Page 1

2104

1/4 DIN Temperature

and Process Controller

• DualPID&FuzzyLogicControl

• ControlLoopProtection

• FiveOutputs-Control,Alarm

orEvent

Controls

• UniversalSensorInputs:TC,

RTD,VoltageandCurrent

• SwitchingPowerSupply

100-240Vacor

12-24Vac/Vdc,50/60Hz

• 16SegmentRamp/Soak

Program

• DigitalCommunicationswith

TM

ChromaSoft

SpecView®

SoftwareCompatibility

• Isolated12VdcPower

SupplyOption

• OperatingAmbientupto150˚F

• ThreeYearWarranty

Description

The Chromalox 2104 1/4 DIN Temperature and

Process Controller is a low cost, high

performance single loop controller that can be

used for temperature, flow, pressure and level

control applications. With universal sensor

inputs and front panel operator setup, one

2104 controller can be easily field configured

for a wide variety of applications, and simply

reconfigured as application needs change.

This makes it an exceptional choice for OEMs

and distributors with multiple control needs,

manufacturing facilities, testing facilities and

testing applications.

Features

• Five (5) Possible Outputs for Single Output

or Heat/Cool Control, plus up to three Alarm

or Event Outputs.

• Universal Sensor Input accepts thermocouple, RTD or analog signals, provides

24Vdc Output for loop power.

• Self-Tuning with Fuzzy Logic optimizes PID

control and minimizes overshoot.

• Digital Input for remote switching of one of

the following:

• AUX Pushbutton and LED for front

panel switching of:

• PID1/PID2

• Remote/Local Setpoint

• Main/Auxiliary Setpoint

• Ramp/Soak Operation

• Manual/Auto Control

• Security Code Protection prevents

unauthorized access.

• Setpoint Ramp Rate provides Soft

Start at powerup, or on setpoint

changes, to prevent uneven heating

and overshoot.

• Control Loop Protection provides

process protection from:

• Open Sensor

• Shorted Sensor

• Sensor Reversed

• Control Output Open or Shorted

• Power Control Device Open or

Shorted

• Load Power Missing and Self

Diagnostics.

H-8

• PID1/PID2

• Remote/Local Setpoint

• Main/Auxiliary Setpoint

• Ramp/Soak Operation

• Manual/Auto Control

• Alarm Reset for Latching Alarms

• 16 Interval Ramp/Soak Program with guar-

anteed soak, 3 event outputs and looping.

• Programmable Analog Output

and Remote Setpoint Input

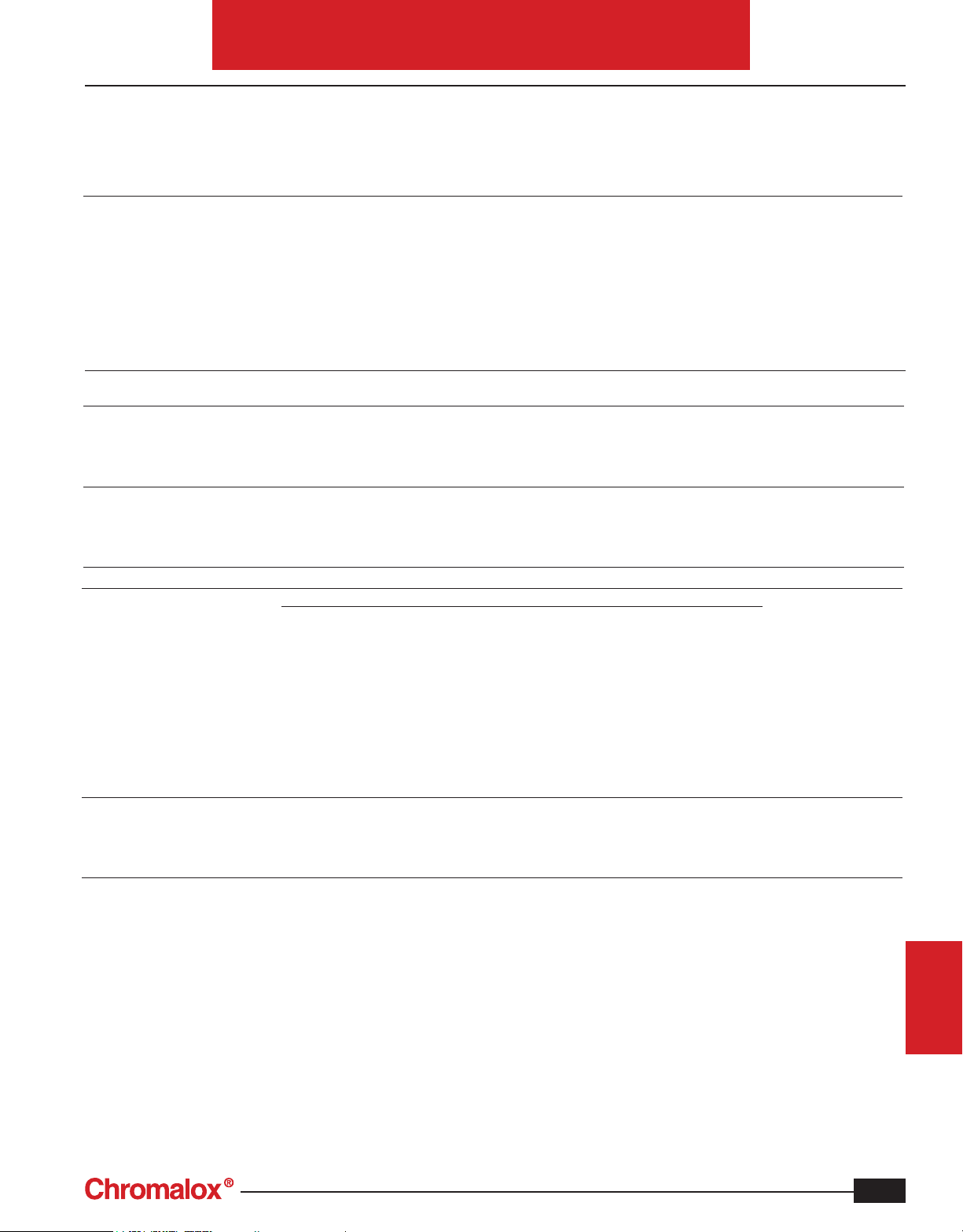

Self-Tuning with Fuzzy Logic

Setpoint

Typical PID Control

PID + Fuzzy Logic

Temperature

Time

Control

Page 2

Controls

2104 Controller (cont’d.)

Specifications

Control Modes Automatic ...........................................On/Off, Proportional (P), PID, PID + Fuzzy Logic, Heat/Cool

Control Adjustments Control Setpoint .................................Sensor Range

Setpoint Limits ...................................Sensor Range

Deadband ...........................................1-100˚F

Proportional Band ..............................Sensor Range

Manual Reset .....................................-99.9 to +99.9

Automatic Reset .................................0-99.99 repeats/min.

Rate ...................................................0-500 sec.

Output Cycle Time ..............................0.0-60.0 sec.

Output Limit .......................................0-100%

Open Sensor/Out of Range Output .....0-100%

Display Offset .....................................-100 to +100˚F

Heat/Cool Adjustments Output Offsets ....................................0-100% Prop. Band

Cooling Medium .................................Air, Water or Oil

Alarm Adjustments Setpoints ............................................High and Low Settings for each Alarm Output

Alarm Types .......................................Absolute: High, Low and High/Low

...........................................................Tracking: + Deviation, - Deviation and +/- Deviation

Relay Action .......................................Latching or Non-Latching, Energized or De-Energized

Alarm Deadband ................................Adjustable, 0-100˚F

Control/Alarm Outputs Total of five (5) Control/Alarm outputs possible

Relay ..................................................Relay–Form A contacts, 1 Amp at 120/230 Vac (resistive load)

Solid State Relay Drive .......................24Vdc nominal at 40mA

Triac ...................................................1 Amp continuous, 10 Amp in-rush, at 120 or 230 Vac

Current/Voltage ..................................4-20mA into 0-800Ω, field changeable to 1-5Vdc

Output #5 (Optional) Relay–NO. Form C contact, 5A at 120 or 2.5A at 230 Vac

Sensor Input Specifications Range ˚F Range ˚C

J T/C ..................................................-100 to +1400 -73 to +760

K T/C ..................................................-300 to +2400 -184 to +1316

T T/C ..................................................-350 to +750 -212 to +399

E T/C ..................................................-100 to +1100 -73 to +593

R T/C ..................................................0-3200 -18 to +1760

S T/C ..................................................0-3200 -18 to +1760

B T/C ..................................................50-3300 10-1816

100Ω Pt RTD (a = 0.00385) .................-200 to +1000 -128 to +538

RTD (0.1˚ res.) ...................................-99.9 to +899.9 -73.3 to +482.2

4-20mA ..............................................-500 to +5000 (programmable)

0-5 Vdc ..............................................-500 to +5000 (programmable)

1-5 Vdc ..............................................-500 to +5000 (programmable)

Ramp/Soak Programming Intervals .............................................16 intervals

Loops .................................................1 loop, 0-255 times or continuous

Event Outputs ....................................Up to 3

Guaranteed Soak Differential ..............Off, 1˚F to sensor span

Time Units ..........................................Seconds, Minutes, Hours (1 second to 99.99 hours/segment)

Remote Setpoint Input Input Signal .......................................4-20mA or 1-5Vdc, Field Selectable

Digital Input Accepts dry-contact closure

Analog Output Option Assignable Functions .........................Process Variable Output #1 Command

...........................................................Active Setpoint Output #2 Command

Output Signal .....................................4-20mA into 0-800Ω load, 1-5Vdc into 100KΩ or greater load

...........................................................Selectable via DIP switch

Range .................................................Programmable for retransmission of Process Variable and Active Setpoint

Isolated DC Power Supply Option 12Vdc, 50mA Max

Digital Communications (Optional)

RS-232 Single drop, isolated

RS-422/485 Multi-drop, isolated, field selectable by switch

Baud Rates .........................................1200, 2400, 4800, 9600, 19200

Protocols ASCII Line, Computer Interface

Instrument Power 100-240 Vac, +10%, -15%; 12-24 Vac/Vdc, ± 10%; 50-60 Hz, 15vA

Operating Environment 32-150˚F (0-65˚C) ambient temperature, relative humidity < 95%, non-condensing

SINGLE CHANNEL

H-9

Page 3

2104

1/4 DIN Temperature

and Process

Controller

(cont’d.)

Dimensions

3.8

(96)

Controls

3.8

(96)

0.8

(19)

3.8

(96)

3.5

(90)

3.6

(92)

3.6

(92)

Ordering Information

Complete the Model Number using the

Matrix provided.

In Stock:

Model PCN

2104-R0000 306510

2104-R0100 306528

2104-A0000 306579

2104-A0100 306587

All other models, one day delivery.

Front View

Model Temperature and Process Controller

2104 Microprocessor-based 1/4 DIN Temperature Controller. Universal Sensor Input

accepts Thermocouple, RTD, Current or Voltage Inputs with 24Vdc Transmitter

Power Supply. PID, ON/OFF and Fuzzy Logic Control Capability. One Digital Input,

Analog Remote Setpoint, and 16 Segment Ramp/Soak Program.

Code Output #1 - Single Output Control

RO Relay/SSR Drive (jumper selectable)

Relay–NO. Form A Contact, 1A at 120 or 230 Vac

SSR Drive–24Vdc at 40mA

TO Triac–1 Amp at 120 or 230 Vac

AO Analog–4-20mA or 1-5 Vdc, non-isolated

Outputs #1 & #2 - Heat/Cool Control

RR Relay/Relay

TT Triac/Triac

AA Analog/Analog

SS SSR Drive/SSR Drive

AR Analog/Relay

AT Analog/Triac

SR SSR Drive/Relay (SSR Drive/Triac is Obsolete, replaced by SR)

Code Outputs #3 & #4 or Power Supply Option

0 None

1 Dual Relay–Form A contact, 1A at 120 or 230 Vac with

shared common terminal

7 Isolated Power Supply 12Vdc, 50mA

Code Isolated Digital Communications, Output #5

(Alarm/Event Output) and Analog Output Option

0 None

1 RS-422/485 Digital Communications and Output #5

2 RS-232 Digital Communications and Output #5

3 Analog Output Option

4 RS-422/485 Digital Communications, Output #5

and Analog Output Option

5 RS-232 Digital Communications with Output #5, and

Analog Output Option

Code Power Supply

0 100-240 Vac

1 12-24 Vac/Vdc

Side View

All Dimensions in Inches (mm)

Panel Cutout

H-10

2104 - RO 1 1 0 Typical Model Number

Loading...

Loading...