Part Number 41920-18 Standard, and 44458-18 Chain Drive Version

1083-10 1/99

Linear LiftTM 800 Assembly

Installation & Operator’s Instruction Manual

September 2018

MV1654F

Chore-Time Warranty Linear LiftTM 800 Assembly

Chore-Time Warranty

Chore-Time Group, a division of CTB, Inc. (“Chore-Time”) warrants new CHORE-TIME Linear LiftsTM and Linear Lift

TM

Components manufactured by Chore-Time to be free from defects in material or workmanship under normal usage and

conditions, for One (1) year from the date of installation by the original purchaser (“Warranty”). If such a defect is

determined by Chore-Time to exist within the applicable period, Chore-Time will, at its option, (a) repair the Product or

Component Part free of charge, F.O.B. the factory of manufacture or (b) replace the Product or Component Part free of

charge, F.O.B. the factory of manufacture. This Warranty is not transferable, and applies only to the original purchaser of

the Product.

CONDITIONS AND LIMITATIONS

THIS WARRANTY CONSTITUTES CHORE-TI

ME’S ENTIRE AND SOLE WARRANTY AND CHORE-TIME

EXPRESSLY DISCLAIMS ANY AND ALL OTHER WARRANTIES, INCLUDING, BUT NOT LIMITED TO,

EXPRESS AND IMPLIED WARRANTIES, INCLUDING, WIHTOUT LIMITATION, WARRANTIES AS TO

MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSES. CHORE-TIME shall not be liable for any direct,

indirect, incidental, consequential or special damages which any purchaser may suffer or claim to suffer as a result of any

defect in the Product. Consequential or Special Damages as used herein include, but are not limited to, lost or damaged

products or goods, costs of transportation, lost sales, lost orders, lost income, increased overhead, labor and incidental costs,

and operational inefficiencies. Some jurisdictions prohibit limitations on implied warranties and/or the exclusion or

limitation of such damages, so these limitations and exclusions may not apply to you. This warranty gives the original

purchaser specific legal rights. You may also have other rights based upon your specific jurisdiction.

Compliance with federal, state and local rules which apply to the location, installation and use of the Product are the

responsibility of the original purchaser, and CHORE-TIME shall not be liable for any damages which may result from noncompliance with such rules.

The following circumstances shall render this Warranty void:

· Modifications made to the Product not specifically delineated in the Product manual.

· Product not installed and/or operated in accordance with the instructions published by the CHORE-TIME.

· All components of the Product are not original equipment supplied by CHORE-TIME.

· Product was not purchased from and/or installed by a CHORE-TIME authorized distributor or certified

representative.

· Product experienced malfunction or failure resulting from misuse, abuse, mismanagement, negligence, alteration,

accident, or lack of proper maintenance, or from lightning strikes, electrical power surges or interruption of

electricity.

· Product experienced corrosion, material deterioration and/or equipment malfunction caused by or consistent with

the application of chemicals, minerals, sediments or other foreign elements.

· Product was used for any purpose other than for the care of poultry and livestock.

The Warranty and Extended Warranty may only be modified in writing by an officer of CHORE-TIME. CHORE-TIME

shall have no obligation or responsibility for any representations or warranties made by or on behalf of any distributor,

dealer, agent or certified representative.

Effective: April, 2014

2

MV1654F

Contents

Topic Page User

Chore-Time Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 C,D

Support Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 C,D,I

Distributor and Installer Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

About This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 C,I

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 C,I

Safety–Alert Symbol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Understanding Signal Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Follow Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Decal Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

DANGER : Moving Auger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

DANGER : Electrical Hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Available Sizes and Speed of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Cable/Pulley Combinations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Linear LiftTM 800 41920-18 Side Wall Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Linear LiftTM 800 44458-18 (Chain Drive) Side Wall Installation . . . . . . . . . . . . . . . . . . . .9

Linear LiftTM 800 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 C,I

Grease Recommendation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 I

Optional Suspension Parts Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 C,D,I

Linear LiftTM 800 Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 C,D,I

Parts Listing and Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 C,D,I

MV1654F

* Legend: C = Customer (end user), D = Distributor (sales), I = Installer of equipment

3

General Linear LiftTM 800 Assembly

Please fill in the following information about your Product.

Keep this manual in a clean, dry place for future reference.

Distributor’s Name___________________________________________________

Distributor’s Address ________________________________________________

Distributor’s Phone _______________________ Date of Purchase ___________

Installer’s Name _____________________________________________________

Installer’s Address___________________________________________________

Installer’s Phone _______________________ Date of Installation ___________

System Specifications ________________________________________________

___________________________________________________________________

General

Support Information

The Chore-Time Linear LiftTM 800 Assembly is designed to open inlet doors. Using this equipment for any other

purpose or in a way not within the operating recommendations specified in this manual will void the warranty and

may cause personal injury.

This manual is designed to

information. The Table of Contents provides a convenient overview of the information in this manual. The Table

of Contents also specifies which pages contain information for the sales personnel, installer, and consumer (end

user).

provide comprehensive planning, installation, safety, operation, and parts listing

Distributor and Installer Information

4

MV1654F

Linear LiftTM 800 Assembly About This Manual

About This Manual

The intent of this manual is to help you in two ways. One is to follow step-by-step in

the order of assembly of your product. The other way is for easy reference if you have

questions in a particular area.

Important ! Read ALL instructions carefully before starting construction.

Important ! Pay particular attention to all SAFETY information.

• Metric measurements are shown in millimeters

specified. “ " ” equals inches and “ ' ” equals feet in English measurements.

Examples:

1" [25.4]

4' [1 219]

• Optional equipment contains nec

• Major changes from the last printing will be listed on the back cov

• This Planning Symbol is used in areas where planning needs to take place before

construction continues.

• Very small numbers near an illustration (i.

not a part number.

Safety Information

Caution, Warning and Danger Decals have been placed on the equipment to warn

of potentially dangerous situations. Care should be taken to keep this information

intact and easy to read at all times. Replace missing or damaged safety decals

immediately.

Using the equipment for purposes other than specified in this manual ma

personal injury and/or damage to the equipment.

and in brackets, unless otherwise

essary instructions for assembly or operation.

er.

e., 1257-48) are identification of the graphic,

y cause

Safety–Alert Symbol

This is a safety–alert symbol. When you see this symbol on your equipment, be alert

to the potential for personal injury. This equipment is designed to be i

operated as safely as possible...however, hazards do exist.

Understanding Signal Words

Signal words are used in conjunction with the safety–alert symbol to identify the

severity of the warning.

DANGER indicates an imminently hazardous situation which, if not avoided, WILL

result in death or serious injury.

WARNING indicates a potentially hazardous sit

COULD result in death or serious injury.

CAUTION indic

minor or moderate injury.

MV1654F

nstalled and

uation which, if not avoided,

ates a hazardous situation which, if not avoided, MAY result in

5

Safety Information Linear LiftTM 800 Assembly

Safety Information

Follow Safety Instructions

Carefully read all safety messages in this manual and on your equipment safety signs.

Follow recommended precautions and safe operating practices.

Keep safety signs in good condition. Replace missing or damaged safety

signs.

Decal Descriptions

DANGER : Rotating Parts

Severe personal injury will result, if the electrical power is not disconnected, prior to

servicing the equipment.

DANGER : Electrical Hazard

Disconnect electrical power before inspecting or servicing equipment unless

maintenance instructions specifically state otherwise.

Ground all electrical equipment for safety.

All electrical wiring must be done

and national electric codes.

Ground all non-current carrying metal parts to guard against elec

With the exception of motor overload protection, electrical disconnects

current protection are not supplied with the equipment.

by a qualified electrician in accordance with local

trical shock.

and over

6

MV1654F

Linear LiftTM 800 Assembly Safety Information

Same Speed

(Ratio 1:1)

Linear Lift

TM

800

12"/Minute

800 lb. max.

Load

12"/Minute

800 lb. max.

Load

Speed Up

(Ratio 1:2)

Linear Lift

TM

800

12"/Minute

800 lb. max.

Load

24"/Minute

400 lb. max. Load

Slow Down

(Ratio 2:1)

(Standard)

Linear Lift

TM

800

12"/Minute

800 lb. max.

Load

6"/Minute

1600 lb. max. Load

Figure 1. Cable Ratio Diagram (side view).

Available Sizes and Speed of Operation

• The Linear LiftTM 800 has a total stroke of 18".

• The lifting speed is 1

2" per minute.

• Total Weight Capacity of the Lift is 800 lbs.

Cable/Pulley Combinations

MV1654F

7

Safety Information Linear LiftTM 800 Assembly

8

MV1654F

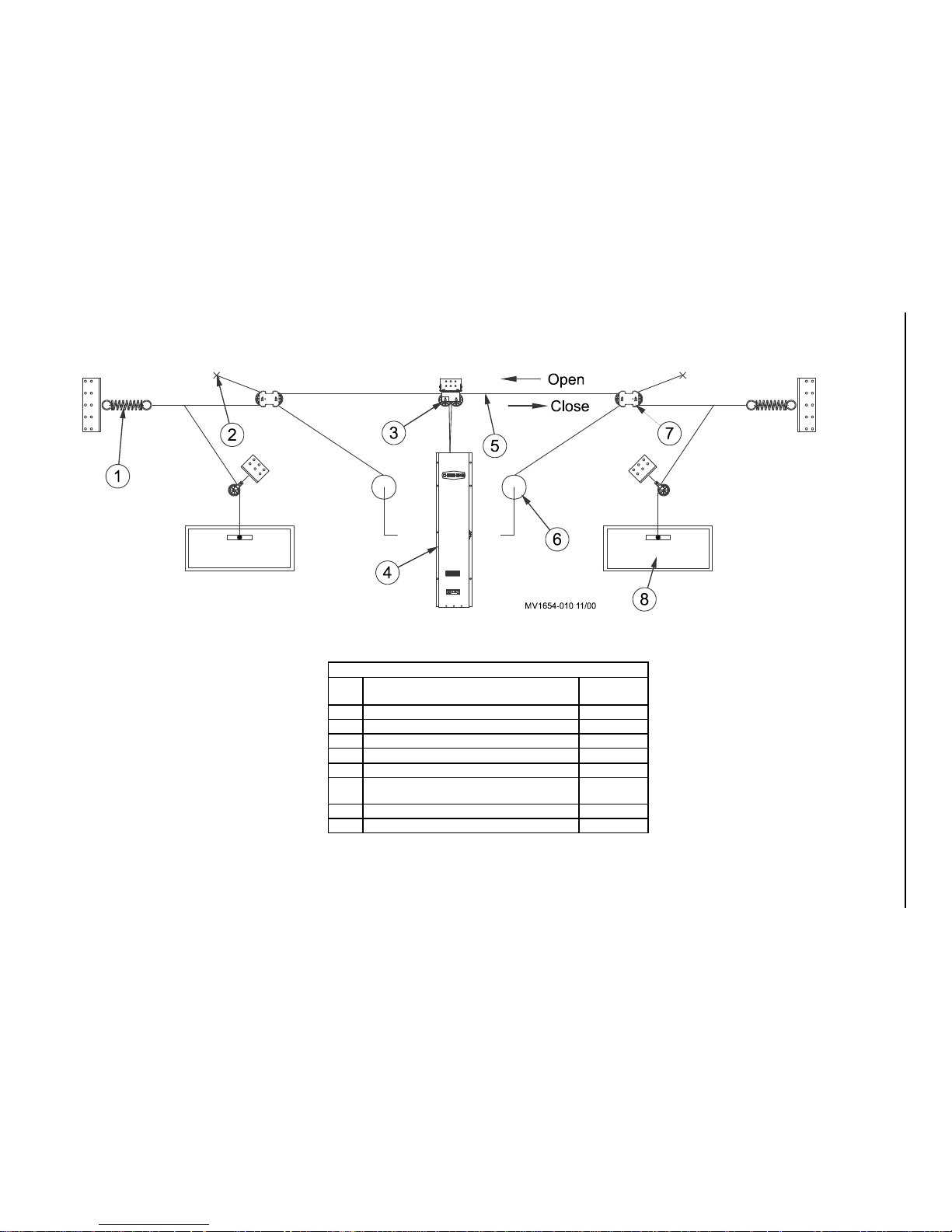

Linear LiftTM 800 (41920-18) Side Wall Installation With Spring Tension Closing Inlet

Doors

Linear Lift

TM

800

Item Description

Part

Number

1 Inlet Spring (Close Doors) 41143

2 Tie Down

3 Double Pulley Assembly 43272

4

Linear Lift

TM

800 (Open Doors)

41920-18

5 Curtain Cable

6 Hand Winch

Winch Mounting Assembly

1212

1193

7 Double Pulley Assembly 27772

8 Inlet Door

Figure 4. Linear LiftTM 800 Side Wall Installation with a 1:1 double-back cable arrangement

Linear LiftTM 800 Assembly Safety Information

MV1654F

9

Linear LiftTM 800 (44458-18 Chain Drive) Installation with Spring Tension Closing Inlet

Doors

(Chain Drive) Linear LiftTM 800

Item Description

Part

Number

1 Inlet Spring (Close Doors) 41143

2 Tie Down

3 Double Pulley Assembly 44520*

4

Chain Drive Linear Lift

TM

800 (Open Doors)

44458-18

5 Curtain Cable

6 Hand Winch

Winch Mounting Assembly

1212

1193

7 Double Pulley Assembly 27772

8 Inlet Door

*Standard with Chain Drive Linear Lift

TM

800

Figure 5. Side Wall (Chain Drive) Linear LiftTM 800 with a 1:1 double-back cable arrangement

Linear LiftTM 800 Installation Linear LiftTM 800 Assembly

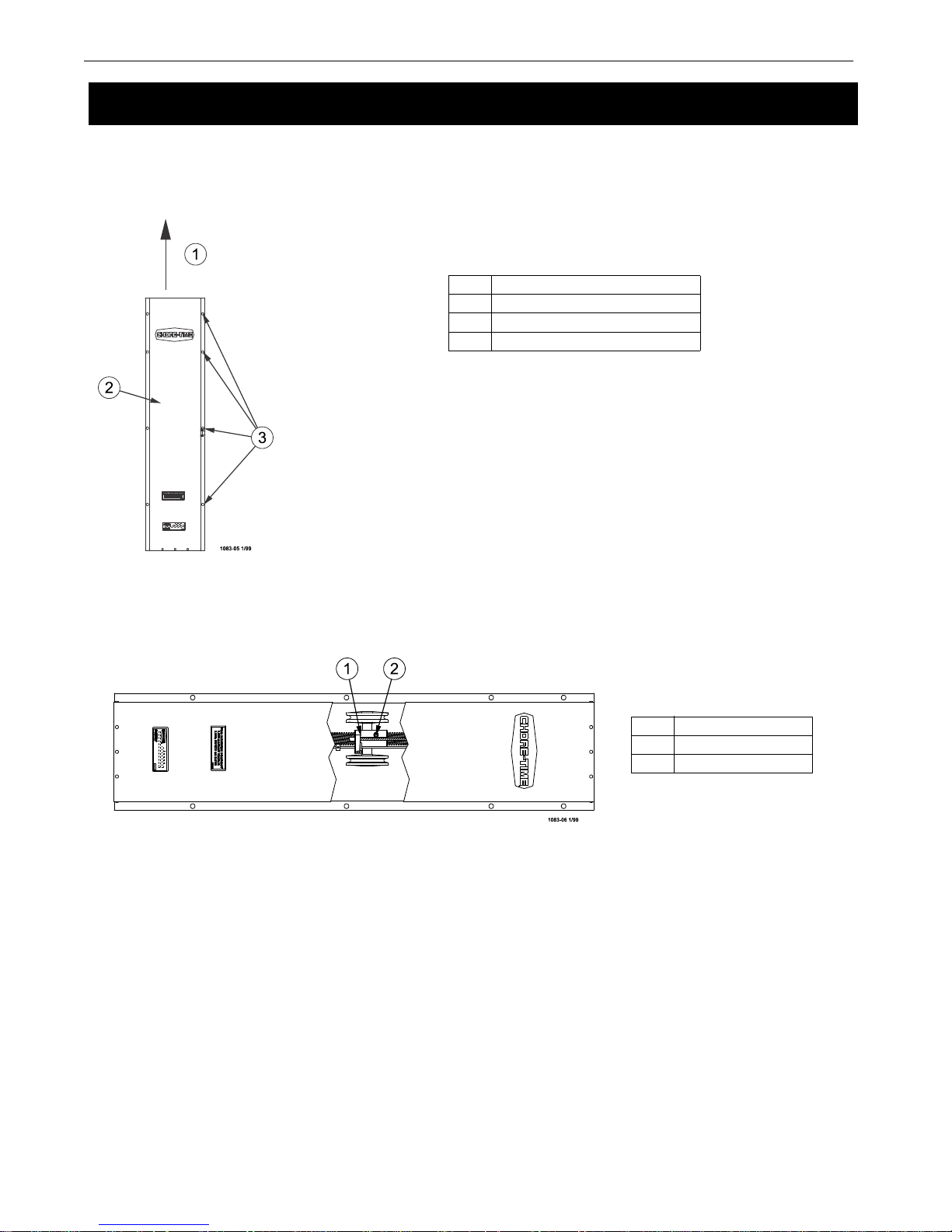

Item Description

1 Cable Routing

2

Linear Lift

TM

800

3 Mounting Hole Locations

Figure 8. Linear LiftTM 800 Installation (vertical wall view)

Figure 9. Linear LiftTM 800 Critical Grease Fitting Locations (horizontal wall mount view)

Item Description

1 Machined Nut

2 Grease Fitting

Linear LiftTM 800 Installation

The Linear LiftTM 800 may be mounted to the wall or ceiling, using (8) 3/8" Lag

Screws (included in the Hardware Package). See Figure 8.

1. Route the cable as required to the main curtain or baf

2. Mount the Linear LiftTM 800 to the wall or ceiling using the hardware provided.

See note below.

Grease Recommendation

fle board cable.

The LINEAR–LIFTTM is fully greased at the factory. However, for maximum life,

Chore-Time strongly recommends greasing the Linear Lift

monthly. For best results apply grease through grease fitting while Linear Lift

is in operation to put an even coating of grease over the entire length of the Threaded

Shaft.

Recommended Grease: Sunoco Construc

(available through Grainger) or similar water-resistant with moly, extreme pressure

(E.P.) grease. See Figure 9.

IMPORTANT: Grease monthly for maximum life.

TM

800 at each grease fitting

tion Grease or Mobile CMP Grease

TM

800

10

MV1654F

Linear LiftTM 800 Assembly Linear LiftTM 800 Installation

Linear LiftTM 800 Switch Adjustment

The Linear LiftTM 800 has adjustable stops (Set Collars) that may be moved to

accommodate a variety of inlet opening lengths.

A 1/8" Allen wench is required to loosen the se

(see Item 2 below).

Slide the Set Collar(s) on the Switch Rod allow for the maximum

t screw on the Set Collar

inlet opening travel (see Item 4 below).

Figure 10 shows the maximum travel settings (at a 1:

TM

Linear Lift

800s available.

Figure 10. Linear LiftTM 800 Adjustment (side view)

Item Description Part No.

1 Switch Rod 41915-1

2 Adjustable Stops (set collar) 41857

3 Nut Assembly 41957

4 Threaded Rod 35945-6

5 Maximum Travel (18") 6 Switch Assembly 41916

1 ratio) of the

MV1654F

11

Wiring Diagram

Wiring Diagram Linear LiftTM 800 Assembly

12

MV1654F

1

5

2

3

4

7

10

6

16

14

8

9

12

15

13

Mv1654-012 11/00

Item Description Part No.

1 Corner Pulley Assembly 35597

2 Double Pulley Assembly 27772

3 Pulley Kit 27301

4 Center Pulley Assembly 27302

5 3/16" Cable (150')—7/19

3/32" Cable—galvanized

13976

4973

6 3/16" Cable Clamp 732

7 Pulley Assembly 2500

8 Double Pulley Mounting Brkt. 35404

9 Single Pulley Mounting Brkt. 35405

10 3/16-18x7" U Bolt with Nuts 35602

11 5/16-18x7" Bolt 4412-20

12 Double Eye Pulley 2501

13 Double Pulley Assembly 43272

14 Double Sprocket Assembly 44520

15 Pulley Assembly 28429

16 Inlet Spring 41143

Linear LiftTM 800 Assembly Optional Suspension Parts Listing

Optional Suspension Parts Listing

Items 7, 8, 10, & 11 with a quantity of 2 each--may be ordered as a Double Pulley Assembly. Part No. 35600.

Items 7, 9, 10, & 11 with a quantity of 1 each--may be ordered as a Single Pulley Asse

MV1654F

mbly. Part No. 35598.

13

Linear LiftTM 800 Parts List Linear LiftTM 800 Assembly

Linear Lift

TM

800 Parts List

14

MV1654F

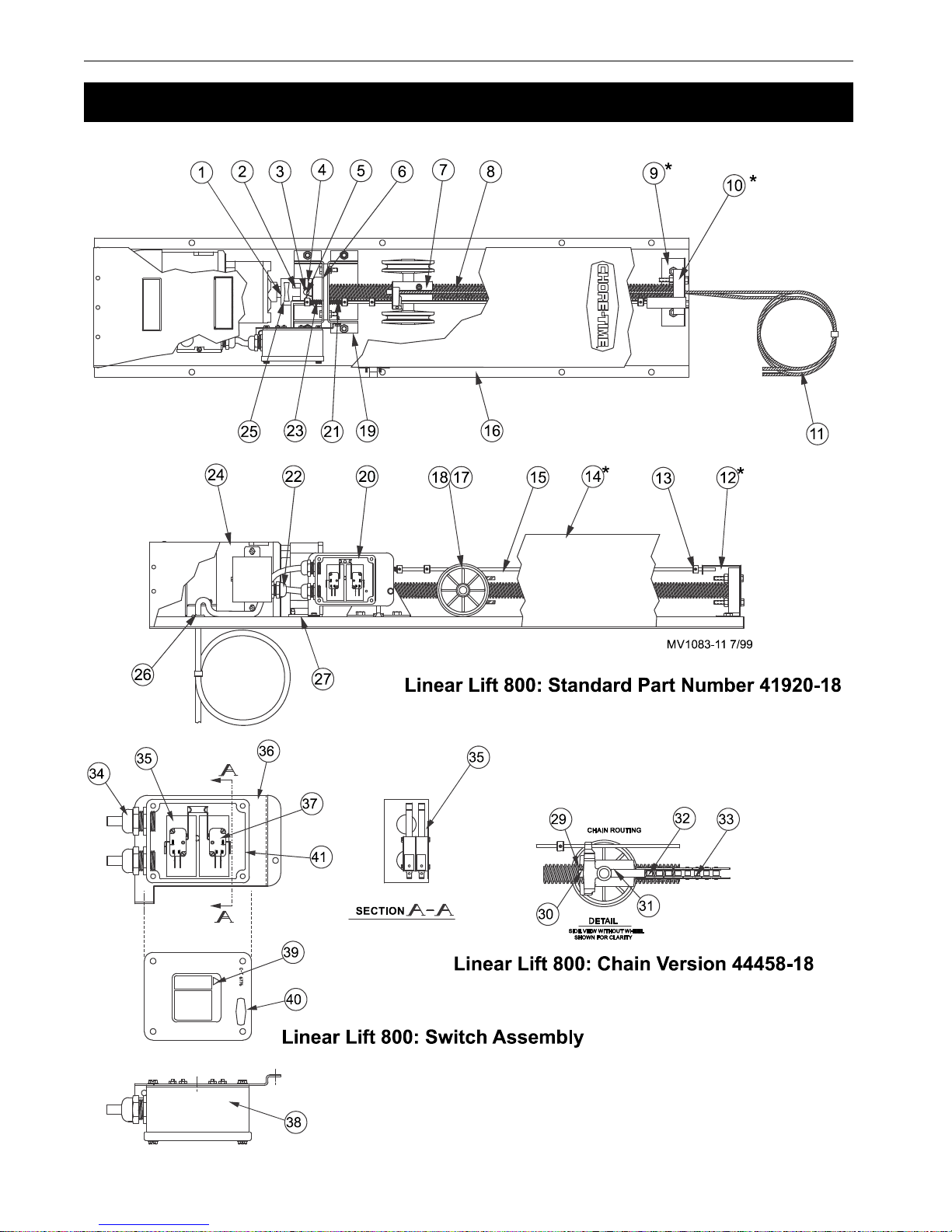

Parts Listing and Identification

Linear LiftTM 800 Assembly Parts Listing and Identification

MV1654F

15

*Parts listed are Standard unless otherwise marked or stated.

Item Description Part No. Item Description Part No.

1 3/16 x 1 Square Key 2112-1 24 1/6 H.P. Gear Motor 28:1 Ratio 46379

2 "Sox" Spider Spacer 36333 25 Flexible Coupling 36363-3

3 Cotter Pin 2663 26 Rubber Grommet 7256

4 Flexible Coupling 35944 27 Bison Motor Spacer 42859

5 Clevis Pin 36466-1 *Chain Drive Version

6 Thrust Plate 41911 9* Pilot End Bracket 44457

7

Linear Lift

TM

Nut Assembly

41957 10* Threaded Shaft Pilot 44413

8 Threaded Shaft 35945-6 12* Rod Support 44459

9 End Bracket 41913 14* Cover Assembly 56086-2

10 Threaded Shaft Pilot 35569 29 1/4-20 x 1-1/2 Socket HD Cap Screw 5083-8

11

Linear Lift

TM

Cable

41342 30 1/4-20 x 2-1/4 Socket HD Cap Screw 5083-2

12 Rod Support 42385 31 Chain Connecting Rod 44417

13 Set Collar 41857 32 Connecting Link (# 40) 20017

14 Cover Assembly 56086-1 33 Drive Chain #10 (#40 Roller) 21045-12

15 Switch Rod 41915-1 Switch Assembly

16 Base 41912 34 Liquid Tight Connector 23779

17 Retaining Ring 41525 35 Switch Insulation 1907-8

18 Machined Pulley Wheel 41540 36 Switch Mount Bracket 42857

19 LL 800 Thrust Bracket 42848 37 Micro Switch 46324

20 Switch Assembly 41916 38 Terminal Box 36334

21 Compression Spring 49813 39 Danger Decal 2527-35

22 Liquid Tight Connector 4999-95 40 Switch Box Cover 6776

23 Thrust Bearing 36397 41 Gasket 6777

Made to work.

Built to Last.

Note: The original, authoritative version of this manual is the [English] version produced

by CTB, Inc. or any of its subsidiaries or divisions, (hereafter collectively referred to as

"CTB"). Subsequent changes to any manual made by any third party have not been

reviewed nor authenticated by CTB. Such changes may include, but are not limited to,

translation into languages other than [English], and additions to or deletions from the

original content. CTB disclaims responsibility for any and all damages, injuries, warranty

claims and/or any other claims associated with such changes, inasmuch as such changes

result in content that is different from the authoritative CTB-published [English] version of

the manual. For current product installation and operation information, please contact the

customer service and/or technical service departments of the appropriate CTB subsidiary

or division. Should you observe any questionable content in any manual, please notify CTB

immediately in writing to: CTB Legal Department, P.O. Box 2000, Milford, IN 465422000 USA.

Page No. Description of Change ECO

15 Changed Switch from 6049 to 46324 33946

For additional parts and information, contact your nearest Chore-Time distributor or representative.

Find your nearest distributor at:

Revisions to this Manual

www.choretime.com/contacts

Chore-Time Group, A division of CTB, Inc.

PO Box 2000

Milford, Indiana 46542-2000 USA

Phone (574) 658-4101 Fax (877) 730-8825

Email: choretime@choretime.com

Internet: www.choretime.com

MV1654F

Loading...

Loading...