Page 1

INSTALLATION INSTRUCTIONS

Chief Manufacturing, a division of Milestone AV Technologies

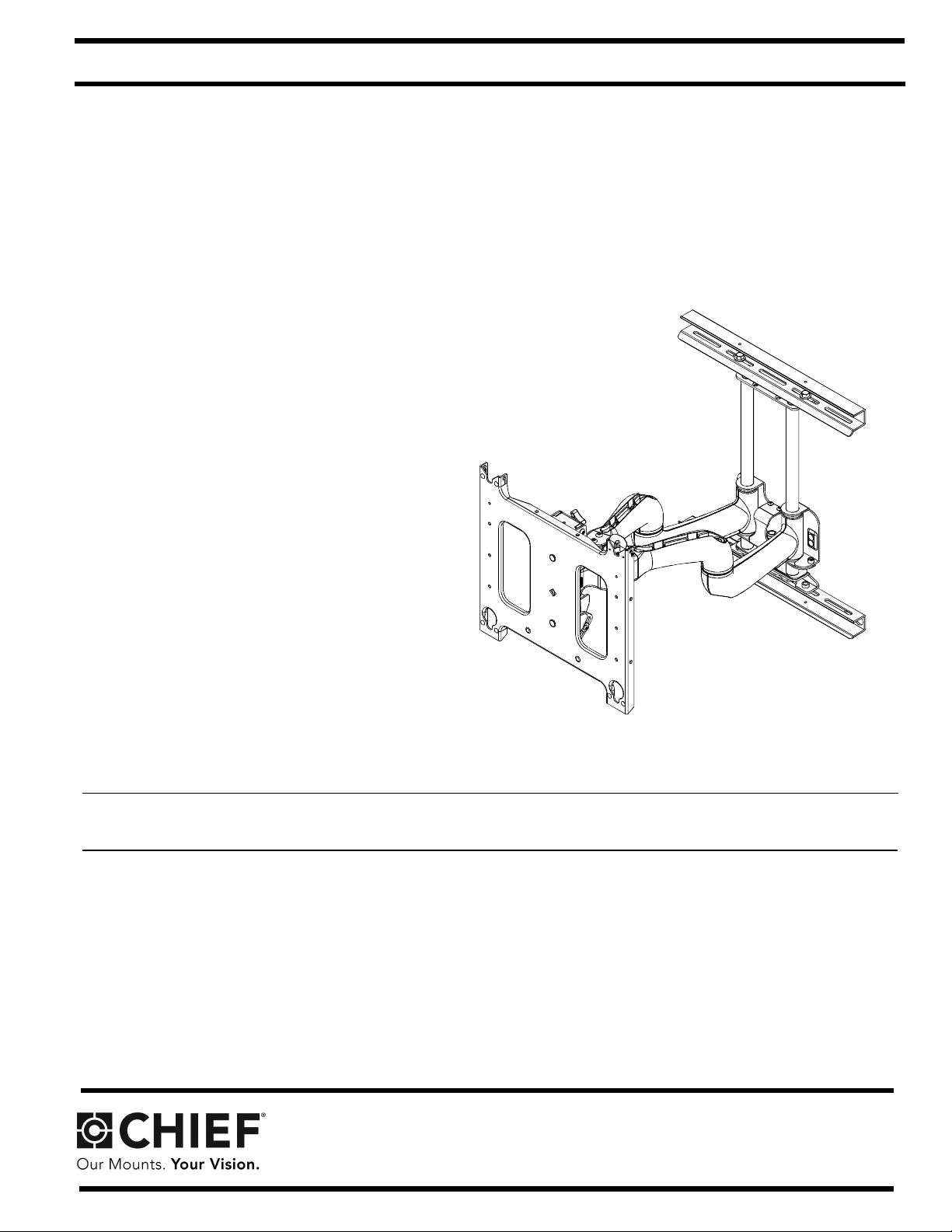

Large Flat Panel Dual Arm Wall Mount

Model PNR™

The PNR is wall-mounted, rugged, versatile, and

installer-friendly. The PNR is compatible with the

standard (14” x 14”) PSB interface bracket in which a

display can be mounted in either the landscape or

portrait position on the PNR.

The dual arms on the PNR:

Extend from the wall 25” in length

Pivot up to 90º left or right of center

The standard PNR is shipped with the support posts for

the dual arms centered in the mount. The support posts

can be moved laterally right or left of center to readily

accommodate sites with limited wall space. The mount

also has over an i nch of height adjustment. The til t ra nge

for the display is 5º up and 15º down.

The PNR was designed f or fast i nstallati on. After dr awing

the plumb line and installing the two top l ag bo lts i nt o the

dual wall studs, the installer hangs the PNR on its top

bracket and installs two lag bolts in the bottom bracket.

Next, the installer makes the height adjustment, mounts

the display, and connects the power/audio/video cables,

which are diverted into the built-in path in the swing-out

arms. After making the lateral, rotational, and tilt

adjustments, the installation process is complete.

BEFORE YOU BEGIN

CAUTION: To prevent damage to the PNR, which could affect or void the Factory warranty, and to the equipment that

will be attached to it, thoroughly study all instructions and illustrations before you begin the installation. Pay particular

attention to the “Important Warnings and Cautions” on Page 2.

• The combined weight of the components installed on the PNR must not exceed 200 lbs. (90.72kg).

• The PNR wall mount must be installed on dual wall studs or supporting framework. The wall to which the PNR is

anchored must be capable of supporting five times the total weight of the mount and all attached equipm ent.

• If you have any questions about this installation, contact Chief Manufacturing at 1-800-582-6480.

8401 Eagle C reek Parkway, Savage, MN 55378

P: 800.582.6480 / 952.894.6280 F: 877.894.6918 / 952.894.6918

8831-000007 Rev I

©2008 Milestone Technologies

11/08

Page 2

Model PNR™ Installation Instruc tions

IMPORTANT WARNINGS AND CAUTIONS!

WARNING: A WARNING alerts you to the possibility of serious injury or death if you do not follow the instructions.

CAUTION: A CAUTION alerts you to the possibility of dam age or d estruction of equipment if you do not follow the

corresponding instructions.

WARNING: Improper installation can result in serious personal injury! Make sure that the structural members can

support a redundant weight factor five times the total weight of the equipm ent: if not, reinforce the structure before

installing the PNR.

WARNING: Be aware also of the potential for personal injury or damage to the unit if it is not adequately mounted.

WARNING: The installer is responsible for verifying that the wall to which the PNR is anchored will safely support

the combined load of all attached components or other equipment.

WARNING: The weight of the display placed on the PNR must not exceed 200 lbs. (90.72kg), the maximum load

capacity of the PNR.

WARNING: Watch for pinch points. Do not put your fingers between movable parts.

WARNING: Make sure the mount and brackets are correctly oriented.

WARNING: Make sure the flag securing the display is completely low ered at all times except when removing or

installing the display.

CAUTION: Check the unit for shipping damage before you begin the installation.

Chief®, ClickConnect™ and Centris Select™ are registered trademarks of Milestone AV Technologies. All rights reserved.

CONTENTS

IMPORTANT WARNINGS AND CAUTIONS! .............................2

Inspect The Unit Before Installing ............................................... 4

SPECIFICATIONS ......................................................................4

INTERFACES ..............................................................................4

TOOLS REQUIRED FOR INSTALLATION ................................. 4

PARTS LIST ................................................................................4

INSTALLATION ...........................................................................5

Install the Mount .......................................................................... 5

Mounting the top bracket .............................................................5

Mounting the bottom bracket .......................................................5

Adjust Height on the PNR ...........................................................6

Install Cover Plates and End Caps ..............................................6

Mount the Display ........................................................................7

CABLE MANAGEMENT ..............................................................7

Adjustments ................................................................................. 8

Removing Display from Mount ...................................................11

2

Page 3

Installation Instructions Model PNR™

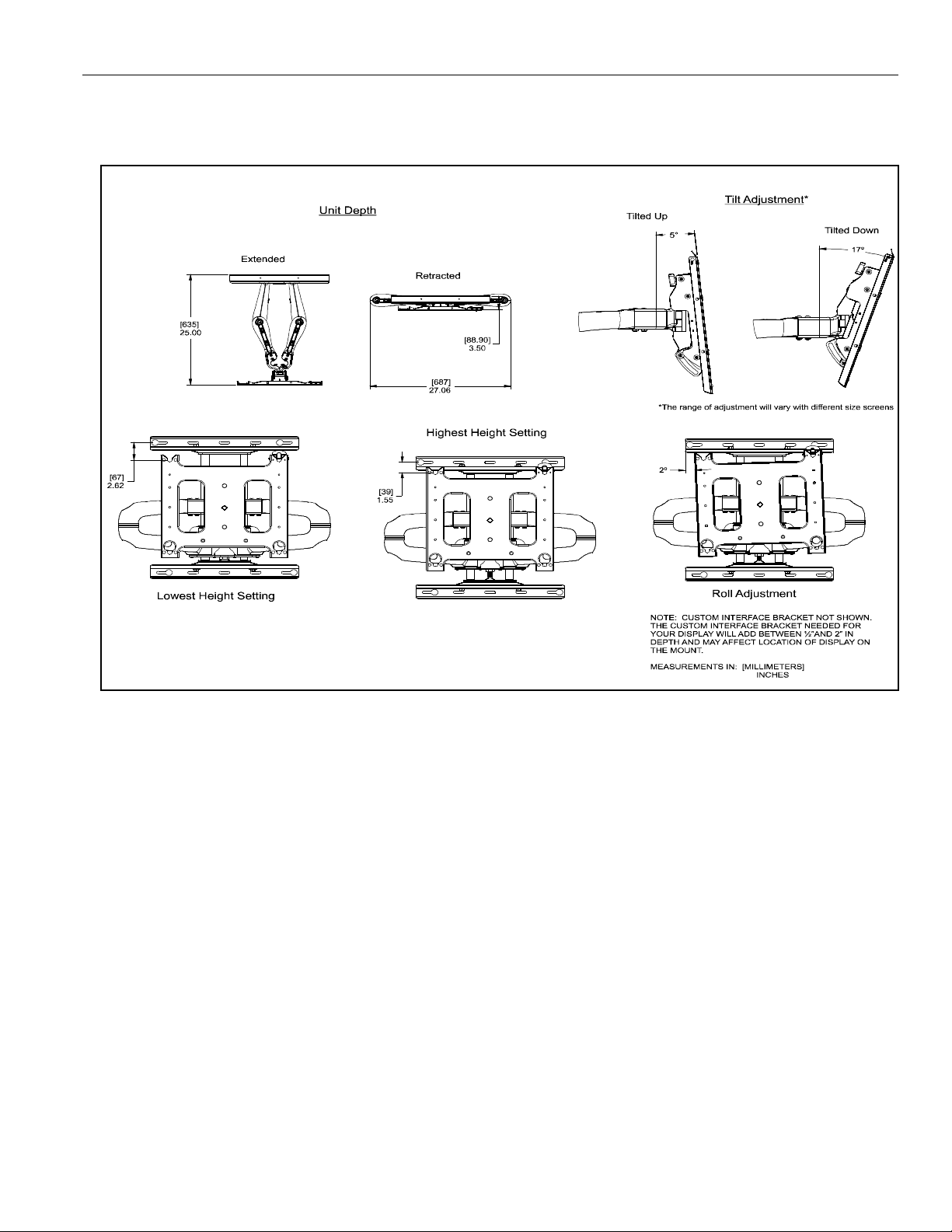

DIMENSIONAL DRAWING

3

Page 4

Model PNR™ Installation Instruc tions

Inspect The Unit Before Installing

WARNING: Watch for pinch points. Do not put your

fingers between movable parts.

1. Carefully inspect the PNR for shipping damage. If any

damage is apparent, call your carrier claims agent

and do not continue w ith the installation until the

carrier has reviewed the damage.

NOTE: Read all instructions before starting installation.

2. Lay out components to ensure you have all the

required parts before proceeding. See

“DIMENSIONAL DRAWING” on page 3.

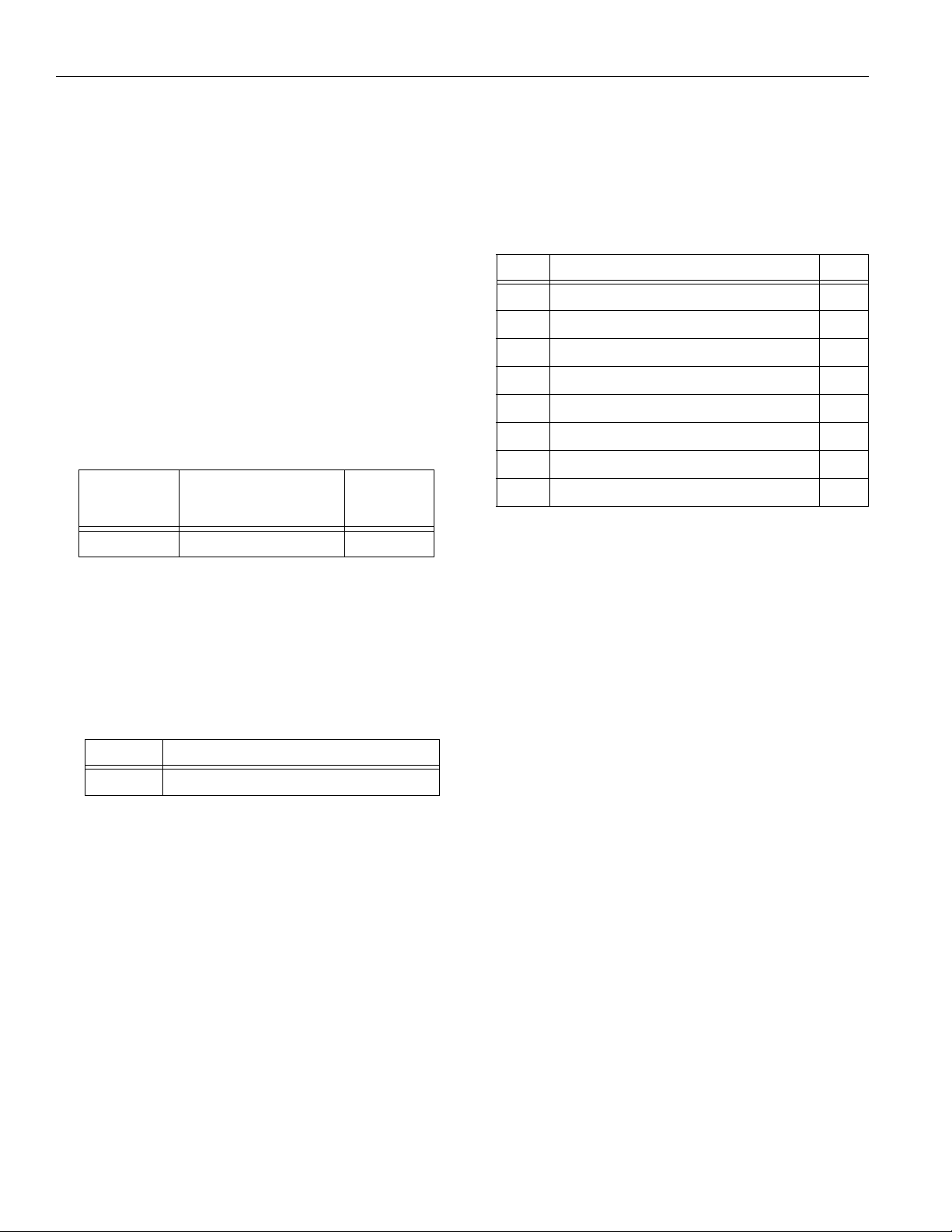

SPECIFICATIONS

Table 1 provides the specificiations for the mount.

Table 1: Mount Specifications

Model Max Sup port Weight Mount

Extended

from Wall

PNR 200 lbs. (90.72k g) 25”*

PARTS LIST

Unpack the carton and verify the content s listed in Table

3. If you are missing any of the listed parts, contact

Customer Service at: 1-800-582-6480.

Table 3: Parts List

REF DESCRIPTION QTY

10 PNR Wall Mount 1

20 Cover Plates 2

30 End Caps 4

40 Tiewraps 12

50 Lag Bolts , 3/8” x 2-1/2” 4

60 Flat Washers, 3/8” 4

— Wrench, Adjustment 1

— Bar, Adjustment 1

NOTE: *Dimension does not include the PSB interface

bracket.

INTERFACES

Table 2 lists the interface for the PNR.

Table 2: PNR Interfaces

Model Interface

PNR 14” x 14” Plasma Static Brackets (PSB)

TOOLS REQUIRED FOR INSTALLATION

• Allen wrench set

• Drill and bit set

• Wrench set

NOTE: Other tools may be required depending on the

method of installation.

4

Page 5

Installation Instructions Model PNR™

INSTAL LATION

WARNING: Improper installation can result in serious

personal injury!

WARNING: It is the responsibility of the installer to

verify that the wall to which the PNR is anchored will

safely support five times the combined load of all

attached components and equipment. If not, reinforce

the structure before installing the PNR.

1. Locate two wood studs 16” apart on center

2. Determine the exact mounting location prior to

installation, considering screen size and the unit’s

total swing arm radius. Keep in mind that the PNR

must be mounted to wood studs that are 16” apart on

center.

NOTE: Mount the PNR between parallel wall studs or

other supporting framework that is vertical or

horizontal.

3. Using a stud sensor, locate the two wood studs where

you will mount the PNR.

4. Draw a level plumb line to indicate the desired height

of the top mounting bracket.

5. With an assistant, lift and hold the PNR against wall.

Use a pencil, awl, or small nail to mark the mounting

holes where two pilot holes will be drilled into the

center of the wood studs. Make sure the mounting

holes are level.

6. With an assistant, lay the PNR down on the floor.

7. Drill two pilot holes using a 9/32” dr ill bit where the

mounting holes were marked for anchoring the top

bracket. See Figure 1.

8. Install two 3/8” x 2-1/2” lag bolts (50) and two 3/8” flat

washers (60), through PNR Top Bracket and into

upper pilot holes.

NOTE: Do not tighten the lag bolts down at this time.

Leave enough space between the wall and lag

bolts to hang the PNR.

16"

Wood Studs

Wall

Pilot

Holes

Figure 1

Install the M ount

Mounting the top bracket

WARNING: Improper installation can result in serious

personal injury!

1. With an assistant, lift and hang the PNR on the two

lag bolts and washers previously installed on the wall.

(See figure 2).

NOTE: Make sure washers are installed in front of the

top bracket, not behind the bracket.

2. Slide the PNR into the desired position on the wall

and tighten the two lag bolts.

Mounting the bottom bracket

1. Mark the two mounting holes in the bottom mounting

bracket (See figure 3). Make sure to align the holes

parallel to the holes drilled in the top bracket.

2. Drill two pilot holes in the wall studs using a 9/32” drill

bit.

3. Install two 3/8” x 2-1/2” lag bolts (50) and two 3/8”

washers (60) through PNR Bot tom Bracket into the

lower pilot holes.

4. Tighten all lag bolts.

5

Page 6

Model PNR™ Installation Instruc tions

Install Cover Plates and End Caps

Mount (Hang) the PNR on Lag Bolts

Figure 2

NOTE: The cover plates and end caps have pressure

fitting ends that lock in place with each other.

1. Install cover plate (20) over the top bracket.

(See figure 5)

2. Install end cap (30) on the cover plate (20).

(See figure 5)

3. Repeat steps 1 and 2 for the bo ttom mounting

bracket. (See figure 5)

Use Lag Bolts and Washers to Fasten PNR to the Wall.

Figure 3

Adjust Height on the PNR

NOTE: Height adjustment range up to 1.08 inches.

To adjust the PNR heig ht:

1. Check PNR for the desired height. If needed, use the

adjustment wrench (40) to adjust the PNR height.

• Turn adjustment nut (see Figu re 4) clockwise

(CW) to lower the unit he ight, or

• Turn adjustment nut counterclockwise (CCW) to

raise the unit height.

Adjustment Nut

Figure 4

End Caps (30)

Cover Plate (20)

Bottom Mounting Bracket

Figure 5

6

Page 7

Installation Instructions Model PNR™

holes

Mount the Display

1. Make sure power is not supplied (turned off) to the

display before attempting to mount the display.

2. Following the instructions for mounting the PSB

interface bracket of your specific plasma display

panel, install the mounting bracket on your plasma

display panel.

WARNING: Watch for pinch points. Do not put your

fingers between movable parts.

3. While supporting both sides of display, align four mounting

buttons on display or interface bracket with four mountin g

holes in head assembly. (See Figures 6 and 7)

3

Figure 6

WARNING: DISPLAY MAY WEIGH IN EXCESS OF 40

LBS! Always use two people and proper lifting techniques

when installing or positioning display on stand.

4. Lower display into place listening for audible " click" to

ensure recessed area of mounting buttons are properly

seated in lower ar ea of mount in g holes .

(See Figures 6 and 7)

WARNING: IMPROPER INSTALLATION CAN LEAD TO

DISPLAY FALLING CAUSING SERIOUS PERSONAL

INJURY OR DAMAGE TO EQUIPMENT! Ensure mounting

buttons are completely engaged in mounting holes.

NOTE: Holes are provided in the faceplate for use with a

padlock or similar locking device, if desired. In

addition, the pin and nut may be removed from

the upper holes and moved to the lower holes for

use as a more permanent locking device. (See

Figure 7)

Remove pin

and nut and

move to lower holes

4

5

A padlock or bolt may

be placed through latch

Figure 7

5. Connect and secure power/audio/video cables,

making sure to leave sufficient slack to allow for

movement of the swing arms.

CABLE MANAGEMENT

WARNING: Make sure your cables do not run through

a pinch point.

1. Route power/audio/video cables through the cable

channel in top arm (see Figure 8), allowing su fficient

slack in cables for extension and avoiding pinch

points, and secure cables using two clips and two

tiewraps (50, not shown).

2. Route power/audio/video cables along bottom arm

(see Figure 9), using tiewraps (50, not shown) to

secure cables to each arm, and through cable

channel.

CAUTION: To prevent equipment damage, do not

route cables through holes in the display mounting

plate.

3. Route power/audio/video cables to an open area

behind the mounting plate (not shown). Leave a

sufficient amount of slack in cables to allow for

connection and extension where needed.

7

Page 8

Model PNR™ Installation Instruc tions

Management Channel

Figure 8

Centris Sel e ct

Adjustment Knob

Figure 10

3. To lock the mount at the desired vertical tilt, tighten

the vertical tilt lock screw. (See figure 11)

TM

Bottom Cable

Management Channel

Figure 9

ADJUSTMENTS

TENSION ADJUSTMENTS

Vertical Tilt Tension Adjustment

1. With display mounted, check for desired vertical tilt

tension.

2. Adjust the Centris SelectTM knob until desired ver tical tilt

tension is obtained. (See figure 10)

Vertica l Ti lt

Lock Screw

Figure 11

Lateral Tilt Tension Adjustment

CAUTION: Overtightening lateral adjustment will

cause excessive wear and may distort adjustment

components.

1. Using a 9/16” wrench (not provided), slightly tighten or

loosen lateral tilt tension adjustment nut

(See figure 12).

2. Mount the display and check for desired tilt tension.

3. Repeat Steps 1 and 2 until desired tilt tension is

obtained.

Rotational Tilt Tension Adjustment

1. If necessary, loosen or tighten bottom rotational tilt

tension adjustment nut (See figure 12).

2. Mount the display and check for desired rotational tilt

tension.

3. Repeat Steps 1 and 2 until desired rotational tilt

tension is obtained.

8

Page 9

Installation Instructions Model PNR™

reconfiguring the mount. Use the first and third slotted

holes in the top and bottom mounting brackets.

• Reconfiguring the Swing Arms Right of Center

With some disassembly and reassembly, you can move

Lateral Tilt

Adjustment Nut

the swing arms to the right of center by reconfiguring the

mount. Use the third and fifth slotted holes in the top and

bottom mounting brackets.

Adjusting the Swing Arms Off Center

To adjust the dual swing arm mount configuration:

1. Remove the display from the mount.

2. Loosen four bolts (two on the top and two on the

bottom) securing the swing arm assembly to the top

and bottom mounting brackets (See figure 13).

3. Move the swing arm assembly to desired location.

4. Tighten the bolts.

5. Install the display on the mount.

Rotational Tilt

Adjustment Nut

Figure 12

Swing Arm Adjustments

The dual swing arms are shipped installed in the center

of the top and bottom mounting brackets, which is the

standard mounting configuration.

The top and bottom mounting brackets have slotted

holes, allowing for lateral adjustment of the dual swing

arms.

After the top and bottom mounting brackets have been

installed between two wood studs 16” on center, the

swing arms can be adjusted or moved off center,

depending on the location of the mount, the size of the

display, and the lateral movement needed to rotate the

display.

The swing arms can be adjusted, as follows:

• Adjusting the Swing Arms Off-Center

With no disassembly required, you can adjust the swing

arms up to 1-inch to the left of center or up to 1-inch to

the right of center.

• Reconfiguring the Swing Arms Left of Center

With some disassembly and reassembly required, you

can move the swing arms to the left of center by

Top Bolts

Figure 13

Reconfiguring the Swing Arms to the Left or

Right of Center

To change of the dual swing arm mount configuration:

1. Remove the display from the mount.

2. Remove four bolts (two on the top and two on the

bottom) securing the swing arm assembly to the top

and bottom mounting brackets (See figure 14).

WARNING: The next step will release the arm

assembly from the mount. The arms and plate may fall

if you are not careful.

3. Move the swing arm assembly to desired location.

• For Left of Center, see Figure 14.

• For Right of Center, see Figure 15.

4. Install retaining pin assemblies (one top and one

9

Page 10

Model PNR™ Installation Instruc tions

bottom) and secure using two bolts (one top and one

bottom).

5. Install four bolts (two on the top and two on the

bottom) to secure the swing arm assembly to the top

and bottom mounting brackets (See figure 14).

6. Tighten the bolts.

7. Install the display on the mount.

Top Bolts

Figure 14

NOTE: The display may need to be repositioned in order

to gain access to the tension adjustment

screw(s).

3. Using the wrench provided with the mount, turn

adjustment bar clockwise to increase swing arm

tension or counterclockwise to reduce swing arm

tension. (See figure 17) and (See figure 18)

NOTE: Small adjustments of 1/8 turn or less are typically

all that is required to achieve desired tension.

4. Check swing arm tension. If desired tension is

present, tension adjustment is complete. If additional

tension adjustment is required, repeat steps 2 and 3

until desired tension is achieved.

NOTE: If changing from a smaller display to a larger

display it may be necessary to in crease swing

arm tension.

Wrench

Adjustment

Bar

Top Bolts

Figure 15

Swing Arm Tension Adjustment

Swing arm tension is pre-set at the factory and is adjusted to

accommodate displays with weights near the top of the mounts

capacity.

If smaller displays are used it may be difficult to

reposition the display after moun ting. Swing arm tension

can be adjusted to compensate for smaller display by:

NOTE: The display must be mounted prior to adjusting

swing arm tension.

Socket Head

Capscrew

Figure 16

Reduce

1. Locate the adjustment bar and wrench provided with

the mount.

2. Place adjustment bar into socket head cap screw

located at swing arm pivot point. (See fi gure 16)

10

Figure 17

Page 11

Installation Instructions Model PNR™

Remove bolt

1

Increase

Figure 18

or padlock

if used

Pin in

"Closed"

position move to

"Open"

position to

remove

display

2

Removing Display from Mount

1. Remove bolt or padlock from faceplate (if used).

NOTE: The pin may have been used as a more permanent

locking device. If so, remove nut and pin and move

from the lower holes to the upper holes.

4

2. Pull back on flag on upper mounting hole and press pin

down into "Open" position. (See Figure 19)

WARNING: DISPLAY MAY WEIGH IN EXCESS OF 40

LBS! Always use two people and proper lifting techniques

when installing or pos itioning display on mount.

3. Carefully lift display from mount.

4. Lift up on pin an d place flag back agains t faceplat e to return

it to "Closed" position.

Pin in

"Open"

position move to

"Closed"

position

after display

is removed.

Figure 19

11

Page 12

Model PNR™ Installation Instruc tions

12

Loading...

Loading...