Zone 1: 3-phase load, open delta

connection

L1

L2

F1

F2

U1

U2

LOAD 2

LOAD 1

LOAD 3

F3 U3

33

Page 36

9. Inductive and Transformer Coupled Load Guidelines

The model C4 should not be used for Inductive or Transformer Coupled Loads. The model C4-IR is capable of being used for these types of loads. Please refer to the C4-IR Hardware Manual for more details.

10. Communications Port (Modbus RTU/RS485)

A network typically has a Master that “manages” communication by means of “commands,” and Slaves that

carry out these commands.

Parameter Default Range

ID 1 1...99

BaudRate 19.2kbits/s 1,2...57.6k bits/s

Parity None Parity/Odd Parity/None

StopBits 1 -

DataBits 8 -

C4 modules are considered Slaves to the network master, which is usually a supervision terminal or a PLC.

They are positively identified by means of a node address (ID) set on rotary switches (tens + units).

A maximum of 99 C4 modules can be installed in a serial network, with node address selectable from “01”

to “99” in standard mode in which each C4 identifies

4 zones with sequential node address starting with the

code set on the rotary switches.

C4 modules have a ModBus serial (Serial 1) and, optionally (see order code) a Fieldbus serial (Serial 2) with

one of the following protocols: Modbus RTU, Profibus

DP, CAN open, DeviceNet, and Ethernet Modbus TCP.

The ModBus RTU port 1 has the following factory settings (default):

Position of

Rotary

Switches

Procedures

AutoBaud 0 0

AutoNode* A 0

The following procedures are indispensable for the

Modbus protocol. For the other protocols, see the specific manuals. The use of rotary switches (A...F) letters

is for particular procedures described in the following

paragraphs.

DescriptionTens Units

It enables to set the

correct BaudRate Value

It enables to transfer

the correct node (ID)

address (tens)

34

Page 37

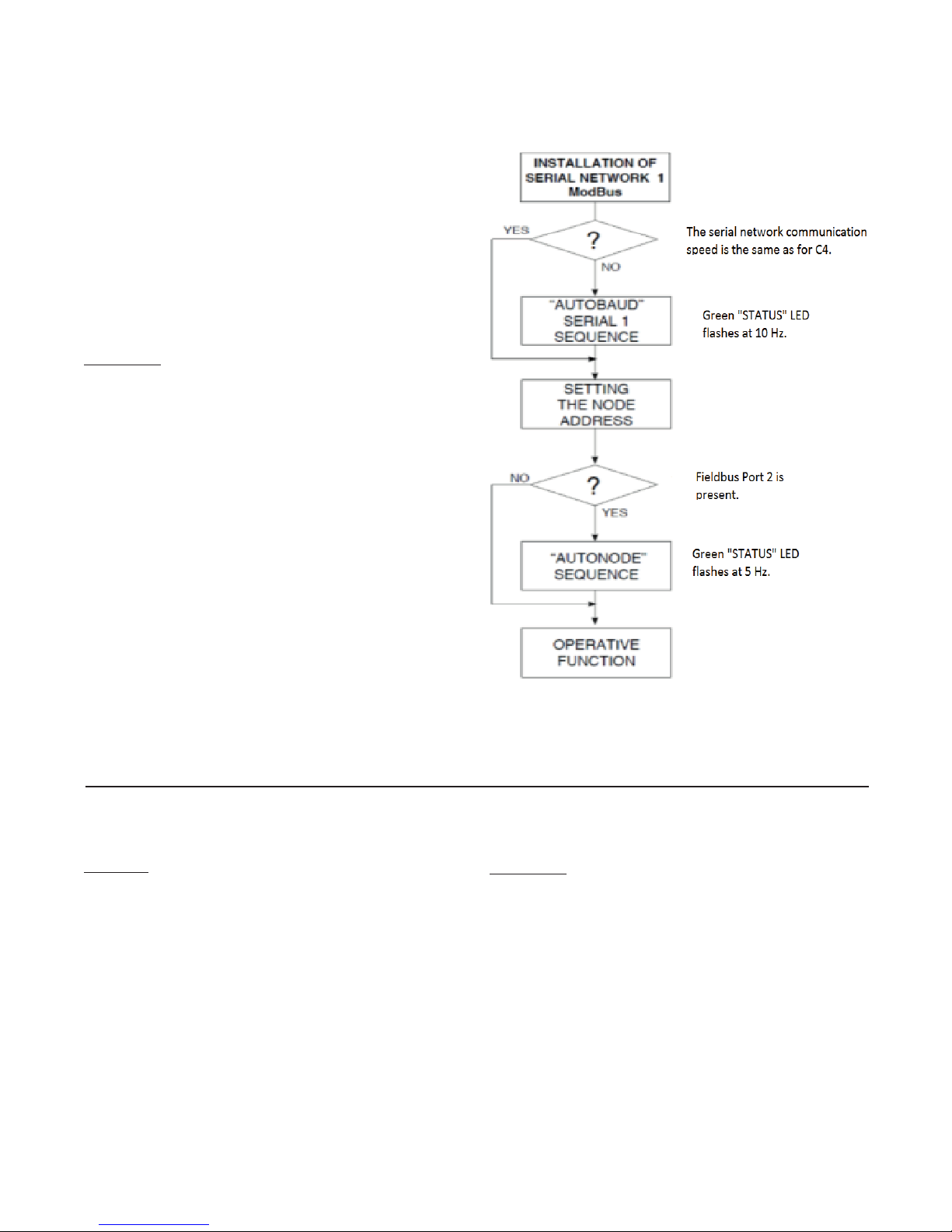

Section 11 Autobaud Function

11.1 Autobaud Port 1 Sequence

11.2 Autonode Sequence for Fieldbus Use Function

Adapt the serial communication speed and parity of

the C4 modules to the connected supervision terminal

or PLC. If a fieldbus card (port 2) is used then port 1

settings must remain at factory settings.

Green LED L1 “STATUS” mentioned in the procedure

can vary its behavior based on parameter Ld.1, which

is set to a default value of 16.

Procedure

1. Connect the serial cables for all modules on the network to serial 1 and to the supervision terminal.

2. Set the rotary switch on the C4 modules to be installed, or on all modules present in case of first installation, to position “0+0”.

3. Check that the green “STATUS” LEDs flash at high

frequency (10Hz).

4. The supervision terminal must transmit a series of

generic “MODBUS” read messages to the network.

5. The procedure is over when all of the green L1

“STATUS” LEDs on the C4 modules flash at a normal frequency (2Hz) (if parameter 197 Ld. 1 = 16 as

default).

The new speed parameter is saved permanently in each

C4; therefore, the “AUTOBAUD SERIAL 1” sequence

does not have to be run at subsequent power-ups.

When the rotary switch is turned, the green “STATUS”

LED stays on steadily for about 6 seconds, after which

it resumes.

11.2 Autonode Sequence for Fieldbus Use

Function

Autonode should be run for all field bus installations.

The L1 “STATUS” green LED mentioned in the procedure can vary its behavior according to the Ld.1 parameter which is 16 as default.

Procedure

1. Connect the serial cables to all the module in the

serial 1 network, disconnect supervision or C4-OP

terminals.

2. Turn the rotary switches from the set node address

to the position “A + 0”.

3. Check that the “STATUS” green LED is blinking at

an average frequency (5Hz) for 10 seconds and then

that it returns to normal blinking (2Hz).

4. Turn the rotary switches in the position of the node

address.

35

Page 38

12. Specifications

INPUTS

IN1 Analog Process Inputs

Function Acquisition of process variable

Max. Error 0,2% f.s. ± 1 scale point at room temperature of 25°C

Thermal drift < 100 ppm/˚C f.s.

Sampling time 120 ms

J,K,R,S,T

Thermocouple Tc (ITS90)

Resistance thermometer RTD (ITS90)

Voltage

Current

IN5, ... ,1N8 Auxiliary Analog Inputs (option)

Function Acquisition of variables

Accuracy 1% f.s. + 1 scale point at room temperature of 25°C

Sampling time 480 ms

Thermocouple Tc (ITS90)

Voltage linear: 0, ... ,60mV, Ri>1 Mohm

IN9, ... IN12 Inputs Internal Current Transformers CT

Function

Accuracy 1% f.s. ± 1 scale point at room temperature of 25°C

Sampling time 60 ms

DI1 ... DI2 Digital Inputs

Function Configurable (default: disabled)

Type PNP, 24 VDC, 8mA 3500V isolation

OUT1, ... , OUT4 Heat Control Outputs Connected Directly to Solid State Power Units

Function

OUT5, ... , OUT8 Cool Control Outputs (option)

Function Configurable (default: cool control)

Relay Type 3A NO Contact, 250V/30Vdc COSw =1

Continuous Type

Logic Type 24 Vdc, > 18V a 20mA

Triac Type

(IEC 584-1 ,CEI EN 60584-1, 60584-2)

Fault cold junction comp 0,1˚/˚C

Pt1 00 (DIN 43760)

MMax line resistance 20ohm

linear: 0, . .. ,60mV, Ri>1 Mohm

0, ... , 1V, Ri> 1 Mohm

a 32 segment custom linearization can be inserted

Linear: 0/4 ... 20mA, Ri =50ohm

a 32 segment custom linearization can be inserted

J,K,R,S,T

(IEC 584-1, CEI EN 60584-1, 60584-2)

Fault cold junction comp 0,1˚/˚C

Read internal CTs; (The acquisition of current values is valid for voltages in a range of 90 ... 530Vac)

OUTPUTS

Configurable (default: heat control)

Control state is displayed by LED (01 , . .. ,02)

0/2 .. . 10V, (default) max 25mA

protection against short circuit

0/4 . .. 20mA, max. load 500ohm

1500V isolation

230V/max 4A AC51

(1 A for every channel)

36

Page 39

OUT9, ... , OUT10 Alarms

Function Configurable (default: alarms)

Relay Type 5A NO Contact, 250V/30Vdc COSw =1

COMMUNICATIONS

PORT 1 (present)

Function Local serial communication

Protocol ModBus RTU

Baudrate Settable to 1,2...57.6kbits/s, (default 19.2 kbit/s)

Address Node Settable by rotary switch

Type

RS485

1500V isolation, double connector RJ10 telephone type 4-4

PORT 2 (Fieldbus Option)

Function Fieldbus serial communication

ModBus RTU, type RS485, baudrate 1,2...57.6 kbit/s

CANOpen 10K….1Mbit/s

Protocol

DeviceNet 125K...0.5Mbit/s

Profibus DP 9.6K...12 Mbit/s

Ethernet Modbus TCP, Ethernet IP 10/100Mbps

EtherCAT, ProfiNET 100Mbps

POWER (SOLID STATE POWER UNITS, 4 UNITS)

Rated Voltage 480VAC

Work Voltage Range 24...530 Vac

Non- repetitive Voltage 1200Vp

Zero Switching Voltage <20V

Rated Frequency 50/60Hz self-setting

Rated Current AC51 30KW 60KW 80KW

4 x 16A 4 x 30A 4 x 40A

Non- Repetitive Overcurrent (t=20 msec)

2

t For Fusion (t=1...10 msec) 645A’s 1010A’s 6600A’s

I

400A 600A 1150A

Critical Dv/dt with output Deactivated 1000V/usec

Rated Isolation Voltage 4000V

Safety

Selection ˚C/˚F Configurable

Linear scale range -1999 ... 9999

Control Actions

pb-dt-it 0,0 ... 999,9 % - 0,00 ... 99,99 min - 0,00 ... 99,99 min

Action - Control Outputs heat/cool - ON/OFF, PWM, GTT

Heat/Cool Max. Power Limitation 0,0 ... 100,0%

Cycle Time – Softstart

Fault Power Setting -100,0 ... 100,0%

Shut-Down Function Maintains sampling of process variable PV; when active, disables control

FUNCTIONS

Detects short circuit or open probe circuit, probe, power supply failure, LBA

alarm, HB alarm

4 control loops:

Double action (heat/cool) PID, on-off

Self-tuning at power-up, Continuous Autotuning, One-shot Autotuning

0 ... 200 s - 0,0 ... 500,0 min

Softstart at phase slicing

37

Page 40

Configurable Alarms

Alarm is assigned to an output, configurable as: maximum, minimum, symmetrical, absolute/deviation, LBA, HB

Alarm Masking Exclusion at power-up, latch, reset by digital input

SCR in short circuit (presence of current with control OFF)

Diagnostics

SCR open (presence of voltage on SCR with control ON)

Load interrupted or no voltage (no current, no voltage on SCR with control ON)

Connection and Load Types

Selection with Dip-Switches

4 loads single-phase,

2 loads 3-phase, star without neutral controlled on two phases

2 loads 3-phase, closed triangle controlled on two phases

1 load 3-phase, star with neutral controlled on one phase

1 load 3-phase, open triangle controlled on one phase

(with 3-phase load, 4 CTs are needed if diagnostics is required)

GENERAL DATA

Power Supply 24VDC +/-25%, max 8VA

Eight LEDS:

RN CPU in run state

Indicators

ER Fault Signal

DI1, DI2 state of digital inputs

O1,...O4 state of outputs

Protection IP20

Work/Storage Temperature 0 - 50˚C (see dissipation curves) / -20˚C...70˚C

Relative Humidity 20 - 85% RH non-condensing

Ambient Work Conditions Indoor use, altitude up to 2000m

Installation DIN RAIL EN50022 or panel using screws

Installation category II, Pollution level 2, double isolation

Installation Instructions

Max surrounding air temperature 50˚C (for UL)

Open type equipment

Weight(s)

Models 30KW, 60KW, 80KW 1200g

Models 30KW, 60KW, with fuse holder 1600g

38

Page 41

C4

164

(4x16A)

304

(4x30A)

404

(4x40A)

VOLTAGE/CURRENT CONSIDERATIONS

Current (Amp) Voltage (VAC) Power (kW)

Max. Per Channel Range Nominal Working Per Channel Controller Total

120 1.9 7.7

208 3.3 13.3

16

30

40

24 - 530 480

240 3.8 15.4

277 4.4 17.7

400 6.4 25.6

480 7.7 30.7

120 3.6 14.4

208 6.2 25.0

240 7.2 28.8

277 8.3 33.2

400 12.0 48.0

480 14.4 57.6

120 4.8 19.2

208 8.3 33.3

240 9.6 38.4

277 11.1 44.3

400 16.0 64.0

480 19.2 76.8

DISSIPATING CURVES

39

Page 42

13. Ordering Information

Model C4 SCR Power Controller

C4

Code Current Per Loop @ 40˚C (104˚F) Ambient, continuous service (110 Vac to 480 Vac) (See note 3)

164

16 Amps/Loop

304

30 Amps/Loop

404

40 Amps/Loop

Code Auxiliary Outputs

0

None

R

Relay

D

Logic

A

Analog

T

Triac

Code Auxiliary Inputs

1

One Current Transformer

2

4 Current Transformers

3

1 Current Transformer + 4 Linear Inputs

4

4 Current Transformers + 4 Linear Inputs (See Note 1)

Code Fusing

0

None

F

Fuse holder & Extra rapid fuses (See Note 2)

Code Second Fieldbus Option

00

None

MR

Modbus RTU (RS485)

ET

Modbus TCP/Ethernet

ER

Ethernet IP, Real Time

PB

PN

EC

CN

DN

EM

Profibus DP

ProfiNET

EtherCAT

CANopen

DeviceNet

Euromap 66

1

1

1

C4- 304 D 4 - F 00 Typical Model Number

1

Not available with EC, PN & ER Fieldbus Codes.

2

Not available with 404 Current Code

3

Refer to the C4X for higher amperages

40

Page 43

14. Configuration and Programming

14.1 C-PWR Configuration Software Program

See C-PWR Configuration Software Program instruction manual for proper program installation.

14.2 C4/C4X/C4-IR Programming Manual

See C4/C4X/C4-IR Programming Manual for complete controller set-up of communications, inputs, outputs,

alarms and control modes.

15. Accessories

15.1 Fuses and Fuse Holders

2

T Extra Rapid Fuses Fuse Holder

I

Fuse Rating,

C4 Model

Amps I

C4-164 16A 645A

2

T

2

C4-304 30A 1010A

15.2 Fieldbus Cards

Fieldbus Type Part No.

Modbus RTU 0149-50103 C4-MOD F032357 Card for Modbus RTU protocol (serial 2)

Profibus DP 0149-50104 C4-PROFI F032358 Card for Profibus DP protocol (serial 2)

CANopen 0149-50105 C4-CAN F032359 Card for CANopen protocol (serial 2)

DeviceNet 0149-50106 C4-DNET F032360 Card for DeviceNet protocol (serial 2)

Modbus TCP/IP 0149-50107 C4-ETH F033532 Card for Ethernet Modbus TCP protocol (serial 2)

EtherCat 0149-50108 C4-ETH2 F049411 Card for EtherCat protocol (serial 2)

Profinet 0149-50109 C4-ETH4 F054949 Card for Profinet protocol (serial 2)

Ethernet IP (Real-Time) 0149-50110 C4-ETH5 F058234 Card for Real Time Ethernet/IP protocol

Power

Dissipation Fuse Size

Manufacturer’s

Model Code Part No. Part No.

Fuse Holder

Rating (UL)

s 3.5W 10x38 FUS-016 0024-07824 0024-12124 30A@600V

2

s 4.8W 10x38 FUS-030 0024-07825 0024-12124 30A@600V

Model No.

(Fieldbus

Card)

Manufacturer’s

Model Code Description

Additional Spare Parts

Part No.

Manufacturer’s

Model Code Description

0149-50099 F032861 Connection cable for serial Modbus (RJ10) 0.3M

0149-50100 F032862 Connection cable for serial Modbus (RJ10) 1M

0149-50101 F032863 Connection cable for serial Modbus (RJ10) 2M

0149-50102 F032864 Connection cable for serial Modbus (RJ10) 5M

0149-50111 VEN-61 Fan (flow 39m3/h) for C4-164

0149-50112 VEN-62 Fan (flow 56m3/h) for C4-304 and C4-404

0149-50113 GRI-4 Grill fan for C4

0149-50114 FLT-4 Filter for fan

0149-50115 COUT4-9 9-Terminal Connector (J1) For C4 Controller

0149-50116 COUT4-4 4-Terminal Connector (J1a) For C4 Controller

0149-50117 CSIG4-7 7-Terminal Connector (J2) For C4 Controller

0149-50118 CSIG4-12 12-Terminal Connector (J4) For C4 Controller

0149-50119 CSIG4-4 4-Terminal Connector (J3a) For C4 Controller

41

Page 44

15.3 Configuration Software and Cabling

Configuration kit for C4 product line by means of PC with USB (Windows environment). Software is compatible

with all C4 models. Download free at www.Chromalox.com

- Allows you to read and write all of the parameters of a single C4 device

- Easy and rapid configuration

- Saving and management of parameter recipes

- On-line trend and saving of historical data

Description Part No.

Communication Cable, USB to TTL 309171

Communication Cable, USB to RS485 309180

15.4 C4-OP

Operator terminal for in-field configuration of the entire C4 product line.

Two types of terminals: - for installation on DIN guide

- for panel installation

See C4-OP Hardware Manual for more details.

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

© 2018 Chromalox, Inc.

Limited Warranty:

Chromalox, Inc.

1347 Heil Quaker Boulevard

Lavergne, TN 37086

(615) 793-3900

www.chromalox.com

42

Loading...

Loading...