Christie P35GPSZ-MT, P35GPSZ-AT, M35GPSZ-AT, P35GPS-MT, P35GPS-AT Operating Instructions Manual

...

CHRISTIE

I N C O R P O R A T E D

Operating Instructions

For

35mm Film Projector

Manual Turret Model P35GPS(Z)-MT

Automatic Turret Model P35GPS(Z)-AT

Automatic Turret Model M35GPS(Z)-AT

115VAC, 60Hz Motor or 220VAC, 50Hz Motor

TD-621: Version 3.5

HRISTIE

HRISTIE

CCCC

HRISTIE HRISTIE

10550 Camden Drive

Cypress, CA 90630

714-236-8610 Fax: 714-229-3185

NCORPORATED

NCORPORATED

IIII

NCORPORATEDNCORPORATED

Operator’s Manual

P35GPS-MT/P35GPS-AT

TD621GPS(Z)

The information in this document is subject to change without notice and does not represent a

commitment on the part of

HRISTIE

C

document.

).

C

HRISTIE

C

HRISTIE

does not assume responsibility for errors that may appear in this

or its subsidiaries, designated representatives, and any other vendor of

HRISTIE

C

NCORPORATED

, I

(hereinafter referred to as

the P35GPS Film Projector are not responsible in any way for any liabilities or loss resulting

from the use or misuse of this document.

Copyright © 1998 by

HRISTIE

C

NCORPORATED

, I

All Rights Reserved

Ultramittent© is a copyright of

HRISTIE

C

NCORPORATED

, I

.

All other copyrights and trademarks are the property of their respective owners.

CHRISTIE

I N C O R P O R A T E D

I N C O R P O R A T E D

I N C O R P O R A T E DI N C O R P O R A T E D

10550 Camden Drive

Cypress, CA 90630

Telephone 714-236-8610

FAX 714-229-3185

TABLE OF CONTENTS

TABLE OF CONTENTS............................................................................ i

LIST OF FIGURES AND TABLES............................................................. v

1. INTRODUCTION ................................................................................. 1-1

1.1. Contents of the Manual..................................................................................................1-1

1.2. Who Should Use This Manual? .....................................................................................1-1

1.3. Special Notices...............................................................................................................1-1

1.3.1. Warning ..................................................................................................................1-2

1.3.2. Caution....................................................................................................................1-2

1.3.3. Note.........................................................................................................................1-2

2. General Description........................................................................... 2-1

2.1. Optional Features ...........................................................................................................2-1

2.2. Specifications.................................................................................................................2-1

3. Projector installation and Assembly................................................ 3-1

3.1. Unpacking the Projector.................................................................................................3-1

3.2. Installation......................................................................................................................3-1

3.3. Electrical Connections ...................................................................................................3-3

3.3.1. Solar Cell Wiring....................................................................................................3-3

3.3.2. A-C Projector Wiring..............................................................................................3-4

4. OPERATING THE PROJECTOR ........................................................ 4-1

4.1. General...........................................................................................................................4-1

4.2. Pre-Operating Procedures ..............................................................................................4-1

4.2.1. Flywheel Installation...............................................................................................4-1

4.2.2. Turret Installation....................................................................................................4-1

4.2.3. Lens Installation......................................................................................................4-2

4.3. Film Threading and Operating Procedure......................................................................4-2

5. MAINTENANCE .................................................................................. 5-1

5.1. General Maintenance .....................................................................................................5-1

5.2. Visual Inspection............................................................................................................5-1

5.3. Cleaning .........................................................................................................................5-2

5.4. Removal of Assemblies .................................................................................................5-2

5.4.1. Removal of the Trap and Gate Assembly...............................................................5-2

CHRISTIE INCORPORATED

June, 1998

P35GPS Projector i

P35GPS Dual Lens Turret Projector

5.4.2. Outer Timing Belt...................................................................................................5-3

5.4.3. Inner Timing Belt ...................................................................................................5-3

5.4.4. Shutter Timing Belt................................................................................................5-4

5.4.5. Upper, Center, and Lower Constant-Speed Sprocket Assemblies .........................5-5

5.4.6. Ultramittent Assembly............................................................................................5-6

5.4.7. Removal of LED Soundhead and Solar Cell Assembly.........................................5-6

5.4.8. Removal of Digital Soundhead Assembly..............................................................5-6

5.4.9. Removal of Electric Changeover Assembly...........................................................5-6

5.4.10. Removal of Shutter Driver Assembly ....................................................................5-7

5.4.11. Removal of Motor Assembly .................................................................................5-7

5.4.12. Removal of Fan ......................................................................................................5-7

5.4.13. Removal of Framing Lamp.....................................................................................5-7

6. CALIBRATION, ALIGNMENT, AND ADJUSTMENT PROCEDURES.6-1

6.1. LED Soundhead Alignment and Adjustments...............................................................6-1

6.1.1. Preliminary Procedures...........................................................................................6-2

6.1.2. Cell Positioning: Vertical Alignment.....................................................................6-2

6.1.3. Horizontal Alignment.............................................................................................6-2

6.1.4. Focus and Azimuth.................................................................................................6-2

6.1.5. Alignment Verification...........................................................................................6-3

6.1.6. Performance Check: Crosstalk ..............................................................................6-3

6.1.7. Illumination Uniformity .........................................................................................6-3

6.1.8. Final Check.............................................................................................................6-3

6.2. Digital Soundhead Alignment .......................................................................................6-3

6.2.1. Preliminary Steps....................................................................................................6-3

6.2.2. Alignment Procedure..............................................................................................6-4

6.3. Dashpot Adjustment ......................................................................................................6-5

6.4. Inner, Outer, and Shutter Timing Belt Adjustment .......................................................6-5

6.4.1. Inner Timing Belt ...................................................................................................6-5

6.4.2. Shutter Timing Belt................................................................................................6-5

6.4.3. Outer Timing Belt...................................................................................................6-6

6.5. Shutter Timing...............................................................................................................6-6

6.6. The

CHRISTIE

6.6.1. General Description................................................................................................6-7

6.6.2. The Manual Turret System.....................................................................................6-7

6.6.3. The Automatic Turret System ................................................................................6-7

6.6.4. Timing Adjustments – Turret and Aperture Motor ................................................6-7

6.7. Optical Image Alignment and Adjustment Procedures .................................................6-8

Dual-Lens Turret............................................................................6-7

7. Troubleshooting Procedures ............................................................7-1

7.1. Motor .............................................................................................................................7-1

7.1.1. SYMPTOM: Motor Not Working.........................................................................7-1

7.2. Ultramittent Assembly...................................................................................................7-2

7.2.1. SYMPTOM: Excessive Ticking............................................................................7-2

7.2.2. SYMPTOM: Excessive Film Noise ......................................................................7-2

7.2.3. SYMPTOM: Film Instability (Jump) ....................................................................7-2

CHRISTIE INCORPORATED

June, 1998

P35GPS Projector ii

Table of Contents

7.2.4. SYMPTOM: Shutter Streaking..............................................................................7-2

7.3. Constant-Speed Sprocket Assembly ..............................................................................7-2

7.3.1. SYMPTOM: Excessive Noise ...............................................................................7-2

7.3.2. SYMPTOM: Film Sprocket Hole Damage............................................................7-2

7.3.3. SYMPTOM: Sprocket Riding ...............................................................................7-2

7.4. Belts ...............................................................................................................................7-3

7.4.1. SYMPTOM: Excessive Noise ...............................................................................7-3

7.4.2. SYMPTOM: Excessive Belt Dust .........................................................................7-3

7.4.3. SYMPTOM: Excessive Belt Failure......................................................................7-3

7.5. Changeover Assembly....................................................................................................7-3

7.5.1. SYMPTOM: Operating Inconsistently ..................................................................7-3

7.5.2. SYMPTOM: Not Operating...................................................................................7-3

CHRISTIE INCORPORATED

June, 1998

P35GPS Projector iii

iii

P35GPS Dual Lens Turret Projector

7.6. Shutter Drive (Shutter Driver and Jackshaft System)....................................................7-3

7.6.1. SYMPTOM: Excessive Noise...............................................................................7-3

7.6.2. SYMPTOM: Shutter Streak ..................................................................................7-4

7.7. Trap and Gate Assembly................................................................................................7-4

7.7.1. SYMPTOM: Excessive Jump and Weave.............................................................7-4

7.7.2. SYMPTOM: Aperture Binding.............................................................................7-4

7.8. Lens Turret.....................................................................................................................7-4

7.8.1. SYMPTOM: Not Rotating ....................................................................................7-4

7.8.2. SYMPTOM: Focus Knob Inoperative...................................................................7-4

7.8.3. SYMPTOM: Turret Hinge Too Loose ..................................................................7-5

7.8.4. SYMPTOM: Turret Hinge Too Tight ...................................................................7-5

Appendix A: Replaceable Assemblies and Components ................. A-1

Appendix B: Diagrams and Parts Lists P35GPS ............................... B-1

B-1: Changeover Douser Assembly...................................................................................... B-2

B-2: Automatic Curved Trap and Gate Assembly................................................................ B-4

B-3: Fixed Idler Assembly.................................................................................................... B-8

B-4: Fixed Idler Assembly, Flanged..................................................................................... B-9

B-5: Jackshaft Assembly .................................................................................................... B-10

B-6: Center and Upper Constant-Speed Sprocket Assembly ............................................. B-11

B-7: Lower Constant-Speed Sprocket Assembly................................................................ B-13

B-8: Shutter Driver Assembly ............................................................................................ B-14

B-9: 30-Groove Flanged Idler Assembly............................................................................ B-17

B-10:30-Groove Non-Flanged Idler Assembly.................................................................... B-18

B-11:Outer Timing Belt Tensioner Assembly..................................................................... B-19

B-12:Inner Timing Belt Tensioner Assembly...................................................................... B-20

B-13:Analog Central Pivot Soundhead Assembly............................................................... B-20

B-14:Digital Central Pivot Soundhead Assembly ............................................................... B-22

B-15:Intermittent Shoe Closure Assembly.......................................................................... B-25

Appendix C: Diagrams and Parts Lists M35GPS................................ C-1

Appendix D: Schematic Diagrams...................................................... D-1

Index...................................................................................................... D-3

CHRISTIE INCORPORATED

June, 1998

P35GPS Projector iv

Table of Contents

LIST OF FIGURES AND TABLES

Figure 2-1: Table of Equipment Specifications...........................................................................2-1

Figure 2-2: Projector, Front View ...............................................................................................2-2

Figure 2-3: Projector, Rear View ................................................................................................2-3

Figure 3-1: Installing the Projector..............................................................................................3-2

Figure 3-2: Tools and Materials Required for Assembly and Maintenance................................3-3

Figure 3-3: Projector Wiring Diagram (50- and 60-Hz models).................................................3-4

Figure 3-4: Table of A-C Terminal Connections ........................................................................3-5

Figure 4-1: Threading Diagram...................................................................................................4-3

Figure 5-1: Schedule for Periodic Maintenance Operations........................................................5-1

Figure 5-2: Outer Timing Belt.....................................................................................................5-3

Figure 5-3: Inner Timing Belt......................................................................................................5-4

Figure 5-4: Shutter Timing Belt ..................................................................................................5-5

Figure 6-1: LED Soundhead Assembly.......................................................................................6-1

Figure 6-2: Digital Soundhead Assembly....................................................................................6-4

Figure 6-3: Dual Turret (Front View)..........................................................................................6-7

Figure 6-4: Dual Turret (Rear View)...........................................................................................6-8

Table A-1: P35GPS Projector Replaceable Assemblies and Components ................................A-1

Figure B-1: Changeover Douser Assembly (P/N 121195-001)..................................................B-2

Table B-1: Changeover Douser Assembly Parts List.................................................................B-3

Figure B-2: Automatic Curved Trap and Gate Assembly (P/N 194615-001)............................B-4

Table B-2: Parts List for Automatic Curved Trap and Gate Assembly......................................B-4

Figure B-3: Fixed Idler Assembly (P/N 194756-001)................................................................B-8

Table B-3: Fixed Idler Assembly Parts List ...............................................................................B-8

Figure B-4: Fixed Idler Assembly, Flanged (P/N 194756-002) .................................................B-9

Table B-4: Fixed Idler Roller Assembly, Flanged, Parts List ....................................................B-9

Figure B-5: Jackshaft Assembly (P/N 194810-001).................................................................B-10

Table B-5: Jackshaft Assembly Parts List................................................................................B-10

Figure B-6: Center and Upper Constant-Speed Sprocket Assembly (P/N 194856-001)..........B-11

Table B-6: Center and Upper Constant-Speed Sprocket Assembly Parts List.........................B-12

Figure B-7: Lower Constant-Speed Sprocket Assembly (P/N 194857-001)............................B-13

Table B-7: Lower Constant-Speed Sprocket Assembly Parts List...........................................B-13

Figure B-8: Shutter Driver Assembly (P/N 194866-001).........................................................B-15

Table B-8: Shutter Driver Assembly Parts List........................................................................B-16

Figure B-9: 30-Groove Flanged Idler Assembly (P/N 194880-001)........................................B-17

Table B-9: 30-Groove Flanged Idler Assembly Parts List .......................................................B-17

Figure B-10: 30-Groove Non-Flanged Idler Assembly (P/N 194895-001)..............................B-18

Table B-10: 30-Groove Non-Flanged Idler Assembly Parts List .............................................B-18

Figure B-11: Outer Timing Belt Tensioner Assembly (P/N 196055-001)...............................B-19

Table B-11: Outer Timing Belt Tensioner Assembly Parts List ..............................................B-19

CHRISTIE INCORPORATED

June, 1998

P35GPS Projector v

v

P35GPS Dual Lens Turret Projector

Figure B-12: Inner Timing Belt Tensioner Assembly (P/N 196056-001) ............................... B-20

Table B-12: Inner Timing Belt Tensioner Assembly Parts List............................................... B-20

Figure B-13: Central Pivot Analog Soundhead Assembly (P/N 196260-001) ......................... B-20

Table B-13: Central Pivot Analog Soundhead Assembly Parts List........................................ B-20

Figure B-14: Central Pivot Analog Soundhead Assembly (P/N 196260-001) ......................... B-22

Table B-14: Central Pivot Analog Soundhead Assembly Parts List........................................ B-22

Figure B-15: Intermittent Shoe Closure Assembly (P/N 120651M001)................................... B-25

Table B-15: Intermittent Shoe Closure Assembly Parts List ................................................... B-26

Table C- 1: Schematic Diagrams for P35GPS Projector ........................................................... C-1

CHRISTIE INCORPORATED

June, 1998

P35GPS Projector vi

1. INTRODUCTION

1

1.1. C

This manual contains installation, operation, and operator maintenance procedures for

CHRISTIE

covered includes:

• general description

• installation and assembly

• operating the projector

• periodic maintenance

• calibration, alignment, and adjustments

• troubleshooting.

1.2. W

This manual provides information suitable for various purposes. For details on operating the

projector and for general information, see:

• Section 2: General Description

• Section 3: Installation and Assembly

• Section 4: Operating the Projector.

Before performing adjustments and periodic maintenance during normal operation, see:

ONTENTS OF THE MANUAL

P35GPS Projector models having serial numbers P-1201 and up. The material

HO SHOULD USE THIS MANUAL

?

• Section 5: Periodic Maintenance

• Section 6: Calibration, Alignment, and Adjustments.

If a problem occurs, see:

• Section 7: Troubleshooting Procedures.

Additional reference information is contained in the appendices.

1.3. S

Three kinds of specific notices are used within this manual to emphasize specific

information.

CHRISTIE INCORPORATED

June, 1998

PECIAL NOTICES

P35GPS Projector 1-1

P35GPS Dual Lens Turret Projector

1.3.1. W

WARNING

1.3.2. C

1.3.3. N

ARNING

WARNING: Indicates the presence of a hazard that can cause personal

injury if the hazard is not avoided.

AUTI ON

CAUTION: Indicates the presence of a hazard that could cause damage

to projection system.

OTE

NOTE: Provides additional information.

CHRISTIE INCORPORATED

June, 1998

P35GPS Projector 1-2

2. GENERAL DESCRIPTION

The CHRISTIE P35GPS Projector, manufactured exclusively by CHRISTIE

INCORPORATED in Cypress, California, is a dual-lens 35mm movie projector that

employs a revolutionary sealed-bearing intermittent movement called the Ultramittent©.

This movement, coupled with uncompromising design and assembly workmanship, results in

the finest possible theater picture reproduction. The Ultramittent movement is standard on

all CHRISTIE projectors.

2

2.1. O

Options available for enhancing the standard features of the P35GPS projector include:

• manual dual-lens turret

• automatic dual or triple lens turret, including automatic aperture changer

• inboard Dolby digital reader

• all models available in 50 Hz or 60 Hz

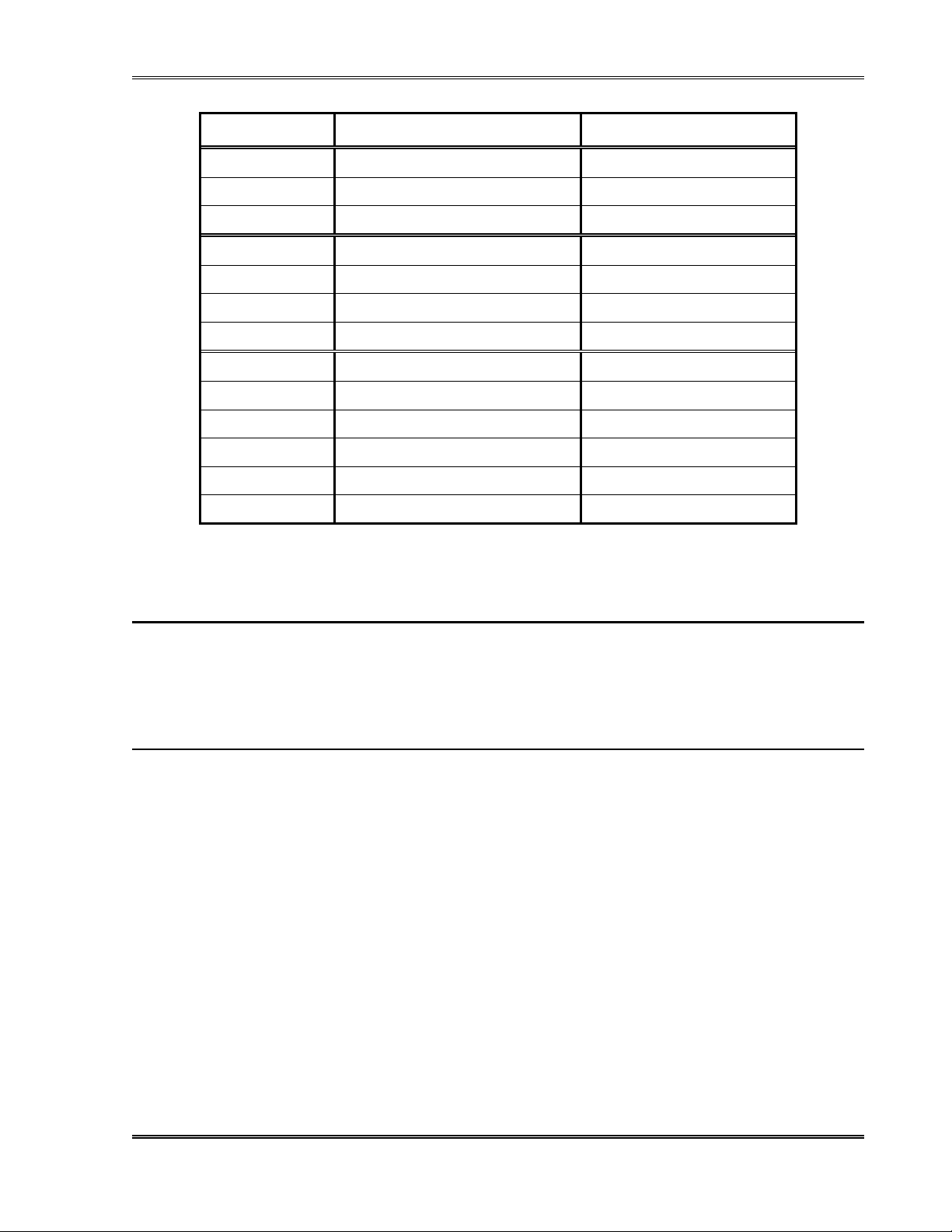

2.2. S

Standard specifications for the P35GPS projector family are listed in the Table shown in

Figure 2-1, below.

PTIONAL FEATURES

PECIFICATIONS

POWER REQUIREMENTS:

Input Voltage 115 VAC, 5 Amp, 60 Hz

OR

220 VAC, 3 Amp, 50 Hz

DIMENSIONS:

Height 23 inches

Width 18 inches

Depth 16 inches

WEIGHT

FILM SPEED:

OPERATING TEMPERATURE:

MOTOR:

:

Standard: approximately 90 lb.

Standard: 24 frames/sec (90 ft/min)

0 to +45°C

Synchronous split phase, 1800 rpm, 60 Hz

OR

1500 rpm, 50 Hz

Figure 2-1: Table of Equipment Specifications

These specifications may vary slightly, depending upon the particular model and options

chosen.

CHRISTIE INCORPORATED

June, 1998

P35GPS Projector 2-1

P35GPS Dual Lens Turret Projector

1.

Dual Lens Turret (121433-001)

*

2. Turndown Knob (194510-001)

3. Center Sprocket Assembly (194856-002)

4. Upper Sprocket Assembly (194856-001)

5. Ultramittent Assembly (119450-005)

6. Trap and Gate Assembly (194615M001)

7. Aperture Plate (121117-00X)

8. Intermittent Shoe Closure (120651M001)

* Manual or Motorized

Figure 2-2: Projector, Front View

CHRISTIE INCORPORATED

June, 1998

P35GPS Projector 2-2

9. Shutter Belt Cover (194600-001)

‡

10.

Soundhead Assembly

11. Aperture Drive Assembly (121435-001)

12. Fan Grill (598931-547)

13. Baffle Light Cover (119039-001)

14. Soundhead Access Door (19041-001)

‡

15.

Light Shield (194434-00X)

‡

Analog or Digital

2: General Description

16: Motor Assembly (50- or 60-Hz)

17: Lower Sprocket Assembly (194857-001)

18: Shutter Driver Assembly (194866-001)

19: Ultramittent Pulley (194818-001)

20: Center Sprocket Pulley (194858-001)

21: Inner Belt Tensioner (196056-001)

22: Flanged Idler Assembly (194880-001)

23: Non-Flanged Idler Assembly (194756-001)

10: Sounddrum Shaft (196315-001)

24: Digital LED Supply (194834-001)

25: Turret Control Module (121428-001)

Figure 2-3: Projector, Rear View

CHRISTIE INCORPORATED

June, 1998

P35GPS Projector 2-3

26: Flanged Idler Assembly (194880-001)

27: Analog Power Supply (194908-001)

28: Upper Sprocket Pulley (194858-001)

29: Jackshaft Assembly (194810-001)

30: Changeover Douser (121195-001)

31: Outer Belt Tensioner (196055-001)

32: Framing Light Switch (598931-214)

33: Inner Timing Belt (598931-179)

34: TB1 Connector (586210-602)

35: Outer Timing Belt (598931-528)

36: Sounddrum Flywheel (119166-001)

3. PROJECTOR INSTALLATION AND

ASSEMBLY

3

3.1. U

The CHRISTIE P35GPS projector may be shipped in more than one container. Each

P35GPS projector normally comes complete with the following items:

• dual aperture plate (shipped in place)

•

•

•

•

• drive motor assembly

• instruction manual.

The console and projector are shipped in a single carton, with special pockets containing

smaller items. The lens turret and soundhead flywheel are shipped separately.

NPACKING THE PROJECTOR

Before opening box(es), carefully inspect outside of carton(s). If carton

has been damaged, notify shipper immediately; do not open carton

unless instructed to do so.

framing lamp (installed)

soundhead flywheel (not installed)

soundhead assembly (factory-aligned)

dual-lens turret

To unpack:

1. Open carton(s).

2. Remove all protective material from framing lamp, soundhead assembly, and lens holder.

3. Remove protective material around side panel.

3.2. I

To install the projector, refer to Figure 3-1. The required materials and tools for installing

and assembling the P35GPS projector are outlined in the Table in Figure 3-2.

1. Loosen but do not remove nut on projector mounting stud (item 4 in Figure 3-1). Verify

CHRISTIE INCORPORATED

June, 1998

NSTALLATION

that lock washer (item 5 in Figure 3-1) and flat washer (item 6 in Figure 3-1) are correctly

positioned on mounting stud. Flat washer should be next to lock washer, followed by nut.

P35GPS Projector 3-1

P35GPS Dual Lens Turret Projector

2. Insert lock washer (item 2 in Figure 3-1) and flat washer (item 3 in Figure 3-1) onto

second hex bolt (item 1 in Figure 3-1). Insert hex head bolt, with lock washer and flat

washer, into upper left opening of projector mount. Rotate hex head bolt four full turns.

3. Lift and mount projector to console or pedestal. Thread two remaining hex head bolts

with lock washer and flat washer. Insert into two bottom mounting holes on projector.

4. Level projector on lamphouse or pedestal.

5. Tighten nut on mounting stud using 9/16" wrench.

6. Tighten three hex head screws using same wrench.

CHRISTIE INCORPORATED

June, 1998

Figure 3-1: Installing the Projector

P35GPS Projector 3-2

3: Projector Installation and Assembly

Category Item Use

Tools

Equipment

Materials

Figure 3-2: Tools and Materials Required for Assembly and Maintenance

3.3. E

Miscellaneous Allen wrenches General Maintenance

Small standard screwdriver

Phillips screwdrivers

Oscilloscope Soundhead Alignment

Voltmeter

Real-Time Analyzer

SK1994-3 alignment tool Lateral Guide Alignment

P35-BT (SMPTE) Buzz Track Test Loop

P35-FL Flutter Loop

Cat 69 Loop Dolby Tone, Pink Noise

Cat 566 Loop Illumination Uniformity

Cat 97 Loop Left/Right Alignment

RP-40 Loop Optical Alignment

LECTRICAL CONNECTIONS

Before wiring the projector, refer to Figure 3-3 for the wiring interface diagram. Use

stranded wire. Strip and tin the wire prior to connection. Use crimp connectors on all sound

connections. For projectors equipped with an automatic turret, refer to Section 6.6.3.

3.3.1. S

OLAR CELL WIRING

Solar cell wiring requires a shielded, four-conductor audio cable. (red – left (+), black – left

(-), green – right (+), white – right (-)). The best signal-to-noise ratio is achieved by

maintaining the same ground potential between the soundhead and the cinema processor.

Refer to the directions in the sound system instruction manual for proper connection of the

sound system.

CHRISTIE INCORPORATED

June, 1998

P35GPS Projector 3-3

P35GPS Dual Lens Turret Projector

Figure 3-3: Projector Wiring Diagram (50- and 60-Hz models)

3.3.2. A-C P

ROJECTOR WIRING

A-C wiring to the projector requires stranded, 14-gauge wire. Be sure to follow all local and

national electrical codes for A-C wiring. The terminal connection numbers in the table in

Figure 3-4 refer to terminals TB-1 in Figure 3-3.

CHRISTIE INCORPORATED

June, 1998

P35GPS Projector 3-4

Terminal TB1 Connection

1 Motor (A-C neutral)

2 Motor switch lead (A-C hot, switched externally)

3 Framing lamp and cooling fan (A-C hot)

4 Changeover coil OPEN (A-C, switched externally)

5 Changeover coil CLOSE (A-C, switched externally)

6 Framing lamp, cooling fan, and changeover (A-C neutral).

Figure 3-4: Table of A-C Terminal Connections

The voltage and frequency rating of the projector (shown on the

nameplate) must match the power line frequency and voltage being

used.

3: Projector Installation and Assembly

CHRISTIE INCORPORATED

June, 1998

P35GPS Projector 3-5

4. OPERATING THE PROJECTOR

4

4.1. G

Before operating the projector, verify that all phases of installation and assembly have been

completed.

WARNING

4.2. PRE-O

4.2.1. F

1. Back out flywheel set screw far enough to let flywheel slide onto shaft without scoring

2. Slide flywheel onto shaft until it stops.

ENERAL

• Verify that cover for belt side of projector is installed before and

during operation.

• Do not make adjustments on belt side of projector while cover is

removed or power is on.

• Do not make adjustments or perform maintenance on projector

while it is in operation.

PERATING PROCEDURES

LYWHEEL INSTALLATION

shaft or damaging threads on set screw.

3. Position set screw over flat portion of shaft and tighten set screw.

4. Spin flywheel by hand to check for smooth operation.

CHRISTIE

CHRISTIE

CHRISTIECHRISTIE

this time.

4.2.2. T

1. Secure turret hinge plate with four Allen head screws.

2. Install turret latch assembly using same holes and hardware (if it is not already installed).

3. Connect turret wiring to TB4-1 (Red) and TB4-2 (Black).

CHRISTIE INCORPORATED

June, 1998

URRET INSTALLATION

recommends that any projector accessories be installed at

P35GPS Projector 4-1

P35GPS Dual Lens Turret Projector

ENS INSTALLATION

4.2.3.

L

1. Install lens system in lens holder. If it is necessary to open lens holder wider than normal:

a) Loosen two lens locking screws.

b) Turn jack screw clockwise until lens slides into lens holder.

2. Set focus knob at mid-position.

3. Secure lens system with two locking screws.

Over-tightening can cause focus mechanism to bind.

4.3. F

ILM THREADING AND OPERATING PROCEDURE

Refer to Figure 4-1 for film threading and positioning.

1. Set Ultramittent to its rest position. There should be no sprocket movement when manual

turn-down knob (N) is turned.

2. Center framing knob (P) by aligning mark on knob with line on projector housing marked

CENTER FRAME

.

3. Swing out pad rollers (B, F, and L) on upper constant-speed sprocket assembly (A),

center constant-speed sprocket assembly (G), and lower constant-speed sprocket

assembly (M).

4. Swing out film shoe on Ultramittent assembly (E).

5. Pull out catch knob (D) and swing out trap and gate assembly (C).

6. Using slightly more film length than is required to reach film transport system, begin to

thread film into projector.

7. Align film on Ultramittent sprocket and close Ultramittent film shoe.

8. To form proper loop between Ultramittent and center constant-speed sprocket assembly:

a) Pull film loosely over pad roller while pad roller is in open position (R) and then onto

center constant-speed sprocket.

b) Mate film sprocket holes with sprocket roller pins.

c) Hold film in position and close pad roller.

The required film loop has now been formed.

9. Thread film on soundhead assembly as shown in Figure 4-1:

a) Holding two lateral guide rollers (H and K) towards each other, pull film tight and

align film on lower constant-speed sprocket assembly (M).

b) Tighten film on one sprocket hole so lateral guides barely float off sound drum.

CHRISTIE INCORPORATED

June, 1998

P35GPS Projector 4-2

4: Operating the Projector

c) Wrap film around sprocket and close pad roller (L) of lower constant-speed sprocket

assembly.

A: Upper constant-speed sprocket assembly K: Lateral guide roller

B: Upper constant-speed sprocket pad roller L: Lower constant-speed sprocket pad roller

C: Trap and gate assembly M: Lower constant-speed sprocket assembly

D: Cat ch knob N: Manual turn-down knob

E: Ultramittent assembly P: Framing knob

F: Center constant-speed sprocket pad roller Q: Airpot

G: Center constant-speed sprocket assembly R: Open center constant-speed sprocket pad roller

H: Lateral guide r oller S: Aperture linkage

J: Soundhead Assembly T: Gate bands

Figure 4-1: Threading Diagram

CHRISTIE INCORPORATED

June, 1998

P35GPS Projector 4-3

P35GPS Dual Lens Turret Projector

10. Place film at upper part of Ultramittent in film guide (R).

11. Align film on steel bands of trap and gate assembly (T).

12. Close gate (C) and lock catch knob (D) in place.

13. Form 1.5-inch loop between upper constant-speed sprocket and gate (C), as shown in

Figure 4-1.

14. Align the film on upper constant-speed sprocket (A) and close film shoe (B).

15. To verify that film is correctly aligned on all sprocket rollers, move turn-down knob (N)

clockwise.

•••• Framing lamp can be turned “on” or “off” with black rocker switch

located on top of projector.

•••• Framing lamp is functional with picture changeover in either

position.

•••• If film reel is used, be sure take-up tension is in accordance with reel

manufacturer’s instructions.

CHRISTIE INCORPORATED

June, 1998

P35GPS Projector 4-4

5. MAINTENANCE

This projector has been designed to provide years of optimum performance while requiring

only routine maintenance and cleaning. However,

periodic maintenance program of scheduled operational checks and preventive maintenance.

CHRISTIE

strongly recommends a

5

5.1. G

Use the program outlined in the schedule in Figure 5-1 to maximize projector life and

operating efficiency. Procedures for these operations are described in the referenced sections

of this manual.

5.2. V

1. Visually inspect projector for signs of excessive dust, dirt, physical damage, frayed or

damaged cables, and loose hardware.

2. Remove, replace, and repair as necessary.

3. Visually inspect inner, outer, and shutter timing belts. Replace belts that are frayed or show

signs of wear.

4. Check belt deflection (Sections 6.4.1, 6.4.2, and 6.4.3) and re-adjust if necessary.

ENERAL MAINTENANCE

Frequency Maintenance Operation Section

Daily Visual inspection 5.2

Daily Clean projector 5.3

Bi-weekly Oil lateral guides and jewels 5.3

Annually Replace belts and blow out belt dust 5.4.2

Figure 5-1: Schedule for Periodic Maintenance Operations

ISUAL INSPECTION

Ultramittent should be visually checked every 30 days. If leak is

detected, contact

Ultramittent. If leak is very slow, you may continue to operate

Ultramittent for 30 to 90 days.

CHRISTIE INCORPORATED

June, 1998

CHRISTIE

CHRISTIE

CHRISTIECHRISTIE

P35GPS Projector 5-1

to arrange for loan of substitute

P35GPS Dual Lens Turret Projector

5.3. C

LEANING

Projector should be kept clean at all times

.

1. Remove dust and foreign matter from projector and assemblies. Use soft, lint-free cloth, or

spray with compressed air at force no greater than 20 psi.

2. Using camel-hair brush or toothbrush, remove dust and foreign matter from pad rollers,

sprockets, Ultramittent shoe closure, and sound idler rollers, and from pads and shoes in trap

and gate assembly.

3. Using cotton-tip swabs, remove dirt and dust from soundhead optics.

4. Lightly oil lateral guide rollers and springs with very fine machine oil. Inner flange of lateral

guide should move easily and should spring back to rest position without sticking.

Do not adjust lateral guides without proper alignment tool (SK1994-3).

5.4. R

EMOVAL OF ASSEMBLIES

The following sections contain instructions and procedures necessary to remove assemblies

and components from the projector. Use only the specified tools to perform these

procedures. The use of any other tools will cause damage to the assemblies and components.

Appendix A contains a list of replaceable assemblies and components and their part numbers.

Removal and replacement of the assemblies discussed in Sections 5.4.1 through 5.4.13 may

be performed by the customer. The customer may also repair broken leads, solder

connections, and repair timing belts. All other repairs and replacements are to be performed

only by an authorized service representative. In general, any problem that does not appear to

be treatable by a minor procedure should be treated by removing the defective assembly and

returning it to

5.4.1. R

CHRISTIE

EMOVAL OF THE TRAP AND GATE ASSEMBLY

for repair.

Refer to item 6 in Figure 2-2 on page 2-2.

1. Open trap and gate assembly by pulling catch knob (item 56 in Figure B-2).

2. Remove two socket head cap screws (items 39 in Figure B-2) securing assembly to main

frame.

3. Remove assembly by gently pulling free from locating pins.

CHRISTIE INCORPORATED

June, 1998

P35GPS Projector 5-2

5: Maintenance

4. For projectors equipped with automatic turret, slide aperture carrier dovetail out of

plunger connector.

5.4.2. O

UTER TIMING BELT

Refer to Figure 5-2 below.

1. Loosen outer belt tension adjust assembly screw (item 6 in Figure 5-2) and slide idler

(item 3 in Figure 5-2) up to release tension on outer timing belt (item 5 in Figure 5-2).

2. Remove outer timing belt.

1: Jackshaft Pulley

2: Motor Pulley

3: Idler

4: Flanged Idler

5: Outer Timing Belt

6: SHC Screw

7: Inner and Outer Idler

Assembly

Figure 5-2: Outer Timing Belt

5.4.3. I

NNER TIMING BELT

Refer to Figure 5-3 below.

1. Remove outer timing belt (see Section 5.4.2).

2. Loosen adjustable inner idler pulley screw (item 1 in Figure 5-3).

3. Remove inner timing belt (item 10 in Figure 5-3).

8: Intermittent Pulley

9: Screw

CHRISTIE INCORPORATED

June, 1998

P35GPS Projector 5-3

P35GPS Dual Lens Turret Projector

1: Inner Belt Tensioner

2: Non-Flanged Idler

3: Upper Sprocket

Pulley

4: Center Sprocket

Pulley

5: Inner Belt Pulley

6: Non-Flanged Idler

7: Shutter Driver

Assembly

8: Screw

9: Single Blade Shutter

Assembly

10: Inner Timing Belt

11: Lower Sprocket

Pulley

12: Changeover Douser

13: Shutter driver

Standoff

Figure 5-3: Inner Timing Belt

5.4.4. S

HUTTER TIMING BELT

Refer to Figure 5-4 below.

1. Loosen three Allen head screws securing jackshaft assembly to mainframe (item 5 in

Figure 5-4).

2. Pull jackshaft assembly down approximately 0.5 inch.

3. Remove shutter timing belt (item 1 in Figure 5-4).

CHRISTIE INCORPORATED

June, 1998

P35GPS Projector 5-4

5: Maintenance

1: Shutter Timing Belt

2: 12-Groove Pulley

3: Shutter Driver

Housing

4: Single Blade Shutter

Assembly

5: Jackshaft Housing

6: 16-Groove Pulley

Figure 5-4: Shutter Timing Belt

5.4.5. U

SSEMBLIES

A

PPER

ENTER, AND LOWER CONSTANT-SPEED SPROCKET

, C

Refer to items 3 (center sprocket assembly) and 4 (upper sprocket assembly) in Figure 2-2 on

page 2-2 and item 2 (lower sprocket assembly) in Figure 2-3 on page 2-3.

1. Remove inner timing belt (see Section 5.4.3).

2. Beginning with the lower sprocket assembly, remove each constant speed sprocket

assembly:

a) Remove screw mounting turn-down knob to shaft of lower constant-speed sprocket

assembly (lower sprocket assembly only).

b) Remove turn-down knob (lower sprocket assembly only).

c) Remove three Allen head screws from operating side of mainframe.

d) Carefully slide sprocket assembly out of non-operating side of mainframe.

CHRISTIE INCORPORATED

June, 1998

P35GPS Projector 5-5

Loading...

Loading...