Page 1

Chief Manufacturing, a division of Milestone AV Technologies

INSTALLATION INSTRUCTIONS

The PPD is a highly functional video conferencing s olution. The cart provides agile mobility for two Large Flat

Panel Displays, side-by-side, with a combined weight of

up to 200 pounds. Optional equipment shelves and video

conferencing accessory shelves can be easily added for

a complete system.

Using Chief’s exclusive Cl ickConnect™ Mounting System for easy installation, the cart provides stable mounting, quick release and optional security. Additionally, its

streamline shape eliminates trip hazar ds and allows the

display to roll smoothly up to a conference table

Large swivel casters with lock brakes, pitch adjustment,

and cable management make t he cart u se r friendly.

BEFORE YOU BEGIN

• CAUTION: To prevent damage to the cart, which could a ffect or void the Factory warranty, thoroughly

study all instructions and illustrations before you begin to install or operate the unit. Pay particular attention to the “I mportant Wa rnings and Cautions” on Page 2.

• The maximum weight to be installed on the PPD is 200 pounds (90.72 Kg).

• If you have any questions about this assembly, contact Chief Manufacturing at 1-800-582-6480 or 952-894-6280.

Chief® and ClickConnect™ are trademarks of Milestone AV Technologies. All rights reserved.

8809-000004 Rev E

www.chiefmfg.com

8401 Eagle C reek Parkway, Savage, MN 55378

P: 800.582.6480 / 952.894.6280 F: 877.894.6918 / 952.894.6918

©2008 Milestone AV Technologies

05-08

Page 2

Installation Instuctions PPD-Series

IMPORTANT WARNINGS and CAUTIONS!

WARNING: A WARNING alerts you to the possibility of serious injury or death if you do not follow the

instructions.

CAUTION: A CAUTION alerts you to the possibility of damage or de struction of equipment if you do not follo w the

corresponding instructions.

• WARNING: Do not attempt to hang the plasma displays onto the cart alone. Always use two people to

mount each display.

• WARNING: Always park the cart on a level surface. The locking wheels of the cart are not designed to

hold the cart on an inclined surface.

• WARNING: Do not use the cart to transport your plasma displays on ramps or steep angles. The cart is

designed to move on smooth, flat surfaces.

• CAUTION: Inspect the unit for shipping damage.

• CAUTION: Do not use cleanser or harsh cleaning agents on acrylic shelves.

2

Page 3

Installation Instuctions PPD-Series

CONTENTS

INSPECT PARTS BEFORE ASSEMBLY ................... 3

OPTIONAL ACCESSORIES ....................................... 3

TOOLS REQUIRED FOR INSTALLATION ................. 3

PARTS .................................. ...................................... 4

ASSEMBLE CART ................................................. ... .. 6

MOUNT PLASMA DISPLAYS ON CART .................... 8

INSPECT PARTS BEFORE ASSEMBLY

• Refer to Table 1 on page 4 and “PARTS” on page 4.

Carefully inspect the parts for shipping damage.

• If any damage is apparent, call your carrier claims

agent and do not continue with the assembly pro ce dure until the carrier has reviewed the damage.

OPTIONAL ACCESSORIES

• Acrylic Shelf.

• Video Conferencing Shelf

TOOLS RE QUIRED

FOR INSTALLATION

• 7/16” and 3/4” wrench

• Allen wrenches

• Socket set with extension

NOTE: Other tools may be required depending on the

method of installation.

3

Page 4

Installation Instuctions PPD-Series

160

120

110

100

10

20

130

150

30

90

40

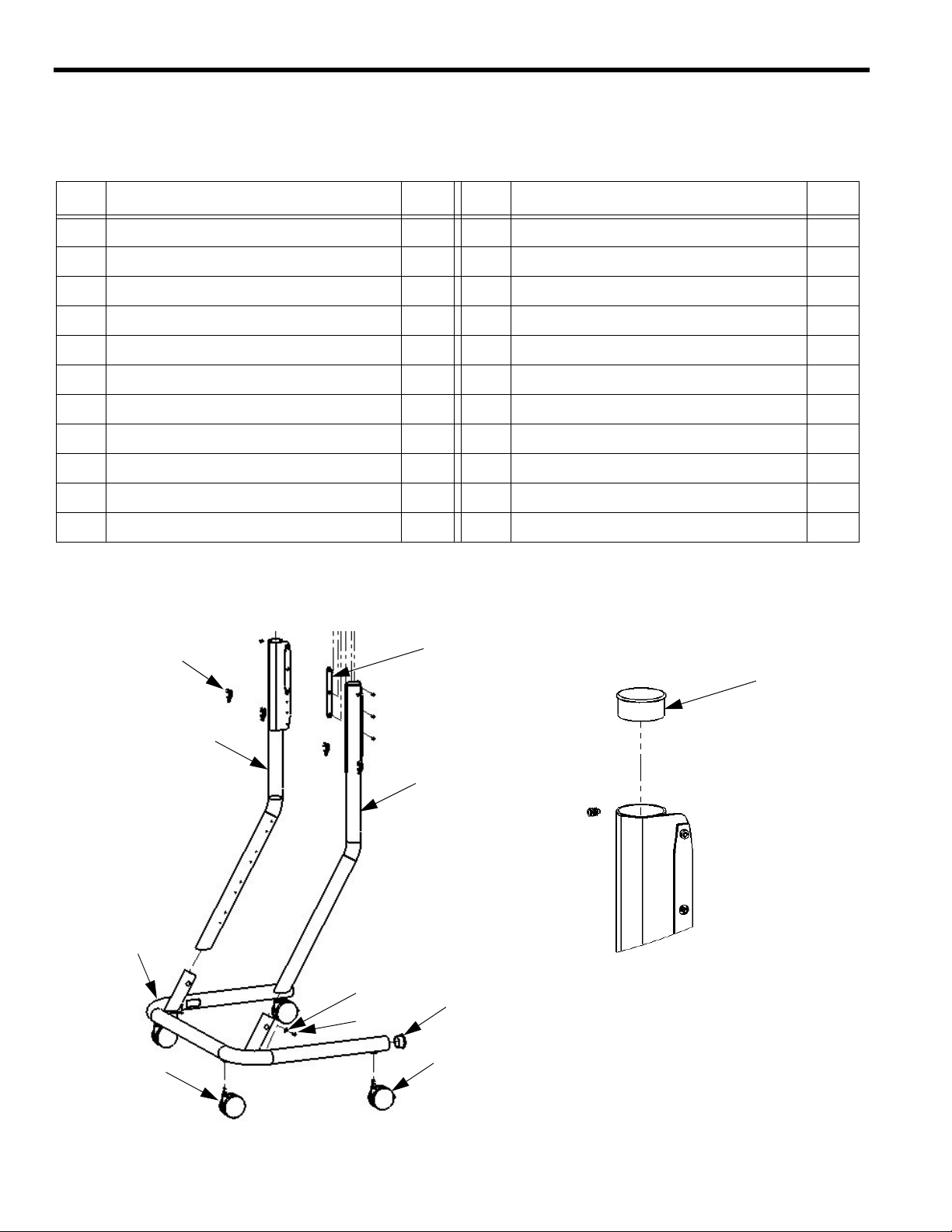

PARTS

Table 1: Parts List

REF DESCRIPTION QTY REF DESCRIPTION QTY

10 CASTERS, Front (No Locks) 2 120 LEG, Right 1

20 CASTERS, Rear (Locking) 2 130 SCREW, Cap, Button head, 1/4 20 x 5/8” 28

30 PLUG, Cap (hard plastic - use with base) 2 140 SCREW, Cap, Button head, 5/16-18 x 3/4” 6

40 PLUG, Cap (slip on vinyl - use with legs) 2 150 WASHER, 1/4” 2

50 PLATE, Face 2 160 WRENCH, Allen, 3/16” (Not Shown) 1

60 FACEPLATE, Sides 4

70 HEAD, Mounting (PPC Tilt Head) 1

80 BRACKET, Dual Screen Mounting 1

90 SPREADER, Head tilt (viewed from inside) 2

100 BASE, With corner supports 1

110 LEG, Left 1

4

Page 5

Installation Instuctions PPD-Series

50

70

80

130

140

60

PARTS (CONT’D)

5

Page 6

Installation Instuctions PPD-Series

Rear Casters (Locking)

Front Casters

(10)

(20)

Mounting tabs

face inward

Left arm

(Example)

Cap Plug

Posts may need to be

lifted slightly to insert

fasteners (130 and 150)

with star cut

(30)

Install 1/4-20 screw (130) securing

mounting head on each side first

1/4-20 Screws (130)

Securing Tilt Plate

Tilt Plate (90)

Cap Plug (40)

(threads into mounting head)

Mounting Head (70)

ASSEMBLE CART

NOTE: Read all instructions before assembly. Also,

refer to Table 1 on page 4 and “PARTS” on

page 4 for the numbers shown in parenthesis ( ).

1. Place base (100) upside down (see Figure 1).

a. Thread two regular casters (10) into the holes

near the corner support posts in the base (front)

as shown in Figure 1.

b. Thread two locking casters (20) into the holes at

the end of the support posts for the base (front)

as shown in Figure 1.

2. Place base (100) upright on casters.

3. Install legs for base (100) as follows:

a. Insert left leg (110) and right leg (120) into the

support posts on the base. Make sure the

mounting tabs face inward (see Figure 2).

Figure 1. Install Casters

b. Secure both legs using two washers (150) and

two 1/4 x 1/2” screws (130).

c. Install cap plugs (30) in base (see Figure 3).

d. Install cap plugs (40) on top of left leg (110) and

right leg (120). See Figure 4.

4. Using two 1/4-20 x 5/8” button head screws (130),

one on each side, secure the mounting head (70) to

the top of the legs (110 and 120) of the cart

(see Figure 4).

5. Using four 1/4-20 x 5/8” button head screws (130),

(two on each side), secure two tilt head spreaders

(90), one per side (see Figure 4).

Figure 2. Turn Mounting Tabs Inward

Figure 3. Install Legs

6

Figure 4. Install Mounting Head

Page 7

Installation Instuctions PPD-Series

Dual

Loosen Screws

Loosen Screws

Tilt Head Spreader

0 to 7.5 Degrees

(80)

Mounting

Bracket

(90)

Tilt

Mounting

Head

(70)

Screen

5/16-18 Screws (140)

Tilt Mounting

Dual Screen

Mounting Bracket (80)

Head (70)

ASSEMBLE CART (CONT’D)

6. Adjust tilt head (70) to desired tilt by slightly loosen-

ing four 1/4-20x5/8” button head cap screws (130)

securing tilt head spreaders (90), adjust tilt head t o

desired angle (0º to 7-1/2º), and tighten four

1/4-20x5/8” button head cap screws (130).

See Figure 5).

7. Using six 5/16-18X3/4” screws (140), secure the dual

screen mounting bracket (80) to the tilt mounting

head (70) (see Figure 6).

Figure 6. Attach Dual Screen Mounting Bracket to Mounting Head

Figure 5. Adjust Tilt Mounting Head

7

Page 8

Installation Instuctions PPD-Series

Mounting Bracket (80)

Dual Screen

Face Plates (50)

MOUNT PLASMA DISPLAYS ON CART

1. Measure the distance from the center of your display

to its outermost edge.

NOTE: Make sure to leave some space between

displays when mounted.

2. Using the measurement found in Step 1 and the

faceplate (50) as a template, measure from the center of the dual screen mounting bracket (80) to find

the correct mounting holes for your application (see

Figure 7).

3. Secure each face plate (50) using four 1/4-20x5/8”

screws (130) (see Figure 8).

Figure 7. Dual Screen Mounting Bracket Head Measurements

Figure 8. Dual Mounting Head with Face Plates Attached

8

Page 9

Installation Instuctions PPD-Series

To use as a

A padlock or bolt may

be placed through latch

holes

more permanent lock,

remove pin and nuts and

move to lower holes.

MOUNT PLASMA DISPLAYS ON CART (CONT’D)To install display:

WARNING! Make sure cart wheels are locked

before installing the display to the cart!

4. While supporting both sides of display, align four

mounting buttons on display or interface bracket

with four mounting holes in faceplate.

(See Figure 9)

5. Lower display into place listening for audible

"click" to ensure recessed area of mounting buttons

are properly seated in lower area of mounting holes

and ClickConnect mechanism has engaged.

(See Figure 9) and (See Figure 10)

NOTE: Holes are provided in the faceplate for use with a

padlock or similar locking device, if desired. In addition,

the pin and nut may be removed from the upper holes

and moved to the lower holes for use as a more

permanent locking device. (See Figure 10 )

Figure 10: Secure Display

Figure 9 : Hang Display

9

Page 10

Installation Instuctions PPD-Series

10

Page 11

Installation Instuctions PPD-Series

11

Page 12

Installation Instuctions PPD-Series

12

Loading...

Loading...