Page 1

SSMMDD44330000SSNNLL225500TT55

Datasheet revision 1.1 www.chipquik.com

Solder Paste Water-Washable SAC305 in Jar 250g T5 Mesh

Product Highlights

Printing speeds up to 100mm/sec

Long stencil life

Wide process window

Clear residue

Low voiding

Excellent wetting compatibility on most board finishes

Print grade

Compatible with enclosed print heads

Passes BONO test @1.56%

RoHS II and REACH compliant

Specifications

Alloy: Sn96.5/Ag3.0/Cu0.5

Mesh Size: T5

Micron (µm) Range: 15-25

Flux Type: Synthetic Water-Washable

Flux Classification: REL0

Metal Load: 88.25% Metal by Weight

Melting Point: 217-220°C (423-428°F)

Packaging: Jar 250g

Shelf Life: Refrigerated >6 months, Unrefrigerated >2 months *See notes below:

*Shelf Life Notes:

inspect the solder paste to ensure it is not dried out or clumpy, or check stencil release. If stored in a jar, stir the product

thoroughly for 2-3 minutes before inspection and use.

Chip Quik® solder paste is manufactured using Made in USA high quality synthetic flux and precision atomized metal

powder. Chip Quik® solder paste is guaranteed for 12 months from date of manufacture, regardless of refrigeration. If you

have any issues with our solder paste, please contact Chip Quik® directly for no charge warranty replacement. Please retain

original bill of sale, and solder paste in original container as we may request its return for internal R&D testing purposes.

Printer Operation

Print Speed: 25-100mm/sec

Squeegee Pressure: 70-250g/cm of blade

Under Stencil Wipe: Once every 10-25 prints, or as necessary

Stencil Life

>8 hours @ 20-50% RH 22-28°C (72-82°F)

>4 hours @ 50-70% RH 22-28°C (72-82°F)

Stencil Cleaning

Automated stencil cleaning systems for both stencil and misprinted boards. Manual cleaning using isopropyl alcohol (IPA).

Storage and Handling

Refrigerate at 3-8°C (37-46°F). Do not freeze. Allow 4 hours for solder paste to reach an operating temperature of 20-25°C

(68-77°F) before use.

Chip Quik® solder paste is good past its quoted shelf life, regardless of refrigeration. Before use, visually

1 © 1994-2015 Chip Quik® Inc.

Page 2

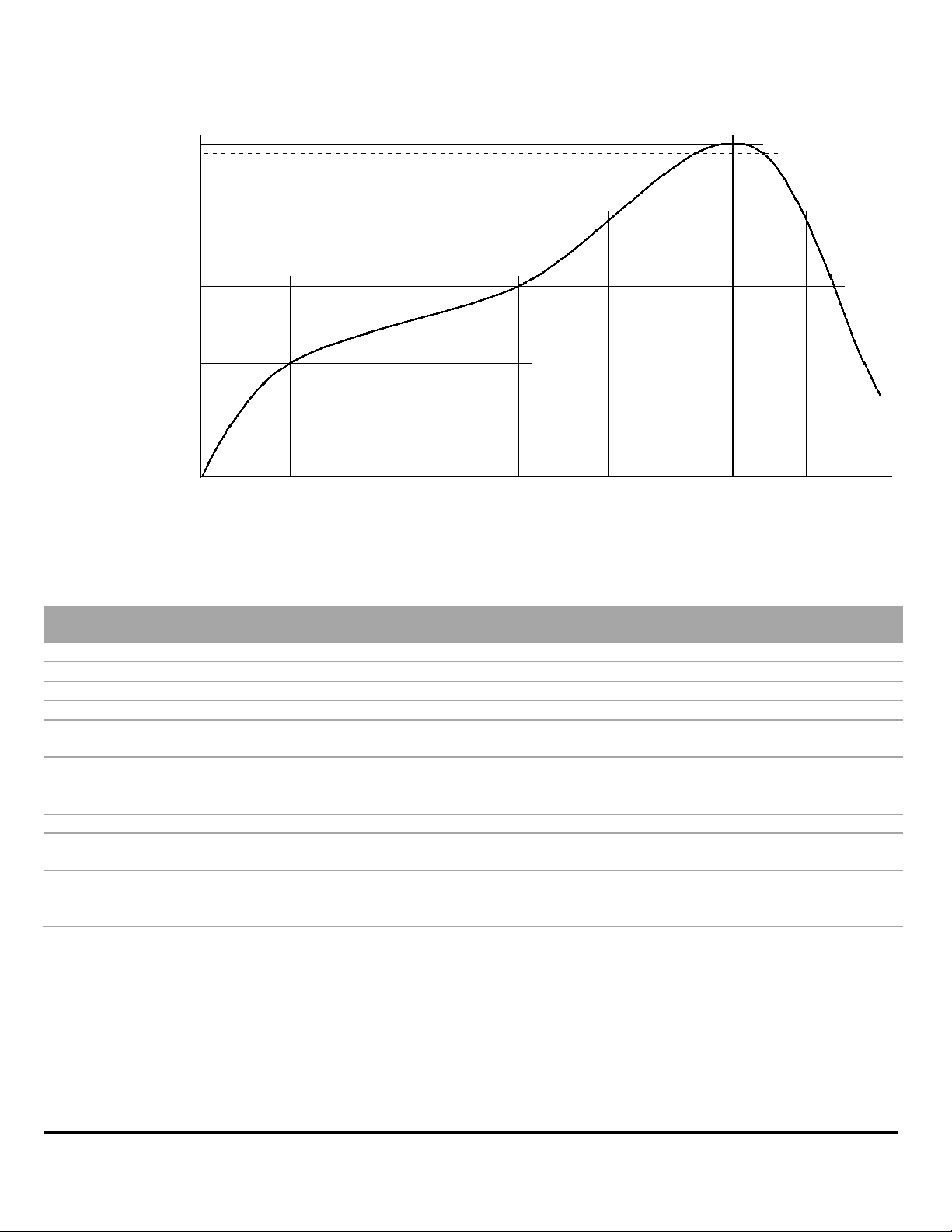

Recommended Profile

Reflow profile for Sn96.5/Ag3.0/Cu0.5 solder assembly, designed as a starting point for process optimization.

249°C (480°F)

217°C (423°F)

175°C (347°F)

Temperature

150°C (302°F)

25°C (77°F)

Test Results

Test J-STD-004 or other

requirements as stated

Copper Mirror IPC-TM-650: 2.3.32 L: No breakthrough

Corrosion IPC-TM-650: 2.6.15 L: No corrosion

Quantitative Halides IPC-TM-650: 2.3.28.1 L: <0.5%

Electrochemical Migration IPC-TM-650: 2.6.14.1 L: <1 decade drop (No-clean)

Surface Insulation Resistance 85°C,

85% RH @ 168 Hours

Tack Value IPC-TM-650: 2.4.44 37g

Viscosity – Malcom @ 10 RPM/25°C

3

mPa/s)

(x10

Visual IPC-TM-650: 3.4.2.5 Clear and free from precipitation

Conflict Minerals Compliance Electronic Industry Citizenship

REACH Compliance Articles 33 and 67 of Regulation (EC)

Conforms to the following Industry Standards:

J-STD-004B, Amendment 1 (Solder Fluxes): Yes

J-STD-005A (Solder Pastes): Yes

J-STD-006C, Amendments 1 & 2 (Solder Alloys and Fluxed/Non-Fluxed Solders): Yes

RoHS 2 Directive 2011/65/EU: Yes

0sec

90sec 180sec 210sec 240sec 270sec

Time

Test Requirement Result

IPC-TM-650: 2.6.3.7 L: ≥100MΩ (No-clean)

IPC-TM-650: 2.4.34.4 Print: 155-215, Dispense: 80-115

Compliant

Coalition (EICC)

Contains no substance >0.1% w/w that

No 1907/2006

is listed as a SVHC or restricted for

use in solder materials

2 © 1994-2015 Chip Quik® Inc.

Loading...

Loading...