CHIEF CH1015T-NGE, CH1015T-NGEM, CH2025T-NGE, CH2025T-NGEM, CH1015T-LPGE Installation And Operation Manual

...Page 1

CENTRIFUGAL HEATER - CSA

INSTALLATION &

OPERATINGMANUAL

P/N 416274 Rev 0

NATURAL GAS

CH1015T-NGE/NGEM

CH2025T-NGE/NGEM

LIQUID PROPANE

CH1015T-LPGE / LPGEM

CH2025T-LPGE / LPGEM

VAPOR PROPANE

CH1015T-VPGE

CH2025T-VPGE

Page 2

WARNING: If the information in this manual is not followed exactly, a

fire or explosion may result causing property damage, personal

injury or loss of life.

- Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

o Do not try to light any appliance.

o Extinguish any open flames.

o Do not touch any electrical switch.

o Immediately call your gas supplier. Follow the gas

supplier’s instructions.

o If you cannot reach your gas supplier, call the fire

department.

- Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

WARNING: Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death. Read the

installation, operating and maintenance instructions thoroughly

before installing or servicing this equipment.

FOR YOUR SAFETY

The use and storage of gasoline and other flammable vapors and

liquids in open containers in the vicinity of this appliance is

hazardous.

C H I E F I N D U S T RI E S, I N C. – AG RI / I N D U S TR I A L D I V I S I O N

Installation Manual

For more information about Chief Industries, Inc. and additional products or services please visit our website

Chief Industries, Inc. 800-359-7600 TOC – 416274 Page 2

Chief Industries, Inc.

4400 East 39th Street • PO Box 848

Kearney, NE 68847

Phone 800.359.7600

www.agri.chiefind.com

Page 3

Table of Contents

Introduction ........................................................................... 4

Model Number Description .............................................................. 4

Packing List ..................................................................................... 5

Before You Begin ................................................................. 6

Safety and Precautions ..................................................... 8

Heater and Control Enclosure Components ............. 11

Accessories: .................................................................................. 11

Explanation of Components: ......................................................... 12

Replacement Parts Common to All Models: .................................. 17

Replacement Parts for Specific Models: ....................................... 18

Heater Location and Foundation ................................................... 20

Gas Supply Installation ................................................................. 22

High Limit Installation .................................................................... 24

Fan Electrical Installation .............................................................. 25

Heater Electrical Installation .......................................................... 25

Installation of External Plenum Controls ....................................... 26

Operating Instructions ..................................................... 26

Heater Control: .............................................................................. 26

Start-Up Procedure: ...................................................................... 27

Drying Temperature Recommendations: ...................................... 28

Adjustments: ................................................................................. 30

Shut Down Procedures ................................................................. 31

Firing Rate Guideline Tables ......................................................... 32

Heater Maintenance ...................................................................... 37

Heater Wiring Diagram .................................................................. 38

Generic Sequential Operations Check: ......................................... 40

Condition Specific Faults: .............................................................. 41

STANDARD LIMITED WARRANTY......................................... 45

Chief Industries, Inc. 800-359-7600 TOC – 416274 Page 3

Page 4

C E N T R I F U G A L H E A T E R - C S A

Introduction

Thank you for purchasing a Caldwell Centrifugal Heater compliant to the Canadian Standards

Association performance guidelines. Proper installation will ensure you the best overall experience with

your heater and guarantee smooth operation. This manual is for the installation and operation of the

Caldwell Centrifugal Heater system that has been 100% factory quality control inspected, field simulated

and stress tested prior to shipment.

This proprietary information is loaned with the expressed agreement that the drawings and information

therein contained are the property of Chief Industries, Inc. and will not be reproduced, copied, or

otherwise disposed of, directly or indirectly, and will not be used in whole or in part to assist in making

or to furnish any information for the making of drawings, prints or other reproduction hereof, or for

the making of additional products or equipment except upon written permission of Chief Industries,

Inc. first obtained and specific as to each case. The acceptance of this material will be construed as an

acceptance of the foregoing agreement.

The technical data contained herein is the most recent available at the time of publication and is subject

to modification without notice. Chief Industries, Inc. reserves the right to modify the construction and

method of operation of their products at any time without any obligation on their part to modify any

equipment previously sold and delivered.

Model Number Description

The heater model nomenclature distinguishes the application of the heater. The information includes a

designation of the applicable fan and type of fuel to be utilized (natural gas, vapor propane, or liquid

propane). The model number is stamped on the serial number plate and the definition of the model

number nomenclature is as follows:

Example: CH 1015 - T - NGE

(a) (b) - (c) - (d)

(a) CH = Heater Unit (Canadian)

(b) 1015 = Fan Model Required by Horsepower

Where: 1015 = C27-10 or C27-15

Where: 2025 = C30-20 or C30-25

(c) T = Transformer and Flame Probe Ignition System

(d) NGE = Type of Fuel to be Utilized

Where

NGE = Natural Gas Fuel (Electric)

VPGE = Vapor Propane Gas Fuel (Electric)

LPGE = Liquid Propane Gas Fuel (Electric)

LPGEM = Liquid Propane Gas Fuel (Electric) with Modulating Valve

Chief Industries, Inc. 800-359-7600 INTRODUCTION -416274 Page 4

Page 5

C E N T R I F U G A L H E A T E R - C S A

Quantity

Component

Description

1

Heater

Heater Assembly

1

Warranty Registration Card

Bulletin

1

Manual

Bulletin (464D)

1

Bolt Bag

Assembly

1

Orifice

Package

Packing List

The shipment should contain the following items. Verify and inspect all items carefully when unpacking

and before installing. In case of any shortage, contact your dealer. In case of damage during shipment,

file a claim with the carrier.

Note: Before starting the installation of the heater, verify that all items called out on the

packing list have been received.

Please note that this manual, part number 416274 includes and references Bulletin 464D. This manual

is for the installation, operation and maintenance of heater models with serial numbers 15F and above,

and is effective 5/1/2015.

Chief Industries, Inc. 800-359-7600 INTRODUCTION -416274 Page 5

Page 6

C E N T R I F U G A L H E A T E R - C S A

Date

Operator Signature

Owner Signature

Before You Begin

Read this manual thoroughly before operating this heater. Keep this manual in a

location for quick access and reference.

“The equipment shall be installed in accordance with the Natural Gas and Propane Installation Code,

CSA B149.1 and the Propane Storage and Handling Code, CSA B149.2, or applicable provincial

regulations, which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.”

Your Caldwell heater is designed for safe and reliable operation when properly installed in combination

with a Caldwell fan. However the heater requires electricity and flammable gas, which when improperly

installed or when operated improperly, can be potentially dangerous. Anyone who will operate this unit

should read the manual before installing or operating this unit. The following table, provided for your

convenience, will aid in verifying that these individuals understand the proper operation of the heater.

After completely reading the manual, this table should be filled in.

Chief Industries, Inc. 800-359-7600 INTRODUCTION -416274 Page 6

Page 7

C E N T R I F U G A L H E A T E R - C S A

Special Service Note: If you are unable to remedy any service problem after thoroughly studying this

manual, contact the dealer from whom you purchased the unit. Your dealer is your first line of service.

The following information is required for service:

1. Heater model number: __________________________________

2. Heater serial number: ___________________________________

3. Fan model number: ____________________________________

4. Fan serial number: _____________________________________

5. Type of fuel: _________________________________________

6. Type of external plenum control used: _____________________

7. Setting of the external plenum control: _____________________

8. Approximate operating pressure: __________________________

9. Hours the unit has been in operation: ______________________

10. Diameter and eave height of bin: _________________________

11. Grain depth: _________________________________________

12. Type of grain stored: ___________________________________

13. Moisture content of the grain: ____________________________

14. Dealer purchased from: _________________________________

15. Dealer address and phone number: ________________________

16. Date purchased: _______________________________________

17. Service contractor:

a. Name: _____________________________________________

b. Address: ____________________________________________

c. Phone: _____________________________________________

Chief Industries, Inc. 800-359-7600 INTRODUCTION -416274 Page 7

Page 8

C E N T R I F U G A L H E A T E R - C S A

Safety and Precautions

Your safety and the safety of others is a primary concern to Chief Industries, Inc. This manual was

written to assist in the safe installation and operation of the Caldwell Heater.

It is your responsibility as the owner, builder, operator, or supervisor to know what specific

requirements, precautions and hazards exist and to make these known to all personnel working with

equipment or on the jobsite so that they can observe any necessary safety precautions.

All personnel, including the installation crew, must read and understand the information contained in

this manual before starting construction. Chief Industries, Inc. is not responsible or liable for the

misuse of equipment or operation of personnel or equipment in an unsafe manner.

Chief Industries, Inc. assumes no liability with respect to proper construction and inspection, assembly,

or use of its products established under applicable laws, all of which is the sole responsibility of the

purchaser and those authorized for the installation.

Follow all local and federal safety laws and regulations. Verify that all equipment and personnel

conform to any applicable jurisdiction regulations.

Work Area Safety Statement

To ensure the safety of all individuals in the work area, only authorized and trained persons shall install,

maintain and use the Caldwell Heater.

Under no circumstances should unauthorized individuals be allowed to trespass or be present in the

work area.

It shall be the duty of all operators to ensure that the work area is clean, organized and kept free of all

debris and tools that might cause an accidental tripping or falling hazard.

Special care should be taken when working from unsafe heights. Common sense dictates that when

conditions such as rain or wind prohibit the safe use of equipment, the installation be discontinued.

Chief Industries, Inc. strongly recommends that equipment meeting the current specifications be used,

whether the individual operator is required by law to do so or not. Proper climbing equipment and a

secured safety harness should be used at all times when performing operations work, installation or

maintenance.

Field modifications without the authorization of the manufacturer may present unknown dangers to the

operator and must be avoided.

Auxiliary Equipment Safety

You may decide to purchase and install “auxiliary equipment” made by other manufacturers. Chief

Industries, Inc. has no control over the design and manufacture of this equipment. In view of this, at a

minimum, we suggest you do the following:

Chief Industries, Inc. 800-359-7600 SAFETY - 416274 Page 8

Page 9

C E N T R I F U G A L H E A T E R - C S A

1. Obtain, read and understand the instructions and safety cautions of the auxiliary equipment

manufacturer. Be certain that all equipment is installed in agreement with those instructions.

2. Check with Chief Industries, Inc. to verify that your system is designed to support any additional

loads supplied by the auxiliary equipment.

3. Obtain any applicable safety decals from the manufacturer and make certain they are displayed

in a visible location.

4. Make certain that all electrical equipment is properly installed and grounded by a qualified

electrician.

5. Check availability and operation of electrical lock out and emergency stop systems.

6. Be certain that all guards and shields are securely in place.

7. Store all operation / maintenance manuals in a safe place for future use.

Heater Safety

Before operating the unit, perform the following checks:

1. Verify the fan, heater and transition units are bolted securely together. Verify the screen guard is

secured in place.

2. Verify the units are wired in compliance with the national electrical code, and the ground wire is of

sufficient size to provide lightening protection.

3. Verify the gas supply is installed correctly according to instructions.

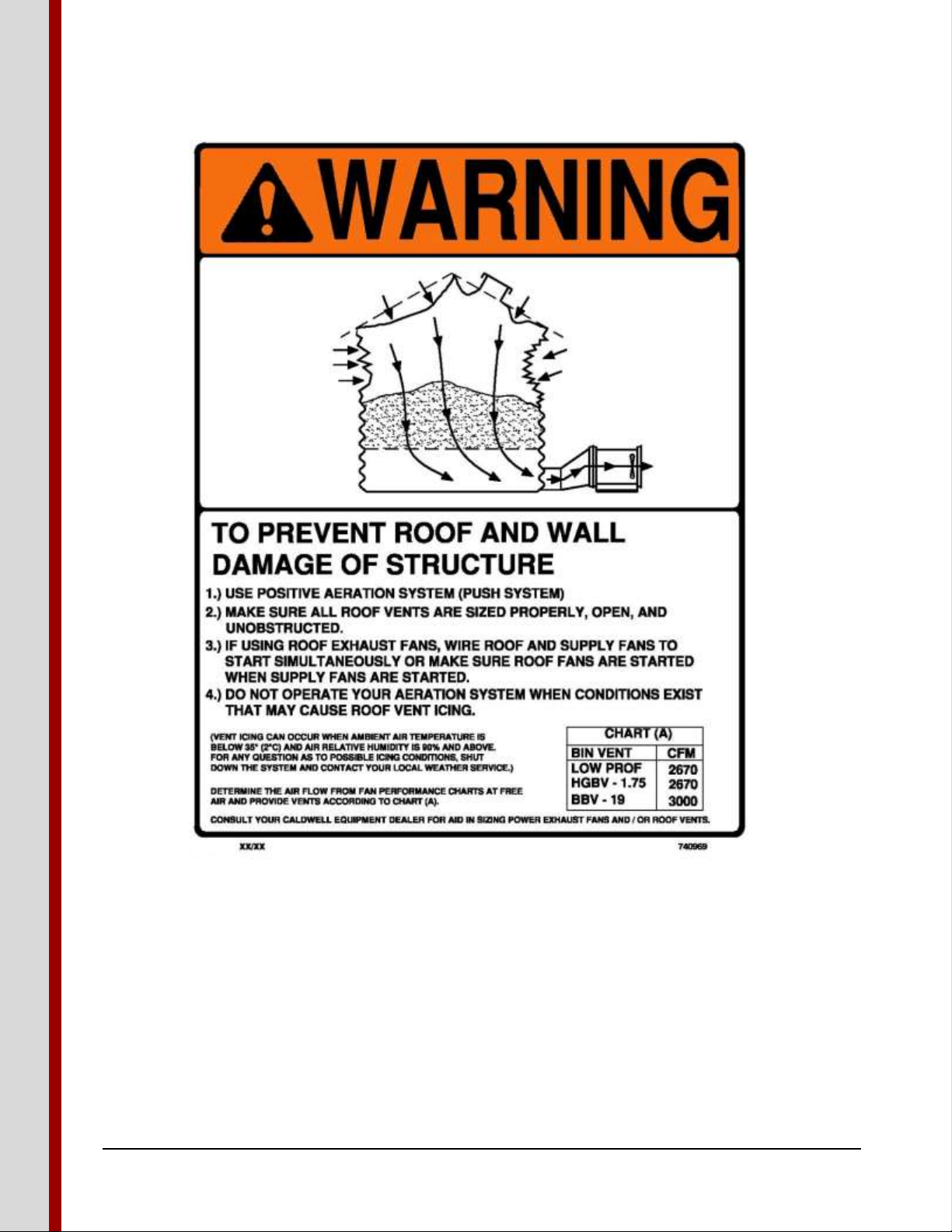

4. Provide sufficient bin exhaust vents or fans, and verify that they are open and operational before

starting the drying system. These vents or fans are necessary to provide an exhaust path for moisture

laden air (reducing condensation), and also to prevent pressurization of the bin above the grain mass

and causing damaging loads on the bin and roof structure. Do not operate units when conditions are

such that freezing of the vents could occur.

a. Heed the following warning:

Chief Industries, Inc. 800-359-7600 SAFETY - 416274 Page 9

Page 10

C E N T R I F U G A L H E A T E R - C S A

Chief Industries, Inc. 800-359-7600 SAFETY - 416274 Page 10

Page 11

C E N T R I F U G A L H E A T E R - C S A

Heater and Control Enclosure Components

The following outlines the accessories, general components and replacement part numbers for the

Caldwell heater models.

Accessories:

1. A humidistat, thermostat, or thermostat-humidistat control is not included with the standard heater.

These controls are to be ordered separately. A dual humidistat-thermostat kit can be ordered so that

one control assembly can be used when two heater units are used on the same bin.

2. Caldwell requires using a fuel line strainer in the fuel line just before the fuel enters the heater

plumbing. A line strainer is provided on all units. A line strainer can be obtained from Caldwell, or

your gas company. Caution: Your warranty could be jeopardized if the heater should malfunction

due to foreign material in the heater plumbing lines if the fuel supply line is not fitted with a line

strainer.

3. When wiring a heater to a 460 or 575 volt fan, a step down transformer must be used to develop 115

volt, single phase, 60 cycle power (part #9717033).

Chief Industries, Inc. 800-359-7600 COMPONENTS - 416274 Page 11

Page 12

C E N T R I F U G A L H E A T E R - C S A

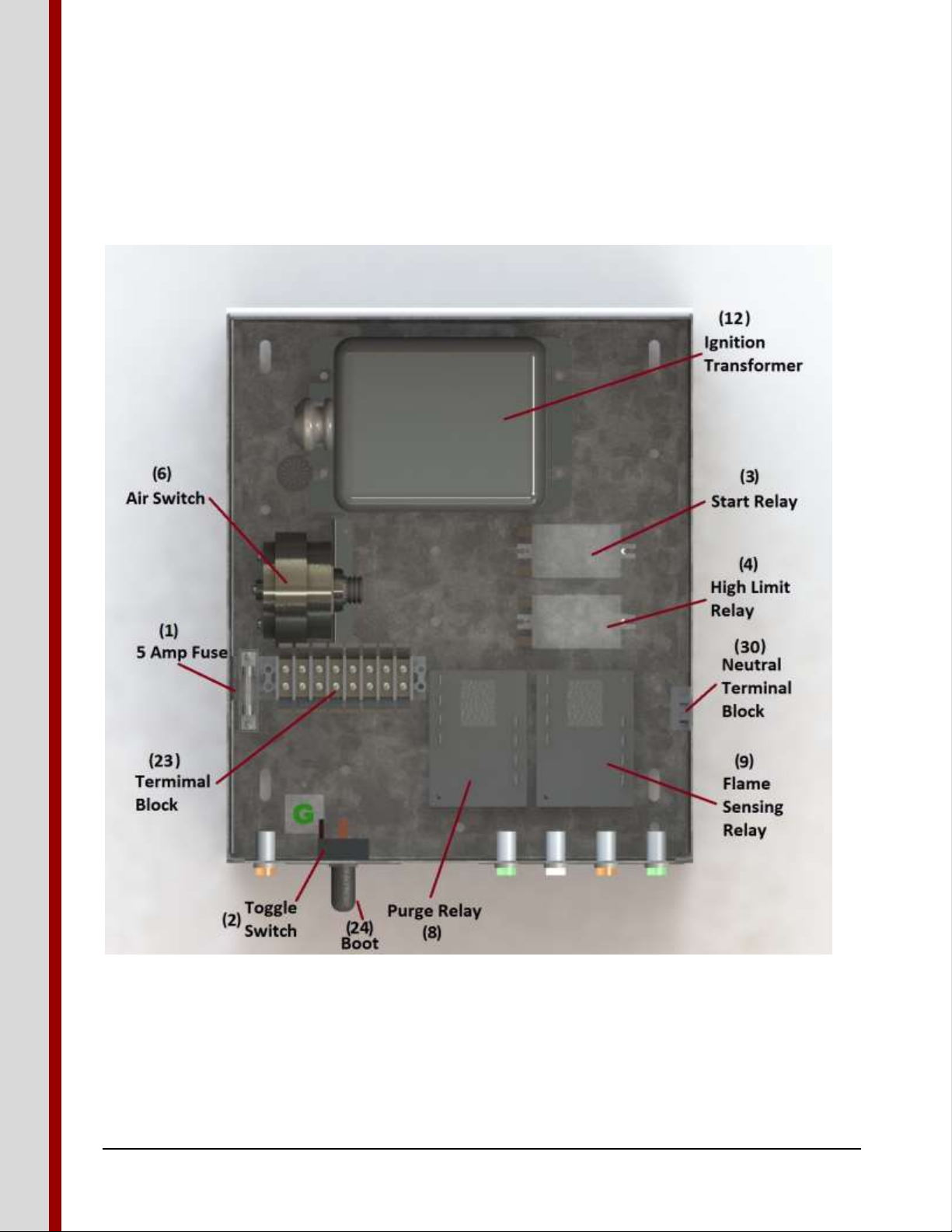

Explanation of Components:

Please note the location and general description of the primary components and their function.

Control Enclosure Components:

Chief Industries, Inc. 800-359-7600 COMPONENTS - 416274 Page 12

Page 13

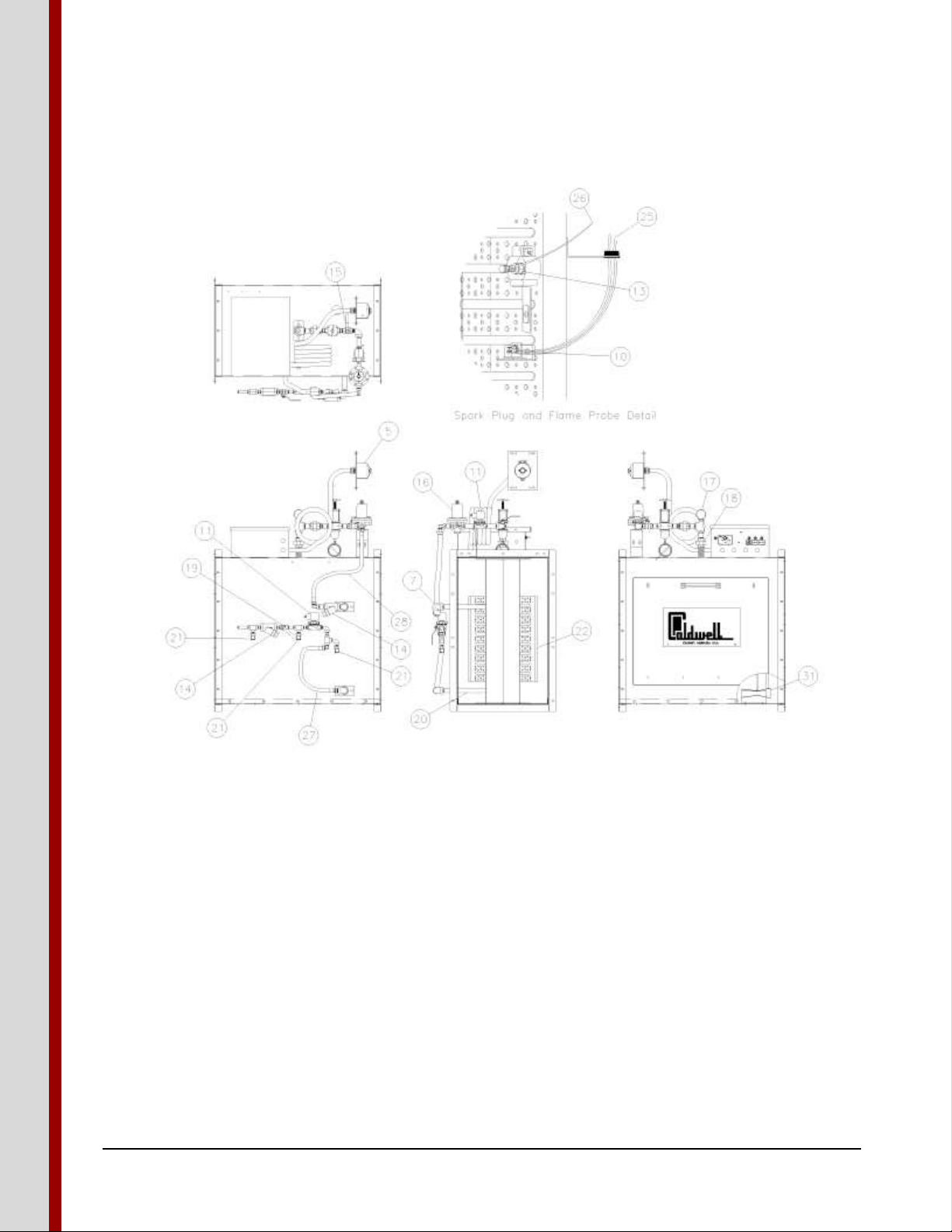

Heater Body Components:

C E N T R I F U G A L H E A T E R - C S A

The balloon callouts shown in the above illustration specify each component of the heater.

1. 5 Amp Fuse (#850412) - The fuse protects the heater control circuit from excessive current draw.

2. Toggle Switch (#710707) - The toggle switch is the heater "On" and "Off" and “Momentary Start”

switch.

3. Start Relay (#756692) – A start relay is utilized to prove that the flame probe is functioning properly

with every trial for ignition. If the flame probe is functioning properly the relay allows the purge to

energize. If the flame probe is not functioning properly the start relay prevents the initiation of the

ignition process.

4. High Limit Relay (#756692) – The high limit relay is activated by the high limit. The slave relay

shuts off the spark and fuel to the burner and maintains the off condition until the operator

Chief Industries, Inc. 800-359-7600 COMPONENTS - 416274 Page 13

Page 14

C E N T R I F U G A L H E A T E R - C S A

determines the reason for the high limit activation. The slave relay is reset by turning the heater

toggle switch to the off position.

5. High Limit (#776443) - The high limit control, located in the bin plenum, is a manual resetting

temperature limiting control, used to protect the heater, not the bin plenum, from excessive heat.

The high limit control activates the slave relay to shut off the heater if the plenum temperature

reaches 230° F (110° C). Note: The high limit is not an operating control; the operator must utilize

an operating control to set the firing rate for the desired drying plenum temperature.

6. Air Switch (#785691) - The air switch is a control that senses the flow of air from the fan to the

heater. If, for any reason, the air flow is stopped, the air switch will shut off the heater. The air

switch will keep the heater shut off until air flow from the fan is re-established. If the air switch cycles

off from a lack of air, turn the heater toggle switch off before restarting the fan.

7. Vapor Temperature Limit (#157200) - The vapor temperature limit is an automatic resetting

temperature limiting control used to protect the solenoid valve and regulator from being damaged

due to excessive gas temperature coming from the vaporizer. Also, the vapor temperature limit

protects the vaporizer from re-cracking the propane and causing an oil film to deposit on the burner.

The vapor temperature limit is set to shut off the heater if the gas from the vaporizer reaches a

temperature of 160°F (71°C). The control will allow the heater to reignite after the vaporizer cools.

The vapor temperature limit is only on LPGE heaters.

8. Purge Delay with 30 sec Time Delay (#719914) - Purge delay is a time delay relay used to delay the

energizing of the ignition transformer and solenoid valves for 30 seconds after the heater is turned on

to allow for the removal of any raw gas from the heater before ignition is tried. The purge delay calls

for a 30-second delay before ignition, regardless which control is sued to turn the heater on.

9. Flame Sensing Relay with 30 sec Time Delay (#719914) - The flame sensing relay has a 30

second delay and is used to break the circuit to the solenoid valves and ignition transformer if the

flame probe does not establish the presence of the flame at the burner. The operator will have to

manually reset the flame sensing relay by moving the power switch to off, before retrying for ignition.

10. Flame Probe (#749812) - The flame probe is a switch that is sensitive to heat, and is used to

establish the presence or absence of flame at the burner. The flame probe is used with the flame

sensing relay, as the flame safeguard circuit of the heater. The switch is opened on temperature rise.

11. Solenoid Valves - Solenoid valves are shut-off valves that are electrically operated. The valves are

opened automatically when energized, and are closed automatically when de-energized.

12. Ignition Transformer (#851790) - The ignition transformer is a transformer used to create the

6,000 secondary volts necessary for spark at the spark plug.

13. Spark Plug (#851402) - The spark plug is used to ignite the fuel at the burner. The spark plug will

spark while the ignition transformer is energized.

Chief Industries, Inc. 800-359-7600 COMPONENTS - 416274 Page 14

Page 15

C E N T R I F U G A L H E A T E R - C S A

14. Fuel Line Strainer - The fuel line strainer is used to remove foreign particles from the fuel before

the fuel enters the heater plumbing. If these particles are not removed, possible operating difficulties

could occur.

15. Vapor Valve - The vapor valve is used for preliminary adjustment of the firing rate by opening and

closing the valve to generate the proper plenum temperature. Once the proper firing rate is

established, the regulator needs to be adjusted to the firing rate that is required.

16. Regulator - The regulator is used to regulate the firing rate of the heater. The regulator is not used to

regulate the fuel from the fuel sources. A separate regulator should be used for regulating the fuel at

the fuel source.

17. Pressure Gauge - The pressure gauge is used to indicate the amount of fuel pressure at the orifice.

The pressure is used as a tool to set the firing rate.

18. Orifice - The orifice is an opening at the end of the heater plumbing that develops a restriction to gas

flow, which allows the pressure gauge to develop a pressure reading, so that the firing rate of the

heater can be field set.

19. Liquid Shut-Off Valve (#714949) - The liquid shut off valve is used as a manual shut off valve and

is used to stop fuel from entering the heater. The liquid shut off valve has only two positions: open

or closed. The liquid shut off valve is only on LPGE heaters.

20. Vaporizer (#9752584) - The vaporizer is used on LPGE heaters only, and is used to convert the

liquid propane gas to propane vapor gas by using the heat supplied by the burner.

21. Hydrostatic Pressure Relief Valve (#716878) - The hydrostatic pressure relief valve is used to

protect the heater plumbing components from excessive fuel pressure by relieving the excessive fuel

pressure from gas trapped between shut off valves to the atmosphere. If a hydrostatic pressure relief

valve opens, replace the relief valve.

22. Burner - The burner is a component in the heater where the fuel and air are mixed and then burned.

23. Terminal Block 8 POLE (#749614) - The terminal block is used as a junction block for connecting

the lead wires of the various electrical parts.

24. Toggle Switch Protective Boot (#712034) - The toggle switch boot is used to eliminate water

entering the heater controls through the toggle switch.

25. Flame Probe Wire - The flame probe wire is used to connect the flame probe to the control box.

26. Spark Plug Wire - The spark plug wire is used to connect the spark plug to the ignition transformer.

27. Liquid Propane Hose (#715276) - The liquid propane hose is used to connect the liquid plumbing

line to the inlet of the vaporizer.

28. Vapor Propane Hose (#155820) - The vapor propane hose is used to connect the vaporizer to the

vapor propane line.

Chief Industries, Inc. 800-359-7600 COMPONENTS - 416274 Page 15

Page 16

C E N T R I F U G A L H E A T E R - C S A

29. Burner High Limit Wire (#9701961) - Wiring that connects the burner high limit and burner

exhaust limit to the control box.

30. Neutral Terminal Block 3 POLE (#850255) - This terminal block is used as a junction block to

establish a common neutral for connection of the neutral leads.

31. Venturi Weldment (#9415661) - The venturi weldment creates a high and low pressure area in the

airflow, which aids the air switch in measuring air velocity.

32. Humidistat Control (#9850982) - The humidistat control is an electrical operating control that is

wired into the heater to cycle the heater "On" and "Off" with respect to the relative humidity of the

drying air. The humidistat control is typically set at about 50% - 60% relative humidity of the drying

air. When the relative humidity is higher than the humidistat setting, the heater is cycled "On" and is

left on until the relative humidity is below the humidistat setting. If the relative humidity of the drying

air is less than the humidistat setting, the heater is cycled "Off" until such time that the relative

humidity would become greater than the setting of the humidistat. The humidistat control is for low

temperature drying.

33. Thermostat Control (#9851014) - The thermostat control is an electrical operating control that is

wired into the heater to cycle the heater "On" and "Off" with respect to the temperature of the drying

air. The thermostat is set at a desired temperature, and if the drying air temperature is higher than the

thermostat setting, the heater is cycled "Off." If the drying air temperature is less than the thermostat

setting, the heater is cycled "On," and is left on until such time that the drying air temperature is

above the thermostat setting.

34. Humidistat-Thermostat Control (#9870974) - The humidistat-thermostat control is an electrical

operating control that is wired into the heater to cycle the heater "On" and "Off" with respect to both

the drying air relative humidity and temperature. The humidistat-thermostat control will cycle the

heater on if either the drying air relative humidity is too high, or the drying air temperature is too low

with respect to the humidity setting or temperature setting of the control. NOTE: The optional

external plenum controls do not function in the same manner as a thermostat in a residential house.

When the bin plenum controls reach the set point the heater is then shut off. In the off mode the

bin’s plenum temperature will drop below the set point of the control due to the rapid air change in

the plenum from the fan. The controls do not sense the instantaneous change in air temperature but

take time to reach the plenum control setting before controlling the heater operation. NOTE: The

firing rate must be set by the operator to verify excessive temperature is not present in the plenum.

35. Modulating Valve - The modulating valve is a non-electrical operating control. The modulating

valve is placed in the heater plumbing, and controls the amount of fuel burned by the heater

depending upon the temperature of the drying air. If the temperature of the drying air is lower than

the temperature setting of the modulating valve, the modulating valve opens up and more fuel is

burned to raise the drying air temperature. If the drying air temperature is higher than the

temperature setting, the modulating valve restricts the amount of fuel to the heater. The modulating

valve has an interchangeable by-pass orifice to maintain continuous low heat operation regardless of

modulating valve setting. The orifice is interchangeable for establishing lower or higher by-pass flow

through the modulating valve, depending on conditions.

Chief Industries, Inc. 800-359-7600 COMPONENTS - 416274 Page 16

Page 17

Replacement Parts Common to All Models:

ITEM #

PART DESCRIPTION

PART NUMBER

1

5 Amp Fuse

850412

2

Toggle Switch

710707

3

Slave Relay

756692

4

High Limit

776443

5

Air Switch

785691

6

Vapor Temperature Limit (LPGE units only)

157200

7

Purge Relay (30 sec. time delay)

719914

8

Flame Sensing Relay (30 sec. time delay)

719914

9

Flame Probe

749812

11

Ignition Transformer

851790

12

Spark Plug

851402

16

Pressure Gage LP

851543

16

Pressure Gage NG

715011

22

Terminal Block (8 POLE)

749614

23

Toggle Switch Boot

712034

26

Liquid Propane Hose

715276

27

Vapor Propane Hose

155820

29

Neutral Terminal Block (3 POLE)

850255

31

Venturi

9415661

32

Nylon Humidistat Control (Not Shown)

9850982

33

Thermostat Control (Not Shown)

9851014

34

Humidistat-Thermostat Control (Not Shown)

9850974

35

Modulating Valve Kit (Propane) (Not Shown)

9701862

35

Modulating Valve Kit (Nat. Gas) (Not Shown)

9767954

C E N T R I F U G A L H E A T E R - C S A

Chief Industries, Inc. 800-359-7600 COMPONENTS - 416274 Page 17

Page 18

Replacement Parts for Specific Models:

CH1015TNGE

CH1015TVPGE

CH1015TLPGE

CH1015TLPGEM

ITEM #

PART DESCRIPTION

PART #

PART #

PART #

PART #

10

Vapor Solenoid Valve

789263

789255

789255

189255

10

Liquid Solenoid Valve

753863

753863

13

Vapor Fuel Line Strainer

851626

851626

851626

851626

13

Liquid Fuel Line Strainer

851634

851634

14

Vapor Valve

714931

714931

714931

714923

15

Regulator

753905

715003

715003

715003

17

Orifice

9720516

9422253

9422253

9422253

18

Liquid Valve

714949

914949

19

Vaporizer

9752584

9752584

20

Hydrostatic Pressure Relief Valve

716878

716878

21

Burner

9784793

9784793

9784793

9784793

24

Flame Probe Wire

9730515

9730515

9730515

9730515

25

Spark Plug Wire

9701995

9701995

9701995

9701995

CH2025TNGE

CH2025TVPGE

CH2025TLPGE

CH2025TLPGEM

ITEM #

PART DESCRIPTION

PART #

PART #

PART #

PART #

10

Vapor Solenoid Valve

789263

789263

789263

789263

10

Liquid Solenoid Valve

753863

753863

13

Vapor Fuel Line Strainer

851626

851626

851626

851626

13

Liquid Fuel Line Strainer

851634

851634

14

Vapor Valve

714931

714931

714931

714931

15

Regulator

775502

715003

715003

715003

17

Orifice

9719328

9714881

9714881

9714881

18

Liquid Valve

714949

914949

19

Vaporizer

9752584

9752584

20

Hydrostatic Pressure Relief Valve

716878

716878

21

Burner

9787840

9787840

9787840

9787840

24

Flame Probe Wire

9730531

9730531

9730531

9730531

25

Spark Plug Wire

9701995

9701995

9701995

9701995

C E N T R I F U G A L H E A T E R - C S A

Chief Industries, Inc. 800-359-7600 COMPONENTS - 416274 Page 18

Page 19

C E N T R I F U G A L H E A T E R - C S A

Installation Requirements

The following illustration describes the components necessary for a typical installation. The drying unit

(fan, heater, and transition) should be located such that the heated air can enter the bin plenum chamber

uniformly. Verify all the components needed for the drying system are present. The fan and heater

should be located opposite the unloading tube for best air distribution.

Chief Industries, Inc. 800-359-7600 INSTALLATION - 416274 Page 19

Page 20

C E N T R I F U G A L H E A T E R - C S A

Heater Location and Foundation

The following illustration shows a typical installation of 2 drying units and optional plenum controls. If

two drying units are used on the same bin, locate them 4’ (1.21m) to within 45° of each other and

centered opposite the unloading tube. Locate any humidistat or thermostat control between the two

heater units, making sure control senses heat from both units (order kit #9735035).

Chief Industries, Inc. 800-359-7600 INSTALLATION - 416274 Page 20

Page 21

C E N T R I F U G A L H E A T E R - C S A

For proper operation of heater, the fan and heater are to be mounted on a level pad. The pad should be

the same height as the concrete floor. The size of the pad should be as indicated in the following

illustration.

Chief Industries, Inc. 800-359-7600 INSTALLATION - 416274 Page 21

Page 22

C E N T R I F U G A L H E A T E R - C S A

Before installing heater please verify the following:

1. That the spark plug is gapped at 1/8" (.32cm). If not, gap to 1/8" (.32cm).

2. That the flame probe and spark plug wires are attached.

3. That all bolts, including carriage bolts and screws are tight.

4. The heater is installed on the air discharge end of the fan. Check air flow decals on the fan and heater

to verify heater is oriented properly. Connect the heater to the transition with bolts provided in the

fan bolt bag. The installation should appear as illustrated previously.

Gas Supply Installation

Refer to the dryer rating plate to locate the minimum gas supply pressure for obtaining the maximum

gas capacity for which this dryer is specified.

The gas piping installer is to locate a manual emergency shutoff valve in an appropriate location that

allows access to this valve in case of a fire, explosion or other emergency at the heater.

Propane Gas

Chief Industries, Inc. 800-359-7600 INSTALLATION - 416274 Page 22

Page 23

C E N T R I F U G A L H E A T E R - C S A

For a typical propane tank installation a 1000 gallon tank is recommended as the minimum size to avoid

frequent refilling. (Raising the air temperature 100°F (38°C) on an airflow rate of 10,000 CFM

(283m³/min) would require approximately 300 gallons of liquid propane per day.) Also the larger tank

will aid in the vaporization of the liquid propane.

Note: Never use an anhydrous ammonia tank as your LP gas tank. Contaminants in the tank can be harmful

to the heater, and safety devices may not meet liquid propane storage codes.

The supply tank should be placed at least 10’ (3.05m) from the heater. Because some areas may require

a greater distance, please consult your local authorities.

The supply tank should be equipped with a liquid valve and vapor valve. The inlet of the liquid valve

should be located 12” (31cm) from the tank bottom to avoid impurities getting into the gas line and

heater.

The liquid valve and vapor valve on the propane tank should be connected as illustrated. This allows

the operator to run the LPGE and LPGEM units on vapor or liquid propane.

A minimum 60 psig (414kPa) pressure regulator is recommended, located as shown. The regulator

provides uniform flow, and reduces the pressure on the gas line from the regulator to the heater for

added safety. The regulator is required on vapor and liquid propane installations. Verify that the supply

tank has a relief valve present and that it is properly sized and located.

Chief Industries, Inc. 800-359-7600 INSTALLATION - 416274 Page 23

Page 24

C E N T R I F U G A L H E A T E R - C S A

Natural Gas

The natural gas service should be able to provide a minimum of 5 psig (34kPa) when the heater is

operating. Check with your gas supplier to verify that the supply pressure has the pressure potential to

deliver natural gas for the length of the service line.

A line strainer must be located at the heater (order part #714709).

The natural gas service should be regulated. Contact your gas supplier. A regulator can be obtained

from Caldwell (order part #753905).

Fuel Line Installation

The suggested tubing size to be used from the supply to the heater is 5/8" (1.59cm) O.D. type K

copper tubing or 1/2" (1.27cm) black schedule 80 steel pipe. If copper tubing is used, make a loop in

the tubing within 3’ (0.9m) of the heater to absorb shock. If 1/2" (1.27cm) steel pipe is used, run the

plumbing to within about 3’ (0.9m) of the heater, and use three feet of 3/8" (.95cm) minimum I.D. high

pressure flexible hose, (CGA approved for propane). Be careful not to turn or twist the heater

plumbing parts because the proper operation of these can be affected or leaks in joints can be

developed. Verify all foreign material is out of the gas line before connecting the line to the heater.

If your natural gas supply pressure is not adequate to maintain 10 psig (69kPa) at the heater, use a one

inch or larger service line and verify that 5 psig (34kPa) natural gas pressure is available when the heater

is operating. Install a line strainer between the natural gas heater and the service line.

Check all connections for leaks with a soap test. Open the supply valve at the source and use a liquid

detergent and brush all fittings and joints. If bubbles are generated at the fitting, gas is escaping from

the joint. With the installation of the service line, inspect all parts that are added, and the heater

plumbing parts affected by the installation. Tighten the components that are not sealing and replace if

cracked or defective.

Note: Do not use galvanized pipe fittings.

High Limit Installation

The High Limit control is connected by conduit to the control enclosure of the heater. The High Limit

will need to be installed into the bin plenum as shown in the following illustration. Install the high limit

on the right hand side of the transition, 2’ - 3’ (.60m - .91m) from the transition, approximately midway

up in plenum space under the drying floor. Drill a 4.0" (10.16cm) diameter hole centered on a valley of

the bin corrugation. Next place the limit control in the 4.0" (10.16cm) hole and match drill (4) 7/32"

(.55cm) diameter mounting holes located on the corrugation hill. Field seal around the high limit and

fasten using (4) 1/4" (.64cm) sheet metal screws located in the bolt bag to secure the High Limit to the

bin wall.

Chief Industries, Inc. 800-359-7600 INSTALLATION - 416274 Page 24

Page 25

Fan Electrical Installation

C E N T R I F U G A L H E A T E R - C S A

Connect the fan unit to the electric power source following the recommended wiring procedure

indicated in the fan manual. The electrical disconnect switch for the fan shall be sized with adequate

ampacity for the fan rating and installed in accordance with the Canadian Electrical Code Part 1 (CSA

Standard C22.1) and any local requirements.

Heater Electrical Installation

Note: The heater is electrically interlocked with the fan electrical service.

The heater operates on 115 volt, single phase, 60 cycle power. For fans wired for 230 volt, verify that

the fan is wired with a neutral wire to the middle terminal of the fan terminal block (#2), as well as a

ground wire linked to the bottom terminal of the fan terminal block (#3) as shown. The heater power

cord is wired into the fan controls by connecting the black wire to the terminal (#1), the white wire to

terminal (#2), and the green wire to terminal (#3) of the fan terminal block, as shown. With the heater

wired into the fan circuitry, the fan must be operating before power is available to the heater.

Chief Industries, Inc. 800-359-7600 INSTALLATION - 416274 Page 25

Page 26

C E N T R I F U G A L H E A T E R - C S A

For fans wired for 460 or 575 volt, three phase power and 230 volt, three phase power, a step down

transformer must be used to convert the 460 or 575 volt system and 230 volt system to 115 volt, single

phase, 60 cycle power for the heater.

When installing a thermostat, humidistat, or thermostat-humidistat control, the control power cord is

wired into terminals #6 and #7 of the heater terminal block. Remove the jumper wire linking terminals

#6 and #7, and connect one lead of the control power cord to terminal #6 and the other lead to

terminal #7. The control leads can be interchanged.

Installation of External Plenum Controls

For the proper installation of a thermostat, humidistat, or thermostat-humidistat control to the bin, the

installation of a dual humidistat-thermostat kit, or the installation of a vaporizer or a modulating valve

to the heater, refer to the installation instruction provided with each accessory.

Operating Instructions

Heater Control:

Information on the operating characteristics of the Centrifugal heater with a flame sensing system is

outlined in the following illustration. The flame sensing relay is reset by de-energizing the heater circuit

after a loss of flame condition.

Chief Industries, Inc. 800-359-7600 INSTALLATION - 416274 Page 26

Page 27

C E N T R I F U G A L H E A T E R - C S A

The operating characteristics of the flame sensing circuit are outlined as follows:

1. The flame probe is checked for proper functionality every time the heater is started. The heater

toggle switch is pushed to the “START” position. If the flame probe is in good condition, the purge

light is illuminated. If the flame probe is not good, the flame probe will require replacement.

2. Once the flame probe is checked, the remaining internal and external heater sensors have power

available. If all sensors call for heater operation, after a 30 second time frame to complete the purge

cycle, the transformers and solenoids are energized, and the ignition light is illuminated.

3. If no flame is at the burner or the flame probe is not positioned to monitor the flame, the flame

sensing relay will de-energize the solenoids and transformer after approximately 30 seconds. The

flame lock-out light will be illuminated. The condition that resulted in the loss of flame at the flame

probe needs to be addressed. The flame sensing relay is reset by switching the heater power switch to

“OFF”.

4. The heater then can be restarted by repeating the operation steps.

Start-Up Procedure:

Note: The heater is designed to operate at various firing rates. The operator must adjust

the firing rate for correct operation based upon the conditions present.

Chief Industries, Inc. 800-359-7600 OPERATION - 416274 Page 27

Page 28

C E N T R I F U G A L H E A T E R - C S A

Refer to the dryer rating plate to locate the minimum gas supply pressure for obtaining the

maximum gas capacity for which this dryer is specified.

1. Verify all roof vents are open and unobstructed. Note: if freezing of roof vents could occur,

do not operate the system.

2. Verify all controls are installed correctly. Refer to the ratings plate for determining the

minimum gas supply pressure to achieve the maximum gas capacity for which the heater is

specified.

3. Turn fan on by placing fan switch in an "On" position.

4. Open supply valve at the regulator.

a. It is preferable to start liquid propane units on vapor fuel. (After warm up, open liquid

valve on the supply tank approximately 1 turn, and close vapor valve.)

5. Open liquid valve (on LPGE Heaters only).

6. Open vapor valve.

7. Turn heater on by placing toggle switch to “Momentary Start” then "On" position.

8. Open regulator at heater slowly to 2 psig (14kPa) fuel pressure for low temperature start.

9. Set plenum external controls for desired heater operation. (See adjustment section of this

manual for more information.)

10. Wait at least 40 seconds for ignition to occur. The heater has a 30-second pre-purge before

ignition.

11. Perform a gas leak check during start up to verify the gas tightness of the gas train components

and piping under normal operating conditions.

12. If burner fails to ignite in 40 seconds, close regulator and vapor valve and turn off the heater by

placing toggle switch to the "Off" position. (Refer to service section of this manual for trouble

shooting of heater.)

13. If the high limit shuts the burner off, the high limit indicator light will be illuminated. Once the

high limit has cooled to a lower temperature, the high limit is reset by turning the heater switch

off and then back on. The repeated shutting off of the burner by the burner high limit is caused

by excessive static pressure, lack of air flow or a firing rate set too high. Reduce the static

pressure or air blockage before re-firing unit. If needed adjust the firing rate.

Drying Temperature Recommendations:

To determine the appropriate drying temperature, the crop to be dried and the drying system used must

be established. When this information is known, refer to the following table for the recommended

maximum plenum temperatures.

In using the recommended drying temperatures please be aware of the following information:

1. The rate of drying is increased with increased temperature, however susceptibility to grain

damage also increases.

Chief Industries, Inc. 800-359-7600 OPERATION - 416274 Page 28

Page 29

C E N T R I F U G A L H E A T E R - C S A

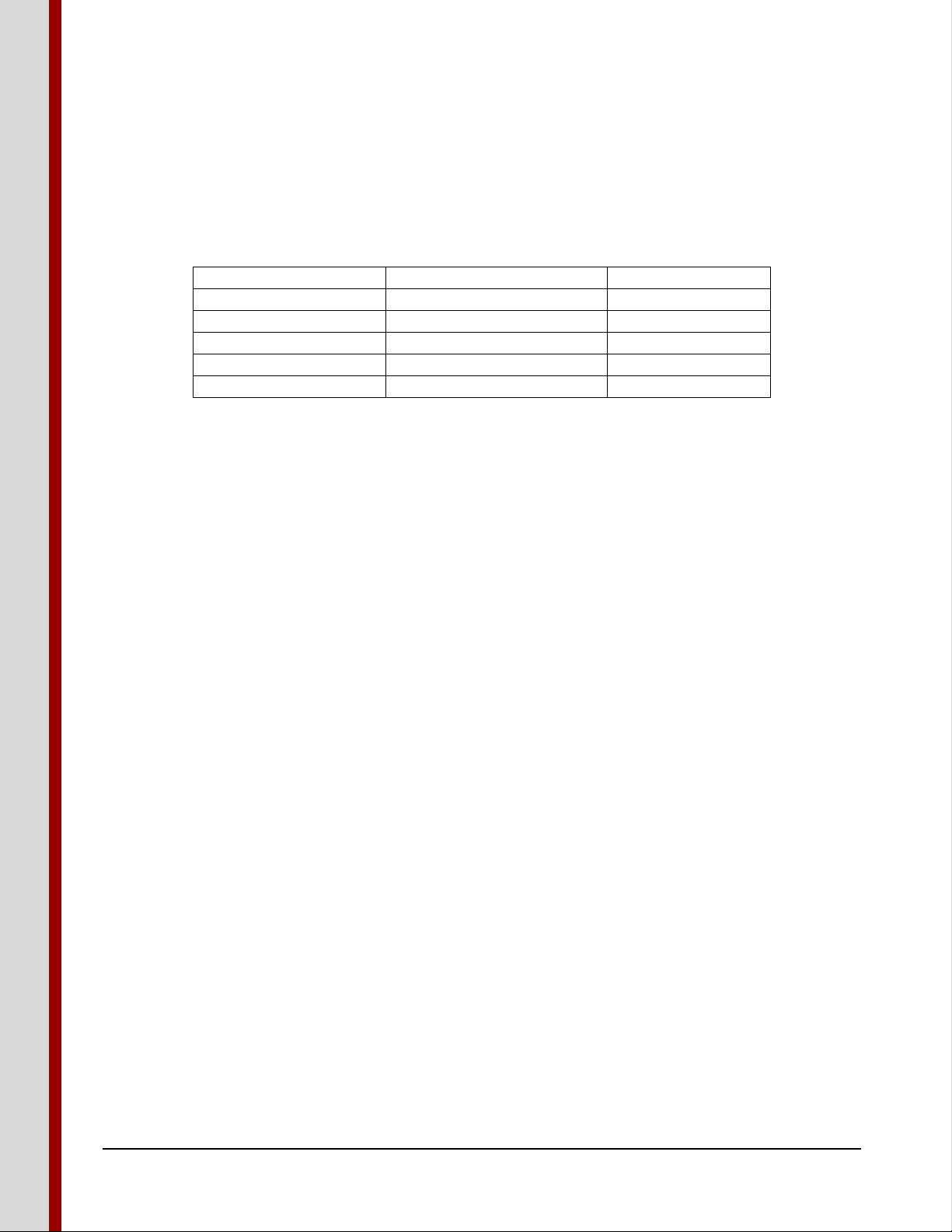

Recommended Drying Temperatures of Non-Seed Crops

Crop

In Bin Continuous Drying

Stir Drying

In Bin Batch Drying

Corn

160°F (71°C)

140°F (60°C)

120°F (49°C)

Grain Sorghum

160°F (71°C)

140°F (60°C)

120°F (49°C)

Wheat

140°F (60°C)

120°F (49°C)

110°F (43°C)

Rice

105°F (40°C)

100°F (38°C)

90°F (32°C)

Oats

140°F (60°C)

120°F (49°C)

110°F (43°C)

Sunflowers

110°F (43°C)

110°F (43°C)

100°F (38°C)

Soybeans

120°F (49°C)

120°F (49°C)

110°F (43°C)

Pinto Beans

100°F (38°C)

100°F (38°C)

100°F (38°C)

2. Wet grain will remain relatively cool due to moisture evaporation from the kernel, however dry

grain will warm to the drying temperature.

3. The drying front moves from the base of the bin upward. When operated as a batch system and

when a stirring machine does not reach the floor, significant over drying can occur at the base of

the bin.

4. When drying grain and focusing on kernel quality, use as low a plenum temperature as possible.

Note: Do not automatically set the plenum temperature at the maximum

recommendation.

5. When the grain is nearly dry, reduce the plenum temperature to complete the drying. This will

reduce the quantity of cracked grain generated and reduce the fire hazard.

6. When drying sunflowers, exercise caution because sunflowers are very flammable. Do not

exceed the temperature recommendations. Also, be aware that the chaff from sunflowers is

very flammable. Good housekeeping in the plenum chamber and around the bin is essential.

- Note: Temperature recommendations are based on non-seed crops (to be marketed

commercially). For seed crops, do not exceed 110°F (43°C), except for pinto beans

do not exceed 100°F (38°C).

- For other crops contact your extension service or Chief for drying temperature

recommendations.

Chief Industries, Inc. 800-359-7600 OPERATION - 416274 Page 29

Page 30

C E N T R I F U G A L H E A T E R - C S A

Adjustments:

The following adjustments will have to be made, depending upon the kind of heater and plenum

external controls being used. These adjustments cannot be made at the factory due to the differences in

bin setups, drying methods, and weather climates. These adjustments should be checked at least twice a

day or every 6 hours of operation to verify that the heater is functioning properly, and that the desired

results are being achieved. In using the recommended drying temperatures keep the following

considerations in mind:

Vaporizer Adjustment

The vaporizer is used on LPGE units and is located in the flame established by the burner. The

vaporizer uses heat from the burner to convert the liquid propane at the vaporizer entrance to vapor

propane. The burner requires vapor propane for proper operation.

The vaporizer outlet is connected to the vapor plumbing line by a vapor propane hose. The

temperature of the vapor plumbing line is sensed by a vapor limit thermostat, which will cycle the heater

off if the temperature exceeds 160°F (71°C). The proper location of the vaporizer will establish a vapor

plumbing line temperature of about 110°F (43°C). At this temperature, the vapor plumbing line should

be warm to touch. If the temperature of the vapor plumbing line is too low, move the vaporizer into

the flame by loosening the square headed setscrew holding the vaporizer in place, adjusting the

vaporizer location and re-tightening the setscrew. If the temperature of the vapor plumbing line is too

high, the vaporizer should be moved out of the flame with the procedure indicated above.

Regulator Adjustment

The regulator should be set at the firing rate required. This can be done by first setting the heater to the

desired firing rate with the vapor valve, then reopening the vapor valve and adjusting the regulator by

turning the adjusting screw until the pressure gauge shows the desired pressure at the desired firing rate.

When setting the heater at the desired firing rate, the operator must take into account the heater size,

the static pressure the fan is working against, the ambient temperature, orifice size, and fuel used and

the type of plenum control. Refer to operation instructions that are supplied with the humidistat,

thermostat, or modulating valve. The Firing Rate Tables of this manual are set up to help the operator

select the desired firing rate.

Humidistat Control Adjustment (Heater Operation)

Set the humidistat control at the desired setting (50% - 60% relative humidity is recommended). To

obtain even drying, adjust the firing rate of the heater unit so that the humidistat maintains a constant

humidity of the drying air. The heater should be set at a firing rate of approximately 2 psig (14kPa) for

propane, or 1 psig (7kPa) for natural gas, and then be adjusted to maintain correct operation of the

heater. The heater firing rate must be checked as humidity conditions change.

Thermostat Control Adjustment (Heater Operation)

Chief Industries, Inc. 800-359-7600 OPERATION - 416274 Page 30

Page 31

C E N T R I F U G A L H E A T E R - C S A

Set the thermostat control to the desired temperature setting. Initially, set the firing rate of the heater at

2 psig (14kPa) pressure for propane, or 1 psig (7kPa) pressure for natural gas. To obtain even drying,

adjust the firing rate of the heater unit so that the thermostat calls for heat 90% of the time. The heater

firing rate must be checked as temperature conditions change.

Warning: The plenum thermostat is used as a drying thermostat, not as a plenum high limit.

Humidistat - Thermostat Control Adjustment

1. Humidistat Control Only

Set the thermostat at the lower temperature limit. This is the temperature wanted for heater operation,

whether the humidistat is calling for heat or not, 40°F-50°F (4.4°C-10°C) is recommended. Set the

humidistat and heater according to the humidistat instructions previously given.

2. Thermostat Control Only

Set the humidistat at 100% relative humidity. Then adjust the thermostat and heater controls according

to the thermostat instructions given.

3. Humidistat - Thermostat Combination

Set the humidistat and thermostat at the desired operating conditions. Then adjust the firing rate of the

heater according to the humidistat and thermostat instructions.

Modulating Valve Adjustment (Heater Operation)

The modulating valve is used to maintain a constant plenum temperature by allowing more gas to flow

to the burner if the plenum temperature is lower than desired, or by restricting the gas flow if the

temperature is higher than desired.

To set the modulating valve, use the following procedures:

1. Determine what plenum temperature is desired.

2. Using the vapor valve, set the operating pressure at 8 psig (55kPa) for propane, or 3 psig

(21kPa) for natural gas.

3. Adjust the "T" Handle of the valve until the bin thermometer maintains the desired plenum

temperature. The handle is turned in, (clockwise) to get a higher temperature, or out (counterclockwise) to get a lower temperature.

4. Set the regulator 2 psig (14kPa) higher than the modulating valve operating condition, by

turning the modulating valve handle in (clockwise) 2 revolutions, adjusting the regulator to the

desired pressure, and then resetting the modulating valve to the desired plenum temperature

Shut Down Procedures

If the heater is to be shut off for a prolonged period, carry out the following steps:

Chief Industries, Inc. 800-359-7600 OPERATION - 416274 Page 31

Page 32

C E N T R I F U G A L H E A T E R - C S A

1. Close the fuel valve at tank.

2. Allow the fuel to be burned out of the fuel line.

3. After the flame burns out, close vapor valve, regulator valve and liquid valve.

4. Turn off heater, placing toggle switch to "Off" position.

5. Allow fan to run for 2 minutes in order to cool off heater. Next shut the fan off. Finally shut

off the power at the fan service disconnect.

6. The thermostat or humidistat external plenum controls should be removed and stored in a

clean, dry place.

Firing Rate Guideline Tables

The following tables are to be used as a guide for setting the firing rate of the heater. The values are an

estimate - the actual values may vary, depending upon the bin setup and weather conditions. Once the

predicted firing rate is obtained, a bin thermometer should be used to determine the actual plenum

temperature, and then the firing rate should be adjusted to obtain the desired plenum temperature. Use the

following procedures in conjunction with the "Drying Temperature Recommendations", in determining the

firing rate needed for your application:

1. Determine the ambient temperature at which the heater will be operating (e.g. the outside air

temperature).

2. Find the difference of the desired drying temperature and the ambient temperature. This value

is the temperature rise desired.

3. Use a static pressure gauge to determine the static pressure at which the fan and heater are

operating.

4. Refer to the following tables which list the size of your heater, the gas used, and the temperature

rise desired. Locate the required firing rate for the operating static pressure.

5. If the ambient temperature is 50°F (10°C), then the firing rate can directly be read for your

heater, gas used, and plenum temperature for 50°F (10°C) ambient air.

Note: As conditions vary, the firing rate should be adjusted to obtain the desired plenum

temperature.

Chief Industries, Inc. 800-359-7600 OPERATION - 416274 Page 32

Page 33

C E N T R I F U G A L H E A T E R - C S A

STATIC PRESSURE (INCHES OF WATER COLUMN)

1.0 2.0 3.0 4.0

PLENUM PLENUM PLENUM PLENUM

FIRING TEMP. TEMP. FOR TEMP. TEMP. FOR TEMP. TEMP. FOR TEMP. TEMP. FOR

RATE RISE

50oF AMBIENT

RISE

50oF AMBIENT

RISE

50oF AMBIENT

RISE

50oF AMBIENT

PSIG

(oF) AIR (oF) (oF) AIR (oF) (oF) AIR (oF) (oF) AIR (oF)

3.0 79 129 84 134 90 140 98 148

4.0 91 141 97 147 104 154 113 163

5.0 101 151 108 158 116 166 126 176

6.0 112 162 119 169 128 178 139 189

7.0 126 176 134 184 144 194 156 206

8.0 138 188 147 197 158 208 171 221

9.0 148 198 157 207 167 217 181 231

10.0 156 206 166 216 178 228 193 243

11.0 164 214 174 224 187 237 203 253

12.0 171 221 182 232 195 245 211 261

STATIC PRESSURE (INCHES OF WATER COLUMN)

1.0 2.0 3.0 4.0

PLENUM PLENUM PLENUM PLENUM

FIRING TEMP. TEMP. FOR TEMP. TEMP. FOR TEMP. TEMP. FOR TEMP. TEMP. FOR

RATE RISE

50oF AMBIENT

RISE

50oF AMBIENT

RISE

50oF AMBIENT

RISE

50oF AMBIENT

PSIG

(oF) AIR (oF) (oF) AIR (oF) (oF) AIR (oF) (oF) AIR (oF)

1.0 73 123 78 128 83 133 90 140

1.5 90 140 96 146 103 153 112 152

2.0 104 154 111 161 119 169 129 179

2.5 116 166 124 174 133 183 144 194

3.0 128 178 136 186 146 196 158 208

3.5 139 189 148 198 159 209 172 222

4.0 150 200 160 210 172 222 186 236

Approximate firing rates for CH1015T heater with C27-10 Centrifugal fan operated on vapor

propane with 7/32” (5.55mm) diameter orifice:

Approximate firing rates for CH1015T heater with C27-10 Centrifugal fan operated on

natural gas with 3/8" (9.52mm) diameter orifice:

Chief Industries, Inc. 800-359-7600 OPERATION - 416274 Page 33

Page 34

C E N T R I F U G A L H E A T E R - C S A

STATIC PRESSURE (INCHES OF WATER COLUMN)

1.0 2.0 3.0 4.0

PLENUM PLENUM PLENUM PLENUM

FIRING TEMP. TEMP. FOR TEMP. TEMP. FOR TEMP. TEMP. FOR TEMP. TEMP. FOR

RATE RISE

50oF AMBIENT

RISE

50oF AMBIENT

RISE

50oF AMBIENT

RISE

50oF AMBIENT

PSIG

(oF) AIR (oF) (oF) AIR (oF) (oF) AIR (oF) (oF) AIR (oF)

3.0 64 114 68 118 74 124 80 130

4.0 73 123 78 128 85 135 92 142

5.0 81 131 86 136 94 144 102 152

6.0 90 140 96 146 105 155 115 165

7.0 101 151 108 158 118 168 129 179

8.0 111 161 118 168 129 179 141 191

9.0 119 169 127 177 139 189 152 202

10.0 126 176 134 184 146 196 159 209

11.0 132 182 141 191 154 204 168 218

12.0 138 188 147 197 160 210 175 225

STATIC PRESSURE (INCHES OF WATER COLUMN)

1.0 2.0 3.0 4.0

PLENUM PLENUM PLENUM PLENUM

FIRING TEMP. TEMP. FOR TEMP. TEMP. FOR TEMP. TEMP. FOR TEMP. TEMP. FOR

RATE RISE

50oF AMBIENT

RISE

50oF AMBIENT

RISE

50oF AMBIENT

RISE

50oF AMBIENT

PSIG

(oF) AIR (oF) (oF) AIR (oF) (oF) AIR (oF) (oF) AIR (oF)

1.0 59 109 63 113 68 118 74 124

1.5 72 122 77 127 83 133 91 141

2.0 84 134 89 139 96 146 105 155

2.5 93 143 99 149 107 157 117 167

3.0 103 153 110 160 118 168 129 179

3.5 112 162 119 169 128 178 140 190

4.0 121 171 129 179 139 189 152 202

Approximate firing rates for CH1015T heater with C27-15 Centrifugal fan operated on

propane with 7/32" (5.55mm) diameter orifice:

Approximate firing rates for CH1015T heater with C27-15 Centrifugal fan operated on

natural gas with 3/8” (9.52mm) diameter orifice:

Chief Industries, Inc. 800-359-7600 OPERATION - 416274 Page 34

Page 35

C E N T R I F U G A L H E A T E R - C S A

STATIC PRESSURE (INCHES OF WATER COLUMN)

1.0 2.0 3.0 4.0

PLENUM PLENUM PLENUM PLENUM

FIRING TEMP. TEMP. FOR TEMP. TEMP. FOR TEMP. TEMP. FOR TEMP. TEMP. FOR

RATE RISE

50oF AMBIENT

RISE

50oF AMBIENT

RISE

50oF AMBIENT

RISE

50oF AMBIENT

PSIG

(oF) AIR (oF) (oF) AIR (oF) (oF) AIR (oF) (oF) AIR (oF)

3.0 44 94 46 96 49 99 53 103

4.0 60 110 63 113 67 117 72 122

5.0 75 125 79 129 84 134 90 140

6.0 90 140 95 145 100 150 107 157

7.0 100 150 105 155 111 161 119 169

8.0 108 158 114 164 120 170 129 179

9.0 116 166 122 172 129 179 138 188

10.0 123 173 129 179 136 186 146 196

11.0 129 179 136 186 144 194 155 205

12.0 135 185 142 192 150 200 161 211

STATIC PRESSURE (INCHES OF WATER COLUMN)

1.0 2.0 3.0 4.0

PLENUM PLENUM PLENUM PLENUM

FIRING TEMP. TEMP. FOR TEMP. TEMP. FOR TEMP. TEMP. FOR TEMP. TEMP. FOR

RATE RISE

50oF AMBIENT

RISE

50oF AMBIENT

RISE

50oF AMBIENT

RISE

50oF AMBIENT

PSIG

(oF) AIR (oF) (oF) AIR (oF) (oF) AIR (oF) (oF) AIR (oF)

1.0 37 87 39 89 41 91 44 94

1.5 46 96 48 98 51 101 55 105

2.0 53 103 56 106 59 109 63 113

2.5 71 121 75 125 79 129 85 135

3.0 83 133 87 137 92 142 99 149

3.5 90 140 95 145 100 150 107 157

4.0 110 160 116 166 122 162 131 181

Approximate firing rates for CH2025T heater with C30-20 Centrifugal fan operated on

propane with 1/4" (6.35mm) diameter orifice:

Approximate firing rates for CH2025T heater with C30-20 Centrifugal fan operated on

natural gas with 7/16” (11.11mm) diameter orifice:

Chief Industries, Inc. 800-359-7600 OPERATION - 416274 Page 35

Page 36

C E N T R I F U G A L H E A T E R - C S A

STATIC PRESSURE (INCHES OF WATER COLUMN)

1.0 2.0 3.0 4.0

PLENUM PLENUM PLENUM PLENUM

FIRING TEMP. TEMP. FOR TEMP. TEMP. FOR TEMP. TEMP. FOR TEMP. TEMP. FOR

RATE RISE

50oF AMBIENT

RISE

50oF AMBIENT

RISE

50oF AMBIENT

RISE

50oF AMBIENT

PSIG

(oF) AIR (oF) (oF) AIR (oF) (oF) AIR (oF) (oF) AIR (oF)

3.0 37 87 39 89 41 91 44 94

4.0 51 101 53 103 56 106 59 109

5.0 64 114 67 127 70 120 74 124

6.0 77 127 81 131 84 134 88 138

7.0 85 135 89 139 93 143 98 148

8.0 92 142 97 147 100 150 106 156

9.0 99 149 103 153 108 158 114 164

10.0 105 155 109 159 114 164 120 170

11.0 110 160 115 165 121 171 128 178

12.0 115 165 120 170 126 176 133 183

STATIC PRESSURE (INCHES OF WATER COLUMN)

1.0 2.0 3.0 4.0

PLENUM PLENUM PLENUM PLENUM

FIRING TEMP. TEMP. FOR TEMP. TEMP. FOR TEMP. TEMP. FOR TEMP. TEMP. FOR

RATE RISE

50oF AMBIENT

RISE

50oF AMBIENT

RISE

50oF AMBIENT

RISE

50oF AMBIENT

PSIG

(oF) AIR (oF) (oF) AIR (oF) (oF) AIR (oF) (oF) AIR (oF)

1.0 32 82 33 83 35 85 37 87

1.5 39 89 41 91 43 93 46 96

2.0 45 95 48 98 49 99 52 102

2.5 60 110 64 114 66 116 70 120

3.0 71 121 74 124 77 127 82 132

3.5 77 127 81 131 84 134 88 138

4.0 94 144 98 148 102 152 108 158

Approximate firing rates for CH2025T heater with C30-25 Centrifugal fan operated on

propane with 1/4" (6.35mm) diameter orifice:

Approximate firing rates for CH2025T heater with C30-25 Centrifugal fan operated on

natural gas with 7/16” (11.11mm) diameter orifice:

Chief Industries, Inc. 800-359-7600 OPERATION - 416274 Page 36

Page 37

C E N T R I F U G A L H E A T E R - C S A

Heater Maintenance

The following procedures should be followed and maintenance performed before starting the unit at the

beginning of every season, and also during operation:

1. The fuel line strainers should be taken out and cleaned. A plugged screen will restrict the gas

flow to the unit. On liquid propane units, liquid and vapor line strainers both should be

checked. Warranty is void if the strainer or screen is removed, and not reinstalled after cleaning.

2. The burner should be checked for obstructions and debris. To check, use a piece of wire or drill

bit that will fit the holes in the burner. To clean the inside of the burner, remove from the

heater and tap lightly around the burner. Then pour the foreign material out of the inlet.

3. The air switch inlet screen should be cleaned. This screen keeps debris from entering the air

switch; however, during operation the screen can become clogged or dirty.

4. Check all plumbing joints for leaks using the "soap test." The gas tightness of the gas train

should be checked at least on an annual basis. (See previous installation instructions).

5. Check all wires to verify they are not bare or causing a short. Pests can destroy insulation on

wires, including the spark plug, flame probe, burner limit wires if protective measures to control

rodents are not implemented.

6. Examine and gap spark plug. Through wear, the spark plug can go out of adjustment. Verify

during operation every two days. The gap of the plug should be 1/8” (.32cm).

7. The flame probe needs to be checked to be sure that it has not been burnt off due to lack of

proper adjustment in and out of the flame. The flame probe can also become damaged. Verify

every two days during operation and replace or adjust as needed. (See adjustment section).

8. Check all wire connections to be sure they are tight.

9. All external plenum controls (nylon humidistat or thermostat combination) should be inspected,

cleaned, and checked every three days during operation.

10. Caldwell recommends that external plenum controls be removed and stored in a clean, dry place

when not in use.

11. Check adjustment of the vaporizer twice daily, or as changing weather conditions demand. (See

heater adjustment section).

Chief Industries, Inc. 800-359-7600 MAINTAINENCE - 416274 Page 37

Page 38

C E N T R I F U G A L H E A T E R - C S A

Heater Wiring Diagram

Note: When used with a 575 volt, 460 volt, or 230 volt fan, a step down transformer must be used to

develop 115 volt, 1 phase, 60hz power.

Chief Industries, Inc. 800-359-7600 MAINTAINENCE - 416274 Page 38

Page 39

C E N T R I F U G A L H E A T E R - C S A

Chief Industries, Inc. 800-359-7600 MAINTAINENCE - 416274 Page 39

Page 40

C E N T R I F U G A L H E A T E R - C S A

Servicing the Heater:

The following will help you find any problems that may occur in the heater unit and includes tips for

repair. For servicing of electrical systems, open the control box cover. Inside the cover you will find a

wiring schematic to help you service the unit. In the checks shown below, locate the symptoms you are

experiencing with your unit and follow the list of corresponding possible causes and remedies:

Note: Unless otherwise indicated, checks are made with the power off using a voltmeter on resistance

setting.

Generic Sequential Operations Check:

1. Lack of power going to the unit (check made with power on).

a. Take a voltmeter or continuity tester, put one lead to ground and the other on the top

terminal of terminal block in fan control box. Power lead is the black wire on the top

terminal (#1) on the terminal block. When the fan is operating, it should indicate 115

volts on the voltmeter or the light should come on using a continuity tester.

2. Improper Neutral.

a. Verify neutral wire is connected to the terminal block in the fan control box. Neutral to

be provided from disconnect to fan control box with the power supply.

3. Fuse may be blown.

a. Visually check fuse. If dark in color, replace.

b. Check fuse and holder. Put one lead on each side of the fuse on the fuse holder screws.

Meter should show continuity through fuse.

4. Check for power at toggle switch in heater (check made with power on).

a. Put one lead of voltmeter to toggle switch where power cord is connected and the other

lead to ground. If there is not any power, check cord and fuse for damage.

5. Flame probe may be in an open condition. Note: The heater control is wired to check the

continuity of the Flame Probe each time the heater is started. If the Flame Probe is in an open

condition, the Flame Probe will prevent heater operation. Verify all wires are connected

properly.

a. Use a voltmeter and check for continuity across the flame probe. If no continuity is

present and the flame probe has cooled down, replace the flame probe. Check the wires

to the flame probe. If they are damaged replace the flame probe wire.

6. Thermostat or Humidistat control may be open.

a. Use a voltmeter and check continuity across the terminal block where the 2 leads of the

control are connected (terminals 6 and 7).

b. If no continuity is present, check the control setting to call for heater operation. Check

for damaged wires to the control. If either wire is damaged replace the wire. Replace

entire thermostat or humidistat.

7. The vapor limit switch may be defective (LPGE units only)

Chief Industries, Inc. 800-359-7600 MAINTAINENCE - 416274 Page 40

Page 41

C E N T R I F U G A L H E A T E R - C S A

a. Use voltmeter and check continuity between terminals 5 and 6 on terminal block. If

there is no continuity, replace switch. (Verify that the vapor limit switch has had

sufficient time to cool and automatically reset).

8. Air switch may be defective.

a. With the fan running, check continuity across the air switch. If no continuity is present

and the fan is delivering air, the problem is in the air switch or in the venturi.

b. Verify the screen on the venturi is not plugged. If the fan is working against 4" static

pressure or lower, the heater should operate.

9. High limit may be closed.

a. Use voltmeter to check for continuity between the two leads going to high limit channel.

(Terminal #1 on the terminal block and #3 on the start relay.)

b. If there is no continuity, remove the sensor from the bin. Check the switch individually

by putting leads of voltmeter on the two screws that have wires attached. The switch

should not show continuity. Replace switch if defective. If switches are functional, the

limit wire is defective. Replace damaged wire.

10. Flame sensing relay is not completing the circuit.

a. Turn off switch to de-energize the circuit. Check the continuity of the contacts of the

relay. Check for continuity in the normally closed set of contacts (2 and 4, also 5 and 7).

A lack of continuity indicates a defective relay. Replace the relay.

b. Supply power (115V and neutral) to the coil (terminals 1 and 8). Check power at the

normally open set of contacts (2 and 3, also 6 and 7). After power has been supplied to

the relay for 30 seconds, power should be present at the terminals. If not, replace the

relay.

11. Purge delay may be defective.

a. Turn off switch to de-energize the circuit. Check the continuity at the contacts of the

relay. Check for continuity in the normally closed set of contacts (2 and 4, also 5 and 7).

A lack of continuity indicates a defective relay. Replace the relay.

b. Supply power (115v and neutral) to the coil (terminals 1 and 8). Check power at the

normally open set of contacts (2 and 3, also 6 and 7). After power has been supplied to

the relay for 30 seconds power should be present at the terminals. If not replace the

relay.

12. Check all wires and connectors to verify they are functional and installed correctly.

a. See wiring schematic for correct installation.

Condition Specific Faults:

1. Symptom: No ignition, Lack of ignition spark, Gas is present.

a. Transformer is defective (power on).

i. Take the cap holding the spark plug wire off and remove the spark plug wire

from the transformer. With the transformer energized, ground an insulated

Chief Industries, Inc. 800-359-7600 MAINTAINENCE - 416274 Page 41

Page 42

C E N T R I F U G A L H E A T E R - C S A

screwdriver and arc to the transformer post where spark plug wire was

connected. Caution: Do not touch the screwdriver shaft.

ii. If no arc is present or is less than 1/8” (.31cm) replace transformer.

b. Spark plug wire is defective (power on).

i. Take wire off spark plug and arc to heater. Caution: Do not touch the

mounting terminal of the spark plug wire. If no arc is present or is less than

1/8” (.31cm) replace wire.

c. Spark plug is defective

i. Check gap of plug. Verify gap is 1/8” (.31cm).

ii. If transformer and spark plug wire are functional replace the spark plug.

2. Symptom: No ignition, Lack of gas with spark present. Note: The check to verify gas is

present should be made after all the electrical component checks are made, and the electrical

controls are confirmed to be functioning properly. Note: that the purge delay develops a 30

second delay for the solenoids to open.

a. Lack of gas to the heater.

i. Check tank to see if ample pressure is available to start unit. Unit requires 35

psig (241kPa) of propane pressure and 5 psig (34kPa) of natural gas available at

the unit for startup.

ii. Check to see if the tank, regulator, or line going to the unit is blocked.

b. Check to see if the solenoids are functioning.

i. (Power On) Put your hand on the top of the solenoid and turn the heater toggle

switch on and allow 30 seconds for the purge. If you feel a click at the top of

the solenoid, the coil is functional and the solenoid is working electrically. If

there is no click, the coil is defective and should be replaced.

ii. (Power Off) Check solenoid to see if screen is plugged or the diaphragm is

defective. Unscrew the top of the brass fixture and locate the screen and

diaphragm inside. Be sure to reassemble properly. Reversing any parts in the

solenoid will cause the solenoid not to function properly. Keep all foreign

material out of the solenoid.

c. Obstruction in the gas line.

i. Install pressure gauges at available locations in the plumbing line to determine

where a fuel restriction could exist.

d. If gas is present at the pressure gage but unit lacks gas for ignition.

i. Check orifice size, and be sure it is clean. (See Firing Rate Tables.)

ii. Check burner. See that holes are not plugged. See that the tubing isn't plugged

by debris.

3. Symptom: Flame sensing relay locks ignition out.

a. If ignition is not present.

Chief Industries, Inc. 800-359-7600 MAINTAINENCE - 416274 Page 42

Page 43

C E N T R I F U G A L H E A T E R - C S A

i. Refer to the steps outlined previously in: “Condition Specific Faults/No ignition,

Lack of gas with spark present” and “Condition specific Faults/No ignition,

Lack of ignition spark, Gas present”

b. If ignition is present.

i. Check position of the flame probe for proper adjustment.

ii. Defective flame probe. When flame is present, the flame probe contacts should

be in an “open” position. If contacts are “closed”, replace the flame probe.

iii. Check flame probe wire and replace if defective. Check wire for bare spots and

shorts to ground. Flame probe should not show continuity from either wire to

ground. Check the two wires in the flame probe wire assembly to see if they are

shorting across in the assembly. With the wires removed from the flame probe,

there should be no continuity.

c. Defective flame sensing relay (power on).

i. With the switch off, shut off gas supply at heater plumbing with ball valve. Push

the switch to the start position and release. Remember that there is a 30 second

purge delay. After the 30 second purge delay, the flame sensing relay should

have power to the coil for an additional 30 seconds. After 30 seconds elapses

the circuit collapses and the flame lockout light turns on. If the coil does not

activate the contacts within 30 seconds, or the light does not illuminate

afterwards, replace the flame sensing relay.

4. Symptom: High limit is activated.

a. Fan limit may be obstructed. Keep the fan screen clean of all foreign material.

b. Fan motor may be failing. Check the motor to verify that it is obtaining full speed.

c. Verify that static pressure is not excessive with a static pressure gage. Verify that roof