Page 1

INSTALLATION

INSTRUCTIONS

PLASMA TV WALL MOUNT

TILT Universal

(RGTU-210)

WARNINGS

WARNING

CAUTION

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION

A WARNING alerts you to the possibility of serious injury or death if you do not follow

the instructions.

A CAUTION alerts you to the possibility of damage or destruction of equipment if you do

not follow the corresponding instructions.

Improper installation can result in serious personal injury! Make sure that the structural

members can support a redundant weight factor

equipment: if not, reinforce the structure before installing the RGTU.

Be aware also of the potential for personal injury or damage to the unit if it is not

adequately mounted.

The installer is responsible for verifying that the wall to which the RGTU is anchored will

safely support the combined load of all attached components or other equipment.

The weight of the display placed on the RGTU must not exceed 175 lbs. (79.38 kg), the

maximum load capacity of the RGTU.

Watch for pinch points. Do not put your fingers between m ovable parts.

Make sure the mount and brackets are correctly oriented.

CAUTION: Check the unit for shipping damage before you begin the installation.

Over-tightening adjustment bolt will cause excessive wear and may distort adjustment

components.

If you have any questions about this installation, contact Chief Manufacturing at:

1.800.582-1373 or 952.277.3901.

five times

the total weight of the

Page 2

ASSEMBLY DIAGRAM

LARGE SCREEN DISPLAY MOUNT

(RGTU-210)

TOOLS REQUIRED FOR INSTALLATION

• Phillips screwdrivers, No. 1 and No. 2 TIP

• Drill and bit set

• Wrench set

NOTE: Other tools may be required depending on the

method of installation.

PARTS LIST

Table 1: Parts List

REF DESCRIPTION QTY REF DESCRIPTION QTY

10 PLATE, Wall with two latches attached 1 140 SCREW, Phillips, M4 x 20 (Parts Bag D) 8

20 BRACKET, Interface (Rt) 1 150 SCREW, Phillips, M4 x 25 (Parts Bag D) 8

30 BRACKET, Interface (Lft) 1 160 WASHER, Flat, #10 (Parts Bag E) 8

40 BRACKET, Tilt Assembly 2 170 WASHER, Flat, 1/4” (Parts Bag F) 8

50 SCREW, Phillips, M8 x 20 (Parts Bag A) 6 180 SPACER, 1/4” (Parts Bag G) 8

60 SCREW, Phillips, M8 x 30 (Parts Bag A) 6 190 SPACER, 1/2” (Parts Bag G) 8

70 SCREW, Phillips, M8 x 45 (Parts Bag A) 6 200 WASHER, Shoulder, .195”ID

(Parts Bag E)

80 SCREW, Phillips, M6 x 25 (Parts Bag B) 8 210 WASHER, Shoulder, .320”ID

(Parts Bag F)

90 SCREW, Phillips, M6 x 16 (Parts Bag B) 8 220 SCREW, Self-Tapping 2

100 SCREW, Phillips, M5 x 16 (Parts Bag C) 8 230 BOLT, Carriage, 1/4-20 x 1/2” 6

110 SCREW, Phillips, M5 x 20 (Parts Bag C) 8 240 NUT, Nylock, 1/4-20 6

120 SCREW, Phillips, M5 x 25 (Parts Bag C) 8 250 BOLT, Lag, 5/16” 4

130 SCREW, Phillips, M4 x 16 (Parts Bag D) 8 260 WASHER, 5/16” 4

8

8

2

Page 3

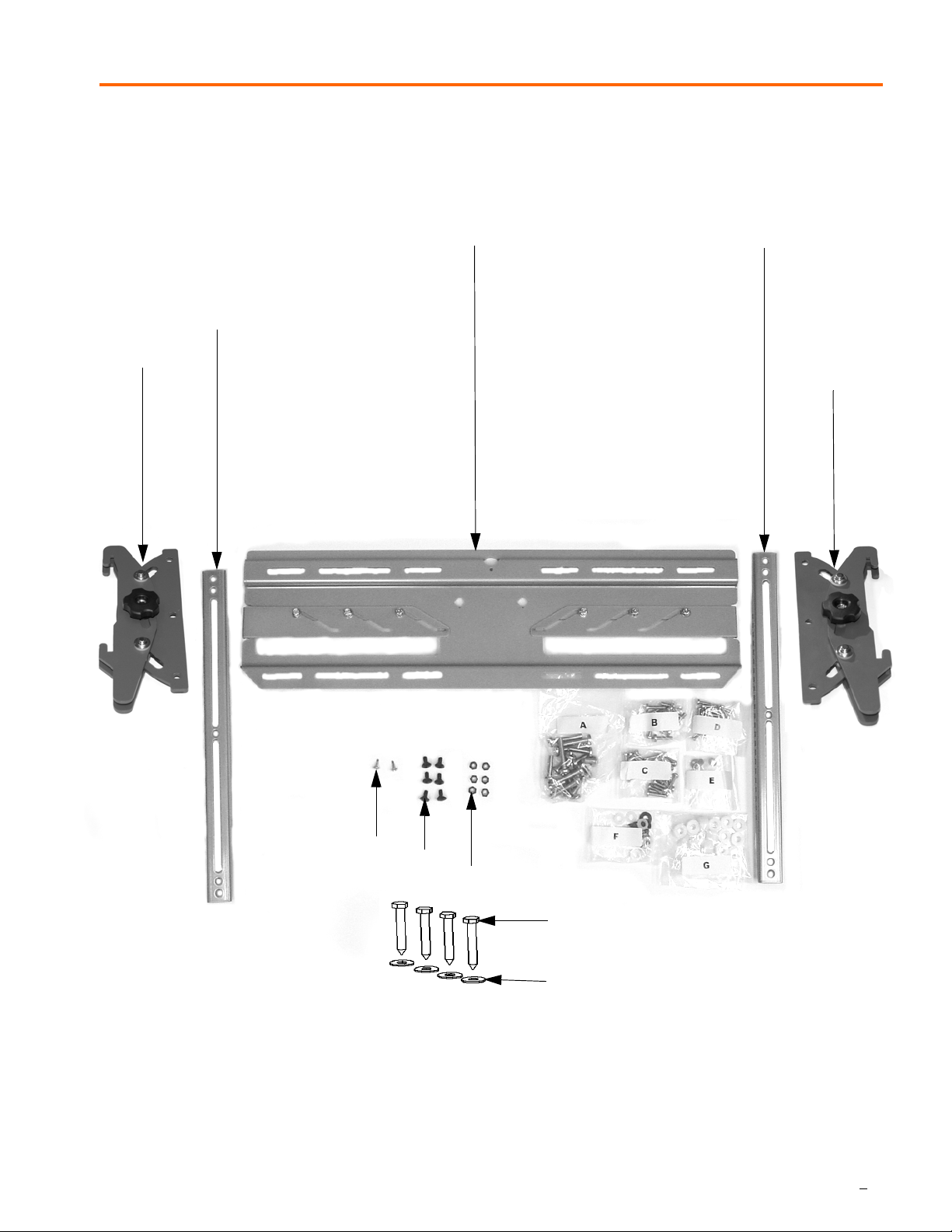

ASSEMBLY DIAGRAM

LARGE SCREEN DISPLAY MOUNT

PARTS

30

40

(RGTU-210)

10

20

40

220

230

240

Figure 1. Parts

250

260

3

Page 4

INSTALLATION

INSTRUCTIONS

INSPECT THE MOUNT BEFORE ASSEMBLY

1. Carefully inspect the mount for shipping damage (see

Figure 1). If any damage is apparent, call your carrier claims

agent and do not continue with the installation until the carrier

has reviewed the damage.

NOTE: Read all assembly instructions before starting

assembly.

2. Carefully inspect mount components for damage.

INSTALL INTERFACE BRACKETS

ON DISPLAY

Install the interface brackets as follows:

1. Place the interface brackets (20 and 30) on the back of

the display, aligning one of the holes or top of the slots as

a reference point to align horizontally with the square

holes facing toward the center of the display (see

Figure 2 and Figure 3).

Figure 2. Place Brackets on Display

NOTE: Spacers (180 or 190) are used to offset the

bracket if the mounting holes are recessed or to get

around the protrusions.

2. Secure the left and right factory assembled interface

bracket assemblies (20 and 30) to the display. Select the

mounting hardware that fits your application. Read the

following list and refer to Figure 4 and Figure 5.

• Use spacers (180 or 190), if necessary.

• Use M6 screws (80 or 90) or M8 screws (50, 60, or

70), steel washers (170), and shoulder washers

(210).

• Or, use M4 screws (130, 140, or 150) or M5 screws

(100, 110, or 120) steel washers (160), and shoulder washers (200).

Figure 3. Align Holes

Figure 4. Attachment Parts

4

Figure 5. Attachment

Page 5

INSTALLATION

3.Find the center line of the display (see Figure 6).

4. Using six bolts (230) and six Nylock nuts (240), attach the

tilt brackets (40) with the center hole of the tilt assembly

as close to the center line of the display as possible (see

Figure 7), positioning the assembly with the knob side

toward the outside of the display.

INSTRUCTIONS

NOTE:

Dimensions shown are

for example only

Figure 6. Center Line of Display

Figure 7. Attach Tilt Brackets

5

Page 6

INSTALLATION

INSTRUCTIONS

INSTALL WALL PLATE

Install the wall plate as follows:

WARNING: It is the responsibility of the installer to verify that

the structure to which the mount is anchored will

safely support five times the combined load of all

attached components and equipment.

1. Determine suitable a mounting location and lift the wall

plate (10) into place (see Figure 8).

2. Using a small nail or screw (not provided) in the center

hole, lightly hold wall plate at the mounting location (see

Figure 9).

3. Level the wall plate (10) and drill pilot holes for anchoring

the wall plate. If drilling into wood studs, use a 15/64” drill

bit.

4. Using four 5/16” lag bolts (250) and 5/16” washers (260),

install the wall plate on the wall.

5. Slide the latches to the outside (see Figure 10).

Figure 8. Wall Plate Dimensions

Figure 9. Wall Plate Installation

6

Figure 10. Slide Latches Outward

Page 7

INSTALLATION

INSTRUCTIONS

INSTALL DISPLAY

Install the display as follows:

1. Place the display on the wall plate (10) by hooking the

hooks of the brackets (20 and 30) in the top of the wall

plate (see Figure 11 and Figure 12).

2. Secure the display by sliding the latches, one on each

side, inward (see Figure 13).

3. If desired, install self tapping screws (220) and/or padlocks (not provided) for additional security (see Figure

14).

Figure 11. Hooks On Top (View 1)

Figure 13. Slide Latches In

Figure 14. Added Security

Figure 12. Hooks On Top (View 2)

7

Page 8

PART NO. 8805-000069 (Rev.B)

07/04

Loading...

Loading...