Page 1

2110 Temperature

Load

Alarm

Point

Temp

2110

°F

°C

Set Point

Chromalox

C

US

U

L

®

Controller

User Manual

0037-75409

PK498-1

May, 2012

Page 2

Page 3

Table of Contents

Manual Sections

Illustrations

1–Quick Setup ........................................................................................1

2–Introduction ........................................................................................2

3–Installation and Wiring ........................................................................4

4–Adjusting Setpoint and Configuration ..............................................12

5–Controller and Alarm Operation ........................................................16

6–Replacing Output Modules ...............................................................17

7–Calibration ........................................................................................19

8–Specifications ...................................................................................21

9–Troubleshooting ................................................................................22

1.1 Dip Switch Settings ........................................................................1

1.2 Establishing the Set Point ..............................................................1

1.3 Adjusting the Set Point ...................................................................1

2.1 Front Panel Identification ...............................................................2

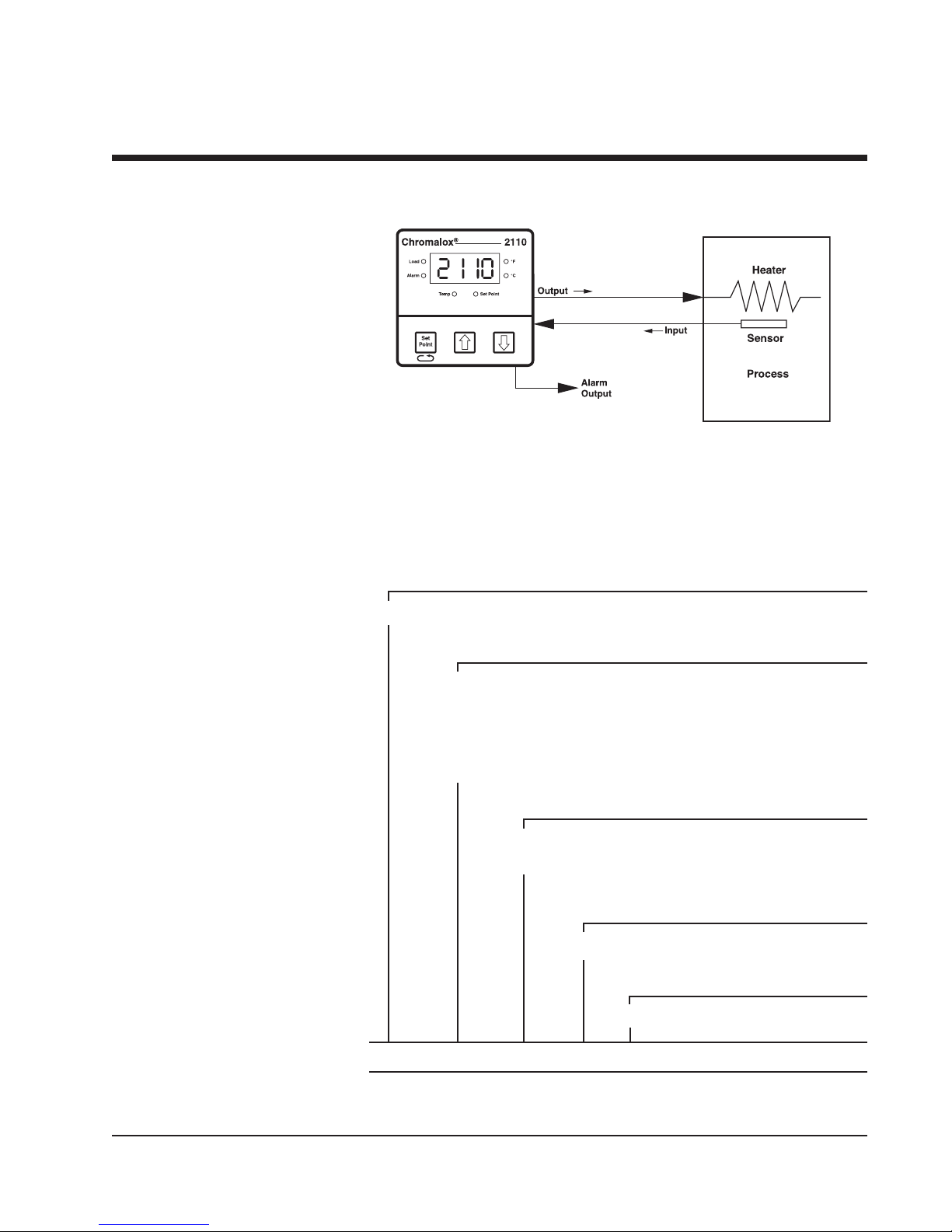

2.2 Typical Application .........................................................................3

2.3 Model Identification ........................................................................3

3.1 Default Dip Switch Settings ...........................................................4

3.2 Removing Mounting Collars ...........................................................5

3.3 Mounting Dimensions ....................................................................6

3.4 Mounting the 2110 .........................................................................6

3.5 Wiring Terminal Identification .........................................................7

3.6 Thermocouple Connections with Shield ........................................8

3.7 Three-Wire RTD Connections with Shield ......................................9

3.8 Two-Wire RTD Connections ...........................................................9

3.9 Control Output Wiring–R1 and S0 ................................................10

3.10 Control Output Wiring–R3 ............................................................10

3.11 Control Output Wiring–V0 ............................................................10

3.12 Control Output Wiring–S1 and S2 ................................................11

3.13 90-260 VAC Instrument Power Connections ...............................11

3.14 Alarm Connections .......................................................................11

4.1 Establishing the Set Point ............................................................12

4.2 Adjusting the Set Point .................................................................12

4.3 Configuring 2110 ..........................................................................13

4.4 Configuring 2110 ..........................................................................13

4.5 Configuring 2110 ..........................................................................13

4.6 Configuring 2110 ..........................................................................13

4.7 Configuring 2110 ..........................................................................13

4.8 Configuring 2110 ..........................................................................13

6.1 Replacing Output Module ............................................................18

iii

Page 4

Chromalox 2110

Page 5

2110 Temperature Controller

Section 1—Quick Setup

After the controller is properly wired into the system, the user

only needs to verify the sensor input and control type and adjust

the set point.

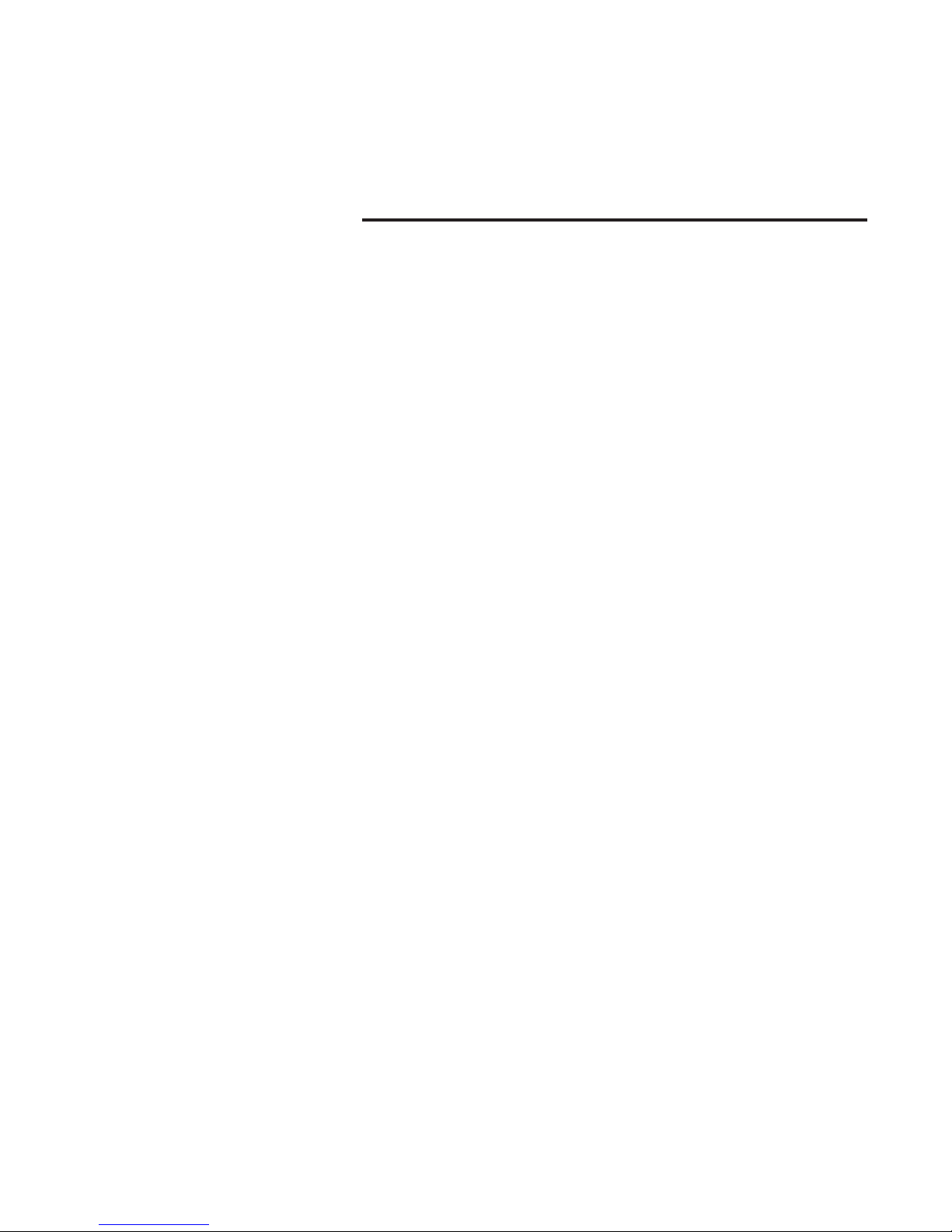

Setting the Sensor and Control Mode

Adjust the dip switches located on the bottom of the unit as

shown in Figure 1.1. The factory settings are J, TC, °F, and PI. It

is simpler to adjust the dip switch prior to mounting the 2110.

RTD

ONOF

J

˚C

K

TC

˚F

PI

K

J

TC

RTD

˚F

˚C

PI

ONOF

Figure 1.1

Dip Switch Settings

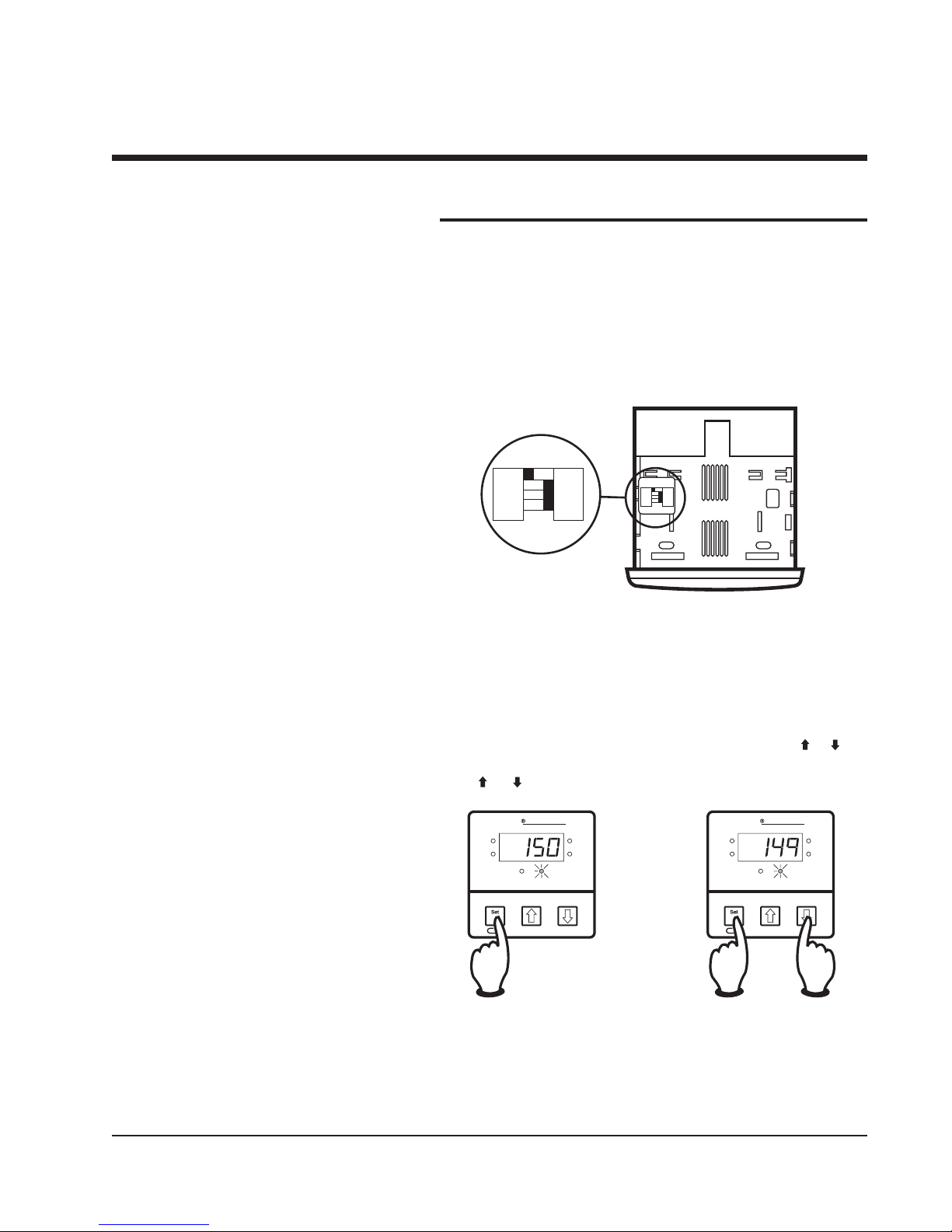

Adjusting the Set Point

1. Apply power to the unit.

2. To adjust the set point on the Chromalox 2110 Temperature Controller, press and hold the Set Point button (see Figure 1.2). The

Set Point light is illuminated.

3. While still pressing the Set Point button, press either the or

button to adjust the set point to the desired value (see Figure 1.3).

Holding the or button increases the speed of the set point

changes.

Chromalox 2110

Load

Alarm

Temp

Point

°F

°C

Set Point

Chromalox 2110

Load

Alarm

Temp

Point

°F

°C

Set Point

Section 1–Quick Setup

Figure 1.2

Establishing the Set Point

Figure 1.3

Adjusting the Set Point

The Controller is now operational with factory settings. For more

precise control, set up of the alarm, etc., see Section 4 – Adjust-

ing Set Point and Configuration.

1

Chromalox 2110

Page 6

Section 2—Introduction

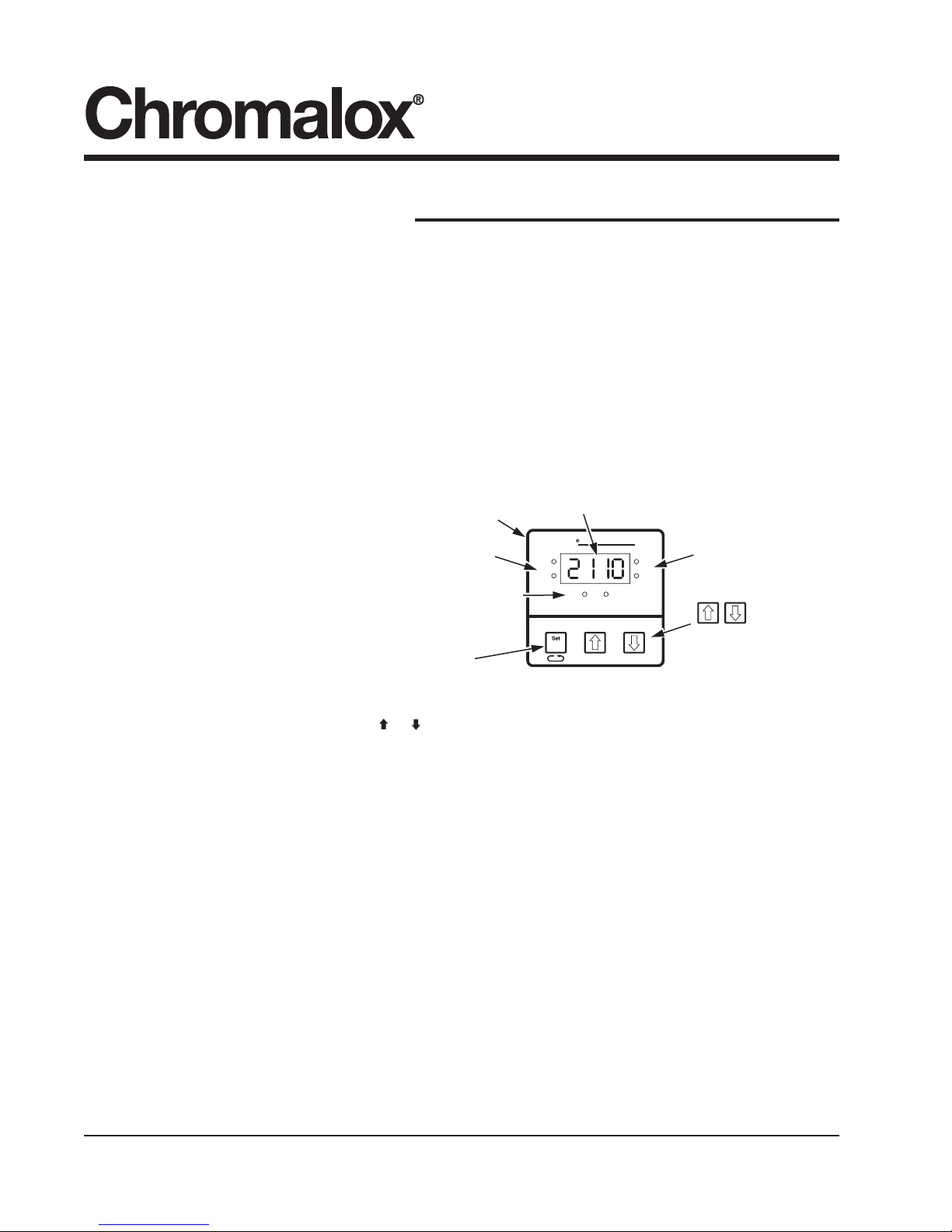

Display

Description

The Chromalox 2110 Temperature controller offers simple setup,

flexibility and control features in an attractive, compact design.

The 2110 is housed in a rugged, plastic 1/4 DIN package that

only requires four inches behind the mounting surface. Straightforward operation and easy-to-use control features are major

strengths of the 2110 controller.

Easy Three-Step Setup: The 2110 delivers exceptional process

temperature control. Your process is up and running after three

easy setup steps: 1) Select the sensor and control type, 2) Hook

up the system and 3) Select the desired temperature.

NEMA 4X Front Panel

Construction for

hosedown applications

Output LEDs

Indicates control load

ON and alarm status

Temp and Set Point LEDs

Indicates actual or set point

temperature is displayed

Set Point Button

• In Operation Mode, adjusts

Set Point

• In Configuration Mode with

the or button, serves

as “Menu” button

(4 Green, 7-Segment LEDs)

Actual process temperature displayed

Chromalox 2110

Load

Alarm

Temp

Point

°F

°C

Set Point

Green LEDs

Indicates °F or °C

selected for temperature

display

• In Operation Mode,

pushbuttons adjust Set

Point.

• In Setup Mode,

pushbuttons increase/

decrease MENU values.

Figure 2.1

Front Panel Identification

Inspection and

Unpacking

Chromalox 2110

Your Chromalox 2110 controller should arrive in good condition.

Upon arrival, inspect the packaging for any visible damage.

Unpack the controller and carefully inspect for product damage

that may have occurred during shipment. If the package or contents have been damaged in shipping, you must file a claim with

the delivery service. The delivery service will not accept a claim

from the shipper.

If not immediately installing the controller, store in a cool, dry

environment in its original protective packaging. Temperature

extremes and excessive moisture can damage the instrument.

2

Section 2–Introduction

Page 7

2110 Temperature Controller

Typical Application

Model

Identification

Figure 2.2 shows the 2110 in a typical application.

Figure 2.2

Typical Application

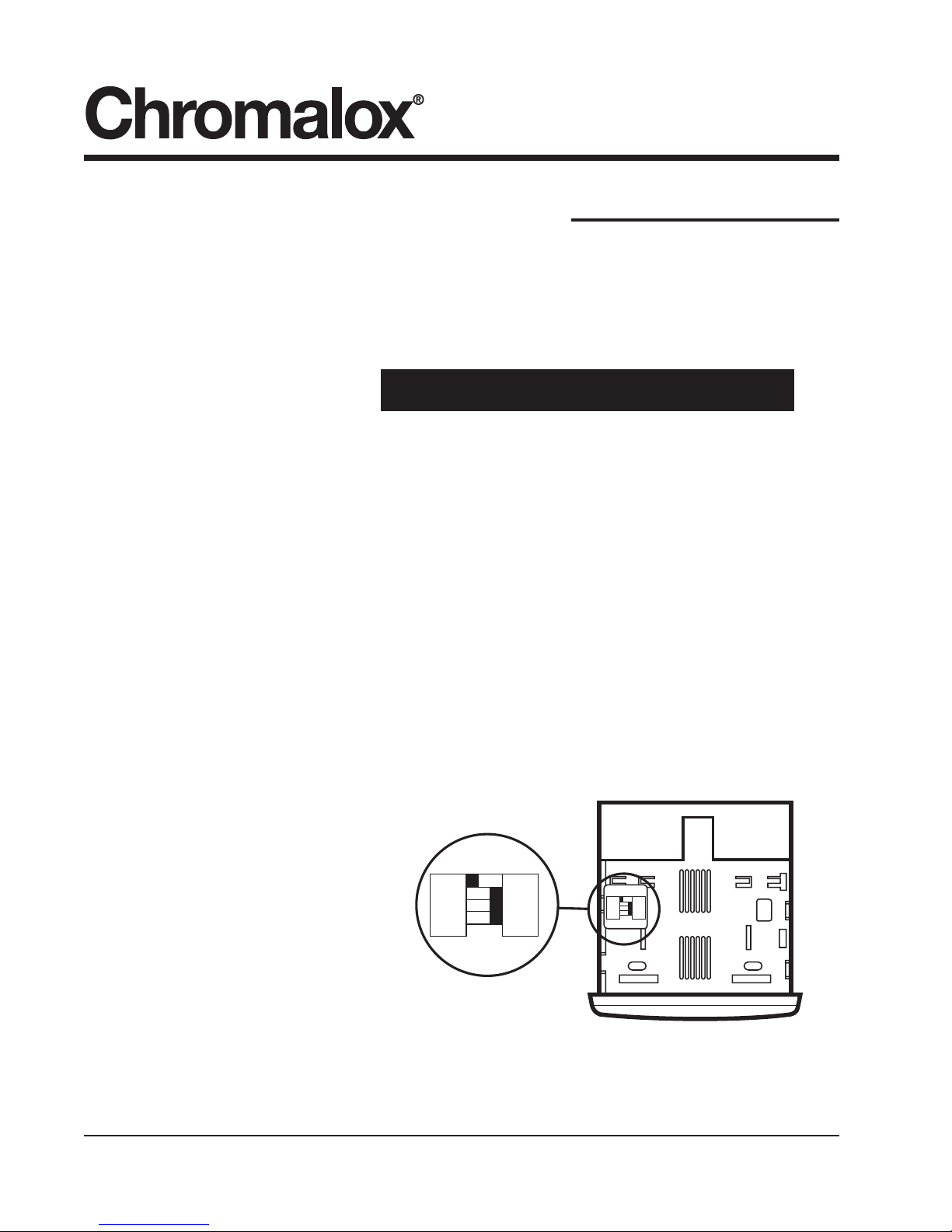

Before installation, please identify your controller model number.

The model number appears on a label on the side of the housing.

Use Figure 2.3 to identify the options in your controller.

Model

2110

Code Control Output

1/4 DIN Controller, with Selectable Thermocouple or RTD Inputs

R1 Relay, 1 Amp Form A, 120/240Vac

R3 Relay, 20 Amps Form A, 120/240Vac

V0 Solid State Relay Drive, 24Vdc @ 40ma

S0 Solid State Relay, 1 Amp, up to 240 Vac

S1 Solid State Relay, 5 Amps, up to 240Vac

S2 Solid State Relay, 10 Amps, up to 240Vac

Code Alarm Output (Kit Option)

0 No Alarm

1 Alarm Form “C” Relay, 5 Amps at 120Vac,

2.5 Amps at 240Vac

Code

0 Add to Complete Part Number

Code Power Supply

0 90-260Vac

2110 - R3 1 0 0 Typical Model Number

Figure 2.3

Model Identification

Section 2–Introduction

3

Chromalox 2110

Page 8

Section 3—Installation and Wiring

Sensor and Control

Type Selection

Switches

Set the Chromalox 2110 controller’s configuration via mechanical

dip switches, located on the bottom of the unit. Factory settings are

J, TC, °F, and PI Control. Switches are easier to set before mounting.

To change the switch settings, first disconnect all wiring and power

from the unit. Adjust switch settings as follows:

Setting Factory

Switch Function Options Setting

A Thermocouple J or K J

B Input Type TC or RTD TC

C Temperature Units °F or °C °F

D Control Type ON-OFF or PI PI

If input type is thermocouple, switch A selects either thermocouple

type J or K.

Switch B selects input type thermocouple or RTD (resistance temperature detector). Note: If RTD is selected, switch A is ignored.

Switch C selects temperature units °F or °C.

Switch D selects either PI (Proportional-Integral) or ON-OFF control.

Chromalox 2110

J

RTD

˚C

ONOF

Figure 3.1

Default Dip Switch

Settings

4

K

TC

˚F

PI

K

J

TC

RTD

˚F

˚C

PI

ONOF

Section 3–Installation and Wiring

Page 9

2110 Temperature Controller

Mounting

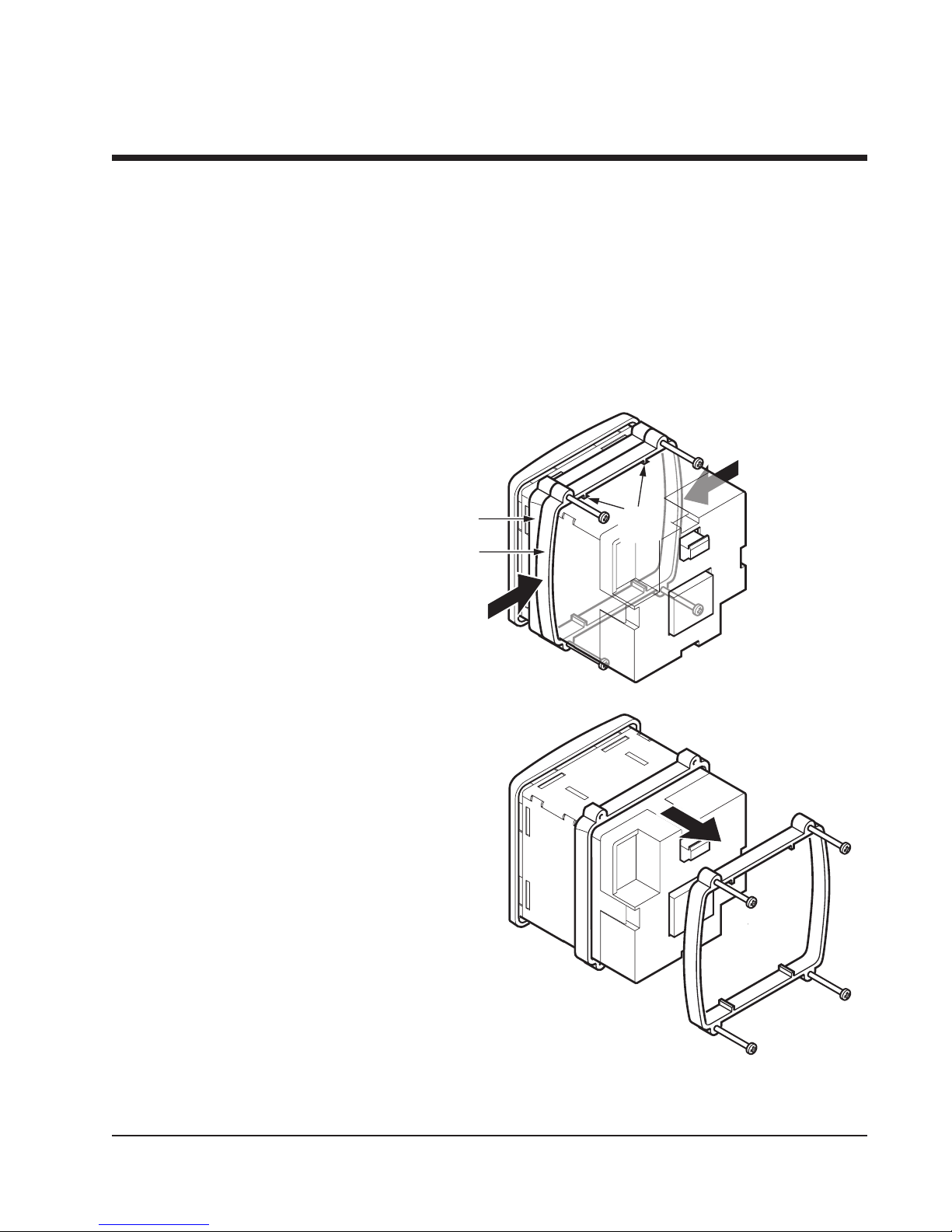

Two mounting collars securely hold the 2110 controller in the

mounting hole. Remove these mounting collars before installation.

Removing Mounting Collars

1. To remove the rear collar, press the sides of the collar. This

releases holding tabs on the top and bottom of the collar.

2. Slide the collar off the back of the unit.

3. Slide the front collar off the back of the unit

Press In

Front Collar

Holding

Tabs

Rear Collar

Press In

Section 3–Installation and Wiring

Figure 3.2

Removing Mounting Collars

5

continued

Chromalox 2110

Page 10

Mounting

Holding

continued

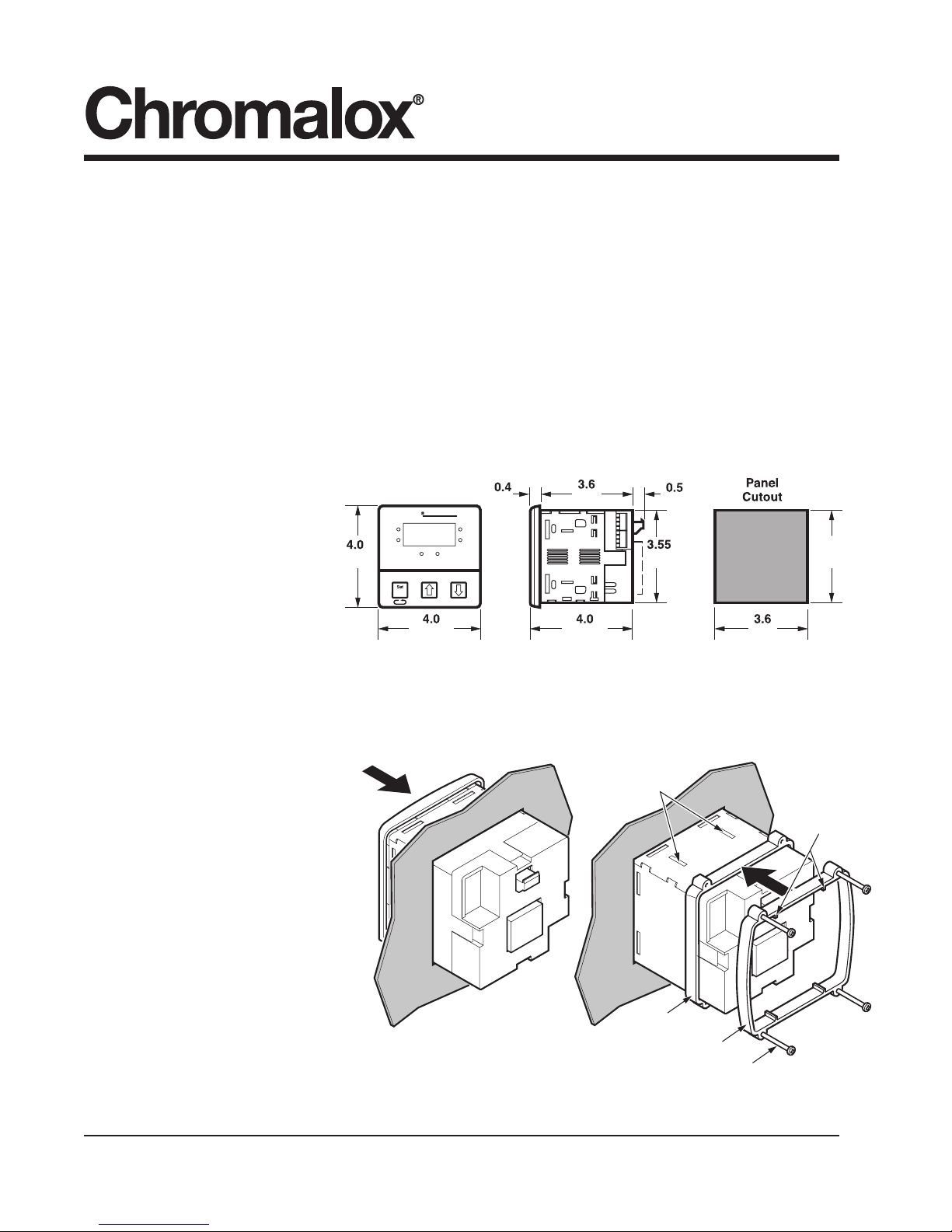

Mount the 2110

1. Cut out a 1/4 DIN, 3.6-inch (92mm) square hole in the mounting panel.

2. Insert the unit into the mounting hole as shown in Figure 3.4.

3. Slide the front mounting collar onto the back of the controller.

4. Slide the rear mounting collar onto the back of the controller

until the holding tabs securely engage with the holding tab

slots in the controller housing (see Figure 3.4).

5. Tighten the four rear collar mounting screws until the unit is

held firmly in the panel. CAUTION: Do not overtighten.

The controller will now be held firmly in place.

Chromalox 2110

(101.6)

Load

Alarm

Temp

Point

(101.6) (102) (92)

Set Point

°F

°C

Figure 3.3

Mounting Dimensions

(10)

(92)

Tabs

Slots

(90)

(12.7)

3.6

(92)

Holding

Tabs

Chromalox 2110

Figure 3.4

Mounting the 2110

6

Front Collar

Rear Collar

Rear Collar

Mounting Screw

Section 3–Installation and Wiring

Page 11

2110 Temperature Controller

Good Wiring

Practices

!

Separate wire into bundles—When planning the system wiring,

separate wiring into functionally similar bundles, e.g.

• Powerleads

• Sensorleads(ifpowerleadsmustcrosssensorleads,theyshould

cross at a 90° angle)

• Outputsignallines

Separate sources of electrical noise—Locate all sources of electrical

noise in your system, and separate these sources from the control

system, e.g.

• Motors

• Contacts

• Solenoids

Electrical noise can affect the function of any control system. When

driving a contactor coil or other inductive load, an appropriate rated

AC snubber circuit is recommended (Chromalox Part No. 0149-01305).

Connect before power is applied—Make all electrical wiring connec-

tions to the back of the controller before power is applied to the unit.

C

omply with regulations—WARNING: All wiring practices must comply with local regulations. Failure to do so could result in damage to

controller and/or personal injury or death from electrical shock.

This instrument is intended for panel mounting and the terminals

must be enclosed within a panel. Use National Electric Code (NEC)

Class 1 wiring for all terminals except the sensor terminals.

Section 3–Installation and Wiring

Check wiring decal—Check the wiring decal on the side of the unit

to verify the model number. The wiring decal shows the wiring terminations. All wiring will be connected to the terminals on the back

of the instrument case. Specific wiring instructions for different input

and output types are given in this section. See also Figure 3.5.

Additional information—For sensor wiring practices, see “Sensor

Input Wiring”. For additional information on good wiring practice, request IEEE Standard No. 518-1982 from IEEE, 345 East 47th St., New

York, NY 10017 or www.ieee.org.

Sensor Input

Wiring

Output

Wiring

(S1, S2)

Figure 3.5

Wiring Terminal Identification

7

NCNOCOM

Output Wiring

(R1, R3, V0, or S0)

Alarm Wiring

Instrument

Power Wiring

Chromalox 2110

Page 12

Sensor Input Wiring

Sensor Wiring Notes

For safety and best controller performance,

• Sensor leads (thermocouple and RTD) should not be run in the

same conduit as power wiring.

• Twisted pair, shielded wire is recommended for sensor connections.

• False temperature readings can occur if the sensor wire is exposed

to electrical noise.

• Ungrounded thermocouples are recommended.

• Thermocouple extension wire, if required, must be the same type

as the thermocouple (i.e. if a Type K thermocouple is used, then

Type K extension wire must be used.)

• Shielded thermocouple wire, if used, must have the shield grounded at one end only, preferably at the shield ground terminal on the

controller as shown in Figure 3.6.

• Three-wire RTDs are recommended for greatest accuracy.

• Standard shielded copper wire is recommended for RTD exten-

sions.

Thermocouple Inputs

It is important to observe polarity (+,-) when connecting thermocouple

leadwires. ANSI color coding for the thermocouples used with this

instrument are

Thermocouple

Type Material Polarity (+) Polarity (-)

J iron/constantan white red

K chromel/alumel yellow red

Make thermocouple wiring connections to terminals as shown in Figure 3.6.

TC +

TC -

NCNOCOM

Shield Ground

Figure 3.6

Thermocouple Connections with Shield

Chromalox 2110

8

Section 3–Installation and Wiring

Page 13

2110 Temperature Controller

Sensor Input Wiring

continued

Three-Wire RTD Inputs

IMPORTANT: When making the three-wire RTD input connection,

make the resistance of all three extension leadwires equal by using the same gauge and same length of wire for optimum accuracy. A three-wire RTD will generally have two wires of the same

color. Connect the same colored wires to the RTDL connections.

Connect the alternate colored wire to the RTDH connection.

Make three-wire RTD connections to terminals as shown in Figure 3.7.

RTDH

RTDL

RTDL

NO

COM

NC

Shield Ground

Figure 3.7

Three-Wire RTD Connections with Shield

Section 3–Installation and Wiring

Two-Wire RTD Inputs

If using a two-wire RTD input, use heavier gauge leadwires to

reduce leadwire resistance. Any leadwire resistance adds directly

to sensor resistance, thus adding error to the process temperature measurement. It is also necessary to jumper the two RTDL

terminals on the instrument to complete a two-wire hookup.

RTDH

RTDL

RTDL

NO

COM

NC

Figure 3.8

Two-Wire RTD Connections

9

Chromalox 2110

Page 14

Control Output

Wiring

The following figures show the proper control output wiring for

the various 2110 configurations.

R1 (1 Amp Relay) and S0 (1 Amp, Solid State Relay)

Output Wiring

When driving a contactor coil or other inductive load, an appropriately rated AC snubber circuit is recommended (Chromalox

Part. No. 0149-01305), as shown in Figure 3.9.

120/240

VAC

Neutral

Fuse

Load

Snubber

NCNOCOM

Figure 3.9

Control Output Wiring–R1 and S0

R3 (20 Amp Relay) Output Wiring

1/4” fast-on tabs are provided with the R3 output.

NO

COM

NCNOCOM

120/240

Figure 3.10

Control Output Wiring–R3

VAC

Neutral

Fuse

Load

NCNO

COM

Chromalox 2110

V0 (Solid State Relay Drive, 24Vdc, 40mA) Output Wiring

-

+

120/240VAC

AC Neutral

Fuse

Load

Figure 3.11

Control Output Wiring–V0

SSR

4115

+

-

NCNOCOM

Section 3–Installation and Wiring

Page 15

2110 Temperature Controller

Figu

90-260 V

Control Output

Wiring

continued

Instrument Power

Wiring

S1 (Solid State Relay, 5 Amps) and

S2 (Solid State Relay, 10 Amps) Output Wiring

Note: 2110 model S2 has a fan. 2110 model S1 does not have a fan.

Fan

NCNOCOM

Fuse

Load

120/240

VAC

Neutral

Figure 3.12

Control Output Wiring–S1 and S2

Make 120 or 240 VAC instrument power connections to terminals

as shown in Figure 3.13.

120/240VAC

Neutral

Ground

NCNOCOM

Alarm Wiring

Section 3–Installation and Wiring

re 3.13

AC Instrument Power Connections

The Form C Relay Output is connected as shown in Figure 3.14.

Alarm Out

CNO

COM

Figure 3.14

Alarm Connections

11

NC

NCNOCOM

NO

NC

Chromalox 2110

Page 16

Section 4—Adjusting Set Point and Configuration

Adjusting the

Set Point

1. Set selection switches (see Figure 3.1).

2. Apply power to the unit.

3. To adjust the set point on the Chromalox 2110 Temperature Con-

troller, press and hold the Set Point button (see Figure 4.1). The

Set Point light is illuminated and the set point value is displayed.

4. While still pressing the Set Point button, press either the

or

button to adjust the set point to the desired value (see Figure 4.2).

5. Release the Set Point button.

Chromalox 2110

Load

Alarm

Temp

Point

°F

°C

Set Point

Figure 4.1

Establishing the Set Point

Chromalox 2110

Load

Alarm

Temp

Point

°F

°C

Set Point

Figure 4.2

Adjusting the Set Point

Configuration

Chromalox 2110

While the 2110 default settings make it a simple setup controller

for most applications, additional programmable menus can be

configured through three front-panel pushbuttons.

To access the user configuration menus,

1. Press and hold the and buttons. After three seconds the

display will begin to toggle between the current security code

and LocH (LOCK). The Temp and Set Point LEDs will turn on.

See Figure 4.3.

2. Press the or button to adjust the value to the appropriate

security number (see Security Codes and Levels). Only the

value is displayed during adjustment. See Figure 4.4.

3. Press and hold the Set Point ( ) button and press the or

buttons to scroll the configuration menus. The display will

show the name of the menu and then begin to toggle between

the name and the current value. See Figures 4.5 and 4.6.

12

Section 4–Adjusting Set Point and Configuration

Page 17

2110 Temperature Controller

Configuration

continued

4. Press the or buttons to adjust the value (only the value is

displayed during adjustment). See Figure 4.7. The new value

is set when the or button is released.

5. Press and hold the Set Point ( ) button and press the

button to advance to the next menu. See Figure 4.8. (Holding

the Set Pointt ( ) button and pressing the button moves

through menus in the opposite direction.)

Repeat steps 4 and 5 through the configuration menus.

Figure 4.3

Chromalox 2110

Load

Alarm

Temp

Set Point

Set

Point

Chromalox 2110

Load

Alarm

Temp

Set Point

Set

Point

˚

F

C

˚

Figure 4.4

˚

F

˚

C

Chromalox 2110

Load

Alarm

Set Point

Temp

Set

Point

Adjust lock

to 458

Chromalox 2110

Load

Alarm

Set Point

Temp

Set

Point

˚F

˚C

˚

F

˚

C

Figure 4.5

Figure 4.7

Move to

next menu

Chromalox 2110

Load

Alarm

Set Point

Temp

Point

Adjust the

set point

value

Figure 4.6

Chromalox2110

°F

°C

Load

Alarm

Temp

Set

Point

Figure 4.8

Continue

until SP is

displayed

˚

F

˚

C

Set Point

Continue

through the

configuration

menus

Exit Configuration

To exit configuration mode, press and hold both the and buttons for three seconds to return to the operation mode.

Note: If no buttons are pressed for three minutes while in user

configuration mode, then the controller will exit user configuration and return to the operation mode.

Section 4–Adjusting Set Point and Configuration

13

Chromalox 2110

Page 18

Security Codes and

Levels

To limit access to the user configuration interface, security codes

are assigned to different menu levels. Make security codes available to operators, maintenance crew, supervisors, etc. according

to what function level you want for each group. Security Level C

is not recommended for most users. Gain access to configuration menus using the following codes.

Security Level Security Code Function

A All Values Allows adjustment of

the Set Point

B 458 Basic menus

C 736 Calibration menus

Configuration

Menus

The following configuration menus can be accessed through the

user interface (see Configuration, page 12).

Menu

Code Function

Loch

Proc

SP

Pb

ArSt

Security Lock

Process Variable Display

Displays the actual process

temperature.

Process Set Point Adjust

Adjusts the target process

temperature.

Proportional Band

Temperature range above/below

set point where proportional

control is active. Most

applications require a band

between 10 to 200°F. This menu

is active only when the dip

switch is set to “PI”

Automatic Reset

Control feature that

automatically corrects for small

temperature offsets that occur

in proportional control. The

higher the setting, the faster the

correction occurs. A high setting

could cause overshoot during

start-up. A low setting will not

allow process temperature

to reach to set point quickly

enough. A setting of “0” turns

off automatic reset. This menu

is active only when the dip

switch is set to “PI”.

Adjustable

Range

0-999 458

Read Only

°F or °C

Sensor

Range

°F or °C

1 to Sensor

Span

Maximum

°F or °C

0.0 to 100.0

Repeats/

Min.

Factory

Default

N/A

0°F A

25 B

0.1

Security

Level

A

A

Chromalox 2110

14

Section 4–Adjusting Set Point and Configuration

Page 19

2110 Temperature Controller

Configuration

Menus

continued

Menu

Code Function

CYCL

db

ALty

ALSP

ALdb

SPLL

SPUL

outl

Cycle Time

The time for the output to

complete ON to OFF to

ON cycle. Used only with

proportional control. A fast

cycle time provides better

control, but can cause

premature wear to contactor or

other power switching devices.

Magnetic contactors should not

be switched at less than a 30

second cycle time. This menu

is active when the dip switch is

set to “PI”.

On/Off Dead Band

The range above/below set

point in which no control action

takes place. Determines at

what temperature the output

switches ON and OFF. For a 5°F

dead band, 2.5°F is above and

below the set point. This menu

is active when the dip switch is

set to “ONOF”.

Alarm Type

Select high or low alarm.

Alarm Set Point

Temperature level that will

actuate the alarm.

Alarm Dead Band

Difference of temperature from

alarm set point before an active

alarm resets.

Set Point Lower Limit

Lower limit to which set point

may be set without security

code access.

Set Point Upper Limit

Upper limit to which set point

may be set without security

code access. This prevents

an operator from setting the

set point temperature to a

level which would damage

equipment or process.

Output Limit

Limits the percentage of

output that can be applied in

proportional control.

Adjustable

Range

.1 to 60.0

Sec.

Factory

Default

Output

R1, R3 =

Security

Level

30 sec.

S0, S1,

S2, V0 =

1 sec.

1 to 100 °F

5 Foc

or °C

Off, Hi or Lo OFF B

0 to 100 °F

5 B

or °C

0 to 100 °F

5 B

or °C

Sensor

Range

Span

Low

°F or °C

Sensor

Range

Span

High

°F or °C

0 to 100% 100 B

B

B

B

B

Section 4–Adjusting Set Point and Configuration

For calibration menus (CoFF, dFLt, & CALS), see Section 7–

Calibration

15

Chromalox 2110

Page 20

Section 5—Control and Alarm Operation

Control Operation

Alarm Operation

(optional)

The 2110 is shipped from the factory with PI (proportional/integral) control. Proportional control actually determines the percent of heat needed

to control the process. The factory setting for the Proportional Band is

25°F and the Automatic Reset (Integral) is set at 0.1 repeats/minute.

These settings will control many processes without any changes to the

controller. If the process is unstable or too sluggish, the Proportional

Band and Automatic Reset can be changed in the menu configuration.

Tuning PI Control

Adjust Proportional Band The objective of the proportional band ad-

justment is to find the proportional band setting at which the process

temperature stabilizes and does not oscillate. If the temperature display

is oscillating, increase the Proportional Band (doubling the value) until

the temperature display has stopped oscillating. To establish a quick

response to control upsets, adjust for the smallest band that provides

stable control (does not oscillate). Note: The temperature at this point

may not be at set point, but will be stable.

Adjust Automatic Reset (Integral) The Automatic Reset (Integral) au-

tomatically removes the offset between process temperature and set

point. If the process is too sluggish in approaching set point, double the

automatic reset. Too much automatic reset will make a process unstable.

Cycle Time Cycle time setting determines how often to switch the

output to the heater. For example, if the cycle time is 1 second and the

2110 needs a 75% output, the output will be on for 3/4 of a second

and off 1/4 of a second. Units with relay control outputs (R1 or R3) are

shipped with a 30-second cycle time. Units with solid state relays or

solid state relay drives (S0, S1, S2, or V0) are shipped with a 1-second

cycle time.

An alarm relay output is optional on the 2110. An alarm can help protect

the process when a too high or too low temperature occurs.

High Alarm: This alarm is a high absolute alarm that actuates when the

process temperature is equal to or greater than the alarm set point. For

example, if the high alarm set point is 500°F, the alarm will always actuate when the process temperature reaches 500°F.

Low Alarm: The low absolute alarm actuates when the process tempera-

ture is equal to or less than the alarm set point. The low alarm features a

power-up inhibit to prevent undesirable alarms during process start up.

After the unit reaches control set point, the low alarm will respond.

Alarm Dead Band: The alarm relay de-energizes (resets) when the tem-

perature crosses out of the alarm dead band. For example, if the high

alarm is set to 500°F and the alarm dead band is 5°F, the alarm condition

will not reset until the process temperature reaches 495°F.

To enable the alarm relay, select either high or low alarm type and set the

alarm set point. An alarm condition is indicated when the Alarm light to

the left of the display illuminates. Alarm type, set point, and dead band

are selectable through the user configuration interface.

Chromalox 2110

16

Section 5–Control and Alarm Operation

Page 21

2110 Temperature Controller

!

Section 6—Replacing Output Modules

The Chromalox 2110 Temperature Controller was shipped with the

output modules installed as ordered. The 10A Solid State Relay and

20A Mechanical Relay output cards control small cartridge heater or

strip heater loads directly, eliminating the need for a remote contactor or solid state relay. If a larger load is required, the 2110 can be

configured with a 1A Pilot Duty Relay or Solid State Relay Drive.

The 2110 may be optionally configured with a 5A/120V Alarm Relay.

Alternate modules, configured with or without alarm, can be installed

as needs change.

Control and alarm outputs can be changed in the field.

Module Option

Descriptions

Output Module options are as follows

Factory

Default

Load/Sourcing

Description

R1 Relay Form A contact, SPST,

R3 Relay Form A contact, SPST,

V0 SSR

Drive

S1 TRIAC 1 amp continuous, 10

S1 Solid

State Power

Controller

S2 Solid

State Power

Controller

Specification

N.O. 1.0 Amp at 120/240

VAC resistive load

N.O. 20 Amp at 240

VAC, 28 VDC resistive

load

24 VDC nominal at 40

mA

Amp in-rush 120/240

VAC

120/240 VAC, 5 Amp @

40°C ambient

120/240 VAC, 10 Amp @

40°C ambient with builtin cooling fan mounted

on rear of housing

Cycle

Time

30 sec. 0149-27133 0149-27147

30 sec. 0149-27132 0149-27146

1 sec. 0149-27135 0149-27149

1 sec. 0149-27134 0149-27148

1 sec. 0149-27136 0149-27150

1 sec. 0149-00022

Part No

w/o Alarm

(Fan Kit)

Part No. w/

Alarm

0149-00022

(Fan Kit)

Module Installation

Section 6–Replacing Output Modules

WARNING: Remove power from the controller before changing the

output module. Failure to do so could cause damage to controller

and/or personal injury or death from electrical shock.

When handling output modules, be careful to guard the module

against static discharge. Follow the steps below to remove an existing output module and replace it with a new module.

Removal

1. Remove power from the controller.

2. Remove all terminal connections.

17

continued

Chromalox 2110

Page 22

Module Installation

continued

!

3. Remove the back cover by lifting four housing clips on the controller. This releases the back cover. Then pull cover straight off

the controller.

4. Gently pry around the sides to loosen and remove the module.

Pull module straight out to avoid bending pin connections.

WARNING: Do not remove module by the handling components on

the module board. This could damage the module.

When removing an S2 output module (SSR with fan), a cable connects the fan to the far right center of the S2 board. Gently disconnect the cable from the connector on the output board. Do not

remove the fan from the back cover. This is a single assembly.

For the S2 output module, reconnect the fan cable to the connec-

tor on the far right center of the module. Tuck the cable around

the heatsink.

Replacement

1. Line up pins on the controller with pin connections on either side

of the module and push the new module into place.

2. Reinstall the back cover.

Controller

Pin

Module

Chromalox 2110

Housing

Clip

Back Cover

Figure 6.1

Replacing Output Module

Auto Cycle Time

The Control Output Modules have a default cycle time of 1 second

(fast switching) or 30 seconds (slow switching) (See table on page

17). After replacing a control output, the 2110 verifies at power up

if a slow or fast cycle time output has been installed. If an output

with a different default cycle time is installed, the 2110 will change

the cycle time to the new device’s default. If the user has changed

the cycle time in configuration, the 2110 retains this value unless

an output with a different default cycle time has been installed.

18

Section 6–Replacing Output Modules

Page 23

2110 Temperature Controller

Section 7—Calibration

Calibration Offset

Factory Default

Recovery

Calibration offset offsets the displayed value. Usually, this option is

used to match displays of two different instruments that are measuring the same temperature, but are displaying different temperatures due to different thermocouple accuracy or placement of the

thermocouples. Caution is advised when adding an offset to the

display, since the actual sensed temperature will not be displayed.

Calibration offset (coFF) is available in the configuration mode, but

only displays if the security lock (LocH) is set to 736.

This option allow you to return the controller’s configuration parameters back to the factory default values (except for the LocH menu).

This parameter could be used when moving a unit from one application to another to give the operator an easy place to begin setup of

the unit.

Factory Default Recovery is performed in the Configuration Mode,

menu dFLt. The security lock (LocH) must be set to 736 to perform

a factory default recovery.

To reestablish the factory default values:

1. Disconnect load power.

2. In the Configuration Mode, set security level (LocH) to 736.

3. Go to menu dFLt and press . The controller will automatically

reset the values. When the display cycles from rEdy to donE, the

recovery is complete.

Calibration

Section 7–Calibration

The Chromalox 2110 Temperature Controller is factory calibrated

before shipment. Recalibration is not needed when you receive

and install the product. Periodic calibration checks or adjustments

should not be necessary under normal operating conditions. Chromalox recommends you recalibrate the controller if all instruments in

your facility are periodically calibrated to a known standard.

The 2110 always retains the original factory calibration values for

the J, K, and RTD inputs. In an application, only one of these sensor

inputs will be used. The 2110 only can retain manual calibration for a

single sensor.

Calibration Notes:

continued

19

Chromalox 2110

Page 24

Calibration

continued

When calibrating the 2110

1. You must have a sensor simulator to calibrate the 2110 controller.

Substitute a precision sensor simulator (Thermocouple simulator

or resistance simulator box) for sensor inputs.

2. Disconnect load power to prevent damage to the process or load.

3. Calibrate RTD inputs using copper (Cu) wire. Calibrate thermocouple inputs using thermocouple extension wire of the same

type as the thermocouple you are calibrating.

4. Allow the controller to warm up with the appropriate sensor simulator connected for at least one hour prior to calibration.

5. To access the calibration menu, you need level C (736) security.

Sensor Calibration:

1. Set the 2110 selection switch to RTD or TC. If TC is selected,

then set the selection switch to J or K.

2. Connect the sensor simulator to the sensor input terminals.

3. Set the simulator to the low value of the sensor selected J TC

(-100°F), K TC (-100°F), RTD (-200°F or 48.46W).

4. Go to the CALS parameter on the 2110. The display will toggle

between CALS and inLo.

5. Wait 30 seconds for the electronics to fully stabilize. Press .

Dashes will appear in the display while the controller calibrates

the low end of span.

6. When the controller prompts inHi in the display, adjust the sensor

simulator to the high end of the selected sensor span.

J TC (1400°F), K TC (2400°F), RTD (1000°F or 293.49W).

7. Wait 30 seconds for the electronics to fully stabilize. Press .

Dashes will appear in the display while the controller calibrates

the high end of span. When finished, the controller will display

donE.

8. Calibration is complete.

Factory Calibration

Recovery

Chromalox 2110

This procedure allows you to return the controller to its factory

calibration settings in the event it is severely out of calibration

due to poor technique or unauthorized calibration.

1. Disconnect load power.

2. Cycle the sensor selection switch twice from its original position (TC or RTD) to the opposite position (RTD or TC) and

back to its original position. This brings back the factory calibration and deletes the manual calibration settings.

20

Section 7–Calibration

Page 25

2110 Temperature Controller

Section 8—Specifications

Control Modes ................................ ON/OFF; PI—Proportional with integral

Control Adjustments

Proportional Band ..................... 1 to sensor span maximum

Automatic Reset ........................ 0.0 to 100.0 repeats/minute

Cycle Time................................. 0.1 to 60.0 seconds

On/Off Deadband ...................... 1° to 100°F or °C

Set Point Upper Limit ................ sensor range °F or °C

Set Point Lower Limit ................ sensor range °F or °C

Output Limit............................... 0 to 100%

Alarm Adjustments

Type ........................................... Absolute High or Low

Set Point .................................... Sensor range °F or °C

Alarm Dead Band ...................... 0° to 100°F or °C

Control/Alarm Outputs

Relay (R1) .................................. 1 Amp Form A, 120/240VAC

Relay (R3) .................................. Form A, 120/240VAC resistive loads at 30 sec. cycle time

20 Amps, 500,000 Operations

15 Amps, 1 Million Operations

10 Amps, 5 Million Operations

5 Amps, 5 Million Operations

Solid State Relay Drive (V0) ....... 24VDC at 40mA

Solid State Relay (S0) ................ 1A Triac, up to 240VAC

Solid State Relay (S1) ................ 5A, up to 240VAC at 40°C

Solid State Relay (S2) ................ 10A, up to 240VAC at 40°C

Alarm ......................................... Form C, Relay 5 Amps at 120VAC,

2.5A at 240VAC

Sensor Input .................................... Switch selectable; J,K Thermocouple; RTD

Input Update Rate .......................... Four samples per second

Input Specifications ....................... Range °F Range °C Accuracy at 77°F ambient

J TC ...........................................

K TC ..........................................

100W Pt RTD (a=.00385) ...........

Readout Stability

J and K TC ................................ +/-1°F per 10°F change in ambient temperature

RTD ........................................... +/-0.5°F per 10°F change in ambient temperature

Open Sensor and

Out-of-Range Conditions .............. Displays “SEnS”, Control output 0%

Instrument Power ........................... 90 to 260VAC Less than 10 VA

Operating Environment .................. 0° to 65°C (32° to 150°F)

Dimensions

Overall ....................................... 4.0 x 4.0 x 4.0 inches (102 mm)

Depth Behind Display ................ 3.6 inches (92 mm)

Front Panel Projection ............... 0.4 inches (10 mm)

Panel Cutout.............................. 3.6 x 3.6 inches (92 mm x 92 mm)

Enclosure Material ......................... High temp ABS plastic rated for 0° to 175°F

Front Panel NEMA 4X construction, requires surface finish not rougher

than 0.000032 inch

Influence of Line Voltage Variation

nominal line voltage

Noise Rejection

Common Mode Noise ............... Less than 2°F with 240 VAC, 60 Hz applied from sensor

input to earth ground

Series Mode Noise ....................

RFI ............................................. Typically less than 0.5% of sensor span at distance

of 1 meter (3.1 feet) from a transmitter of 4W at 464MHz

Sensor Leadwire Effect

J Thermocouple ........................ +1°F for 1000 ft. of 18 AWG

K Thermocouple ........................ +2°F for 1000 ft. of 18 AWG

RTD

resistance (20W is the total loop resistance)

-100 to 1400°F -73 to 760°C 0.2% Span +/-1 least significant digit

-100 to 2400°F -73 to 1316°C 0.2% Span +/-1 least significant digit

-200 to 1000°F -128 to 538°C 0.2% Span +/-1 least significant digit

.. +/-0.1% of sensor span per 10% change in

Less than 2°F with 100mV, peak to peak series mode noise

+/-0.1% of sensor span per 20W balanced leadwire

thermocouple extension wire

thermocouple extension wire

Section 8–Specifications

21

Chromalox 2110

Page 26

Section 9—Troubleshooting

The following Troubleshooting Guide offers simple solutions to

common problems and explains the 2110’s Error Messages. Review this section for a possible solution to your problem before

contacting Chromalox.

Note: For each symptom, perform correction steps in the order

listed.

Symptom Probable Cause Correction Steps

Power applied, display does not light,

and controller does

not function

1. No power applied

2. External fuse open

1. Check power wiring and

fusing

2. Power down and

repower up

Display alternates

between HI and

SENS, 2110 disables

control output

Process does not

heat up

Erratic operation 1. Intermittent sensor

1. Open sensor

2. Out of calibration

1. No power being

applied to the load

2. Load fuse open

connections

2.

Controller failure

(internal electronics)

3. External electrical

noise

1. Check sensor wiring

2.

Check selection switches

3. To verify that controller is at fault, remove

the thermocouple and

place a jumper across

the sensor terminals of

the 2110. If the display

reads approximately

ambient, then the sensor is open. Replace the

thermocouple.

4. See Section 7–Calibra-

tion

1. Verify Load LED is ON

2. Verify the heater or fuse

is not open

3. Verify output limit is set

to 100%

4. Verify set point is

greater than process

temperature

5. Verify output wiring

1. Check sensor wiring or

substitute sensor

simulator

2. Power down and

repower up

3. Contact Chromalox

Chromalox 2110

22

Section 9–Troubleshooting

Page 27

2110 Temperature Controller

Troubleshooting

continued

Symptom Probable Cause Correction Steps

Process not in

control

Instrument continually goes through

power-up reset

1. Incorrect settings

2. Thermocouple

Wiring

1. Severe electrical

noise

1. Check Proportional

Band setting and Automatic Reset setting

2. Check thermocouple

polarity

1. Separate sensor wiring

from other wiring

2. Apply power line filter

3. Contact Chromalox

Section 9–Troubleshooting

23

Chromalox 2110

Page 28

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

1347 HEIL QUAKER BLVD., LAVERGNE, TN 37086

Phone: (615) 793-3900 www.chromalox.com

Limited Warranty:

Loading...

Loading...