Christie Crimson HD25, Crimson WU25, Mirage WU25, Crimson WU31, Mirage HD25 User Manual

...Page 1

Service Guide

020-102733-02

Crimson

Crimson HD25, Crimson WU25, Crimson HD31,

Crimson WU31, Mirage HD25, Mirage WU25

Page 2

NOTICES

COPYRIGHT AND TRADEMARKS

yright © 2020 Christie Digital Systems USA Inc. All rights reserved.

Cop

All brand names and product names are trademarks, registered trademarks or trade names of their respective holders.

GENERAL

Every effort has been made to ensure accuracy, however in some cases changes in the products or availability could occur which may not be reflected in this

document. Christie reserves the right to make changes to specifications at any time without notice. Performance specifications are typical, but may vary

depending on conditions beyond Christie's control such as maintenance of the product in proper working conditions. Performance specifications are based on

information available at the time of printing. Christie makes no warranty of any kind with regard to this material, including, but not limited to, implied

warranties of fitness for a particular purpose. Christie will not be liable for errors contained herein or for incidental or consequential damages in connection

with the performance or use of this material. Manufacturing facilities in Canada and China are ISO 9001 certified. Manufacturing facilities in Canada are also

ISO 14001 certified.

WARRANTY

Products are warranted under Christie’s standard limited warranty, the complete details of which are available by contacting your Christie dealer or Christie. In

addition to the other limitations that may be specified in Christie’s standard limited warranty and, to the extent relevant or applicable to your product, the

warranty does not cover:

Problems or damage occurring during shipment, in either direction.

a.

Problems or damage caused by combination of a product with non-Christie equipment, such as distribution systems, cameras, DVD players, etc., or use

b.

of a product with any non-Christie interface device.

Problems or damage caused by misuse, improper power source, accident, fire, flood, lightning, earthquake, or other natural disaster.

c.

Problems or damage caused by improper installation/alignment, or by equipment modification, if by other than Christie service personnel or a Christie

d.

authorized repair service provider.

Use of third party product enclosures for environmental protection during outside use must be approved by Christie.

e.

Problems or damage caused by use of a product on a motion platform or other movable device where such product has not been designed, modified or

f.

approved by Christie for such use.

Except where the product is designed for outdoor use, problems or damage caused by use of the product outdoors unless such product is protected from

g.

precipitation or other adverse weather or environmental conditions and the ambient temperature is within the recommended ambient temperature set

forth in the specifications for such product.

Defects caused by normal wear and tear or otherwise due to normal aging of a product.

h.

The warranty does not apply to any product where the serial number has been removed or obliterated. The warranty also does not apply to any product sold

by a reseller to an end user outside of the country where the reseller is located unless (i) Christie has an office in the country where the end user is located or

(ii) the required international warranty fee has been paid.

The warranty does not obligate Christie to provide any on site warranty service at the product site location.

PREVENTATIVE MAINTENANCE

Preventative maintenance is an important part of the continued and proper operation of your product. Failure to perform maintenance as required, and in

accordance with the maintenance schedule specified by Christie, will void the warranty.

REGULATORY

The product has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference when the product is operated in a commercial environment. The product generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of the product in a residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at the user’s own expense. Changes or modifications not expressly approved by the party responsible for compliance could void the user's

authority to operate the equipment

CAN ICES-3 (A) / NMB-3 (A)

이 기기는 업무용(A급)으로 전자파적합등록을 한 기기이오니 판매자 또는 사용자는 이점을 주의하시기 바라며, 가정 외의 지역에서 사용하는 것을 목적으로 합니다.

ENVIRONMENTAL

The product is designed and manufactured with high-quality materials and components that can be recycled and reused. This symbol

and electronic equipment, at their end-of

to local regulations. In the European Union, there are separate collection systems for used electrical and electronic products. Please help us to conserve the

environment we live in!

-life, should be disposed of separately from regular waste. Please dispose of the product appropriately and according

means that electrical

Page 3

Content

Introduction...................................................... 6

Model name.......................................................6

Site requirements...................................................6

Ph

ysical operating environment........................................ 6

Power connection................................................. 7

Projector components.................................................7

IR remote keypad...................................................8

Product documentation...............................................10

Related documentation.............................................11

Service guidelines.................................................12

Ordering parts.................................................... 12

Replacing modules..................................................12

Interconnections and line drawings....................................... 12

Servicing live equipment..............................................12

Safety and warning guidelines.......................................... 13

Light intensity hazard distance..........................................14

Product labels.....................................................16

General hazards................................................. 16

Mandatory action.................................................17

Electrical labels..................................................17

Laser labels....................................................17

Service setups................................................... 18

Turning on the projector..............................................18

Turning off the projector..............................................18

Adjusting offset....................................................18

Aligning the boresight................................................19

Optimizing the Integrator Focus and Zoom...................................22

Adjusting the fold mirror..............................................23

Adjusting DMD convergence............................................24

Replacing or refilling the coolant.........................................25

Maintenance and cleaning.......................................... 27

Guidelines for cleaning...............................................27

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 3

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 4

Content

Ventilation.......................................................28

Cleaning the projector optics........................................... 28

Cleaning the lens...................................................28

R

emoving dust from the projection lens...................................28

Removing fingerprints, smudge, or oil from the projection lens....................29

Parts and module replacement.......................................30

Maintenance prerequisites .............................................30

Tools required for service..............................................30

Index of parts and modules............................................31

Lens mount components........................................... 35

Lens efficiency ratings............................................... 35

Installing a projection lens.............................................35

Calibrating the lens motor.............................................37

Removing the lens..................................................37

Replacing the lens mount..............................................38

Filtration........................................................40

Replacing the air filter................................................40

Projector covers..................................................41

Removing the front cover............................................. 41

Removing the top cover.............................................. 42

Removing the rear cover..............................................42

Removing the electronics-side cover.......................................43

Removing the air intake-side cover....................................... 43

Removing the bottom cover............................................44

Removing a projector's foot............................................45

Ventilation and cooling.............................................46

Replacing the light engine intake fans (#1, 2, 3, 4)............................. 46

Replacing the laser radiator exhaust fans (#5, 6, 7, 8, 9, 10).......................49

Replacing light engine exhaust fan (#11)....................................50

Replacing the light engine exhaust fan (#12).................................51

Replacing the user interface intake fan (#16).................................52

Replacing the rear exhaust fans (#17, 18, 19) for Crimson/Mirage 25..................53

Replacing the rear exhaust fans (#13, 14, 17, 18, 19) for Crimson HD31/WU31........... 54

Replacing the light engine exhaust fan (#24).................................55

Replacing the card cage exhaust fan (#25).................................. 56

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 4

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 5

Content

Replacing the card cage intake fan (#26)....................................57

R

eplacing the light engine radiator........................................58

Removing the light engine liquid cooling module...............................61

Replacing the laser liquid cooling module....................................63

Replacing the laser liquid cooling module radiator.............................. 65

Electronics......................................................66

Removing the card cage.............................................. 66

Replacing the option cards.............................................67

Removing the user interface module.......................................67

Replacing the 500W power supply........................................68

Replacing the 3kW power supply.........................................70

Replacing the line filter...............................................71

Replacing the AC inlet detect module (ACIDM)................................ 71

Replacing the light module.............................................73

Optics..........................................................77

Replacing the integrator rod............................................77

Replacing the light engine cover......................................... 79

Removing the light dump..............................................80

Replacing the light engine.............................................81

Replacing the fold mirror..............................................83

Replacing the integrator zoom adjustment knob............................... 84

Replacing the shutter................................................86

Printed circuit boards and sensors....................................87

Replacing the IMXB board.............................................87

Replacing the card cage convenience light boards (CLB).......................... 87

Replacing the light driver board..........................................88

Replacing the housekeeping board (HKBC)...................................89

Replacing the image processing board (WIP)................................. 89

Replacing the backplane board (C4LBP).....................................90

Replacing the fan control board (CFCB).....................................91

Replacing the dual temperature sensor module (DTSM)...........................91

Replacing the front IR sensor board (front IRB)................................92

Replacing the rear IR sensor board (rear IRB).................................93

Replacing the status LED board (SLB)......................................94

Replacing the color sensor board (CSB).....................................95

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 5

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 6

Introduction

This manual is intended for professionally tr

systems.

The illustrations in this document are for representation only and may not depict your projector model

exactly

.

Only Christie qualified technicians who are knowledgeable about the hazards associated with highv

oltage, ultraviolet exposure, and the high temperatures generated by the projector are authorized to

assemble, install, and service the projector.

For complete Crimson product documentation and technical support, go to www.christiedigital.com.

ained operators of Christie high-brightness projection

Model name

• Crimson HD25

• Crimson WU25

• Crimson HD31

• Crimson WU31

• Mirage HD25

• Mirage WU25

Site requirements

To safely install and operate the projector, the installation location must have restricted access for

authorized personnel only and meet these minimum requirements.

Physical operating environment

Provides specifications for the operating environment.

• Crimson and Mirage HD25/WU25: Ambient temperature (operating) 5 to 40°C (41 to 104°F)

up to 457.2 m (1500 ft)

• Crimson HD31/WU31: Ambient temperature (operating) 5 to 40°C (41 to 104°F) up to 304.8

m (1000 ft)

• Humidity (non-condensing) 10 to 80%

• Operating altitude: 3,000 m (10,000 ft) maximum at 5 to 25°C (41 to 77°F) ambient

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 6

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 7

Power connection

Introduction

The projector uses an inno

vative dual AC inlet power system that offers two power modes.

To operate at full brightness, power the projector using AC Input 1 if the appropriate high power

source is available. To operate in limited power mode, power the projector using standard lower power

sources using AC Input 2. A different power cord is provided for each power source. A 20 A rated wall

breaker is required at the installation when using Input 1. A 15 A rated wall breaker is required at the

installation when using Input 2.

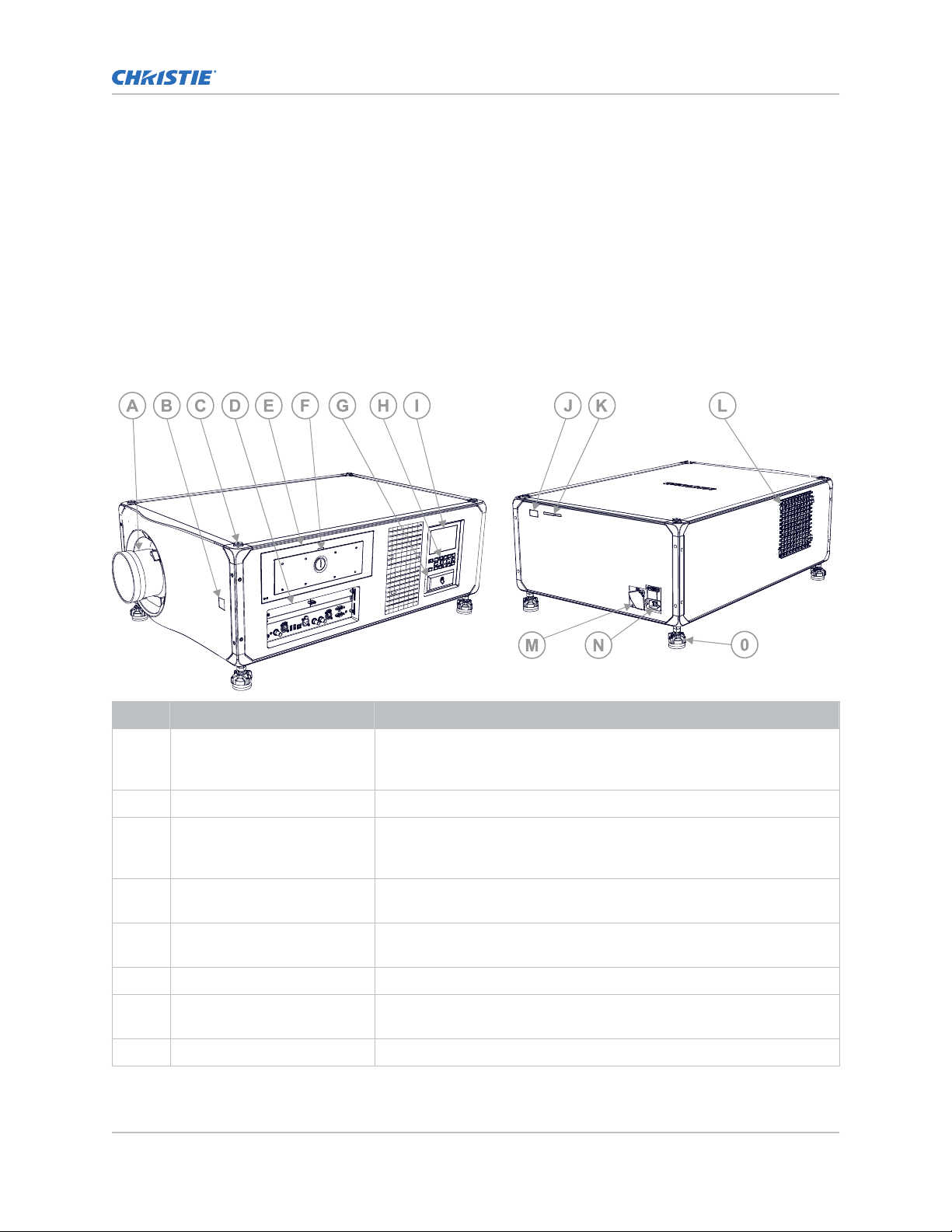

Projector components

Identify the main components of the projector.

ID Component Description

A Projection lens A variety of lenses can be used with the projector. Available lenses are

listed in the Crimson and Mirage Specifications Guide (P/N:

020-102724-XX).

B Front IR Receives transmissions from the IR remote.

C Mounting and rigging holes. M12 x 1.75 holes for projector feet installation and offer mounting and

rigging points. F

bottom.

D Communication and input

panel

E Service compartment Access to fold mirror, optical zoom/focus, and DMD convergence

F Tool box Provides tools for Christie qualified technicians.

G Christie TAP Enables Android devices to communicate with the projector using near

H Keypad interface Controls the projector.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 7

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Connects media sources to either the ports on the option cards or the

IMXB.

adjustments.

field communication.

our holes located on the top, and four located on the

Page 8

ID Component Description

I Display panel Displays the projector menus and status.

J Rear IR Receives transmissions from the IR remote.

Introduction

K LED and shutter LED status

indicator

L Air Filter door Provides access to the air filter.

M AC Input 2: limited power For use in limited power mode.

N AC Input 1: full power For use in full power mode.

O Adjustable feet Raise or lower these feet when positioning the projector to make sure it

Indicates power status and shutter status.

is lev

el on all sides so the displayed image appears rectangular without

any keystone.

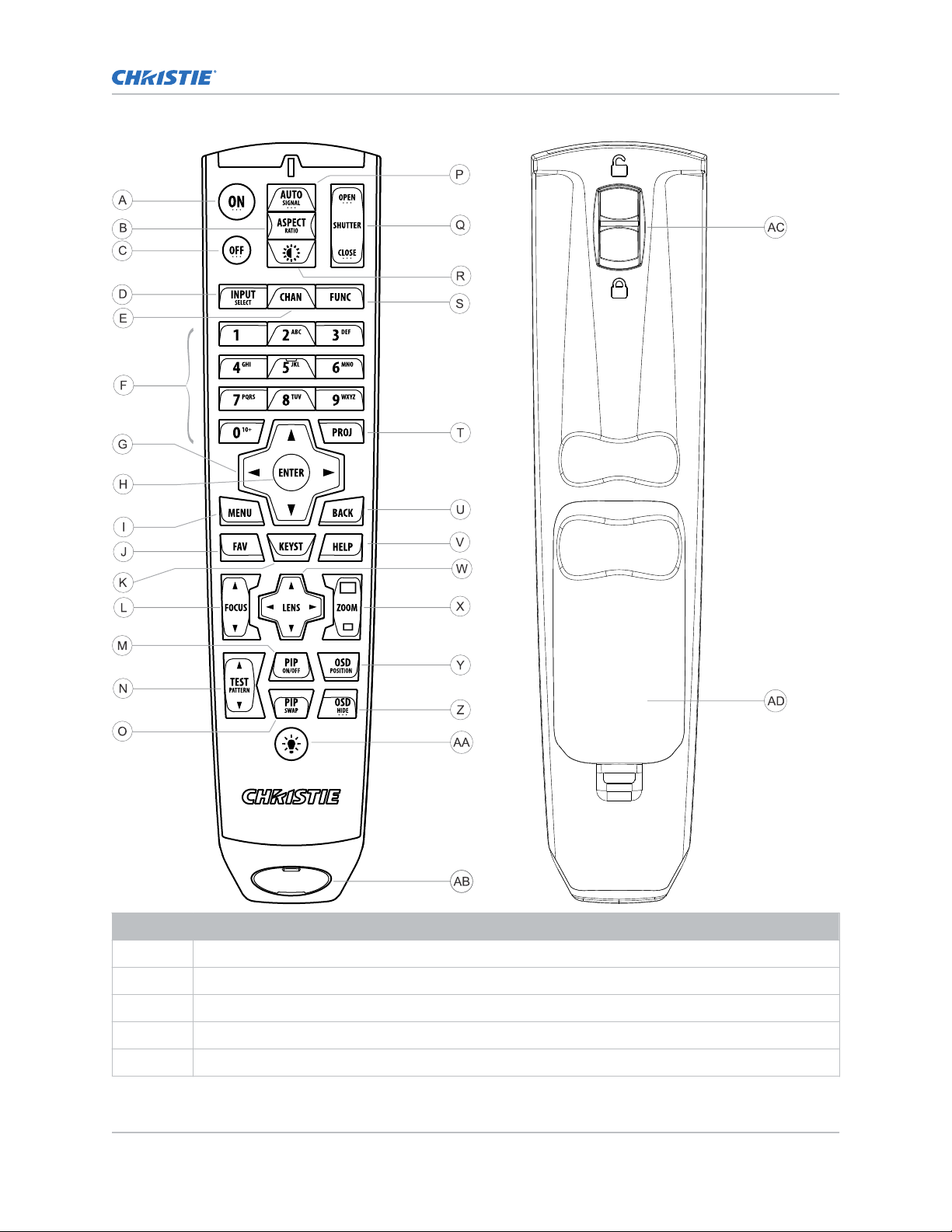

IR remote keypad

The IR remote k

powered infrared (IR) transmitter.

To use the IR remote, direct the keypad toward the projector’s front or rear IR sensor and press a

function key. One of the two IR sensors on the projector detect the signal and relay the commands for

internal processing. The remote also offers a connector for wired connections to the projector.

Only use the wired connection to the projectors for setup and service.

eypad controls the projector by way of wireless communications from a battery-

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 8

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 9

Introduction

Button Description

A Powers on the projector light source.

B Opens the aspect ratio dialog.

C Turns off the light source and puts the projector in standby.

D Selects an active or inactive input on any slot.

E Not supported.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 9

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 10

Button Description

F Enter a number, such as menu, item index or value.

G Use the arrows to navigate within a menu or to adjust settings.

H Selects a highlighted menu item and changes or accepts a value.

I Toggles the menus on/off.

J Not supported.

K Opens the keystone dialog.

L Adjusts the lens focus.

M Not supported.

N Displays a test pattern.

O Not supported.

P Optimizes the image automatically.

Q Opens or closes the shutter.

R Not supported.

S Initiates a custom action when a number is selected.

Introduction

T Selects a projector in multi-projector installations.

U Returns to the previous menu level or exits menus if at the top level.

V Displays context-sensitive help.

W Arrows adjust the lens offset.

X Adjust the lens zoom.

Y Opens the on-screen display position menu.

Z Shows or hides the on-screen display menus.

AA Turns the remote backlight on.

AB Male 3-pin XLR connector for wired option.

AC Lock/unlock the keypad.

AD Battery door.

Product documentation

or installation, setup, and user information, see the product documentation available on the Christie

F

Digital Systems USA Inc. website. Read all instructions before using or servicing this product.

Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31

1. Access the documentation from the Christie website:

• Go to this URL:bit.ly/2nOplCa.

• Scan the QR code using a QR code reader app on a smartphone or tablet.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 10

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 11

Introduction

2. On the product page, select the model and switch to the Downloads tab

Mirage HD25, Mirage WU25

1. Access the documentation from the Christie website:

• Go to this URL:bit.ly/2C6H4HZ.

• Scan the QR code using a QR code reader app on a smartphone or tablet.

2. On the product page, select the model and switch to the Downloads tab

Related documentation

Additional information on the projector is available in the following documents.

• Crimson and Mirage Installation and Setup Guide (P/N: 020-102647-XX)

• Crimson and Mirage User Guide (P/N: 020-102649-XX)

• Crimson and Mirage Product Safety Guide (P/N: 020-102648-XX)

• Crimson and Mirage Specifications Guide (P/N: 020-102724-XX)

• Crimson and Mirage Serial Commands Guide (P/N: 020-102660-XX)

• Crimson and Mirage Status System Guide (P/N: 020-102661-XX)

.

.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 11

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 12

Service guidelines

R

eview safety guidelines and information required for replacing modules.

Ordering parts

When ordering replacement parts, quote the part numbers of the items required. Quote the projector

model number, serial number, and date of manufacture, as indicated on the license label.

Not all parts are available separately. In addition, some parts stocked as inventory are available only

until the current supply lasts.

All part numbers are subject to change.

Replacing modules

T

o ensure you have the correct module and the projector module is replaced correctly, check module

markings, parts lists, and the relevant disassembly and replacement procedures.

Components must be replaced with exact equivalents or Christie approved replacement parts. Failure

to do so may result in unsafe operation.

Interconnections and line drawings

The interconnect diagram illustrates the path of electrical connections between modules.

Manufacturer’s part numbers are included. Part numbers are subject to change.

Line drawings provide projector dimensions and sizes for installation.

To download the latest interconnect diagram or line drawings, visit www.christiedigital.com.

Servicing live equipment

Only Christie accredited technicians who are knowledgeable about the hazards associated with

hazardous voltage, ultraviolet exposure, and high temperatures are authorized to assemble, install,

and service Christie equipment.

To make sure you remain safe when servicing energized (live) Christie equipment:

• Locate the main AC power shut off prior to servicing the equipment. This will allow you to turn

the power off quickly in an emergency.

• Disconnect the projector from the communication and management network so it cannot

receive commands to turn the light source on, open the shutter, and move the lens.

• Familiarize yourself with all potential safety hazards prior to servicing the equipment. This

includes, but is not limited to, the location and accessibility of hazardous voltages.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 12

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 13

Service guidelines

• Read and understand all written procedures prior to commencing a service procedure.

•

Understand and follow all local safety codes and requirements when servicing energized (live)

equipment.

• Perform equipment service in a location free of obstructions and other hazards. For example,

you must have an unobstructed view of the area being serviced.

Wear personal protective equipment (PPE) clothing appropriate to the service you are performing. This

includes, but is not limited to, protective (electrically insulated) footwear, safety glasses, and gloves

rated for the working voltage of the equipment you are servicing.

Safety and warning guidelines

Read all safety and warning guidelines before installing or operating the projector.

This projector is intended for use in a non-cinema environment.

This projector must be operated in an environment that meets the operating range specification. Use

only the attachments and/or accessories recommended by Christie. Use of others may result in the

risk of fire, shock, or personal injury.

Warning! If not a

• This product must be operated in an environment that meets the operating range as specified in

this document.

• FIRE HAZARD! Keep hands, clothes, and all combustible material away from the concentrated

light beam of the projector.

• Keep fingers and other body parts away from the moving parts in the product. Tie back long

hair, and remove jewelry and loose clothing before manually adjusting the product.

• FIRE AND SHOCK HAZARD! Use only the attachments, accessories, tools, and replacement parts

specified by Christie.

• Do not operate the product without a lens installed.

• Always use a lens plug when installing or moving the product. This prevents contaminants from

entering the product.

• UV EXPOSURE! Protective UV safety glasses with side shields and Christie approved protective

safety clothing must be worn when performing optical adjustments or servicing the product.

• FIRE AND SHOCK HAZARD! Use only the attachments, accessories, tools, and replacement parts

specified by Christie.

Caution! If not a

• SHOCK HAZARD! Disconnect the product from AC before installing, moving, servicing, cleaning,

removing components, or opening any enclosure.

• Christie products must be installed and serviced by Christie qualified technicians.

• TRIP OR FIRE HAZARD! Position all cables where they cannot contact hot surfaces, be pulled, be

tripped over, or damaged by persons walking on or objects rolling over the cables.

Notice. If not a

• SHOCK HAZARD! All harnessing must be properly routed and secured as originally installed,

especially in high voltage areas.

• FIRE HAZARD! Do not use a power cord, harness, or cable that appears damaged.

voided, the following could result in death or serious injury.

voided, the following could result in minor or moderate injury.

voided, the following could result in property damage.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 13

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 14

Service guidelines

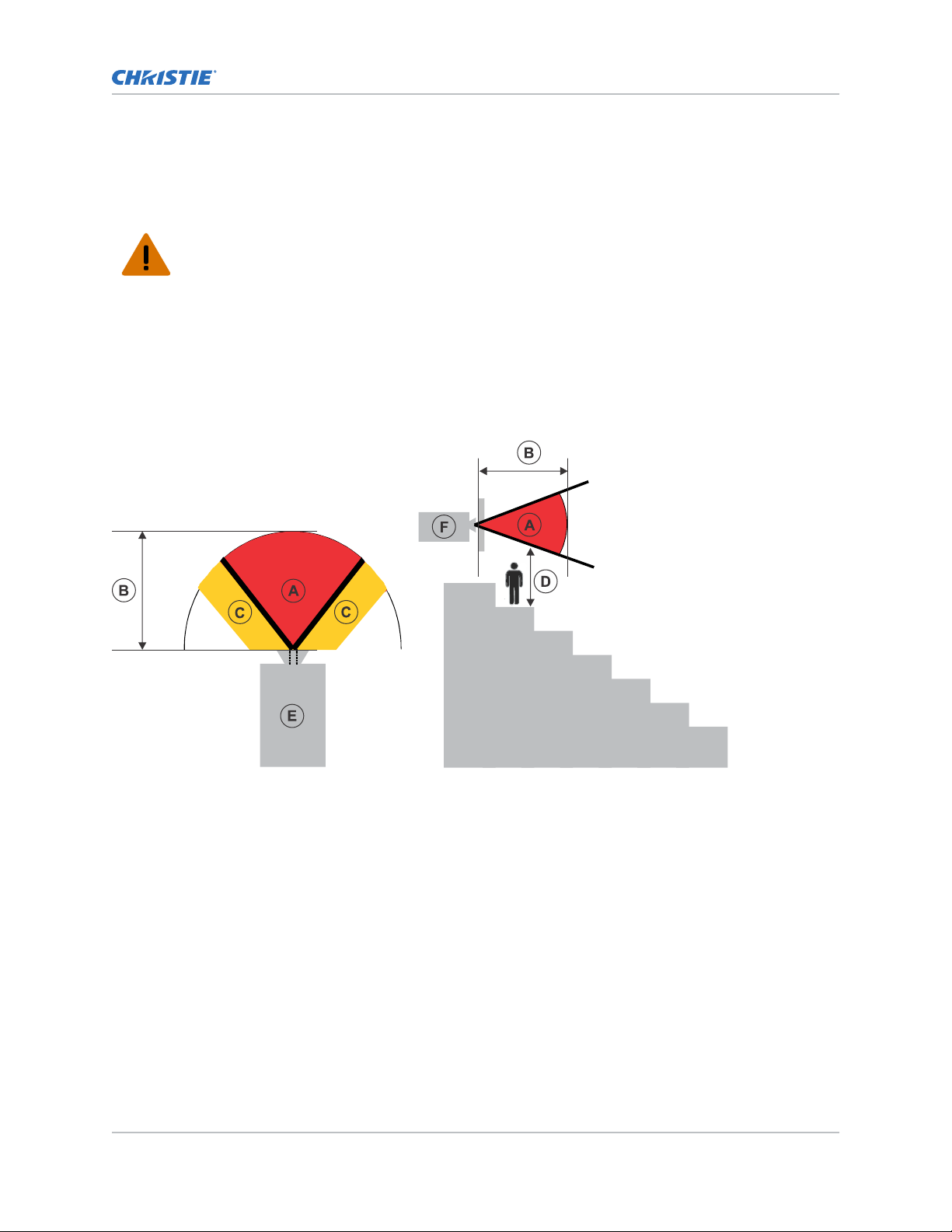

Light intensity hazard distance

This projector has been classified as Risk Group 3 as per the IEC 62471-5:2015 standard due to

possible hazardous optical and thermal r

Warning! If not a

• PERMANENT/TEMPORARY BLINDNESS HAZARD! No direct exposure to the beam must be

permitted. Class 1 Laser Product - Risk Group 3 according to IEC 60825-1:2014 and IEC

62471-5:2015.

• PERMANENT/TEMPORARY BLINDNESS HAZARD! Operators must control access to the beam

within the hazard distance or install the product at the height that prevents exposure of

spectators' eyes within the hazard distance. The hazard zone must be no lower than 3.0 meters

above the floor and the horizontal clearance to the hazard zone must be a minimum 2.5 meters.

• EXTREME BRIGHTNESS! Do not place reflective objects in the product light path.

voided, the following could result in serious injury.

The following diagram and table show the zones for ocular and skin hazard distances:

adiation being emitted.

• A—Hazard zone. The region of space where the projection light from the laser-illuminated

projector is abo

ve emission limits for Risk Group 2. The light intensity may cause eye damage

after a momentary or brief exposure (before a person can avert his or her eyes away from the

light source). The light may cause skin burns to occur.

• B—Hazard distance. Operators must control access to the beam within the hazard distance or

install the product preventing potential exposure of the spectators' eyes from being in the

hazard distance.

• C—No access zone. Horizontal clearance of the no access zone must be a minimum of 2.5

meters.

• D—Vertical distance to hazard zone. The hazard zone must be no lower than 3.0 meters above

the floor.

• E—Represents the top view of the projector.

• F—Represents the side view of the projector.

For US and international hazard distances based upon IEC 62471-5:2015, Photobiological Safety of

Lamps and Lamp Systems – Part 5: Image Projectors.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 14

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 15

Service guidelines

Projection lens Part number Hazard distance (m)

Crimson/Mirage 25K Crimson 31K

0.37:1 HD ILS 118-131106-XX 1.0 1.0

0.67:1 HD ILS 118-100110-XX 1.0 1.0

0.8-1.16:1 HD ILS 118-130105-XX 1.0 1.2

1.1:1 HD ILS 118-100117-XX 1.0 1.2

1.16-1.49:1 HD ILS 118-100111-XX 1.0 1.6

1.4-1.8:1 HD ILS 118-100112-XX 1.1 1.9

1.8-2.6:1 HD ILS 118-100113-XX 1.8 2.7

2.6-4.1:1 HD ILS 118-100114-XX 2.3 4.5

4.1-6.9:1 HD ILS 118-100115-XX 6.3 7.6

6.9-10.4:1 HD ILS 118-100116-XX 12.6 11.2

For Installations in the United States

The following must be in place for laser

• Any human access to the hazard zone, if applicable, must be restricted by barriers to enforce

the no access zone.

• Permanent show installations containing Risk Group 3 laser-illuminated projectors must meet

the following conditions:

• Installed by Christie or by Christie-authorized and trained installers.

Refer to the Laser Illuminated Projector - Class 1 Risk Group 3 Installation training (Course

code: CF-LIPI-01) on the http://www.christieuniversity.com site.

• Performed according to instructions provided by Christie.

• Ensure the projection system is securely mounted or immobilized to prevent unintended

movement or misalignment of the projections.

• A copy of the FDA variance approval letter must be with the operator or other responsible

individual.

FDA variances can be found in the online training course–Laser Illuminated Projection - Class 1

Risk Group 3 Installation.

• Temporary show installations containing Risk Group 3 laser-illuminated projectors may be

installed by Christie or sold or leased only to valid laser light show variance holders (laser light

show manufacturers) for image projection applications. Such manufacturers may currently

hold a valid variance for production of Class IIIb and IV laser light shows and/or for

incorporation of the Risk Group 3 laser-illuminated projectors into their shows. This

requirement applies also to dealers and distributors of these laser-illuminated projectors.

• For temporary installations, the FDA variance holder must maintain complete records of all

show itineraries with dates, locations, operator name, and contact information clearly and

completely identified.

• The Christie Laser Projection System Installation Checklist must be fully completed after the

installation and sent to lasercompliance@christiedigital.com. A copy can remain on-site. This

checklist can be found as a separate document in the accessory box with the manual.

-illuminated projector installations in the United States:

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 15

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 16

Service guidelines

• Certain US states have additional laser regulatory requirements. Go to www.christiedigital.com

for additional regulatory requirements.

Product labels

Learn about the labels that ma

y be used on the product. Labels on your product may be yellow or

black and white.

General hazards

Hazard warnings also apply to accessories once they are installed in a Christie product that is

connected to power.

Fire and Shock Hazard

To prevent fire or shock hazards, do not expose this product to rain or moisture.

Electrical Hazard

Do not alter the power plug, o

Do not remove the product enclosure.

Only Christie qualified technicians are authorized to service the product.

Risk of electric shock.

Do not remo

Only Christie qualified technicians are authorized to service the product.

General hazard.

ve the product enclosure.

verload the power outlet, or use it with extension cords.

Electric shock hazard. To avoid personal injury, disconnect all power sources before

performing maintenance or service.

Electrocution hazard. To avoid personal injury, always disconnect all power sources before

performing maintenance or service procedures.

Hot surface hazard. To avoid personal injury, allow the product to cool for the recommended

cool down time before performing maintenance or service.

Burn hazard. To avoid personal injury, allow the product to cool for the recommended cool

down time before performing maintenance or service.

Moving parts hazard. To avoid personal injury, keep hands clear and loose clothing tied back.

Fan hazard. To avoid personal injury, keep hands clear and loose clothing tied back. Always

disconnect all power sources before performing maintenance or service procedures.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 16

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 17

Voltage hazard. To avoid personal injury, always disconnect all power sources before

performing maintenance or service procedures.

Cut hazard. To avoid personal injury, keep hands clear or wear protective gloves.

Not for household use.

Mandatory action

Consult the service manual.

Disconnect all power sources before performing maintenance or service procedures.

Service guidelines

Electrical labels

Indicates the presence of a protective earth ground.

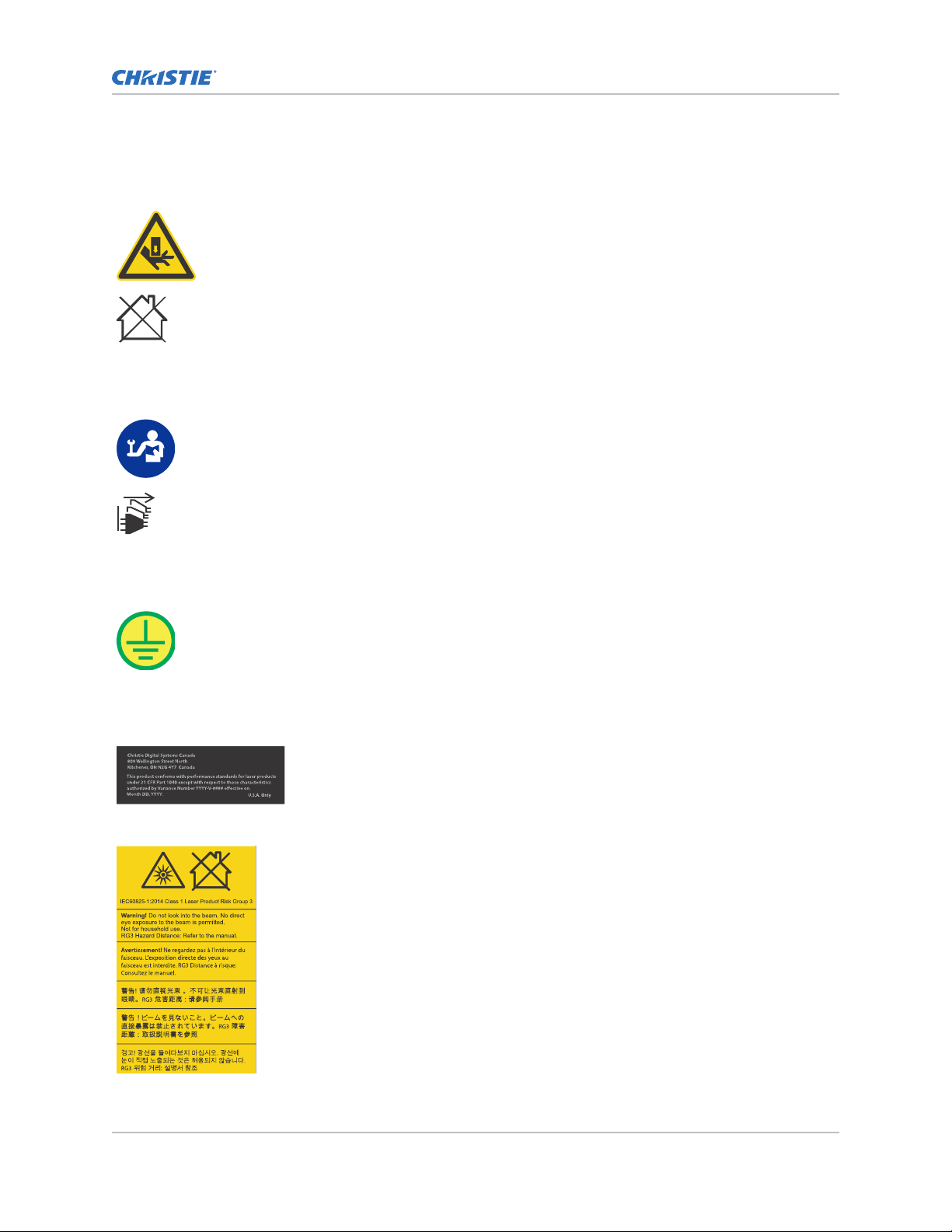

Laser labels

FDA laser variance (US projectors only)

This product conforms with performance standards for laser

products under 21 CFR Part 1040 except with respect to those

characteristics authorized by Variance Number 2016-V-1838

effective on June 20, 2017.

Indicates a light hazard. Do not look directly into the lens. The

extreme high brightness can cause permanent eye damage. Class 1

Laser Product - Risk Group 3 according to IEC 60825-1: 2014 and

IEC 62471-5:2015

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 17

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 18

Service setups

Understand the special internal hardw

require the attention of a qualified service technician, whether done periodically or after a specific

module replacement.

are and software adjustments and related details that may

Turning on the projector

When the projector AC power supply is plugged in, the power is on.

Warning! If not a

• SHOCK HAZARD! Do not attempt operation if the AC supply is not within the specified voltage

and current, as specified on the license label.

1. Plug the projector in to AC power.

The projector automatically powers on to standb

functionality becomes available.

2. To turn the light source on using the projector keypad, press and hold the power

until y

ou hear a beep.

To turn on the light source using the remote, press and hold the ON button until you hear a

beep.

voided, the following could result in death or serious injury.

y mode when plugged in. The display panel

button

Turning off the projector

When powering off in preparation for inspection or maintenance, always disconnect from AC.

1. To turn the light source off using the projector keypad, press and hold the

hear a beep

To turn off the light source using the remote, press and hold the OFF button until you hear a

beep.

When powering off the projector, allow the projector to complete its cool down cycle. Do not

immediately unplug the projector if this can be avoided.

2. To turn off power to the projector, disconnect from AC power.

.

button until you

Adjusting offset

Adjust the offset to align the image on the screen. Always adjust offset before adjusting boresight.

For the best optical performance and minimal keystone, use offsets instead of aiming at the center of

the image, in off

pattern indicate extreme offset that should be avoided using mechanical alignment.

1. Project an image with the primary lens.

2.

Select a framing test pattern.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 18

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

-axis installations. Avoid extreme tilts or offsets. Corner vignettes on a white test

Page 19

Service setups

3. Select LENS OFFSET.

4.

Use the arrows to adjust the offset to display a square image on the screen, with minimal

projector aiming error.

5. To exit to the home page, select Back.

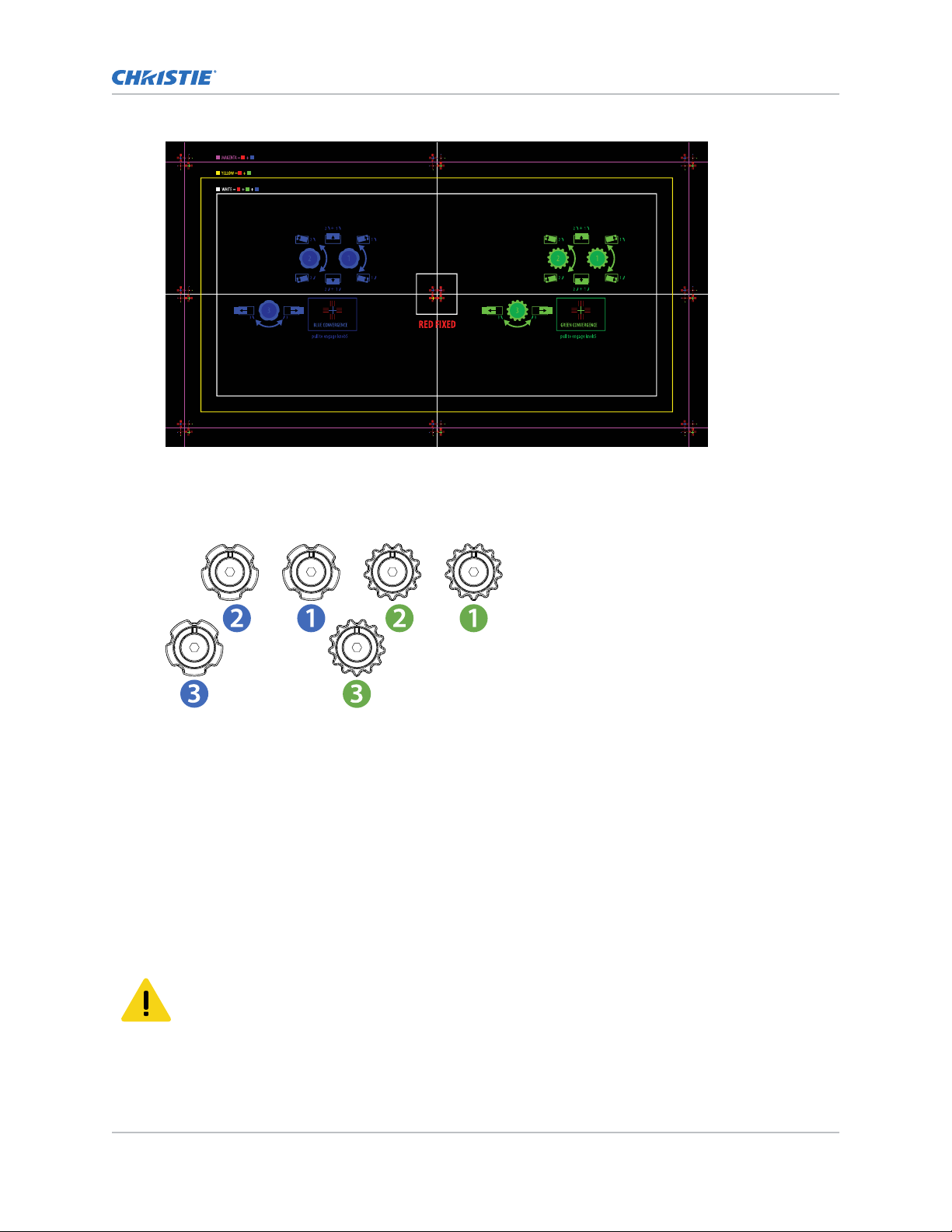

Aligning the boresight

The boresight adjustment balances the tilt of the lens mount to compensate for screen-to-projector

tilt.

1. Display the boresight test pattern.

a) On the remote keypad, press Test.

On the built-in keypad, press the soft key that displays Test on the display panel

b) To cycle to Boresight, press the Up Arrow key.

c) Press Enter.

2. Focus the image on cross-hair image I.

Evaluate the focus on cross-hair image II and III.

3.

• If all three images are in focus, no further action is required.

• If boresight is required, continue to step 4.

The adjustment screws (A) on the lens mount affects the corresponding cross-hairs on the test

pattern.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 19

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 20

Service setups

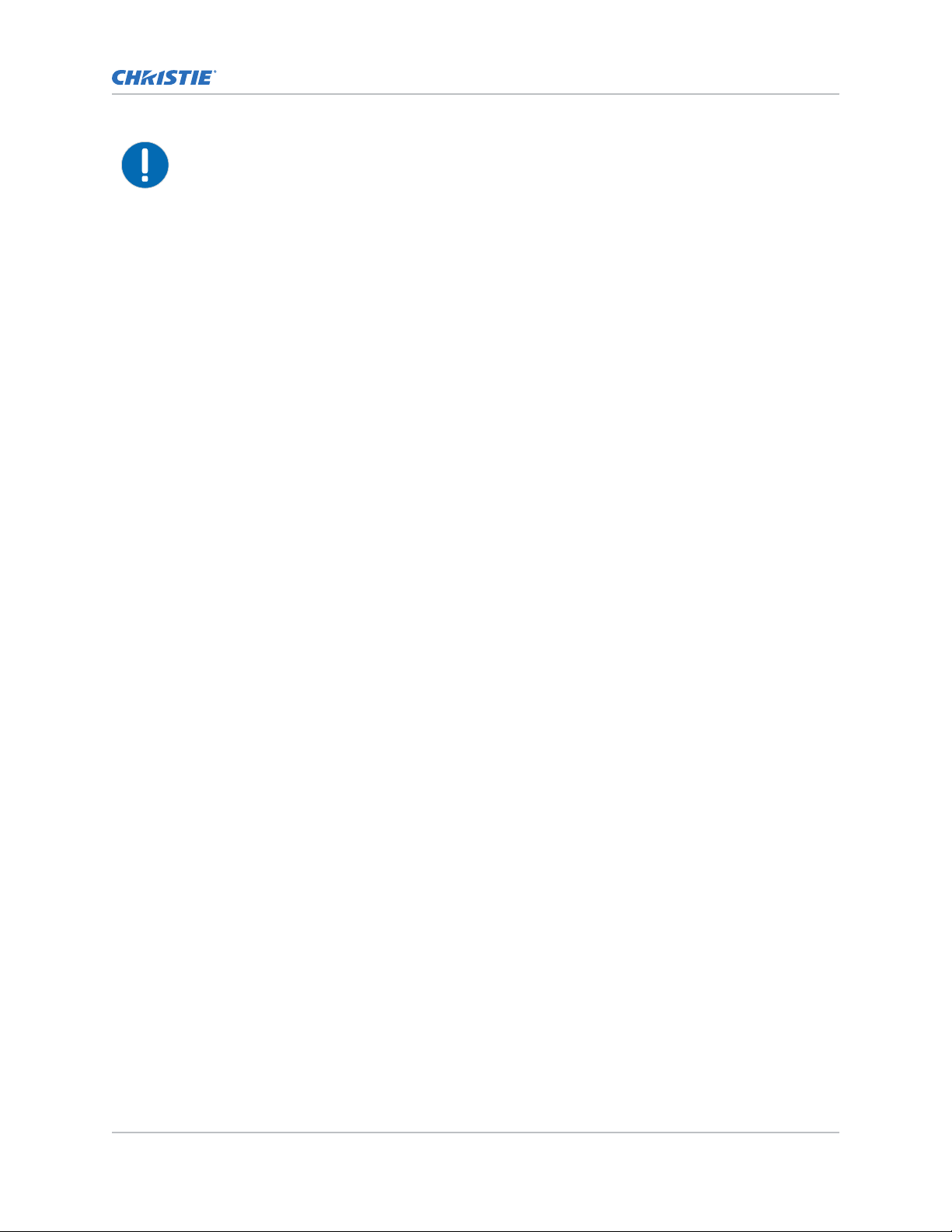

4. To loosen the three setscrews (B) on the lens mount, use a 5 mm hex driver.

The setscrews must be back

ed out several turns to avoid contact with the inner lens mount

plate.

5. To fine tune the focus of cross-hair pattern I, adjust the appropriate adjustment screw (A)

until the cross-hair image is in focus with minimal flare.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 20

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 21

Service setups

6. To fine tune cross-hair pattern II, adjust the appropriate adjustment screw until the cross-hair

image is in focus with minimal flare.

7. To fine tune cross-hair pattern III, adjust the appropriate adjustment screw until the crosshair image is in focus with minimal flare.

8. Repeat step 5 to 7 as required until all three cross-hair patterns are in equal sharp focus.

• If the boresight is acceptable, proceed with step 11.

• If the boresight does not appear to be converging to an acceptable level of image quality,

or if the lens does not focus over the correct range of throw distances, proceed with step

9.

9. To approximately recover the original factory boresight, position the three setscrews flush with

the front face of the lens mount plate and in contact with the inner lens mount plate.

This may require adjusting both setscrews and adjustment screws.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 21

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 22

Service setups

10. If further action is required, repeat steps 2 to 9.

11.

Lock the setscrews, and re-check the boresight quality.

Tighten the setscrews to 2.1 Nm (18 in-lb) to ensure they do not shift.

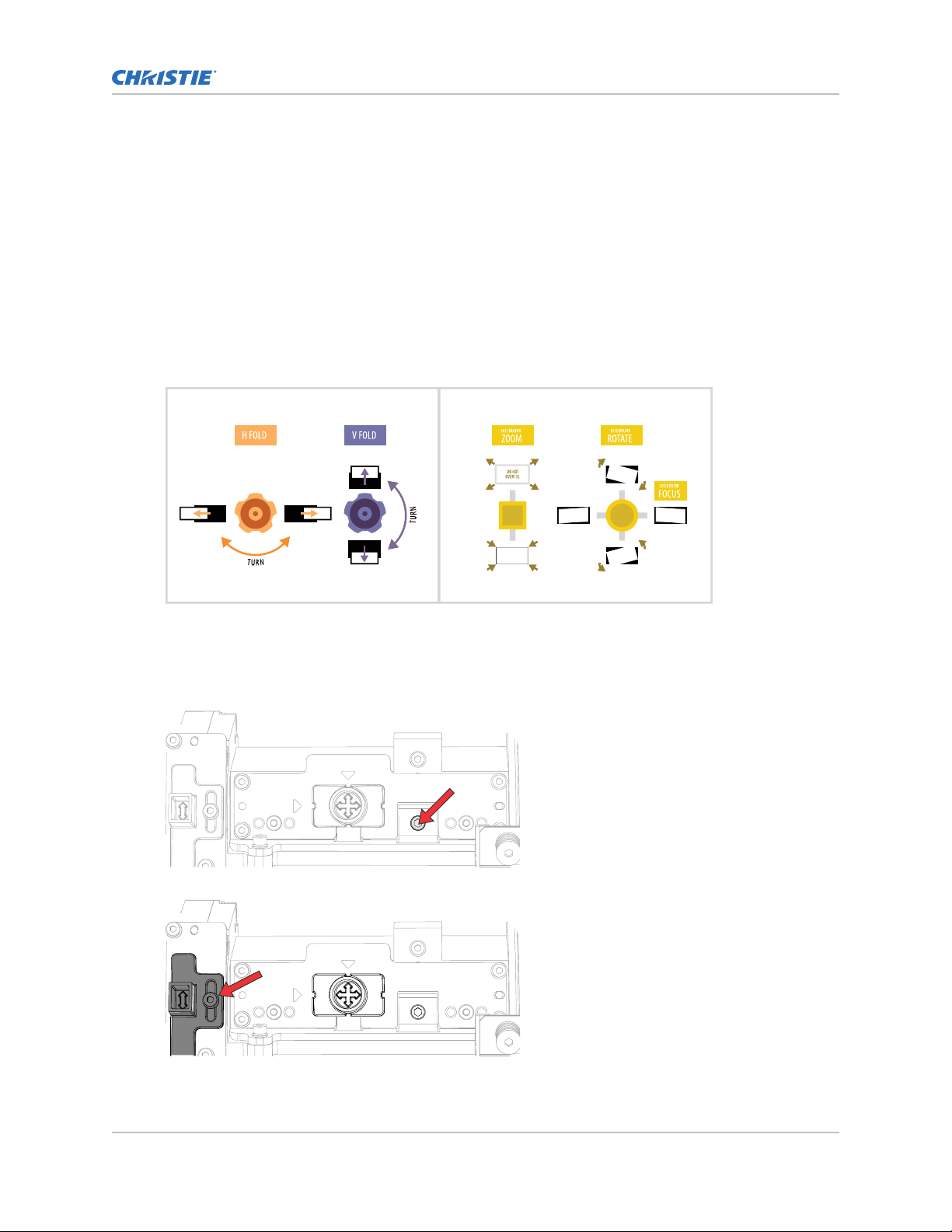

Optimizing the Integrator Focus and Zoom

Extreme misalignment of projection optics can cause permanent damage to critical optical

components. Only Christie qualified technicians can perform internal optical adjustments.

1. From the Test Pattern menu, select the Integrator Rod test pattern.

The Integrator Rod test pattern includes guided information for integrator zoom and focus

adjustments.

2. Set the projector brightness level to approximately 50% to 60%.

3.

Retrieve the 3 mm hex driver located inside the toolbox.

4. To open the Service door on the side of the projector, loosen the two captive screws.

5. Loosen the Rotate and Focus lockscrew located next to the adjustment slider.

6. Loosen the integrator magnification Zoom lockscrew located next to the adjustment slider.

7. Move both adjustments to the nominal position before optimizing.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 22

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 23

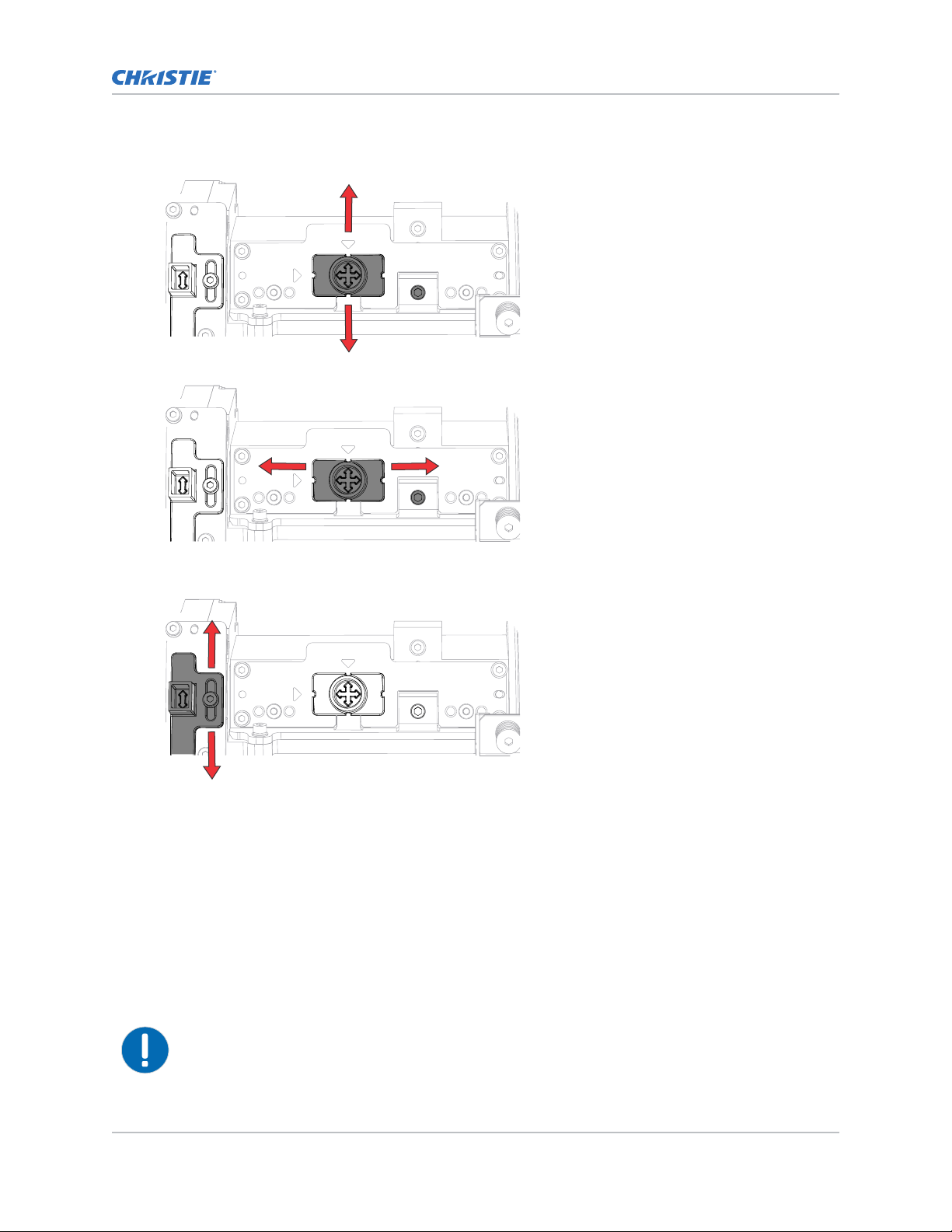

Service setups

8. To focus the integrator rod, adjust the slider vertically to rotate the image temporarily

exposing the top and bottom edges.

9. Adjust the slider horizontally to sharpen the top and bottom edges.

10. To rotate the focused image back to fill the shadows, adjust the slider vertically.

11.

To optimize the DMD brightness, adjust the integrator magnification lens using the Zoom slider.

12. Adjust the Zoom slider vertically until shadows are not visible on the projected image.

Check the image quality.

13.

If shadows still appear in the projected image after adjusting the integrator zoom, repeat steps

6 to 11.

14. Tighten the Zoom lockscrew.

15. Tighten the Rotate and Focus lockscrew.

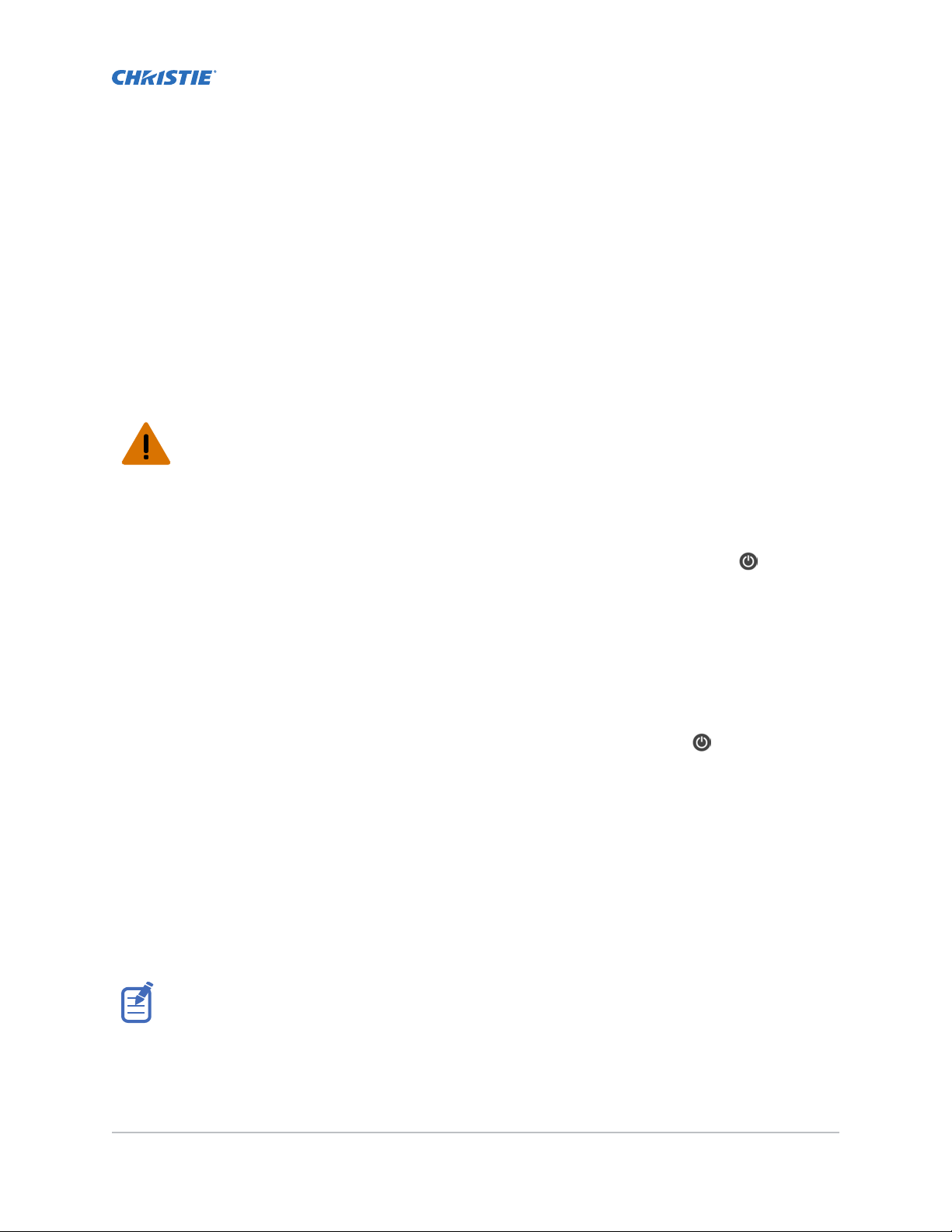

Adjusting the fold mirror

Fold mirror adjustment must be completed by trained personnel.

Notice. If not a

• Misalignment of the fold mirror may cause permanent damage to the product.

voided, the following could result in property damage.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 23

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 24

Service setups

1. Set the projector to minimum power.

2.

From the Test Pattern menu, select the Integrator Rod test pattern.

3. Open the Service door on the side of the projector.

4. Unlock the fold mirror screws to unlock the adjustment knobs.

5. To make horizontal adjustments, use the orange knob labeled Horizontal.

6.

To make vertical adjustments, use the purple knob labeled Vertical.

7. To continue to refine the fold mirror adjustment, repeat the horizontal and vertical

adjustments.

8. Lock the fold mirror screw to lock the adjustment knobs.

9. Once satisfied with the alignment, increase the projector power.

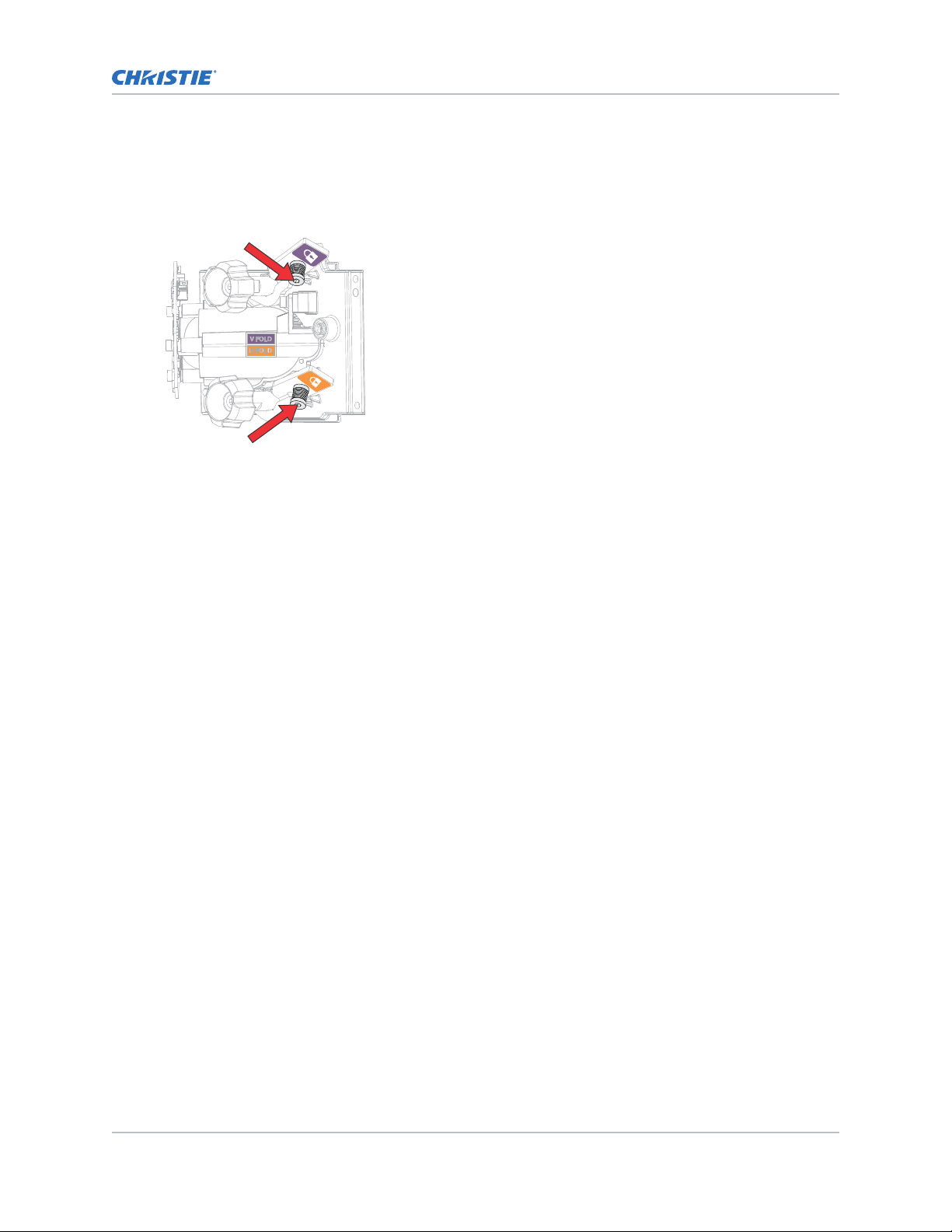

Adjusting DMD convergence

A convergence problem occurs when one or more projected colors (red, green, and blue) appears

misaligned when examined with a convergence test pattern.

The three colors should overlap to form pure white lines throughout the image and one or more poorly

converged individual colors may appear adjacent to some or all of the lines.

When adjusting the convergence, you are adjusting blue and green to red.

1. From the Test Pattern menu, select the Convergence test pattern.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 24

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 25

Service setups

2. Open the Service door on the side of the projector.

To adjust the convergence knobs, use the 3 mm tool included with the projector.

3.

If adjusting by hand without using the tool, pull out the convergence adjustment knobs to

engage them.

4. Use the Convergence test pattern to assist with adjusting the horizontal and vertical lines.

V

ertical convergence and rotation is done by adjusting two knobs. Christie recommends

rotating a single knob a maximum of a quarter rotation before adjusting the second knob a

quarter rotation. For example, if using one hand, turn the left knob a quarter rotation and then

the right knob a quarter rotation, and so on. Adjusting a single knob for vertical or rotational

adjustment to an extreme before adjusting the second knob may result in the convergence

mechanism binding.

5. When complete, push in all the convergence adjustment knobs to disengage the knobs.

Replacing or refilling the coolant

Follow these instructions for filling the liquid cooling module and handling the coolant.

Caution! If not a

• Use protective eye wear and gloves. Follow workplace guidelines for using personal protective

equipment when installing, cleaning, and servicing the product.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 25

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

voided, the following could result in minor or moderate injury.

Page 26

Service setups

Notice. If not a

• Do not attempt to fill the coolant reservoir when it is installed in the projector chassis.

• Fill the coolant to the recommended level only. Do not fill above the maximum level line shown

on the reservoir unit.

voided, the following could result in property damage.

1. Remove the liquid cooling module.

• Light engine liquid cooling module (on page

61)

• Laser liquid cooling module (on page 63)

2. Ensure the liquid cooling module is placed on a flat surface.

3. Open the top cap on the reservoir fill port.

4. Pour the required coolant (Propylene Glycol 740—P/N: 003-005179-XX) into the fill port.

Fill only to the recommended level as indicated on the fill port.

5. Replace and tighten the cap on the reservoir fill port.

6. Use a soft cloth to wipe away any coolant that drips outside the reservoir.

7. Re-install the liquid cooling module.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 26

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 27

Maintenance and cleaning

Maintain the cleanliness of all internal components during an

optics must remain free of contaminants to perform at the level specified. Even a small amount of dust

or a fingerprint may degrade the image or cause a noticeable reduction of brightness.

Always power down and disconnect/disengage all power sources to the projector before servicing or

cleaning the lens or before any of the projection head covers or doors are loosened and removed. If

the seal is broken while the intake fans are still operating, internal components are immediately

vulnerable to contamination from inbound particles.

Notice. If not a

• Avoid touching optical elements.

• Always wear clean, lint-free gloves when handling the product.

voided, the following could result in property damage.

y service procedure. All of the projector

Guidelines for cleaning

Use the following guidelines when cleaning components.

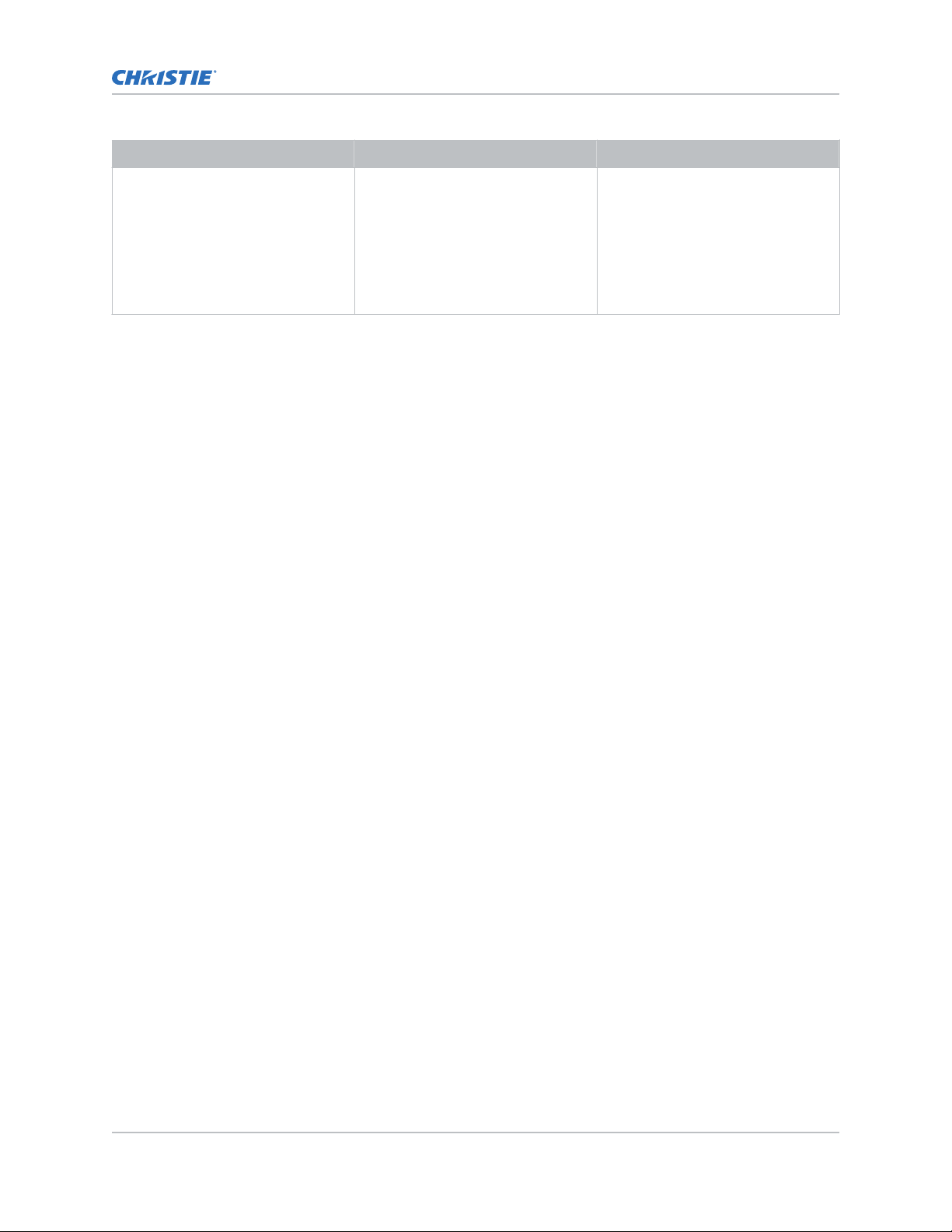

Component Preventative measures How to clean

Illumination Optics System Never touch or blow on exposed

components. W

(supplied).

Integrator Never disassemble the integrator

module.

Illumination system, internal lenses/

prisms

Never touch or blow on interior

components. Wear gloves

(supplied).

ear gloves

Normally the internal

parts should not be

accessed.

Use ionized pneumatic guns only.

Keep imaging components and

yourself grounded at all times.

Blow off particles with clean, dry deionized air.

Blow off particles with clean, dry deioniz

ed air. If necessary, wipe in a

single direction with a clean high

quality optical cloth.

Light engine components Never touch or blow on components.

Wear gloves (supplied).

Light engine, DMD panels Never touch or blow on the panels. Blow off particles with clean, dry de-

Projection lens To avoid the risk of scratching the

lens, only clean the lenses if

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 27

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Blow off particles with clean, dry deionized air. If necessary, use a Q-tip

with pure isopropyl alcohol on the

glass surface. Never touch the

imaging panels. The green imaging

panel also has glass behind it.

ionized air.

Use filtered compressed air to blow

out dust and a clean lint-free cloth.

Page 28

Maintenance and cleaning

Component Preventative measures How to clean

absolutely necessary. A small

amount of dust on the lenses has

little effect on picture qualit

projection lens should be free of

dust and fingerprints. If the lenses

must be cleaned, use a dry, soft

cotton cloth and gently rub in a

circular motion.

y. The

Ventilation

Use the following guidelines when maintaining v

• Do not place the projector near a heat source or in an enclosure, unless proper ventilation is

provided.

• Do not insert objects into the ventilation openings of the projector.

• Do not spill liquids of any kind into the projector. Should an accidental spill occur, immediately

unplug the projector and have it serviced by a qualified service technician.

entilation.

Cleaning the projector optics

Learn about cleaning the optical components in the projectors.

Unnecessary cleaning of optics, increases the risk of degrading delicate coatings and surfaces. Only

clean optics when dust, dirt, oil, fingerprints or other marks are obvious and are causing performance

problems. Maintenance of optical components requires a qualified service technician. Inspect exposed

optical surfaces periodically in a clean, dust-free environment using a flashlight.

Never touch an optical surface with your bare hands. Always wear latex lab gloves.

Use the following products when cleaning the optical surfaces:

• Soft camel-hair brush

• Dust-free blower—filtered dry nitrogen blown through an anti-static nozzle.

• Dust-free lens tissue, such as Melles Griot Kodak tissues (18LAB020), Opto-wipes (18LAB022),

Kim Wipes or equivalent

• Cotton swabs with wooden stems only

• Lens cleaning cloth/microfibre, such as Melles Griot (18LAB024) or equivalent

Cleaning the lens

To avoid the risk of scratching the lens, clean the lens only if absolutely required.

Removing dust from the projection lens

Remove dust from the projection lens to ensure optimum image display.

1. Brush most of the dust off with a camel-hair brush or use a dust-free blower.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 28

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 29

Maintenance and cleaning

2. Fold a microfiber cloth and wipe the remaining dust particles off the lens with the smooth

portion of the cloth that has no folds or creases.

Do not apply finger pressure. Instead, use the tension in the folded cloth to remo

3. If significant dust remains on the lens surface, dampen a clean microfiber cloth with lens

cleaning solution and wipe gently until clean.

ve the dust.

Removing fingerprints, smudge, or oil from the projection lens

Remove fingerprints, smudges, or oil from the projection lens to ensure optimum image display.

Clean the lens only if absolutely required.

1. Brush most of the dust off with a camelhair brush or use a dust-free blower.

2. Wrap a lens tissue around a swab and soak it in lens cleaning solution.

The tissue should be damp but not dripping. Do not use a cleaning solvent that contains

ammonia. Avoid lens contact with Xylene and Ether.

3. Gently wipe the surface using a figure eight motion.

4. Repeat until the blemish is removed.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 29

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 30

Parts and module replacement

When ordering replacement parts, pro

label:

• Projector Model

• Projector Serial Number

• Manufacture Date

vide the following information found on the product license

Maintenance prerequisites

Before servicing the projector, perform the following tasks.

• Always power down and disengage all power sources (on page 18) to the projector prior to

servicing.

• Follow all service safety guidelines (on page 13).

• For detailed breakdown of serviceable modules, see Index of parts and modules (on page

31).

• When re-connecting harnesses, see the interconnect drawings on www.christiedigital.com.

Tools required for service

Before servicing the projector, ensure the following tools are available.

• Long and stubby neck magnetic-tip ball drivers—2.5 mm, 3 mm, and 5 mm (provided in

projector toolbox)

• #2 Phillips™ screwdriver

• 1.5 mm and 2.0 mm hex screwdriver

• Slotted screw driver

• Side cutters and cable ties

• Needle nose pliers

• 19 mm wrench

• Magnetiser

• Electrostatic protective strap and pad

• Disposable lint-free gloves (included with optical components)

• Cloth wipes

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 30

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 31

Index of parts and modules

Parts and module replacement

The following table lists the parts and modules for

Crimson.

Description Part number

Light engine

Light engine HD Crimson/Mirage 25: 003-107494-XX

Crimson 31: 003-109609-

Light engine WU Crimson/Mirage 25: 003-107766-XX

Crimson 31: 003-109616-XX

Power supply and electronics

Power supply LV 500W 003-107582-XX

Power supply 3KW 003-107583-XX

ACIDM 003-121553-XX

Line filter and inline harness 003-006423-XX

Light module 25K 003-121562-XX

Light driver module 25K 003-121564-XX

Light module 31K 003-121830-XX

Light driver module 31K 003-121832-XX

Printed circuit boards

XX

Housekeeping board (HKBC) 003-113675-XX

IR sensor board 1.2 003-112635-XX

Dual temperature sensor module (DTSM) 003-111269-XX

Convenience light board (CLB) 003-005261-XX

Backpane 3.0 board (C4LBP) 003-112433-XX

Image processing board (WIP) 3.0 003-112431-XX

IMXB board 003-112351-XX

Status LED board 003-112245-XX

Fan control board (CFCB) Crimson/Mirage 25: 003-006159-XX

Crimson 31: 003-006937-XX

Color sensor board (CSB) 003-113367-XX

Light driver board Crimson/Mirage 25: 003-121564-XX

Crimson 31: 003-121832-XX

Ventilation and cooling

Light engine radiator intake individual fan (1-4) Crimson/Mirage 25: 003-121612-XX

Crimson 31: 003-121829-XX

Light engine radiator intake fan pack (1-4) Crimson/Mirage 25: 003-00061620XX

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 31

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 32

Description Part number

Crimson 31: 003-006932-XX

Laser system cooling fan pack (includes fans 5-10) 003-107557-XX

Laser system cooling fans 5-10 003-121615-XX

Light engine exhaust fans 11-12 003-121610-XX

Parts and module replacement

Phosphor wheel fan 16

003-006002-XX

Card cage fan 25-26

Rear exhaust fan 3 pack (includes fans 17-19) Crimson/Mirage 25: 003-107562-XX

Rear exhaust fan (used for fans 17-19) Crimson/Mirage 25: 003-121618-XX

Rear exhaust fan 5 pack (includes fans 13, 14, 17-19) Crimson 31: 003-109582-XX

Rear exhaust fan (used for fans 13, 14, 17-19) Crimson 31: 003-121828-XX

Light engine exhaust fan 24 003-121614-XX

Light engine radiator 003-121608-XX

Light engine radiator 003-121608-XX

Liquid cooling module 003-121607-XX

Laser module cooling module 003-121565-XX

Propylene Glycol 740 coolant 003-005179-XX

Laser module fan 003-005960-XX

Harnesses

Main and limited IN/ACIDM harness Crimson/Mirage 25: 003-006422-XX

Crimson 31: 003-006933-

XX

Fans harnesses Crimson/Mirage 25: 003-006474-XX

Crimson 31: 003-006935-XX

Harness to housekeeping board (HKBC) 003-006424-XX

Power supplies harness 003-006425-XX

Harness to backpane board (C4LBP) Crimson/Mirage 25: 003-006473-XX

Crimson 31: 003-006934-XX

Light engine mini SAS harness 003-006161-XX

Convenience light board (CLB) harness 003-006160-XX

Auto optical switch harness 003-111558-XX

Covers and feet

Top/bottom cover 003-107563-XX

Front cover 003-107564-XX

Intake right-side cover 003-107567-XX

Electronics left-side cover 003-107568-XX

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 32

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 33

Parts and module replacement

Description Part number

Rear cover Crimson/Mirage 25: 003-107565-XX

Crimson 31: 003-109568-

Light engine cover Crimson/Mirage 25: 003-006158-XX

Crimson 31: 003-006931-XX

Feet 003-006113-XX

Optics

Integrator rod HD 003-107574-XX

Integrator rod WUXGA 003-107579-XX

Front IOS 003-107572-XX

Fold mirror adjustment 003-107577-XX

L1 adjustment knob 003-006420-XX

Integrator knob 003-006421-XX

Fold mirror 003-001979-XX

Color sensor 003-113367-XX

XX

Lenses

0.73SX+/0.67 HD ILS 118-100110-XX

1.25-1.6SX+/1.16-1.49 HD ILS 118-100111-XX

1.5-2.0SX+/1.4-1.8 HD ILS 118-100112-XX

2.0-2.8SX+/1.8-2.6 HD ILS 118-100113-XX

2.8-4.5SX+/2.6-4.1 HD ILS 118-100114-XX

4.5-7.5SX+/4.1-6.9 HD ILS 118-100115-XX

7.5-11.2SX+/6.9-10.4 HD ILS 118-100116-XX

1.2SX+/1.1 HD ILS 118-100117-XX

0.80-1.16:1 HD ILS 118-130105-XX

0.37:1 HD ILS 118-131106-XX

Lens mount components

Lens mount ILS 003-107581-XX

Offset motor 003-005247-XX

Miscellaneous

User interface 003-107560-XX

003-109117-XX

Remote control 003-120918-XX

Air clean filter 003-006157-XX

EMI filter 003-000311-03

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 33

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 34

Description Part number

Precision 1 rigging frame 165-101103-XX

Retro-fit rigging frame kit 003-006427-XX

Shutter 003-107847-XX

1/4 turn screws 003-006170-XX

HBMIC input card 144-116109-XX

Terra SDVoE input card (TSIC) 144-132107-XX

Parts and module replacement

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 34

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 35

Lens mount components

The lens mount pro

the lens boot, lens mount barrel, and the lens mount offset.

vides a means of securing a projection lens to the projector. Components include

Lens efficiency ratings

The following table lists the available lenses for Crimson and their associated transmission efficiency.

Lens transmission efficiency affects the brightness of the projected image.

Lens Part number Efficiency rating

0.37:1 HD 118-131106-XX 77%

0.73:1 SX+/0.67:1 HD fixed 118-100110-XX 92%

0.8-1.16:1 HD 118-130105-XX 85%

1.2:1 SX+/1.1:1 HD fixed 118-100117-XX 88%

1.25-1.6:1 SX+/1.16-1.49:1 HD zoom 118-100111-XX 94%

1.5-2.0:1 SX+/1.4-1.8:1 HD zoom 118-100112-XX 91%

2.0-2.8:1 SX+/1.8-2.6:1 HD zoom 118-100113-XX 100%

2.8-4.5:1 SX+/2.6-4.1:1 HD zoom 118-100114-XX 93%

4.5-7.3:1SX/4.1-6.9:1 HD zoom 118-100115-XX 99%

7.5-11.2:1 SX+/6.9-10.4:1 HD zoom 118-100116-XX 100%

Installing a projection lens

The projection lens, shipped separ

projector.

Notice. If not a

• Always use a lens plug when installing or moving the product. This prevents contaminants from

entering the product.

• Do not insert the lens into the product at an angle. This can damage the lens and the optical

components inside the product.

• Always place the lens cap onto the lens when moving the projector to avoid scratching the lens.

• Remove the lens cap before turning the product on to avoid damaging the lens.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 35

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

voided, the following could result in property damage.

ately from the projector, must be installed prior to setting up the

Page 36

Lens mount components

The projector includes a motorized lens mount that allows automated lens control and adjustment:

v

ertical and horizontal offsets, zoom, and focus. The projection lens is shipped separately from the

projector. Use the lens cap when transporting the lens to avoid scratching and damaging the lens,

which could affect your displayed image.

• Zoom and Focus—Two internal lens motors allow for quick motorized adjustment of zoom and

focus. Adjust zoom to fit the displayed image on the screen and adjust focus to improve the

clarity of the image.

• Lens Offset—The motorized lens mount allows vertical and horizontal offset of the displayed

image.

• Shutter—Sets the screen to absolute black, when in the closed state.

Do not adjust motorized lenses by hand without first setting them for manual operation; otherwise,

the zoom and focus motors may be damaged.

1. Ensure the lens cap is on the lens.

2. Rotate the lens clamp to the open position.

3. Align the lens interface plate with the lens mount and align the lens electrical connector with

the mating connector on the lens mount.

4.

Fully insert the assembly straight into the lens mount opening without turning and press with

your hand as shown.

5. To lock the lens assembly in place, while holding the lens flat against the lens mount, push the

lens clamp down.

6.

Remove the front lens cap.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 36

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 37

Lens mount components

7. For added stability and safety such as motion applications, or if the projector is hoisted or

installed in an o

with the lens mount or hand tighten the lens retaining screws attached to the lens.

Christie recommends doing this for all lenses.

verhead position, use a 5mm hex driver to fasten the security screws provided

Calibrating the lens motor

Ensure the lens motor is calibr

If the lens motors are not calibrated properly, implications may include:

• Incorrect reporting of the lens motor position.

• Inability to use the full range of the lens motors.

• Lens motors traveling outside of the pre-defined keep-out area.

• Damage to the projector.

Calibrate the lens motors when any of the following conditions are met:

• After a lens change.

• After the projector is moved and/or jostled.

• After any manual adjustment is made to the zoom or focus.

To calibrate the lens:

1. Select MENU > Configuration > Lens Settings > Lens Calibration.

2. Select Enter.

ated before using the projector.

Removing the lens

Complete the following procedure to remove the lens.

1. Remove and retain the two security screws (for installation) from the lens mount.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 37

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 38

Lens mount components

2. Rotate the lens clamp counter-clockwise to the open position.

3.

Pull the lens straight out of the lens mount.

Replacing the lens mount

The lens mount, located at the front of the projector is an assembly of mechanical and electrical

components that securely holds and positions the projection lens.

1. Remove the top cover (on page 42).

2. Remove the front cover (on page 41).

3. Disconnect the lens mount harness connector J88 from the HKBC board.

4. Release the lens mount harness from all the cable clips.

5. Remove the four screws and washers from the corners of the lens mount.

6. Remove the lens mount.

The horiz

ontal and vertical adjustment have posts that the motors sit on; they look like

manual slotted adjustment screws. They are not adjustment screws. Adjusting these screws

will damage the lens mount.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 38

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 39

Lens mount components

7. Replace the lens mount.

8.

To re-install, follow these steps in reverse order.

When re-installing the screws from step 5, make sure the washers are also re-installed.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 39

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 40

Filtration

Filters help to prev

Notice. If not a

ent dust, smoke, fog, and other foreign materials from entering the projector.

voided, the following could result in property damage.

• Do not operate the product without the filter installed.

• Do not operate the product with an incorrectly installed filter.

• Do not reuse an old air filter.

Replacing the air filter

The air filter is located on the air intak

e side cover.

1. To open the air filter door, loosen the two captive screws.

Replace the used air filter with a new one.

2.

The airflow indicator on the new filter must point into projector.

3. Close the air filter door.

4. Tighten the two screws.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 40

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 41

Projector covers

Learn how to remo

ve the covers of the projector.

Removing the front cover

The front cover provides access to the lens assembly and front sensors.

1. Loosen the four screws securing the front cover.

2.

Remove the front cover.

3. Replace the front cover, if required.

4. To re-install, repeat these steps in reverse order.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 41

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 42

Removing the top cover

Projector covers

The top co

1. Loosen the six captive screws securing the top cover.

2.

3. Replace top cover, if required.

4. To re-install, repeat these steps in reverse order.

ver provides access to the light engine, electronics, and various other internal components.

Remove the top cover.

Removing the rear cover

The rear cover provides access to the power supplies, AC input/line filter, and rear exhaust fans.

1. Loosen the four captive screws securing the rear cover.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 42

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 43

2. Remove the rear cover.

3.

Replace the rear cover, if required.

4. Regularly clean the steel mesh shield when servicing the rear cover.

5. To re-install, repeat these steps in reverse order.

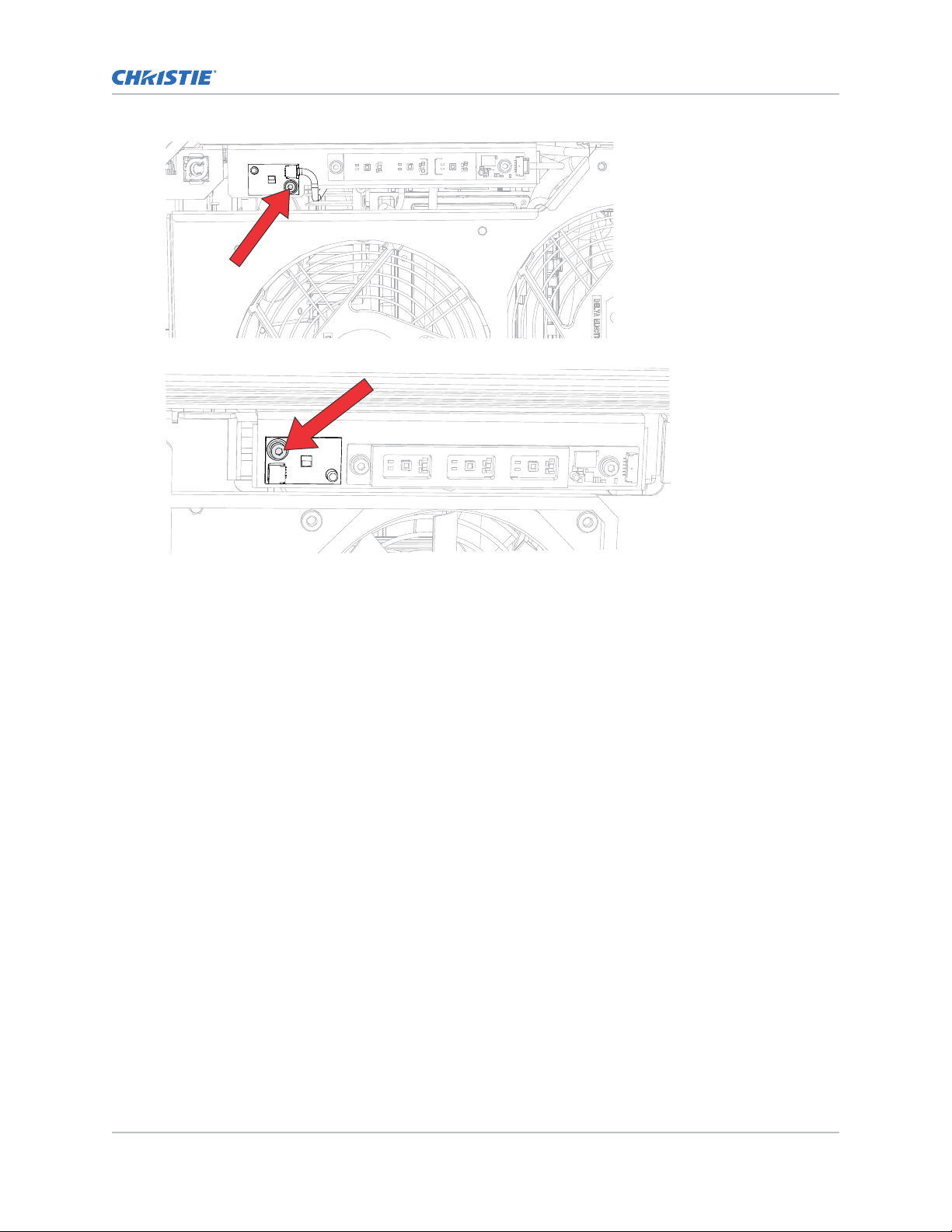

Removing the electronics-side cover

The electronics-side cover provides access to side panel display and card cage.

Projector covers

1. Loosen the six captive screws securing the electronics-side cover.

2.

Remove the electronics-side cover.

3. Replace the electronics-side cover, if required.

4. To re-install, repeat these steps in reverse order.

Removing the air intake-side cover

The air intake-side cover provides access to the radiator.

1. Loosen the six captive screws securing the air intake-side cover.

Remove the air intake-side cover.

2.

3. Replace the air intake-side cover, if required.

4. To re-install, repeat these steps in reverse order.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 43

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 44

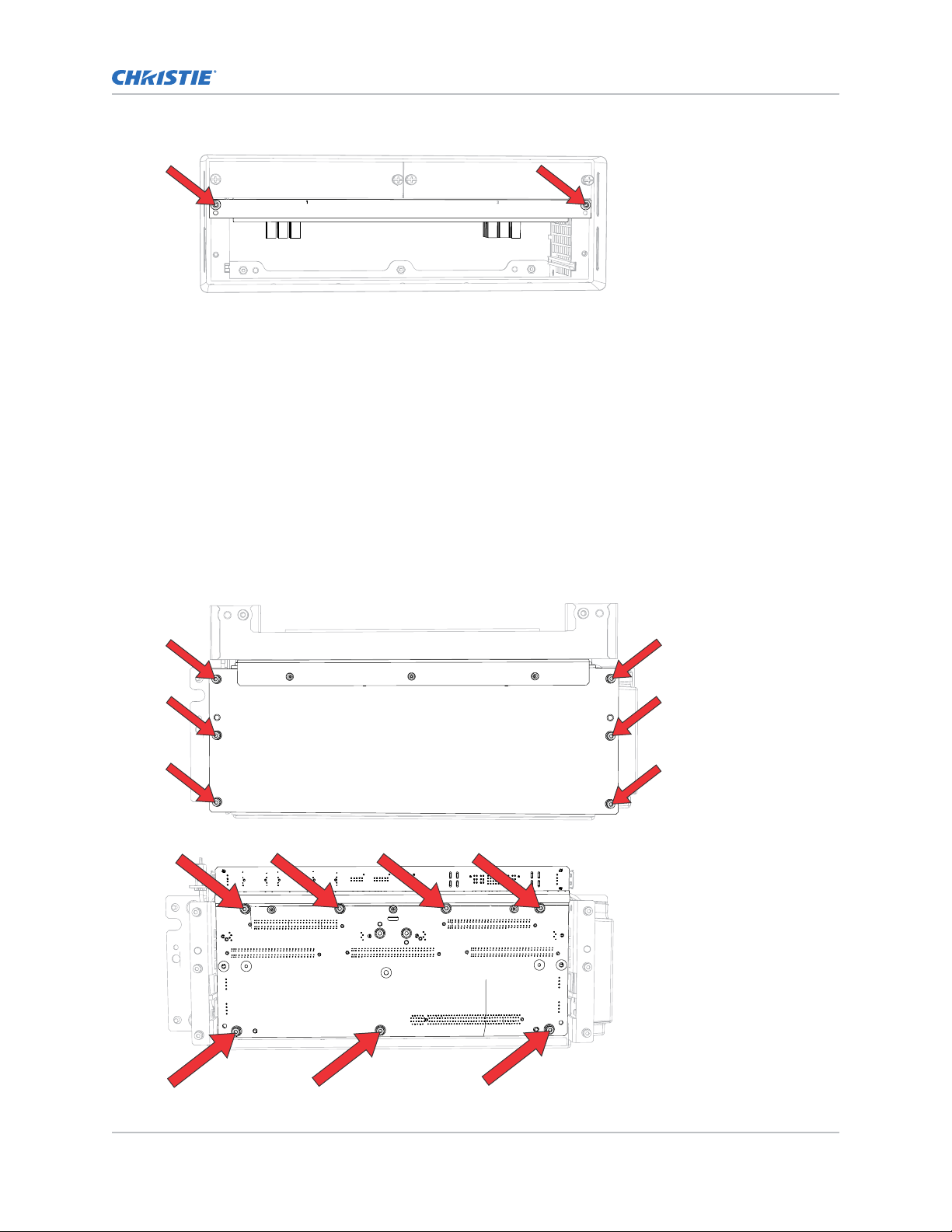

Removing the bottom cover

Projector covers

The bottom co

ver provides access to the blower fan under the light engine.

1. Flip the projector onto its side.

2.

Loosen the six captive screws securing the bottom cover.

3. Remove the bottom cover.

4. Replace the bottom cover, if required.

5. To re-install, repeat these steps in reverse order.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 44

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 45

Removing a projector's foot

Projector covers

The adjustable feet can be r

aised or lowered when positioning the projector to make sure it is level on

all sides so the displayed image appears rectangular without any keystone.

1. Ensure the projector is in a secure position.

Christie does not recommend ha

ving the projector overhang when replacing the feet, unless

the projector is securely positioned.

2. Loosen the lock nut on the affected foot.

3. Uninstall the foot.

4. Replace the foot, if required.

5. To re-install, follow these steps in reverse order.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 45

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 46

Ventilation and cooling

V

ents and louvers provide ventilation, both for intake and exhaust, keeping the projector components

within their operating temperature specifications.

When replacing fans, ensure you confirm the fan direction for airflow. The correct orientation of the

fan also ensures that the fan harness reaches the connector.

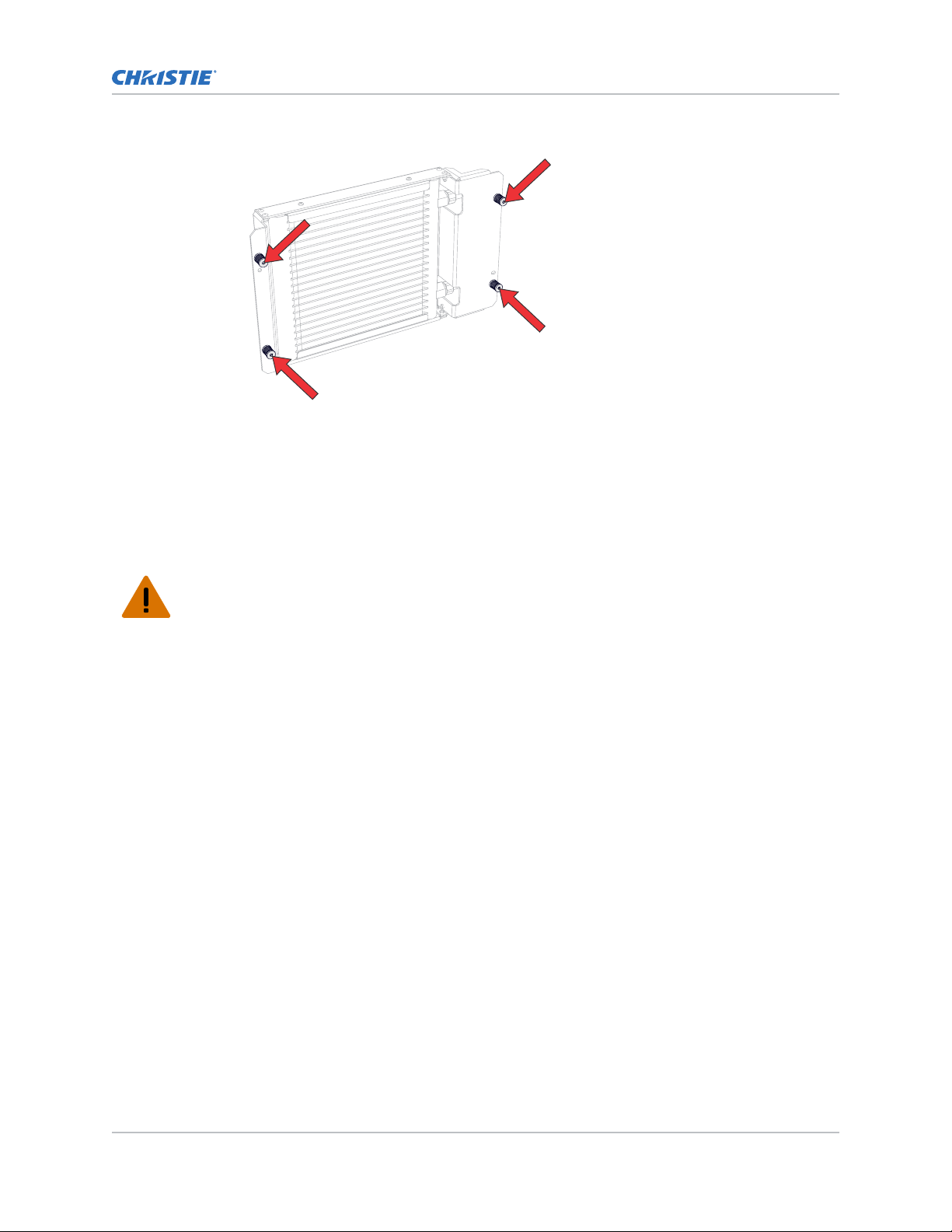

Replacing the light engine intake fans (#1, 2, 3, 4)

The light engine intake fans draw air into the projector for the light engine.

1. Remove the top cover (on page 42).

2. Remove the intake side cover (on page 43).

3. Disconnect the four fan harness connectors located above the light engine radiator assembly.

4. Loosen the four captive screws securing the light engine radiator assembly.

5. Pull out the light engine radiator assembly.

6.

Disconnect the two inline hose connections going to the radiator and remove from clips.

Hose disconnect locations:

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 46

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 47

Ventilation and cooling

7. Place the light engine radiator assembly on a flat surface.

8.

Loosen the four captive screws securing the fan pack to the radiator.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 47

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 48

9. Remove the four screws securing the fan pack to the bracket.

Ventilation and cooling

10. To replace an individual fan.

Pull up the rubber boot from the fan bracket.

a)

Make note of the harness routing.

b) Remove the affected fan from the rubber boot and replace.

11. To re-install, follow these steps in reverse order.

Make sure to align the arrow on the fan with the arrow on the rubber boot.

Crimson Service Guide–Crimson HD25, Crimson WU25, Crimson HD31, Crimson WU31, Mirage HD25, Mirage WU25 48

020-102733-02 R

Copyright © 2020 Christie Digital Systems USA, Inc. All rights reserved.

ev. 1 (01-2020)

Page 49

Ventilation and cooling

Replacing the laser radiator exhaust fans (#5, 6, 7, 8, 9, 10)

The laser r

1. Remove the top cover (on page 42).

2. Remove the intake side cover (on page 43).

3. Disconnect the J103 harness from the housekeeping (HKBC) board.

4. Disconnect the four harnesses from the light engine intake fans.

5. Loosen the captive screw securing the harness bracket.