Page 1

INSTALLATION INSTRUCTIONS

Instrucciones de instalación

Installationsanleitung

Instruções de Instalação

Istruzioni di installazione

Installatie-instructies

Instructions d´installation

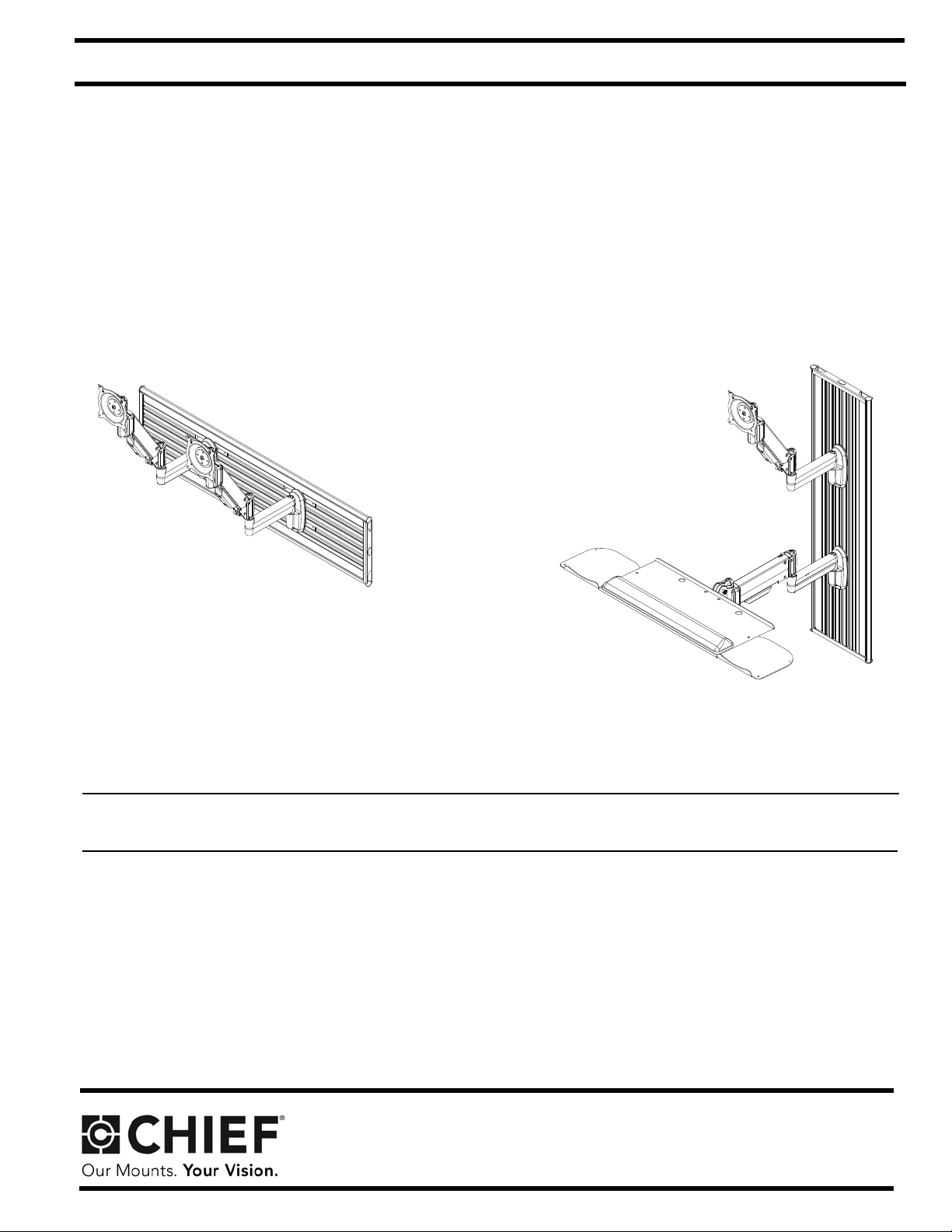

SFP WALL TRACK ACCESSORY

Spanish Product Description

German Product Description

Portuguese Product Description

Italian Product Description

Dutch Product Description

French Product Description

KSA-1022

Page 2

KSA-1022 Installation Instructions

9.47

240

36.15

918

FLEXIBLE/REMOVEABLE

CABLE MANAGEMENT

COVERS

.88

22

.60 DEPTH FROM WALL

TO ACCESSORY

MOUNTING SURFACE

15

CABLE

MANAGEMENT

CHANNELS

KSA-1022 SHOWN WITH

KWG AND KWK MOUNTS

(KWG AND KWK MOUNTS

SOLD SEPARATELY)

VERTICAL INSTALLATION

4.50

114

.50

13

6.91

176

.25 TYP.

HOLE SIZE

6

10.00

254

16.00

406

20.00

508

32.00

813

KSA-1022 SHOWN WITH

KWG MOUNTS

(KWG MOUNTS SOLD SEPARATELY)

HORIZONTAL INSTALLATION

DISCLAIMER

Milestone AV Technologies and its affiliated corporations and

subsidiaries (collectively "Milestone"), intend to make this

manual accurate and complete. However, Milestone makes no

claim that the information contained herein covers all details,

conditions or variations, nor does it provide for every possible

contingency in connection with the installation or use of this

product. The information contained in this document is subject

to change without notice or obligation of any kind. Milestone

WARNING:

Failure to provide adequate structural strength

for this component can result in serious personal injury or

damage to equipment! It is the installer’s responsibility to

make sure the structure to which this component is attached

can support five times the combined weight of all equipment.

Reinforce the structure as required before installing the

component.

makes no representation of warranty, expressed or implied,

regarding the information contained herein. Milestone assumes

no responsibility for accuracy, completeness or sufficiency of

the information contained in this document.

WARNING:

Exceeding the weight capacity can result in

serious personal injury or damage to equipment! It is the

installer’s responsibility to make sure the weight of each

Chief® is a registered trademark of Milestone AV T echnologies.

All rights reserved.

component attached to the KSA-1022 wall track accessory

does not exceed 25 lbs (11.3 kg) or the specific weight limit

for the attached mounting device. Additionally, there is a limit

on how many components may be mounted on each bracket

depending on the mounting method. Refer to the table below

IMPORTANT WARNINGS AND

for details.

CAUTIONS!

Two Mount Maximum Three Mount Maximum

WARNING:

A WARNING alerts you to the possibility of

serious injury or death if you do not follow the instructions.

CAUTION:

A CAUTION alerts you to the possibility of

damage or destruction of equipment if you do not follow the

corresponding instructions.

WARNING:

Failure to read, thoroughly understand, and

follow all instructions can result in serious personal injury,

damage to equipment, or voiding of factory warranty! It is the

installer’s responsibility to make sure all components are

properly assembled and installed using the instructions

provided.

DIMENSIONS

Horizontal, dual stud mounting Horizontal, triple stud mounting

Vertical, drywall mounting Vertical, single stud mounting

WARNING:

be installed horizontally on drywall without the use of wood or

steel studs. The drywall must have a minimum thickness of

1/2".

The KSA-1022 wall track accessory CANNOT

2

Page 3

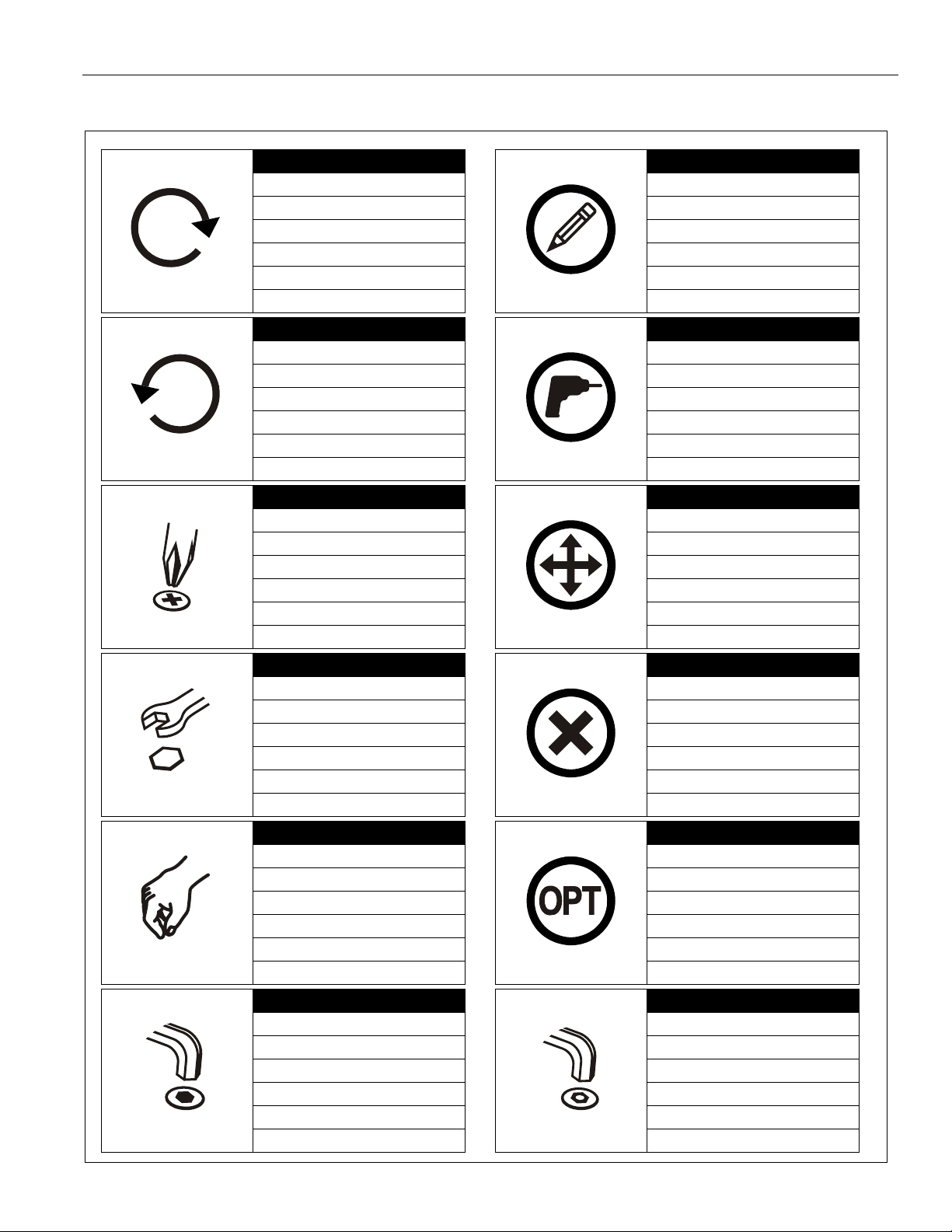

Installation Instructions KSA-1022

Tighten Fastener

Apretar elemento de fijación

Befestigungsteil festziehen

Apertar fixador

Serrare il fissaggio

Bevestiging vastdraaien

Serrez les fixations

Loosen Fastener

Aflojar elemento de fijación

Befestigungsteil lösen

Desapertar fixador

Allentare il fissaggio

Bevestiging losdraaien

Desserrez les fixations

Phillips Screwdriver

Destornillador Phillips

Kreuzschlitzschraubendreher

Chave de fendas Phillips

Cacciavite a stella

Kruiskopschroevendraaier

Tournevis à pointe cruciforme

Open-Ended Wrench

Llave de boca

Gabelschlüssel

Chave de bocas

Chiave a punte aperte

Steeksleutel

Clé à fourche

By Hand

A mano

Von Hand

Com a mão

A mano

Met de hand

À la main

Hex-Head Wrench

Llave de cabeza hexagonal

Sechskantschlüssel

Chave de cabeça sextavada

Chiave esagonale

Zeskantsleutel

Clé à tête hexagonale

Pencil Mark

Marcar con lápiz

Stiftmarkierung

Marcar com lápis

Segno a matita

Potloodmerkteken

Marquage au crayon

Drill Hole

Perforar

Bohrloch

Fazer furo

Praticare un foro

Gat boren

Percez un trou

Adjust

Ajustar

Einstellen

Ajustar

Regolare

Afstellen

Ajuster

Remove

Quitar

Entfernen

Remover

Rimuovere

Verwijderen

Retirez

Optional

Opcional

Optional

Opcional

Opzionale

Optie

En option

Security Wrench

Llave de seguridad

Sicherheitsschlüssel

Chave de segurança

Chiave di sicurezza

Veiligheidssleutel

Clé de sécurité

LEGEND

3

Page 4

KSA-1022 Installation Instructions

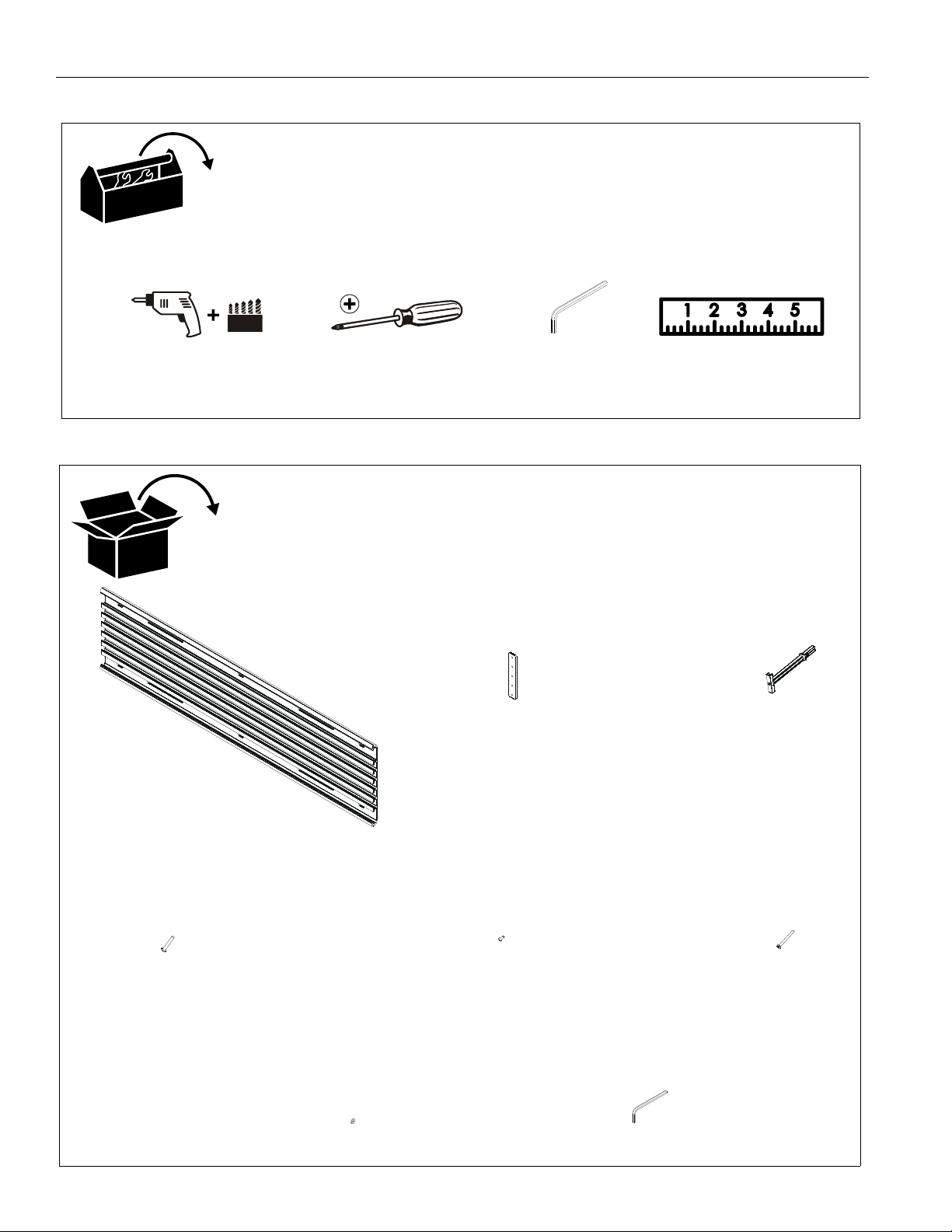

1/2"

#2

7/64

1/8"(included)

A(1)

B(6) C(6)

D(6)

E(6)

F(6)

H(6)

J(1)

1/4-20 x 1 3/4"

#10-24 x 1/2"

#12 x 2 1/2"

#10

1/8"

TOOLS REQUIRED FOR INSTALLATION

PARTS

4

Page 5

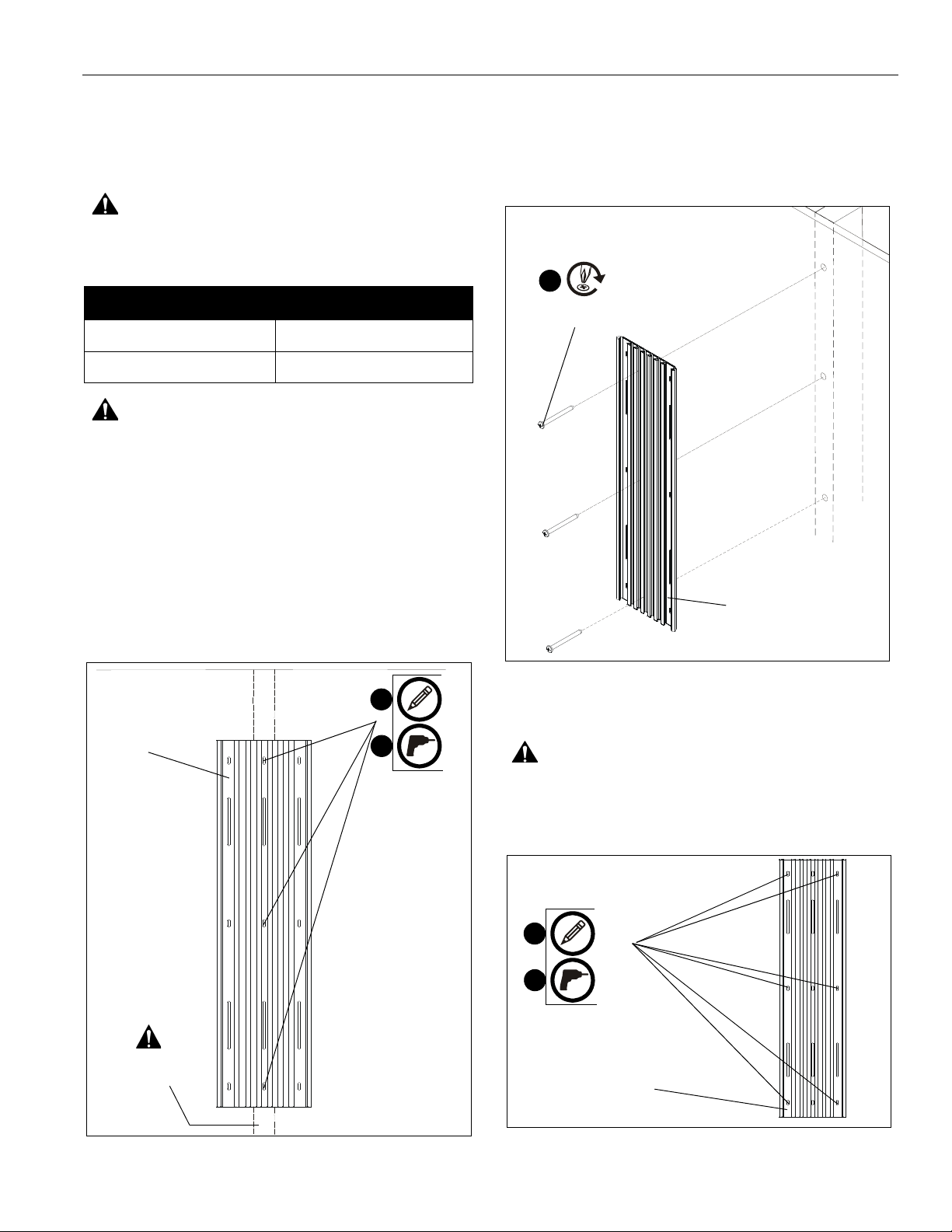

Installation Instructions KSA-1022

3

4

X 3

X 3

Mounting holes

centered on stud

(A)

(F) x 3

5

(A)

1

2

X 6

X 6

(A)

WA LL TRACK INSTALLATION

1. Determine mounting location on wall.

2. Determine whether wall track accessory will be mounted

horizontally or vertically.

WARNING:

be mounted on each bracket depending on the mounting

method. Refer to the table below for details.

Two Mount Maximum Three Mount Maximum

Horizontal, dual stud mounting Horizontal, triple stud mounting

Vertical, drywall mounting Vertical, single stud mounting

WARNING:

be installed horizontally on drywall without wood or steel

studs.

NOTE:

There is a limit on how many components may

The KSA-1022 wall track accessory CANNOT

It may be necessary to remove cable management

flaps from wall track accessory in order to expose holes

to be used for installation.

3. Using wall track accessory (A) as a template, mark location

of three mounting holes on wall. (See Figure 1)

4. Drill three 7/64" holes. (See Figure 1)

5. Install three #12 x 2 1/2" round pan wood screws (F) through

small center bracket holes and into drilled holes. (See

Figure 2)

Vertical Installation using Wood Studs

1. Using a stud finder or similar method locate stud.

2. Align the middle mounting holes on mount with stud making

sure mounting holes are centered on stud. (See Figure 1)

Figure 2

Vertical Installation on Drywall

WARNING:

install wall track accessory.

1. Using wall track accessory (A) as a template, mark location

of six mounting holes on wall making sure it will be level.

(See Figure 3)

Drywall must be at least 1/2" thick in order to

Figure 1

Figure 3

5

Page 6

KSA-1022 Installation Instructions

(C) x 6

Drywall

Plastic Straps

3

Plastic Cap

Drywall

Anchor Metal Channel

SIDE VIEW

(C) x 6

5

Plastic Straps

Drywall

Anchor Metal Channel

Plastic Cap

SIDE VIEW

6

Drywall

Anchor Metal Channel

Wall Track Accessory

SIDE VIEW

(D) x 6

9

2. Drill six 1/2" holes at locations marked in Step 1. (See

Figure 3)

3. Hold metal channel on anchor (C) flat alongside plastic

straps and slide channel through hole. (See Figure 4)

Figure 4

4. Holding plastic straps on anchor (C), pull anchor away from

wall until channel rests flush behind wall making sure

anchor channel is positioned vertically on stud. (See Figure

5)

5. Slide plastic cap on anchor (C) towards wall until flange of

cap is flush with wall. (See Figure 5)

8. Place wall track accessory over anchors and align mounting

holes in display mount with holes in anchors. (See Figure 6)

9. Insert 1/4-20 x 1 3/4" Phillips pan head screws (D) through

corresponding mounting hole on wall track accessory and

into anchor (C) and tighten until flush against mount. DO

NOT overtighten! (See Figure 7)

10. Repeat steps 8 through 9 for remaining 5 mounting holes.

Figure 6

Figure 5

6. Snap off plastic straps on anchor at wall by pushing side to

side, snapping off straps level with flange of plastic cap.

(See Figure 6)

7. Repeat steps 3 through 6 for each mounting hole.

6

Figure 7

Page 7

Installation Instructions KSA-1022

(Dual Studs)

(Triple Studs)

(A)

studs

x 4

x 6

3

2

2

3

(Dual studs)

(Triple studs)

(F) X 4

(F) X 6

(A)

5

5

(A)

Horizontal Installation using Wood Studs

NOTE:

1. Use a stud finder or similar method to determine location of

2. Draw a vertical line down the center of the studs to be used.

3. Remove cable management flaps from wall track accessory

4. Using wall track accessory (A) as a template, mark location

Wall track accessory may be mounted horizontally to

two studs that are 16", 20" or 24" apart or to three studs

that are 16" apart.

studs.

(See Figure 8)

to expose holes to be used for installation.

of three mounting holes on wall. Make sure wall track

accessory is level. (See Figure 8)

WARNING:

on dual studs. DO NOT mount device using the small holes

unless mounting on three studs.

Only long holes may be used to mount device

Figure 8

5. Drill 7/64" holes at each marked location. (See Figure 8)

6. Install four (two studs) or six (three studs) #12 x 2 1/2" round

pan wood screws (F) through wall accessory holes into the

holes drilled in Step 4. (See Figure 9)

Figure 9

7

Page 8

KSA-1022 Installation Instructions

There must be a minimum of

1 7/8" (48mm) clearance

to a minimum of one stud left and right of the stud(s)

Stud type and structural strength must conform to the North American

Drywall

**1/2" minimum

Drywall Thickness

Only 16" Studs may be used for Triple Studs.

FRONT

(Must be centered on stud)

inside wall

16", 20" or 24" Studs may be used for Single or Dual Studs (shown)

If back side of wall is unfinished, drywall must be installed

being used to install the mount. Drywall must be

secured to studs with screws 12" on center

Steel Stud (2 x 4 / 25ga minimum)

Specification for the Design of Cold-Formed Steel Structural Members.

[362 S 125 18, C-Shaped, S-Stud Section]

**See hazard statement

on page 2!

Site Requirements for Steel Studs

WARNING:

OR DAMAGE TO EQUIPMENT! The figure below identifies the minimum reguirements for installation of display mounts onto a

steel stud structure. If the structure or its components do not meet these requirements contact the mount manufacturer for specific

instructions before attempting installation. It should also be noted that no other equipment should be mounted to the same stud.

IMPROPER INSTALLATION CAN LEAD TO EQUIPMENT FALLING CAUSING SERIOUS PERSONAL INJUR Y

8

Page 9

Installation Instructions KSA-1022

3

4

X 3

X 3

Mounting holes

centered on stud

(A)

(C) x 3

Drywall

Plastic Straps

6

(C) x 3

Plastic Cap

Drywall

Anchor Metal Channel

SIDE VIEW

8

Steel Stud

Plastic Straps

Drywall

Anchor Metal Channel

Plastic Cap

SIDE VIEW

9

Steel Stud

anchor channel is positioned vertically on stud. (See Figure

12)

8. Slide plastic cap on anchor (C) towards wall until flange of

Vertical Installation using Steel Studs

After determining the site meets the installation requirements:

1. Identify desired mounting location on wall.

2. Using a stud finder or similar method locate stud .

3. Align the middle mounting holes on mount with stud making

sure mounting holes are centered on stud. (See Figure 10)

4. Using wall track accessory (A) as a template, mark location

of three mounting holes on wall. (See Figure 10)

cap is flush with wall. (See Figure 12)

5. Drill three 1/2" holes in locations marked in Step 4.

6. Hold metal channel on anchor (C) flat alongside plastic

7. Holding plastic straps on anchor (C), pull anchor away from

Figure 10

straps and slide channel through hole. (See Figure 11)

wall until channel rests flush behind wall making sure

Figure 11

Figure 12

9. Snap off plastic straps on anchor at wall by pushing side to

side, snapping off straps level with flange of plastic cap.

(See Figure 13)

10. Repeat steps 6 through 9 for each mounting hole.

Figure 13

1 1. Place wall track accessory over anchors and align mounting

holes in display mount with holes in anchors. (See Figure

13)

12. Insert 1/4-20 x 1 3/4" Phillips pan head screws (D) through

corresponding mounting hole on wall track accessory and

into anchor (C) and tighten until flush against mount. DO

NOT overtighten! (See Figure 14)

13. Repeat steps 11 through 12 for remaining 2 mounting holes.

9

Page 10

KSA-1022 Installation Instructions

Drywall

Anchor Metal Channel

Wall Track Accessory

SIDE VIEW

(D) x 3

9

Steel Stud

4

(Dual Studs)

(Triple Studs)

(A)

studs

x 4

x 6

5

4

5

(C) x 4 or 6

Drywall

Plastic Straps

6

WARNING:

EQUIPMENT FALLING CAUSING SERIOUS PERSONAL

INJURY OR DAMAGE TO EQUIPMENT! Overtightening of

mounting hardware can damage the steel studs. DO NOT

overtighten mounting hardware!

IMPROPER INSTALLATION CAN LEAD TO

Figure 14

Horizontal Installation Using Steel Studs

NOTE:

After determining the site meets the installation requirements:

1. Identify desired mounting location on wall.

2. Use a stud finder or similar method to determine location of

3. Draw a vertical line down the center of the studs to be used.

4. Using wall track accessory (A) as a template, mark location

5. Drill 1/2" holes at each marked location. (See Figure 8)

Wall track accessory may be mounted horizontally to

two studs that are 16", 20" or 24" apart or to three studs

that are 16" apart.

studs.

(See Figure 8)

of three mounting holes on wall. Make sure wall track

accessory is level. (See Figure 8)

WARNING:

on dual studs. DO NOT mount device using the small holes

unless mounting on three studs.

Only long holes may be used to mount device

Figure 15

6. Hold metal channel on anchor (D) flat alongside plastic

straps and slide channel through hole. (See Figure 16)

Figure 16

7. Holding plastic straps on anchor (C), pull anchor away from

wall until channel rests flush behind wall making sure

anchor channel is positioned vertically on stud. (See Figure

17)

8. Slide plastic cap on anchor (C) towards wall until flange of

cap is flush with wall. (See Figure 17)

10

Page 11

Installation Instructions KSA-1022

Plastic Cap

Drywall

Anchor Metal Channel

SIDE VIEW

(C) x 4 or 6

8

Steel Stud

Plastic Straps

Drywall

Anchor Metal Channel

Plastic Cap

SIDE VIEW

9

Steel Stud

Drywall

Anchor Metal Channel

Wall Track Accessory

SIDE VIEW

(D) x 4 or 6

9

Steel Stud

Figure 17

9. Snap off plastic straps on anchor at wall by pushing side to

side, snapping off straps level with flange of plastic cap.

(See Figure 18)

10. Repeat steps 6 through 9 for each mounting hole.

Figure 19

1 1. Place wall track accessory over anchors and align mounting

holes in display mount with holes in anchors. (See Figure

13)

12. Insert 1/4-20 x 1 3/4" Phillips pan head screws (D) through

corresponding mounting hole on wall track accessory and

into anchor (C) and tighten until flush against mount. DO

NOT overtighten! (See Figure 14)

13. Repeat steps 11 through 12 for remainin g mounting holes.

Figure 18

Computer Hardware Installation on

Horizontal Bracket

WARNING:

serious personal injury or damage to equipment! It is the

installer’s responsibility to make sure the weight of each

component attached to the KSA-1022 wall track accessory

does not exceed 25 lbs (11.3 kg) or the specific weight limit

for the attached mounting device. Additionally, there is a limit

on how many components may be mounted on each bracket

depending on the mounting method. Refer to the table below

for details.

Two Mount Maximum Three Mount Maximum

Horizontal, dual stud mounting Horizontal, triple stud mounting

Vertical, drywall mounting Vertical, single stud mounting

WARNING:

steel studs, a minimum distance of 8" must exist between

mounted devices. For horizontal triple stud mounting on

wood or steel studs, a minimum distance of 14" must exist

between mounted devices. (See Figure 20)

Exceeding the weight capacity can result in

For horizontal dual stud mounting on wood or

EQUIPMENT FALLING CAUSING SERIOUS PERSONAL

INJURY OR DAMAGE TO EQUIPMENT! Overtightening of

mounting hardware can damage the steel studs. DO NOT

overtighten mounting hardware!

WARNING:

IMPROPER INSTALLATION CAN LEAD TO

11

Page 12

KSA-1022 Installation Instructions

8" minimum

Dual Stud Mounting

Triple St ud Mounting

14" minimum

2

(B) x 2

(E) x 2

(H) x 2

wall bracket

1

3

1. Remove side cover to slide locking plate brackets (B) into

wall track accessory (A) at the desired mounting location.

(See Figure 21)

NOTE:

2. Reinstall side cover to wall track accessory after all locking

3. Use hex key (J) to install #10 button head cap screws (E)

4. Refer to corresponding installation manual to complete

Locking plate brackets must be inserted into the top

channel and second channel from the bottom.

plate brackets have been inserted. (See Figure 21)

through #10 washers (H) and wall plate (not included) into

center holes of locking plate brackets (B). (See Figure 21)

installation of specific computer hardware.

Figure 20

Figure 21

12

Page 13

Installation Instructions KSA-1022

Wood or Steel Studs

Drywall

8"

minimum

16"

min

((B)

(E) x 2

3

(H) x 2

wall bracket

1

2

(B)

Computer Hardware Installation on Vertical

Bracket

WARNING:

serious personal injury or damage to equipment! It is the

installer’s responsibility to make sure the weight of each

component attached to the KSA-1022 wall track accessory

does not exceed 25 lbs (11.3 kg) or the specific weight limit

for the attached mounting device. Additionally, there is a limit

on how many components may be mounted on each bracket

depending on the mounting method. Refer to the table below

for details.

Two Mount Maximum Three Mount Maximum

Horizontal, dual stud mounting Horizontal, triple stud mounting

Vertical, drywall mounting Vertical, single stud mounting

WARNING:

minimum distance of 8" must exist between mounted

devices. For vertical mounting on drywall, a minimum

distance of 16" must exist between mounted devices. (See

Figure 22)

Exceeding the weight capacity can result in

For vertical mounting on wood or steel studs, a

1. Remove side cover to slide locking plate brackets (B) into

wall track accessory (A) at the desired mounting location.

(See Figure 23)

NOTE:

2. Reinstall side cover to wall track accessory after all locking

Locking plate brackets must be inserted into center

channel on wall track accessory.

plate brackets have been inserted. (See Figure 23)

Figure 22

Figure 23

3. Use hex key (J) to install #10 button head cap screws (E)

through #10 washers (H) and wall plate (not included) into

center holes of locking plate brackets (B). (See Figure 23)

4. Refer to corresponding installation manual to complete

installation of specific computer hardware.

NOTE:

Wall brackets must be secured by installing screws

through the top and bottom holes of the bracket. (See

Figure 23)

Cable Management

NOTE:

1. Tuck cable inside cable management flap. (See Figure 22)

2. Remove side cover to wall track accessory.

3. Pull cable through cable management flap until cable outlet

Complete installation of computer hardware prior to

enclosing the cable within the wall track accessory.

plug extends outside the wall track accessory. (See Figure

22)

13

Page 14

KSA-1022 Installation Instructions

1

cable management flap

cable path

4

3

(typical)

4. Reinstall side cover making sure the cable runs through the

cable hole. (See Figure 22)

Figure 24

14

Page 15

Installation Instructions KSA-1022

15

Page 16

KSA-1022 Installation Instructions

Chief Manufacturing, a division of

Milestone AV Technologies

8834-00004

©

2008 Milestone AV Technologies

www.chiefmfg.com

10/08

USA/International A

Europe A

Asia Pacific A

8401 Eagle Creek Parkway, Savage, MN 55378

P

800.582.6480 / 952.894.6280

F

877.894.6918 / 952.894.6918

Fellenoord 130 5611 ZB EINDHOVEN, The Netherlands

P

+31 (0)40 2668620

F

+31 (0)40 2668615

Room 24F, Block D, Lily YinDu International Building

LuoGang, BuJi Town, Shenzhen, CHINA.

P

+86-755-8996 9226

F

+86-755-8996 9217

Loading...

Loading...