Chigo CS/CU-32H3A-V84, CS/CU-25H3A-V84, CS/CU-51H3-P88, CS/CU-51H3A-P84, CS/CU-35V3A-M84 Failure code manual

...

Failure code manual

content

一、wall split AC series………… …………………………………………2

二、floor standing AC series………….……………………………………4

三、portable AC series…………..…………………………………………5

四、dehumidifer……………………………………………………………6

五、DC inverter single split series…………................................................7

六、DC inverter multi-split series…………………………………………10

1

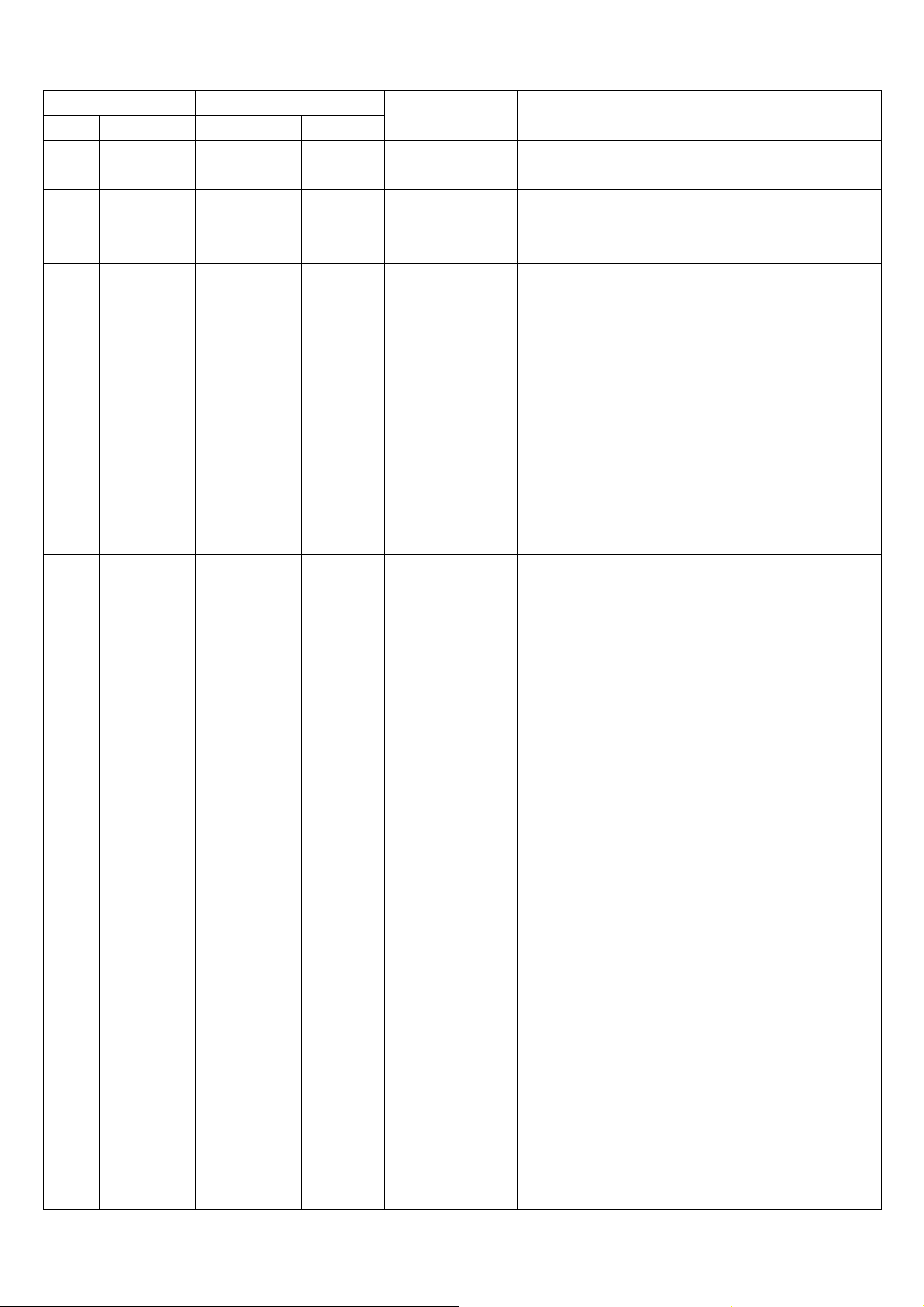

一、wall split AC series

LED lamp display

code explain code explain

display at

DF

E2

E3

display at

display at

display at

on state

off state

off state

off state

display at

E4

on/off

state

flicker 1/1

SEC

flicker 1/3

SEC

flicker 1/1

SEC

flicker 3/5

SEC

flicker 4/6

SEC

display

at on/off

state

display

at on/off

state

display

at off

state

failure

defrost

indication

anti cold wind

room temp.

sensor fault

coil temp.

sensor fault

outdoor unit

abnormal

2

The reason of fault and solution

Normal, the defrost state is removed, it will return to

normal condition automatically

1、 Normal (during heating mode )

2、It will be removed when the coil pipe temperature

sensor reaches certain temperature.

1、Check whether the resistance of the sensor is normal

(the resistance is 5КΩ in the normal temperature

25 )℃ , when it is abnormal the sensor should be

replaced.

2、Check whether there is short circuit or open circuit in

the wire of the sensor, and whether the plug is

connected well, whether there is welding off or

rosin joint on the electric control board, if there is

any, it should be repaired.

3、When the 1 and 2 are both normal, then the

components or integrated circuit is damaged, the

electric control board should be replaced.

1、Check whether the resistance of the sensor is normal

(the resistance is 5КΩ in the normal temperature

25 )℃ , when it is abnormal the sensor should be

replaced.

2、Check whether there is short circuit or open circuit in

the wire of the sensor, and whether the plug is

connected well, whether there is welding off or

rosin joint on the electric control board, if there is

any, it should be repaired.

3 、 When the 1 and 2 are both normal, then the

components or integrated circuit is damaged, the

electric control board should be replaced.

1、 Check whether the winding resistance and

operation current of the compressor are normal.

2、Check whether the high and low pressure is normal

when the unit is running.

3、Check (whether the coil pipe sensor is normal)

whether the contact of the inserter on the circuit

board is well, the coil pipe temperature sensor is

fixed, the evaporation of the indoor unit is well,

the key is to check the evaporator temperature

detected by the coil pipe temperature sensor has

reached the cooling or heating temperature.

4、Check whether the surface of the condenser is too

dirty, it should be cleaned when it is too dirty.

5、Check whether the capacitance of the outdoor motor

and the fan is damaged, it should be replaced when

it is damaged.

6、If the above items are normal, the electric control

board should be replaced.

1、Check whether two sets of plugs on the outlet end of

the motor have loosed from the socket of the

electric control board, insert it firmly when loosing.

E5

E6

E7

E8

PG motor

display at

off state

PG motor

display at

off state

display at

off state

display at

off state

flicker 5/7

SEC

flicker 6/8

SEC

flicker 7/9

SEC

flicker 8/10

SEC

display

at off

state

display

at off

state

display

at off

state

display

at off

state

no feedback

signal of indoor

fan

no over zero

signal

outdoor

feedback fault

frost

protection/over

heat protection

2、Check whether the indoor motor has damaged, the

motor should be replaced when it is damaged

3、 Check whether the controllable silicon and other

components on the electric control board have

damaged, replace the controllable silicon or electric

control board when they are damaged.

1、Firstly check whether the indoor fan is normal.

2、Check whether the signal outputting from the

integrated chip of the electric control board is

normal, the electric control board should be

replaced when the signal is abnormal.

1、Check whether the winding resistance and operation

current of the compressor are normal

2、Check whether the high and low pressure is normal

when the unit is running.

3、Check whether the indoor and outdoor wiring is

right; when it is wrong, connect them again

according to the circuit diagram

4、 Check whether the contact of the inserter on the

circuit board and the connection are well, otherwise

repair.

5、Check whether the signal feedback wire is

disconnected, replace or connect the feedback

signal wire.

6、Check whether the supply power is phase-lacking or

phase opposition.

7、Check whether the AC electromagnetic contactor is

well.

1、Check whether the filter of the indoor unit is dirty or

blocked, and clean if it is dirty.

2、Check whether the indoor fan is running normally,

and replace the motor if it is abnormal.

3、Check whether indoor pipe temperature sensor is

normal, and replace the sensor if it is abnormal.

4、Check whether the system pressure is normal, if

abnormal, should check whether there is leakage,

and fill the refrigerant again.

3

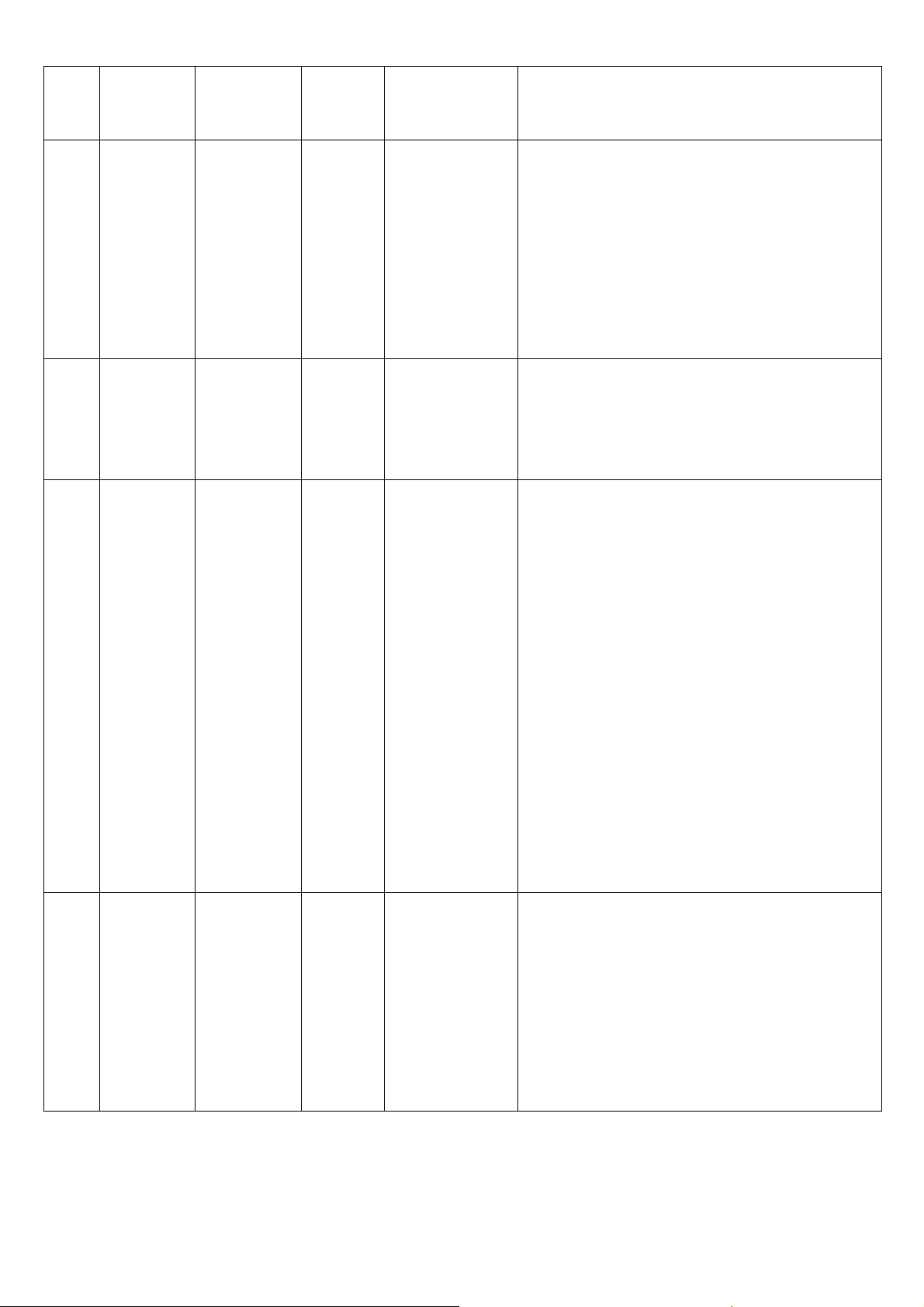

二、floor standing AC serial

LED lamp display

code explain code explain

display

at on/off

state

display

at on/off

state

display

at off

state

display

at off

state

E2

E3

E4

E7

display at

off state

display at

off state

display at

on/off

state

display at

off state

flicker 2/4

flicker 3/5

flicker 4/6

flicker 7/9

SEC

SEC

SEC

SEC

failure

room temp.

sensor

fault

coil temp.

outdoor

abnormal

outdoor

feedback

sensor

fault

unit

fault

The reason of fault and solution

1、Check whether the resistance of the sensor is normal (the

resistance is 5КΩ in the normal temperature 25 )℃ ,

when it is abnormal the sensor should be replaced.

2、Check whether there is short circuit or open circuit in the

wire of the sensor, and whether the plug is connected

well, whether there is welding off or rosin joint on the

electric control board, if there is any, it should be

repaired.

3、When the 1 and 2 are both normal, then the components

or integrated circuit is damaged, the electric control

board should be replaced.

1、 Check whether the resistance of the sensor is normal

(the resistance is 5КΩ in the normal temperature 25 )℃ ,

when it is abnormal the sensor should be replaced.

2、Check whether there is short circuit or open circuit in the

wire of the sensor, and whether the plug is connected

well, whether there is welding off or rosin joint on the

electric control board, if there is any, it should be

repaired.

3、When the 1 and 2 are both normal, then the components

or integrated circuit is damaged, the electric control

board should be replaced.

1、 Check whether the winding resistance and operation

current of the compressor are normal.

2、Check whether the high and low pressure is normal when

the unit is running.

3、Check (whether the coil pipe sensor is normal) whether

the contact of the inserter on the circuit board is well, the

coil pipe temperature sensor is fixed, the evaporation

of the indoor unit is well, the key is to check the

evaporator temperature detected by the coil pipe

temperature sensor has reached the cooling or heating

temperature.

4、 Check whether the surface of the condenser is too dirty,

it should be cleaned when it is too dirty.

5、Check whether the capacitance of the outdoor motor and

the fan is damaged, it should be replaced when it is

damaged.

6、If the above items are normal, the electric control board

should be replaced.

1、Check whether the winding resistance and operation

current of the compressor are normal

2、Check whether the high and low pressure is normal when

4

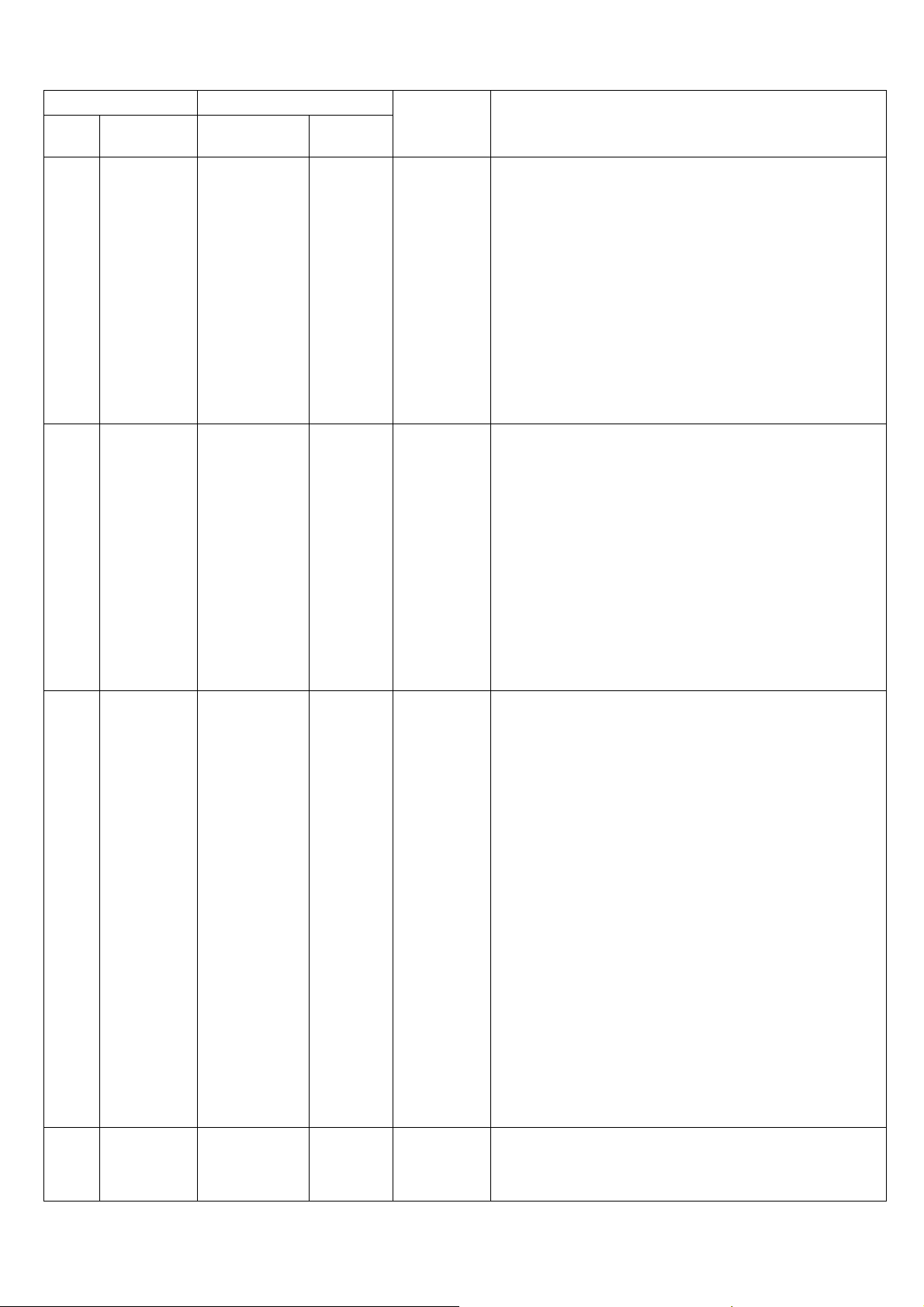

Loading...

Loading...