Mini Door/Window Contact Detector (HSM01)

Installation and Operating Instructions

These instructions should be read in conjunction

with your System Installation and Operating

Manual and be retained for future reference.

The Door/Window contact detector is comp atible with a

series of Everspring control panels – SC801, SC811,

SC821, or IP Gateway HSC04….,operating at 868

MHz or 923 MHz only.

The Door/Window contact detector consists of two

parts; a Detector and a Magnet. They are designed to

be fitted to doors or windows with the Magnet mounted

on the opening part and the Detector mounted on the

fixed frame. Opening the protected door/window will

remove the magnetic field, trigger the Detector and

generate an alarm condition, (if the system is armed).

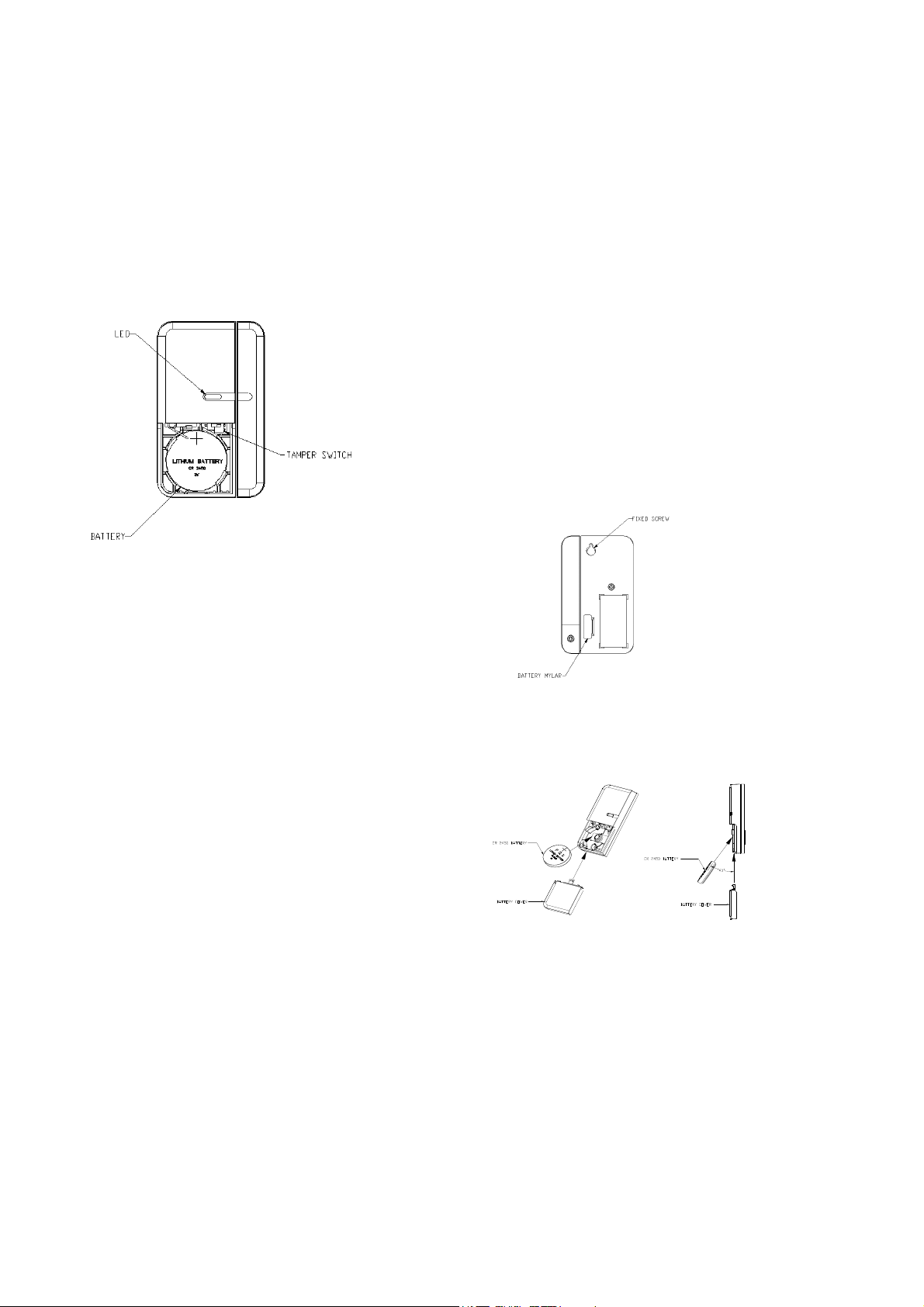

The Detector is powered by 1 pieces of 3V CR2450

battery which under normal conditions will have typical

life in excess of 3 years. Under normal battery

conditions with tamper switch being pressed, the LED

on the Detector will not illuminate when the Detector is

triggered. However, under low battery conditions this

LED will be illuminated when the detector is triggered.

When this occurs the battery should be replaced as

soon as possible.

CHOOSING A MOUNTING LOCATION

The Door/Window Contact is suitable for mounting in

dry interior locations only.

Decide which doors/windows are to be protected by

Door/Window Contact, (usually the front and back

doors as a minimum will have Door/Window Contact

fitted). Additional detectors may also be fitted where

required to other vulnerable doors or windows, (e.g.

garage, patio/conservatory doors etc).

Note: Take care when fixing the Detector to a metal

frame, or mounting within 1m of metalwork (i.e.

radiators, water pipes, etc) as this could af fect the radio

range of the device. If required, it may be necessary

to space the magnet and detector away from the metal

surface using a plastic or wooden spacer to achieve

the necessary radio range.

INSTALLING THE DOOR/WINDOW

CONTACTS

Ensure that the system properly powered.

Factory default built in a CR2450 battery inside the

detector and uses a Mylar film to isolate battery from

electric circuit of the detector. Remove the battery

Mylar film when ready to let the detector work.

If there is no battery inside the detector or need to

replace a new battery please insert the battery in 45°

angle as below figure

FIX AND TEST THE DOOR/WINDOW CONTACTS

1. Using the adhesive tape to fit detector on the door

or window.

2. Fit the Magnet to the moving part of the

door/window opposite the Detector using the

adhesive tape.

3. Ensure that the parallel gap between the Magnet

and Detector is less than 20mm and that the

matching line on the Magnet is pointing towards

and aligned with the line on the Detector. An alarm

1

condition will be occurred if the gap is greater than

35mm.

4. Remove the battery cover with the tamper switch

not being pressed on the Detector (test mode),

detach or close the magnet from the Detector, the

LED on the Detector will illuminate.

5. After proper installation and test, put the battery

cover back to the detector and the Detector enters

the normal mode.

Learning ID code

In order to communicate with the control panel, the

Detector and control panel need to be learned its

ID code with each other. By pressing the tamper

switch, located on the PCB of the Detector, more

than 3 seconds will emit the ID code to the control

panel instantly, subject to the control panel being

set at the ID code learning mode.

To emit the ID code to the control panel, proceed

with the following steps in sequence:

a. Press the learning key located on the PCB

more than 3 seconds until the LED of the

Detector flashes. It implies that the Detector

enters ID code learning mode.

b. A 30-second countdown will start. If the ID

code has been learned within 30 seconds by

the control panel successfully, the LED of the

Detector will be on shortly. If failure, the LED of

the Detector will flash three times rapidly.

c. If next ID code needs to be learned, start from

step a accordingly.

Clearing ID code

a. Press the tamper switch located on the PCB

more than 3 seconds until the LED of the

Detector flashes. It implies that the Detector

enters ID code learning mode.

b. Press the learning key again more than 6

seconds and release before 10 seconds. The

LED of the Detector will be on. The ID code

learned from the Control Panel has been

cleared.

TESTING THE DOOR/WINDOW CONTACTS

Ensure the system is in test mode.

1. With the tamper switch not being pressed, the

Detector enters the test mode.

2. Open the door/window to detach the magnet from

the Detector. As the magnet is parted from the

detector, the LED will illuminate for approx. 1

second to indicate that the Detector has been

triggered.

3. If connected, operate the wired Magnetic Contact.

As the contact is opened the LED on the Detector

should illuminate for 1 second to indicate that it

has been triggered.

4. When the tamper switch is pressed, the Detector

enters the normal mode.

5. It is recommended that the operation of the

detector is also tested with the alarm in normal

operating mode to ensure that the Detector will

successfully trigger a Full Alarm condition.

Refer to your System Installation and Operating

Manual for further details on operating and testing the

system.

SPECIFICATIONS

RF

Mechanical

Battery

Environment

Hardware

Condition 1. Send trigger signal to U-Net Controller like HSE01 or HSC04 in

any direction at open space

Condition 2 .

Frequency

Distance

weight

Dimension (W x H x D)

CR2450

Battery life

Operation Temperature

Humidity

Magnetic gap(Open→Close)

Magnetic gap(Close→Open)

At normal connect situation and trigger 10 times per day

*specifications are subject to change without prior notice.

923(Taiwan USA)/868

(EU) MHz

150M @condition 1

23.6 g (without

battery)

31x70x11.5 mm

620mAh

3 years @condition 2

-10 ~ 40° C

85%RH max

20 mm

35 mm

FCCID: ZGXHSM01

Warning:

Do not dispose of electrical appliances as unsorted

municipal waste, use separate collection facilities.

Contact your local government for information

regarding the collection systems available.

If electrical appliances are disposed of in landfills or

dumps, hazardous substances can leak into the

groundwater and get into the food chain, damaging

your health and well-being.

2

When replacing old appliances with new once, the

retailer is legally obligated to take back your old

appliance for disposal at least for free of charge.

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference.

(2) This device must accept any interference received,

including interference that may cause undesired

operation.

Class B:

FEDERAL COMMUNICATIONS COMMISSION

INTERFERENCE STATEMENT

This equipment has been tested and found to comply with

the limits for a Class B digital device, pursuant to part 15 of

the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a

residential installation. This equipment generate s, uses

and can radiate radio frequency energy and, if not inst alled

and used in accordance with the instructions, may cause

harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be

determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or

more of the following measures:

-Reorient or relocate the receiving antenna.

-Increase the separation between the equipment and

receiver.

-Connect the equipment into an outlet on a circuit different

from that to which the receiver is connected.

-Consult the dealer or an experienced radio/ TV technician

for help.

CAUTION:

Any changes or modifications not expressly approved by

the grantee of this device could void the user's authority to

operate the equipment.

3

Loading...

Loading...