Thank You The employees of CTB Inc. would like to thank you for your recent Chore-Time

57" Endura® Fan

Installation & Operator’s

Instruction Manual

Operating static pressure should be less than 0.15 inches water column [37.5 Pa].

The Fan Inlet and exhaust must be kept clear of obstructions. Failure to keep the Fan

airflow path clear of obstructions could cause loss of Fan performance and Fan damage.

purchase. If a problem should arise, your Chore-Time distributor can supply the necessary information

to help you.

Fan Part Numbers and Specifications

Static Pressure at

Fan Part No. Bess Lab

53464-21

53464-21S

53464-22

53464-22S

53464-23 17224 230 1 60 538 4.0 27.5 21200

53464-41

53464-41S

53464-42

53464-42S

53464-51

53464-51S

53464-52

53464-52S

Te st N o .

12615 230 1 60 542 6.9 36.0 30400

12614 230 1 60 543 5.4 27.5 27100

12616 230 3 60 534 4.8 40.0 30000

12619 230 3 60 539 4.1 40.0 26900

12617 230 3 50 527 5.2 45.0 29500

12618 230 3 50 534 4.7 45.0 26500

Voltage Phase Hz Nominal

RPM

Amps Starting

Amps

CFM

[cmh]

[51600]

[46100]23[39.1]

[36000]

[51100]

[45600]

[50100]

[45100]

.10" w.c.

[25 Pa]

CFM/W

[cmh/W]

[34.7]

[41.7]

[35.6]

[39.6]

[35.3]

[38.9]

20.4

24.6

20.9

23.3

20.8

22.9

Static Pressure

at .15" w.c.

[37.5 Pa]

CFM

[cmh]

28400

[48200]

25100

[42700]

18900

[32200]

27800

[47200]

24800

[42200]

27200

[46200]

24500

[41600]

CFM/W

[cmh/W]

18.1

[30.7]

20.1

[34.2]

20.8

[35.3]

18.1

[30.8]

20.4

[34.6]

18.1

[30.8]

20.1

[34.1]

MV2406PAugust 2018

Safety Information 57" Endura® Fan

Component Part Extended Warranty Period

Endura

®

Fan Housing and Cones (Including Composite Shrouds, Composite Doors and HDPE Cone Panels)

Five (5) Years

Safety Information

Carefully read all safety messages in this manual and on your equipment safety signs. Follow recommended precautions

and safe operating practices. Keep safety signs in good condition. Replace missing or damaged safety signs.

DANGER : Electrical Hazard

Disconnect electrical power before inspecting or servicing equipment. Ground all electrical

equipment for safety. All electrical wiring must be done by a qualified electrician in

accordance with local and national electric codes. Ground all non-current carrying metal

parts to guard against electrical shock. With the exception of motor overload protection,

electrical disconnects and over current protection are not supplied with the equipment.

DANGER : Rotating Fan Blade

Keep Hands away. Disconnect power before servicing. Fan may start automatically.

Do not operate the Fan without the screens in place. Disregard to these things will

cause serious injury including death.

Warranty

LIMITED WARRANTY

®

Chore-Time Group, a division of CTB, Inc. (“Chore-Time”) warrants new CHORE-TIME Endura

to be free from defects in material or workmanship under normal usage and conditions, for One (1) year from the date of installation by

the original purchaser (“Warranty”). Chore-Time provides for an extension of the aforementioned Warranty period (“Extended

Warranty Period”) with respect to certain Product parts (“Component Part”) as set forth in the table below. If such a defect is

determined by Chore-Time to exist within the applicable period, Chore-Time will, at its option, (a) repair the Product or Component

Part free of charge, F.O.B. the factory of manufacture or (b) replace the Product or Component Part free of charge, F.O.B. the factory of

manufacture. This Warranty is not transferable, and applies only to the original purchaser of the Product.

Fans manufactured by Chore-Time

CONDITIONS AND LIMITATIONS

THIS WARRANTY CONSTITUTES CHORE-TIME’S ENTIRE AND SOLE WARRANTY AND CHORE-TIME EXPRESSLY

DISCLAIMS ANY AND ALL OTHER WARRANTIES, INCLUDING, BUT NOT LIMITED TO, EXPRESS AND IMPLIED

WARRANTIES, INCLUDING, WIHTOUT LIMITATION, WARRANTIES AS TO MERCHANTABILITY OR FITNESS FOR

PARTICULAR PURPOSES. CHORE-TIME shall not be liable for any direct, indirect, incidental, consequential or special damages

which any purchaser may suffer or claim to suffer as a result of any defect in the Product. Consequential or Special Damages as used

herein include, but are not limited to, lost or damaged products or goods, costs of transportation, lost sales, lost orders, lost income,

increased overhead, labor and incidental costs, and operational inefficiencies. Some jurisdictions prohibit limitations on implied

warranties and/or the exclusion or limitation of such damages, so these limitations and exclusions may not apply to you. This warranty

gives the original purchaser specific legal rights. You may also have other rights based upon your specific jurisdiction.

Compliance with federal, state and local rules which apply to the location, installation and use of the Product are the responsibility of

the original purchaser, and CHORE-TIME shall not be liable for any damages which may result from non-compliance with such rules.

The following circumstances shall render this Warranty void:

· Modifications made to the Product not specifically delineated in the Product manual.

· Product not installed and/or operated in accordance with the instructions published by the CHORE-TIME.

· All components of the Product are not original equipment supplied by CHORE-TIME.

· Product was not purchased from and/or installed by a CHORE-TIME authorized distributor or certified representative.

· Product experienced malfunction or failure resulting from misuse, abuse, mismanagement, negligence, alteration, accident, or

lack of proper maintenance, or from lightning strikes, electric

· Product experienced corrosion, material deterioration and/or equipment malfunction caused by or consistent with the

application of chemicals, minerals, sediments or other foreign elements.

· Product was used for any purpose other than for the care of poultry and livestock.

The Warranty and Extended Warranty may only be modified in writing by an officer of CHORE-TIME. CHORE-TIME shall have no

obligation or responsibility for any representations or warranties made by or on behalf of any distributor, dealer, agent or certified

representative.

al power surges or interruption of electricity.

2

MV2406P

57" Endura® Fan Un-Assembled Parts Packages

Un-Assembled 57" Endura

®

Fan Component Part Numbers

Fan Part No. Drive Assembly Motor Hardware Pkg. Fan Blade

53464-21 53753-1 50496 53788-21XX 53219

53464-21S 53753-1S 50496 53788-21XXS 54529

53464-22 53753-1 49903 53788-22XX 53532

53464-22S 53753-1S 49903 53788-22XXS 54530

53464-41 53753-1 48608 53788-41XX 53219

53464-41S 53753-1S 48608 53788-41XXS 54529

53464-42 53753-1 48608 53788-42XX 53532

53464-42S 53753-1S 48608 53788-42XXS 54530

53464-51 53753-2 48608 53788-51XX 53219

53464-51S 53753-2S 48608 53788-51XXS 54529

53464-52 53753-2 48608 53788-52XX 53532

53464-52S 53753-2S 48608 53788-52XXS 54530

XX= Number of Fans that can be built with components in Package.

Fan Blade Package

(53219-XX, 53532-XX, 54529-XX, or 54530-XX)

(53843-XX)

Component Package

(53850-XX)

Shroud and Door Package

(See Table Below)

Motor Pallet

(53129) Grill

(48794) Inlet Screen

(53788-AAXX, or -AAXXS)

Hardware Package

(53753-1, -2, -1S, -2S)

Drive Assembly 1 or 2

Drives per Box

Grill

Screen

Fan Blade Part No.

(on Blade Spider)

Un-Assembled Parts Packages

MV2406P

3

Assembled Fan Component Part Numbers 57" Endura

®

Fan

4

MV2406P

Assembled Fan Component Part Numbers

Assembled 57" Endura

®

Fan Component Part Numbers

Part Number 53464-21 53464-21S 53464-22 53464-22S 53464-23 53464-41 53464-41S 53464-42 53464-42S 53464-51 53464-51S

Qty

Fan Assembly 1 53464-21P 53464-21PS 53464-22P 53464-22PS 53464-23P 53464-41P 53464-41PS 53464-42P 53464-42PS 53464-51P 53464-51PS

Fan Grill 1 53219 53219 53219 53219 53219 53219 53219 53219 53219 53219 53219

Diverter Kit 1 -- -- -- -- 53057 -- -- -- -- -- --

(53464-XXXP)

Fan Assembly

(53129)

57" Fan Grill

57" Endura® Fan Hardware Needed Per Fan (Un-Assembled)

57" Endura

®

Fan Hardware Items Per Fan

Items are Bulk packed in 53788-AAXX, or 53788-AAXXS (See previous page).

Item Qty. Description Part No.

1 1 Bottom Pivot Plate 53036

2 1 Top Pivot Plate 53037

3 4 Door Hinge Pin 53038

4 1 1/4 x 1-1-8" Sq. Key (For Blade) 2419-2

5 40 5/16-18 x 1 SS Hx Hd Shoulder Bolt 54287

6 55 5/16-18 Hx. Serrated SS Flange Nut 46764

7 2 .38 SS Flat Washer ST99070

8 1 72.5" Fan Cone Cable 53399

9 1 5/16-18 x 3" Eye Bolt 30663

10 2 Ø1/2" x 11" Door Spring 49629

11 24 1/4-10 x 1-1/2" Lag Screw SS 41561

12 7 Open Eye Hook 1214

13 1 Screen Spring (4 pc. per package) 54480-4

14 6 Orifice Frame Bracket 53611

15 2 Cable Clamp 732

16 1 Fan Description Decal 39002-XXX

17 1/3 Anti-Seize Lubricant 47749

18 --

57" Endura

®

Fan Instruction Manual

MV2406

Hardware Needed Per Fan (Un-Assembled)

MV2406P

5

Tools Needed and Supplies 57" Endura® Fan

3/8" socket, 1/2"socket or wrench, Side cutters, 1/4" nut driver, Motor power cord, Wire nuts / terminals, Optional

screw hook installation tool (CTB part number 13150-1), Caulking, 5/32" allen wrench (un-assembled)

Planning the layout of the spacing between Fans is very important. Spacing too close together will cause interference

between the discharge Cones.

5" [12.7cm]

!Important: Provide Shelter over Cones in areas where

snow or ice could cause damage. CTB Inc. Warranty Does

Not cover damage from external sources.

1-3/4" [4.4cm] required at

the bottom of the opening.

Important!

Fan

mounting

surface must be flat.

60-1/16" [152.5cm]

Minimum Spacing if

sides of Cone are flat-

tened (See page 17).

72" [182.9cm]

Recommended Spacing

13-11/16" [34.8cm] Inside Wall to Screen

Minimum Wall Thickness 3-1/2" [8.9cm]

42-13/16"

[108.7cm]

56-5/16" [143cm]

Square

70-1/8" [178.1cm]

60-1/8" [152.7cm]

4-5/16"

[10.9cm]

5-11/16" [14.4cm]

57-1/16" [

144.9cm] Max.

55-5/8" [

141.3cm] Min.

60-1/4" [

153cm]

60-1/4" [153.0cm]

57-3/8" [145.7cm] Max.

55-1/4" [140.3cm] Min.

Tools Needed and Supplies

New Installation Planning

6

MV2406P

57" Endura® Fan Installation

(53626) Center V-Post

(53398) Cross Rod

(7791-3)

Press Stud

(53896) Rod Coupler

(48427) Magnet

(53026) Magnet Side Plate

Third Hole designates the

Top of Shroud.

Danger Decal is located in Bottom

Right corner of the Shroud.

Exhaust Side Down

Top of Fan Shroud

Installation

Inspecting the Shroud (For assembled versions skip to page 12)

Inspect the Shroud assembly for hardware as received.

Fan Shroud Assembly (Unassembled version)

Rest Fan Shroud on Saw Horses for ease of Assembly

MV2406P

7

Installation 57" Endura

®

Fan

8

MV2406P

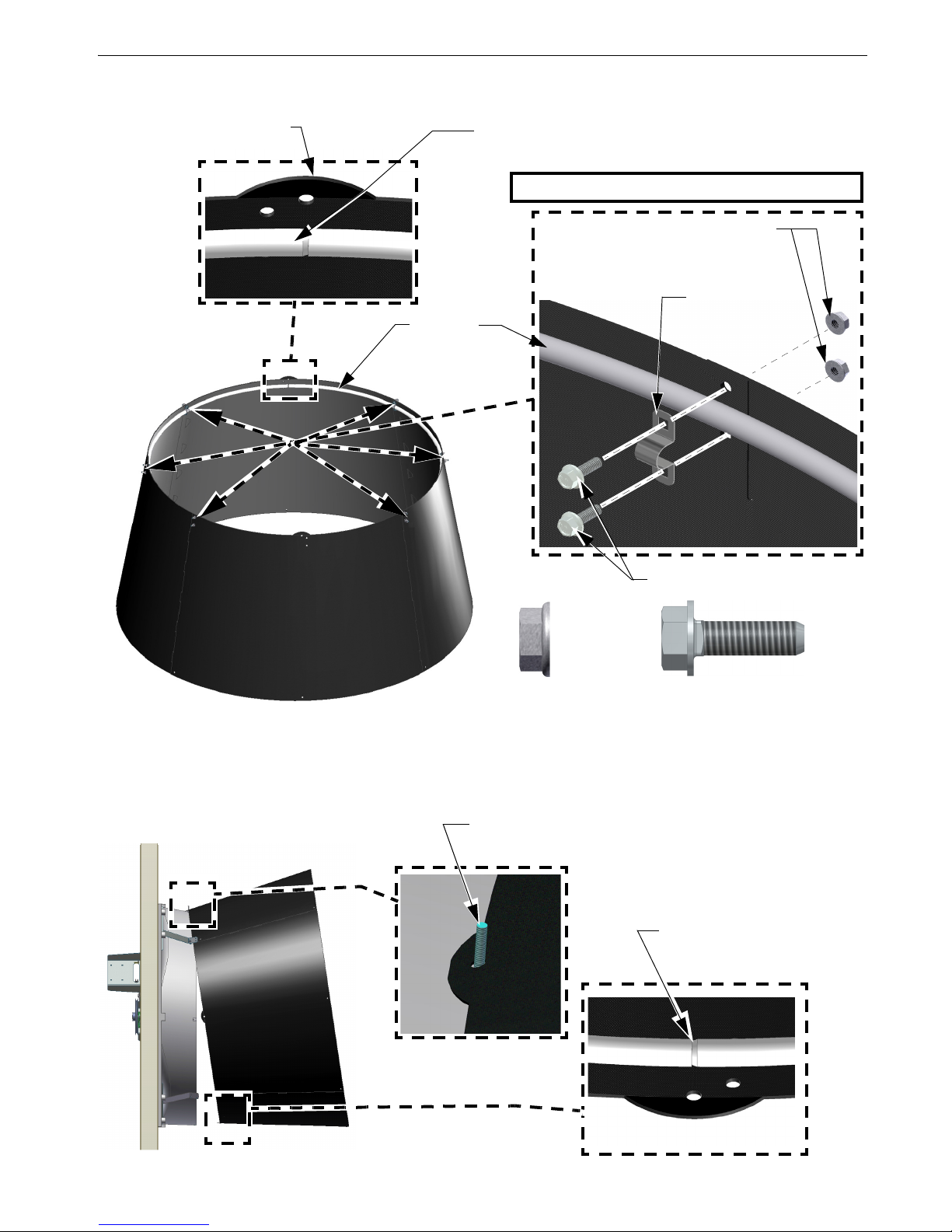

Attaching Fan Posts

(46764) x3

Nut

(53204)

Fan Post

Decal

(46764) x3

Nut

(27868-1) x3

Bolt

(53039)

Cone Bracket

(53206) Bottom Corner

Support Bracket

One Notch

1st Hole

View from Front of Fan

(bottom left corner)

Hardware Full Scale

2nd Hole

Two Notches

(53205) Top Corner

Support Bracket

(53039)

Cone Bracket

(53204)

Fan Post

(27868-1) x3

Bolt

(54287) 5/16-18 x 1.00

SS Shldr. Bolt

(46764) 5/16 Flg. Nut

57" Endura

®

Fan Installation

MV2406P

9

Cone Brackets, Corner Brackets (Corners without Posts)

(46764) Nut

(53205)Top

Corner Sup-

port Bracket

(27868-1)

Bolt

(53039)

Cone Bracket

Two Notches

1st Hole

2nd Hole

One Notch

(53039)

Cone Bracket

(27868-1) Bolt

(53206) Bottom

Corner Support

Bracket

(46764)

Nut

(54287) 5/16-18 x 1.00

SS Shldr. Bolt

(46764) 5/16 Flg. Nut

Hardware Full Scale

Installation 57" Endura® Fan

Apply a Fan Description Decal to the Shroud

as shown

. (Included in Parts Package)

(53753-X)

(46764)

Drive Assembly

(46764)

(48396C) Motor Support

(54287) x8

(54287) 5/16-18 x 1.00

SS Shldr. Bolt

(46764) 5/16 Flg. Nut

Hardware Full Scale

Use the Bottom Set of Holes in the

Posts as shown.

Installing the Drive Assembly and Motor Mount

10

MV2406P

57" Endura® Fan Installation

(53037)

Top Pivot Plate

(46764) Nut

(3066) Eyebolt

(53036) Bottom Pivot Plate

(46764) Nut

(46764)

Nut

Insert (53399) Door Stop Cable

Assembly into Top Pivot Plate

(46764) 5/16 Flg. Nut

Hardware Full Scale

Pivot Plate Tab

Centered in V-Post

V-Post

Pivot Plate Tab

Centered in V-Post

V-Post

Top and Bottom Pivot Plates and Eyebolt, Door Stop Cable

MV2406P

11

Installation 57" Endura® Fan

SS 1/4-10 x 1-1/2" Lag Screws

Tighten until Snug only. Do not

Deform the Bottom Shelf.)

(41561)

(41561) 1/4 x 1-1/2 Lag Screw

Center of Rough

Opening

Outside of House

(53338)

Bottom

Shelf

Center of Bottom

Shelf

If the Shelf is too long Trim

equal amounts from both ends.

This Flange must not be

bowed after installation!

Eyebolt indicates the Top of

the Fan.

Line up the four Holes in the

Shroud with the Holes in the

Bottom Shelf.

Set Fan Shroud on the

Bottom Shelf.

Bottom Shelf Installation

Attaching the Fan to the Wall

12

MV2406P

57" Endura® Fan Installation

It is important when attaching the Fan to the Wall to keep edges of Shroud straight.

5

5

(41561)

(41561)

Pre-drill holes to 3/16" [4.8 mm] to

avoid splitting lumber. If holes do not

line up with the lumber it may be necessary to put Screws through Shroud.

Important! Attach the Fan to the

Wall with 1/4 x 1-1/2" Lag Screws

(41561) in the specific order shown.

Attach with a total of 20 Lag Screws.

5

5

4

1

3

A 600 Lb. Hand Clamp can be used

to straighten Shroud if necessary.

Keep edges of Shroud Straight

2

Use the Hole in the Corner Bracket that is

centered with Lumber to avoid splitting.

(41561) 1/4 x 1-1/2 Lag Screw

MV2406P

13

Installation 57" Endura® Fan

Assemble Cone Panels as shown below.

Two Holes

Prop the Cone

Panels up off

the ground to

ease assembly

One Hole

Tabs Up

Tabs Snap positively

in place

Cone Assembly

14

MV2406P

57" Endura® Fan Installation

(46764)

(54287)

Rounded Tab on the Cone

Orifice Frame Shown Gray for Clarity.

Important! Line up the Seam in the Orifice Frame

with one of the rounded Tabs on the Cone.

(53416)

Orifice

Frame

(53611)

Frame

Bracket

(54287) 5/16-18 x 1.00

SS Shldr. Bolt

(46764) 5/16 Flg. Nut

Hang the Cone on the Eye-Bolt extruding from the top of the Shroud using the hole in

the Cone as shown.

(30663) Eyebolt

Seam in Orifice Frame

Installing the Orifice Frame

Cone Installation

MV2406P

15

Installation 57" Endura® Fan

Attach the cone to the Shroud as shown below.

Use the Bolts in the Cone to attach the Cone to

the Cone Brackets. Use the Bottom set of holes

in the Cone Brackets.

If necessary, slip a thin piece of metal between

the Shroud and Cone and work it around the

Cone to get it on.

Slip the Orifice Frame behind the Bottom Pivot Plate.

Bottom Pivot

Plate

5/16 Flg. Nut (46764)

5/16 Flg. Nut (46764) (46764) 5/16 Flg. Nut

16

MV2406P

57" Endura® Fan Installation

Insert Door Pins in both Doors as shown.

Push Pins in until they bottom out.

Doors are Left and Right specific.

Insert Door Pins into Bottom

Pivot Plate.

Grab the Door in the Center, Bow the Door outward,

and insert the Top Door Pin into the Top Pivot Bracket

as shown. Do not Overbow the Doors!

(53038) Door Pin

Door

Top Pivot Plate

Bottom Pivot Plate

Door Pin

Spring

Holes in

Doors

View of Back of Door View of Back of Door

(53038) Door Pin

Door Assembly and Installation

MV2406P

17

Installation 57" Endura® Fan

Install the Fan Cone Grill (as shown). Attach the end of the Door Stop Cable to the bottom Grill Leg as shown.

(54287)

(46764)

If it is desired to Mount Fans at the minimum spacing cutting the Grills is required as

shown.

(46764)

(ST99070)

(46764)

(54287)

Door Stop

Cable

Door Stop Cable

even with the

edge of Cone

(ST99070)|

3/8 SS Flat Washer

(46764)

5/16 Flg. Nut

(54287)

5/16-18 x 1.00 Bolt

Cut the Grill here

Push the Cone Side

in and use a Clamp to

secure the Grill

Wires.

(732) Clamp (In Parts Package)

Grill Installation

18

MV2406P

57" Endura

®

Fan Installation

MV2406P

19

Rotate Motor Support (Assembled Fans)

Rotate the Motor Support Bracket into the upright position by removing the

upper Bolt and Nut, and loosening the lower Bolt and Nut.

Attach the Motor Support Bracket to the Posts with

5/16 Bolts (54287) and 5/16 Flange Nuts (46764).

Remove Bolt

4x (54287) 5/16-18 x 1.00

SS Shldr. Bolt

4x (46764) 5/16 Flg. Nut

Loosen Bolt

(46764)

5/16 Flg. Nut

(54287)

5/16-18 x 1.00 SS Shldr. Bolt

Installation 57" Endura® Fan

Attach Motor to Z-Bracket.

Motor

(54287)

Torque Set Screw to 150-165 IN-LBS

[16.9-18.6 NM]

Motor

Anti-Seize

Motor

Sheave

3/16" Key Supplied (Taped to Motor)

Center the Sheave with the

Hole in the Z-Bracket

(54287) 5/16-18 x 1.00 SS

Shldr. Bolt

(46764)

5/16 Flg. Nut

Z-Bracket

(46764)

Motor Installation

20

MV2406P

57" Endura® Fan Installation

Blade Installation

Motor Sheave

Tensioner Pulley

Belt

Driven Sheave

Fan Blade Part

Number

Push

Anti-Seize

Blade

1/4" Key

Torque Blade Set

Screws to 150 - 160 IN

[16.9-18.1 NM] LBS.

Fan Blade Flush with

the End of Shaft.

Belt Installation

MV2406P

21

Installation 57" Endura® Fan

Spin the Blade by hand and check that there is

minimum of 1/8" [3 mm] Clearance from the

Shroud all the way around orifice.

If Clearance is insufficient, check that the

mounting surface is flat, and that the sides of

the Shroud are straight. To Gain more Tip

Clearance, remove the Lag Screws from the

side with inadequate clearance, push out on the

Shroud orifice. (Push only on the inner most

2" [5.08 cm]of the Shroud or damage could

occur) Re-install Lag Screws in new holes.

Push only on inner most

2" [5.08 cm] of Shroud

1/8" [3mm] Minimum

Door Springs

Rounded end of Springs attached to Eyehook

Elongated end of Spring

attached to Door Hole

Door Spring Installation

22

MV2406P

57" Endura® Fan Installation

Caulk both Ends of the Bottom Shelf and as needed to fill any gaps between the Shroud

and the Framed opening.

Caulk Both Ends of the Bottom Shelf

Caulking

MV2406P

23

Installation 57" Endura® Fan

1. Check that the electrical power

being supplied to the Fan

matches the electrical Specifications on the Fan and Motor

Decals.

2. Remove the Motor Access

Cover.

3. Install an electrical disconnect

within reach of each Fan

installed.

4. Connect the cord to the motor

according to the wiring diagram

on the motor. Verify that the

motor is connected for counter

clockwise rotation (viewing the

back of the motor, opposite the

shaft end.)

5. Follow local, state, and national

electrical codes for wiring.

6. Attach the Cord to the Wall using

a Screwhook as shown. Allow

enough slack in the cord to form

a "drip loop" for moisture to fall

away from the cord and not into

the motor.

Screwhook

Motor Access Cover

Drip Loop

Motor Wiring

24

MV2406P

57" Endura® Fan Installation

2. Install a spring (54480) in the

upper left corner following

steps A through D below. After

Step D is complete go to step 3.

A) Slide a Spring (54480)

over both Screen Panel Wires

exactly as shown.

B) Rotate the Spring CounterClockwise until the end of the

Spring snaps over the Side Panel

Wire.

C) Slide and Pull Spring over

Corner Panel Wire.

D) Twist Spring Clockwise until it is passed

the outside wire and snapped firmly in place.

1. Fold the Screen Sides as shown.

3. Rotate the Screen in the direction

shown installing a Spring at a second

corner. Repeat for remaining Corners.

Pull

Install Spring

per steps A-D

below.

Install a Spring

at each corner.

Adjust Screen Panels so

they are as even as possible

Spring snapped firmly

between wires.

Corner Wire

Slide

Snapped over Side Panel Wire

Screen Assembly

MV2406P

25

Screen Installation

3/4" [1.9cm]

14" [35.6cm]

[71cm]

28"

3/4" [1.9cm]

3/4" [1.9cm]

1" [2.5cm]

3/4"

[1.9cm]

1" [2.5cm]

3/4"

[1.9cm]

[71cm]

28"

14" [35.6cm]

3/8" [1cm]

Depth of

all Screwhooks

3/4" [1.9cm]

Screen Installation 57" Endura® Fan

Continued on next page.....

26

MV2406P

57" Endura® Fan Screen Installation Continued

.

Motor Cord

Hang Screen on Top Screwhooks

Screen Rests on Side

Screwhooks as shown.

Screen Installation Continued

MV2406P

27

Test Fan for proper operation. 57" Endura® Fan

1747-054 04/03

Bad Belt (Needs Replaced)

Bad BeltGood Belt

Tensioner

Tensioner Base

Alignment Mark

1st Line

Idler Support Bracket

1747-053 04/03

Bad Sheave (Needs Replaced)

Good Sheave

Bad Sheave

Test Fan for proper operation.

Plug the Fan in and test for proper operation

Maintenance

IMPORTANT! Disconnect Power Prior To Maintaining Or Cleaning The Fan. The fan may start automatically causing

serious injury or death.

• Service and repair of fans should be done only by a qualified technician.

• Minimize contact of moisture or corrosive chemicals to the surfaces of the fan components to maximize fan life.

• After washing fans, operate fans long enough to remove moisture from all fan surfaces.

• Keep the fan clean for maximum life and best performance. Do Not spray water on the Fan Shaft Bearings, the Belt

Tensioner, or the Motor.

• Periodically check the V-Belt and replace if necessary. A worn Belt will cause a substantial drop in Fan performance or

it can break and cause Fan failure. If a Belt rides below the Sheave edge, replace the belt. (See below)

• Check Belt Tension. The Belt should be tensioned just tight enough to minimize Belt

slippage. Over tensioning the belt will cause

premature Belt and Bearing wear.

• The Alignment Mark on the Tensioner Base

should be lined up with the 1st line on the

Idler Support Bracket.

• Check Sheaves for wear. Replace if a Sheave groove is worn.

28

MV2406P

57" Endura® Fan Maintenance

Note: Some Parts removed for Clarity

Grease Zerk

Grease Zerk

Fan Bearing and Belt Tensioner Lubrication

• Grease zerks are provided for lubrication on the fan shaft bearings and the belt tensioner.

• Lubricate the fan every 2-6 months or whenever these components get wet.

• Disconnect power to the fan before lubricating.

• Clean the zerk before lubricating to prevent contamination from entering the bearing.

• Use a high quality lithium based, NLGI #2, grease such as Shell Gadus S2 V100 2. Do not use incompatible greases

containing aluminum, barium, calcium, bentonite clay or polyurea thickeners.

• Slowly rotate the fan shaft by hand while slowly applying the grease. Rapidly applying grease to a stationary bearing

can damage the bearing seals.

• Apply about .10 oz (2.8 g, 3.1 cc) of grease at a time or until a slight amount of grease can be seen purging from the

seal.

MV2406P

29

Part Numbers (Itemized) 57" Endura

®

Fan

30

MV2406P

Part Numbers (Itemized)

25

6

15

17

x4

26

31

32

32

32

41

46

51

2

47

42

55

40

40

7

56

*

1

31

48

8

49

11

One Notch

Two Notches

Detail "B"

Detail "A"

50

57" Endura

®

Fan Part Numbers

MV2406P

31

Part Numbers

57" Endura

®

Fan Part Numbers 53464-XX, -XXS

Item Qty. Description Part No. Models

1 1 Motor, 1.5H 1PH-60HZ-230V 49903 -22, -22S, -23

Motor, 1.5H 3PH-60/50HZ-200/380-460V 48608 -41,-42,-51,-52,-41S,-42S,-51S,-52S

Motor, 1.5H 1PH-60HZ-230V 50496 -21,-21S

2 2 57" Fan Post 53204 All

3 2 1" Pillow Block Bearing 50553 All

4 1 Idler Drive Bearing Support 48395C All

5 1 Idler Drive Motor Support 48396C All

*6 1 57" Fan Shroud Assembly 52925 All

7 2 Upper Corner Support (2 Notches) 53205 All

8 2 Lower Corner Support (1 Notch) 53206 All

9 1 AFD99100 Composite Sheave 54118 -21,-22,-41,-42,-21S,-22S,-41S,-42S

AK94 x 1.00" Bore Driven Sheave 40274 -51,-52,-51S,-52S

10 1 AK30 3" O.D. x 5/8 Bore Motor Sheave 8773 -21,-22,-41,-42

AK34 37919 -51,-52

11 1 AX60 V-Belt 48541 All

12 1 1" x 11.97" Fan Shaft 52083 -21,-22,-41,-42,-51,-52

1" x 11.97 SS Fan Shaft 54438 -21S,-22S,-41S,-42S,-51S,-52S

13 1 Tensioner Support 49737 All

14 1 Tensioner Assembly 3.5" Arm 3" Dia. 48429 All

15 1 57" Galv. High Capacity Fan Blade 53219 -21,-41,-51

57" Galv. E. Efficiency Fan Blade 53532 -22,-42,-52

57" High Capacity SS Fan Blade 54529 -21S,-41S,-51S

57" E. Efficiency SS Fan Blade 54530 -22S,-42S,-52S

57" Galv. Min. Vent Fan Blade 56108 -23

16 2 1/4" Sq. 1.13" Key 2419-2 All

Item Qty. Description Part No. Models

17 4 Cone Bracket 53039 All

25 1 57" Fan Support Shelf 53338 All

26 1 56 x 56 x 12.35 Inlet Screen 48794 All

31 42 5/16-18 x 1 SS Shoulder Bolt 54287 All

32 57 5/16-18 Hx. Serrated SS Flange Nut 46764 All

33 4 3/8-16 x 1.50 SS HH Bolt 4413-10 All

34 4 3/8-16 SS Serrated Flange Nut 50191 All

35 1 3/8-16 x .75 SS Hx. Bolt ST99277 All

36 1 3/8 SS Lock Washer ST99780 All

40 24 1/4-10 x 1-1/2 Lag Screw SS 41561 All

41 9 Open Eye Hook 1214 All

42 1 Fan Decal 39002-XXX All

46 4 .125 x .50 Magnet 48427 All

47 8 Magnet Side Plate 53026 All

*48 1 57" Fan Cross Rod 53398 All

*49 2 57" Fan Cross Rod Coupler (Rivet) 56339 All

50 2 1/8 x .40 Countersunk SS Pop Rivet 48936 All

*51 1 57" Center V-Post 53626 All

55 1 Screen Spring (Package of 4) 54480-4 All

*56 2 Fan Danger Decal 2527-50 All

57 1 3/16 x 1-3/8 Key (w/motor) -- All

* Fan Shroud Assembly (Item 6) Includes items 48,49,50,51, and 56

9

12

13

14

32

33

32

32

x4

1

10

Detail "A" (From previous page)

31

32

31

31

36

35

31

5

32

34

3

4

16

31

32

57

Detail "B" (From previous page)

Part Numbers Itemized (Continued) 57" Endura

®

Fan

32

MV2406P

Part Numbers Itemized (Continued)

18

20

x4

22

24

27

28

30

32

32

31

32

29

32

32

39

52

32

31

53

21

32

37

**

32

31

23

29

19

57" Endura

®

Fan Part Numbers (Continued)

MV2406P

33

Part Numbers (Continued)

57" Endura

®

Fan Part Numbers 53464-XX, or 53464-XX,XXS

Item Qty. Description Part No. Models

18 1 Orifice Frame 53416 All

19 6 Orifice Frame Bracket 53611 All

20 4 57" Cone Panel 53163 All

21 1 Top Pivot Plate 53037 All

22 1 Bottom Pivot Plate 53036 All

23 1 Ø1/2" x 11" Door Spring 49629 All

24 1 72.5" Fan Cone Cable 53399 All

27** 1 Left 57" Door Assembly 52926L All

28** 1 Right 57" Door Assembly 52926R All

29 4 1/4 x 1-3/4 420 SS Spring Pin 53038 All

30 1 70" Cone Grill 53129 All

31 42 5/16-18 x 1 HXWH SS Shoulder Bolt 54287 All

32 57 5/16-18 Hx. Serrated Flange Nut 46764 All

37 2 3/8 SS Flat Washer ST99070 All

39 1 5/16-18 x 2 SS Eye Bolt 30663 All

52 4 Striker Plate 53027 All

53 2 Cable Clamp 732 All

54 1/3 Anti-Seize (Not Shown) 47749 All

**Doors Include 53027 Striker Plates (Item 52)

Part Numbers (Continued) 57" Endura® Fan

Made to work.

Built to last.

®

Revisions to this Manual

Page No. Description of Change ECO

34 Updated Contact Info 33817

11 Added Pivot Plate Tab Detail

30,31 Item 50 was (7791-3) 1/4-20 x 1/2 Press Stud

30,31 Item 49 was 53896

For additional parts and information, contact your nearest Chore-Time distributor or representative.

Find your nearest distributor at: www.choretime.com/contacts

34

Chore-Time Group, A division of CTB, Inc.

PO Box 2000

Milford, Indiana 46542-2000 USA

Phone (574) 658-4101 Fax (877) 730-8825

Email: choretime@choretime.com

Internet: www.choretime.com

MV2406P

Loading...

Loading...