Chore-T ronics® 3 Control

Installation & Operator’s Instruction Manual

MT2398CNovember 2013

Chore-Time Warranty Chore-Tronics® 3 Control

Chore-Time Warranty

Chore-Time Equipment (“Chore-Time”) warrants each new Chore-Time product manufactured by it to be free

from defects in material or workmanship for one year from and after the date of initial installation by or for the

original purchaser. If such a defect is found by the Manufacturer to exist within the one-year period, the

Manufacturer will, at its option, (a) repair or replace such product free of charge, F.O.B. the factory of

manufacture, or (b) refund to the original purchaser the original purchase price, in lieu of such repair or

replacement. Labor costs associated with the replacement or repair of the product are not covered by the

Manufacturer.

Conditions and Limitations

1. The product must be installed by and operated in accordance with the instructions published by the

Manufac

turer or Warranty will be void.

2. W arranty is void if all components of the system are

3. This product must be purchased from and installed by a

not original equipment supplied by the Manufacturer.

n authorized distributor or certified representative

thereof or the Warranty will be void.

4. Malfunctions or failure resulting from misuse, abuse,

negligence, alteration, accident, or lack of proper

maintenance, or from lightning strikes, electrical power surges or interruption of electricity, shall not be

considered defects under the Warranty.

5. This Warranty applies only to systems fo

r the care of poultry and livestock. Other applications in industry

or commerce are not covered by this Warranty.

The M

anufacturer shall not be liable for any Consequential or Special Damage which any purchaser may suffer

or claim to suffer as a result of any defect in the product. “Consequential” or “Special Damages” as used herein

include, but are not limited to, lost or damaged products or goods, costs of transportation, lost sales, lost orders,

lost income, increased overhead, labor and incidental costs and operational inefficiencies.

THIS WARRANTY CONSTITUTES THE MANUFACTURER’S ENTIRE AND SOLE WARRANTY AND

MANUFACTURER EXPRESSLY DISCLAIMS ANY AND ALL OTHER WARRANTIES,

THIS

INCLUDING, BUT NOT LIMITED TO, EXPRESS AND IMPLIED WARRANTIES AS TO

MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSES SOLD AND DESCRIPTION OR

QUALITY OF THE PRODUCT FURNISHED HEREUNDER.

Chore-Time Distributors are not authorized t

o modify or extend the terms and conditions of this Warranty in any

manner or to offer or grant any other warranties for Chore-Time products in addition to those terms expressly

stated above. An officer of CTB, Inc. must authorize any exceptions to this Warranty in writing. The Manufacturer

reserves the right to change models and specifications at any time without notice or obligation to improve previous

models.

P.O. Box 2000 • Milford, In

Email: ctb@ctbinc.com • Internet: http//www.ctbinc.com

2

CTB, Inc.

diana 46542-2000 • U.S.A.

Phone (574) 658-4101 • Fax (877) 730-8825

Effective: Nov

ember 2013

MT2398C

Contents

Topic Page

Chore-Time Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Support Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Follow Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Decal Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Introduction to the Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Display Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Relay Box Indication Lights and Auto/Manual Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Glossary of Terms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Analog Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Anticipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Back Up Relay Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Bend Point (BP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cool Pad Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Curve Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Day Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Digital Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Event . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mode Sensor(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Natural Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Power Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Set Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Spare Temp Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Static Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Tunnel Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Wind Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Overview of Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Alarms (Active or Recovered). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Control Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

General Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Analog Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Analog Input Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Setup House . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Output Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Ventilation Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Management Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Programs/Setup Key Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Clocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

MT2398C

* Legend: C = Customer (end user), D = Distributor (sales), I = Installer of equipment

3

Contents - continued

Topic Page

History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Control Operation Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Standard Mode Functionality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Control Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Mounting the Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Wiring the Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Analog Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Remote Light Dimmer Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Bird Scale Wiring using the LCC Board (Scales Less than 150’ from Control). . . . . . . . . . . .105

Bird Scale Wiring using the LCC Board (Scales More than 150’ from Control) . . . . . . . . . . .106

Testing the Back Up Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

MS Board Dip Switch Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

PC Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Programming Trouble Shooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

Programming Troubleshooting Continued..... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

Programming Trouble Shooting Continued..... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Equipment and Potentiometer Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

IONet Error Addr:xx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Backup Control Wiring (24Vdc) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Fan Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

Linear Lift Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

Turbo-Cool™ Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

I/O Board Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

Brooder Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

Improving Lightning Surge Suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Itemized Parts (Main Box). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Parts Listing (Main Box) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Itemized Parts (Relay Box) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Parts Listing (Relay Box). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Extra Parts and Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Analog Input Add-On Kit (Part No. 49663) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

Digital Input Add-On Kit (Part No. 49665). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

Expansion Board Kit (Part No. 49667) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

IMSCM.8 Red Repair Board (Part No. 49672) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

IMSCM.16 Red Repair Board (Part No. 49673) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

Input Wiring Assignment Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

4

MT2398C

General Chore-Tronics® 3 Control

Technical Specifications140Technical Specifications139

General

Support Information

The Chore-Tronics® 3 Controls are used to control the Climate in a structure to insure efficient growth of

Livestock. Using this equipment for any other purpose or in a way not within the operating recommendations

specified in this manual will void the warranty and may cause personal injury.

This manual is designed to provide comprehensive planning, inst

information. The Table of Contents provides a convenient overview of the information in this manual. The Table

of Contents also specifies which pages contain information for the sales personnel, installer, and consumer (end

user).

allation, safety, operation, and parts listing

Safety Information

Caution, Warning and Danger Decals have been placed on the equipment to warn

of potentially dangerous situations. Care should be taken to keep this information

intact and easy to read at all times. Replace missing or damaged safety decals

immediately.

Using the equipment for purposes other than specified in this manual ma

personal injury and/or damage to the equipment.

Follow Safety Instructions

Carefully read all safety messages in this manual and on your equipment safety signs.

Follow recommended precautions and safe operating practices.

Keep safety signs in good condition. Replace missing

Decal Descriptions

or damaged safety signs.

y cause

DANGER : Electrical Hazard

Disconnect electrical power before inspecting or servicing equipment unless

maintenance instructions specifically state otherwise.

Ground all electrical equipment for safety.

All electrical wiring must be done by a qualified el

and national electric codes.

Ground all non-current carrying metal parts to guard a

With the exception of motor overload protection, electrical disconnects and over

current protection are not supplied with the equipment.

5

ectrician in accordance with local

gainst electrical shock.

MT2398C

Introduction to the Control Chore-Tronics® 3 Control

Introduction to the Control

Display Screen

The display screen is a 10.1 in. Full Color Touch screen. This screen will display the requested

information when an Icon on the Touch Screen is pressed. The Display Screen always remains lit. When

the Control is left dormant, the Current Conditions Screen will be visible.

Display Screen

Figure 1. Display Screen

Navigation

Navigating the Control can be done in one of two ways.

Navigating option 1. (Touch)- Touch the Icon or simulated button displayed on the screen with your

finger or stylus.

Figure 2. Navigation-Touch

6

MT2398C

Introduction to the Control Chore-Tronics® 3 Control

Navigating option 2. (Mouse)- A USB mouse can be used by plugging it into the USB port located on

the left side of the main Control Box.

To navigate using a mouse, position the cursor on the Icon or

and press the left mouse button to select.

USB Port

USB Mouse

the simulated button displayed on the screen,

Figure 3. Navigation-Mouse

7

MT2398C

Introduction to the Control Chore-Tronics® 3 Control

1. Displays the Path and the house name or number.

2. (T ask Bar) Navigation buttons from left to right are; Back button, Main menu, Forward button, Current

Condition, Alarm, Password and the Help.

3. All menus, viewable data and editable fields.

4. Time, Date and Age.

2

4

3

Figure 4. Screen Layout

Screen Layout

In the top left corner of every screen the path and the screen name is displayed to the screen you are

viewing. In this example the Current Conditions screen is displayed.

1

Navigating the Control’s Screens

In the Current Conditions screen you can view current data and some settings. Each button has an Icon

that represents the data to be displayed.

Selecting the button with the water droplet

Figure 5. Screen Navigation

8

will display the current water usages from 12:00 am.

MT2398C

Introduction to the Control Chore-Tronics® 3 Control

Notice the path displayed (Current Condition/Today's Water)

Current Path

Figure 6. Current Path

To return to the Current Conditions screen, select the back

or select the CC

return you back to the Current Conditions

button. Note: Regardless of the screen you are in selecting the CC button will

screen.

OR

button at the top left corner of the screen,

Figure 7. Returning to Current Conditions Screen

9

MT2398C

Introduction to the Control Chore-Tronics® 3 Control

2

1

3

4

5

1. Scrolls the value up or down.

2. Removes the last number on the right.

3. Changes the entre from a positive to a negative number.

4. Removes the pop up with no changes to the value.

5. After you have made changes select "OK" to confirm the change. The pop up will disappear and the

change will be displayed in the field.

Figure 8. Numeric Keypad

Numeric Keypad

In a screen that has editable fields, select the value you want to edit (In this example: Set Temperature).

A Numeric Key Pad will be displayed. The name of the field will be displayed at the top of the Key pad.

Name of Field being edited.

Editable field

In some editable fields you can enter text, if these fields are selected a Key Board will be displayed. If a

number is needed with the text, select the button labeled 123 on the Key Board and a Numeric Key Pad

will be displayed. To go back to the Key Board select the AZ button on the Numeric Key Pad. The OK

button will save your entry.

Press "OK" to save entry

Toggle back and forth from Keyboard to Number Pad

using the

and the button.

10

Figure 9. Toggling between Keyboard or Numeric Key Pad

MT2398C

Introduction to the Control Chore-Tronics® 3 Control

1. A Graph icon will be displayed in the upper right

of a screen if there is a graphical representation.

1

Graphs

Relay Box Indication Lights and Auto/Manual Switches

Each Relay Output has its own three position switch that allows the user to select manual, off or automatic

control of each Relay. The Relays and their corresponding Switches are located in a separate box. Decals

are supplied to label each Switch for the Output function that is assigned to that Switch. The Switches can

be placed in three positions - "on", "off", or "auto". The "auto" position is for normal automatic operation.

Changing a Switch to "on" or "off" overrides "auto" operations. When a switch that is assigned is placed

in a position other than "auto", a message will appear in the Current Conditions screen advising you to

"Check Switches". The light above each Switch indicates that the Switch's Relay is activated.

1

2

3

Item Description

1 Indication Light

2 Switch

3 Decal

Figure 10. Indication Lights and Switches

11

MT2398C

Glossary of Terms Chore-Tronics® 3 Control

Glossary of Terms

Analog Input

Analog Inputs can consist of the following:

Temperature sensors

Static Pressure sensor (4-20 mA)

Relative Humidity Sensor (0-10 volts)

Potentiometer (Natural Ventilation)

Anticipation

When the control is turning on the fans assigned to the Minimum Ventilation Timer, the control will open

the inlets to the correct position for static pressure control before the fans are turned on. If calculated

anticipation is used (default), the control teaches itself how much adjustment was required during the

previous on-off cycle, and uses that amount of "anticipation" for the next cycle. If the optional fixed

anticipation is used, the control will NOT teach itself what the correct anticipation should be. It uses the

amount of "anticipation" that is entered in the Static Pressure screen (Screen 11). Anticipation will occur

when the fans assigned to the Minimum Ventilation Timer turn on due to the timer reaches an ON cycle

or the sensor(s) assigned to the fans reach the fans' ON temperature.

Back Up Relay Output

The backup up relay output is a relay that will be energized as soon as the backup output is assigned to a

relay. This relay will stay energized as long as the control is communicating with the manual switch board

where the output is assigned. The 24 Vdc signal that comes from the control to the back up box should be

routed through this relay. If communication is lost between the main box and the manual switch board,

the relay will drop out allowing the first fan stage in the back up box to turn on. See the Wiring Diagrams

section of this manual for more wiring information.

Bend Point (BP)

The Bend Points (BPs) are simply the points on the curve that define the curve. For the Set Temperature

and Minimum Ventilation Timer curves, the curve values are gradually changed between bend points. The

bend point values are the exact values at midnight beginning the day # of each bend point. The curve takes

over when you turn the curve "on" and the day number is equal to or greater than the day number assigned

to BP #1.

Cool Pad Output

The COOL PAD Output is a special function for controlling evaporative cooling that allows you to

modulate the addition of water to the cooling pad in such a way that the usual large temperature swings

associated with a cooling pad are avoided.

Curve

A "curve" is a listing of up to 10 points in time (bend points) that defines how you

want a parameter to automatically vary as the animals age.

Curve Value

The Control will list what the current value(s) the curve would be, if the current day

number is greater than the day # of bend point #1, and the curve is "on", and there is

no "offset" to the curve.

Day Number

The intention is that the day # is the age of the animals whose environment is being

controlled. Day # 0 does not exist. Negative days (down to - 7) are allowed.

Changing the day # in any screen that sho

in all the other screens that show the day #.

12

ws the day number, will change the day #

MT2398C

Glossary of Terms Chore-Tronics® 3 Control

Mt1701-Naturalmode 11/01

Digital Input

Digital Inputs can consist of the following:

Water meter

Feed scale

Air speed sensor

Low water pressure switch

Max feed run time Input

PDS flush feed back

Event

This term applies to the time clock Outputs. An "event" is an "on at" time combined

with an "off at" time.

Mode Sensor(s)

The concept of Mode Sensor(s) is essential to the understanding what makes the

Control change from one mode to another. The Mode Sensor(s), of a currently

operating mode, determines when the Control will leave that mode. As an example,

while in the Power Mode, the Power Mode Sensor(s) determines when it's too

stay in the Power Mode (i.e. above the tunnel "on" temperature)

converts to the Tunnel Mode (assuming there

temperature. It comes back to the Power Mode from the

Tunnel Mode Sensor(s) say it's

too cold to stay in the Tunnel Mode (i.e. below the

is no Natural Mode) at the tunnel "on"

Tunnel Mode, when the

. Because of this, it

tunnel "off" temperature).

hot to

Natural Mode

Natural Mode requires the house to be equipped with Curtains in the side walls that

are powered by Drive Units (Curtain Machines). The Control converts to this mode

of operation when the temperature(s) inside the house raise to a level that the Fans of

the Power Mode can't keep the temperature(s) under control. While in the Natural

Mode of operation, the Curtains are opened or closed, as required, to control the

temperature(s). This mode of operation generally happens during moderate weather.

Noticing an Alarm

"Noticing" an alarm is a very important part of using the alarm system. See how to Notice an Alarm

(Active or Recovered) in the "Alarm" section of this manual.

13

MT2398C

Glossary of Terms Chore-Tronics® 3 Control

Mt1701-Powermode 11/01

Offset

The term "offset" applies to the Set Temperature and Minimum Ventilation Timer

curves only. If you manually adjust either the Set Temperature or the Minimum

Ventilation Timer settings, while the curve is on, you create an "offset" to that curve

relative to it's "curve value". The "curve value" is not changed. (see the "curve

value" definition above.) The curve value is shown as a convenience so that you

know what you have to change it back to in order to get back on the actual curve's

table listing. While an "offset" is in effect, the parameter of the curve is still modified

versus time. However, the actual parameter value is the "curve value" modified by

the "offset".

Power Mode

The building is closed up except for Inlets (usually Baffle Doors) which are powered

open and close in order to control the static pressure level. In some cases Gravity

Inlets are used where the static pressure is not controlled directly. The only

ventilation provided is due to Fans mounted in the end

operation generally happens when the outside temperatures are somewhat lower than

the set temperature.

or side walls. This mode of

14

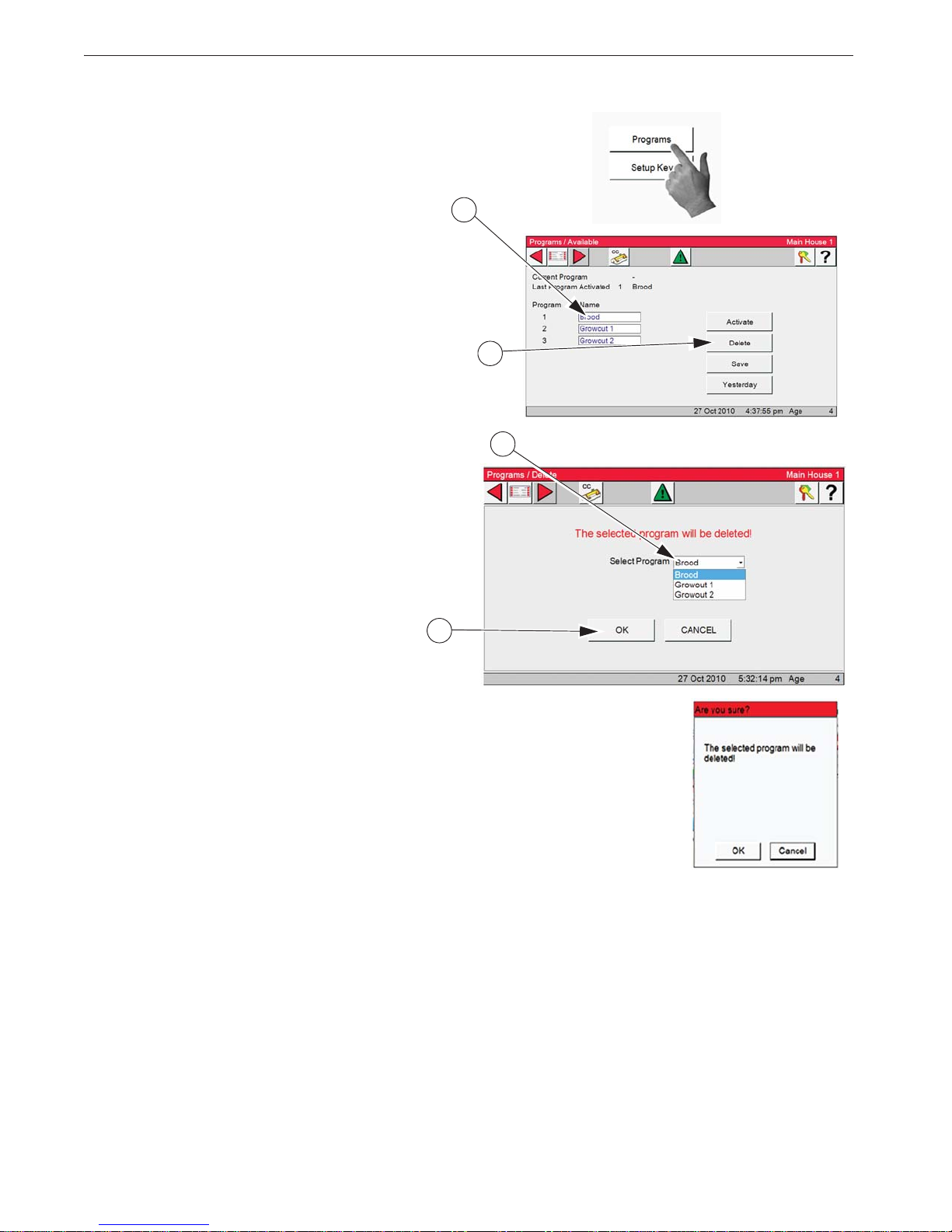

Program

A "program" is a complete set up of all the screens of a Control. In the main menu Program Tab, six

different "programs" can be saved and later activated. This can be very convenient when it is desired to

change the set up at different points during the grow out, barn cycle, or times of the year.

Set Temperature

The set temperature is another very important, basic, concept. All temperatures are referenced to the set

temperature. When the set temperature is adjusted either manually, or because the set temperature curve

is on, all other temperature settings move up or down by the same amount. For instance, even though you

program an actual temperature for each Fan to come on and off, when you change the set temperature,

those Fan's on and off temperatures are adjusted by the same amount

you changed the set temperature.

Spare Temp Sensor

The spare temperature sensor is a temperature sensor that is separate from one of the 12 controlling

sensors. This sensor can be used to control the temperature in a separate area of the house. The sensor has

its own maximum and minimum alarm parameters that can be set up in the Alarms screen. The sensor can

also turn on and off the Spare Temperature Sensor Output. This output functions like a fan output. The

output has lower Off temperature than its On temperature. The On and Off temperatures for the Spare

Temperature Sensor output are defined in the Outputs and Temperatures screen. The spare temperature

sensor can not be used to control any other output.

MT2398C

Glossary of Terms Chore-Tronics® 3 Control

Static Pressure

Static pressure refers to the pressure difference that exists between the inside of the house and the outside

of the house. This pressure difference is the result of Fans in the walls running. The air that they exhaust

enters the house through various types of air inlet openings. In the Power Mode the typical powered baffle

inlets is where the vast majority of the air enters. In the Tunnel Mode, the tunnel inlet at the end of the

house is where the air enters. The pressure drop, due to the resistance to the air flowing through the inlets,

is the reason a static pressure difference exists. If the inlets are all the same size, the same amount of air

will enter through each inlet. In the Natural Mode of operation, the outside wind is the source of the air,

with no exhaust fans running. In general there is little or no static pressure during the Natural Mode due

to the huge area of the open side wall curtains. When the incoming air is cooler than the inside air, it will

tend to drop down onto the birds before it is warmed up. Adequate static pressure brings the air into the

house high and fast so that it heats up before it can fall.

Tunnel Mode

This mode of operation requires a group of large fans at one end of the house with a large air Inlet area at

the opposite end of the house. The control converts to this mode of operation from the Power or Natural

Mode (if used), when the temperature(s) while in those modes get too high. The typical 5 or 6 mph. breeze,

which can be created by the Tunnel Fans running, produces a wind chill effect that is significant. This

mode of operation happens during warm to hot weather.

Mt1701-Tunnelmode 11/01

Wind Delay

The static pressure has to be out of the control limits continuously for the "wind

delay" amount of time before the inlets are adjusted. If a fan or fans has turned

on or off within the last 10 seconds, the wind delay does not happen and the inlets

respond as soon as the static pressure leaves the control limits.

15

MT2398C

Overview of Screens Chore-Tronics® 3 Control

Alarms Button

Message

Alarm Status

Notice Button

From any screen you can select the Alarm button. This will take you to the Alarm Overview

screen.

Alarm Overview Screen- In the Alarm Overview screen an Alarm is listed in three columns.

Message (Type of alarm), Status (Alarm, Recovered and Off For) and a Notice button.

History

Tab

Active Alarm- Select the Notice Button to notice

the Alarm

If the alarm condition is still active, Off For x:xx

will be displayed in the Status column. The specific

alarm will be inactive until it has recovered to within its normal range, at that point the alarm will be

sent to the Alarm History (See below left).

Overview of Screens

Alarms (Active or Recovered)

Active Alarms

To see any current "Active" alarms press the Alarms Button. If there are any Active alarms they will be

listed here (See Figure below).

Alarm Time

Recovered

Noticed

Message

16

Alarm Date

MT2398C

Overview of Screens Chore-Tronics® 3 Control

Alarms Button

Notice Button- Select the Notice button to notice the

alarm, the alarm will be sent to the Alarm History screen.

From any screen you can select the Alarm button. This will take you to the Alarm Overview

screen.

Alarm Overview Screen- If there is a Recovered alarm it will be listed here (See above).

Alarm History- To view the alarm history, select

the History tab at the bottom of the Alarm screen.

The alarm date, time, message, noticed and recovered is displayed for each alarm listed (See below).

Recovered Alarms

To see "Recovered" alarms press the Alarms Button. If there are any Recovered alarms they will be listed

here (See Figure below)

Recovered

Alarm Date

Alarm Time

Recovered

Noticed

Message

17

MT2398C

Control Setup Chore-Tronics® 3 Control

1. Select the Setup button.

3. From the Setup/General screen select

Settings .Setup/General/Settings screen.

2. Select the General button to access the

Setup/General screen.

4. Enter the Computer Number. This will be your house number.

5. Enter the House Name. The house name can be whatever you want, it will be displayed at the

top right of ever screen. A maximum of 14 digits.

6. Choose the Language by pressing the dropdown and select English or Spanish.

7. Choose the Clock Type by pressing on the dropdown and select 12 hour or 24 hour clock.

8. Set the Time of Day by pressing on the time box, a numeric keypad will open allowing you to

set the time of day. (See following page).

9. Set the Date by pressing the date box, a numeric keypad will open allowing you to set the date.

Follow the same procedure used to set the Time (See Following Page).

10. The IP, IP mask and Gateway are used only if C-Central, WebLink and or C-Collect are in use.

These settings are determined by the local network settings.

Note: Path to the Screen being viewed

4

5

6

7

8

9

10

Control Setup

General Setup

From any screen select the Main Menu button at the top left of the screen.

18

MT2398C

Time of Day

1. Highlight the hours by selecting the hours.

Change the hours by using the up/down arrows or the keypad.

2. Highlight the minutes by selecting the minutes. Change the minutes by using the up/

down arrows or the keypad.

3. Highlight the am/pm by selecting the am/

pm. Use the up/down arrows to toggle.

4. Select OK to save.

Date

The date must be enter in a specific format (

Day.Month.Year )

The example shows, 05.10.2010 for 5 October

2010

Control Setup Chore-Tronics® 3 Control

19

MT2398C

Units

In this screen you will choose the unit

of measurement you want to display.

2. Select the Units button

1. Select the General Button in the Setup

Screen.

3. Choose the unit of measurement you

want to display.

Control Setup Chore-Tronics® 3 Control

20

MT2398C

Control Setup Chore-Tronics® 3 Control

1. Select the Setup button. 2. Select the Analog inputs

1. Select the Sensor Type button

In this screen you choose what type of Analog

Inputs (temperature sensors, relative humidity

sensor, and potentiometers) are connected to

the Control. The Static Pressure Sensor and

House Temperature Sensors 1-3 come from

the factory pre-assigned.

2.

Enter Sensor Types installed

Select the box to the left of the sensor types installed. When a Sensor type is grayed out, that

specific item cannot be selected.

The number of specific sensors (Nbr Sensors)

will be added as you continue with setup.

Grayed out (Cannot select)

Sensor Types

Installed

Number of Sensors

Analog Inputs

To access the Analog Inputs Setup screen start by accessing the Main Menu screen.

Analog Inputs-Sensor Type

21

MT2398C

Control Setup Chore-Tronics® 3 Control

1. Select the House Temp. Sensor button

From the Setup/Analog Inputs screen select

House Temp. Sensors button. The Setup/Analog Input/House Temperature screen should be

displayed at this time

2. Factory assigned

Sensor numbers

Temperature sensors 1-3 come from the factory pre-assigned. To assign the next sensor select the Add button and the next sensor will

appear (See below right).

3.

Adding Sensor assignments

Fill in the Board, Input, and backup by selecting from the dropdowns. Continue until all the

temperature sensors have been assigned. If it is

desired to skip a sensor and move to the next

sensor in the list, select the - (not assigned) on

the sensor that needs to be skipped and select

the ADD button, next sensor will appear in the

list.

4

4. Board

The number of the Board the Sensor is connected. Board number 0 is the IOM16 Board.

If the sensor is connected to an additional analog input board, then the Board number

matches the address of the add on Board (see

the installation section of this manual).

5.

Input

This is the input number that the Sensor is

connected to on the Board. On the IO Board

the input number will be 1 thru 16. If the Sensor is connected to an additional Analog Input

Board then the Input number will be 1-4.

5

6

6. Value

This is the current temperature reading.

7. Corr.

This is the amount of correction made when the sensor was calibrated. Calibration will be gone over

later in the manual.

8. Backup

This is the sensor you want to be the backup if the sensor fails.

2

45

7 8

Analog Inputs-House Temperature Sensors.

Select the Back button after all the House temperatures have been assigned.

22

MT2398C

Control Setup Chore-Tronics® 3 Control

1. Select the Outside Temp. Sensor button

In this screen the Outside sensor is assigned.

Calibration is also done from this screen. Skip

this Screen if no outside sensors are installed.

2. Adding Sensor Assignments

Fill in the Board and Input by selecting from

the dropdowns.

Analog Inputs-Outside Temperature Sensor

Select the Back button after the Outside temperature sensor has been assigned.

23

MT2398C

Control Setup Chore-Tronics® 3 Control

1. Select the Static Pressure Sensor button

2. Assign Static Pressure input as you did for the House Temperature

Sensors. Calibration is also done from this screen.

3. Select the Control Tab button

In this screen you set up the specifications for the Static Pressure Sensors

4. Current Safety Limit

Static Pressure Safety limit- Example: When the

static pressure stays above 0.20 for a continuous

minute, the Tunnel Curtain (if in Power Mode)

and the Inlets (if in Tunnel Mode) will open until

the static pressure reduces below 0.20. Once the

problem is fixed and the static pressure reduces

below 0.18, the Control returns to normal operation. The safety limit can be set from .18 to .27.

This situation will always result in a High Pressure Alarm.

4

Analog Inputs-Static Pressure Sensors

24

MT2398C

5. Second Static Pressure

Selecting this feature a second level of Power

Mode static pressure can be chosen. The Temperature Sensor(s), (Inside Only), that measure

that temperature is defined in this screen. Select the sensor edit field and a sensor assignment window will be displayed.

6. Select/Deselect sensor check box

Select or deselect the sensor check box to

choose the sensor or sensors you want to use.

Select OK to save. The temperature at which

the second static pressure takes over is entered

in Output and Temperature screen.

Control Setup Chore-Tronics® 3 Control

25

MT2398C

8. Tunnel Inlet Static Pressure assist in Power

If in the Power Mode, there is inadequate inlet area

to keep the static pressure within the high control

limits, the Tunnel Curtain will open to give additional air inlet area. The Inlets are given continuous open

signals as the Tunnel Curtain takes over the responsibility of controlling the static pressure. The static

pressure has to be above the high Static Pressure

Control limit continuously for one minute with 3 or

more Fans running for this to happen. Responsibility

for Static Pressure Control is passed back to the Inlets as soon as there are fewer than 3 Fans running or

the Tunnel Curtain cannot bring the static pressure

back into the control range (while closing) from the

low side. The static pressure has to be below the low Static Pressure Control limit continuously for

one minute for this to happen.

Select the Back button twice after the Static pressure has been assigned and Control screen is completed

Control Setup Chore-Tronics® 3 Control

1. House Relative humidity Sensor

From the Setup/Analog Input screen select House

RH sensor Button.

2. Assign the House RH sensor input as you did

the House Sensors. Calibration is also done from

this screen. See next manual section "Calibrating

Analog Inputs".

Analog Inputs-Relative Humidity Sensor

26

MT2398C

3. Select the Control tab.

4. Select the RH Influence On Minimum Ventilation

box if you want the min/vent timer to be influenced

by the RH.

5. The Minimum Ventilation timer will be adjusted

based on house RH when the temperature is between

set temperature and the Min-Vent fan's ON temperature. The Control will adjust the amount of ON time

between the Min Ventilation value and the Max value. The OFF time will be adjusted by the same

amount of time that the ON is adjusted, thus keeping

the total cycle time constant. The temperature is

checked 30 seconds before the beginning of the ON time cycle of the Minimum Ventilation Timer. This is in addition to any time added by Ventilation

Timer Ramping.

6. Amount Of Influence (sec)- is the amount of decrease or increase time pre movement.

7. Maximum Influence(sec)- is the maximum amount of RH timer influence you need.

Once the fans' temperature sensor(s) reach the fans' ON temperature, the

fan will turn on and run continuously until the fans' OFF temperature is

reached.

Once the fans' temperature sensor(s) reach the fans' ON temperature, the fan will turn on and run continuously until the fans' OFF temperature is reached.

6

7

Control Setup Chore-Tronics® 3 Control

27

MT2398C

Control Setup Chore-Tronics® 3 Control

1. From the Setup/Analog Input screen select

Type & Number.

2. Put a Check in the Bird Scale Box.

3. Select the Back Button and then select

the Bird Scale Button.

4. Select the Board number from the drop down.

5. Select the Input from the drop down. Select 1.

Analog Inputs-Bird Scale

28

MT2398C

Control Setup Chore-Tronics® 3 Control

1. To re-calibrate the Temperature Sensors, first obtain a digital thermometer that has a readout of at

least + - 1°. Do not use a temperature gun. A temperature gun measures an object’s temperature, not

air temperatures.

2. Place the digital thermometer next to

the Temperature Sensor that is being

re-calibrated. Take the reading from

the digital thermometer and enter that

number under the Value column of the

Sensor being calibrated.

3. The Correction column is used only

for service information and to return

the Control to the factory settings. The

settings should be reset to factory

whenever a re-calibrated Temperature

Sensor is replaced. To return to factory

settings change the number under the correction column by one digit. This will cause the correction to

automatically zero out and return to factory setting.

All Temperature Sensors are calibrated the same way. (Outside, Spare and Aux temperature sensors)

1. To re calibrate the Relative Humidity Sensor first obtain a sling psychrometer or another humidity

measuring device.

2. Operate the psychrometer in the

same area that the Relative Humidity

Sensor is installed. Take the reading

on the psychrometer and compare it to

the reading on the Setup/Analog Inputs/ House RH Screen. If the readings do not match, then change the

reading under the Value column to

match the reading of the psychrometer.

3. The correction column is to be used for service information and for returning to factory settings

only.

2

3

Analog Input Calibration

The re-calibration section of this screen should not need to be used at initial installation and start-up of

the Control unless natural ventilation is used. If natural ventilation is being used, then the Potentiometers

will need to be calibrated at this time. If it is felt that one of the Inputs needs to be re-calibrated perform

the following steps…

Temperature Sensor Calibration

Relative Humidity Sensor Calibration

2

3

29

MT2398C

Control Setup Chore-Tronics® 3 Control

1. To re-calibrate the Static Pressure Sensor first obtain a manometer or other static pressure measuring

device. Then disconnect both hoses

from the Static Pressure Sensor.

2. Go to Setup/Analog Inputs/Static

Pressure screen and look at the Pressure reading in the Zero Level value

box. If the reading is not zero then

change the zero level value pressure to

read zero. The zero level has now been

calibrated.

3. To calibrate the high level, first

make sure that the Manometer has

been installed in the house and reconnect the hoses to the Static Pressure

Sensor. Open the Inlets slightly and turn on enough Fans to create a static pressure of at least 0.15 inches of w.c. at the Manometer. Compare the Manometer reading to the reading on the High Level line on

the Control. If the readings do not match, edit the pressure reading on the High Level value box to

match the reading of the Manometer. As with the Temperature Sensors, the Correction column of the

static pressure calibration is used for service, and to return the Control to factory settings only. This

completes the re-calibration of the static pressure Sensor.

2

3

1. Go to the Setup/Analog Inputs/Bird Scale

Screen and Select Calibrate. (Platform

should be hanging from the Load Cell)

2. With no weight on the Platform select the OK

Button. If there is no error then continue.

3. Place a 5.00 lb. weight on the Platform. In the

"Calibration Weight Box" enter 5.00. Click the

Ok Button. If no error then the calibration is

done.

Static Pressure Sensor Calibration

Bird Scale Calibration

30

MT2398C

Control Setup Chore-Tronics® 3 Control

2. Select the Type & Number button.

3. Select the Digital inputs you have connected to the Chore-Tronic's 3.

Digital Inputs

1. Select the Main menu button. Select the Setup button from the Main Menu screen. Finally, select the Digital inputs Button.

Digital Inputs

The Digital Input Screens are very similar to the Analog Input screens and setup the same way. In these

screens the Control is told what digital inputs (Water Meters, Feed Scales, Airspeed Sensor, Low Water

Pressure Switch, Flush Feed Back, Auger Run Time Alarm, etc.) are connected to the Control and where.

All digital or pulsed inputs that are connected to the Control must be assigned a board number and an

Input number. It is highly recommended that the Input Decal located inside the main box of the Control

be completed before entering information in this screen.

Board- This is the number of the board where the water meter or other digital input device is connected.

Board number 0 is the I/O Board. If the sensor is connected to an additional digital input board, then the

board number matches the address of the add on board (see the installation section of this manual).

Input- This is Input number that the water meter or other digital input device is connected to on the board.

For the I/O Board the input number will be 1 thru 8. If the sensor is connected to an additional

analog input board then the input number will be 1-4.

Name- A name can be entered for the Water meter, feed scale, and auxiliary digital inputs using the al-

phanumeric keypad. The name entered here will appear in the Auxiliary Data and History screens.

Select Add and the next Sensor will appear in the list.

Select Remove and the last Sensor in the list will be deleted.

Type and Number

31

MT2398C

Control Setup Chore-Tronics® 3 Control

1. Select the Main menu button. Select the Setup but-

ton from the Main Menu screen. Finally, select the Digital inputs Button.

2. Select the Water Meters button.

3. Enter all Drinker/Water Meters that are connect-

ed to the CT3 here. A Drinker Water Meter is a Water Meter that is monitoring the water being used by

drinker water lines or the entire house (1 meter for

both drinker lines and Cool Pads). If a Water Meter

is assigned an input here, its daily usage will be added to the total amount of consumed water in the

management screen. When a Water Meter or other

digital input is assigned to a board and an input on

that board, to add the next Water Meter or digital input select the ADD button and Meter #2 will appear.

If it is desired to skip a Meter or other digital input

and move to the next digital input in the list, enter

(not assigned) for the input that needs to be skipped.

it is desired to skip a Meter or other digital input and

move to the next digital input in the list, enter (not

assigned) for the input that needs to be skipped.

4. Select the Control tab

Water Flow Rate Alarm- Put a check in the box if

you want an alarm when flow rate is too high. The parameters are setup in the Alarm screen under the Production tab.

Water Meter

32

MT2398C

Control Setup Chore-Tronics® 3 Control

1. Select the Dump Scale Button.

All feed scales that are connected to the Control

needs the input it is connected to assigned here.

All feed scales that are assigned inputs here will

have their daily usage added to the total amount

of feed consumed in the management screen.

2. Assign an input to each of the feed scales connected to the Control here. Each Input assigned

here will have its daily usage added to the total

amount of feed consumed in the management

screen.

1. Press Auxiliary Input button

Many different types of auxiliary digital Inputs

can be used with the Ct3.

2. Types of auxiliary Inputs include non-drinker

water meters (water meters attached to evaporative cool pads, etc.), pulsed output electric meters, pulsed output gas meters, etc. Each inputs

usage will be monitored separately and will not

be added to any total usage.

1. Press the Air Speed button. 2. Enter the board and input numbers for the Air

speed meter. The parameters are setup in the

Alarm screen under the Environment tab.

Dump Scale

Auxiliary Inputs

Airspeed Sensor

33

MT2398C

Control Setup Chore-Tronics® 3 Control

1. Press the Feed Lines button. 2. Enter the board and input of each Feed Line

connected to the Control. Feed Line run times

will be generated from these inputs.

1. Press the Water Pressure button. 2. Enter the board and input for the Water pressure switch. Switch must open with low pressure.

The parameters are setup in the Alarm screen under the Production tab.

1. Press the Auger Run Time button.

2. Enter the board and input of the Auger run time

relay. The parameters are setup in the Alarm

screen under the Production tab.

Feed Lines

Water Pressure

Auger Run Time

34

MT2398C

Control Setup Chore-Tronics® 3 Control

1. Press the Flush Feedback button. 2. Enter the board and input of the PDS flush feed-

back. The parameters are setup in the Alarm screen

under the Production tab.

Flush Feedback

35

MT2398C

Control Setup Chore-Tronics® 3 Control

1. Select the Main menu button. Select the

Setup button from the Main

Menu screen. Finally, select the House Button.

2. In this Screen you set what type of ventilation

is being used in the House.

3. Temp. Influence on Minimum Ventilation.

Select this box if you want the Min. Vent Timer

to ramp up & down based on temperature. See

explanation and example below.

Ventilation timer ramping- If the sensor(s) that are assigned to the Minimum Ventilation fan(s) tem-

perature is at or below set temperature then the fans will use the ON and OFF times that are listed for

the Minimum Ventilation Timer. If the sensor (s) assigned to the Ventilation Time Ramping temperature is between set temperature and the fans' ON temperature the control will adjust the amount of ON

time between the Min Ventilation value and the Max value. The OFF time will be adjusted by the same

amount of time that the ON is adjusted, thus keeping the total cycle time constant. The temperature is

checked 30 seconds before the beginning of the ON time cycle of the Minimum Ventilation Timer.

Once the fans' temperature sensor(s) reach the fans' ON temperature, the fan will turn on and run continuously until the fans' OFF temperature is reached.

Example:

The set temperature is 70.0°F and the fans assigned to the Min Vent timer ON temperature is 72.0°F.

The Minimum Ventilation Timer values are 30 seconds ON time and 270 seconds OFF time. The maximum ON time is 210 seconds. If the sensor(s) assigned to the Ventilation Time Ramping temperature

is 71.0°F at the beginning of the anticipation cycle, then the fans will have an ON time of 125 seconds

and an OFF time of 175 seconds.

4. Mortality

Select this box if you want to keep track of the

Mortality. To separate male and female select

Separate Male Female.

Setup House

36

MT2398C

Control Setup Chore-Tronics® 3 Control

1. Select the Main menu button. Select the Setup but-

ton from the Main Menu screen.

2. Press the Outputs button

Some of the buttons on this screen may be

grayed out at this point of the setup.

1. Press the Outputs button

Some of the buttons on this screen may be

grayed out at this point of the setup.

2. Press the Equipped/Numbers button

Some of the buttons on this screen may be

grayed out at this point of the setup.

3. In this screen the Control is told what equipment it is connected to: Fans, Curtains, Inlets,

clock type and backup relays. The Nbr. Of Outputs column is read only and will be filled in as

Setup continues.

4. Select the Back button to return to the

Setup/Output screen.

Continued to next page.....

Output Assignments

Outputs-Equipped/Numbers

37

MT2398C

Control Setup Chore-Tronics® 3 Control

Notice that all the buttons are now active.

1. Select the Ventilation button.

2. Every Output needs to have a relay, mode of operation (Power, Natural, Tunnel, or combinations of the

three), and temperature sensor(s) assigned to it. Initially when pressing the Cool, Exhaust Fan, Stir Fan, Tunnel Fan and Heat Zone buttons only one output will

appear.

3. Select the Tunnel Fans button.

Continue to next page.....

Outputs-Ventilation

Ventilation-Tunnel Fans

38

MT2398C

Refer to the Relay Assignment Decal (Inside the

Relay Box) to assign relays to each of the fans.

2. Select the Relay dropdown

to assign the proper Relay to each Tunnel Fan.

3. Select the Mode dropdown

A list of available Modes will appear. Select the

mode (modes) that the Fan needs to operate in.

Relay assignment Decal

(inside Relay Box)

4. In the Sensors column select the senor/sensors

to be assigned to the Fan. Touch the sensor window and a select sensor box will appear with the available sensors. Select or deselect the sensors to come up

with the sensor or sensors to control the Fan. Select OK

to save.

This completes Tunnel Fan 1.

5. To assign additional Tunnel Fans, select the

Add button. The next fan will appear. Follow the same

steps as used for Tunnel Fan 1 to assign the relay, mode,

and sensor assignments.

Using the same steps continue to add Tunnel fans until

finished.

Control Setup Chore-Tronics® 3 Control

39

MT2398C

Control Setup Chore-Tronics® 3 Control

1. Select the Ventilation button.

2. Select the Stir Fans button.

3. Assign Relays, Sensors and Mode values to the

Stir Fans just as you did for Tunnel Fans. (See

previous page)

2. Select the Exhaust Fans button.

3. Assign Relays, Sensors and Mode values to the

Exhaust Fans just as you did for Tunnel Fans.

(See Tunnel Fans previous)

1. Select the Ventilation button.

Ventilation-Stir Fans

Ventilation-Exhaust Fans

40

MT2398C

Control Setup Chore-Tronics® 3 Control

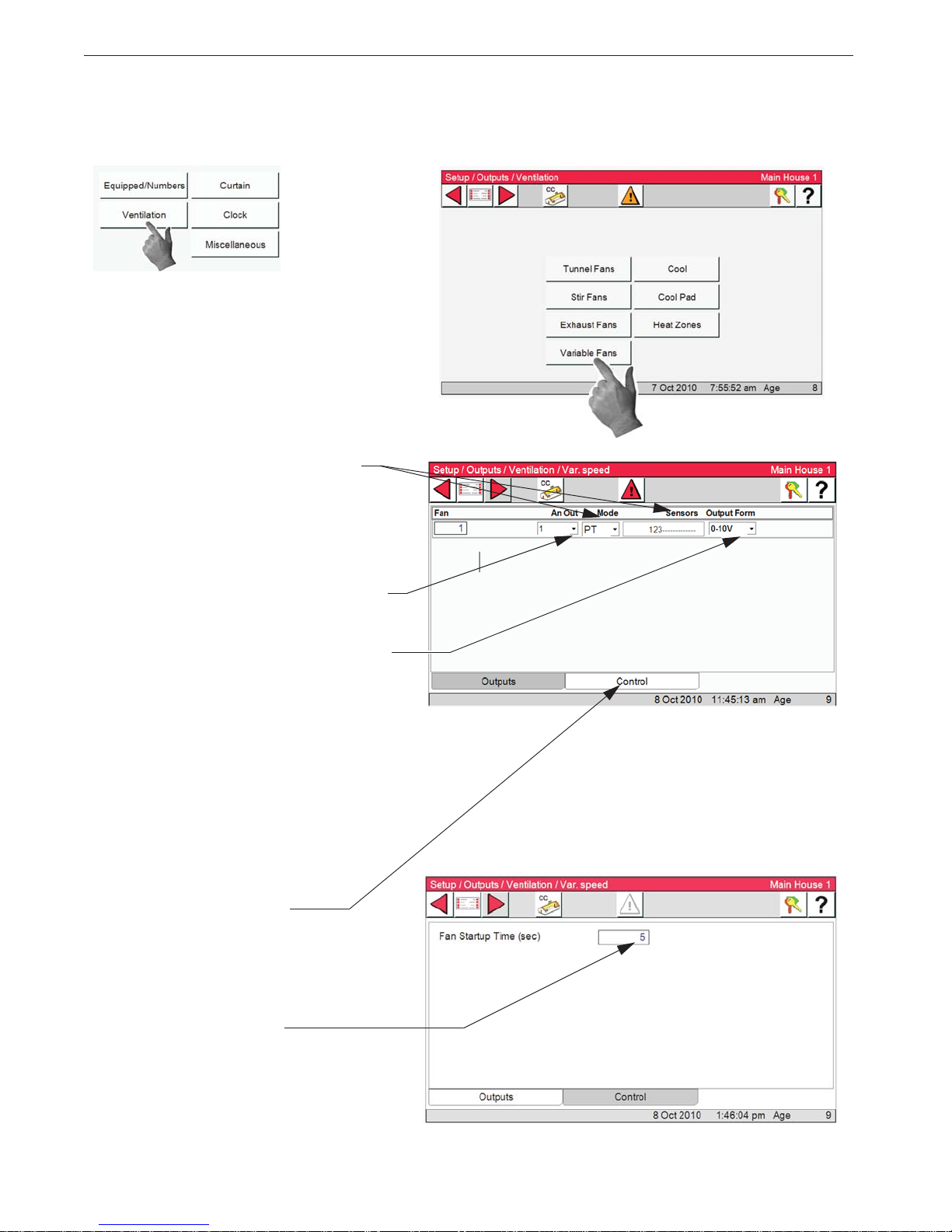

1. Select the Ventilation button.

2. Select the Variable Fans button.

3. Assign Sensors and Mode values

to the Variable Speed Fans.

4. Assign the analog output from the

dropdown.

5. Assign the Output Form- You will

need to know the input range of the

Frequency drive before choosing 0-10

or 10-0 vdc from the dropdown.

5. Assign the Output Form- You will

need to know the input range of the

Frequency drive before choosing 0-10

or 10-0 vdc from the dropdown.

5. Press the Control Tab

6. Enter the amount of startup time needed

to open the fan shutters.

Example: If 5 is entered, the Variable

speed fan will run at full speed for 5 sec. at

startup, then return to the current speed.

Ventilation-Variable Fans

Note: The Var. Speed output is a 0-10 or 10-0 vdc output on the IO board not the Relay box.

41

MT2398C

Control Setup Chore-Tronics® 3 Control

1. Select the Ventilation button.

2. Select the Cool button to assign the Cool outputs..

3. Assign Relays, Sensors and Mode

values to each Cool item.

Relays

Mode

Sensors

Ventilation-Cool

The Cool outputs can be used for cool pads, fogger pads and or inside foggers. The Cool output can be

setup to be on/off based the temperature setting in the Output & Temperature. A t

imer can be assigned to

the Cool output. If a timer is assigned, at the on temperature the output will start timing on/off based on

the timer setting and will not run constant.

Sixteen Cool outputs can be assigned up to four relays per Cool output.

42

MT2398C

Control Setup Chore-Tronics® 3 Control

1. Select the Ventilation button.

2. Select the Cool Pad button to assign the Cool Pad outputs.

3. Assign a Relay, Sensors and a

Mode value to the Cool Pads.

Ventilation-Cool Pad

The COOL PAD output is very different from a COOL output.

It is not intended that the COOL PAD

output and the COOL output would be used together, but it is possible. Both outputs are there to give the

user the choice on which type of output to use. The COOL PAD's relay operation is designed to begin the

cooling caused by the cooling pad by first adding 5 seconds of water to the pad every 5 minutes. If the

temperature is still with the "Cool Pad Range" after 4 doses of 5 seconds of water, the amount of water

added to the pad every 5 minutes remains the same. If the temperature is above or below the temperature

limits of the "Cool Pad Range", the amount of water "on" time each 5 minutes is increased or decreased

5 seconds. With the default settings the temperature is only checked every 20 minutes. If it is desired for

the temperature to be checked more often if a sudden large temperature change occurs, then values should

be entered in the "Extra aggressive if" lines (Items and , Figure ). For example, The Control is set to be

extra aggressive if 3.0 degrees above the upper limit of the COOL PAD range. Whenever the temperature

is more than 3.0 degrees above the upper limit of the COOL PAD range the Control will begin checking

the temperature every 5 minutes (every repetition rate) instead of every 20 minutes (every 4 repetition

rates) until the temperature returns to less than 3.0 degrees above the COOL PAD range. The default extra

aggressive settings are 3 degree.

43

MT2398C

Control Setup Chore-Tronics® 3 Control

1. Select the Control Tab.

2. Measure the number of seconds it takes for water to start

coming out of the holes in the pad system's top distribution

pipe after turning on the COOL PAD manual toggle switch.

This should be entered as the "Water pre-fill time" (Item 2,

right) and is likely to be different for the different system

manufacturers. This amount of time is added to the water

run time each repetition because the top distribution pipe

drains out during the off time of the on-off cycle.

Important!! The parameters that determine exactly how the

COOL PAD function reacts are programmed in two separate

screens, (Setup/Outdputs/Ventilation/Coolpad and Ventilation Setting/CoolPad). Chore-Time strongly recommends that the factory default settings be used, unless poor control of temperature during pad operation is noticed. Chore-Time also recommends

that CTB service personnel is contacted before changing the settings.

2

3. Measure the number of seconds it takes for water to start

dripping out the bottom of a dry pad after the COOL PAD

manual toggle switch is turned to the on position. This amount of time should be entered as the "Time

to wet dry pad" (Item 3, above). This will be less than the time to make the pad completely soaked.

When the actual water on time reaches this "Time to wet dry pad" value, the next step is to run the

water continuously, assuming that the temperature is above the Cool Pad Range at the next temperature

3

4

4. If water running on the pad continuously is not

desired, then the "Max water allowed" value

(Item 4, right) should be changed so that it is less

than the repetition rate time. Once the temperature

decreases back below the Cool Pad Range, the actual water on time will return to the "Time to wet

dry pad" value again. From there the water on time

changes in the normal way, with 5 second changes

every 20 minutes, depending on the temperature

check points.

5

5. The "Actual water on time" is for information

only. Showing the value makes it possible to create a graph of it's variations if you have the PC

connection (C-Central). The "Flush cool pad", (Item 5, previous page) is a feature that allows you

to run the water continuously at a time of day each day for the duration you specify. This will guarantee that at least once a day the pad will be flushed to keep it as clean as possible and help lengthen

the pad life. Leaving dashes for the settings disables this feature. Flushing the pad in the night will

have the advantage of causing very little unwanted temperature drop.

On a very hot day it would be possible for the water to be running continuously and the temperature to be

in the "Cool Pad Range". A more moderate day might result in the water running a very small amount of

time in order to keep the temperature within the "Cool Pad Range". Similarly, on a low humidity day the

amount of water required to keep the temperature within the "Cool Pad Range" would be less than for a

high humidity day. The Control will adjust the water as required to keep the temperature in the "Cool Pad

Range". If it is desired to not allow the water to run continuously, then the Max water allowed (Item 4,

Below) value should be changed so that it is less than the repetition rate value.

44

MT2398C

Control Setup Chore-Tronics® 3 Control

1. Select the Heat Zones button.

3. Assign Relays, Sensors, Mode values and

Names just as you did for Tunnel Fans. (See pre-

vious)

3. Select the Control Tab.

4. Select the box if you do not want the Heat

Zones to run in Tunnel assist.

1. Select the Ventilation button.

1. Use the Back button to get to the Setup/Outputs screen and push the Curtain Button.

Ventilation-Heat Zones

Curtain

45

MT2398C

Control Setup Chore-Tronics® 3 Control

2. In this screen you will assign Relays to any

and all of the air inlets connected to the Control.

3. Select Sidewall Inlet

Once you enter in the Open relay number the Control

will automatically enter the Close relay.

Two inlet machines can be assigned to the Sidewall

inlet output. Both machines will be given an open or

close signal at the same time.

Note. The Open and Close outputs must always be side by side on the same relay row.

4. Select the Control tab and choose Calculated or Fixed

Anticipation.

Calculated Inlet Anticipation– The Control determines

the amount of time the Inlets will open prior to the Fans

assigned to the Minimum Ventilation timer turn on at a

given static pressure control limits. (Screen not shown)

Fixed Inlet Anticipation- The amount of time the Inlets

will open prior to the Fans assigned to the Minimum Ventilation timer turn on.

Open Relay Number

Close

Relay Number

Sidewall Inlet

46

MT2398C

Control Setup Chore-Tronics® 3 Control

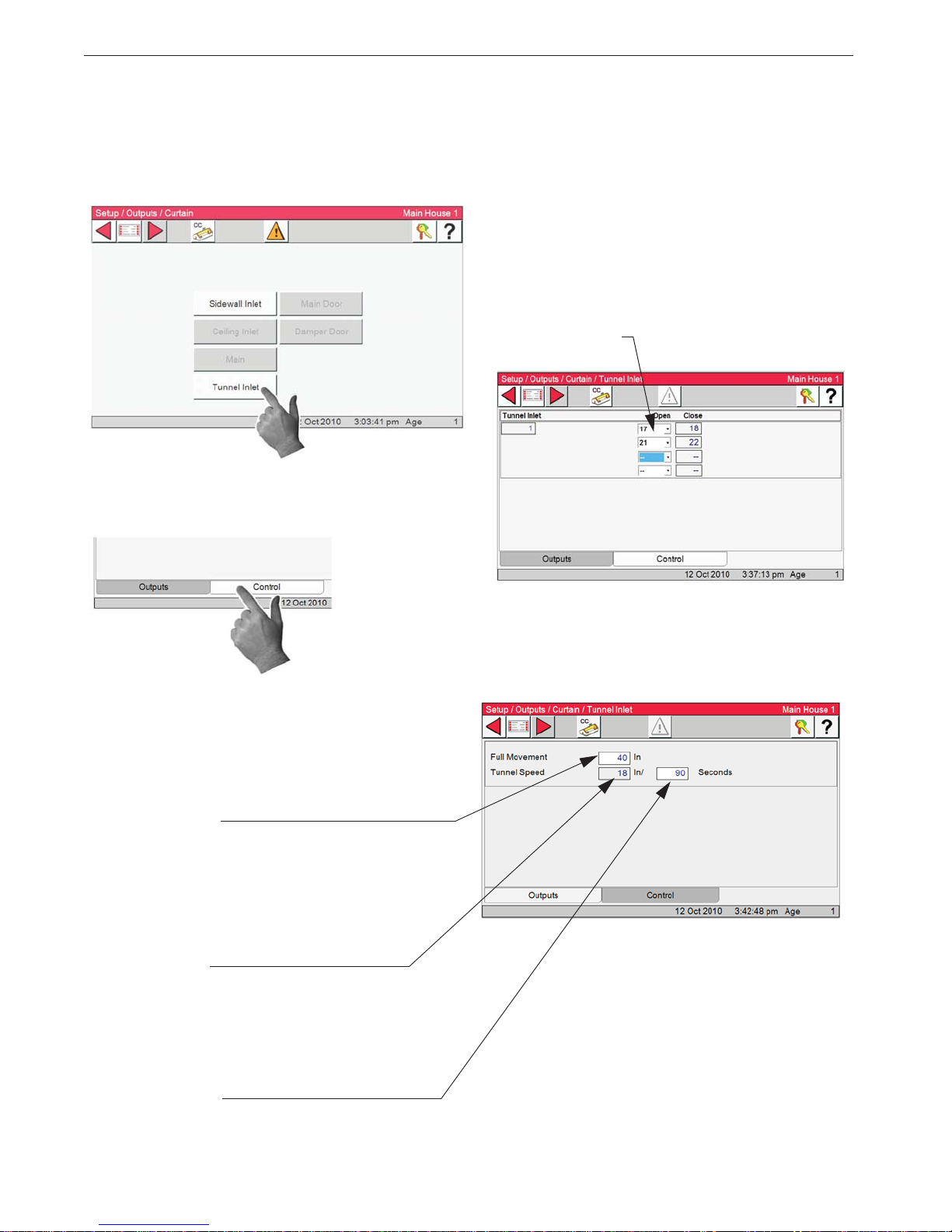

1. Use the Back button to get to the Setup/Outputs screen and push the Tunnel Inlet Button.

2. When you enter in the Open relay number

the Control will automatically enter the Close

relay.

Up to four machines can be assigned to the

Tunnel inlet output. All machines will be given an open or close signal at the same time.

Note. The Open and Close outputs must always be side by side on the same relay row.

Open Relay Number

3. Press the Control Tab

4. These numbers are needed for proper

Mode transitions. (Power to Tunnel and

Tunnel to Power).

Full Movement

Measure the full movement of the Curtain or

Tunnel door and enter that number in the FULL

Movement edit box.

Tunnel Speed

With a closed inlet measure 18 inches of the tunnel curtain or door movement. Toggle the open

relay switch to the Manual position.

Time how long it takes to move the the Inlet 18

inches. Enter that number in to the Tunnel

Speed edit box.

Tunnel Inlet

47

MT2398C

Control Setup Chore-Tronics® 3 Control

2. Press the Clock button.

All of the Clock output Relays are assigned

here.

1. Select the Main menu button. Select the

Setup button from the Main

Menu screen. Finally, select the Outputs

button.

1. Press the Light button.

2. Up to four Light clocks can be assigned

with four relays for each Light clock. Use the

Add button to add additional clocks.

External Light Dimmer Control

3. In the "An Out" column, select from the drop-

down the Analog out (on the IO board) used to

control the Dimmer.

4. In the Output from column select ether 0-10

vdc or 10 to 0 vdc.

( 0 vdc = no light or 10 vdc = no light)

2

3

4

Clock Assignments

Light Clock

48

MT2398C

Control Setup Chore-Tronics® 3 Control

1. Press the Feed button.

2. Enter the Relay or Relays that the feeders

have been wired to. Only one Feed clock can

be assigned with up to four relays. All four relays will be activated at the same time.

3. Select the Control Tab.

4. If the you wish to turn the Fill System OFF,

check the box.

If a Dry Contact Relay whose coil is energized

when the fill system's Hopper Level Switch

calls for the fill system to run is connected to

a digital input of the Control Then the Control

can be set to detect excessive fill system run

time and activate the Alarm Relay.

Feed Clock

49

MT2398C

Control Setup Chore-Tronics® 3 Control

2. The Spare Clocks have 8 on and

off events and cannot be curved. A

maximum of 8 Spare Clocks can be

used, with up to four Relays per

Clock. To add additional Spare

Clocks to the list, select the Add

button. Each Spare Clock can be

given a specific name to identify the

Clock with a particular use.

Enter the Relay number (s) For each

Clock in the list and change the

name if needed.

1. Press the Spare button.

Four Relays per Clock

Clock Name

(editable)

Select "Add" to add Clocks

Spare Clock

50

MT2398C

Control Setup Chore-Tronics® 3 Control

1. Select the Main menu button. Select the

Setup button from the Main

Menu screen.

2. Press the Outputs button.

3. Press the Miscellaneous button.

4. select the Backup button.

5. Assign a Backup relay from the dropdown list of avalible Relays.

Backup Relays are needed when the

Chore-Tronic's Standard or Expanded

backup is installed for backing up the

Control. If the the brain of the Control

goes down for any reason, the Backup Relay will open, and the first stage of backup

will be activated. See backup wiring di-

agram in the Backup installation manuals. Part # MT1805A of MT1561b

Miscellaneous Outputs

Backup Relay

51

MT2398C

Control Setup Chore-Tronics® 3 Control

1. Select the Main menu button. Select the Setup button from the Main Menu screen.

2. Select the Sensor button.

Verify Relay Assignments

After assigning all the outputs, verify the Relay assignments with the Output Stickers on the

Manual Toggle Switches.

Manual Toggle Switches

Feed Clock 1

Feed Clock 2

Feed Clock 3

Relay Assignments

(Inside Cover of Relay Box)

Assignments

Sensors

52

MT2398C

3. Power Mode- The temperature sensor (s) assigned here will determine what the control will use to

transition from Power to Tunnel mode.

4. Temp. Influence On Minimum Ventilation

The temperature sensor (s) assigned here will determine the amount of time added or subtracted

away from the Minimum Ventilation timer in Power mode.

For this feature you must first check the box in the (Setup/house screen) for Temp. Influence On

Minimum Ventilation.

Ventilation timer rampingIf the sensor(s) that are assigned to the Minimum Ventilation fan(s) temperature is at or below set temperature then the fans will use the ON and OFF times that are listed for the Minimum Ventilation Timer. If the sensor (s) assigned to the Ventilation Time Ramping temperature is between set temperature

and the fans' ON temperature the control will adjust the amount of ON time between the Min Ventilation value and the Max value. The OFF time will be adjusted by the same amount of time that the

ON is adjusted, thus keeping the total cycle time constant. The temperature is checked 30 seconds before the beginning of the ON time cycle of the Minimum Ventilation Timer. Once the fans' temperature sensor(s) reach the fans' ON temperature, the fan will turn on and run continuously until the fans'

OFF temperature is reached.

Example: The set temperature is 70.0°F and the fans assigned to the Min Vent timer ON temperature

is 72.0°F. The Minimum Ventilation Timer values are 30 seconds ON time and 270 seconds OFF

time. The maximum ON time is 210 seconds. If the sensor(s) assigned to the Ventilation Time Ramping temperature is 71.0°F at the beginning of the anticipation cycle, then the fans will have an ON

time of 125 seconds and an OFF time of 175 seconds

34

Control Setup Chore-Tronics® 3 Control

53

MT2398C

Control Setup Chore-Tronics® 3 Control

1. Select the Main menu button. Select the Setup

button from the Main Menu screen.

2. Select the Function button.

4. Stir Timer Delay time (sec)

Enter the amount of time you want the Stir fans to delay after the Min.Vent.

fans have turned off.

In screen Setup/Output/Equipped, Stir fans must be checked, and at least one

Relay assigned in the Setup/Outputs/Ventilation/Stir Fans screen to use this

feature.

3. Alternate Min Vent Fans

(Select if you want feature)

The Min Cycle (Alternate Minimum Ventilation

fans) allows the fan(s) assigned to the Min Vent

Timer to alternate with the fans assigned to the

Min Cycle. In the above

example, Exhaust Fans 1 and 2 will run on the

Min Vent timer first. At the next ON time

of the Min Vent Timer the fans assigned Exhaust

Fans 3 and 4 (the fans assigned to the Min Cycle)

will run. The feature will stop when the fans assigned to the Min Vent Timer turn on due to temperature.

3

4

Function

54

MT2398C

Control Setup Chore-Tronics® 3 Control

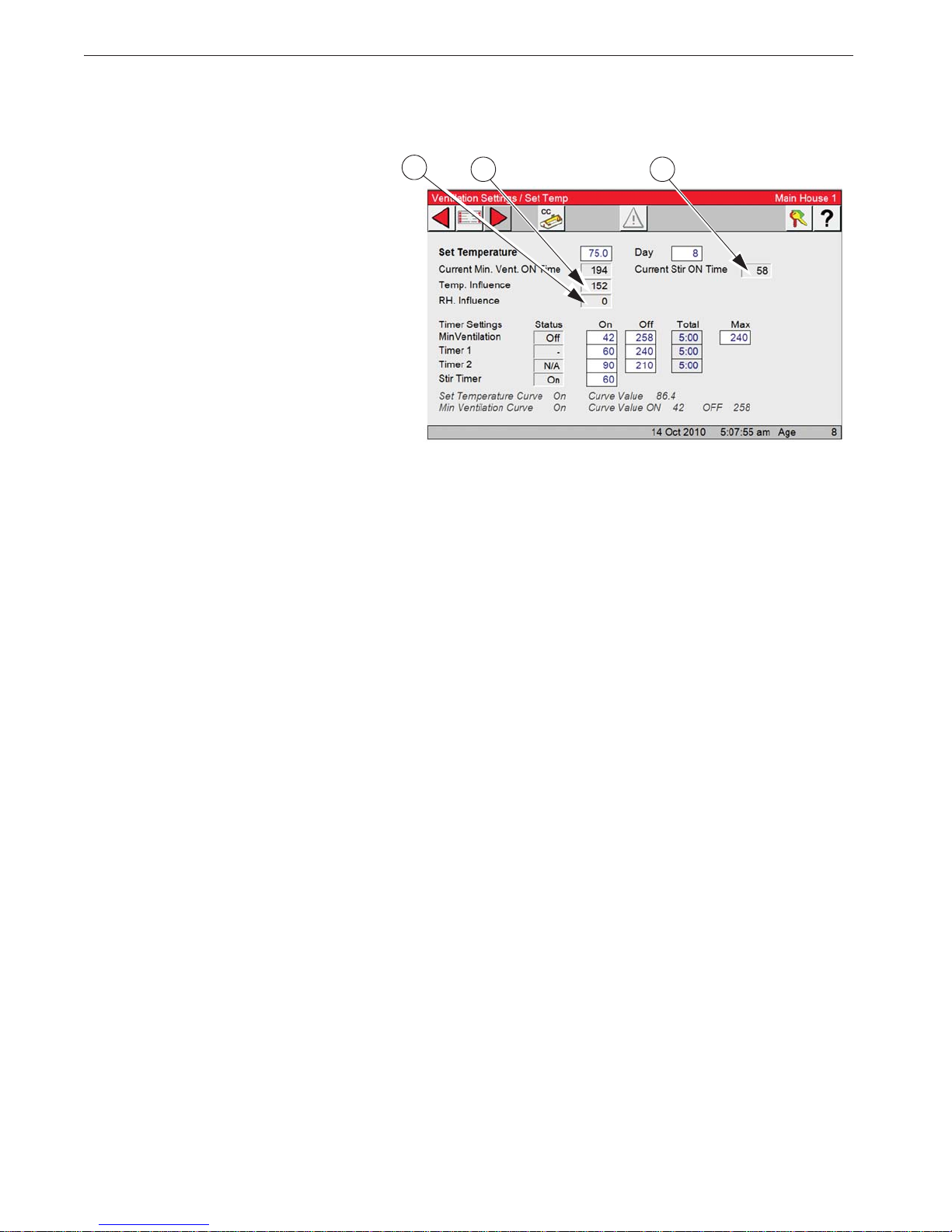

1. Select the Main menu button. Select the Ventilation Settings button.

2. Select the Set Temp Timer button.

Note: Only the values with a white background

are editable. All other boxes are information only.

3. Set temperature

Set Temperature is a very important parameter. All other temperatures are dependant on the set temperature. When the

set temperature is changed, all other temperature settings are also changed by the

same amount to maintain the same temperature differences relative to the set

temperature.

4. Day

Day is the age of the animals or birds.

Changing the age with Set temp and or

Min Vent curve on will change their values to the current curve values.

3

4

5. Current Min.Vent. ON Time

Current Min. Vent. ON Time is the current amount of ON time the fans assigned to the Minimum

Ventilation Timer will run while cycling on the timer. This amount of time compines both Temperature and if being used RH influence. If (TMP) is displayed the Min. Vent. Fan (s) are on by

temperature.

6. The status of the Set Temperature and Min Vent curve and curve values are displayed at the

bottom of this screen.

The Temp Curve and Min Vent Curve "on" indications are not editable. They only indicate that

the curve(s) are "on" and the curve's value. If a curve is not "on", there is no indication in this area.

The values shown at the bottom of the screen are the current curve's values. If the actual values

are different, the difference represents the "offset". Editing the actual values to be the same as the

values displayed at the bottom of the screen will erase the offset(s). An "offset" is caused if you

change a value when its curve is on.

5

6

Ventilation Settings

Set Temp Timer

55

MT2398C

7. Current Stir ON Time

Current Stir ON Time is the current amount of Stir On Time. If (TMP) is displayed the Stir Fan

(s) are on by temperature.

The "stir on" Timer is different than

the other Timers. It can only be attached to Stir Fan Outputs in the "Outputs" screen. The "stir on" time value

is set in this screen. The purpose of

this feature is to allow you to cause a