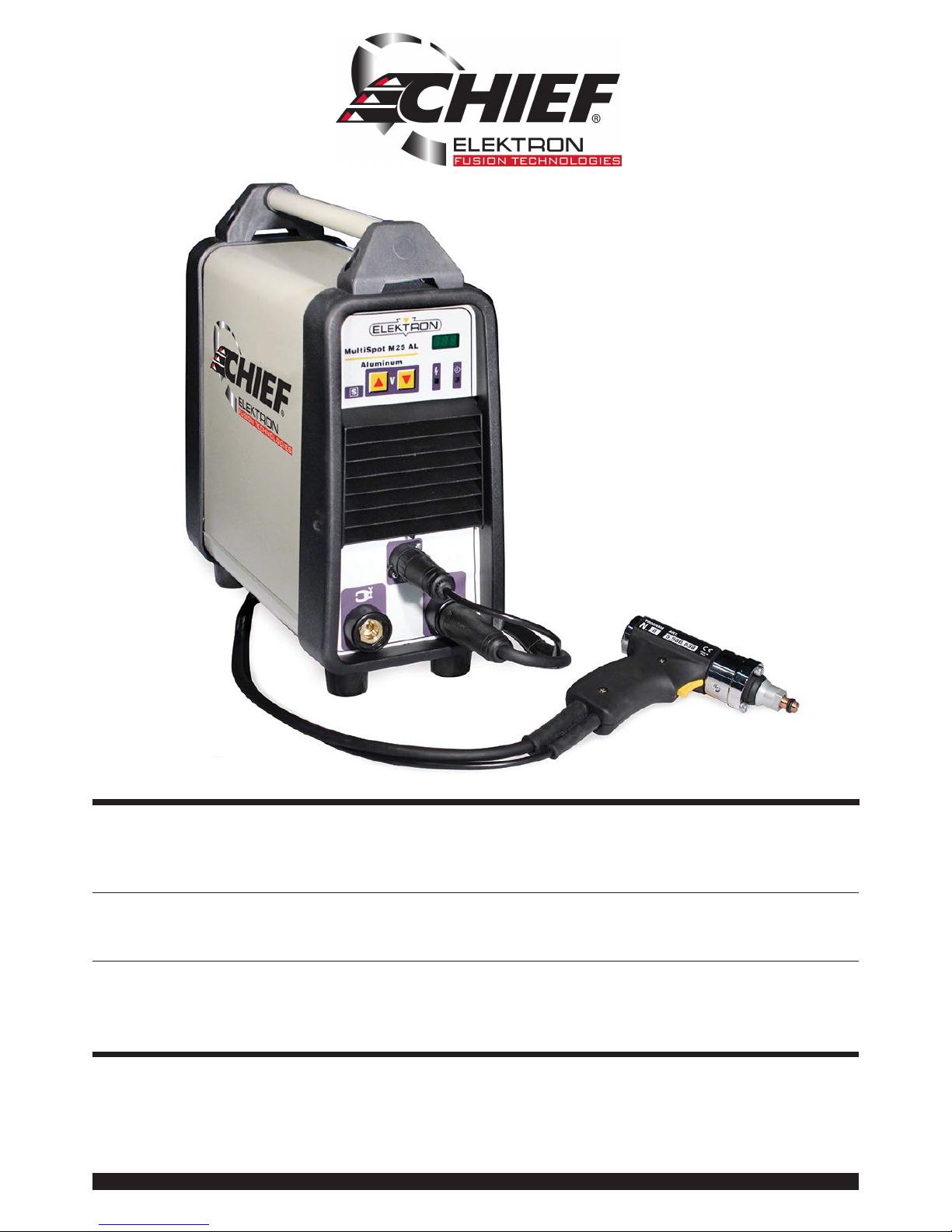

Page 1

US INSTRUCTION MANUAL FOR CAPACITOR DISCARGE

WELDING MACHINE page 2

F MANUEL D’INSTRUCTIONS POUR POSTE A SOUDER

A DESCHARGE DE CONDENSATEURS page 9

E MANUAL DE INSTRUCCIONES PARA SOLDADORA

DE DESCARGA DE CONDENSADORES pag. 16

Spare parts and electrical schematic

Pièces détachées et schéma électrique

Partes de repuesto y esquema eléctrico

Page: 24÷ 27

05/03/2015

3.300.081

Page 2

2

INSTRUCTION MANUAL FOR CAPACITOR DISCARGE WELDING MACHINE

IMPORTANT: BEFORE STARTING THE EQUIPMENT,

READ THE CONTENTS OF THIS MANUAL, WHICH MUST

BE STORED IN A PLACE FAMILIAR TO ALL USERS FOR

THE ENTIRE OPERATIVE LIFE-SPAN OF THE MACHINE.

THIS EQUIPMENT MUST BE USED SOLELY FOR WELDING OPERATIONS.

1 SAFETY PRECAUTIONS

WELDING AND ARC CUTTING CAN BE

HARMFUL TO YOURSELF AND OTHERS. The

user must therefore be educated against the hazards, summarized below, deriving from welding operations. For more

detailed information, order the manual code 3.300.758

NOISE

These power source alone do not produce noise

levels exceeding 80 dB. The welding procedure,

however, may produce noise levels in excess of

80 dB. in which case the machine operator must take the

necessary safety precautions as prescribed by the national safety regulation.

ELECTRIC AND MAGNETIC FIELDS INFORMATION

· Electric current following through any conductor causes localized Electric and Magnetic Fields (EMF). Welding/cutting current

creates EMF elds around cables and power sources.

· The magnetic elds created by high currents may affect

the operation of pacemakers. Pacemaker wearers are

prohibited from using the machine or approach the

cables.

· Exposure to EMF elds in welding/cutting may have

other health effects which are now not known.

· All operators should use the followingprocedures in or-

der to minimize exposure to EMF elds from the welding/

cutting circuit:

- Route the electrode and work cables together

- Secure them with tape when possible.

- Never coil the electrode/torch lead around your body.

- Do not place your body between the electrode/torch

lead and work cables. If the electrode/torch lead

cable is on your right side, the work cable should also

be on your right side.

- Connect the work cable to the workpiece as close as

possible to the area being welded/cut.

- Do not work next to welding/cutting power source.

EXPLOSIONS

· Do not weld in the vicinity of containers under pres-

sure, or in the presence of explosive dust, gases or

fumes. · All cylinders and pressure regulators used

in welding operations should be handled with care.

DISPOSAL OF ELECTRICAL AND ELECTRONIC

EQUIPMENT.

Do not dispose of electrical equipment together

with normal waste! Electrical equipment that has reached

the end of its life must be collected separately and returned to an environmentally compatible recycling facility. As the owner of the equipment, you should get information on approved collection systems from our local

representative.

Extra precautions are to be observed when working

on elevated positions.

Electromagnetic compatibility

In Canada, the EMC classication does not apply to arc

welding power source.

Safety standards

To provide minimum requirements and recommendations to protect persons who work in an

environment affected by welding, cutting, and allied processes see CAN/CSA-W117.2 standard.

IN CASE OF MALFUNCTIONS, REQUEST ASSISTANCE

FROM QUALIFIED PERSONNEL.

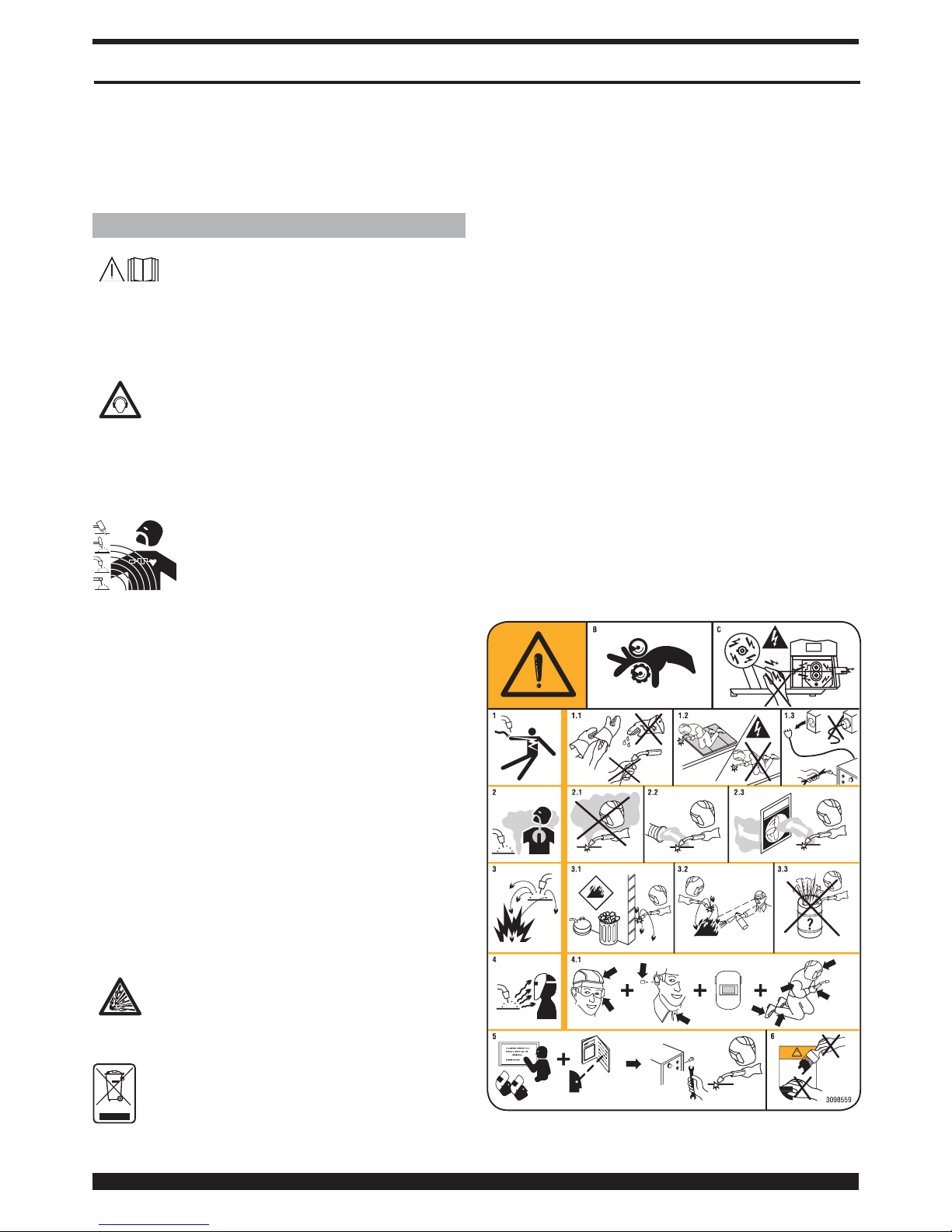

1.1 WARNING LABEL

The following numbered text corresponds to the label

numbered boxes.

B. Drive rolls can injure ngers.

Page 3

3

C. Welding wire and drive parts are at welding volta-

ge during operation - keep hands and metal objects

away.

1 Electric shock from welding electrode or wiring can kill.

1.1 Wear dry insulating gloves. Do not touch electrode

with bare hand. Do not wear wet or damaged gloves.

1.2 Protect yourself from electric shock by insulating

yourself from work and ground.

1.3 Disconnect input plug or power before working on

machine.

2 Breathing welding fumes can be hazardous to your

health.

2.1 Keep your head out of fumes.

2.2 Use forced ventilation or local exhaust to remove

fumes.

2.3 Use ventilating fan to remove fumes.

3 Welding sparks can cause explosion or re.

3.1 Keep ammable materials away from welding.

3.2 Welding sparks can cause res. Have a re extingui-

sher nearby and have a watchperson ready to use it.

3.3 Do not weld on drums or any closed containers.

4 Arc rays can burn eyes and injure skin.

4.1 Wear hat and safety glasses. Use ear protection and

button shirt collar. Use welding helmet with correct

shade of lter. Wear complete body protection.

5 Become trained and read the instructions before

working on the machine or welding.

6 Do not remove or paint over (cover) label.

2 GENERAL DESCRIPTIONS

2.1 SPECIFICATIONS

The machine has been designed and built for welding

ferrous and non-ferrous stud bolts, Ø 3, 4, 5, 6 and 8 mm.

This welding system uses the extremely rapid (2-3 ms)

discharge of a battery of charged capacitors, which allows

the welding of stud bolts with contact point start-up.

2.2 EXPLANATION OF THE TECHNICAL

SPECIFICATIONS LISTED ON THE MACHINE

PLATE

N° Serial number, which must be indicated on any

request regarding the welding machine

1

~

Single-phase transformer-rectier with device

for charging and discharging the capacitors

U0 Secondary open-circuit voltage

E Welding energy

C Capacity value

Uc Voltage adjustable on the capacitors

U1 Rated supply voltage. The machine is set up for

voltages of 120V and 240V with automatic

voltage change.

1-50/60Hz 50- or 60-Hz single-phase power supply

I1 Max Max. absorbed current at the corresponding

supply voltage.

I1 Eff This is the current absorbed considering the duty

cycle at the corresponding input voltage.

IP21S Protection rating for the housing.

Note:

The machine has also been designed for use in

environments with a pollution rating of 3. (See IEC 60664).

2.3 DESCRIPTION OF PROTECTIVE DEVICES

2.3.1 Thermal protection

This machine is protected by a thermostat, which prevents

the machine from operating if the allowable temperatures

are exceeded. Under these conditions the fan keeps

running and the display will show "Warning 08".

3 INSTALLATION

WARNING

See complete listing of safety messages at the beginning

of this manual.

Only skilled personnel should install the machine. All

connections must be carried out according to current

regulations, and in full observance of safety laws.

1. Do not place the welding machine on oor with

inclination greater than 10°.

Air must circulate freely, both incoming and outgoing,

and the welding machine must be protected from entry

by liquids, dirt, metal lings, etc.

2. Make sure that the supply voltage is either 120 volts

and a minimum of 20 amp service or 240 volt and a

minimum of 20 amp service. If connected to a circuit

protected by fuses, use time dely fuse marked "D".

Use a plug Nema type 5-20P for 120 V and make sure

that the "green conductor" of the power supply cable

is connected to the ground or “earth” terminal. Make

sure that the white wire is connected to the W plug

terminal.

Use a plug Nema type 6-20P for 240 V and make sure

that the "green conductor" of the power supply cable

is connected to the ground or “earth” terminal. Make

sure that the white wire is connected to the Y plug

terminal.

The machine must be switched off when changing

the power supply.

3. Pacemaker wearers are prohibited from using the

machine or approach the cables.

4. Fully insert the earth cable plug into the socket B and

turn clockwise.

5. Fully insert the gun plug into the socket C and turn

clockwise.

6. Turn on the welding machine using the E switch.

(start-up and shutdown should not be repeated

frequently, because dissipating the energy contained

in the capacitors may cause overheating and damage).

7. To limit exposure to the magnetic eld, keep the gun

cable on the side of the hand holding it, avoiding

wrapping the cable around.

Page 4

4

3.1 DESCRIPTION OF THE EQUIPMENT

A- Display for the setting and control of welding operations

B- Positive output terminal

C- Negative output terminal

D- Torch trigger connector

E- Main switch

F- Fuse Ø 6.3x32 (delayed type). The equipment is tted

with a 12A-T fuse.

G- Knob for the setting and control of welding operations.

3.2 GUN DESCRIPTION

K- Gun body

L- Grip

M- Control cable

N- Welding current cable

O- Welding command button (works only with the gun

pressed against the sheet metal)

P- Force setting indicator

Q- Force adjustment screw (increases when turned clock

wise)

R- Ring to hold spacer Z

S- Clamp locking ring-nut

T- Safety bellows

U- Holding screws for ring R

V- Screw to adjust stud bolt protrusion

W- Holding nut.

X- Stud bolt gripping clamp

Y- Screw

Z- Spacer

X

M N L

S Z T

R U

O P QK

Fig. 2

X W V

1÷1,5 mm

Y

3.2.1 Preparing the gun

Always use high-quality studs with contact point startup for capacitor discharge welding, which comply with

standards and are made of a metal compatible with the

welding to be done.

Having selected the stud bolt to be welded for type,

diameter, length and material, use and adjust the gripping

clamp according to the corresponding diameter.

A

B C

G

D

E

F

Fig. 1

Page 5

5

Insert the stud bolt in the clamp X so that it is rmly held

in place by the four springs.

Adjust the protrusion of the stud bolt from the front of the

clamp to 1 ÷ 1.5 mm using the screw V, then tighten with

the nut W ( gure 2).

Insert the clamp X into the chuck of the gun ( g. 2), press

until you feel it rest all the way down, and tighten the nut

S using the 17-mm hexagon wrench provided.

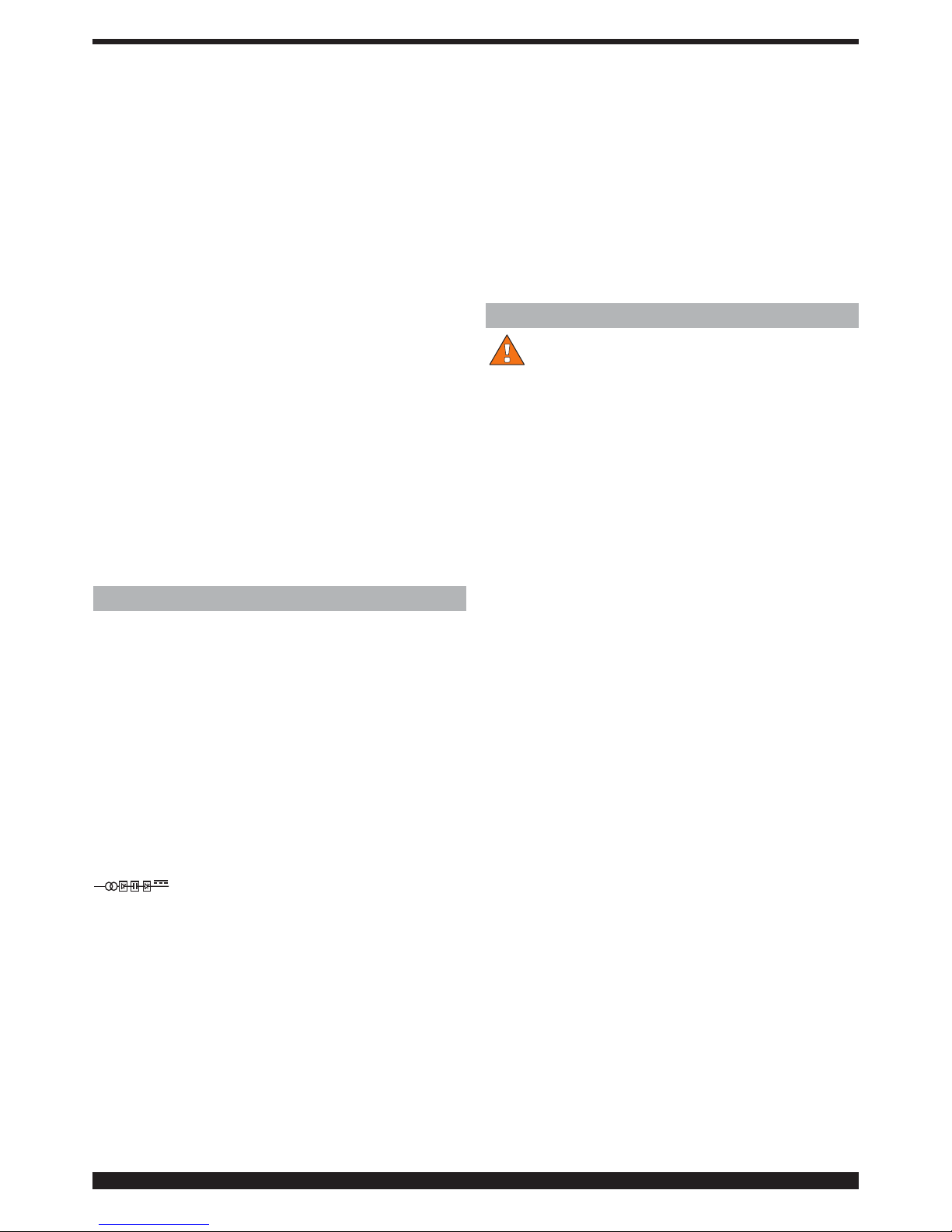

3.3 DESCRIPTION OF FUNCTIONS SHOWN ON THE

DISPLAY A.

When the machine is switched

on, for a few seconds the

display A will show the

machine item number, version

and development date of the

software.

A few seconds later, the following screen will appear on

the display A:

a

b

f

c

d

e

g h

a Stud bolt

b Base material

c Rivet material and dimensions

NOTE: the maximum rivet length that can be used is

30mm (1-1/4”)

d Type of base material

e Indication as to weld quality.

This symbol with the letter Q indicates that the stud

material and the base material that have been selected

are weldable, poorly weldable or non-weldable (See

table 1).

good weldability

poor weldability

non-weldable

f Indications/warnings during the welding phase.

During welding phases these symbols provide

process-related indications:

f

f steadily lit: indicates that the generator is ready

to carry out a welding operation.

f

f steadily lit: indicates that the stud bolt is in

contact with the base material and

the generator is ready to carry out the

welding operation.

f

f ashing: indicates that, after the welding was

completed, the gripping clamp X of

the gun was not removed from the

stud bolt.

f

f ashinge: indicates that, after the welding

was completed, the start button

and microswitch inside the gun

were pressed during charging of the

capacitors.

g Value suggested by the force of the spring inside the

gun (if the force setting is changed, it is recommended

also to change the value indicated on the display so

that in the future this change will remain memorized.

The change from the suggested value will be indicated

by an arrow pointing upward if it is increased or

downward if it is decreased).

h Charge voltage of the capacitors (if the voltage

setting is changed from the suggested value, it will

be indicated by an arrow pointing upward if it is

increased or downward if it is decreased).

During the adjustment, the voltage value will ash to

indicate that the generator is working to reach the

requested value.

Whilst the voltage value is ashing, it is not possible

to perform any welding operation.

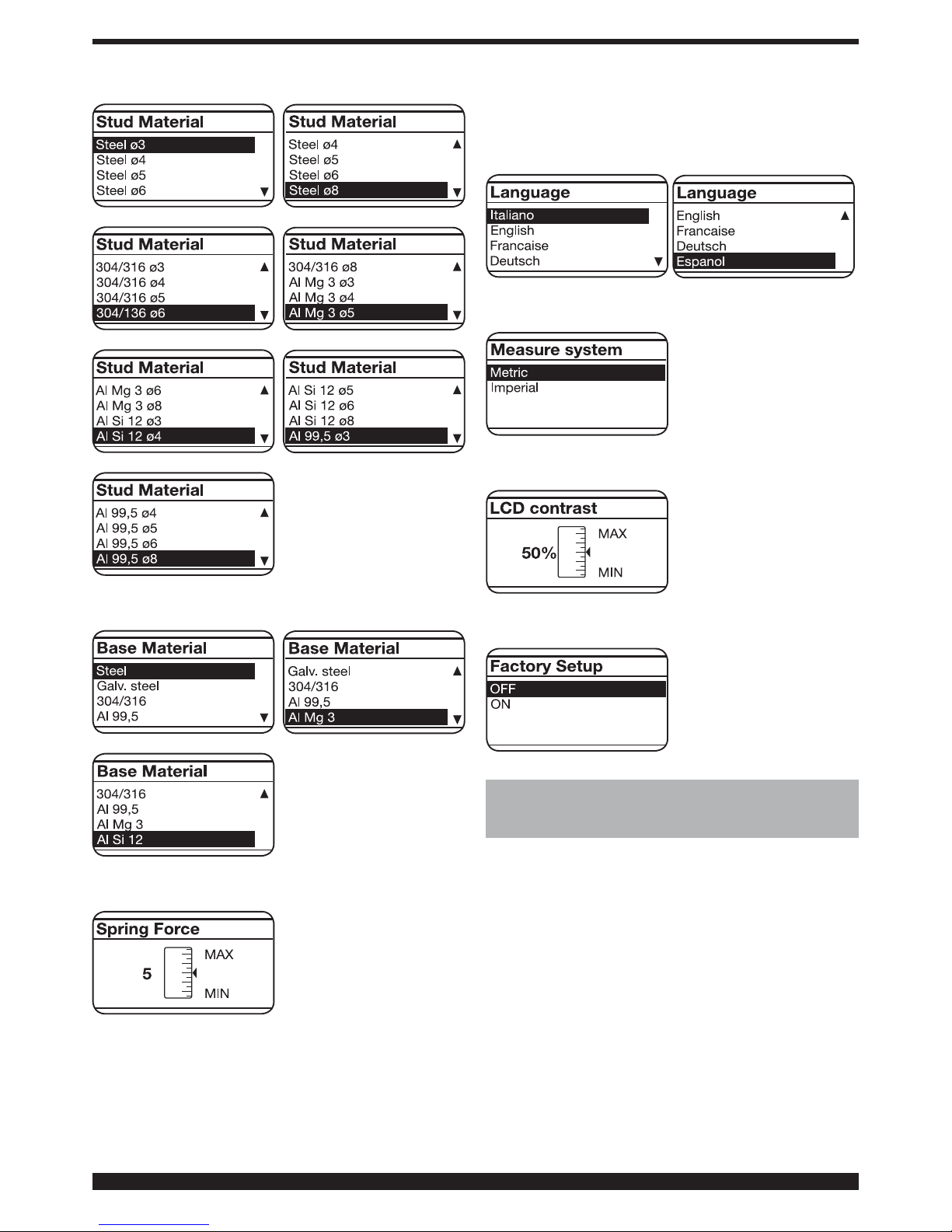

3.3.1 SETTINGS

Press the knob G for at least 2 seconds to open the

“Process Params” (Process Parameters) menu.

The following parameters are selectable from this menu:

- Stud Material

- Base material

- Spring Force

- Language

- Measure system

- LCD contrast

- Factory Setup

To access each parameter, select it by turning the knob G

and then press it for less than 2 seconds.

Once you have accessed the parameter, turn the knob G

to make the desired choice and then press it again for less

than 2 seconds to con rm the choice made and go back

to the menu with the list of parameters. To go back to the

initial screen, press the knob G for more than 2 seconds.

Page 6

6

• “Stud Material” parameter.

• “Base Material” parameter.

• “Spring Force” parameter.

The value can be changed by

means of the knob Q.

Note: if the force on the gun

is changed from the proposed value, we recommend

adjusting this value. The

newly changed value will appear on the display and next to

it an arrow pointing downward if the value was decreased

or upward the value was increased.

Based on the choices made, the force and voltage to be

used will be indicated on the display.

It is possible to change the voltage by means of the knob

G, whereas the force displayed on the scale P can be

changed by means of the knob Q.

• “Language” parameter.

• “Measure system” parameter.

• “LCD contrast” parameter.

The value can be changed

from 0 to 100% by means of

the knob G.

This function enables you

to increase or reduce the

brightness of the display A.

• “Factory setup” parameter.

“ON” can be selected by

turning the knob G and

pressing it brie y; the

message “Factory Done”

will appear to con rm that

the reset was successful.

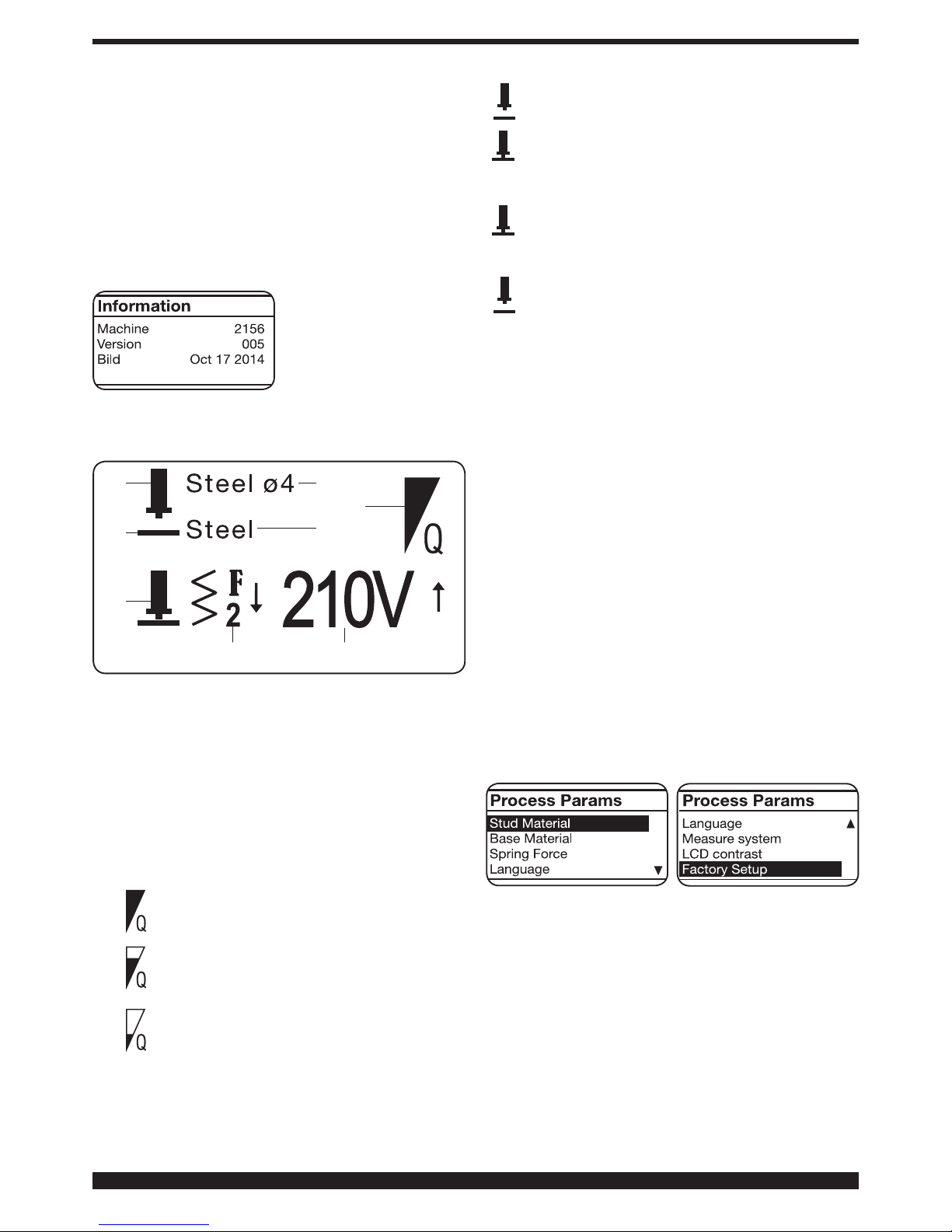

4 OPERATING PRINCIPLE OF WELDING THREADED

STUD BOLTS WITH CONTACT POINT START-UP

(Fig. 3)

The stud bolt is inserted in the clamp X (phase 1), then

positioned and pressed with its start-up contact directly

against the surface of the sheet metal to be welded (phase

2). The spring of the gun presses the stud bolt against

the metal, the start command begins sending current

which melts the start-up contact, and the electrical arc

is propagated along the entire surface of the stud bolt

(phase 4) pushed against the metal surface. The molten

metal solidi es, thereby welding the stud bolt (phase 5).

The gun must be extracted in perfect alignment with the

bolt to avoid deforming the clamp, and thus ensuring its

long life-span (phase 6).

Page 7

7

Stud material

Base metal

Copper plated steel

up to 0.2 C%

Stainless steel

304/316

Al Mg 3 AI Si 12 Al 99,5

Steel up to 0.30 C % A A - - Galvanized steel B B - - Stainless steel 304/316 A A - - Al 99,5 - - A B B

Al Mg 3 - - B A B

Al Si 12 - - B A B

High weldability: A Low weldability: B Not weldable: -

Tab. 1

Fig. 3

1 2 3 4 5

5 WELDABILITY OF TYPICAL STUD BOLT/BASE

METAL COM BINATIONS FOR CAPACITOR

DISCHARGE WELDING. (Table 1)

It is important to pay careful attention to the resistance and

deformity at the welding point between the stud bolt and base

metal. In the case of steel, you must pay particular attention

to brittleness. The material and resistance of the stud bolt

have limited tolerance; the carbon content in steel threaded

stud bolts must be < 0.20%.

The surface of the base metal must be clean. Layers

of paint, rust, waste, grease and non-weldable metal

coatings must be removed from the welding area. This

must be done using appropriate means. Base metals with

layers of waste and rust must be cleaned thoroughly.

6 WELDING

This technology makes it possible to weld stud bolts on

clean, but not oxidized, surfaces of mild steel, galvanized

steel, stainless steel, aluminum and brass.

The rapidity of the process does not alter the surfaces on the

side opposite from the welding. Welding is not possible on

case-hardened steel, oxidized or painted metal.

Before beginning production it is essential to carry out a

few test welds to determine the proper setting of the power

source and gun (spring force), proceeding as follows:

• Insert the chosen stud bolt in the clamp X (previously

adjusted as described in Fig. 2).

• Arrange the base sheet metal in conditions identical to

those that will be used for the job in terms of thickness,

earth connection area, size of the workpiece, material

quality.

• The terminals of the earth cable should be placed

symmetrically, and as close as possible to the welding

point.

• Activate the power source by means of the lighted

switch E.

• Hold the gun and place the stud on the welding spot,

avoiding to give blows, consequently damaging the

striking tip of the stud. Press the trigger O and, holding it

pressed, push the gun evenly and not quickly. Once the

right pressure is reached, the weld will be automatically

activated. If the surface of the material on which the stud

bolt is to be welded is at, we recommend mounting the

three spacers Z after rst unscrewing the screws Y

• In this case it is recommended to push the gun until the

three spacers are in touch with the piece and then press

the trigger to activate the welding.

These procedures are required to obtain the same

pressure of the stud on the base material and

consequently a higher quality of the weld.

• The voltage and force values recommended on the display

are intended as a starting point for calculating the correct

power source setting and for calibrating gun force.

These values have been tested on samples of “base

materials” 0.079" (2 mm) thick for steel and stainless steel

and 0.047" (1.2 mm) thick for aluminium.

Page 8

8

• Carry out a few welds, adjusting the voltage using the knob

G, and the force of the gun using the setting knob Q, until

the welding is perfect.

• The gun should be removed keeping it perfectly aligned

with the bolt, to avoid deforming the clamp (Fig4).

• Do not make welds to welded stud bolts.

OK

NO

Fig. 4

7 MAINTENANCE

7.1 ROUTINE

Keep all instructions and gures on the welding machine

clear and legible.

The mains cable and welding cables must be insulated

and in perfect condition; be careful with the tips, which ex:

near the connection terminals, earth clamps and gun input.

Keep the welding current connectors to sockets B and C

clean and rmly tightened (see Fig. 1)

The terminals for connecting to the base metal must

make good contact to avoid overheating, sparks, uneven

current circulation, damage to the components where the

pins are welded, and welding of uneven quality.

Prevent dirt, dust and lings from getting into the welding

machine.

Always make sure the cooling air circulates freely.

Make sure that the fan functions properly.

Make sure that the clamps hold the stud bolts rmly, with

all contact springs.

The clamp must slide freely throughout its length, without

changes due to friction or foreign matter.

7.2 SPECIAL

Only quali ed personnel should perform maintenance.

Some functional errors are highlighted by the appearance

of an error code on the display A.

Wait at least 5 minutes after shutting off the switch E

before opening the welding machine, and unplug the plug

from the power socket.

Use a volt meter to make sure that the capacitors are

discharged.

Carefully remove any dust, metal fragments and lings

from the machine using compressed air to avoid damaging

or projecting metal fragments onto the electronic or

electrical parts.

Make sure that all connectors are fully inserted.

Make sure that all welding circuit terminals are rmly

tightened.

After making a repair, make sure to rearrange the wiring

so that there is secure insulation between the primary and

secondary sides of the machine. Do not allow wires to

come into contact with moving parts or those that heat

up during operation. Reassemble all of the clamps as they

were on the original machine, to prevent an accidental

connection between the primary and secondary circuits if

a conductor should break or disconnect.

Also remount the screws with geared washers as on the

original equipment.

Error code Problem Solution

WARNING 1 It means that the gun start button and microswitch

are pressed at the moment the generator is turned

on.

Release the start button.

ERROR 2 It means that the relay RL1 is faulty. Power circuit fault.

Contact the technical support service.

ERROR 3 It means that the relay RL1 is faulty. Power circuit fault.

Contact the technical support service.

ERROR 4 It means that the SCR has short circuited Contact the technical support service.

ERROR 5 It means that there is a fault in the capacitor

charging circuit

Contact the technical support service.

ERROR 7 It means that there is a fault in the capacitor

charging circuit

Contact the technical support service.

WARNING TH

It means that the thermal protector has tripped.

Wait a few minutes without turning off the welding

machine.

ERROR 9

It means that there is a fault in the circuit that

measures the voltage across the capacitors.

Power circuit fault.

Contact the technical support service.

ERROR 10

It means that there is a short circuit in the

capacitor discharging circuit.

Power circuit fault.

Contact the technical support service.

Page 9

9

MANUEL D’INSTRUCTIONS POUR POSTE A SOUDER A FIL

IMPORTANT: AVANT LA MISE EN MARCHE DE LA MA-

CHINE, LIRE CE MANUEL ET LE GARDER, PENDANT

TOUTE LA VIE OPÉRATIONNELLE, DANS UN ENDROIT

CONNU PAR LES DIFFÉRENTES PERSONNES INTÉRESSÉES. CETTE MACHINE NE DOIT ÊTRE UTILISÉE

QUE POUR DES OPÉRATIONS DE SOUDURE.

1 PRÉCAUTIONS DE SÉCURITÉ

LA SOUDURE ET LE DÉCOUPAGE À L’ARC

PEUVENT ÊTRE NUISIBLES À VOUS ET AUX

AUTRES. L’utilisateur doit pourtant connaître les risques,

résumés ci-dessous, liés aux opérations de soudure. Pour

des informations plus détaillées, demander le manuel

code.3.300758

BRUIT

Cette machine ne produit pas elle-même des bruits

supérieurs à 80 dB. Le procédé de découpage au

plasma/soudure peut produire des niveaux de bruit

supérieurs à cette limite; les utilisateurs devront donc mette

en oeuvre les précautions prévues par la loi.

CHAMPS ELECTROMAGNETIQUES- Peuvent être dangereux.

· Le courant électrique traversant n’importe

quel conducteur produit des champs électromagnétiques (EMF). Le courant de soudure ou de découpe produisent des champs

électromagnétiques autour des câbles ou

des générateurs.

• Les champs magnétiques provoqués par des courants

élevés peuvent interférer avec le fonctionnement des stimulateurs cardiaques. Aux porteurs de stimulateurs

cardiaques il est défendu d'utiliser la machine ou de

s'approcher des câbles.

• L’ exposition aux champs électromagnétiques de soudure ou de découpe peut produire des effets inconnus

sur la santé.

Pour reduire les risques provoqués par l’exposition aux

champs électromagnétiques chaque opérateur doit

suivre les procédures suivantes:

- Vérier que le câble de masse et de la pince porte

électrode ou de la torche restent disposés côte à côte.

Si possible, il faut les xer ensemble avec du ruban.

- Ne pas enrouler les câbles de masse et de la pince

porte-électrode ou de la torche autour du corps.

- Ne jamais rester entre le câble de masse et le câble

de la pince porte-électrode ou de la torche. Si le câble

de masse se trouve à droite de l’opérateur, le câble de

la pince porte-électrode ou de la torche doit être égale

ment à droite.

- Connecter le câble de masse à la pièce à usiner aussi

proche que possible de la zone de soudure ou de découpe.

- Ne pas travailler près du générateur.

EXPLOSIONS

· Ne pas souder à proximité de récipients sous

pression ou en présence de poussières, gaz ou

vapeurs explosifs. Manier avec soin les bouteilles

et les détendeurs de pression utilisés dans les opérations

de soudure.

COMPATIBILITE ELECTROMAGNETIQUE

Cette machine est construite en conformité aux indications contenues dans la norme harmonisée IEC 6097410(Cl. A) et ne doit être utilisée que pour des buts professionnels dans un milieu industriel. En fait, il peut y avoir

des difcultés potentielles dans l’assurance de la compatibilité électromagnétique dans un milieu différent de celui

industriel.

ÉLIMINATION D’ÉQUIPEMENTS ÉLECTRIQUES

ET ÉLECTRONIQUES

Ne pas éliminer les déchets d’équipements élec-

triques et électroniques avec les ordures ménagères! Une fois leur cycle de vie terminé, les équipements électriques et électroniques doivent être collectés

séparément et conférés à une usine de recyclage. Nous

recommandons aux propriétaires des équipements de

s’informer auprès de notre représentant local au sujet

des systèmes de collecte agréés.

Des précautions supplémentaires sont à respecter

lorsque l'on travaille en hauteur.

COMPATIBILITE ELECTROMAGNETIQUE

Au Canada, la classication des EMC ne s'applique pas

aux postes de soudage à l'arc.

NORMES DE SECURITE

Pour fournir les conditions et recommandations mini-

males an de protéger les personnes qui travaillent dans

un environnement concerné par le soudage, le coupage

et les techniques connexes, il faut se référer à la norme

CA N/C SA -W117. 2.

EN CAS DE MAUVAIS FONCTIONNEMENT, DEMANDER

L’ASSISTANCE DE PERSONNEL QUALIFIÉ.

1.1 PLAQUETTE DES AVERTISSEMENTS

Le texte numéroté suivant correspond aux cases numérotées de la plaquette.

B. Les galets entraînement l peuvent blesser les mains.

C. Le l de soudure et le groupe entraînement l sont

sous tension pendant le soudage. Ne pas approcher

les mains ni des objets métalliques.

1. Les décharges électriques provoquées par l’élec-

trode le câble peuvent être mortelles. Se protéger de

manière adéquate contre les décharges électriques.

1.1 Porter des gants isolants. Ne pas toucher l’électrode

avec les mains nues. Ne jamais porter des gants humides ou endommagés.

1.2 S’assurer d’être isolés de la pièce à souder et du sol

1.3 Débrancher la che du cordon d’alimentation avant

de travailler sur la machine.

2. L’inhalation des exhalations produites par la soudure

peut être nuisible pour la santé.

2.1 Tenir la tête à l’écart des exhalations.

2.2 Utiliser un système de ventilation forcée ou de déchar-

gement des locaux pour éliminer toute exhalaison.

2.3 Utiliser un ventilateur d’aspiration pour éliminer les

exhalations.

3. Les étincelles provoquées par la soudure peuvent

causer des explosions ou des incendies.

Page 10

10

3.1 Tenir les matières inammables à l’écart de la zone

de soudure.

3.2 Les étincelles provoquées par la soudure peuvent causer

des incendies. Maintenir un extincteur à proximité et faire

en sorte qu’une personne soit toujours prête à l’utiliser.

3.3 Ne jamais souder des récipients fermés.

4. Les rayons de l’arc peuvent irriter les yeux et brûler la peau.

4.1 Porter un casque et des lunettes de sécurité. Utiliser des dispositifs de protection adéquats pour les

oreilles et des blouses avec col boutonné. Utiliser des

masques et casques de soudeur avec ltres de degré approprié. Porter des équipements de protection

complets pour le corps.

5. Lire la notice d’instruction avant d’utiliser la machine

ou avant d’effectuer toute opération.

6. Ne pas enlever ni couvrir les étiquettes d’avertissement.

2 DESCRIPTIONS GENERALES

2.1 SPECIFICATIONS

La machine a été conçue et réalisée pour la soudure de

goujons letés Ø 3, 4, 5, 6 et 8 mm, ferreux et non ferreux.

Ce système de soudure utilise la décharge extrêmement

rapide (2-3 ms) d'une batterie de condensateurs permettant

de souder les goujons letés avec pointe d'amorçage.

2.2 EXPLICATION DES DONNÉES TECHNIQUES

N° Numéro matricule à citer toujours pour toute

question concernant le poste à souder.

1

~

Transformateur monophasé-redresseur avec

dispositif pour la charge et la décharge de

condensateurs

U0 Tension à vide secondaire

E Energie de soudure

C Valeur de la capacité

Uc Tension réglable sur les condensateurs

U1 Tension nominale d'alimentation. La machine

est prévue pour les tensions 120V et 240V

avec sélection de tension automatique.

1-50/60Hz Alimentation monophasée 50 ou bien 60Hz

I1max Courant maxi absorbé à la correspondante

tension d'alimentation

I1 eff C'est la valerur maximale du courant effectif

absorbé en considérant le facteur de marche.

IP21S Degré de protection estimée pour le logement.

REMARQUES :

En outre, la machine est indiquée pour opérer dans des

milieux avec degré de pollution 3. (Voir IEC 60664).

2.3 DESCRIPTION DES PROTECTIONS

2.3.1 Protection thermique

Cette machine est protégée par un thermostat empêchant

le fonctionnement de la machine lors du dépassement des

températures admises. Dans ces conditions le ventilateur

continue à fonctionner et le display afchera le code

d'erreur "Warning 8".

3 INSTALLATION

WARNING

Voir la liste complète des messages de sécurité au

début de ce manuel.

Seules les personnes qualiées sont autorisées à installer

la machine. Tous les branchements doivent être réalisés

selon la réglementation en vigueur et conformément aux

lois sur la sécurité.

1 Ne placez pas le poste à souder sur le sol avec une

inclinaison de plus de 10°.

L'air doit circuler librement, en entrée et en sortie ,

et la machine de soudage doit être protégée pour

empêcher la pénétration de liquides, de saleté, de

dépôts métalliques, etc.

2. Assurez-vous que la tension d'alimentation est de 120

Volts et de 20 ampères minimum ou de 240 Volts et 20

ampères minimum. En cas de connexion à un circuit

protégé par des fusibles, utilisez des fusibles à action

retardée marqués « D ».

Utilisez une prise Nema type 5-20P pour 120 V et

assurez-vous que le « l conducteur vert » du câble

d'alimentation est relié à la masse ou « borne de mise

à la terre ». Assurez-vous que le l blanc est connecté

à la borne de connecteur W.

Utilisez une prise Nema type 6-20P pour 240 V et

assurez-vous que le « l conducteur vert » du câble

d'alimentation est relié à la masse ou « borne de mise

à la terre ». Assurez-vous que le l blanc est connecté

à la borne de connecteur Y.

La sélection de l'alimentation doit être opérée avec

la machine arrêtée.

3. Les porteurs de stimulateurs cardiaques ne doivent

ni utiliser la machine ni s'approcher des câbles.

4. Insérez complètement la che du câble de terre dans la

prise B et tournez dans le sens horaire.

5. Insérez complètement la che du câble de terre dans la

Page 11

11

prise C et tournez dans le sens horaire.

6. Allumez le poste de soudage en utilisant le commuta-

teur E. Évitez d'allumer et d'éteindre le poste trop

fréquemment car la dissipation d'énergie contenue

dans les condensateurs peut provoquer une surchauffe

et entraîner des dommages.

7. Pour limiter l'exposition au champ magnétique, gardez

le câble du pistolet sur le côté de la main en le tenant

et en évitant d'envelopper le câble autour.

3.1 DESCRIPTION OF THE EQUIPMENT

A- Display for the setting and control of welding operations

B- Positive output terminal

C- Negative output terminal

D- Torch trigger connector

E- Main switch

F- Fuse Ø 6.3x32 (delayed type). The equipment is tted

with a 12A-T fuse.

G- Knob for the setting and control of welding operations.

3.2 DESCRIPTION DU PISTOLET

K- Corps du pistolet

L- Manche

M- Câble de commande

N- Câble de courant de soudage

O- Bouton de commande de soudage (ne fonctionne que

lorsque le pistolet est appuyé contre la tôle)

P- Indicateur de réglage de la force

Q- Vis de réglage de la force (augmente en la tournant

dans le sens horaire)

R- Bague pour tenir l'entretoise Z

S- Écrou à œil de blocage de la pince

T- Souf et de sécurité

U- Vis de xation pour bague R

V- Vis pour régler la saillie du goujon prisonnier

W- Écrou de xation.

X- Pince de serrage du goujon prisonnier

Y- Vis

Z- Entretoise

X

M N L

S Z T

R U

O P QK

Fig. 2

X W V

1÷1,5 mm

Y

A

B C

G

D

E

F

Fig. 1

Page 12

12

3.2.1 Préparation du pistolet

Utilisez toujours des prisonniers de haute qualité

avec démarrage au point de contact pour soudage

à accumulation d'énergie électrostatique, en métal

compatible avec la soudure à réaliser et conformes aux

normes. Après avoir sélectionné le goujon prisonnier à

souder en fonction du type, du diamètre, de la longueur

et du matériau, utilisez et réglez la pince de serrage en

fonction du diamètre correspondant.

Insérez le goujon prisonnier dans la pince X de sorte qu'il

soit fermement maintenu en place par les quatre ressorts.

Ajustez la saillie du goujon prisonnier sur 1 ÷ 1,5 mm à

partir de l'avant de la pince en utilisant la vis V, puis serrez

avec l'écrou W (gure 2).

Insérez la pince X dans le mandrin du pistolet (g. 2),

appuyez dessus jusqu'à ce que vous sentiez qu'elle

est bien au fond, puis serrez l'écrou S à l'aide de la clé

hexagonale de 17 mm qui est fournie.

3.3 DESCRIPTION DES FONCTIONS AFFICHÉES SUR

L'ÉCRAN A.

Lors de l'allumage de

l'appareil, l'écran A afche

pendant quelques instants : la

référence de l'appareil, sa

version et la date de

développement du logiciel.

Après quelques secondes, apparaît sur l'écran A l'afchage

suivant :

a

b

f

c

d

e

g h

a Prisonnier

b Matériau de base

c Matériau du rivet et dimensions

REMARQUE : la longueur maximale du rivet pouvant

être utilisé est de 30 mm (1-1/4”)

d Type de matériau de base

e Indications sur la qualité de la soudure.

Ce symbole avec la lettre Q indique que les matériaux

du prisonnier et du matériau de base qui ont été choisi

sont soudables, peu soudables ou non-soudables

(Cf. tableau 1).

Bonne soudabilité

Faible soudabilité

non soudables

f Indications/avertissements durant la phase de

soudage. Lors des phases de soudage, ces symboles

apportent des indications concernant le processus:

f

f xe: Indique que le générateur est

prêt à exécuter une soudure.

f

f xe: Indique que le prisonnier est en

contact avec le matériau de base

et que le générateur est prêt à

exécuter la soudure.

f

f clignotant: Indique qu'après avoir exécuté la

soudure, la pince X du pistolet n'a

pas été dégagée du prisonnier.

f

f clignotant: Indique qu'après avoir exécuté la

soudure, le bouton de démarrage

et le micro-rupteur à l'intérieur

du pistolet sont maintenus

enfoncé pendant la charge des

condensateurs.

g Valeur suggérée de la force du ressort situé à l'intérieur

du pistolet (s'il y a une modication par rapport

au réglage de la force, il est conseillé de modier

également la valeur indiquée sur l'écran de façon à

ce qu'à l'avenir cette modication reste en mémoire.

La modication par rapport à la valeur suggérée sera

indiquée par une èche tournée vers le haut si elle est

augmentée ou par une èche tournée vers le bas si

elle est baissée)

h Tension de charge des condensateurs (la modication

du réglage de la tension par rapport à la valeur

suggérée sera indiquée par une èche tournée vers le

haut si elle est augmentée ou par une èche tournée

vers le bas si elle est baissée).

Lors du réglage, la valeur de la tension clignote et

indique que le générateur travaille pour arriver à la

valeur requise.

Lorsque la valeur de la tension clignote, il n'est pas

possible de procéder au soudage.

3.3.1 RÉGLAGES

Appuyez pendant au moins 2 secondes sur le bouton G

pour entrer dans le menu « Process Params » (Paramètres

de fonctionnement).

Dans ce menu sont disponibles les paramètres suivants:

- Stud Material (matériau prisonnier)

- Base material (matériau de base)

- Spring Force (force du ressort)

- Language (langue)

- Measure system (système de mesure)

Page 13

13

- LCD contrast (contraste écran à cristaux liquides)

- Factory Setup (réglage usine)

Pour entrer à l'intérieur de chaque paramètre,

sélectionnez-le en tournant le bouton G, puis appuyez

dessus pendant moins de 2 secondes. Une fois dans le

paramètre, tournez le bouton G pour faire votre choix puis

appuyez à nouveau dessus pendant moins de 2 secondes

pour valider l'option et retourner au menu de la liste des

paramètres. Pour revenir à la page initiale, appuyez sur le

bouton G pendant plus de 2 secondes.

• Paramètre « Stud Material » (Matériau prisonnier)

• Paramètre « Base Material » (Matériau de base)

• Paramètre « Spring Force » (Force du ressort)

Il est possible de changer la

valeur par le biais du bouton

Q.

Remarque: au cas où la

tension serait modiée sur

le pistolet par rapport à la

valeur proposée, nous vous suggérons de modier cette

valeur. La nouvelle valeur modiée apparaîtra sur l'écran

avec à côté une èche tournée vers le bas si la valeur a été

baissée et une èche tournée vers le haut si la valeur a été

augmentée.

En fonction des options choisies sur l'écran, la tension et la

force à utiliser sont indiquées.

Par le biais du bouton G il est possible de modier la ten-

sion tandis qu'avec le bouton Q, situé sur le pistolet, il est

possible de modier la force qui est afchée sur l'échelle P.

• Paramètre « Language » (langue)

• Paramètre « Measure system » (Système de mesure)

• Paramètre « LCD contrast » (Contraste de l'écran à

cristaux liquides)

Il est possible de changer la

valeur de 0 à 100% par le

biais du bouton G.

Cette fonction permet de

jouer sur la luminosité de

l'écran A.

• Paramètre « Factory setup » (réglages d'usine)

Par le biais du bouton G il

est possible de sélectionner

ON et en appuyant

brièvement dessus s'afche

le message Factory Done

qui indique que la remise à

zéro a bien été faite.

4 PRINCIPE DE FONCTIONNEMENT DE LA

SOUDURE DE GOUJONS FILETES AVEC POINTE

D'AMORCAGE (Fig. 3)

Le goujon est inséré dans la pince X (phase 1) et est ensuite

positionné et appuyé avec son amorçage directement

sur la surface de la tôle à souder (phase 2). Le ressort du

pistolet appuie le goujon contre le métal, la commande de

start fait commencer le passage de courant qui vaporise

l'amorçage et l'arc électrique se propage sur l'entière

surface du goujon (phase 3) qui est poussé sur la surface

métallique. Le métal fondu solidie en soudant le goujon

(phase 4).

L'extraction du pistolet doit être parfaitement alignée

avec le goujon an de ne pas déformer la pince et assurer

ainsi une longue durée (phase 5).

Page 14

14

5 SOUDABILITE DE COMBINAISONS TYPIQUES

GOUJON ET METAL DE BASE POUR SOUDURE

PAR DECHARE DE CONDENSATEURS. (Tableau 1)

Il est important d'étudier carrément la résistance et la

déformation dans le point de soudure entre goujon et métal

de base. Dans le cas de l'acier, il faut prêter une attention

particulière à la fragilité causée par le durcissement. La

matière et la résistance du goujon ont une tolérance réduite;

la teneur en carbone des goujons letés doit être < 0,20%.

La surface du métal de base doit être propre. Les

éventuelles couches de vernis, rouille, laitiers, graisse

et les revêtements de métaux non soudables doivent

être enlevés de la zone de soudure à l'aide des moyens

appropriés. Les métaux de base avec couches de laitiers

et rouille doivent être parfaitement nettoyés.

6 SOUDURE

Cette technologie permet de souder les goujons letés sur

des surfaces propres, mais non oxydées, d'acier doux, acier

galvanisé, acier inox, aluminium et laiton.

La rapidité du procédé n'altère pas les surfaces à l'envers de

la soudure. La soudure n'est pas possible sur acier trempé,

métal oxydé ou verni.

Avant de commencer la production, il est indispensable

d'effectuer quelques soudures d'essai pour déterminer le

correct réglage du générateur et l'étalonnage du pistolet

(force du ressort) en exécutant les opérations suivantes:

• Insérer le goujon choisi dans la pince X (réglée au préalable

comme décrit dans la Fig. 2)

• Ranger la tôle de base dans des conditions identiques aux

futures conditions de travail pour ce qui de l'épaisseur, aire

des raccordements de masse, dimensions de la pièce,

qualité de la matière.

• Les bornes du câble de masse doivent être placées en

mode symétrique et aussi proches que possible du point

de soudure.

• Mettre en service le générateur à l'aide de l'interrupteur

lumineux E.

• Saisir le pistolet et positionner le prisonnier sur le point

de soudure en évitant de porter des coups pour ne pas

endommager l’amorçage du prisonnier. Appuyer sur la

touche O et, la tenant enfoncée, pousser le pistolet de

manière uniforme et non rapide. Une fois que la pression

correcte a été atteinte, la soudure partira automatiquement.

Si la surface de la matière où le goujon doit être soudé est

plate, il est conseillé de monter trois entretoises Z après

avoir desserré les vis Y.

• Dans ce cas il est conseillé de pousser le pistolet

jusqu’à ce que les trois entretoises battent sur la pièce,

et puis d’appuyer la touche pour activer la soudure.

Ces procédures sont nécessaires pour avoir la même

pression du prisonnier sur le matériel de base et,

par conséquent, une amélioration de la qualité de la

soudure.

• Les valeurs de tension et de force, conseillées à l'écran,

sont à considérer comme base de départ pour déterminer

le bon réglage du générateur et de l'étalonnage de la force

du pistolet.

Ces valeurs ont été expérimentales sur des échantillons de

Métal goujons

Métal de base

Acier 0,2 C

cuivré

inox

304/316

Al Mg 3 AI Si 12 Al 99,5

Acier jusqu'à 0,30 C % A A - - Acier zingué B B - - Acier inoxydable 304/316 A A - - Al 99,5 - - A B B

Al Mg 3 - - B A B

Al Si 12 - - B A B

Bonne soudabilité: A Basse soudabilité: B Non soudables: -

Tab. 1

Fig. 3

1 2 3 4 5

Page 15

15

« matériau de base » d'une épaisseur de 2 mm (0.079")

pour l'acier et l'acier inoxydable et d'une épaisseur de 1,2

mm (0.047") pour l'aluminium..

• Exécuter quelques soudures en réglant la tension à l'aide

des bouton G et la force du pistolet avec le réglage Q

jusqu'à obtenir des soudures parfaites.

Le pistolet doit être extrait en le gardant parfaitement aligné

avec le goujon a n de ne pas déformer la pince (Fig. 4).

• Pas de soudure sur les goujons letés déjà soudé.

OK

NO

Fig. 4

7 ENTRETIEN

7.1 ORDINAIRE

Conserver les indications et les gures sur le poste à

souder bien lisibles et claires.

Le câble de réseau et les câbles de soudure doivent être

isolés et en conditions parfaites; prêter attention aux

points où ils subissent des exions, notamment près

des bornes de raccordement, des pinces de masse et à

l'entrée dans le pistolet.

Garder les connecteurs du courant de soudure aux prises

B et C propres et bien serrés. (voir Fig. 1)

Les bornes pour le raccordement au métal de base doivent

faire un bon contact a n d'éviter surchauffes, étincelles,

circulation non balancée du courant, endommagements

au composant où les goujons doivent être soudés et

soudures de qualité non constante.

Empêcher l'entrée de saleté, poussière et limaille à

l'intérieur du poste à souder.

Garantir toujours la circulation de l'air de refroidissement.

Contrôler que le ventilateur fonctionne régulièrement.

Véri er que les pinces serrent bien les goujons avec tous

les ressorts de contact.

Le mandrin porte-pinces doit glisser sans contrainte tout

au long de sa course sans variations dues à frottements

ou corps étrangers.

7.2 EXTRAORDINAIRE

L'entretien doit être exécuté par du personnel quali é.

Certaines anomalies de fonctionnement sont mises en

évidence par l'af chage d'un code d'erreur sur le display A.

vant d'ouvrir le poste à souder attendre au moins 5

minutes après avoir relâché l'interrupteur E et en outre

débrancher la che de la prise d'alimentation.

Contrôler, à l'aide d'un voltmètre, que les condensateurs

sont chargés.

Enlever poussière, fragments et limailles métalliques de

la machine avec soin en utilisant air comprimé a n de ne

pas endommager ou projeter des fragments métalliques

sur les pièces électroniques ou électriques.

Véri er que tous les connecteurs sont bien enfoncés.

Véri er que tous les terminaux du circuit de soudure sont

bien serrés.

Après l'exécution d'un dépannage, veiller à ranger le

câblage de façon à ce qu'il y ait une isolation sûre entre le

côté primaire et le côté secondaire de la machine. Eviter

que les ls puissent entrer en contact avec des pièces

en mouvement ou des pièces se réchauffant pendant le

fonctionnement. Remonter tous les colliers comme sur

la machine d'origine de façon à éviter que, en cas de

rupture ou débranchement accidentel d'un conducteur,

il n'y ait aucune liason entre le primaire et le secondaire.

En outre remonter les vis avec les rondelles dentelées

comme sur la machine d'origine.

Code d'erreur Anomalie Solution

WARNING 1 Indique que le bouton et le microrupteur du pistolet

sont enfoncés au moment où le générateur se

met en marche.

Désarmez le bouton de démarrage.

ERROR 2 Indique que le relais RL1 est défectueux. Circuit de puissance défectueux.

Contactez le service d'assistance

ERROR 3 Indique que le relais RL1 est défectueux. Circuit de puissance défectueux.

Contactez le service d'assistance

ERROR 4 Indique que l'SCR est en court-circuit. Contactez le service d'assistance

ERROR 5 Indique qu'il y a un défaut dans le circuit de

charge des condensateurs

Contactez le service d'assistance

ERROR 7 Indique qu'il y a un défaut dans le circuit de

charge des condensateurs

Contactez le service d'assistance

WARNING TH

Indique que la protec on thermique s'est

déclenchée.

Il faut a endre quelques minutes sans éteindre le

poste de soudage.

ERROR 9

Indique qu'il y a un défaut dans le circuit

qui mesure la tension aux extrémités des

condensateurs.

Circuit de puissance défectueux.

Contactez le service d'assistance

ERROR 10

Indique qu'il y a un court-circuit dans le circuit

de décharge des condensateurs.

Circuit de puissance défectueux.

Contactez le service d'assistance

Page 16

16

IMPORTANTE: ANTES DE LA PUESTA EN FUNCIONAMIENTO DEL APARATO, LEER EL CONTENIDO DE ESTE

MANUAL Y CONSERVARLO, DURANTE TODA LA VIDA

OPERATIVA, EN UN SITIO CONOCIDO POR LOS INTERESADOS. ESTE APARATO DEBERÁ SER UTILIZADO

EXCLUSIVAMENTE PARA OPERACIONES DE SOLDADURA.

1 PRECAUCIONES DE SEGURIDAD

LA SOLDADURA Y EL CORTE DE ARCO PUE-

DEN SER NOCIVOS PARA USTEDES Y PARA

LOS DEMÁS, por lo que el utilizador deberá ser informado de los riesgos, resumidos a continuación, que derivan

de las operaciones de soldadura. Para informaciones

más detalladas, pedir el manual cod.3.300.758

RUIDO

Este aparato de por sí no produce ruidos superiores a los 80dB. El procedimiento de corte plasma/

soldadura podría producir niveles de ruido superiores a tal límite; por consiguiente, los utilizadores deberán poner en practica las precauciones previstas por la

ley.

CAMPOS ELECTROMAGNÉTICOS- Pueden ser dañosos.

• La corriente eléctrica que atraviesa cualquier conductor produce campos electromagnéticos (EMF). La corriente de soldadura o de corte genera campos

electromagnéticos alrededor de los cables y

generadores.

• Los campos magnéticos derivados de corrientes elevadas pueden incidir en el funcionamiento del pacemaker.

A los portadores de pace maker está prohibido usar la

máquina o acercarse a los cables.

• La exposición a los campos electromagnéticos de la

soldadura o del corte podrían tener efectos desconocidos sobre la salud.

Cada operador, para reducir los riesgos derivados de la

exposición a los campos electromagnéticos, tiene que

atenerse a los siguientes procedimientos:

- Colocar el cable de masa y de la pinza portaelectrodo

o de la antorcha de manera que permanezcan anqueados. Si posible, jarlos junto con cinta adhesiva.

- No envolver los cables de masa y de la pinza portaelectrodo o de la antorcha alrededor del cuerpo.

- Nunca permanecer entre el cable de masa y el de la

pinza portaelectrodo o de la antorcha. Si el cable de

masa se encuentra a la derecha del operador también

el de la pinza portaelectrodo o de la antorcha tienen

que quedar al mismo lado.

- Conectar el cable de masa a la pieza en tratamiento lo

más cerca posible a la zona de soldadura o de corte.

- No trabajar cerca del generador.

EXPLOSIONES

• No soldar en proximidad de recipientes a presión o en presencia de polvo, gas o vapores ex-

plosivos. Manejar con cuidado las bombonas y

los reguladores de presión utilizados en las operaciones

de soldadura.

COMPATIBILIDAD ELECTROMAGNÉTICA

Este aparato se ha construido de conformidad a las indicaciones contenidas en la norma armonizada IEC 6097410 (Cl. A) y se deberá usar solo de forma profesional

en un ambiente industrial. En efecto, podrían presentarse potenciales dicultades en el asegurar la compatibilidad electromagnética en un ambiente diferente

del industrial.

ÉLIMINATION D’ÉQUIPEMENTS ÉLECTRIQUES

ET ÉLECTRONIQUES

¡No está permitido eliminar los aparatos eléctri-

cos junto con los residuos sólidos urbanos! Los

aparatos eléctricos que han concluido su vida útil deben

ser recogidos por separado y entregados a una instalación de reciclado ecocompatible. En calidad de propietario de los aparatos, usted deberá solicitar a nuestro

representante local las informaciones sobre los sistemas

aprobados de recogida de estos residuos. ¡Aplicando lo

establecido por esta Directiva se contribuye a mejorar la

situación ambiental y salvaguardar la salud humana!

Deberán adoptarse precauciones adicionales para

trabajar en posiciones elevadas.

Compatibilidad electromagnética.

En Canadá, la clasicación EMC no se aplica a las fuentes de potencia de arcos de soldadura.

Normas de seguridad.

Para conocer las recomendaciones y requisitos mínimos

de protección de las personas que trabajan en un ambiente en que se realiza soldadura, corte y procesos anes véanse las normas estándar CAN/CSA-W117.2.

EN EL CASO DE MAL FUNCIONAMIENTO, PEDIR LA

ASISTENCIA DE PERSONAL CUALIFICADO.

1.1 PLACA DE LAS ADVERTENCIAS

El texto numerado que sigue corresponde a los apartados numerados de la placa.

B. Los rodillos arrastrahilo pueden herir las manos.

C. El hilo de soldadura y la unidad arrastrahilo están

bajo tensión durante la soldadura. Mantener lejos las

manos y objetos metálicos.

1. Las sacudidas eléctricas provocadas por el electro-

do de soldadura o el cable pueden ser letales. Protegerse adecuadamente contra el riesgo de sacudidas

eléctricas.

1.1 Llevar guantes aislantes. No tocar el electrodo con

las manos desnudas. No llevar guantes mojados o

dañados.

1.2 Asegurarse de estar aislados de la pieza a soldar y

del suelo

1.3 Desconectar el enchufe del cable de alimentación

antes de trabajar en la máquina.

2. Inhalar las exhalaciones producidas por la soldadura

puede ser nocivo a la salud.

2.1 Mantener la cabeza lejos de las exhalaciones.

2.2 Usar un sistema de ventilación forzada o de descarga

local para eliminar las exhalaciones.

MANUAL DE INSTRUCCIONES PARA SOLDADORA DE DESCARGA DE CONDENSADORES

Page 17

17

2.3 Usar un ventilador de aspiración para eliminar las exhalaciones.

3. Las chispas provocadas por la soldadura pueden

causar explosiones o incendios.

3.1 Mantener los materiales inamables lejos del área de

soldadura.

3.2 Las chispas provocadas por la soldadura pueden

causar incendios. Tener un extintor a la mano de

manera que una persona esté lista para usarlo.

3.3 Nunca soldar contenedores cerrados.

4. Los rayos del arco pueden herir los ojos y quemar la piel.

4.1 Llevar casco y gafas de seguridad. Usar protecciones adecuadas para orejas y batas con el cuello

abotonado. Usar máscaras con casco con ltros de

gradación correcta. Llevar una protección completa

para el cuerpo.

5. Leer las instrucciones antes de usar la máquina o de

ejecutar cualquiera operación con la misma.

6. No quitar ni cubrir las etiquetas de advertencia.

2 DESCRIPCIONES GENERALES

2.1 CARACTERÍSTICAS

La máquina ha sido proyectada y realizada para la

soldadura de espárragos leteados Ø 3, 4, 5, 6 y 8 mm,

ferrosos y no ferrosos. Este sistema de soldadura utiliza

la descarga extremadamente rápida (2-3 ms) de una

batería de condensadores que consiente la soldadura de

espárragos leteados con cebado a punta de encendido.

2.2 EXPLICACIÓN DE LOS DATOS TÉCNICOS

CITADOS EN LA PLACA DE LA MÁQUINA

N° Numero de matricula que se citará siempre para

cualquier petición relativa a la soldadora.

1

~

Transformador monofásico-recticador con

dispositivo para la carga y la descarga de

conensadores.

U0 Tensión en vacío secundaria.

E Energía de soldadura.

C Valor de la capacidad.

Uc Tensión regulable en los condensadores.

U1 Tensión nominal de alimentación. La máquina

se ha previsto para tensiones 120V y 240V con

cambiatensión automático.

1-50/60Hz Alimentación monofásico 50 o 60Hz.

I1max Corriente máxima absorbida a la

correspondiente tensión de alimentación.

I1 eff Es el máximo valor de la corriente efectiva

absorbida considerando el factor de servicio.

IP21S Grado de protección de la carcasa.

NOTAS: El aparato además se ha proyectado para

trabajar en ambientes con grado de contaminación 3.

(Ver IEC 60664).

2.3 DESCRIPCIÓN DE LOS DISPOSITIVOS DE

PROTECCIÓN

2.3.1 Protection thermique

Este aparato está protegido por un termostato el cual,

si se superasen las temperaturas admitidas, impide el

funcionamiento de la máquina. En estas condiciones el

ventilador continúa a funcionar y el display indicará el

código de error "Warning 8".

3 INSTALACIÓN

WARNING - ADVERTENCIA

Véase la lista completa de los mensajes de seguridad presente en la parte inicial de este manual.

Solo personal calicado puede instalar la máquina. Todas

las conexiones deben ser efectuadas con observancia de

las normas vigentes y con rigurosa aplicación de las normas sobre seguridad.

1. No instale la máquina soldadora sobre piso con inclina-

ción superior a 10°.

El aire debe circular libremente, tanto en entrada como

en salida, y la máquina soldadora debe quedar protegida contra la entrada de líquidos, suciedad, virutas de

metal, etc.

2. Controle que la tensión de alimentación sea de 120

voltios con un mínimo de 20 amps. de servicio o de

240 voltios con un mínimo de 20 amps. de servicio. Si

está conectada a circuito protegido mediante fusibles,

use fusibles de acción retardada con marca "D".

Utilice un enchufe Nema tipo 5-20P para 120 V, ase-

gurándose de que el "conductor verde" del cable de

alimentación quede conectado a tierra o a terminal de

“tierra”. Asegúrese de que el cable blanco quede conectado al terminal de enchufe W.

Utilice un enchufe Nema tipo 6-20P para 240 V, ase-

gurándose de que el "conductor verde" del cable de

alimentación quede conectado a tierra o a terminal de

“tierra”. Asegúrese de que el cable blanco quede conectado al terminal de enchufe Y.

La máquina debe ser apagada antes de cambiar la

fuente de alimentación.

Page 18

18

3. Los portadores de marcapasos tienen prohibido

usar la máquina o aproximarse a sus cables.

4. Conecte enteramente el enchufe del cable de tierra al

conector B y gire en sentido horario.

5. Conecte enteramente el enchufe de la pistola al conector C y gire en sentido horario.

6. Encienda la máquina soldadora mediante el interruptor

E (la puesta en marcha y la parada no deben repe-

tirse con frecuencia ya que la disipación de la energía

contenida en los condensadores puede provocar sobrecalentamiento y daños).

7. Para limitar la exposición al campo magnético mantenga el cable de la pistola en el lado de la mano que la

sostiene, sin envolver en ella el cable mismo.

3.1 DESCRIPCIÓN DEL EQUIPO

A- Display para con guración y control de las operaciones

de soldadura

B- Terminal de salida positivo

C- Terminal de salida negativo

D- Conector del gatillo antorcha

E- Interruptor principal

F- Fusible Ø 6.3 x 32 (de tipo retardado). El equipo está

provisto de un fusible 12A-T.

G- Mando para la con guración y control de las

operaciones de soldadura.

3.2 DESCRIPCIÓN DE LA PISTOLA

K- Cuerpo de la pistola

L- Empuñadura

M- Cable de control

X

M N L

S Z T

R U

O P QK

Fig. 2

X W V

1÷1,5 mm

Y

N- Cable corriente de soldadura

O- Botón de mando soldadura (opera solo con la pistola

presionada contra la chapa)

P- Indicador ajuste de fuerza

Q- Tornillo de regulación fuerza (aumenta al girarlo en

sentido horario)

R- Anillo de sujeción espaciador Z

S- Mordaza de bloqueo virola

A

B C

G

D

E

F

Fig. 1

Page 19

19

T- Fuelle de seguridad

U- Tornillos de jación para anillo R

V- Tornillo de regulación salida perno prisionero

W- Tuerca de bloqueo

X- Mordaza de bloqueo perno prisionero

Y- Tornillo

Z- Espaciador

3.2.1 Preparación de la pistola

Utilice siempre pernos prisioneros de alta calidad con

punto de contacto inicial para soldadura por descarga

de condensador, que cumplan las normas y que estén

fabricados con metal compatible con la soldadura a ejecutar.

Después de haber seleccionado el perno prisionero que

se debe soldar en cuanto a tipo, diámetro, longitud y

material, ajuste la mordaza de sujeción en función del

diámetro correspondiente.

Inserte el perno prisionero en la mordaza X de modo que

quede rmemente bloqueado en su lugar mediante los

cuatro resortes.

Ajuste la salida del perno prisionero por la parte delantera

de la mordaza entre 1 ÷ 1.5 mm mediante el tornillo V y

bloquee con la tuerca W ( gura 2).

Inserte la mordaza X en el mandril de la pistola ( g. 2),

presione hasta sentir que llega a fondo y apriete la tuerca S

usando la llave hexagonal de 17 mm suministrada adjunta.

3.3 DESCRIPCIÓN DE LAS FUNCIONES MOSTRADAS

EN EL DISPLAY A.

Al encender la máquina en

el display A, por algunos

instantes se visualiza: el

número de artículo de la

máquina, la versión y la

fecha de desarrollo del

software.

Algunos segundos después en el display A aparece la

siguiente pantalla:

a

b

f

c

d

e

g h

a Prisionero

b Material base

c Material del remache y respectivas dimensiones

NOTA: la longitud máxima del remache que puede ser

utilizado es de 30 mm (1-1/4”)

d Tipo de material base

e Indicación relativa a la calidad de la soldadura.

Este símbolo con la letra Q indica que los materiales

del prisionero y del material de base que han sido

elegidos son soldables, poco soldables o bien no

soldables (Véase tabla 1).

buena soldabilidad

baja soldabilidad

no soldables

f Indicaciones/advertencias para efectuar la soldadura.

En las bases de la soldadura estos símbolos

proporcionan indicaciones sobre el proceso:

f

f jo: Indica que el generador está listo para

efectuar una soldadurar.

f

f jo: Indica que el prisionero está en contacto

con el material de base y el generador

está listo para ejecutar la soldadura.

f

f parpadeante: IIndica que después de haber

efectuado la soldadura no ha sido

retirada la pinza X de la pistola desde el

prisionero.

f

f parpadeante: Indica che, después de

haber efectuado la soldadura, ha sido

presionado el botón de arranque y el

microinterruptor en el interior de la pistola

durante la carga de los condensadores.

g Valor sugerido de la fuerza del resorte presente en el

interior de la pistola (si se modi ca la regulación de la

fuerza se sugiere modi car también el valor indicado

en el display a n de que esta modi cación quede

memorizada. La modi cación respecto del valor

sugerido será indicada por una echa, dirigida hacia

arriba si se trata de un aumento o bien hacia abajo si

se trata de una reducción).

h Tensión de carga de los condensadores (la

modi cación de la regulación de la tensión respecto

del valor sugerido será indicada por una echa,

dirigida hacia arriba si se trata de un aumento o hacia

abajo si se trata de una reducción).

Durante la regulación el valor de la tensión parpadea

para indicar que el generador está trabajando a n de

alcanzar el valor requerido.

Mientras el valor de la tensión está parpadeando no

es posible efectuar la soldadura.

3.3.1 CONFIGURACIONES

Presionar por al menos 2 segundos el mando G para

entrar en el menú “Process Params” (Parámetros de

Proceso).

En este menú están disponibles los siguientes parámetros:

Page 20

20

- Stud Material (Material prisionero)

- Base material (Material base)

- Spring Force (Fuerza del resorte)

- Language (Idioma)

- Measure sistem (Sistema de medición)

- LCD contrast (Contraste de el display)

- Facrory Setup (Confi guraciones de fábrica)

Para entrar en cada parámetro seleccionarlo girando el

mando G y presionar el mando mismo al menos durante

2 segundos.

Una vez que se ha entrado en el parámetro, girar el mando

G para ejecutar la elección; presionarlo nuevamente por

un lapso inferior a 2 segundos para con rmar la selección

efectuada y retornar al menú de la lista de los parámetros.

Para retornar a la pantalla inicial presionar el mando G por

más de 2 segundos.

• Parámetro “Stud Material” (Material prisionero)

• Parámetro “Base Material” (Material base)

• Parámetro “Spring Force” (Fuerza del resorte)

Mediante el mando Q es po-

sible modi car este valor.

Nota: en caso de modi car

la fuerza en la pistola respecto del valor propuesto

sugerimos modi car también este valor. El nuevo valor modi cado aparecerá en

el display con una echa al lado, dirigida hacia abajo si

el valor ha sido reducido o hacia arriba si el valor ha sido

aumentado.

Sobre la base de las selecciones efectuadas, en el display

aparecen indicadas la tensión y la fuerza a utilizar.

Mediante el mando G es posible modi car la tensión,

mientras que mediante el mando Q, presente en la pis-

tola, es posible modi car la fuerza, que aparece indicada

en la escala P.

• Parámetro “Language” (Idioma)

• Parámetro “Measure system” (Sistema de medidas)

• Parámetro “LCD contrast” (Contraste del display)

Mediante el mando G es po-

sible modi car el valor entre

0 y 100 %

Esta función permite confe-

rir mayor o menor luminosi-

dad al display A.

• Parámetro “Factory setup” (Confi guraciones de

fábrica)

Mediante el mando G es po-

sible seleccionar ON y, pre-

sionándolo brevemente, en

el display aparece el mensa-

je Factory Done, que señala

la correcta ejecución de la

con guración.

4 PRINCIPIO DE FUNCIONAMIENTO DE LA

SOLDADURA DE ESPÁRRAGOS FILETEADOS

CON CEBADO EN PUNTA DE ENCENDIDO (Fig. 3)

El espárrago viene insertado en la pinza X (fase 1), a

continuación viene colocado y presionado con su cebado

de encendido directamente en la super cie de la chapa

por soldar (fase 2). El muelle de la pistola presiona el

Page 21

21

espárrago contra el metal, el mando de start hace que

inicie el paso de corriente que vaporiza el cebado de

encendido y el arco eléctrico se propaga en toda la

super cie del espárrago (fase 3) que viene empujado

sobre la super cie metálica. El metal fundido solidi ca

soldando el espárrago (fase 4).

La extracción de la pistola se hará perfectamente alineada

con el perno para no deformar la pinza y asegurarle de

esta forma una larga duración (fase 5).

5 SOLDABILIDAD DE COMBINACIONES

TÍPICAS ENTRE ESPÁRRAGO Y METAL

BASE PARA SOLDADUR CON DESCARGA DE

CONDENSADORES. (Tabla 1)

Es importante estudiar con particular atención la

resistencia y la deformación en el punto de soldadura

entre espárrago y metal base. En el caso del acero,

se debe prestar particular atención a la fragilidad de

endurecimiento.

El material y la resistencia del espárrago están sujetos

a tolerancia restringida. El contenido de carbono en los

espárragos leteados de acero deberá ser < 0,20%.

La super cie del metal base deberá estar limpia.

Capas de pintura, herrumbre, escorias, grasa y

revestimientos de metales no soldables, deberán ser

eliminados de la zona de soldadura. Esto se deberá

llevar a cabo con los medios idóneos. Los metales

de base con capas de escorias y herrumbre deberán

estar perfectamente limpios.

6 SOLDADURA

Esta tecnología permite soldar espárragos leteados

sobre super cies limpias, pero no oxidadas, de acero

suave, acero galvanizado, acero inoxidable, aluminio y

latón.

La rapidez del proceso no altera las super cies en el lado

opuesto de la soldadura. La soldadura no es posible

sobre acero templado, metal oxidado o pintado.

Antes de iniciar la producción es indispensable, efectuar

algunas soldaduras de prueba para determinare la

correcta regulación del generador y el calibrado de la

pistola (fuerza del muelle) operando como sigue:

• Insertar el espárrago elegido en la pinza X (previamente

regulada como se describe en la Fig. 2)

• Disponer la chapa de base en condiciones idénticas a

lo que serán las condiciones de trabajo como espesor,

área de las conexiones de masa, dimensiones de la

pieza, calidad del material.

• Los bornes del cable de masa se colocarán de forma

simétrica y los más cerca posible al punto de soldadura.

• Activar el generador mediante el interruptor luminoso E.

• Empuñar la pistola y posicionar el perno prisonero

en el punto a soldar, evitando de dar golpes y por

eso dañar la punta del cebado del perno prisonero.

Pulse el botón O y, manteniendolo presionado, empuje

la pistola de manera uniforme y no rápida. Cuando

alcance la presión correcta la soldadura se activará de

forma automática. Si la super cie del material sobre la

Fig. 3

1 2 3 4 5

Metal espárragos

Metal base

Acero chapado

cobre con más de

0.2 C%

Acero

inoxidable

304/316

Al Mg 3 AI Si 12 Al 99,5

Acero no a 0.30 C % A A - - Acero galvanizado B B - - Acero inoxidable 304/316 A A - - Al 99,5 - - A B B

Al Mg 3 - - B A B

Al Si 12 - - B A B

Buena capacidad de soldadura: A baja capacidad de soldadura: B No soldables: -

Tab. 1

Page 22

22

que soldar el espárrago es plana, aconsejamos montar

los tres distanciadores Z después de haber a ojado los

tornillos Y.

• En este caso se aconseja de empujar la pistola hasta

que los tres espaciadores toquen la pieza a soldar y

luego presionar el botón para activar la soldadura-

Se requieren estos procedimientos para obtener la

misma presión del perno prisonero sobre el material

de base y por consiguiente una mayor calidad de la

soldadura.

• Los valores de tensión y fuerza aconsejados en el display

deben entenderse como base de partida para efectuar la

correcta regulación del generador y la calibración de la

fuerza de la pistola.

Estos valores han sido experimentados efectuando

pruebas de “material base” de 2 mm (0.079") de espesor

para acero y acero inoxidable y de 1,2 mm (0.047") de

espesor para aluminio.

• Ejecutar algunas soldaduras regulando la tensión con

el mando G y la fuerza de la pistola con la regulación Q

hasta obtener soldaduras perfectas.

La pistola se extrae manteniéndola perfectamente

alineada con el perno para no deformar la pinza (Fig4).

• No soldar sobre los espárragos leteados ya

soldado.

OK

NO

Fig. 4

7 MANTENIMIENTO

7.1 ORDINARIO

Conservare legibles y claras las indicaciones y las guras

en la soldadora.

El cable de red y los cables de soldadura deben estar

aislados y en perfectas condiciones; tengan cuidado en

los puntos donde sufren exiones: cerca de los bornes

de conexión, en las pinzas de masa y a la entrada en la

pistola.

Mantener limpios y bien apretados los conectores de la

corriente de soldadura en las clavijas B y C (ver Fig. 1)

Los bornes para la conexión con el metal base deberán

hacer un buen contacto para evitare recalentamientos,

chispas, circulación no equilibrada de la corriente,

daños al componente donde van soldados los pernos y

soldaduras de calidad no constante.

Impedir la entrada de suciedad, polvo y limaduras en el

interno de la soldadora.

Garantizar siempre la circulación del aire del aire de

enfriamiento.

Controlar que el ventilador funcione normalmente.

Veri car que las pinzas aprieten bien los espárragos con

todos los muelles de contacto.

El mandril porta pinzas deberá deslizarse libre en toda

su trayectoria, sin variaciones debidas a roces o cuerpos

extraños.

7.2 EXTRAORDINARIO

El mantenimiento deber ser realizado por personal

cuali cado. Algunas anomalías de funcionamiento están

evidenciadas por el encendido de un código de error en

el display A.

Antes de abrir la soldadora esperar al menos 5 minutos

desde el apagado del interruptor E además desconectar

la clavija de la toma de alimentación.

Controlar con un voltímetro que los condensadores estén

descargados.

Quitar el polvo, fragmentos y limaduras metálicas de la

máquina con cuidado usando aire comprimido para no

dañar o proyectar fragmentos metálicos en las partes

electrónicas o eléctricas.

Veri car que todos los conectores estén insertados a

fondo.

Veri car que todos los terminales del circuito de soldadura

estén bien apretados.

Después de haber realizado una reparación, estén

atentos a reordenar el cableo de forma que exista

un aislamiento seguro entre el lado primario y el lado

secundario de la máquina. Evitar que los hilos puedan

entrar en contacto con partes en movimiento o partes que

se recalientan durante el funcionamiento. Remontar todas

las abrazaderas como en el aparato original de forma que

se pueda evitar, que si accidentalmente un conductor se

rompe o se desconecta, pueda provocar una conexión

entre el primario y el secundario.

Remontar además los tornillos con las arandelas

endentadas como en el aparato original.

Page 23

23

Código de

Error

Anomalía Solución

WARNING 1 Signica que el botón y el microinterruptor de

la pistola están presionados en el momento de

encenderse el generador.

Soltar el botón de arranque.

ERROR 2 Signica que el relé RL1 presenta avería. Circuito de potencia en avería.

Contactarse con el servicio de asistencia.

ERROR 3 Signica que el relé RL1 presenta avería. Circuito de potencia en avería.

Contactarse con el servicio de asistencia.

ERROR 4 Signica que el SCR está en cortocircuito. Contactarse con el servicio de asistencia.

ERROR 5 Signica que hay una avería en el circuito de

carga de los condensadores

Contactarse con el servicio de asistencia.

ERROR 7 Signica que hay una avería en el circuito de

carga de los condensadores

Contactarse con el servicio de asistencia.

WARNING TH

Signica que ha intervenido la protección

térmica.

Es necesario esperar algunos minutos sin apagar la

soldadora.

ERROR 9

Signica que hay una avería en el circuito

que mide la tensión en los extremos de los

condensadores.

Circuito de potencia en avería.

Contactarse con el servicio de asistencia.

ERROR 10

Signica que hay un cortocircuito en el circuito

de descarga de los condensadores.

Circuito de potencia en avería.

Contactarse con el servicio de asistencia.

WIRING DIAGRAM

COLOUR CODE

A BLACK

B RED

C GREY

D WHITE

E GREEN

F PURPLE

G YELLOW

H BLUE

K BROWN

J ORANGE

I PINK

WIRING DIAGRAM

COLOUR CODE

L PINK-BLACK

M GREY-PURPLE

N WHITE-PURPLE

O WHITE-BLACK

P GRE Y-BLU E

Q WHITE-RED

R GREY-RED

S WHITE-BLUE

T BLACK-BLUE

U YELLOW-GREEN

V BLUE

Page 24

24

Page 25

25