Page 1

I N S T R U C T I O N M A N U A L

Plasma Display

Electric

Pop-Up Lift (PUL)

Your Plasma Display Electric Pop-Up Lift is designed for

installation in furniture or cabinets. Display mounting is

made easy using the Q-latch mounting system and your

PUL provides a smooth, quiet and reliable lift for your display.

The versatile Q-latch system not only makes mounting

safe and easy, it makes changing display makes and models quick and inexpensive. Simply install the PSB mounting bracket designed specifically for the display and mount

it on the PUL.

Superior performance and dependability are designed into

your PUL. The lift is made using heavy duty steel and aluminum extrusion construction. All electrical components

are UL/TUV listed and the use of low voltage, solid state

circuitry controls ensure safety and reliability.

BEFORE YOU BEGIN

• CAUTION: To prevent damage to the PUL, which could affect or void the Factory warranty, thoroughly

study all instructions and illustrations before you begin to install or operate the unit. Pay particular attention to the “Important Precautions” on Page 1.

• If you have any questions about this installation, contact Chief Manufacturing at 1-800-582-6480.

CHIEF MANUF A CTURI NG INC.

1-800-582-6480 952-894-6280 FAX 952-894-6918

8401 EAGLE CREEK PARKWAY, STE. 700

SAVAGE, MINNESOTA 55378 USA

PART NO. 8805-000009 (Rev. C)

©2000 Chief Manufacturing

www.chiefmfg.com

05-05

Page 2

Instruction Manual Plasma Display Electric Pop-Up Lift

IMPORTANT WARNINGS and CAUTIONS!

WARNING: A WARNING alerts you to the possibility of serious injury or death if you do not follow the instructions.

CAUTION: A CAUTION alerts you to the possibility of damage or destruction of equipment if you do not follow the corre-

sponding instructions.

• WARNING: Be aware during the installation that this is a motorized device, and there are pinch points for people and

for electrical wiring.

• WARNING: Be aware of the potential for personal injury or damage to the unit if it is not adequately mounted. The

lift (without a projector) weighs approximately 150 lbs (68 kg).

• WARNING: Be sure the lift is installed square and parallel in all dimensions to avoid damage to the lift. Avoid stressing the unit at any time during installation.

• WARNING: Electrical outlets must be installed by a qualified electrician. Follow all electrical codes.

• CAUTION: Vertical travel adjustment must always be made with the shelf in the middle of travel position and the power

switch OFF.

• CAUTION: The unit must always be able to reach its own limit switches and turn itself off.

• CAUTION: Test the unit for shipping damage. See “Inspect and Test the unit before installing,” on page 5.

TOOLS REQUIRED FOR INSTALLATION

• Phillips screwdrivers, No. 1 and No. 2

• Electric drill and 17/64” drill bit

• Socket set with extension

• Allen wrench set

NOTE: Other tools may be required depending on the

method of installation.

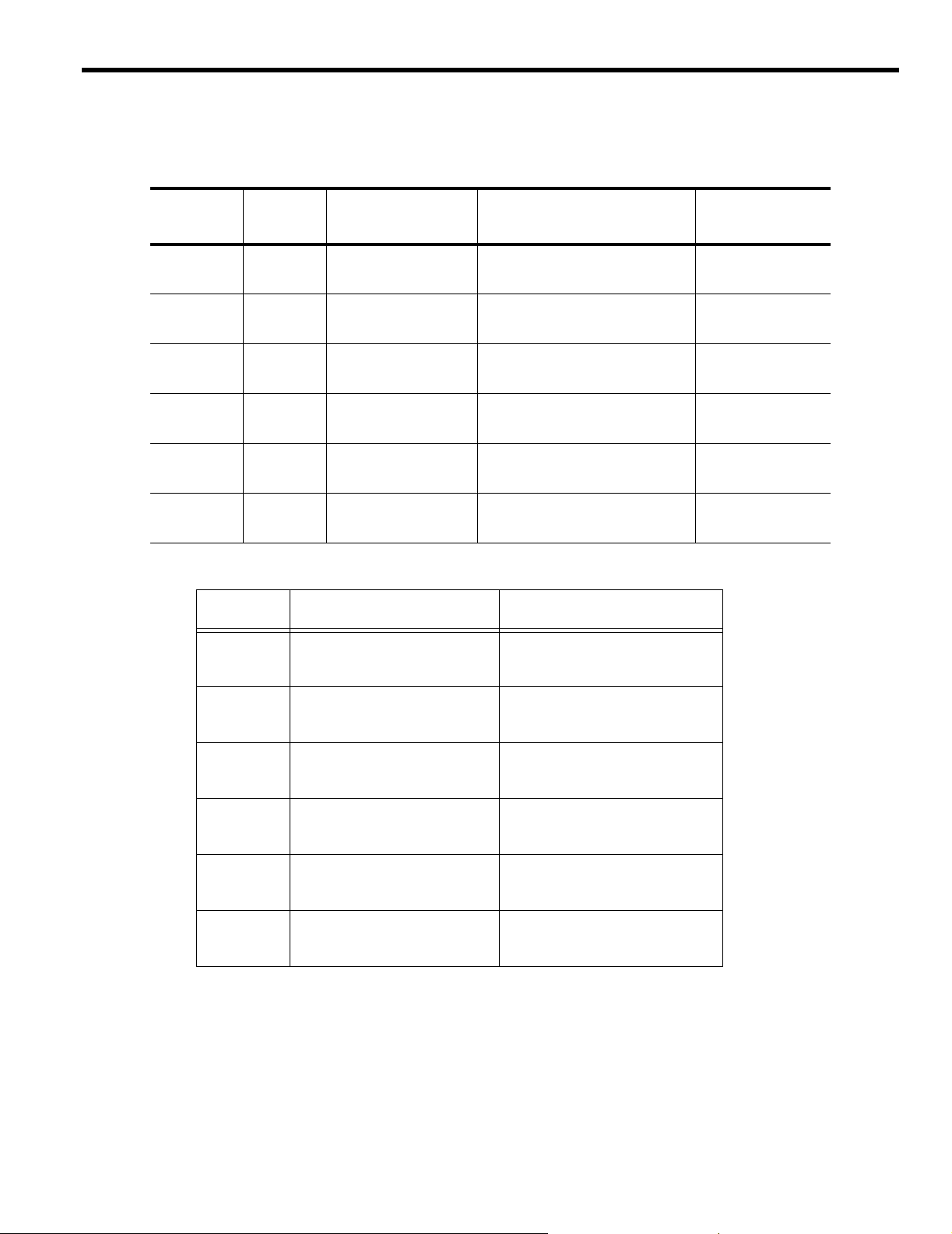

WEIGHT, SIZE, AND VERTICAL TRAVEL SPECIFICATIONS

See Table 1 on page 3 for the weight, size, and vertical travel specifications of your specific model.

1. Determine size and weight of the equipment to be lifted.

2. Determine the vertical travel height required for presentation

viewing.

1

Page 3

Instruction Manual Plasma Display Electric Pop-Up Lift

CONTENTS

WEIGHT, SIZE, AND VERTICAL

TRAVEL SPECIFICATIONS ............................. 3

DIMENSIONAL DRAWING ............................. 4

INSPECT AND TEST THE UNIT

BEFORE INSTALLING ..................................... 5

Inspect The Unit ................................................... 5

Test The Unit ....................................................... 5

PREPARE THE FURNITURE/CABINET

AND INSTALL THE LIFT ................................. 6

General Guidelines ............................................... 6

Prepare the Furniture/Cabinet .............................. 6

Furniture Opening Finish Piece Options ............. 6

Extended Position Finish Piece Option ............... 6

Retracted Position Finish Piece Option ............... 7

Install the PUL into the Cabinet .......................... 9

INSTALL THE DISPLAY ON THE LIFT ......... 10

Attach Brackets to the Display ............................ 10

Mount the Display ............................................... 10

ADJUSTMENTS ................................................. 11

Width Adjustment ................................................ 11

Adjust Vertical Travel .......................................... 11

WIRING ............................................................... 13

Pushbutton ........................................................... 13

Extend and Retract Terminals to beTriggered by

Separate Dry Contacts ......................................... 13

Remote (RC-10) ................................................... 15

12 Volt Out Supply .............................................. 17

24 Volt Out Supply .............................................. 17

Two Dry Contact Closures .................................. 17

Low Voltage Sensing ........................................... 17

TROUBLESHOOTING

..................................... ..... 19

2

Page 4

Instruction Manual Plasma Display Electric Pop-Up Lift

3. Determine the inside dimensions available in your furniture/

cabinet (see Table 2, “Adjustable Width).

Table 1: Weight, Size, and Vertical Travel

Model

PUL4228

PUL4233

PUL4239

PUL4245

PUL4251

PUL4257

Model Outside Inside

PUL4228

Lift

Capacity

230Lbs

104.3Kgs

230Lbs

104.3Kgs

230Lbs

104.3Kgs

230Lbs

104.3Kgs

230Lbs

104.3Kgs

230Lbs

104.3Kgs

1120.8mm to 1425.6mm

Outside

Dimensions

33.75”x7.7”

(857.3mmx195.6mm)

38.75”x7.7”

(984.3mmx195.6mm)

44.75”x7.7”

(1136.7mmx195.6mm)

50.75”x7.7”

(1289.1mmx195.6mm)

56.75”x7.7”

(1441.5mmx195.6mm)

62.75”x7.7”

(1593.9mmx195.6mm)

(1079.5mmx1374.8mmx165.1mm)

(1231.9mmx1374.8mmx165.1mm)

(1384.3mmx1374.8mmx165.1mm)

Table 2: Adjustable Width

44.125” to 56.125”

Max. Equipment Size

HxWxD

25.5”x54.125”x6.5”

(647.7mmx1374.8mmx165.1mm)

30.5”x54.125”x6.5”

(774.7mmx1374.8mmx165.1mm)

36.5”x54.125”x6.5”

(927.1mmx1374.8mmx165.1mm)

42.5”x54.125”x6.5”

48.5”x54.125”x6.5”

54.5”x54.125”x6.5”

42.125” to 54.125”

1070.0mm to 1374.8mm

Vertical

Travel

28”

711.2mm

33”

838.2mm

39”

990.6mm

45”

1143.0mm

51”

1295.4mm

57”

1447.8mm

PUL4233 44.125” to 56.125”

1120.8mm to 1425.6mm

PUL4239 44.125” to 56.125”

1120.8mm to 1425.6mm

PUL4245 44.125” to 56.125”

1120.8mm to 1425.6mm

PUL4251 44.125” to 56.125”

1120.8mm to 1425.6mm

PUL4257 44.125” to 56.125”

1120.8mm to 1425.6mm

42.125” to 54.125”

1070.0mm to 1374.8mm

42.125” to 54.125”

1070.0mm to 1374.8mm

42.125” to 54.125”

1070.0mm to 1374.8mm

42.125” to 54.125”

1070.0mm to 1374.8mm

42.125” to 54.125”

1070.0mm to 1374.8mm

3

Page 5

Instruction Manual Plasma Display Electric Pop-Up Lift

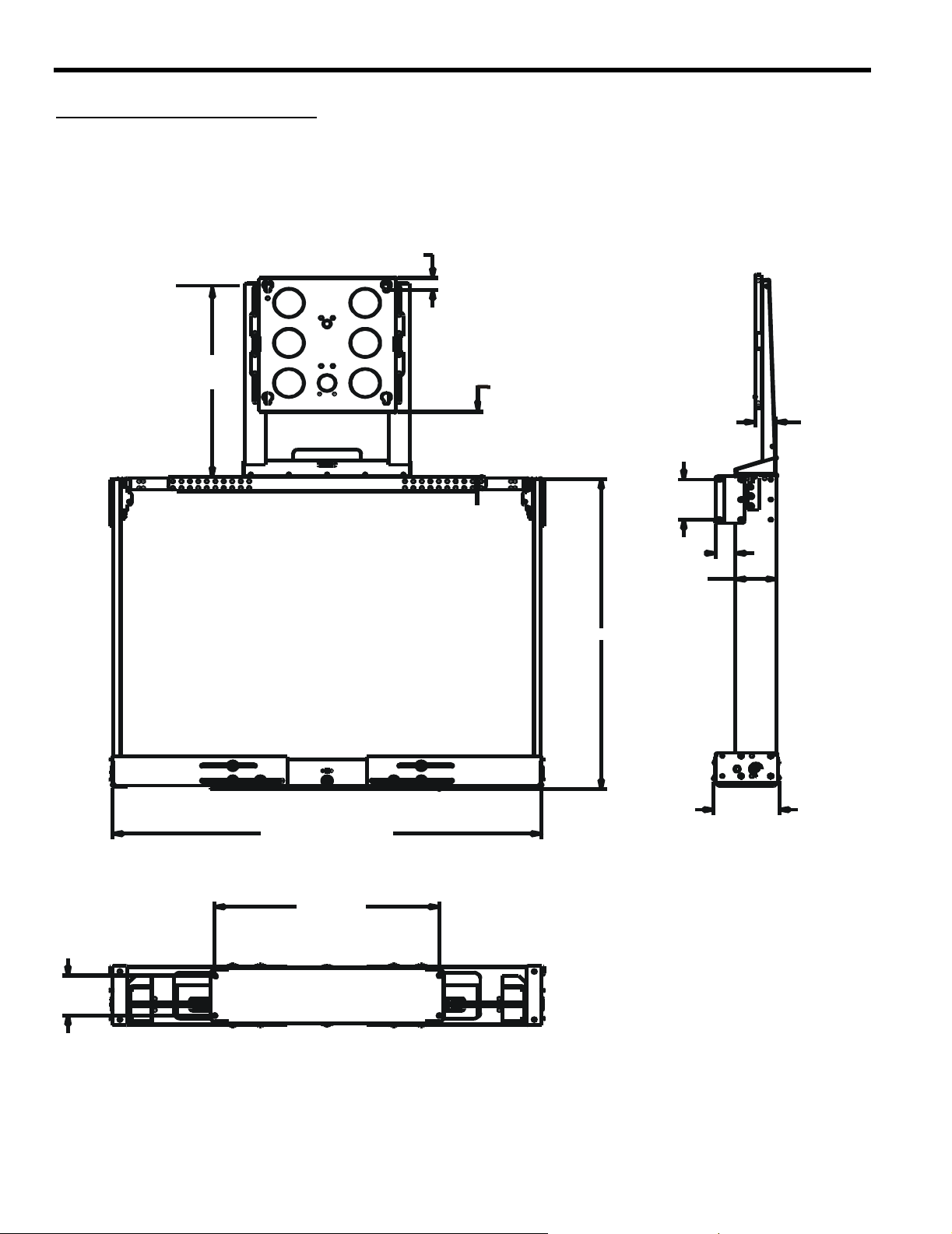

DIMENSIONAL DRAWING

See Table 1 on page 3 for outside adjustable width, dimension “H” and dimension “W”.

24.25

Front View

1.48

4" MIN

11" MAX

ADJUSTMENT

DIMENSION "H"

Side View

2.459

5.000

2.3

4.88

5.0

4

OUTSIDE

ADJUSTABLE

WIDTH

44.125 NIM - 56.125 MAX

26.5

Top View

7.730

Page 6

Instruction Manual Plasma Display Electric Pop-Up Lift

INSPECT AND TEST THE UNIT BEFORE INSTALLING

Inspect The Unit

1. Carefully inspect the Plasma Display Electric Pop-Up Lift

(PUL) for shipping damage. If any damage is apparent, call

your carrier claims agent and do not continue with the installation until the carrier has reviewed the damage.

NOTE: Read all assembly instructions before starting assembly.

2. Carefully inspect PUL components for damage, checking vertical extrusion arms to make sure they are parallel.

IMPORTANT: Before mounting the lift in the furniture/cabinet,

make the following tests to be sure that it operates properly and has

not been damaged in shipping.

Test The Unit

1. Set the PUL on a clean, level surface.

Figure 1. Connection to Housing

2. Connect the motor control box to the control circuit housing

(see Figure 1, Figure 2, and Figure 3).

3. Install two terminal blocks in control box (see Figure 2).

NOTE: The lift is supplied with a momentary push button on

the end of a cable to help you pretest the operation.

3. Connect the momentary push button (provided) cable leads to

terminals #6 and #1 and add a jumper wire (provided - electrical wire about 4 in. long with 1/4 in. stripped at each end)

between terminals #2 and #5 on the same terminal block (see

Fig. 4).

4. Plug the lift’s power cord (see Figure 3) into a 110V 60 Hz or

220V 50 Hz (as appropriate) 15-amp outlet.

NOTE: The lift draws approximately 1.5 amps.

WARNNG: Be aware during the

installation that this is a motorized

device, and there are pinch points for

people and for electrical wiring.

Keep hands and electrical wiring

away from internal components of

the mechanism

Figure 2. Front Connection to Control Box

Figure 3. Back Connection and Power Cord

to Control Box

To

5. Operate the lift much like a garage-door opener: press the button when the lift is at its “bottom” position and it will move

“up”; press again when it is at its “top” position and it will

move “down”; press while moving and it will stop.

Use the push button to check that the lift runs to the top and

bottom of its travel without any interference that might indicate

damage during shipment.

6. Unplug the lift’s power cord.

To push button

To jumper

Figure 4. Test Wiring

5

Page 7

Instruction Manual Plasma Display Electric Pop-Up Lift

PREPARE THE FURNITURE/CABINET AND INSTALL THE LIFT

Because of the wide variety of possible mounting situations, Chief Manufacturing can only pr ovide general guidelines

for lift installation. Study the following information carefully, and adapt it as necessary to fit your specific installation.

WARNING: Be especially aware of the weight of the unit, and

the potential for personal injury or of damage to the unit if it is

not adequately mounted. The lift (without a projector) weighs

approximately 150 lbs (68 kg).

The “General Guidelines” below and the information on the following pages cover the most common mounting situations:

General Guidelines

• Compare the inside dimensions of the furniture/cabinet in which the lift will be installed with the dimensional requirements of

your display and any additional space required for your application. Allow for movement of the lift and the display.

Prepare the Furniture/Cabinet

WARNNG: Be aware during the installation that this is a motorized device,

and there are pinch points for people

and for electrical wiring. Keep hands

and electrical wiring away from internal components of the mechanism

1. Determine size and weight of display to be lifted. See

“Weight, Size, and Vertical Travel” on page 3 for weight

limitations.

2. Determine vertical travel height required for presentation

viewing. See Table 1 for height limitations.

Furniture Opening Finish Piece Options

Because of the wide variety of possible mounting situations, Chief Manufacturing can only provide general guidelines for finish options. Study the following

information carefully, and adapt it as necessary to fit

your specific installation.

NOTE: Always leave access to the lift for maintenance purposes.

Extended Position Finish Piece Option

A finish piece, covering the opening when the unit is

in the fully extended position, may be installed for

estetic purposes. Using the material cut slight smaller

than the opening size, install the finish piece as follows:

1. Measure the width of the finish piece.

2. Measure the distance between the verticle extrusion arms and

subtract a nominal amount for clearance.

CAUTION: Failure to allow clearance for the finish piece to

retract to the fully lowered position may result in damage to the finish piece, damage to the lift, and damage to the plasma.

6

Page 8

Instruction Manual Plasma Display Electric Pop-Up Lift

3. Make sure the finish piece measured in step 1 is smaller than

the clearance distance measured in step 2 and note any cord

management access holes that may be necessary.

4. Measure the thickness of the finish piece, add this thickness to

the length of the five capscrews used to secure the plasma

mounting assembly when a backing is not used, and obtain the

five longer 3/8-16 capscrews for assembly with backing.

5. Place the finish piece on the shelf, making sure it is correctly

positioned to allow clearance when lowered, and transfer the

pattern of the five access holes onto the finish piece.

Plasma Mounting

Assembly

Shelf

6. Drill five through holes, with clearance for 3/8” bolts, in the

finish piece and any cord management holes that may be necessary.

7. Place the finish piece on the shelf.

8. Place the plasma mounting assembly on top of the finish piece

(see Figure 5).

9. Using a 5/16” Allen wrench inserted through the five access

holes on the bottom of the shelf (see Figure 6), install five

longer 3/8-16 cap screws.

10. With the aid of another person, lift the display up to the mount,

aligning the PSB mounting buttons on the display with the

teardrop slots on the mount, set the plasma into place and

adjust mounting assembly to ensure proper clearance is

achieved.

11. Measure and record clearance dimensions and, with the aid of

another person, remove plasma.

WARNNG: Be aware during the installation that this is a motorized device, and

there are pinch points for people and for

electrical wiring. Keep hands and electrical wiring away from internal components

of the mechanism

12. Carefully, without plasma mounted on lift, operate lift to

ensure finish piece has sufficient clearance during full travel.

Retracted Position Finish Piece Option

A finish piece, covering the opening when the unit is

retracted, may be installed for estetic purposes. Install

the finish piece as follows:

Figure 5. Plasma Mounting Assembly

Access Holes

Figure 6. Access Holes

1. Complete the instructions in “Extended Position Finish Piece

Option” on page 6.

2. Cut two side pieces, matching the width of the extended posi-

tion finish piece, to a length slightly longer than the distance

the plasma will travel (this will be trimmed later).

3. Cut a top piece, matching the dimensions of your extended

position finish piece (see Figure 7).

7

Page 9

Instruction Manual Plasma Display Electric Pop-Up Lift

4. With the extended position finish piece and the plasmamounted, lower the unit to its fully retracted position.

5. Place the side pieces in position (do not attach).

Retracted Position

Finish Piece

Backing

6. Place the top piece in position (do not attach).

7. Measure the distance from the top surface of the top piece to

the top surface of your furniture and cut this dimension from

each side piece (see Figure 8).

Side Pieces

8. Remove and assemble finish pieces (bottom, sides and top),

making sure your finished box is square.

CAUTION: A backing is recommended for support. Frame movement could result in damage to the frame, damage to the lift, and

damage to the plasma.

CAUTION: Check plasma ventilation requirements. Provide ventillation for your application.

9. Measure box, construct a backing for lateral support, and

install backing.

WARNNG: Be aware during the installation that this is a

motorized device, and there are pinch po ints f or people and for

electrical wiring. Keep hands and electrical wiring away from

internal components of the mechanism

CAUTION: Failure to allow clearance for the finish pieces to

retract to the fully lowered position may result

in damage to the finish pieces, damage to the

lift, and damage to the plasma.

10. Carefully, without plasma mounted on

lift, operate lift to ensure the finish pieces

have sufficient clearance during full travel

and that top finish piece is flush with the furniture top when

fully retracted.

Plasma

Extendeded Position

Finish Piece

Figure 7. Retracted Position Finish Piece

Finish Piece

Furniture

Figure 8. Side Piece Dimensions

8

Page 10

Instruction Manual Plasma Display Electric Pop-Up Lift

Install the PUL into the Cabinet

1. Adjust motor/control box unit (see Figure 9).

NOTE: The motor/control box unit is factory set to the narrowest horizontal position.

a. Loosen the six 5/16”-18X5/8” hex head bolts on the front

of each half of the motor/control box and eight 1/4-20

socket head allen screws (4 front and 4 back) on the

bracket mounting crossbrace. Slide both halves of the lift

all the way in and out to ensure the lift can be adjusted

freely.

c. Measure the width of the inside enclosure where the lift

will be mounted.

d. Adjust the width of the lift, allowing for clearance, and

hand tighten all bolts loosened in step a.

NOTE: The unit must be installed square an d parallel in ALL

dimensions for smooth and reliable operation. The extrusions

housing the chains must also remain exactly square to the

power box and parallel to each other after it has been installed.

Shims may be required between the unit and the enclosure to

maintain parallel dimensions between the extrusions.

Motor/Control Box

Eight 1/4-20 Socket

Head AllenScrews

Bracket Mounting Crossbrace

Six Hex Head Bolts

Figure 9. Motor/Control Box

2. Place the unit into the enclosure so the load to be lifted is centered over the vertical extrusion beams.

3. With the lift in place, use the base of the lift mechanism as a

template to transfer 4 holes (17/64” diameter) to the enclosure

bottom.

NOTE: If desired, you can use the additional four holes in the corners of the lift, but you must fill the space between the lift and

enclosure bottom to prevent warping.

4. Remove the lift mechanism from the enclosure.

5. Drill the 4 holes (17/64” diameter) in the bottom of the enclosure.

6. Place the unit into the enclosure so the holes in the mechanism

line up with the holes in the enclosure.

7. Secure the unit into the enclosure using 4 thru bolts (1/4-20 or

larger), 8 fender washers, and 4 Nyloc nuts (see Figure 10).

Tighten securely.

Optional holes requiring spacers between

the lift and the bottom of the enclosure

Thru bolt, two fender washers

and Nyloc Nut two places

each side

Figure 10. Secure Lift

9

Page 11

Instruction Manual Plasma Display Electric Pop-Up Lift

d

INSTALL THE DISPLAY ON THE LIFT

Attach Brackets to the Display

1. Follow the instructions accompanying the PSB brackets

designed for your display.

Mount the Display

1. Remove 4 screws and slide back panel cover up and out (see

Figure 11).

2. Make sure the latch on the mount is lowered to the side before

attempting to place the display on the mount (see Figure 12).

3. With the aid of another person, lift the display up to the mount,

aligning the PSB mounting buttons on the display with the

teardrop slots on the mount, and set the plasma into place.

CAUTION: If the latch does not travel to the full upright position,

remove and reset the display.

Figure 11. Back Panel Cover Removal

Remove screws

Latch Lowere

4. While supporting the display, raise the latch.

5. Install Q-clamp (see Figure 13).

6. Install back panel cover and secure using 4 screws.

Raise Latch to Secure Display

Tear Drop Slots

Figure 12. Latch and Tear Drop Slots

10

Q-clamp

Figure 13. Install Q-clamp

Page 12

Instruction Manual Plasma Display Electric Pop-Up Lift

ADJUSTMENTS

WARNING: Be aware during the

installation that this is a motorized

device, and there are pinch points for

people and for electrical wiring.

Width Adjustment

Adjust width as follows (see Figure 14):

1. Loosen the six 5/16”-18X5/8” hex head bolts on the front of

each half of the motor/control box and eight 1/4-20 socket head

Allen screws (4 front and 4 back) on the bracket mounting

crossbrace.

2. Slide the halves of the lift to the disired width and secure by

tightening the bolts and socket head Allen screws loosened in

Step 1.

Adjust Vertical Travel

WARNING: Be aware during the

installation that this is a motorized

device, and there are pinch points for

people and for electrical wiring.

CAUTION: Vertical travel adjustment must always be made with

the shelf in the middle of travel position and the power switch OFF.

There are two knobs for setting the travel limits, which are located

at one end of the base controller housing (see Figure 15). The knob

closest to the outside is the down stop limit adjustment. The knob

closest to the center is the up stop limit adjustment

Eight 1/4-20 Socket

Head AllenScrews

Bracket Mounting Crossbrace

Motor/Control Box

Figure 14. Width Adjustmentr

CCW

Six Hex Head Bolts

CW

1. With the shelf in the middle of travel position and the power

switch OFF , adjust the down limit to the desired height by turning the down stop adjustment knob (clockwise = higher position, counterclockwise = lower position).

CAUTION: The unit must always be able to reach its own limit

switches and turn itself off.

2. Check to be sure the limit switch stops the unit and the unit is

not being stopped due to interference.

3. With the shelf in the middle of travel position and the power

switch OFF , adjust the up limit to the desired height by turning

the down stop adjustment knob (clockwise = higher position,

counterclockwise = lower position)

Figure 15. Vertical Travel Adjustment

11

Page 13

Instruction Manual Plasma Display Electric Pop-Up Lift

THIS PAGE INTENTIONALLY BLANK

12

Page 14

Instruction Manual Plasma Display Electric Pop-Up Lift

WIRING EXAMPLES

The information on the following pages cover the most common wiring options:

• Pushbutton

• Extend and Retract Terminals to be Triggered By

Separate Dry Contacts

• Remote (RC-10)

• 12 Volt out supply

• 24 Volt out supply

• Two dry contact closures

• Voltage Sensing

Pushbutton

Wire for pushbutton operation as follows:

1. Install a wire between terminal 5 (extend/retract common) and

ground terminal 3 (see Figure 16).

Figure 16. 12 Volt Supply Jumper

2. Connect one wire from pushbutton to terminal #4

(12 VDC power supply) and the other wire from the pushbutton to terminal #6 (extend/retract) (see Figure 17).

With the unit plugged in, push the button once and the unit should

extend. Push the button during travel and the unit will stop at that

location. Push the button after the unit is extended or stopped in

mid-travel and the unit will retract.

Extend and Retract Terminals to be Triggered By

Separate Dry Contacts

These terminals can be used with a wall switch or a separate set of

dry contacts for dedicated extend and dedicated retract. Momentary

contacts are preferable.

NOTE: The connection between the ground (#13) and any other

terminal connection must be broken (open) before completing the

next circuit.

1. Connect the common to terminal #13 (see Figure 18).

2. Connect the extend to terminal #11 (see Figure 19).

3. Connect the retract to terminal #12 (see Figure 20).

Completing the circuit between terminal #13 and terminal #11 will

cause the unit to extend to the show position (see “Adjust Vertical

Travel” on page 11 to change height setting). Completing the circuit between terminal #13 and terminal #12 will cause the unit to

retract to the closed position.

Figure 17. Pushbutton Wires

Common

Figure 18. Common for Extend and Retract Contacts

Service Extend

Extend

Figure 19. Extend Contact Wiring

Retract

Figure 20. Retract Contact Wiring

13

Page 15

Instruction Manual Plasma Display Electric Pop-Up Lift

THIS PAGE INTENTIONALLY BLANK

14

Page 16

Instruction Manual Plasma Display Electric Pop-Up Lift

Remote (RC-10)

RC-10 Controller

Circuit Board Box Assembly

RC-10 Remote

Figure 21. Contacts Connection

Wire for remote (RC-10) operation as follows (see Figure 21):

1. Install a jumper wire between terminals #6 and

terminal #2 (see Figure 22).

2. Connect the white wire of the RC-10 controller unit to

terminal #1 (see Figure 23).

3. Connect the red wire of the RC-10 controller unit to

terminal #2.

4. Connect the black wire of the RC-10 controller unit to

terminal #5.

5. Connect the power source to the lift.

NOTE: If the unit does not activate, check to make sure the 9 volt

battery is working and make sure the dip switches in the sending unit match the dip switch settings in the controller unit (see

Figure 24).

Red lead

Figure 22. Contacts Connection

Black lead

Figure 23. Contacts Connection

Figure 24. Dip Switches

15

Page 17

Instruction Manual Plasma Display Electric Pop-Up Lift

THIS PAGE INTENTIONALLY BLANK

16

Page 18

Instruction Manual Plasma Display Electric Pop-Up Lift

12 Volt Out Supply

This internal power supply can be used to power external

devices &/or to initiate specific functions (see Pushbutton

operation and Figure 25).

1. Connect one lead to 12 VOLT GROUND (terminal #9).

2. Connect one lead to 12 VOLTS OUT (terminal #10).

24 Volt Out Supply

This internal power supply can be used to power external

devices & remote controllers (see Figure 26).

1. Connect one lead to 24 VOLT COMMON (terminal #2).

2. Connect one lead to 24 VOLTS OUT (terminal #1).

Two Dry Contact Closures

NOTE: Dry contacts are rated for 1 Amp @ 24 volts.

These contacts can be used to complete circuits to external

devices (see Figure 27 and Figure 28).

1. Connect one lead to terminal #17 (extend limit common).

2. Connect one lead to terminal #16 (closes when unit

reaches full extension).

3. Connect one lead to terminal #19 (retract limit common).

4. Connect one lead to terminal #18 (closes when unit is

fully retracted).

Low Voltage Sensing

1. Connect positive lead (5 - 30 volts AC/DC) to terminal #7

and ground of switching device to terminal #8 (see

Figure 29). Unit extends when voltage is sensed, retracts

when voltage ceases.

Example using internal 12 volt DC supply (Figure 30):

1 2 3 4 5 6 7 8

Figure 25. 12 Volts

Figure 24. 26 Volts

Figure 27. Extend Dry Contacts

Figure 28. Retract Dry Contacts

Figure 30. 12 Volt DC Supply

Figure 29. Low Volt age Sensing

17

Page 19

Instruction Manual Plasma Display Electric Pop-Up Lift

THIS PAGE INTENTIONALLY BLANK

18

Page 20

Instruction Manual Plasma Display Electric Pop-Up Lift

TROUBLESHOOTING

If the lift is installed according to these instructions, it should operate trouble-free indefinitely. If you do encounter a problem, and

it isn’t covered by the troubleshooting suggestions below, call the Technical Services Department at Chief Manufacturing:

1-800-582-6480

952-894-6280

Possible

Symptom(s)

No Movement and No

Sound

Causes Suggested Action

No Power 1. Check power to unit (supply, cord, activation

control, and connections).

No power: Provide power, repair cord, tighten

connections or repair activation control.

Power: Check fuse on circuit board. If fuse is OK,

proceed to next step.

Faulty Circuit Board 2. Check circuit board as follows:

Make three jumper wires with ends stripped.

Install one jumper wire on terminal 11.

Install one jumper wire on terminal 12.

Install one jumper wire on terminal 13.

Momentarily touch j umper wire from termi nal 11 to

terminal 13. Unit should extend.

Momentarily touch j umper wire from termi nal 12 to

terminal 13. Unit should retract.

Unit Operates Noisily

(Squeeling or grinding)

Activates

In both

Directions: Circuit board OK, faulty activation

interface. Check remote switch, circuit, or

batteries in remote control.

Unit

Fails

Both/Either

Direction: Call Chief Manufacturing.

Track Misalignment 1. Check for noise and/or metal shavings in track

Noise or

Shavings: Check and adjust track and/or shelf as

necessary.

No Track

Noise: Possible brake problem, call Chief

Manufacturing

19

Page 21

Instruction Manual Plasma Display Electric Pop-Up Lift

C

C

TERMINAL FUNCTION DEFINITIONS

TERMINAL

NUMBER

1

2

3

4

5

6

FUNCTION

24 VOLT AC

24 VOLT AC

COMMON

GROUND Ground

12 VOLT DC

EXTEND/

RETRACT

EXTEND/

RETRACT

COMMON

DESCRIPTION WIRING OPTIONS NOTES

24 volt AC output

24 volt AC com mon

12 volt DC

Initiates movement if lift is st atic, or

stops movement if lift is in mo tion.

Direction of travel will be opposite

of last direction of travel.

Used in conjunction with

Extend/Retract when using an

external power source to initiate

movement.

To Operate using Internal Power

Source

Connect terminals 3 & 6 with

Jumper Wire. Connect

Momentary Switch to terminal 4.

Connect other line of Momentary

Switch to terminal 5.

To Operate using External Power

Source

Connect External Power Supply’s

Common to terminal 6. Connect

initiating signal to terminal 5.

This is an internal power s u pply for

powering external devices & Remote

Controllers.

Chief Mfg. offers the RC-10 Radio

Frequency Remote Controller which runs

off of this power supply.

This is an internal power s u pply for

powering external devices &/or used for

initiating specific functions

(Extend/Retract 5 or Voltage Sensor 7).

Function operates on momentary switch

only.

Operating range is 5 – 30 Volts AC or D

NOT TO BE USED AS GROUND FOR

FUNCTION OTHER THAN

EXTEND/RETRACT TERMINAL 5.

7

8

9

10

When terminal senses voltage, unit

VOLTAGE

SENSOR

VOLTAGE

SENSOR

COMMON

SERVICE

EXTEND

GROUND Ground

When terminal senses cessation of

Used in conjunction with Voltage

Sensor when using an external

power source to initiate movement.

Extends unit to maximum limit,

bypassing normal-use travel setting.

Often used for servicing projectors

in ceiling lifts on PCL and MD

will extend.

voltage, unit w ill retract.

models

Voltage Sensing

Connect positive lead to terminal

7. Connect Ground of switching

device to terminal 8.

Single-Pull/Throw Latching

Switch

Connect terminals 3 & 8 with

Jumper Wire. Connect first

Switch Terminal to terminal 4.

Connect other Switch Terminal to

terminal 7.

Momentary or Latching contact to

Ground terminals 3, 10, 13, or 20.

Operating range is 5 – 30 Volts AC or D

NOT TO BE USED AS GROUND FOR

FUNCTION OTHER THAN VOLTAGE

SENSOR TERMINAL 7.

Feature not available on all models.

If using Latching Switch, be sure to

disengage Switch prior to initiating any

other function.

20

Page 22

Instruction Manual Plasma Display Electric Pop-Up Lift

5

11

12

13

14

15

16

17

Extends unit to preset travel limit.

EXTEND

RETRACT

GROUND Ground

EXTEND

ERROR

RETRACT

ERROR

EXTEND

LIMIT

RELAY

EXTEND

LIMIT

RELAY

COMMON

Custo mer within a preset maximum

range may adjust travel limits.

Re tracts u nit to p reset tra vel limit.

Travel limits may be adjusted b y

customer within a preset maximum

rang e.

Immediately rever ses direction of

trav el whe n triggered while unit i s

extending .

Immediately rever ses direction of

trav el whe n triggered while unit i s

retracting.

Closes se t of internal dry contacts

when unit reac hes ful l exte nsion.

Momentary or Latching contact to

Ground terminals 3, 10, 13, or 20.

Momentary contact to Ground

terminals 3, 10, 13, or 20.

If using Latching Switch, be sure to

disengage Switch prior to initia ti ng any

other function.

If using Latching Switch, be sure to

disengage Switch prior to initia ti ng any

other function.

Ch ie f M f g. offer s th e SS - 10 Press ure

Sensitive Safety Strip to provide this

function.

Please spec ify how many inches requ ired

spanning entire pinch zone.

The SS-10 must be ordered with the ST-1

Terminals.

RATED FO R 1 A M P @ 24 VOLTS

RETRACT

18

19

20

LIMIT

RELAY

RETRACT

LIMIT

RELAY

COMMON

GROUND

Closes se t of internal dry contacts

when unit re ach e s full retractio n.

Ground

WIRING THE RC-10

Connect white lead to term inal 1, red lead to terminal 2, a nd black lead to termin a l 5.

Pla c e jum p er wire from terminal 2 to terminal 6

WIRING A MOMENTARY PUSH BUTTON

Conne ct terminals 3 & 6 with Jumper Wire. Connect Momenta ry Switch t o terminal

4. Connect other line of Momentary Switch to terminal 5.

RATED FO R 1 A M P @ 24 VOLTS

21

Loading...

Loading...