Page 1

I N S T A L L A T I O N I N S T R U C T I O N S

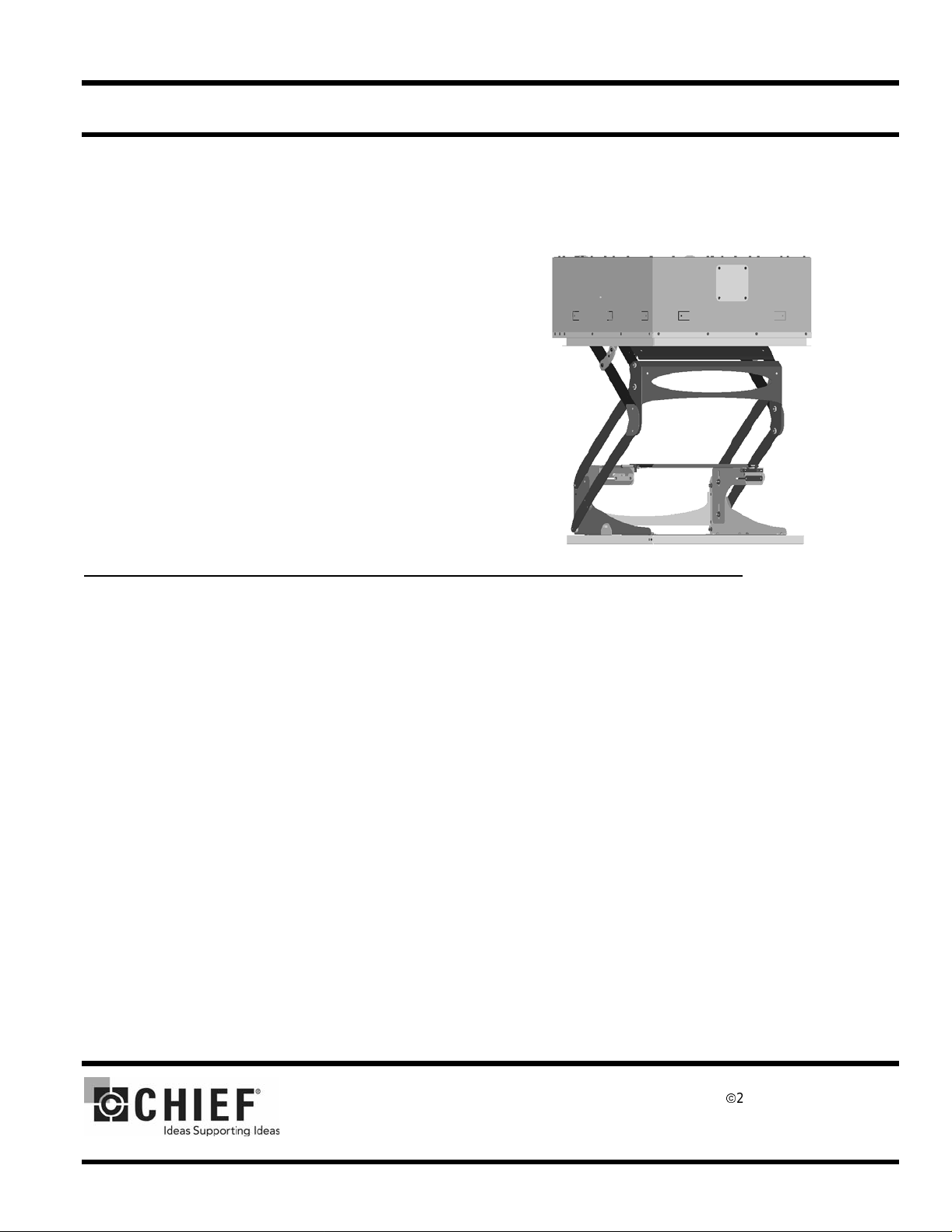

SMART-LIFTTM 236 Electric Ceilin g Lift

The Model SL-236 Electric Ceiling Lift is a reliable,

heavy-duty video lift mechanism for LCD/DLP projectors

requiring an extended drop from their hidden location.

The ceiling lift is designed for home-theater, conference

room, or school applications.

The SL-236 provides an attractive solution to recess a

projector in the ceiling. Th e lift is suitable for finis hed or

suspended ceiling with a finish kit. The concealed bottom

can be finished to match existing ceiling design and color

to conform to room decor.

Plenum Rating requires use of Class II control wiring,

electrically hard wiring the unit, and all open holes in the

housing (except joist tabs) must be sealed using foil tape.

BEFORE YOU BEGIN

• CAUTION: To prevent damage to the ceiling lift, which could affect or void the factory warranty, thoroughly study

all instructions and illustrations before you begin to install or operate the lift. Pay particular attention to the “Important Precautions” on Page 1.

• CAUTION: For smooth and reliable operation, the lift must be installed square and parallel in all dimensions. Avoid

stressing or twisting the lift at any time during installation.

• Because of the size and weight of the lift, Chief Manufacturing recommends that at least two people be available

when installing the lift.

• If you have any questions concerning this installation, contact Chief Manufacturing at 1-800-582-6480.

CHIEF MANUFACTURING INC.

1-800-582-6480 952-894-6280 FAX 952-894-6918

8401 EAGLE CREEK PARKWA Y

SA VAGE, MINNESOTA 55378 USA

PART NO. 8820-000008 (Rev.

©

2008 Chief Manuf acturing

www

.chiefmfg.com

0

4-08

E)

Page 2

Instruction Manual SMART-LIFT 236 Electric Ceiling Lifts

IMPORTANT WARNINGS AND CAUTIONS!

• WARNING: This is an electrical device. All electrical installation proced ures should be performed by a qualified electrician.

• WARNING: Improper installation can result in serious personal injury! Make sure that the ceiling structural members can support a redundant weight factor five times

this weight, reinforce the ceiling before installing the lift.

• WARNING: Be aware during the installation that this is a motorized device, and there are pinch points for people and

for el ectrical wiring.

• W ARNING: Be aware of the potential for pers onal injury or damage to the lift if it is not adequately mounted. The lift

(without a projector) weighs approximately 85 lbs (38.5 kg).

• W ARNING: Plenum rating r equire s the unit to be hard wired through the pr ovided strain r elief, use of Clas s II control

wiring, and all open holes in housing (except joist tabs) must be sealed using foil tape.

• WARNING: Electrical outlets must be install ed by a qualified electrician. Follow all electrical codes.

• CAUTION: Test the lift for shipping damage. See “PRETEST THE LIFT BEFORE INSTALLING” on page 6.

the total weight of the equipment. If the ceiling can not support

• CAUTION: For smooth and reliable operation, the lift must be ins tal led square and parallel in all dimensions. Avoid stress-

ing or twisting the lift at any time during installation.

• CAUTION: Changes or modifications not approved by Chie f Manufacturing could void use r’s warranty.

• CAUTION: Improper weight distributio n could lead to equipment damage. Make certain projector weight is centered on cra-

dle when mounted.

TOOLS REQUIRED FOR INSTA L LATION

• Phillips screwdrivers, No. 1 and No. 2

• Electric drill and bit set

• Pliers (heavy -duty)

• Electrical wire cutter/stripper

• If suspende d from threaded rods: Socket set with extension and open wrenches

NOTE: Other tools may be required depending on the

method of installing the lift in the ceiling.

1

Page 3

Instruction Manual SMART- LIFT 236 Electric Ceiling Lifts

CONTENTS

DIMENSIONAL DRAWING ................................................................... 3

SPECIFICATIONS ................................................................................. 4

ACCESSORIES ..................................................................................... 5

PRETEST THE LIFT BEFORE INSTALLING ........................................ 6

PREPARE THE CEILING OPENING AND

INSTALL THE LIFT ............................................................................... 7

General Guidelines ................................................................... 7

Installation in a Suspe nded Ceiling (using threaded ro ds) ....... 8

Installation in a Wood Framework (or Side-Mounted to Joists) 9

CONNECT POWER TO THE LIFT ........................................................10

Non Plenum Rated Installation .................................................10

Plenum Rated Installation ......................................................... 10

(OPTIONAL) INSTALLING WIRING COVER..........................................11

INSTALL THE PROJECTOR ON THE LIFT ..........................................12

Install and Route Cables ........................................................... 12

ADJUSTMENTS .................................................................................... 13

Adjust Travel .............................................................................13

Adjust the Aim of the Projector ................................................. 13

OUTSIDE TERMINAL WIRING EXAMPLES ......................................... 14

Push Button ..............................................................................14

Supplied SPST Switch Using Internal 24VAC Power Supply ... 14

Supplied SPST Switch Using Internal 12VDC Power Supply ... 14

Supplied SPST Switch Using External Power Supply .............. 14

SPDT Switch or 2 Dry Contact Closures, Momentary or

Latching ....................................................................................15

Internal 12VDC Power Supply 2.5A Maximum .........................15

Internal 24VAC Power Supply, 1.2A Max ................................. 15

Internal Dry Contact Closures....................................................15

Service Position ........................................................................ 15

INSIDE TERMINAL WIRING EXAMPLES .............................................16

Push Button ..............................................................................16

Supplied SPST Switch Using Internal 24VAC Power Supply ... 16

Supplied SPST Switch Using Internal 12VDC Power Supply ... 16

Supplied SPST Switch Using External Power Supply .............. 16

SPDT Switch or 2 Dry Contact Closures, Momentary or

Latching ....................................................................................17

Internal 12VDC Power Supply 1.2 A Maximum ........................ 17

Internal 24VAC Power Supply, 2.5 A Maximum ....................... 17

Internal Dry Contact Closures ...................................................17

Low Voltage Sensing: ...............................................................17

Service position..........................................................................17

INTERIOR TERMINAL DESIGNATIONS .............................................. 18

EXTERIOR TERMINAL DESIGNATIONS ............................................. 20

TROUBLESHOOTING .......................................................................... 22

2

Page 4

Instruction Manual SMART-LIFT 236 Electric Ceiling Lifts

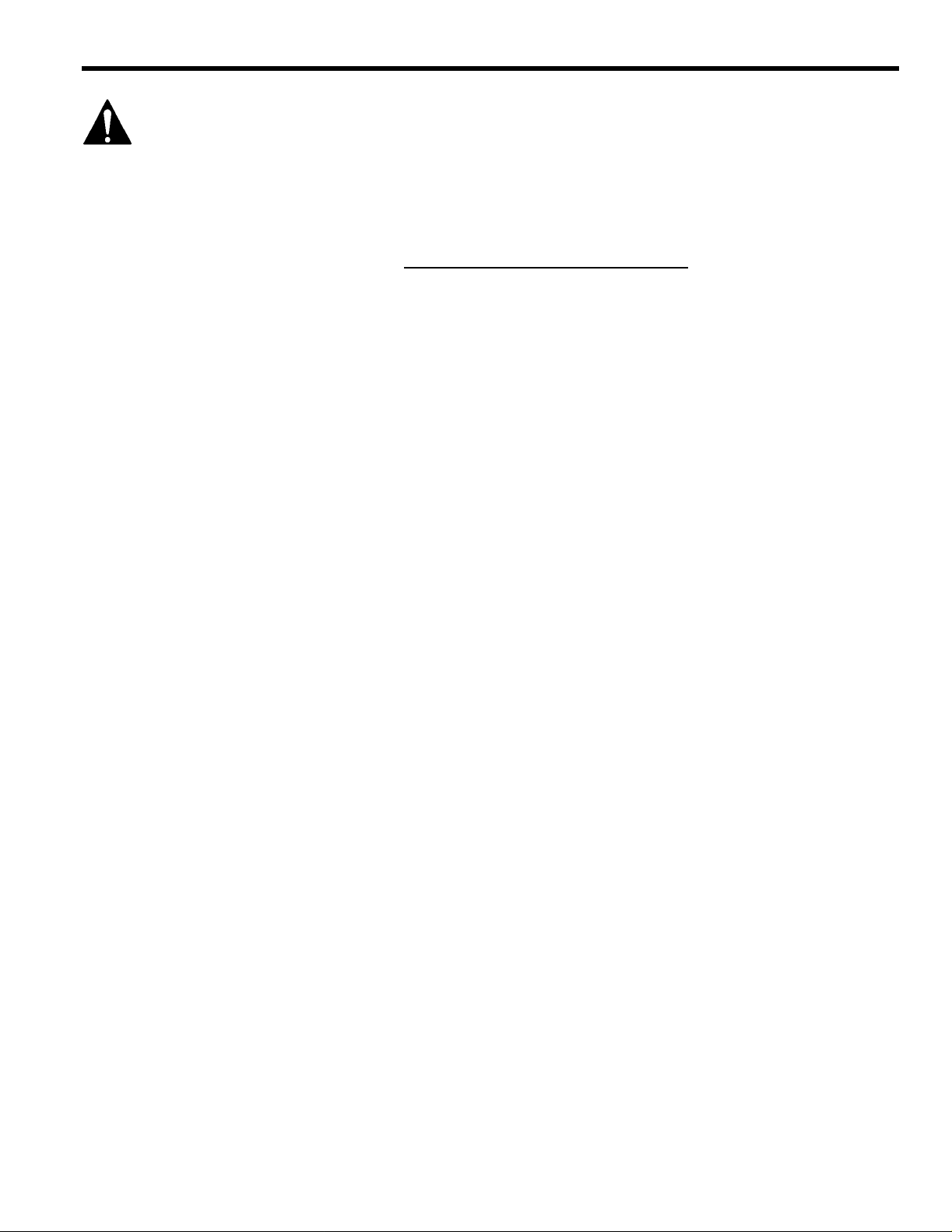

DIMENSIONAL DRAWING

SP

FD

3

Page 5

Instruction Manual SMART-LIFT 236 Electric Ceiling Lifts

SPECIFICATIONS

OVERALL DIMENSIONS CLOSED (HxWxD): FD: 11.0 6 x 26.35 x 28. 85

SP: 12.25 x 25.12 x 28.31

MAXIMUM AVAILABLE SPACE FOR

PROJECTOR AND EQUIPMENT (HxWxD): 9.25 x 20.50 x 22.75

CLOSURE PANEL SIZE (WxD): 23.87 x 23.87

RECOMMENDED CEILING OPENING SIZE (WxD)*: 25.50 x 28.00

AVAILABLE TRAVEL DISTANCE: 36.00"

ROLL ADJUSTMENT: 2°

PITCH ADJUSTMENT: 15°

YAW ADJUSTMENT: 10°

INTERNAL HEIGHT ADJUSTMENT: 2.00"

INTERNAL FORE/AFT ADJUSTMENT: 3.00" (1/2" INCREMENTS)

INTERNAL LEFT/RIGHT ADJUSTMENT: 2.00" (1/2" INCREMENTS)

COLOR: WHITE

MAXIMUM WEIGHT CAPACITY: 35#

NET WEIGHT: 85#

OUTPUT RELAYS: 1.0 AMP@30VDC

0.5 AMP@125VAC

0.3 AMP@60VDC

INTERNAL POWER SUPPLY: 12VDC, 2.5A MAX

24VAC, 1.2A MAX

CURRENT DRAW: .75A

FUSE: 4A, BUSSMAN TYPE GDB

*A NOTCH MAY BE REQUIRED TOW ARD THE REAR OF THE OPENING TO CLEAR THE TERMINAL BLOCK. SEE

DIMENSIONAL DRAWINGS.

4

Page 6

Instruction Manual SMART-LIFT 236 Electric Ceiling Lifts

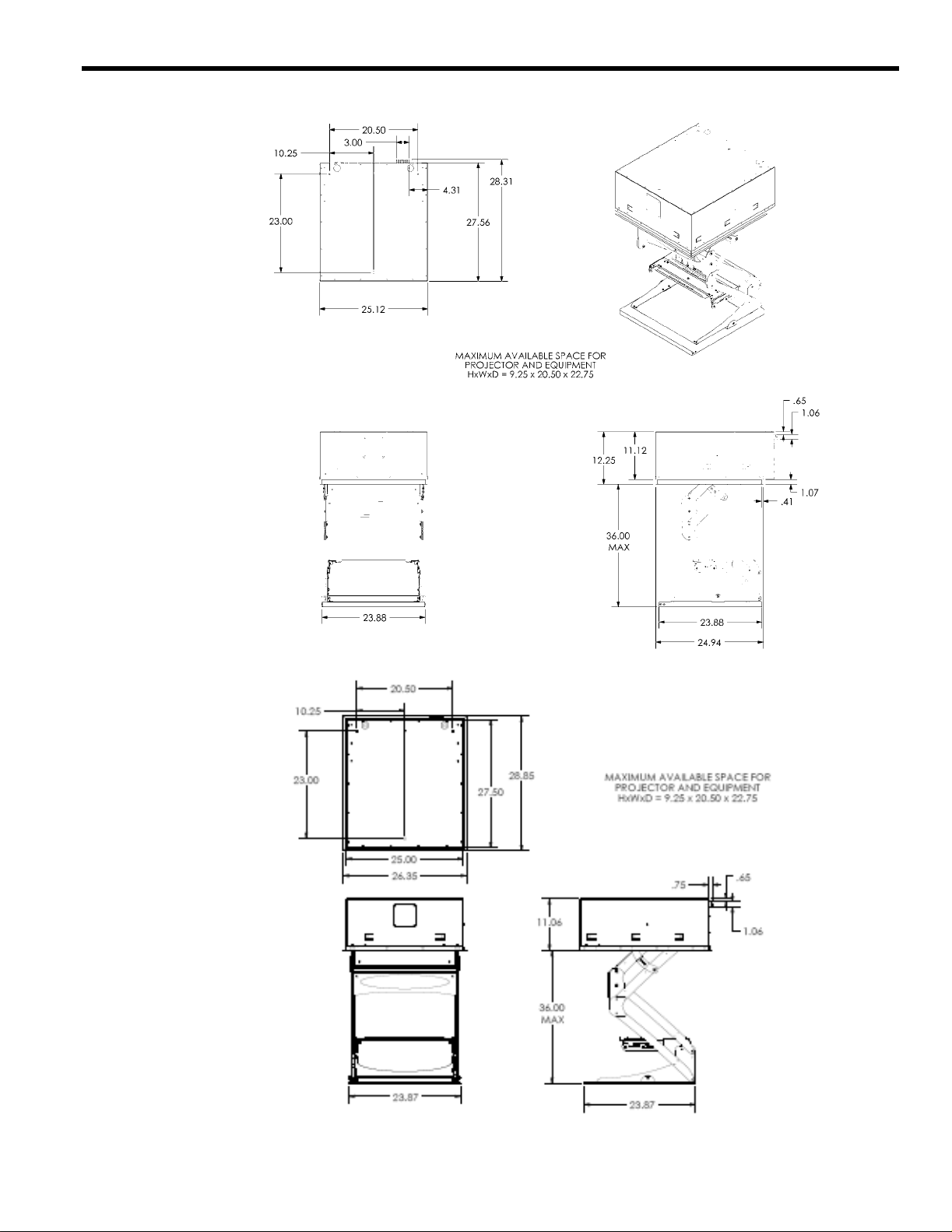

ACCESSORIES

Control

ASP-401

Rocker Switch with Wall Plate

Simple lift control.

RC-10

Radio Frequency

Remote Control

IR-10

Infra-Red Remote Control

Multiple code settings.

Single button control of the lift.

SMA-620

Suspended Ceiling Track

Clip

SMA-601

Single Column Mounting Plate

Discrete UP/DOWN/SERVICE comm an ds .

Used with most universal remotes.

Installation

Securely attaches the suspended ceiling grid to the lift.

Includ es 8 clips.

Attac hes to any 1 1/2 ” NP T ext e nsion col u mn .

Allows 3” fore/aft and 3” left/right adjustment.

Permits slight roll, pitch and yaw adjustment.

Allo w s 2” height adjustm ent after installatio n .

SMA-650

Threaded Rod Adapter

Simplifies ins ta lla tio n usin g threa de d rods .

Allows cable use for support/installation.

5

Page 7

Instruction Manual SMART-LIFT 236 Electric Ceiling Lifts

PRETEST THE LIFT BEFORE INSTALLING

IMPORTANT: Before mounting the lift in the ceiling, perform

the following test to be sure that it operates properly and has

not been damaged during shipping.

1. Attach supports (not supplied) to the top of the lift (see

Figure 1).

2. S us pend the lif t at leas t 3 1/2 f eet hi g h from a su it ab le st ruc tur e

[i.e. s aw hor ses, ladd e rs , o r tab le s (s ee Figure 2)] .

NOTE: The supplied momentary push button and power cord can

be used to pre-test the lift (see and “OUTSIDE TERMINAL

WIRING EXAMPLES” on page 13).

3. Cycle the lift through the “show” and “service” positions, making sure the unit operat es smoothly.

Figure 1. Support the Unit

Figure 2. Suspend the Unit

6

Page 8

Instruction Manual SMART-LIFT 236 Electric Ceiling Lifts

PREPARE THE CEILING OPENING AND INSTALL THE LIFT

Because of the wide variety of possible mounting situations, Chief Manufacturing can only provide general guidelines

for preparing the location where the Smart-Lift wil l be i nst al led. Study the following information carefully, and adapt i t as

necessary to fit your specific installation.

WARNING: Be esp ecia lly aware of the weight of the lift, and the potential for personal injury or of damage to

the lift if it is not adequately mounted. The lift (without a projector) weighs approximately 85 lbs (38.5 kg).

The “General Guidelines” below, and the information on the following pages, covers the most common mounting situations:

• Suspend the lift from threaded rods that secure to the structural cross brace.

• Side-mount the lift to the ceiling joists or secure the lift to a wood framework mounting to the joists.

General Guidelines

• Carefully determin e the posit ion of the ceiling opening and its distance from, and orientation toward, the screen.

• If possible, prepare an area above the ceiling that is sufficiently larger than the lift, Leaving at least an 8” access to

all sides and above the top of the lift for any future maintenance or repair.

WARNING: Improper installation can result in serious personal injury! To avoid such injury, make sure

that the ceiling structural members can support a redundant weight factor five times the tota l w eight of the

equipment you intend to support overhead. If they cannot, the ceiling must be reinforced before you

install the lift.

WARNING: Improper inst allation can result in serious injury! Plenum rated installations require electrically hard wiring the unit through the provided strain relief, the use of Class 2 control wiring, and all open

holes in the housing (except joist tabs) must be sealed using foil tape. You must adhere to all local codes.

CAUTION: For smooth and reliable operation, the lift must be installed square and parallel in all dimensions.

Avoid stressing the lift at any time during installation.

7

Page 9

Instruction Manual SMART-LIFT 236 Electric Ceiling Lifts

SL236 shown with ceiling tile and grid installed in

Installation in a Suspended Ceiling (using threaded rods)

You can suspend the lift housing from three 3/8-in.-dia. threaded

rods (not supplie d by Chi ef Manufa cturing ) First, secur e the rods to

a structural cross brac e in the ceiling. Insert the rods through the

three holes on the top side of the lift housing, or through the holes

of optional br ac kets SMA-651, and secure them to the hous ing

using two jam nuts (one ins ide, one outside). See Fig. 3.

CAUTION: For smooth and reliable operat ion, the lift must be

installed square and parallel in all dimensions. Avoid stre ssing

or twisting the lift at any time during installation.

Install the lift using threaded rods:

1. With the lift in the fully retracted position, remove the cl osure

panel from the bottom of the lift.

2. If you are using the SMA-651, install it now.

3. Insert the 3 threaded rods through the top of the lift or

SMA-651.

4. Us ing nuts and washers, secure the lift to the threaded rods.

Finish the suspended ceiling:

1. Cut the grid to fit the perimeter of th e lift and insert it into the

side channel of lift (the side channe l of the lift will support the

weight of the ceiling grid and tiles).

2. If using the SMA-620, see the SMA-620 instructions and

install them now.

3. Cut surrounding ceiling tile to appropriate size.

4. Make sure the unit is level, square, paralle l and there is no

stress applied to the box (chassis).

5. Us ing the test pus h button, carefull y operate the lif t all the way

up and down to be sure the clearances are adequate. Be prepared to stop the lift immediately if the lift begins to sound

labored or one side begins to travel slower.

6. Replace surrounding ceiling tile.

7. With lift at least partway open, remove four screws securing

ceiling tile ret ainer on bottom of tray (see Figure 4) and

remove ceiling tile retainer.

8. Cut ceiling tile to fit inside ceiling tile retainer [include grid

pieces if neces sary (see Figure 5)] a nd install ceiling tile (grid)

by sliding it into the open end of the ceiling tile retainer.

Figure 3. Threaded Rod Installation

Figure 4. Re m o v e C e iling Retainer

bottom panel

CAUTION: Make sure all parts assem ble easily, without distort-

ing any parts, when installing tile in the ceiling tray. Any parts

protruding from the tray will cause damage when the unit

closes.

9. Install ceiling tile retainer and secure using four screws.

8

Figure 5. Grid Intersection

Page 10

Instruction Manual SMART-LIFT 236 Electric Ceiling Lifts

L

NOTE:Bead flange setback allows

11. After installing the lift, use the test push button to carefully

operat e the lift all the way up and down to b e sure the cl earances are adequa te . Be prepared to stop the li ft immedia tely

if the lift begi ns to sound l abor ed or if on e sid e or the oth er sid e

begins to travel slower.

12. To maintain ple num rating, seal any openings in the lift hous-

ing (except joist tabs) using foil tape.

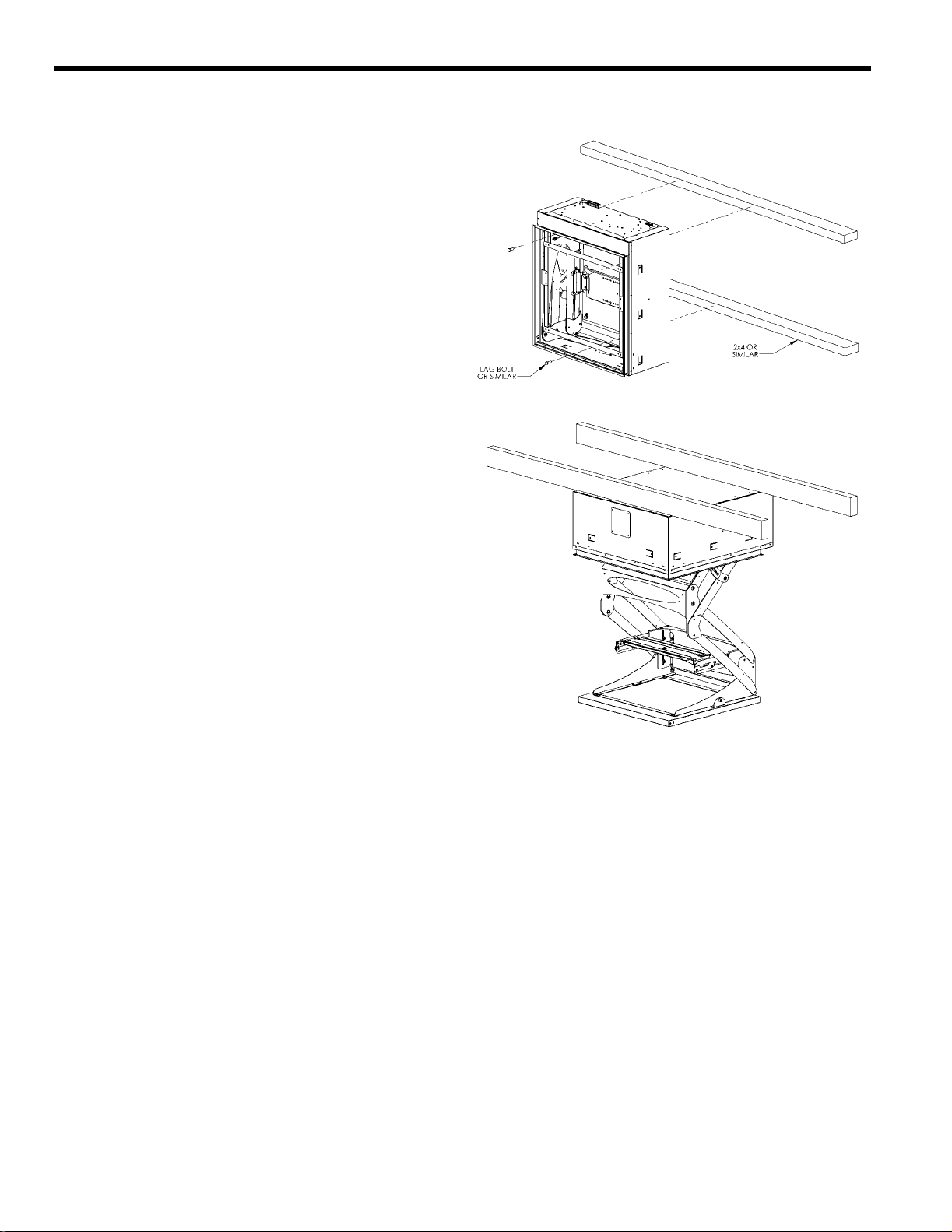

Installation in a Wood Framework (or Side-Mounted to Joists)

A suitable framework must be constructed to support the lift in the

ceiling. Refer to for dimensions of the lift. The lift housing has

mounting tabs to assist in side-mounting the lift to the ceiling joists

or otherwise securing it to a wood framework.

The idea l lift installation time is after the sheetrock has been

installed, but before the sheetrock has been mudded or finished.

1. Remove the closure panel from the bottom of the lift to gain

access to the front a nd back mounting holes.

CAUTION: For smooth and reliable operat ion, the lift must be

installed square and parallel in all dimensions. Avoid stre ssing

the lift at any time during installation.

2. Position the lift in the desired locati on, making sure the unit is

level, squa re, parallel and the re is no stress applied to the box

(chassis).

3. Secure the lift to the joists or wood framework. Drive at least

six 1/4 x1-1/4-in. lag screws through the mounting tabs around

the inside of th e lift housing and mounting holes across the

back of the li ft. The re are 8 tab loc at ions, thr ee in each side and

two in one end, and 3 mounting hole locations across the back

of the lift (see Figure 6 and Figure 7). The lift requires support

on two opposing sides only.

4. After installing the lift, use the test push button to carefully

operat e the lift all the way up and down to b e sure the cl earances are adequa te . Be prepared to stop the li ft immedia tely

if the lift begi ns to sound l abor ed or if on e sid e or the oth er sid e

begins to travel slower.

5. To maintain plenum rating, seal any openings in the lift hous-

ing (except joist tabs) using foil tape.

The bottom of the lift may be painted or textured as necessary to

match the ceiling.

Figure 6. Mounting Locations

1/4 Dia. Lag Screw

ift Housing

Alternate 1/4 Dia.

Bolt Thru

Joist

Sheetrock

finish compound to hide

lift housing seam.

Bead Flange

Figure 7. Mounting Method

Finish C ei lin g

Compound

9

Page 11

Instruction Manual SMART-LIFT 236 Electric Ceiling Lifts

s

CONNECT POWER TO THE LIFT

WARNING: Plenum rating requires hard wiring and use of

Class II control wiring. Follow all loc al building and el ectrical

codes.

NOTE: If the lift is cycled up and down repeatedly, the thermal

overload on the motor may s top operation. Operation will

resume when the therma l overload cools and resets (5 to 15

minutes).

Non Plenum Rated Installation

1. Plug the lift’s power cord (s upplied) into an electrical outlet.

Plenum Rated Installation

WARNING: A licensed elec t rician should

disconnect and terminate the leads to the

power cord receptacle and, using the

access holes provided for a strain relief,

hard wire th e un i t to a pow e r so u rce .

WARNING: Failure to disconnect and terminate power leads

properly m ay result in equipment damage or personal injury.

1. Disconnect and termina te the electrical leads from the power

cord receptacle at the int erior junction box (see Figure 8).

2. Remove the electrical knockout and install the strain relief

(provided).

Terminate Power Lead

Electrical Junction Box

Inside Smartlift

Figure 8. Disconnect and Terminate

Power Cord Leads

3. Ha rd wire the unit to a 110V 60 Hz or 230V 50 Hz (as appropriate) 15-a mp power source.

4. Replace interior outlet in a horizontal position as noted on the

stickers found on th e outlet cover plate.

10

Page 12

(Optional) Installing Wiring Cover

An optional wiring cover may be installed to further protect

wiring from mechanical damage.

WARNING: Make sure that power to SL-236 is OFF before

proceeding!

1. Remove the control harness. (See Figure 9)

2. Using four Phillips head screws, attach cover (included in

kit) over hole created in Step 1.

3. Make control connections directly to the control box. (See

Inside Terminal Wiring Examples sections.)

4. Remove and save two Phillips head screws from opposite

corners of cover plate, and remove cover plate from

SL-236. (See Figure 9)

5. Place switch hole cover behind the cover plate and attach

with two Phillips head screws from the kit.

6. Replace cover plate and attach using two Phillips head

screws removed in Step 4.

7. Remove three Phillips head screws from SL-236.

8. Place motor wiring cover in place and attach with three

Phillips head screws removed in Step 7.

9. Remove three Phillips head screws from SL-236.

10. Place control wiring cover in place and attach with three

Phillips head screws removed in Step 9.

NOTE: Some components not shown for clarity.)

Cover

Plate

5

x 2

Switch Hole

Cover

Motor Wiring

Cover

7

4

x 2

x 3

8

6

x 2

Control Wiring

Cover

10

x 4

Control

Harness

2

1

9

x 3

x 3

Figure 9

11

Page 13

Instruction Manual SMART-LIFT 236 Electric Ceiling Lifts

INSTALL THE PROJECTOR ON THE LIFT

CAUTION: Improper proje ctor weight distribution could lead to

equipment damage. Make certain projector wei ght is centered

on cradle when mounted.

1. Install the SLB bracket on the projector (se e the SLB manual

for details).

2. Remove the yaw adjustment bracket from the lift (see

Figure 9).

3. Place the yaw adjustment bracket over the studs on the SLB as

shown, selecting the set of holes that best cent ers the weight of

the projector.

4. Install tapered thumb nuts (minimum 3), making sure the

tapered end is toward the projector.

5. Reinstall the yaw adjustment bracket with projector attached.

NOTE: If desired, the projecto r can be se t directly on the bottom

plate of the lift, not se cured by the bracke t. The bracket may be

removed for esthetic purpose by removing four roll/height

adjustment nuts (see ADJUSTMENTS).

Install and Route Cables

CAUTION: Do not attach cables to lower lifting arms or sides of

cradle. This may result in damage when lift retracts.

NOTE: Two routing paths are provid ed, one on ea ch side, to sepa-

rate electrical and video cables.

1. Lower lift to service position.

2. Route and secure all electrical and vide o cables using ties and

eyelets provided (see Figure 10), leaving some slack between

securing points .

3. Plug the projector’s power cord into one of the two outlets

inside the lift. One outlet is swi tched and the other is continuously li ve. The swi tched out let is mar ke d wi th an “S ”.

Figure 9. Install Projector

Figure 10. Cable Routing Example

12

Page 14

Instruction Manual SMART-LIFT 236 Electric Ceiling Lifts

ADJUSTMENTS

Adjust Travel

An access hole is located in the corner below the termina l block

(see Fig u re 11). Using a Ph illips screwdr iv er inserted in the access

hole, adjust the stroke of the lift mechanism as follows:

CAUTION: Do not over adjust (exceed maximum trav el) stroke

length.

1. Shorten stroke by tu rning the adjustment screw clockwise one

or two turns, check for the desired stroke length, and repeat as

necessary.

2. Lengthen stroke by turning the adjustment screw clockwise

one or two tu rns , check for the de sire d stro ke le ngth, a nd repeat

as necess ar y.

Adjust the Aim of the Projector

Center the lens (see Fi gure 12). The aim of the projector can be

adjusted in all directions, as shown:

1. Lower the lif t to the 'show' position.

2. Pitch and forward/Aft. There are four 10-24 Nylock nuts

(two on each side) on the outs ide of the carriage. L oos en these

nuts slightly, tip the carriage in the slotted holes to the desired

angle, and tighten the nuts. For forward and aft adjustment,

loosen the four pitch adjustment nuts. Lift sl ightly, moving forward or aft until tray falls into desired notch and tighten the

nuts.

CAUTION: Each side must be ad justed equall y. Failure to adjust

each side equally m ay re sult in equipment and lift damage

when the lift closes .

3. Roll/Height. There are four 1/4-20 n u ts at the rear in side cor -

ners of the cradle assembly. Slightly loosen these nuts, gently

raise or lower the cradle to the desir ed posit ion, and tighte n the

nuts.

4. Yaw. There are four 10-24 Nylock nuts (two on each side) on

the top of the carriage. Loosen these screws slightly, turn th e

carriage in the slotted holes to the desired angle, and tighten

the nuts.

Figure 11. Travel Adjustment

13

Figure 12. Projector Adjustment

Page 15

Instruction Manual SMART-LIFT 236 Electric Ceiling Lifts

OUTSIDE TERMINAL WIRING EXAMPLES

The information on the following pages cover the most common wiring options:

• Supplied Momentary Push Button

• Discrete Extend and Retract for switch or dry contacts

• 12 Volt out supply

• 24 Volt out supply

• Two dry contact closures

• Service Extend

CAUTION: Closing the unit while the projector is running may

cause premature bulb failure and may damage both the lift and projector.

Push Button

Supplied Single Pole Single Throw (SPST) Switch

Using Internal 24VA C Power Supp ly

a. Connect the green jumper wire (supplied) to terminals 1 & 5

(see Figure 13).

b. Connect the SPST switch (supplied) to terminals 2 & 6.

Supplied SPST Switch Using Internal 12VDC Power Supply

a. Connect the green jumper wire (supplied) to terminals 5 & 9

(see Figure 14).

b. Connect the SPST switch (supplied) to terminals 6 & 10.

Supplied SPST Switch Using External Power Supply

a. Connect the negative of your power supply to terminal 5 (see

Figure 15).

b. Connect the SPST swi tch (supplied) to terminal 6 & the pos-

itive of your power supply .

Figure 13. 24VAC Internal

Figure 14. 12DC Internal

Figure 15. External Power Supply

14

Page 16

Instruction Manual SMART-LIFT 236 Electric Ceiling Lifts

Single Pole Double Throw (SPDT) Switch or

2 Dry Contact Closures, Momentary or Latching.

These terminals can be use d with any latc hing cont acts , momen tar y

contacts, or a wall switch.

NOTE: The connection be tween the ground (#9) and any other te r-

minal connectio n must be broke n (open) be fore comple ti ng the

next circuit..

a. Connect the common wire from your switch to

terminal 9 (see Figure 16).

b. Connect the 'up' wire from your switch to terminal 3.

c. Connect the 'down' wire from your switch to terminal 4.

Internal 12VDC Power Supply 2.5A Maximum

(+) = Terminal 10

(-) = Terminal 9

NOTE: Non regulated, open ci rcuit voltage may exceed 18V.

Internal 24VAC power supply, 1.2 A max

(+) = Terminal 1

(-) = Termina l 2

Internal dry contact closures:

Common = Terminal 12

Closed when lift reac hes show position = 14

Closed when lift is fully closed = 13

Service Position

Momentary contact between term inals 9 & 11 will lower the

lift to the service position.

NOTE: To stop the lift before it reaches the service position, make

a momentary contact be twee n terminals 3 & 9.

.

Figure 16. Dry Contacts

15

Page 17

Instruction Manual SMART-LIFT 236 Electric Ceiling Lifts

INSIDE TERMINAL WIRING EXAMPLES

The information on the following pages cover the most common wiring options:

• Supplied Momentary Push Button

• Discrete Extend and Retract for Switch or Dry Contacts

• 12 Volt out supply

• 24 Volt out supply

• Two dry contact closures

• Vol tage Sensing

• Service Extend

CAUTION: Closing the unit while the projector is running may

cause premature bulb failure and may damage both the lift and projector.

Push Button

Supplied Single Pole Single Throw (SPST) Switch Using

Internal 24VAC Power Supply

a. Connect the green jumper wire (supplied) to terminals 2 & 6

(see Figure 17).

b. Connect the SPST switch (supplied) to terminals 1 & 5.

Supplied SPST Switch Using Internal 12VDC Power Supply

a. Connect the green jumper wire (supplied) to terminals 6 &

10 (see Figure 18).

b. Connect the SPST switch (supplied) to terminals 4 & 5.

Supplied SPST Switch Using External Power Supply.

a. Connect the negative of your power supply to terminal 6 (see

Figure 19).

b. Connect the SPST switch (supplied) to terminal 5 & the pos-

itive of your power supply.

Figure 17. 24VAC Internal

Figure 18. 12DC Internal

Figure 19. External Power Supply

16

Page 18

Instruction Manual SMART-LIFT 236 Electric Ceiling Lifts

Single Pole DOUBLE Throw (SPDT) Switch or

2 Dry Contact Closures, Moment ary or Latching.

a. Connect the common wire from your switch to

terminal 13 (see Figure 20).

b. Connect the 'up' wire from your switch to terminal 12.

c. Connect the 'down' wire from your switch to

terminal 11.

Internal 12VDC Power Supply 2.5A Maximum

(+) = Te rminal 4

(-) = Terminal 3

NOTE: Non regula ted, open circuit voltage may exceed 18V.

Internal 24VAC Power Supply, 1.2A Maximum

(+) = Te rminal 1

(-) = Terminal 2

Internal Dry Contact Closures:

Common = Terminal 12

Closed when lif t reaches show position = Terminals 16 and 17

Closed when lift is fully closed = Terminals 18 and 19

Low Voltage Sensing:

a. Connect the positive of your power supply to terminal 7.

b. Connect the negative of your power supply to termina l 8.

NOTE: The lift will complete a full cycle even if the supply is

turned off before the lift reaches full extension.

NOTE: When the lift is in the lowered position using this option,

the li ft wi ll ig nor e al l other com mands u nti l i t has c omple ted i ts

full cy cle.

When the power supply is on, the lift will extend. When the

power supply turns off, the lift will retract.

Figure 20. Dry Contacts

Service position:

Momentary contac t between terminals 9 & 10 will lower the

lift to th e s ervice po s i ti o n.

NOTE: To stop the lift before it reaches the service pos ition, make

a momentary contact between terminals 11 & 13.

17

Page 19

Instruction Manual SMART-LIFT 236 Electric Ceiling Lifts

SMART LIFT INTERIOR BOARD BOX

TERMINAL FUNCTION DEFINITIONS

TERMINAL

NUMBER

1

2

3

4

5

6

FUNCTION

24 VOLT AC 24 volt AC output

24 VO LT AC

COMMON

GROUND Ground

12 VOLT DC 12 volt DC

EXTEND/

RETRACT

EXTEND/

RETRACT

COMMON

DESCRIPTION WIRING OPTIONS NOTES

24 volt AC common

Initiates movement if lift is static, or

stops movement if lift is in motion.

Direction of travel will be opposite

of last direction of travel.

Used in conj unction with

Extend / Retr act when using an

external power source to initiate

movement.

To Operate using Internal Power

Source

Connect terminals 3 & 6 with

Jumper Wire. Connect

Momentary Switch to terminal 4.

Connect other line of Mome ntary

Switc h to terminal 5.

To Operate using External Power

Source

Connect External Power Supply’s

Common to terminal 6. Connect

initiating signal to terminal 5.

This is an internal power supply for

powering external devices & Remote

Controllers.

Chief Mfg. offers the RC-10 Radio

Frequency Remote Controller which runs

off of this power supply.

This is an internal power supply for

powering external devices &/or used for

initiating specific functions

(

Extend/Retract 5 or Voltage Sensor 7).

Function operates on momentary switch

only.

Operating range is 5 – 30 Volts AC or DC.

NOT TO BE USED AS GROUND FOR

FUNCTION OTHER THAN

EXTEND/RETRACT TERMINAL 5.

7

8

9

10

When terminal sen ses volt a ge, uni t

VOLTAGE

SENSOR

VOLTAGE

SENSOR

COMMON

SERVICE

EXTEND

GROUND Ground

When terminal senses cessation of

Used in conj unction with Voltage

Sensor when using an external

power source to initiate movement.

Extends unit to ma ximum li mit,

bypassing normal-use travel setting.

Often used for servicing projectors

will exte nd.

voltage, unit will retract.

in ceiling lifts.

Voltage Sensing

Connect positive lead to terminal

7. Connect Ground of switching

device to terminal 8.

Single-Pull/Throw Latching

Switch

Connect terminals 3 & 8 with

Jumper Wire. Connect fi rst

Switch Terminal to terminal 4.

Connect other Switch Terminal to

terminal 7.

Momentary or Latching contact to

Ground terminals 3, 10, 13, or 20.

Operating range is 5 – 30 Volts AC or DC.

NOT TO BE USED AS GROUND FOR

FUNCTION OTHER THAN VOLTAGE

SENSOR TERMINAL 7.

Feature not available on all models.

If using Latching Switch, be sure to

disengage Switch prior to initiating any

other fun ct i on.

18

Page 20

Instruction Manual SMART-LIFT 236 Electric Ceiling Lifts

11

12

13

14

15

16

17

18

19

20

EXTEND

RETRACT

GROUND

EXTEND

ERROR

RETRACT

ERROR

EXTEND

LIMIT

RELAY

EXTEND

LIMIT

RELAY

COMMON

RETRACT

LIMIT

RELAY

RETRACT

LIMIT

RELAY

COMMON

GROUND

Ext en d s un it to pr ese t tra ve l lim it.

Customer w ithin a preset maximum

range may adjust travel limits.

Re tr a c ts u n it to p r e s et tra v e l limit.

Tra v e l limits m a y be adju s te d b y

customer within a preset maximum

range.

Ground

Imm ediately reverses direction of

travel when triggered while unit is

extending.

Imm ediately reverses direction of

travel when triggered while unit is

retra c tin g .

Closes set of internal dry contacts

when unit reaches full extension.

Closes set of internal dry contacts

wh e n u nit reaches full retr action.

Ground

Momentary or Latching contact to

Ground terminals 3, 10, 13, or 20.

Momentary contact to Ground

terminals 3, 10, 13, or 20.

RATED FOR 1 AMP @ 24 VOLTS

If using Latching Switch, be sure to

disengage S witch pr io r to initiating a n y

other function.

If using Latching Switch, be sure to

disengage S witch pr io r to initiating a n y

other function.

Chief Mfg. offers the SS-10 Pressure

Sen s itiv e Safet y S t rip to p rovide t h is

function.

Please specify how many inches required

spanning entire pinch zone.

S-10 must be ordered with the ST-15

The S

Terminals.

1.0 AMP@30VDC

0.5 AMP@125VAC

0.3 AMP@60VDC

RATED FOR 1 AMP @ 24 VOLTS

1.0 AMP@30VDC

0.5 AMP@125VAC

0.3 AMP@60VDC

19

Page 21

Instruction Manual SMART-LIFT 236 Electric Ceiling Lifts

SMART LIFT EXTERIOR 14 PIN

TERMINAL FUNCTION DEFINITION

TERM INA L

NUMBER

1

2

3

4

5

6

7

8

FUNCTION

24 VOLT AC 24 volt AC output

24 VOLT AC

COMMON

RETRACT

EXTEND

EXTEND/

RETRACT

COMMON

EXTEND/

RETRACT

RETRACT

ERROR

EXTEND

ERROR

DESCRIPTION W IRING OPTIONS N OTES

24 volt AC comm on

Retracts unit to preset travel limit.

Travel limits may be adjusted by

customer within a preset maximum

range.

Ex te n ds u ni t to p res e t tr a v el limit.

Customer within a preset maximum

range may adjust travel limits.

Used in conjunction with

Extend/Retract when using an

external power source to initiate

movement.

Init ia te s m o v e m e n t if lift is s ta tic , o r

stops movement if lift is in motion.

Direction of travel will be opposite

of last direction of travel.

Immediately reverses direction of

travel when triggered while unit is

retracting.

Immediately reverses direction of

travel when triggered while unit is

extending.

Mom entary or Latching contact to

Ground terminals 9, or 11.

To Operate using Internal Power

Source

Connect terminals 9 & 5 with

Jumper W ire. Connect

Momentary Switch to ter minal

10. Connect other line of

Momentary Switch to ter minal 6.

To Operate using External Power

Source

Connect External Power Supply’s

Comm on to terminal 5. Connect

initia t in g s ig n al to te r minal 6.

Mom entary contact to Ground

terminals 9, or 11.

This is an internal pow er supply fo r

powering external devices & Remote

Controllers.

Chief Mfg. offers the RC-10 Radio

Frequency Remote Controller which runs

off of this power supply.

If using Latching Switch, be sure to

disengage Switch prior to initiating any

other function.

If using Latching Switch, be sure to

disengage Switch prior to initiating any

other function.

NOT TO BE USED AS GROUND FOR

FUNCTION OTHER THAN

EXTEND/RETRACT TERMINAL 5.

Function o pe rates on momentary s w itch

only.

Operating range is 5 – 30 Volts AC or DC.

Chief Mfg. offers the SS-10 Pressure

Sensitive Safety Strip to provide this

function.

Please specify how m any inches required

to span entire pinch zone.

The SS-10 must be ordered with the ST-15

Terminals.

9

10

11

GROUND Ground

12 VOLT DC 12 volt DC

Extends un it to maximum lim it,

bypassing normal-use travel setting

Service Extend

Often used for servicing projectors

in ceiling lifts.

Mom entary or Latching contacts

to Ground terminals 3, 10, 13, or

20

This is an internal pow er supply fo r

powering external devices &/or used for

initiating specific functions

Extend/Retract 6).

(

Feature not available on all models.

If using Latching Switch, be sure to

disengage Switch prior to initiating any

other function

20

Page 22

Instruction Manual SMART- LIFT 236 Electric Ceiling Lifts

LIMIT

12

RELAY

COMMON

13

14

RETRACT

LIMIT

RELAY

EXTEND

LIMIT

RELAY

Closes set of internal dry contacts

when unit reaches full retraction.

Closes set of internal dry contacts

when unit reaches full extension.

RATED FOR 1 AMP @ 24 VOLTS

1.0 AMP@30VDC

0.5 AMP@125VAC

0.3 AMP@60VDC

21

Page 23

Instruction Manual SMART-LIFT 236 Electric Ceiling Lifts

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

LIFT DOES NOT RESPOND 12V TRIGGER OPTION BEING USED NORMAL OPERATION

NO POWE R VERIFY POWER TO LIFT

FUSE BLOWN CHECK FUSE ON CONTROL BOX

IMIT SWITCH CALL CHIEF FOR VERIFICATION

L

LIFT WILL NOT LOWER/RAISE

CONTROL BOX CLICKS

MOTOR SILENT

LIFT WILL NOT LOWER/RAISE

CONTROL BOX CLICKS

MOTOR HUMS

PROJECTOR CRADLE / BOTTOM

PANEL LOWER ON ONE SIDE.

FAILED CONTROL BOX CALL CHIEF FOR VERIFICATION

OVERHEATED MOTOR LET MOTOR COOL FOR 5-15 MINUTES.

FAILED MOTOR CALL CHIEF FOR VERIFICATION

BINDING MECHANISM MAKE SUR E CABLES ARE ROUTED PROPERLY

FAILED MOTOR CALL CHIEF FOR VERIFICATION

FAILED CONTROL BOX CALL CHIEF FOR VERIFICATION

NORMAL OPERATION A DIFFERENCE OF UP TO 3/16" WITHIN THE FINAL 4" OF

LIFTING LINKS OUT OF ADJUSTMENT CALL CHIEF

SEE NOTES ON 'LOW VOLTAGE SENSING' PAGE#16

SEE 'INSTALL AND ROUTE CABLES' PAGE#11

TRAVEL IS NORMAL

WHEN THE LIFT IS EXTENDED BEYOND 4", UP TO 3/8"

DIFFERENCE IS NORMAL

PROJECTOR CRADLE / BOTTOM

PANEL SIGNIFICANTLY LOWER ON

ONE SIDE

HOOKS ON LIFTING BRACKET DO

NOT CATCH THE ROLLERS ON THE

PROJECTOR CRADLE.

LIFTING BRACKET DAMAGED CALL CHIEF

DAMAGED HINGE ASSEMBLY CALL CHIEF

LIFTING BRACKET DAMAGED CALL CHIEF

BINDING MECHANISM MAKE SUR E CABLES ARE ROUTED PROPERLY

SEE 'INSTALL AND ROUTE CABLES' PAGE#11

LIFTING LINKS OUT OF ADJUSTMENT CALL CHIEF

LIFTING BRACKET DAMAGED CALL CHIEF

DAMAGED HINGE ASSEMBLY CALL CHIEF

22

Page 24

Instruction Manual SMART-LIFT 236 Electric Ceiling Lifts

PAGE LEFT BLANK INTENTIONALLY

23

Loading...

Loading...