CCH00701:09/00 JCHE p65

DOUBLE DROPSIDE CRIB

child craftchild craft

child craftchild craft

child craft

CHILD CRAFT INDUSTRIES, INC.

P.O. Box 444, Salem, IN USA 47167-0444

PH: 812-883-3111 - FAX: 812-883-1819 - http://www.childcraftind.com

ASSEMBLY DIRECTIONS AND PARTS LIST

ΦREAD ALL INSTRUCTIONS WITH CARE BEFORE STARTING THE ASSEMBLY PROCEDURE.

ΦΦ

ΦΦ

ΦYOU WILL NEED A #2 PHILLIPS SCREWDRIVER, A SLOTTED SCREWDRIVER AND A HAMMER.

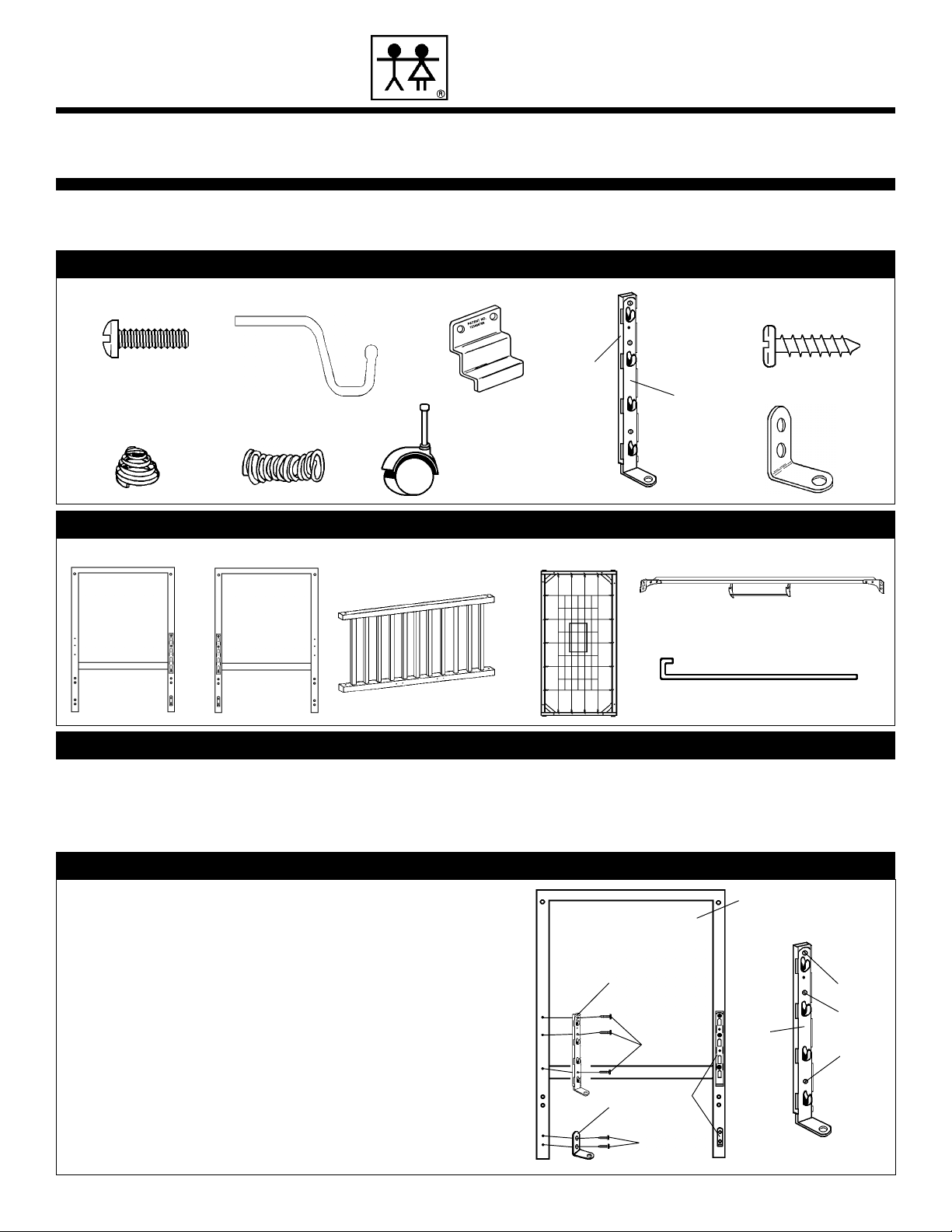

PARTS ENCLOSED IN HARDWARE BAG (NOTED WHEN SHOWN ACTUAL SIZE)

(18) Slotted/Phillips

Wood Screws

EE

EE

E

(12) Slotted/Phillips

Machine Screws

AA

AA

A

(actual size)

BB

BB

B

(4) Spring Hangers

CC

CC

C

(4) Gate Shoes

DD

DD

D

(2)

Moulded

plastic

backers

(2)

4-Position

Spring

Hanger

Brackets

(actual size)

FF

FF

F

(4) Compression

Springs

GG

GG

G

(4) Bumper

Springs

HH

HH

H

(4) Casters

(style may vary)

II

II

I

(2) Angle

Brackets

PARTS INCLUDED IN CARTON

OO

OO

O

(1) Footboard

NN

NN

N

(1) Headboard

PP

PP

P &

QQ

QQ

Q

(2) Crib sides

(Dropsides)

RR

RR

R

(1) Spring

JJ

JJ

J

(2) Stabilizer Bars

KK

KK

K

(4) Crib Rods

PREPARATION

Carefully remove and lay out all hardware and parts. Remove wires securing the (2) Stabilizer Bars

JJ

JJ

J and the (4) Crib Rods

KK

KK

K to Crib Spring

RR

RR

R. Check

quantities and match to the three Parts Lists above. If any part is missing or broken contact your dealer or Child Craft (P.O. Box 444, Salem, IN 471670444 USA (ph# 812/883-3111), service@childcraftind.com for a replacement part or instructional literature. Before making this contact, identify your crib.

A model identification number is stamped on the underneath side of the bottom rail of either a crib end

NN

NN

N/

OO

OO

O or a crib side

PP

PP

P/

QQ

QQ

Q. Record the model

Identification Number now: # ______________________. Include this number with a request for a part or instructional literature. DO NOT SUBSTITUTE

PARTS!

Note the two piece assembly of 4-Position Spring Hanger Brackets

DD

DD

D. Before

attachment to crib

(ends)

NN

NN

N &O, check to be sure the moulded plastic backer

aligns with the 4-Position Spring Hanger Bracket

DD

DD

D as shown. These items are

shipped assembled, in the unlikely event they should become detached during

shipment, simply take the plastic backer, align with the holes in the metal bracket

and snap together to create an assembly as shown in the Hardware Parts Diagram.

IMPORTANT! All four plastic tabs on each moulded plastic backer should project

toward the metal hooks on 4-Position Spring Hanger Brackets

DD

DD

D. If you should

find a tab on an uninstalled 4-Position Spring Hanger Bracket not so projected,

simply use a screwdriver to push tab forward until it contacts the metal hook. If

a plastic tab is not projected on a factory installed 4-Position Spring Hanger Bracket

simply place a small slotted screwdriver underneath the plastic tab and pull

forward until it contacts the metal hook. Attach a 4-Position Spring Hanger Bracket

DD

DD

D,

(2 piece assembly)

, to both Headboard

NN

NN

N & Footboard

OO

OO

O with Slotted/Phillips

Wood Screws

EE

EE

E, to be positioned exactly as the ones already factory installed.

Attach Angle Brackets

II

II

I with Slotted/Phillips Wood Screws

EE

EE

E to Headboard

NN

NN

N

and Footboard

OO

OO

O, to be positioned exactly as the ones already factory installed.DO

NOT REMOVE 4-POSITION SPRING HANGER BRACKETS OR ANY OTHER

HARDWARE ITEM ATTACHED WITH SLOTTED/PHILLIPS WOOD SCREWS

EE

EE

E.

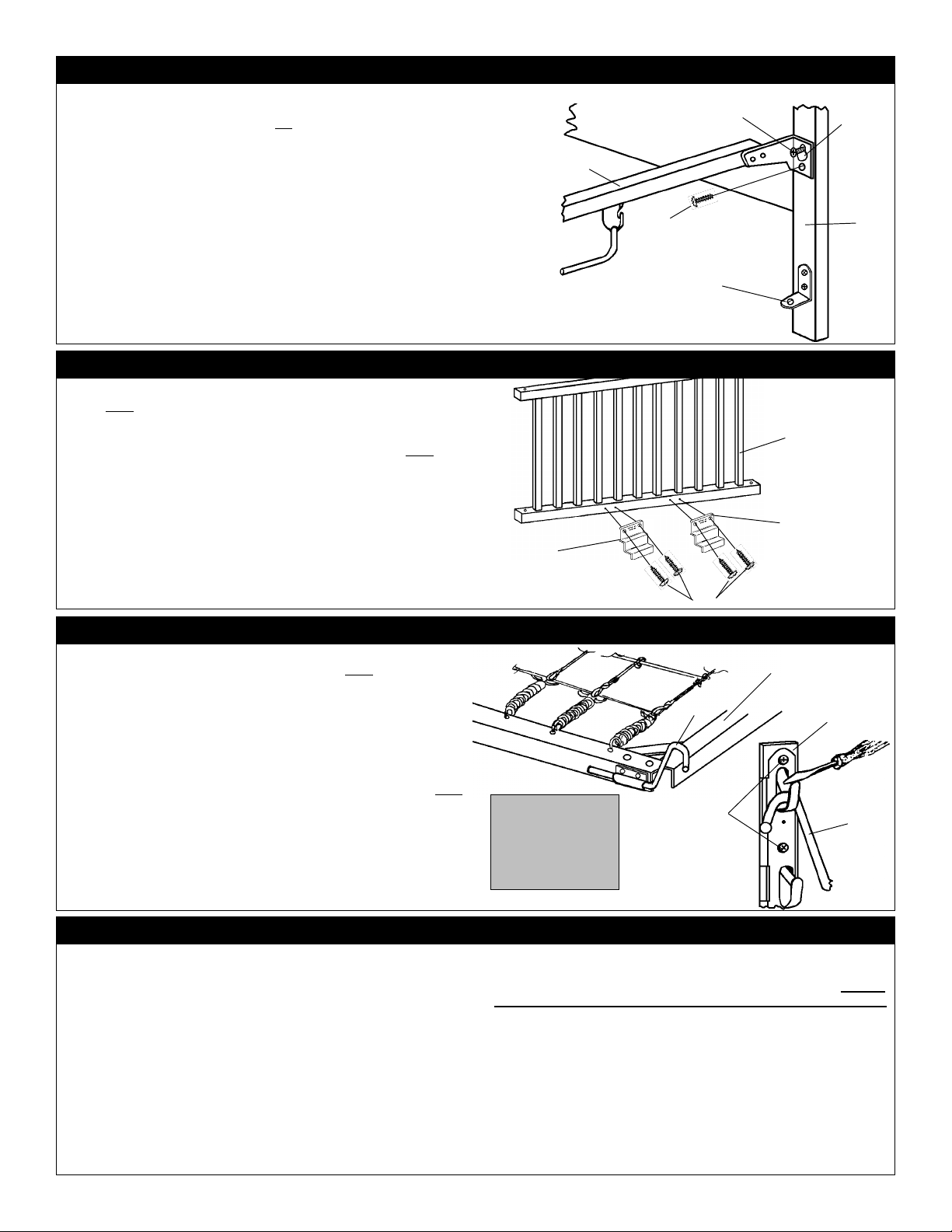

STEP 1 - DIAGRAM 1: ATTACH OF 4-POSITION SPRING HANGER BRACKETS AND ANGLE BRACKETS.

EE

EE

E

EE

EE

E

II

II

I

DD

DD

D

Factory

installed

OO

OO

O

Holes to

receive

Slotted/

Phillips

Wood

Screws

EE

EE

E

DD

DD

D

1

15061,16101,16151,16191,16281

2

STEP 2 - DIAGRAM 2: INSTALL STABILIZER BARS.

Attach each Stabilizer Bar

DIAGRAM 6. You will use a total of (8) Slotted/Phillips Machine Screws

Slotted/Phillips Machine Screw

JJ

Bar

J placement, located in ends

JJ

- do not tighten at this time. Place the keyhole (top hole in each end of Stabilizer Bar

JJ

J, over top extended Screws

JJ

to Diagram. Ends

this procedure for mounting the remaining Stabilizer Bar

in the exact same manner. Place four Slotted/Phillips Machine Screws

receiving holes in each end of both Stabilizer Bars

NN

ends

OO

N &

O, tighten all eight Slotted/Phillips Machine Screws

NN

OO

NN

N and

NN

JJ

J to crib ends

JJ

AA

A into top receiving bushing, designated for Stabilizer

AA

OO

O &

OO

AA

A

(which you have just installed and left extended),

AA

OO

O will now be mounted together on one side of crib, repeat

OO

NN

OO

N and

O. Refer to Diagram 2 and MAIN

NN

OO

NN

N as shown, leave each top screw extended

NN

JJ

J to the other side of the crib

JJ

JJ

J, into receiving bushings located in

JJ

AA

A securely at this time.

AA

AA

A. Place a

AA

refer

AA

A into the lower

AA

STEP 3 - DIAGRAM 3: ATTACH GATE SHOES TO DROPSIDES.

EE

E.

EE

CC

C to lower rail

CC

CC

C over predrilled lead holes on lower rail

CC

and affix with (8) Slotted/Phillips Wood Screws

CC

C. Tighten Screws

CC

(inside)

of each Crib Side

EE

E securely. Note: When

EE

Position two Gate Shoes

shown. Note: Gate Shoe Patent No. will be visible when Gate Shoes

mounted. Align Gate Shoes

of Crib Side

EE

E, two in each Gate Shoe

EE

disassembling crib in the future, DO NOT REMOVE THE GATE SHOES

ANY OTHER HARDWARE ITEM ATTACHED WITH SLOTTED/PHILLIPS

WOOD SCREWS

P/QP/Q

P/Q

P/QP/Q

(dropsides)

P/QP/Q

P/Q as

P/QP/Q

CC

C are

CC

(inside)

CC

C OR

CC

J

A

A

Extended

I

Factory

installed

CCH00701:09/00

Keyhole

O

P orQ

STEP 4 - DIAGRAM 4: INSTALL SPRING HANGERS & CRIB SPRING

Locate Crib Spring

Spring Hangers

side of Crib Spring

6. Also the printing on the plastic pouch

placed upward. Insert Spring Hangers

frame of Crib Spring

required to fully engage Spring Hangers

RR

R by placing each of the 4 Spring Hanger

RR

of the four 4-Position Spring Hanger Brackets

backers), mounted on ends

The lip of the moulded plastic backer will allow the Spring Hanger to be

placed with no difficulty. However, when you decide on another placement

of Crib Spring

screwdriver, on the lip of the moulded plastic backer and hold down in order

to raise Spring Hanger

procedure whenever you opt to change Crib Spring

four positions.

RR

R,

(with plastic pouch factory attached)

RR

BB

B, refer to Main Diagram 6, and 4. Note: Be sure smooth

BB

RR

R wire is placed upward as illustrated in Main Diagram

RR

RR

R as shown, (a light blow with a hammer may be

RR

OO

O and

OO

RR

R you will need to place your thumbnail, or a small

RR

BB

B from its present position. Follow this same

BB

(attached to crib spring)

BB

B into each bracket attached to

BB

BB

B). Carefully install Crib Spring

BB

BB

B into a selected position in each

BB

DD

D, (with moulded plastic

NN

N. See Main Diagram 6, and 4. Note:

NN

DD

, and the four

RR

R to another of the

RR

STEP 5: INSTALL CRIB DROPSIDES

Locate Crib Rods

Springs

a Crib Rod

to Main Diagram 6 for proper placement.)

GG

G and the four remaining Slotted/Phillips Machine Screws

GG

1.1.

1. The top rail of Crib Side

1.1.

KK

K, Crib Sides

KK

KK

K downward through the holes in the following sequence:

KK

(Note: gate shoes will be placed to inside),

2.2.

2. The L- bracket on 4-Position Spring Hanger Bracket

2.2.

3.3.

3. Compression Spring

3.3.

4.4.

4. Bottom Rail of Crib Side

4.4.

5.5.

5. A Bumper Spring

5.5.

6.6.

6. Hole in Angle Bracket

6.6.

GG

G,

GG

P/QP/Q

P/Q, Compression Springs

P/QP/Q

PP

QQ

P or

Q,

PP

FF

F,

FF

II

I.

II

(with plastic teething rail),

QQ

PP

QQ

P or

Q,

PP

QQ

FF

F, Bumper

FF

will be

AA

A. Insert

AA

(Refer

DD

D,

DD

C

C

E

RR

R

RR

BB

B

BB

Top surface

To remove Spring

Hanger

down on lip with

thumbnail or screwdriver and pull Spring

Hanger

Place a Slotted/Phillips Machine Screw

and into receiving bushing located in top corner post of Footboard

Headboard

USE A POWER SCREWDRIVER OF ANY TYPE TO TIGHTEN SCREW

Start Screw A (two or three turns) with your fingers into its threaded

bushing to insure Screw A has a square fit. Once you are sure Screw

A fits squarely into its threaded bushing, tighten securely with a hand

held screwdriver. Attach the other Crib Rod

Side

Machine Screws

tighten if needed.

suggest you rub the crib rod with waxed paper or paraffin. You may want

to repeat this procedure periodically. Attach the remaining Crib Side

or

BB

B press

BB

BB

B upward.

BB

NN

N

. Refer

to Main Diagram 6 for proper placement. DO NOT

NN

PP

QQ

P or

Q,, using the same procedure. Be sure Slotted/Phillips

PP

QQ

AA

A are tightened securely, check periodically and

AA

Tip:Tip:

Tip: To help Crib Rods

Tip:Tip:

QQ

Q, by repeating Step 5.

QQ

EE

E

EE

AA

A into hole in top of Crib Rod

AA

KK

K to the other end of Crib

KK

KK

K function more quietly we

KK

DD

D

DD

CLOSE UPCLOSE UP

CLOSE UP

CLOSE UPCLOSE UP

VIEW VIEW

VIEW

VIEW VIEW

BB

B

BB

KK

K

KK

OO

O/

OO

AA

A.

AA

PP

P

PP

Loading...

Loading...