USER HANDBOOK

PART NUMBER 10H52152PU9C rev.8

EDP70 PLUS

UNINTERRUPTIBLE POWER SYSTEM

24/36/50/80kVA —

3 phase input / 3 phase output

1) SAVE THESE INSTRUCTIONS

This manual contains important instructions for the EDP70 PLUS which should be followed during

installation and maintenance of the UPS and associated batteries.

2)

The installation must be inspected by trained technicians.

The instructions must be followed.

3)

When external batteries are provided by the Customer and not Chloride, reference must be made to

the installation instructions provided by the battery supplier.

1)

The AC and DC supplies to the EDP70 PLUS UPS and the AC output from the UPS MUST be fed

through suitably rated circuit breakers or fuses and isolating switches suitable for branch circuit operation.

2)

Any external battery cabinet connected to the UPS MUST be provided with an over-current protection

device per UL1778 Par. No. 28.4

3)

To reduce the risk of fire or electric shock, the equipment must be installed indoors, in a humidity

and temperature controlled environment which is free from conductive contaminants.

1)

DO NOT REMOVE COVERS DURING NORMAL OPERATION. The panels will be removed during

installation, however this should only be undertaken by qualified technicians. It should be ensured

that the UPS is switched off and that all power sources are disconnected (A.C. mains and Battery)

before either the rear or side panels are removed.

FOREIGN OBJECTS MUST NOT BE INTRODUCED INTO THE VENTILLATION GRILLES.

2)

HAZARDOUS VOLTAGES are present within the EDP70 PLUS even when it is switched off.

3)

Fuses must ONLY be replaced with the same type and rating.

The EDP70 PLUS contains a battery which can be DANGEROUS if interfered with. Contact the

4)

supplier for replacement.

The UPS and/or its components must be disposed of as notifiable waste in accordance with local

5)

pollution control (special waste) regulations.

page

2 --

MI00/10056 rev. 8 —05/2006

3

WARNING

The UPS contains hazardous voltages, even when all switches are open.

In case of fire in the installation area, do not use water to extinguish fire.

ELECTRICAL PRECAUTIONS:

If the UPS is in By-pass mode and the Output switch is closed, no indications will be displayed;

fans will however function, and hazardous voltages are present downline from the static

switches.

EMERGENCY PROCEDURE

In the case of an emergency, the load supply can be interrupted by switching off all the switches

fitted in the UPS.

ELECTRIC SHOCK

Switch off power; use dry insulating material for protection when pulling the injured person clear

of conductors.

NEVER TOUCH THE INJURED PERSON WITH BARE HANDS UNTIL CLEAR OF

CONDUCTORS. SEEK QUALIFIED ASSISTANCE IMMEDIATELY.

INJURIES CAUSED BY CONTACT WITH CORROSIVE LIQUIDS

In normal conditions, installed batteries are sealed. A damaged battery container may however

leak electrolyte, or cause the latter to come into contact with battery parts.

In the event of electrolyte contact with the eyes, rinse eyes thoroughly with a saline solution or

fresh water for at least 10 minutes.

In the event of electrolyte contact with skin, rinse the affected area with abundant water. Remove

contaminated clothing. Cover affected area with dry gauze.

If electrolyte is swallowed, do not induce vomiting. Administer large quantities of milk

or water.

IN ALL CASES, SEEK MEDICAL ATTENTION IMMEDIATELY

MI00/10056 rev. 8 — 05/2006-- page

Contents

1.0 INTRODUCTION ..................................................................................................9

1.1 Summary of the manual...................................................................................................... 9

1.2 Summary of the equipment ................................................................................................ 9

1.3 Block diagram.................................................................................................................... 10

1.4 Functions ........................................................................................................................... 11

1.5 Operational modes............................................................................................................ 12

2.0 SAFETY..............................................................................................................14

2.1 General safety.................................................................................................................... 14

2.2 Symbols ............................................................................................................................. 14

2.3 Electrical precautions ....................................................................................................... 15

2.4 Battery precautions........................................................................................................... 15

2.5 Battery safety equipment.................................................................................................. 15

3.0 STORAGE ..........................................................................................................16

4.0 INSTALLATION .................................................................................................16

4.1 Mechanical characteristics............................................................................................... 16

4.2 Installation ......................................................................................................................... 26

Recommended wire sizes .......................................................................................................... 27

4.4 Ventilation.......................................................................................................................... 29

5.0 CONNECTION....................................................................................................30

5.1 Electrical connections ...................................................................................................... 32

5.2 24 – 12/18/24kVA ............................................................................................................... 33

5.3 36 – 24/30/36kVA ............................................................................................................... 36

5.3 EDP70 PLUS 50/80kVA...................................................................................................... 39

5.4 Signal connections ........................................................................................................... 42

6.0 CONTROLS........................................................................................................43

6.1 User Controls..................................................................................................................... 43

6.2 Control Panel ..................................................................................................................... 44

7.0 START UP..........................................................................................................45

8.0 MAINTENANCE BYPASS .................................................................................45

9.0 SHUT-DOWN .....................................................................................................46

9.1 Installing the EPO.............................................................................................................. 46

10.0 VISUAL AND AUDIBLE ALARMS ....................................................................47

10.1 Silencing Audible Alarm ................................................................................................... 47

page

4 --

MI00/10056 rev. 8 —05/2006

5

10.2 Mimic .................................................................................................................................. 47

10.3 Liquid Crystal Display....................................................................................................... 47

10.4 Display Page Headings ..................................................................................................... 48

10.5 Abnormal operating mode messages.............................................................................. 55

10.6 Power History .................................................................................................................... 60

10.7 Battery Test........................................................................................................................ 61

10.8 Battery Autonomy Test ..................................................................................................... 61

10.9 Resetting data loss manually ........................................................................................... 61

11.0 COMPUTER INTERFACE .................................................................................62

11.1 AS400.............................................................................................................................. 62

11.2 RS232 ................................................................................................................................. 63

12.0 REMOTE ALARMS............................................................................................63

13.0 BATTERIES .......................................................................................................64

13.1 EDP70 PLUS/24/18/12 : Battery Installation/Start-up...................................................... 64

13.2 EDP70 PLUS/24/18/12 : Optional Battery Cubicle ........................................................... 65

13.3 EDP70 PLUS above 24KVA: Battery Installation/Start-up .............................................. 66

13.4 EDP70 PLUS above 24KVA: Battery Cubicle .................................................................. 66

14.0 MAINTENANCE AND SPARE PARTS .............................................................66

MI00/10056 rev. 8 — 05/2006-- page

Figures

Figure 1 – Block diagrams – 24/36kVA

Figure 2 – Block diagram – 50/80kVA

Figure 3 – Normal operation

Figure 4 – Utility Supply failure

Figure 5 – Re-establishing the Utility Supply

Figure 6 – Transferring the Load onto the Reserve Supply

Figure 7 – 24 Footprint and cabinet dimensions

Figure 8 – 36 Footprint and cabinet dimensions

Figure 9 – 50/80 Footprint and cabinet dimensions

Figure 10 – “A” Battery Cabinet Drawing for 24/36kVA Ratings

Figure 11 – “B” Battery Cabinet Drawing for 24/36kVA Ratings

Figure 12 – “E” Battery Cabinet Drawing for 50/80kVA Ratings

Figure 13 – “F” Battery Cabinet Drawing for 50/80kVA Ratings

Figure 14 – “C” Battery Cabinet Drawing for 36/50/80kVA Ratings

Figure 15 – “D” Battery Cabinet Drawing for 50/80kVA Ratings

Figure 16 – UPS Ratings

Figure 17 – Connection diagrams

Figure 18 - 24 – 12/18/24kVA: Switches and Breakers

Figure 19 - 24 – 12/18/24kVA: Switches

Figure 20 - 24 – 12/18/24kVA: Cable Connections

Figure 21 - 36 – 24/30/36kVA: Switches and Breakers

Figure 22 - 36 – 24/30/36kVA: Connections

Figure 23 - 36 – 24/30/36kVA: Cable Connections

Figure 24 – 50/80kVA: Switches and Breakers

Figure 25 – 50/80kVA: Connections

Figure 26 – 50/80kVA: Cable Connections

Figure 27 – Control panel

Figure 28: Power History Structure

Figure 29 EDP 70 Plus Computer Interface Pin Layout

Figure 30 EDP70 PLUS Remote Alarms Pin Layout

Figure 31- EDP70 PLUS/24/18/12: Internal Battery Shelves

12

12

26

43

10

11

13

13

17

18

19

20

21

22

23

25

30

33

34

35

36

37

38

39

40

41

60

62

63

65

24

page

6 --

MI00/10056 rev. 8 —05/2006

7

EQUIPMENT DELIVERY AND STORAGE

Delivery

The equipment and battery are delivered separately. On receipt, the packaging must be checked for any signs of

damage. Any damage or missing parts should be reported to the carrier within 24 hours of delivery.

Unpacking

Care should be taken when unpacking to avoid damaging the equipment or battery; in particular, avoid short circuiting

battery terminals. All packing materials should be checked before disposal to ensure that no items are discarded. The

equipment panel rating plate should be checked to ensure that supply voltage and output rating correspond to the

equipment and load and that the mode of operation is correct.

Handling

Keep equipment and battery upright at all times, and handle with care. Either may be damaged if dropped or subject to

severe impact. Particular care should be taken to protect the controls and instruments.

a) Leave the equipment in its packaging and transport it with a fork lift.

b) Cut the tapes and remove the packing case by lifting it upwards.

c) Unscrew the screws fastening the pallet to the cubicle feet.

d) Lift the cubicle and remove the pallet.

Storage

Store the equipment and battery in a clean, dry place, free from water, condensation, dirt and extremes of temperature.

Sealed lead acid battery cells which are supplied filled and charged must be given a boost charge at least every 3

months.

Sealed Nickel-Cadmium battery cells which are supplied filled and discharged must be charged and discharged before

storage.

Sealed Nickel-Cadmium battery cells which are supplied dry must be filled, charged and discharged before storage.

Sealed spare battery cells must be charged at least every 3 months.

Failure to comply with the Manufacturer’s instructions may result in the battery not reaching its rated performance and

having a shortened life.

MI00/10056 rev. 8 — 05/2006-- page

?

page

8 --

MI00/10056 rev. 8 —05/2006

9

1.0 INTRODUCTION

1.1 Summary of the manual

This handbook provides for the safe installation, startup and use of the EDP70 PLUS Uninterruptible Power System

(UPS). The Company recommends that the equipment be installed and regularly maintained by a Chloride

Authorized personnel.

DO: - read the User Handbook before operating the EDP70 PLUS UPS.

- keep a log of all incidents.

- protect the batteries from damage. Batteries leak acid; avoid contact with skin,

clothes or eyes.

DO NOT: - operate the control switches.

- operate the EDP70 PLUS UPS with any covers removed.

- obstruct the ventilation grilles.

1.2 Summary of the equipment

The EDP70 PLUS Uninterruptible Power System (UPS) totally isolates the load from voltage drops, spikes, transients

frequency variations in the utility supply.

In the event of failure or brownout of the AC utility supply, an internal audible alarm sounds and an LED on the control

panel illuminates, the EDP70 PLUS UPS will continue to provide safe, clean continuous power, without interruption, from

the battery, for a duration dependent on battery capacity and output load.

The audible alarm alerts the user to start a safe orderly shutdown of the load. When the AC utility supply returns to

normal, the EDP70 PLUS UPS automatically recharges the battery ready for any future power failure.

The microprocessor display panel provides access to very detailed information regarding the status of the supplies and

EDP70 PLUS UPS. Refer to current publication for detailed specification.

The block diagram, shows the main functional sub-assemblies of the EDP70 PLUS UPS. The AC three phase utility

supply is rectified to provide direct current, which maintains the battery in a fully charged state and also supplies the

inverter, which provides the three phase output via an electronic static switch.

Normally the supply of the reserve line is taken from the AC utility input, but special units, with a separate reserve input

supply, are available. This allows the inputs to be supplied from independent three phase sources.

Provided the reserve supply is within limits, the inverter will match the output frequency with the reserve supply

frequency. The inverter has its own internal crystal control to stabilize the output frequency if the reserve supply

frequency is out of limits. The electronic static switch switches the output from the inverter to the reserve supply, without

interruption, to meet any load current surges, or to supply the load if the battery is discharged during an AC utility supply

failure.

Maintenance and testing can be carried out on the EDP70 PLUS UPS without interrupting the output, by switching the

load from the reserve supply to the maintenance bypass circuit. This work should only be carried out by Chloride-trained

personnel.

MI00/10056 rev. 8 — 05/2006-- page

1.3 Block diagram

24kVA - STANDARD CONFIGURATION

S3

Reserve Supply

208Y/120V

S2

S1

AC Supply

IN THE ABSENCE OF A SEPARATE RESERVE

SUPPLY THE RESRVE IS DERIVED FROM THE

AC UTILITY INPUT WITH THE JUMPER

CONNECTED AS INDICATED

Reserve Supply

208Y

S1

AC Supply

IN THE ABSENCE OF A SEPARATE RESERVE

SUPPLY THE RESRVE IS DERIVED FROM THE

AC UTILITY INPUT WITH THE JUMPER

CONNECTED AS INDICATED

Maintenance By-pass

290

3

Battery

Contactor

208150

1

5

4

144 Cells

(Internal)

2

36kVA - STANDARD CONFIGURATION

480

208Y

S2

S3

Battery

Contactor

3

250

1

Maintenance By-pass

5

208Y

4

240 Cells

(External)

2

S4

S4

page

Reserve Supply

480V

AC Supply

IN THE ABSENCE OF A SEPARATE RESERVE

SUPPLY THE RESRVE IS DERIVED FROM THE

AC UTILITY INPUT WITH THE JUMPER

CONNECTED AS INDICATED

10 --

MI00/10056 rev. 8 —05/2006

36kVA - 480V/208V CONFIGURATION

S1

S3

S2

208Y

250

480

Maintenance By-pass

3

208Y

1

Battery

Contactor

240 Cells

(External)

2

Figure 1 – Block diagrams – 24/36kVA

5

S4

4

11

S3

Maintenance Bypass

Reserve

Supply

480V

AC Supply

S2

S1

IN THE ABSENCE OF A SEPARATE

RESERVE SUPPLY THE RESERVE IS

DERIVED FROM THE AC UTILITY

INPUT WITH THE JUMPER

CONNECTED AS INDICATED

Battery

Contactor

240 Cells

(External)

3

1

2

S5

5

S4

4

480Y/277V

208Y/120V

Figure 2 – Block diagram – 50/80kVA

The uninterruptible power system consists of the following:

1 - RECTIFIER/INVERTER S1 = Equipment ON/OFF switch

2 - BATTERY S2 = Equipment Reserve switch

3 - BACKFEED PROTECTION S3 = Equipment By-pass switch

4 - INVERTER STATIC SWITCH S4 = Equipment OUTPUT switch

5 - RESERVE STATIC SWITCH (INVERTER OUTPUT switch for 50/80kVA only)

S5 = RESERVE OUTPUT switch for 50/80kVA only

1.4 Functions

The rectifier/battery charger transforms the alternating current of the mains supply to direct voltage to maintain the

battery in a fully charged state and also supply the inverter.

The battery is an energy reserve that is used by the inverter and the load whenever the mains supply fails.

The inverter changes the direct voltage from the rectifier or from the battery into a three phase sinusoidal alternating

voltage for the external supply.

The function of the electronic static switch is to select one of the two sources of alternating voltage and to supply it to the

external load. The two sources of voltage supplied to the static switch are the output of the inverter and the reserve

supply. In normal working conditions, the static switch supplies the load from the inverter.

The switches permits maintenance and repair of the UPS, without interrupting the supply to the load.

MI00/10056 rev. 8 — 05/2006-- page

1.5 Operational modes

S3

S2

Maintenance By-pass

AC Supply

AC Supply

S1

Battery

Contactor

S3

S2

S1

Battery

Contactor

24/36kVA Ratings

Maintenance By-pass

50/80kVA Ratings

LOAD

S4

S5

S4

480Y/277V

LOAD

208Y/120V

Figure 3 – Normal operation

During normal operation the load is supplied by the mains through the rectifier and inverter. The rectifier also supplies

the current for recharging and maintaining the battery in a fully charged state.

Reserve Supply

AC Supply

S3

S2

S1

Maintenance By-pass

S4

LOAD

Battery

Reserve Supply

Contactor

S3

S2

S1

24/36kVA Ratings

Maintenance By-pass

S5

S4

480Y/277V

LOAD

208Y/120V

AC Supply

Battery

Contactor

50/80kVA Ratings

Figure 4 – Utility Supply failure

When the utility supply voltage is absent or outside the allowed tolerances, the battery supplies the inverter. This will be

indicated on the UPS front panel display and the Remote Alarm Unit (if fitted). The standby time available depends both

on the capacity of the battery and on the size of load. It is possible to extend autonomy by reducing the output power by

disconnecting non-important loads. In all cases, the alphanumerical display shows the residual autonomy.

page

12 --

MI00/10056 rev. 8 —05/2006

13

Reserve Supply

S3

S2

Maintenance By-pass

S4

S5

S4

480Y/277V

208Y/120V

AC Supply

Reserve Supply

AC Supply

S1

Battery

Contactor

S3

S2

S1

Battery

Contactor

24/36kVA Ratings

Maintenance By-pass

50/80kVA Ratings

Figure 5 – Re-establishing the Utility Supply

When the utility supply returns within acceptable limits, the UPS returns automatically to normal operation mode as

previously described. The rectifier now starts to recharge the battery. However, until recharge has been completed, any

further mains failure will result in reduced standby times.

Reserve Supply

AC Supply

S3

S2

S1

Battery

Contactor

Maintenance By-pass

S4

24/36kVA Ratings

Reserve Supply

AC Supply

S3

S2

S1

Battery

Contactor

Maintenance By-pass

50/80kVA Ratings

S5

S4

480Y/277V

208Y/120V

Figure 6 – Transferring the Load onto the Reserve Supply

Transfer onto the reserve line is caused by two conditions:

a) inverter stop

b) overload

In both instances the load is transferred onto the reserve without interruption. If the overload is temporary, the system will

re-transfer from reserve to inverter as soon as the it ceases. This allows for the initial start-up of loads with high or

excessive switch-on currents.

MI00/10056 rev. 8 — 05/2006-- page

2.0 SAFETY

Read all instructions carefully before installing or operating the equipment.

2.1 General safety

The procedure described in these instructions is intended for use by persons experienced in the operation of

Uninterruptible Power Systems and ancillary equipment.

Persons unfamiliar with this type of equipment should seek guidance from experienced personnel.

The EDP70 PLUS UPS is designed to be operated in accordance with existing safe operating procedures.

These instructions are not intended to replace existing safety practices.

If there are any questions regarding the safe operation of the system, contact a Chloride service representative.

This equipment is designed and built for safe operation when used to supply its rated load, providing it is installed as

specified by qualified, licensed and competent electricians.

Electrical energy can be supplied by the equipment and the battery.

2.2 Symbols

The following symbols appear in this book and in the unit:

Warning -

electrical shock and danger to personal safety.

DIRECT CURRENT SUPPLY

Hazardous voltages are present. If the instructions are not heeded, there is a risk of

ALTERNATING CURRENT SUPPLY

ON position of the switches

OFF position of the switches

Inverter Start Up

Inverter Shutdown

Audible Alarm Cancel Switch

For explanation see Para. 6.2. of this manual

For explanation see Para. 6.2. of this manual

For explanation see Para. 6.2. of this manual

page

14 --

MI00/10056 rev. 8 —05/2006

15

Page Right Control

Record Up

Record Down

For explanation see Para. 6.2. of this manual

For explanation see Para. 6.2. of this manual

For explanation see Para. 6.2. of this manual

2.3 Electrical precautions

Never handle a component or assembly without first confirming that no voltage is applied or present. Remove only those

protective covers that are essential to perform the repairs or adjustment currently required, and replace them as soon as

possible.

. Use only insulated tools.

. Place a rubber insulating mat in front of all equipment doors.

. Keep all door closed and locked at all times during normal operation.

2.4 Battery precautions

Always isolate the load before connecting or disconnecting the batteries or battery cells.

Ensure that batteries are fully isolated by disconnecting the battery connectors, opening circuit breakers, or both.

Remove all jewellery from hands, wrists and neck before working on batteries or battery cells.

Before leaning over batteries, remove any metal object that could fall out of pockets.

Do not place tools or other conductive objects on the batteries.

2.5 Battery safety equipment

When working on or handling batteries, ensure that the following items are worn:

. Eye goggles

. Rubber gloves

. Rubber apron

. Rubber boots

When batteries are being moved or worked on, ensure the following items are available in the immediate vicinity:

. An eye bath, eyewash station or equivalent

. A clean water source to wash spilled acids

. Absorbent materials to soak up spilled acids

. Disposal for contaminated materials.

MI00/10056 rev. 8 — 05/2006-- page

3.0 STORAGE

If the EDP70 PLUS UPS cannot be installed within sixty days of delivery, there is a danger of the integral battery

becoming discharged thereby sustaining permanent damage and affecting the standby period available and battery life.

The date the battery was last recharged and the date the battery is due for its next recharge are both stamped on the

packaging accompanying the unit. If you intend to store the unit, please refer to the recharge date.

When the EDP70 PLUS is due to be recharged, refer to the Installation instructions and connect the EDP70 PLUS UPS

to a temporary AC supply. The battery MUST be recharged for at least 24 hours every 3 months.

4.0 INSTALLATION

4.1 Mechanical characteristics

- Ambient temperature 18°F[-10°C] to 104°F [+40°C ]

- Relative Humidity (w/out condensing @ 68°F[20°C]) < 90%

- Max altitude (w/out derating) 3300 feet [1000 m] above sea-level

- Protection degree (panel fitted)

- Input cables bottom

- Air inlet bottom

- Air outlet rear

UPS model

Description

Size width

Total

Weight

(UPS +

Battery)

Floor Area

Floor

Loading

(UPS +

Battery)

Air-Flow

Acoustic Noise

100% Linear Load

depth

height

w/out cells

25 Ah cells

30 Ah cells

35 Ah cells

w/out cells

25 Ah cells

30 Ah cells

35 Ah cells

u.m. 24 36 50 80

In

[mm]

Lbs

[kg]

2[m2

In

Lbs/in

[kg/m2]

cfm

[mc/h]

dBA 52 55 55 62

28-.5 [700]

28.7 [730]

56 [1420]

880 [400]

1342 [610]

1456 [662]

1526 [694]

] 789 [0.511] 789 [0.511] 1019 [0.657] 1019 [0.657]

2

1.12 [782]

1.70 [1194]

1.85 [1296]

1.93 [1358]

235

[400]

27.5 [700]

28.7 [730]

56 [1420]

1300 [590]

n.a.

n.a.

n.a.

1.65 [1155]

n.a.

n.a.

n.a.

647

[1100]

35.4 [900]

28.7 [730]

63 [1600]

1342 [610]

n.a.

n.a.

n.a.

1.32 [930]

n.a.

n.a.

n.a.

1165

[1980]

35.4 [900]

28.7 [730]

63 [1600]

1800 [818]

n.a.

n.a.

n.a.

1.77 [1245]

n.a.

n.a.

n.a.

1553

[2640]

Notes: 1) n.a. = not applicable

2) Longer autonomies, and battery for EDP above 20 kVA are available with external

battery cubicles.

page

16 --

MI00/10056 rev. 8 —05/2006

17

ALL MEASUREMENTS ARE IN

MILLIMETERS (AND INCHES)

6

8

0

,

700,0 (27.56)

1

4

2

2

,

0

(

5

6

)

0

(

2

6

.

7

7

)

(28.5)725,0

58,0 (2.28)

N

R

4

X

600,0

ø

8

(

ø

0

,

3

1

)

(23.62)

6

4

5

,

0

3

(

2

0

5

,

0

.

3

(

1

9

.

)

1

8

)

C

2

6

A

0

B

(

L

1

E

0

.

E

2

N

4

)

T

X

R

Y

6

6

(

2

.

6

)

150

(5.9)

(

2

.

6

4

)

(

7

.

8

7

)

SPACE REQUIRED

BY THE WHEEL

WHEN ROTATING

63,0 (2.48)

Figure 7 – 24 Footprint and cabinet dimensions

730,0 (28.7)

6

7

,

0

2

0

0

MI00/10056 rev. 8 — 05/2006-- page

N

R

4

X

(

ø

0

,

3

1

)

ø

8

ALL MEASUREMENTS ARE IN

MILLIMETERS (AND INCHES)

700,0 (27.56)

1

4

2

2

,

0

(

5

6

)

6

8

0

,

0

(

2

6

.

7

7

)

page

6

4

5

3

,

0

0

,

0

(

2

(

1

5

.

.

1

3

8

9

)

)

600,0

18 --

MI00/10056 rev. 8 —05/2006

8

8

,

0

(

700,0

(27.5)

125,0

(4.92)

530 (20.9)

500 (19.7)

CABLE ENTRY

500 (19.68) X 110 (4.33)

(23.62)

150

(5.9)

3

.

4

6

)

200

(7.87)

SPACE REQUIRED

BY THE WHEEL

WHEN ROTATING

50,0

(1.97)

730,0 (28.7)

Figure 8 – 36 Footprint and cabinet dimensions

19

N

R

4

X

ø

8

(

ø

0

,

3

1

)

ALL MEASUREMENTS ARE IN

MILLIMETERS (AND INCHES)

900,0 (35.4)

1

6

0

0

(

6

3

.

0

)

6

8

,

0

(

2

.

6

8

100,0

(3.94)

200

6

4

5

3

,

0

0

,

0

(

2

(

1

5

.

.

1

3

8

9

)

)

CABLE ENTRY

700 (27.56) X 110 (4.33)

800,0

(31.5)

Figure 9 –

(7.87)

150

(5.9)

50/80 Footprint and cabinet dimensions

)

SPACE REQUIRED

BY THE WHEEL

WHEN ROTATING

50,0

(1.97)

730,0 (28.7)

MI00/10056 rev. 8 — 05/2006-- page

Figure 10 — “A” Battery Cabinet Drawing for 24/36kVA Ratings

page

20 --

MI00/10056 rev. 8 —05/2006

21

Figure 11 — “B” Battery Cabinet Drawing for 24/36kVA Ratings

MI00/10056 rev. 8 — 05/2006-- page

Figure 12 — “E” Battery Cabinet Drawing for 50/80kVA Ratings

page

22 --

MI00/10056 rev. 8 —05/2006

23

Figure 13 — “F” Battery Cabinet Drawing for 50/80kVA Ratings

MI00/10056 rev. 8 — 05/2006-- page

70

-

Connection

Points

(Terminal Blocks)

ACCESS

PLATE

+

FUSE

32.13

32.88

22.70

2.75

CABLE

ENTRY

MOUNTING

FEET

ALL MEASUREMENTS ARE IN INCHES

Figure 14 — “C” Battery Cabinet Drawing for 36/50/80kVA Ratings

page

24 --

MI00/10056 rev. 8 —05/2006

25

70

Connection

Points

(Terminal Blocks)

ACCESS

PLATE

+ -

FUSE

40.16

28.35

5.33

CABLE

ENTRY

MOUNTING

FEET

ALL MEASUREMENTS ARE IN INCHES

Figure 15 — “D” Battery Cabinet Drawing for 50/80kVA Ratings

32.68

MI00/10056 rev. 8 — 05/2006-- page

4.2 Installation

Check the rating label on the rear of the front panel of the EDP70 PLUS UPS to ensure the input/output voltages,

frequency and load are all within the rating of the UPS.

EDP70 PLUS is designed to operate in an office environment with an optimum temperature of 68°F [20 C].

A gap of at least 4 in [ 10cm. ] must be maintained at rear of the UPS to ensure adequate ventilation.

Nothing should be placed around the equipment which might restrict the airflow.

Ensure the interconnecting cables do not cause a hazard to the user.

A gap of at least 32 in [ 812 mm] must be maintained above the UPS to ensure adequate space for maintenance.

The appropriate lifting equipment must be used to move the EDP70 PLUS UPS.

Description

Output power

Nominal Load

Maximum input power (with

unit @ nominal Load & battery

recharge)

Maximum dissipation (with

inverter @ nominal Load)

Number of battery cells

Battery voltage range

Battery

end-discharge current

Description

Output power

Nominal Load

Maximum input power (with

unit @ nominal Load & battery

recharge)

Maximum dissipation (with

inverter @ nominal Load)

Number of battery cells

Battery voltage range

Battery

end-discharge current

Figure 16 – UPS Ratings

UPS ratings

U.M. 24

12kVA

kVA 12 18 24 24 30 36

kW 8 12 16 16 20 24

kVA 15 21 28 28 35 42

BTU/H

n 144 240

V 238-327 396-545

A 37 55 74 53 67 80

U.M. 50

kVA 30 40 50 50 65 80

kW 24 32 40 40 52 64

kVA 43 57 71 71 91 112

BTU/H

n 240

V 396-545

A 67 88 110 105 140 173

3750 5460 6800 7700 9500 11300

UPS ratings

30kVA

9300 11700 14300 14300 18600 22100

24

18kVA

50

40kVA

24

24kVA

50

50kVA

36

24kVA

80

50kVA

36

30kVA

80

65kVA

36

36kVA

80

80kVA

page

26 --

MI00/10056 rev. 8 —05/2006

27

Recommended wire sizes

It is recommended that the external cables and protection be selected for the highest rated

1)

unit of the model in use.

Reserve (or primary) input and output Neutral cable size should be greater than that of the

2)

line cables in order to be able to supply non-linear loads having a Crest Factor of up to 3:1 (i.e.

where neutral current = 1.7 x line current).

If non-linear loads are not to be supplied from the Installation, the Neutral can be of the same size

as the load cable.

Recommended AC input overcurrent protection represents 125% of nominal full load

3)

current (continuous) plus the short duration input current (non-continuous) for battery recharging per NEC 215.2.

UPS output cables should be run in separate conduits from input cables.

4)

5)

Grounding conductors are sized per NEC 250.122.

6)

Cable sizes are based upon NEC.

Refer to local codes applying to your installation prior to choosing appropriate

cable size.

Refer to UPS ampacity table on following page.

MI00/10056 rev. 8 — 05/2006-- page

Vin/V

out

current (A)

24/12kVA 42 60 33 33 50

24/18kVA 60 80 50 50 70

208/120-

208/120

24/24kVA

24/12kVA 19 30 33 14 20

24/18kVA 26 40 50 22 30

480-208/120

24/24kVA

24/12kVA 19 30 14 14 20

24/18kVA 26 40 22 22 30

480-480/277

24/24kVA

36/24kVA 78 125 67 67 90

36/30kVA 97 150 83 83 125

208/120-

208/120

36/36kVA

36/24kVA 34 50 67 29 40

36/30kVA 42 60 83 36 50

480-208/120

36/36kVA

36/24kVA 34 50 29 29 40

36/30kVA 42 60 36 36 50

480/277-

480/277

36/36kVA

50/30kVA 132 175 83 83 125

50/40kVA 152 200 111 111 150

208-208/120

50/50kVA

50/30kVA 57 80 83 36 50

50/40kVA 66 90 111 48 60

50/50kVA

50/30kVA 57 80 36 36 50

50/40kVA 66 90 48 48 60

480-208/120

480-480/277

50/50kVA

80/50kVA 192 250 139 139 175

80/65kVA 254 350 180 180 225

208-208/120

80/80kVA

80/50kVA 83 125 139 60 80

80/65kVA 110 150 180 78 100

480-208/120

80/80kVA

80/50kVA 83 125 60 60 80

80/65kVA 110 150 78 78 100

480-480/277

80/80kVA

A.C. Supply Reserve Supply UPS Type

Rated

Protection

device (A)

78 100 67 67 90

34 50 67 29 40

34 50 29 29 40

118 160 100 100 150

51 70 100 43 60

51 70 43 43 60

192 250 138 138 175

83 125 138 60 80

83 125 60 60 80

311 400 222 222 300

135 175 222 96 125

135 175 96 96 125

Output

Nominal

current (A)

Nominal

current (A)

Protection

device (A)

page

28 --

MI00/10056 rev. 8 —05/2006

29

4.4 Ventilation

UPS can work in a continuous environment within 18°F[-10°C] to 104°F [+40°C ] temperature range, although,

ideally the ambient temperature should be below 78°F [25°C].

The heat, dissipated by the UPS (indicated on figure 7), is extracted by internal fans and then dissipated into the air.

The heat can be removed from the UPS room by a forced cooling ventilation system or, alternatively, an air

conditioning system.

The required air changes per hour will depend on the UPS rating and this heat loss and on the cooling air temperature.

To calculate the required air flow for the dissipated power, the altitude and the cooling air temperature, the following

equation can be used:

• P

V = 2770 - - - - - - • e

d

(0.125 h Tk / T0 )

T

- T

r

with: V = air flow [mc/h]

= total dissipated power [kW]

P

d

= max. temperature allowed into the room [104°F = 40°C = 313°K]

T

r

= Temperature of input cooling air

T

k

T

= 273 °K

0

h = altitude above the sea level [km]

k

MI00/10056 rev. 8 — 05/2006-- page

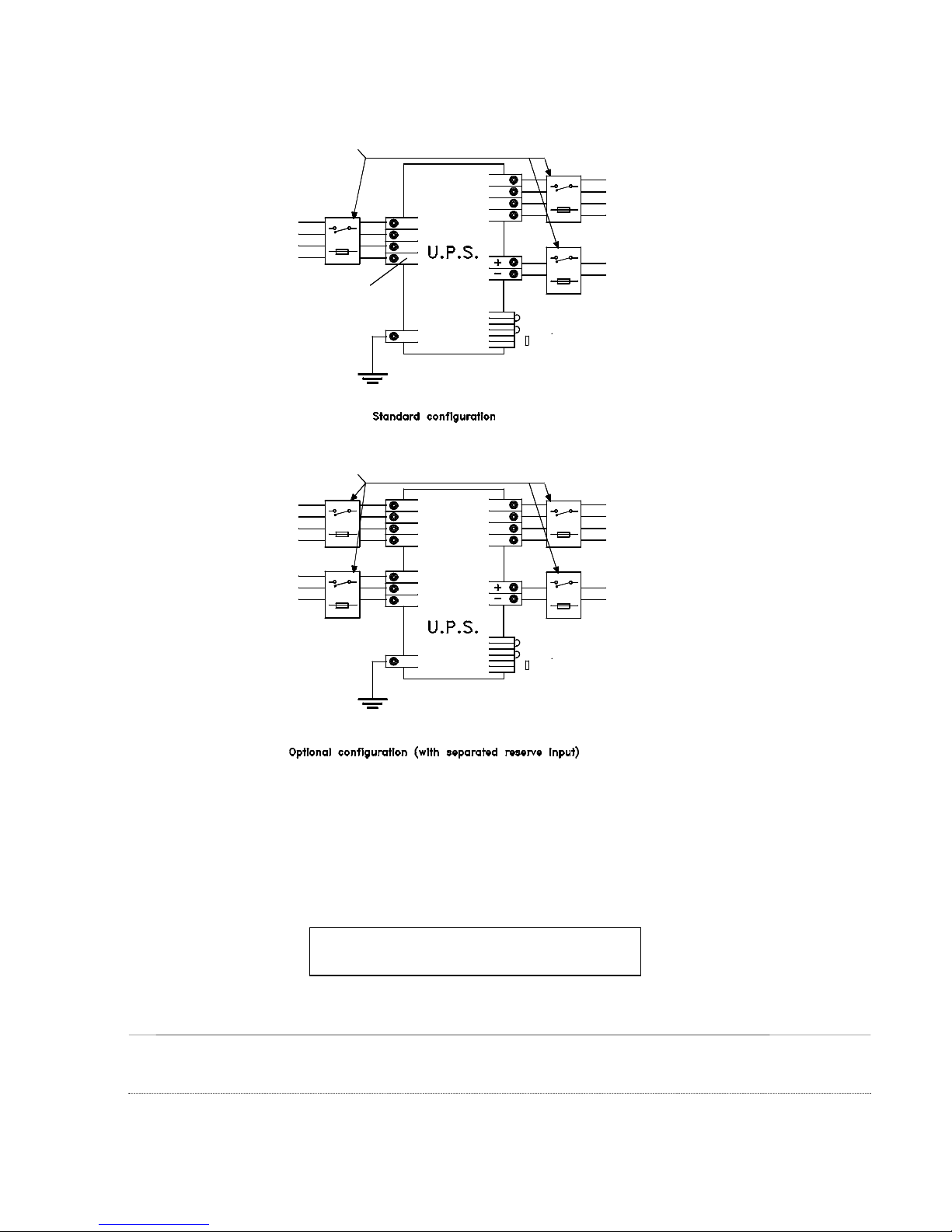

5.0 CONNECTION

Protection devices to be installed by the customer

according to the information shown on page 23

UTILITY

INPUT

RESERVE

INPUT

UTILITY

INPUT

L1

L2

L3

N

Neutral not

present on

50 and 80kVA

ratings

GROUND

Protection devices to be installed by the customer

according to the information shown on page 23

L1

L2

L3

N

L1

L2

L3 W

U

V

W

N

G

U1

V1

W1

Neutral not

N

present on

50 and 80kVA

ratings

U

V

U2

V2

W2

N

1

Remove link to connect remote E.P.O.

2

3

Battery Charge Inhibit

4

5

6

U2

V2

W2

N

L1

L2

OUTPUT

L3

N

(Neutral separately derived

on 50 and 80kVA ratings)

EXTERNAL

BATTERIES

L1

L2

OUTPUT

L3

N

(Neutral separately derived

on 50 and 80kVA ratings)

EXTERNAL

BATTERIES

1

Remove link to connect remote E.P.O.

2

3

Battery Charge Inhibit

4

G

5

6

GROUND

Figure 17 – Connection diagrams

THE AC AND DC SUPPLIES TO THE EDP70 PLUS UPS, AND THE AC OUTPUT FROM THE UPS, SHOULD BE FED THROUGH

SUITABLY RATED CIRCUIT BREAKER OR FUSE(S) AND ISOLATING SWITCH SUITABLE FOR BRANCH CIRCUIT

PROTECTION.

NOTE: INTERRUPTING THE NEUTRAL FEED MAY CAUSE THE CHANGE IN GROUND-NEUTRAL VOLTAGE TO AFFECT

THE LOAD.

NOTE: ALL CIRCUIT BREAKERS OR FUSES AND ISOLATING SWITCHES SHOULD BE FITTED AS CLOSE TO THE EDP70

PLUS UPS AS POSSIBLE AND MARKED WITH THE LABELS PROVIDED WITH THE UNIT.

IT IS ALSO RECOMMENDED A LABEL AS FOLLOWS

UNINTERRUPTIBLE POWER SYSTEM

NO UNAUTHORIZED OPERATION

page

30 --

MI00/10056 rev. 8 —05/2006

31

CAUTION!

All power connection must carried out by qualified

licensed personnel experienced

in wiring this type of equipment

The safety ground wire must

be connected before the power input cables

The correct phase rotation

(phase A leads B leads C)

must be observed on the UPS terminals.

WARNING!

MI00/10056 rev. 8 — 05/2006-- page

5.1 Electrical connections

WARNING!

All electrical connections must

be made by a qualified electrician

and meet local electrical code standards

Before attempting to connect the mains supply, the reserve/bypass supply or the load, ensure that all supplies, including

the battery, are isolated and that all the equipment switches are in their »OFF» position.

Open UPS front access panel and remove internal panel over main switches and terminal blocks.

NOTES:

1) Installation must be performed by a qualified electrician. The terminals require the use of

the proper crimp tools and terminals in order to perform an installation in accordance with the

National Electrical Code (NEC). The recommended crimp tools, terminals and torque are shown

in the following tables:

2) Use Copper Conductors Only

Table 1 – T&B’s Cat. N°s. for terminals and crimp tools

Indentor

(Moveable)

Used ON

EDP70Plus

up to 24kVA

EDP70Plus

above 24kVA

Wire

Size

(AWG)

8 D10711 D975 11803

6 E10711 E975 11803

4 F10711 F975 11805

3 F10711 F975 11805

2 G971 G974 WT117 11806 11802

1 G671 G974 11806

1/0 H971 H974 11807

2/0 J971 J974 11808

3/0 K971 K974 11809

4/0 L971 L974 11810

Terminals

Hole for screw

M6 M10

Toggle

hand

Nest

(stationary)

tool

Table 2 – Recommended torque

Torque Type Screw Wrench

Entrelec

M 35/26.FF

-------

(mm)

M6

M10 17

10

(Nm) (lb.in)

4.5

39 340

39

page

32 --

MI00/10056 rev. 8 —05/2006

33

5.2 24 – 12/18/24kVA

Ensure the AC supplies and load are switched OFF. Check that all the EDP70 PLUS UPS Switches (behind the front

panel) are switched OFF, see

The AC supply cables must be suitable for carrying the maximum supply demand. The voltage drop in the cable

should be minimized to ensure the AC supply voltage at the EDP70 PLUS UPS terminals is within +/- 10% of nominal.

The EDP70 PLUS UPS should be connected to the main/reserve supplies and output load via a wall mounted junction

box.

Installation and connection should only be carried out by qualified electrical personnel.

Figure 18

.

S2 = Equipment Reserve Switch

S1 = Equipment ON/OFF Breaker

S3 = Equipment By-pass Switch

S4 = Equipment OUTPUT Breaker

Battery Compartment

Figure 18 - 24 – 12/18/24kVA: Switches and Breakers

MI00/10056 rev. 8 — 05/2006-- page

Output, Reserve, Input

and External Battery Terminals

Hinged panel security screws

Cable support

Cable channel

Figure 19 - 24 – 12/18/24kVA: Switches

Access to the terminals for electrical connections is as follows:

a) Remove front panel see

b) Remove the two securing screws for the hinged front panel.

c) This exposes the electrical terminal rail, see

d) Remove the screws securing the access plate.

e) Push the interconnection cables up through the cable channel and the access plate.

f) Release the terminal securing nuts by unscrewing fully anti-clockwise. All cables must be

terminated with the correct size lugs and connected on the bottom side terminals as marked.

g) Install or start-up batteries see section 13.1

h) Replace and tighten the terminal securing screws fully clockwise and refit the access plate.

i) Replace the terminal board compartment panel and the front cover.

OBSERVE POLARITIES AND ORIENTATIONS.

See Remote Alarms and Computer Interface for connections to these facilities. For optional battery cubicles, refer to

section 13.2.

page

34 --

MI00/10056 rev. 8 —05/2006

Figure 18.

Figure 20

35

Computer relay

interface - FEMALE

RAU - FEMALE

RS232 - MALE

M6

FRONT

W1V1U1 N PE U V W N

E

V

R

E

S

E

R

T

U

P

N

I

D

N

U

O

R

G

Modem and

Multicom

power supplies

sec. max 14 AWG

U2

Y

R

A

T

M

U

I

P

R

N

P

I

V2 NW2

T

U

P

T

U

O

L

A

N

R

E

T

X

E

S

E

I

R

E

T

T

A

B

.

O

.

P

.

E

r

e

g

r

a

h

C

y

r

e

t

t

a

B

REAR

Label

d

e

t

i

b

i

h

n

I

Figure 20 - 24 – 12/18/24kVA: Cable Connections

MI00/10056 rev. 8 — 05/2006-- page

5.3 36 – 24/30/36kVA

Ensure the AC supplies and load are switched OFF. Check that all the EDP70 PLUS UPS Switches (behind the front

panel) are switched OFF, see figure 13.

The AC supply cables must be suitable for carrying the maximum supply demand. The voltage drop in the cable should

be minimized to ensure the AC supply voltage at the EDP70 PLUS UPS terminals is within +/- 10% of nominal.

The EDP70 PLUS UPS should be connected to the main/reserve supplies and output load via a wall mounted junction

box.

Installation and connection should only be carried out by qualified electrical personnel.

S3 = Equipment By-pass switch

S4 = Equipment OUTPUT Breaker

S1 = Equipment ON/OFF Breaker

S2 = Equipment Reserve switch

Terminal board compartment

Figure 21 - 36 – 24/30/36kVA: Switches and Breakers

page

36 --

MI00/10056 rev. 8 —05/2006

37

S3 = Equipment By-pass switch

S4 = Equipment OUTPUT Breaker

S1 = Equipment ON/OFF Breaker

S2 = Equipment Reserve switch

Output, Input, Reserve

and External Battery Terminals

Access plate

Figure 22 - 36 – 24/30/36kVA: Connections

Access to the terminals for electrical connections is as follows:

a) Remove front panel see

Figure 22.

b) Remove the terminal board compartment panel by unscrewing the fixing screws at the front.

c) This exposes the electrical terminal rail, see

d) Remove the screws securing the access plate.

e) Push the interconnection cables up through the access plate.

f) Release the terminal securing nuts by unscrewing fully anti-clockwise. All cables must be

terminated with the correct size lugs and connected on the bottom side terminals as marked.

g) Install or start-up batteries see section 13.3 and 13.4.

h) Replace and tighten the terminal securing screws fully clockwise and refit the access plate.

i) Replace the terminal board compartment panel and the front cover.

OBSERVE POLARITIES AND ORIENTATIONS.

See Remote Alarms and Computer Interface for connections to these facilities.

Figure 23

MI00/10056 rev. 8 — 05/2006-- page

Computer relay

interface - FEMALE

RAU - FEMALE

FRONT

QS1

Modem and

Multicom

power supplies

QS4

RS232 - MALE

REAR

QS3

UPE

W2U1V W N U2 V2V1 W1

QS2

E.P.O.

Battery charge

inhibited

PRIMARY

INPUT

GROUND

RESERVE

INPUT

OUTPUT

EXTERNAL

BATTERIES

NEUTRAL (RES/OUT)

Figure 23 - 36 – 24/30/36kVA: Cable Connections

page

38 --

MI00/10056 rev. 8 —05/2006

4/2005

39

5.3 EDP70 PLUS 50/80kVA

Ensure the AC supplies and load are switched OFF. Check that all the EDP70 PLUS UPS Switches (behind the front

panel) are switched OFF, see figure 16.

The AC supply cables must be suitable for carrying the maximum supply demand. The voltage drop in the cable should

be minimized to ensure the AC supply voltage at the EDP70 PLUS UPS terminals is within +/- 10% of nominal.

The EDP70 PLUS UPS should be connected to the main/reserve supplies and output load via a wall mounted junction

box.

Installation and connection should only be carried out by qualified electrical personnel.

S5 = RESERVE OUTPUT switch

S4 = INVERTER OUTPUT Breaker

S3 = BY-PASS switch

S2 = Equipment RESERVE switch

S1 = Equipment ON/OFF Breaker

Terminal board compartment

Figure 24 – 50/80kVA: Switches and Breakers

MI00/10056 rev. 8 — 05/2006-- page

S5 = RESERVE OUTPUT switch

S4 = INVERTER OUTPUT Breaker

S3 = BY PASS switch

S2 = Equipment RESERVE switch

S1 = Equipment ON/OFF Breaker

Output, Input, Reserve

and External Battery Terminals

Access plate

Figure 25 – 50/80kVA: Connections

Access to the terminals for electrical connections is as follows:

a) Remove front panel see

b) Remove the terminal board compartment panel by unscrewing the fixing screws at the front.

e) This exposes the electrical terminal rail, see

f) Remove the screws securing the access plate.

e) Push the interconnection cables up through the access plate.

f) Release the terminal securing nuts by unscrewing fully anti-clockwise. All cables must be terminated with

the correct size lugs and connected on the bottom side terminals as marked.

g) Install or start-up batteries see section 13.3 and 13.4.

h) Replace and tighten the terminal securing screws fully clockwise and refit the access plate.

i) Replace the terminal board compartment panel and the front cover.

OBSERVE POLARITIES AND ORIENTATIONS.

See Remote Alarms and Computer Interface for connections to these facilities.

Figure 22

.

Figure 23

page

40 --

MI00/10056 rev. 8 —05/2006

41

Computer relay

interface - FEMALE

RAU - FEMALE

FRONT

QS1

QS2

RS232 - MALE

Modem and

Multicom

power supplies

QS3

QS4

REAR

QS5

U U1 V1 W1V W

Y

R

A

M

I

R

P

W2 N NU2 V2 PE

E

S

L

V

E

A

I

R

T

T

N

E

U

P

N

I

R

U

R

S

E

P

T

E

E

N

T

T

I

R

A

X

B

E

1 2 3 4 5 6

.

s

d

t

e

O

c

t

.

i

a

t

P

b

.

i

n

h

E

o

n

c

i

k

e

c

i

g

t

r

s

a

o

h

c

m

r

y

r

e

e

h

t

t

T

a

B

T

U

P

T

U

O

Figure 26 – 50/80kVA: Cable Connections

MI00/10056 rev. 8 — 05/2006-- page

5.4 Signal connections

a) Emergency Power Off

When the connection between terminals 1 and 2 is opened, the UPS will stop, and it will automatically

restart when the switch is closed. This allows a remote E.P.O. to be installed, in series with the standard

one installed inside the UPS. (See Para. 9.1)

Warning: To avoid unauthorized stopping, it is strongly recommended that some form of security switch be used..

b) Battery charge inhibited

By removing the link between terminals 3 and 4, the battery charge will be inhibited, and a warning

message will be displayed.

Possible uses of this could be one, or more, of the following:

• connect the above terminals to a contact which will be opened if there is Hydrogen within the battery

compartment(s).

In this way the cause of hydrogen generation will be stopped, and a warning about the operating

status of the system will be displayed.

• connect the above terminals to a contact which will be opened when the UPS is supplied by a

Generator (it should be an auxiliary contact of the Line <-> Generator changeover).

In this way it will be possible to limit the power supplied by the Generator to the only value required to

supply the critical loads, and not to charge the battery until the mains supply returns.

In this way it is possible to use a Generator having a power rating less than the maximum input power

of the UPS.

Also in this case a warning about the operating status of the system will be displayed.

c) Thermostick connector (50/80kVA only)

This connection provides the customer with remote control over the output transformer Overtemperature

Alarm (T

NOTE: If more than one of the above applications (or similar) are installed, the contacts MUST be connected in

= 180°C).

CORE

series.

page

42 --

MI00/10056 rev. 8 —05/2006

43

6.0 CONTROLS

6.1 User Controls

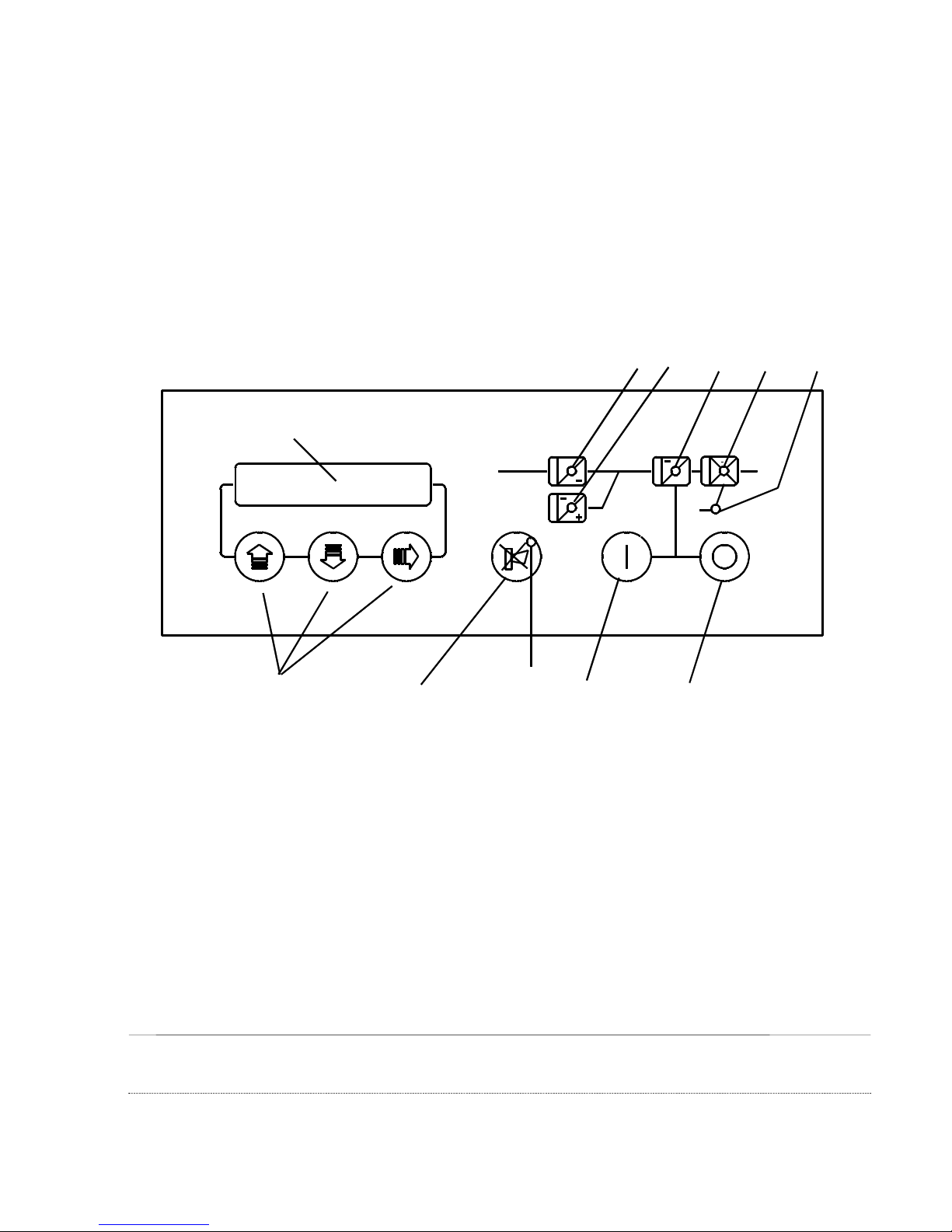

The user controls are situated on the front panel, see Figure 27.

Access to the Equipment Power Switches can be obtained by removing the front cover.

Figure 27 – Control panel

1 2 3 4 5

Illuminated Liquid

Crystal Display

~

R

B

User

Switches Audible Alarm

Cancel Switch

6

Inverter

Start

I

S

~

Inverter

Stop

~

~

~

Display indicators

1) Utility Supply Indicator (Green)

2) Battery Indicator (Green)

3) Inverter Indicator (Green)

4) Static Switch indicator (Green)

5) Reserve Supply Indicator (Green)

6) Warning Indicator (Red)

MI00/10056 rev. 8 — 05/2006-- page

6.2 Control Panel

This allows the user to turn on and reset the inverter. This is normally only used when starting the UPS.

Inverter Shutdown

The switch incorporates a safety feature to prevent inadvertent operation yet still allow rapid

shutdown in the event of an emergency. This is achieved by the requirement that the switch be depressed

for 2 seconds before the inverter stops during which time the audible alarm will be heard.

Audible Alarm Cancel Switch

This switch cancels the audible alarm. When pressed the red warning light goes from continuous

illumination to flashing on and off.

Page Right Control

This switch changes the page headings displayed on the LCD. It also allows the alarm and measurement

statuses to be stepped through when examining the power history (refer to section 10.6)

Inverter Start Up

Record Up

This switch changes the record displayed on the LCD to the previous message displayed. When the top of

the page has been reached the display will no longer scroll.

Record Down

This switch changes the record displayed on the LCD to the next record on the page. When the bottom

of the page has been reached the display will no longer scroll.

page

44 --

MI00/10056 rev. 8 —05/2006

45

7.0 START UP

1. Switch on the AC reserve and the main AC Utility supply to the UPS.

2. Turn on the Utility supply Input, Reserve Input (if fitted) and UPS Output switches located behind the front

panel, see figure 18 for 24kVA, figure 21 for 36kVA or figure 24 for 50/80kVA.

3. Replace the front panel.

4. Press the CANCEL AUDIBLE ALARM switch (see section 6.2)

5. Initially, all the green indicators will flash on the display mimic. After about 30 seconds the supply and

battery indicators should stop flashing.

6. Press the Inverter On push button (I).

7. The inverter should now start and after a delay of approximately 30 seconds the message ‘SYSTEM

NORMAL’, in English, will appear on the liquid crystal display.

8. Select the required language by pressing page right control

message appears on the liquid crystal display. Press the page down control

language is selected. Press the page right control

once more confirm the language selection.

until the ‘SELECT LANGUAGE’

until the required

Thereafter, all messages will appear in the selected language.

8.0 MAINTENANCE BYPASS

The EDP70 PLUS UPS is equipped with Manual Maintenance Bypass systems. If a unit requires servicing, the Manual

Maintenance Bypass allows the load to be connected directly to the AC supply so that the unit may be serviced in safety.

The following instructions must be followed:

1. Ensure that ‘SYSTEM NORMAL’ is displayed on the LCD. (Note: If ‘SYSTEM NORMAL’ is not displayed

check that the inverter is not ‘OUT OF SYNC’, see section 10.7. Turning the inverter off under this fault

condition will interrupt the load supply.)

2. Turn off the inverter by pressing the inverter shutdown button for more than 2 seconds

3. Turn the Maintenance Bypass Switch (located behind front panel, see figure 18, 21 or 24) to ON.

4. Turn off the Primary Input, Reserve Input and UPS Output Switches, see figure 18, 21 or 24.

THE LOAD IS NOW SUPPLIED DIRECTLY FROM THE AC UTILITY SUPPLY AND IS NO LONGER

PROTECTED BY THE UPS

CAUTION: Some components in the UPS will retain a static voltage even after the switches have been

opened. Also, on the 50/80kVA ratings, the isolating transformer and the relative cooling fans

are still supplied from the Bypass.

To return to the normal operating mode, follow the above procedure in reverse.

Note: The EDP70 PLUS UPS must not be left operating with the Maintenance Bypass Switch in the ON

position.

MI00/10056 rev. 8 — 05/2006-- page

9.0 SHUT-DOWN

1. Close down the load in an orderly manner.

2. Push the

(inverter shutdown) button for more than 2 seconds.

3. Turn the main switch to OFF.

Note: If the electricity supply to the site is switched off outside normal working hours, the EDP70 PLUS should be shut

down each evening, by either using the shutdown procedure or wiring in the Emergency Power Off (EPO) function,

see figures 20, 23 or 26 (depending on the UPS size).

This will prevent the battery from discharging.

If, on the other hand, the supply to the site is continuous, the EDP70 PLUS should be operated 24 hours a day.

9.1 Installing the EPO

To wire the EPO, open the link between terminal boards 1 and 2 and connect a signal switch, having the characteristics

of an emergency button, closed under normal operating conditons and held open mechanically when operated: when the

switch is enabled, the inverter and rectifier will stop, the battery relay will be opened and the load will be de-energized

To ensure that the EPO functions correctly, the signal should remain active for a period > 400 msec.

page

46 --

MI00/10056 rev. 8 —05/2006

47

10.0 VISUAL AND AUDIBLE ALARMS

The EDP70 PLUS UPS is equipped with visual and audible alarms which indicate the status of the UPS to the operator.

The visual alarms are displayed on the LCD and the mimic panel.

10.1 Silencing Audible Alarm

The audible alarm sounds when the UPS is in an alarm condition. The sound is silenced by pressing the button marked

.

When pressed, the red warning light which is illuminated continuously starts to flash, providing an even clearer indication

of the alarm condition, even though the audible alarm has been silenced.

10.2 Mimic

The display mimic consists of a pictorial representation of the functional blocks in the EDP70 PLUS UPS. When the

system is in NORMAL OPERATING CONDITION the green indicators are illuminated continuously.

In the event of an ALARM condition the indicators start to flash identifying the part (or parts) of the system in alarm (see

figure 19).

Further information on the alarms can be obtained from the LCD by scrolling through the page headings using the

button (page right control) until the message on the display describes the functional block in the UPS identified by the

flashing LED(s).

The alarms can then be accessed using the

procedure is described in detail in section 10.4.

(scrolling up) and (scrolling down) record buttons. This

10.3 Liquid Crystal Display

The display is a 40-character (2 line x 20 character) module which is back lit.

The messages describing the functioning of the system are accessed via the user switches (see figure 18).

MI00/10056 rev. 8 — 05/2006-- page

10.4 Display Page Headings

After initial power up, under normal operating conditions, the main page heading will be displayed:

UPS xx KVA

SYSTEM NORMAL

The first line displays the power rating of the EDP70 PLUS UPS, the second line is the system status.

During normal operating conditions, the display reading always returns to this page heading whenever the user switches

are not operated for at least 5 minutes.

By pressing the button marked

once, the battery rectifier heading is displayed:

RECT/BATT ALARMS

NO ALARMS ACTIVE

The second line of the display confirms that the rectifier and battery are functioning correctly.

By pressing the button marked

again, the inverter heading is shown on the display:

INVERTER ALARMS

NO ALARMS ACTIVE

The second line of the display confirms that the inverter is functioning correctly.

By pressing the button marked

again, the load output and reserve supply heading is displayed:

LOAD/RES ALARMS

NO ALARMS ACTIVE

The second line of the display indicates that the UPS load output and reserve supply input are correct.

page

48 --

MI00/10056 rev. 8 —05/2006

49

By pressing the button marked

again, the selected battery test period appears on the display:

BATTERY TEST

WEEKLY

The button marked is pressed to scroll through the 4 battery test period available (WEEKLY, FORTNIGHTLY,

MONTHLY and NONE).

The button marked

When the required battery test period appears, press the button marked

selected language heading appears on the display.

is pressed to scroll through the list in reverse order.

to select the battery test period and the

SELECTED LANGUAGE

ENGLISH

The button marked is pressed to scroll through the languages available (English, French, German, Italian and

Spanish).

The button marked

When the required language appears, press the button marked

the main UPS status message.

is pressed to scroll through the list in reverse order.

to select the language and to return the display to

MI00/10056 rev. 8 — 05/2006-- page

If at any time the inverter is blocked then the power history heading appears:

POWER HISTORY

DOWN TO ACCESS

The power history page is described in detail in section 10.6.

The machine measurement signals are accessed from the main page heading as follows:

UPS xx kVA

SYSTEM NORMAL

press once

RECTIFIER

Vdc xxx V Idc xxx A

press once

BATTERY

Vb xxx V Ib xxx A

press once

INVERTER F xx.x Hz

A xxx V B xxx V C xxx V

press once

INVERTER F xx.x Hz

AB xxx V BC xxx V CA xxx V

Displays the output voltage and current supplied by the

rectifier.

Displays the battery voltage and the charge or

discharge current of the battery (ve = charge, - ve =

discharge)

Displays the frequency and phase-neutral voltage at

which the inverter is running.

Displays the frequency and phase-phase voltage at

which the inverter is running.

press once

RESERVE F xx.x Hz

A xxx V B xxx V C xxx V

press once

RESERVE F xx.x Hz

AB xxx V BC xxx V CA xxx V

page

50 --

MI00/10056 rev. 8 —05/2006

Displays the frequency and the phase-neutral voltage

of the reserve supply.

Displays the frequency and the phase-phase voltage of

the reserve supply.

51

press once

LOAD F xx.x Hz

A xxx V B xxx V C xxxV

press once

LOAD F xx.x Hz

AB xxx V BC xxx V CA xxxV

press once

LOAD

A xxx A B xxx A C xxx A

press once

Displays the frequency and phase-neutral voltage

supplied to the load.

Displays the frequency and phase-phase voltage

supplied to the load.

Displays the current supplied to the load.

press once

press once

press once

LOAD

A x% B x% C x%

LOAD P.F. 0.99

P = 80kW s = 80kVA

TIME ON INVERTER

xxg: xxh: xxm: xxs

TIME ON RESERVE

xxg: xxh: xxm: xxs

Displays the load capacity percentage of the UPS rated

value.

Displays the Peak Factor of the load current.

Displays the total time the load has been supplied by

the inverter since the machine was last switched off.

Displays the total time the load has been supplied by

the reserve since the machine was last switched off.

MI00/10056 rev. 8 — 05/2006-- page

press once

LAST MAINS FAILURE

xxd: xxh: xxm: xxs

press once

MAINS FAILURE yy

xxgg: xxh: xxm: xxs

press once

TOTAL MAINS FAILURE yy

xxg: xxh: xxm: xxs

press once

REV A. XX xx-xx-xx

10h00yyy

Displays the duration time of the most recent Mains

Failure

Displays the number of mains failures and the total

duration of these failures since the machine was last

switched off.

Displays the total number of mains failures and their

total duration since the machine was installed.

Displays the code for the version of software resident

(and relevant data) within the EDP70 PLUS UPS

system

page

52 --

MI00/10056 rev. 8 —05/2006

53

The measurement signals are accessed from the battery rectifier page as follows:

Normal operating mode

RECT/BATT ALARMS

NO ALARMS ACTIVE

press once

RECTIFIER

Vdc xxx V Idc xxx A

press once

BATTERY

Vdc xxx V Ib xxxx A

Displays the output voltage and current supplied by the

rectifier.

Displays the battery voltage and the charge or

discharge current of the battery (ve = charge, - ve =

discharge)

The measurement signals are accessed from the inverter page as follows:

Normal operating mode

INVERTER ALARMS

NO ALARMS ACTIVE

press once

INVERTER F xx.x Hz

A xxx V B xxx V C xxx V

press once

INVERTER F xx.x Hz

AB xxx V BC xxx V CA xxx V

press once

INVERTER

A xxx A B xxx A C xxx A

Displays the frequency and phase-neutral voltage at

which the inverter is running.

Displays the frequency and phase-phase voltage at

which the inverter is running.

Displays the current at which the inverter is running.

MI00/10056 rev. 8 — 05/2006-- page

The measurement signals are accessed from the load output - reserve supply page as follows:

Normal operating mode

LOAD/RES ALARMS

NO ALARMS ACTIVE

press once

LOAD f xx.x Hz

A xxx V B xxx V C xxx V

press once

LOAD f xx.x Hz

AB xxx V BC xxx V CA xxx V

press once

LOAD

Displays the frequency and phase-neutral voltage

supplied to the load.

Displays the frequency and phase-phase voltage

supplied to the load.

Displays the current supplied to the load.

A xxx A B xxx A C xxx A

press once

Displays the load capacity percentage of the UPS rated

LOAD

A x% B x% C x%

value.

press once

LOAD P.F. 0.99

P = 80kW s = 80kVA

press once

RESERVE F xx.xHz

A xxx V B xxx V Cxxx V

press once

RESERVE F xx.xHz

AB xxx V BC xxx V CA xxx V

page

54 --

MI00/10056 rev. 8 —05/2006

Displays the Peak Factor of the load current.

Displays the frequency and phase-neutral voltage

supplied to the reserve line.

Displays the frequency and phase-phase voltage

supplied to the reserve line.

55

10.5 Abnormal operating mode messages

Under abnormal operating conditions, the normal functioning heading on the main page

UPS xx KVA

SYSTEM NORMAL

is replaced with the alarm page:

UPS xx KVA

SYSTEM ALARM

If at least 1 alarm is activated for each block; the »NO ALARMS ACTIVE» message in the second line on the display is

replaced with the first active alarm. Whenever there is more than one active alarm, they can be scrolled through using the

and keys.

Each message is associated with one of the following conditions:

Conditions which do not adversely affect the normal functioning of the machine are identified under this heading.

No action is required on the part of the operator.

Transitory conditions which can either return to normal condition or result in a permanent fault are identified under this

heading. No action is required on the part of the operator.

Faults are identified under this heading. The intervention of a qualified technician is required.

Alarms which do not come under any of these headings do not require any action if arising separately.

MAIN PAGE HEADING ALARMS

MESSAGE CONDITION

TESTING BATTERY

EPO ACTIVE

NOT CALIBRATED

TESTING AUTONOMY

SYSTEM TEST MODE

NORMAL

WARNING

FAULT

WARNING

FAULT

MI00/10056 rev. 8 — 05/2006-- page

When the battery is discharging, the machine displays the residual autonomy and the discharging time

information.

1. If no information on autonomy is available, then the following message is displayed:

BATTERY DISCHARGING

AUT calc DIS xx min

where xx represents the discharging time

2. Where AUTONOMY information is available, the following message will appear:

BATTERY DISCHARGING

AUT yy min DIS xx min

where yy represents the residual autonomy of the batteries.

In overload condition, the machine calculates the time remaining before the inverter is switched off.

Under this condition, the following message is displayed:

OVERLOAD

INV STOP xx min: yy:s

If the inverter is inhibited due to overloading, the time at which the inverter will be reactivated is displayed, with the

following message:

STOP DUE TO OVERLOAD

RESTART IN xx min: yy: s

page

56 --

MI00/10056 rev. 8 —05/2006

57

RECTIFIER/BATTERY ALARMS

MESSAGE CONDITION

NOT CALIBRATED

DC FEEDBACK FAULT

VERIFY DC FEEDBACK

PRIMARY SUPPLY FAULT

PHASE SEQUENCE ERROR

BATTERY FAULT

PCB SUPPLY FAULT

BATT CONTACTOR OPEN

BATTERY DISCHARGING

SHUTDOWN IMMINENT

DC VOLTAGE HIGH

DC VOLTAGE LOW

INPUT SWITCH OPEN

HARMONIC FILTER OPEN

RECTIFIER ALARM

RECTIFIER INHIBITED

RECTIFIER BLOCKED

BATT. CHARGE INHIBIT

FAULT

FAULT

NORMAL

WARNING

FAULT

FAULT

FAULT

-

WARNING

WARNING

FAULT

WARNING

FAULT

FAULT

FAULT

WARNING

FAULT

WARNING

MI00/10056 rev. 8 — 05/2006-- page

INVERTER ALARMS

MESSAGE CONDITION

NOT CALIBRATED

PCB SUPPLY FAULT

OUT OF SYNC

DESATURATION

OVER TEMPERATURE

BYPASS SWITCH CLOSED

SHUTDOWN IMMINENT

DC VOLTAGE HIGH

DC VOLTAGE LOW

INVERTER NOT RUNNING

INVERTER INHIBITED

INVERTER BLOCKED

INVERTER VOLTS HIGH

INVERTER VOLTS LOW

OVERLOAD

STOP DUE TO OVERLOAD

CURRENT LIMIT

INV.ST. SWITCH FAULT

INV.FREQ.OUT RANG. 8%

INV. FEEDBACK FAULT

VERIFYING INV. FREQ.

VERIFYING BATT. CONT.

INV.FREQ.OUT 1%

FAULT

FAULT

WARNING

FAULT

FAULT

FAULT

WARNING

FAULT

WARNING

FAULT

FAULT

FAULT

FAULT

FAULT

WARNING

FAULT

WARNING

FAULT

FAULT

FAULT

-

-

FAULT

page

58 --

MI00/10056 rev. 8 —05/2006

59

LOAD/RESERVE ALARMS

MESSAGE CONDITION

NOT CALIBRATED

LOAD ON RESERVE

LOAD NOT SUPPLIED

BYPASS SWITCH CLOSED

RESERVE SUPPLY FAULT

RESERVE FREQ FAULT

RESERVE VOLTS HIGH

RESERVE VOLTS LOW

ST. SW. BLOCKED ON INV

ST. SW. BLOCKED ON RES

INV.ST. SWITCH FAULT

OVERLOAD

OUTPUT SWITCH OPEN

RESERVE SWITCH OPEN

PHASE SEQUENCE ERROR

RESERVE INHIBITED

BACKFEED PROT ACTIVE

FAULT

WARNING

FAULT

FAULT

WARNING

WARNING

WARNING

WARNING

FAULT

FAULT

FAULT

WARNING

FAULT

FAULT

FAULT

WARNING

FAULT

MI00/10056 rev. 8 — 05/2006-- page

10.6 Power History

The power history is only available when the inverter is blocked; it provides a visual display of the status of the alarms

and measurements over a period of 10 seconds before and 1 second after the inverter stops in steps of 0.1 s. The power

history is lost when the inverter is restarted.

Figure 28 provides a graphic representation of how to access the Power History.

Figure 28: Power History Structure

LOAD

ALARMS

Time

(seconds)

-10

Inverter

Shutdown

+1

AlarmsMeasurements

Initial

BATTERY TEST

SELECT

POWER HISTORY

UP TO EXIT

POWER HISTORY

DOWN TO ACCESS

POWER HISTORY MATRIX

position

0

Measurement

RECTIFIER +0.3 SEC

VDC = 327V IB = 5A

page

60 --

MI00/10056 rev. 8 —05/2006

Typical Power History Display

Alarm

-5.3 SEC ON

OVER TEMPERATURE

61

10.7 Battery Test

The EDP70 PLUS has an automatic battery control function which checks the condition of the battery periodically without

affecting the output in any way. While this test is being carried out, the message »TESTING BATTERY» will appear.

This test can also be activated manually. Return to the main title page so that ‘SYSTEM NORMAL’ is displayed.

system normal message

UPS xx KVA

SYSTEM NORMAL

PRESS SIMULTANEOUSLY

UPS xx KVA

TESTING BATTERY

(The test is disabled if the BATTERY TEST selected is NONE)

The battery test is underway and takes approx. 1 minute. If