Chicago Pneumatic RX 2, RX 3, RX 8, RX 4, RX 6 Safety And Operating Instructions Manual

Safety and operating instructions

Hydraulic breakers

RX 2, 3, 4, 6, 8

Prescriptions de sécurité et instructions pour

l’opérateur

Brise-roche hydraulique

Sicherheits- und Betriebsanleitung

Hydraulikhammer

Instrucciones de seguridad y de funcionamiento

Martillo hidráulico

Instruções de segurança e operação

Martelo demolidor hidráulico

Istruzioni per la sicurezza e per l'uso

Demolitore idraulico

Veiligheidsvoorschriften en bedieningshandleiding

Hydraulische sloophamer

Οδηγίες ασφάλειας και χειρισμού

Υδραυλικός θραυστήρας

Turvallisuusohjeet ja käyttöohje

Käsikäyttöiset hydrauliset iskuvasarat

Sikkerhedsinstruktioner og betjeningsvejledning

Hydraulikhammer

Sikkerhetsinstrukser og bruksanvisning

Hydraulisk hammer

Säkerhetsinstruktion och instruktionsbok

Hydraulhammare

Инструкции по безопасности и эксплуатации

Гидромолоты

www.cp.com

RX 2, 3, 4, 6, 8

9800 1050 90 | Original instructions2

RX 2, 3, 4, 6, 8

Contents

ENGLISH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

FRANÇAIS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

DEUTSCH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

ESPAÑOL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

PORTUGUÊS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

ITALIANO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

NEDERLANDS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

ΕΛΛΗΝΙΚΑ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

SUOMI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

DANSK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

NORSK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

SVENSKA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

РУССКИЙ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

39800 1050 90 | Original instructions

RX 2, 3, 4, 6, 8Contents

ENGLISH

Contents

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Safety and operating instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety signal words. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Personal precautions and qualifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Carrier, precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation, precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation, precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Maintenance, precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Storage, precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Design and function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Main parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Transport. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Hoses and connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Hydraulic oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Pressure adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Insertion tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Preparation before breaking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Every second hour. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Every day. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Every week. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Every year. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

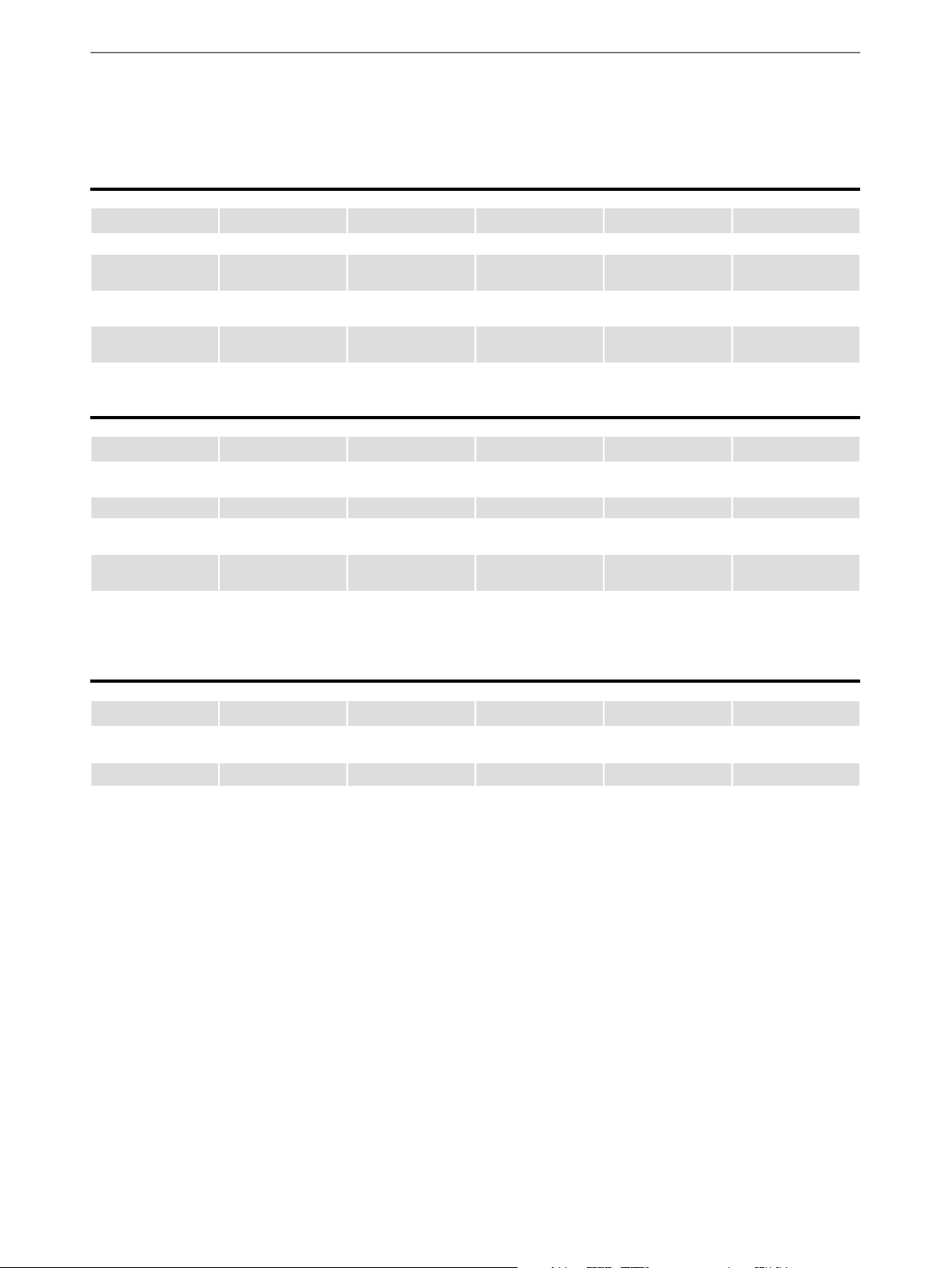

Machine data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Capacities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Noise declaration statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

EC Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

EC Declaration of Conformity (EC Directive 2006/42/EC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9800 1050 90 | Original instructions4

Safety and operating instructionsRX 2, 3, 4, 6, 8

Introduction

Thank you for choosing Chicago Pneumatic brand products. For over a century, the

Chicago Pneumatic brand has represented performance and innovation in the

pneumatic tool industry.

Today the brand is found around the world on a range of pneumatic and hydraulic

tools that includes breakers, rock drills, chipping hammers, clay-diggers, picks and

busters, scabblers, pumps and a whole lot more.

The Chicago Pneumatic brand is associated with powerful and reliable products that

are easy to maintain and that give good value for the money.

For more information please visit www.cp.com

Atlas Copco Construction Tools AB

105 23 Stockholm

Sweden

About the Safety and operating

instructions

The aim of the instructions is to provide you with knowledge of how to use the

hydraulic breaker in an efficient, safe way. The instructions also give you advice and

tell you how to perform regular maintenance on the hydraulic breaker.

Before using the hydraulic breaker for the first time you must read these instructions

carefully and understand all of them.

59800 1050 90 | Original instructions

RX 2, 3, 4, 6, 8Safety and operating instructions

Safety instructions

To reduce the risk of serious injury or death to

yourself or others, read and understand the Safety

and operating instruction before installing,

operating, repairing, maintaining, or changing

accessories on the machine.

Post this Safety and operating instruction at work

locations, provide copies to employees, and make

sure that everyone reads the Safety and operating

instruction before operating or servicing the

machine.

In addition, the operator or the operator's employer

must assess the specific risks that may be present as

a result of each use of the machine.

Safety signal words

The safety signal words Danger, Warning and

Caution have the following meanings:

DANGER

WARNING

CAUTION

Personal precautions and

qualifications

Only qualified and trained persons may operate or

maintain the machine. They must be physically able

to handle the bulk, weight, and power of the tool.

Always use your common sense and good

judgement.

Transport

Transport of the hydraulic breaker may only be

undertaken by persons who:

> are authorised to operate a crane or fork-lift truck

in conformity with the applicable national

directives,

Indicates a hazardous situation

which, if not avoided, will result

in death or serious injury.

Indicates a hazardous situation

which, if not avoided, could

result in death or serious injury.

Indicates a hazardous situation

which, if not avoided, could

result in minor or moderate

injury.

Installation, storage, maintenance and

disposal

Installation, storage, maintenance and disposal of

the hydraulic breaker may only be undertaken by

persons who:

> are aware of all the relevant national safety

instructions and accident prevention instructions

> and have read and understood the Safety and

operating instructions.

Operation

Operation of the hydraulic breaker may only be

undertaken by qualified carrier operators. Carrier

operators are qualified if they:

> are trained to operate a carrier in conformity with

national directives,

> are aware of all the relevant national safety

instructions and accident prevention instructions

> and have read and understood the Safety and

operating instructions.

Testing

Testing of the hydraulic installation must only be

carried out by professional technicians. The

technicians must be authorised to approve a

hydraulic installation in accordance with national

directives.

Personal protective equipment

Always use approved protective equipment.

Operators and all other persons in the working area

must wear protective equipment, including at a

minimum:

> Protective helmet

> Hearing protection

> Impact resistant eye protection with side

protection

> Respiratory protection when appropriate

> Protective gloves

> Proper protective boots

> Appropriate work overall or similar clothing (not

loose-fitting) that covers your arms and legs.

> are aware of all the relevant national safety

instructions and accident prevention instructions

> and have read and understood the safety and

transport chapters of this manual.

9800 1050 90 | Original instructions6

Safety and operating instructionsRX 2, 3, 4, 6, 8

Drugs, alcohol or medication

WARNING Drugs, alcohol or medication

Drugs, alcohol or medication may impair your

judgment and powers of concentration. Poor

reactions and incorrect assessments can lead to

severe accidents or death.

► Never use the machine when you are tired or

under the influence of drugs, alcohol or

medication.

► No person who is under the influence of drugs,

alcohol or medication may operate the machine.

Carrier, precautions

Before using or transporting the carrier with the

hydraulic breaker attached, carefully read the carrier

manufacturer's safety regulations and operating

instructions.

Make sure that the carrier is equipped with adequate

protective features, including a protective screen in

front of the operator.

The hydraulic breaker should only be mounted on

a carrier with sufficient load capacity.

Carriers without sufficient load capacity will not

provide the required degree of stability and could

even fall over during hydraulic breaker use, causing

injury and damage.

WARNING Hydraulic oil at high

pressure

Thin jets of hydraulic oil under high pressure can

penetrate the skin and cause permanent damage.

► Immediately consult a doctor if hydraulic oil has

penetrated the skin.

► Never use your fingers to check for hydraulic fluid

leaks.

► Keep your face away from any possible leaks.

WARNING Hydraulic oil

Spilled hydraulic oil can cause burns, accidents due

to slippery conditions and will also harm the

environment.

► Take care of all spilled oil and handle it according

to your safety and environmental regulations.

► Never dismount the hydraulic machine when the

hydraulic oil is hot.

► Never run any hydraulic lines for attachment of

the hydraulic machine through the drivers cab.

CAUTION Skin eczema

Hydraulic oil can cause eczema if it comes in contact

with the skin.

► Avoid getting hydraulic oil on your hands.

► Always use protective gloves when working with

hydraulic oil.

Installation, precautions

Hydraulic system

DANGER Compressed gas, explosion

hazard

The integrated piston accumulator is pressurized

even when the hydraulic system is shut off. To

dismount the accumulator without first releasing

the nitrogen gas can cause serious personal injury

or death.

► Fill the integrated piston accumulator with

nitrogen (N 2) only.

► Wash hands after contact with hydraulic oil.

Assembly or disassembly

WARNING Moving parts

Risk for leaking oil and personal injury, such as

crushed hands and fingers.

► Never check bores or passages with hands or

fingers.

► Any boom movements shall only be done in

cooperation with the personnel mounting the

hydraulic breaker.

► If the hydraulic breaker is mounted on a quick

hitch coupling, make sure it is locked securely and

all risks of the hydraulic breaker coming loose are

eliminated.

79800 1050 90 | Original instructions

RX 2, 3, 4, 6, 8Safety and operating instructions

Operation, precautions

DANGER Explosion hazard

If an insertion tool comes into contact with

explosives or explosive gases, an explosion could

occur. When working on certain materials and when

using certain materials in machine parts, sparks and

ignition can occur. Explosions will lead to severe

injuries or death.

► Never operate the machine in any explosive

environment.

► Never use the machine near flammable materials,

fumes or dust.

► Make sure that there are no undetected sources

of gas or explosives.

WARNING Operating pressure

If the maximum operating pressure for the hydraulic

machine is exceeded, the accumulator can be over

charged which can result in material damage and

personal injury.

► Always run the hydraulic machine with the correct

operating pressure. See "Technical data".

WARNING Dust and fume hazard

Dusts and/or fumes generated or dispersed when

using the machine may cause serious and permanent

respiratory disease, illness, or other bodily injury (for

example, silicosis or other irreversible lung disease

that can be fatal, cancer, birth defects, and/or skin

inflammation).

Some dusts and fumes created by drilling, breaking,

hammering, sawing, grinding and other construction

activities contain substances known to the State of

California and other authorities to cause respiratory

disease, cancer, birth defects, or other reproductive

harm. Some examples of such substances are:

> Crystalline silica, cement, and other masonry

products.

> Arsenic and chromium from chemically-treated

rubber.

> Lead from lead-based paints.

Dust and fumes in the air can be invisible to the

naked eye, so do not rely on eye sight to determine

if there is dust or fumes in the air.

To reduce the risk of exposure to dust and fumes,

do all of the following:

► Perform site-specific risk assessment. The risk

assessment should include dust and fumes created

by the use of the machine and the potential for

disturbing existing dust.

► Use proper engineering controls to minimize the

amount of dust and fumes in the air and to

minimize build-up on equipment, surfaces,

clothing, and body parts. Examples of controls

include: exhaust ventilation and dust collection

systems, water sprays, and wet drilling. Control

dusts and fumes at the source where possible.

Make sure that controls are properly installed,

maintained and correctly used.

► Wear, maintain and correctly use respiratory

protection as instructed by your employer and as

required by occupational health and safety

regulations. The respiratory protection must be

effective for the type of substance at issue (and if

applicable, approved by relevant governmental

authority).

► Work in a well ventilated area.

► If the machine has an exhaust, direct the exhaust

so as to reduce disturbance of dust in a dust filled

environment.

► Operate and maintain the machine as

recommended in the operating and safety

instructions

9800 1050 90 | Original instructions8

Safety and operating instructionsRX 2, 3, 4, 6, 8

► Select, maintain and replace consumables/

inserted tools/ other accessory as recommended

in the operating and safety instructions. Incorrect

selection or lack of maintenance of consumables/

inserted tools/ other accessories may cause an

unnecessary increase in dust or fumes.

► Wear washable or disposable protective clothes

at the worksite, and shower and change into clean

clothes before leaving the worksite to reduce

exposure of dust and fumes to yourself, other

persons, cars, homes, and other areas.

► Avoid eating, drinking, and using tobacco

products in areas where there is dust or fumes.

► Wash your hands and face thoroughly as soon as

possible upon leaving the exposure area, and

always before eating, drinking, using tobacco

products, or making contact with other persons.

► Comply with all applicable laws and regulations,

including occupational health and safety

regulations.

► Participate in air monitoring, medical examination

programs, and health and safety training

programs provided by your employer or trade

organizations and in accordance with

occupational health and safety regulations and

recommendations. Consult with physicians

experienced with relevant occupational medicine.

► Work with your employer and trade organization

to reduce dust and fume exposure at the worksite

and to reduce the risks. Effective health and safety

programs, policies and procedures for protecting

workers and others against harmful exposure to

dust and fumes should be established and

implemented based on advice from health and

safety experts. Consult with experts.

WARNING Electric shock

The hydraulic breaker is not insulated against electric

current. Should the hydraulic breaker come in

contact with electric circuits or other electrical power

sources, there is a risk of severe injury or death.

► Never work in the proximity of electric circuits or

other electrical power sources.

WARNING Projectiles

Failure of the work piece, of accessories, or even of

the hydraulic breaker itself may generate high

velocity projectiles. During breaking, splinters, or

other particles may become projectiles and cause

bodily injury by striking the operator or other

persons. Also, breakage of the work piece,

accessories, or the insertion tool may generate high

velocity projectiles that can cause bodily injury. In

addition, objects falling from a height can cause

bodily injury. To reduce risks:

► Close off the working area.

► Before starting, make sure that no persons are in

the danger area, 20 meters both horisontally and

vertically from the hydraulic breaker.

► Immediately switch off the hydraulic breaker when

persons are present in the danger area.

► Press the insertion tool against the working

surface before you start.

► Never operate unless the inserted tool is retained

in the hydraulic breaker with a proper tool

retainer.

WARNING Noise hazard

High noise levels can cause permanent and disabling

hearing loss and other problems such as tinnitus

(ringing, buzzing, whistling or humming in the ears).

To reduce risk and prevent an unnecessary increase

in noise levels:

► Risk assessment of these hazards and

implementation of appropriate controls is

essential.

► Operate and maintain the machine as

recommended in these instructions.

► Select, maintain and replace the insertion tool as

recommended in these instructions.

► If the machine has a muffler, check that it is in

place and in good working condition.

► Always use hearing protection.

► Use damping material to prevent work pieces

from "ringing".

► Make sure there are no hidden electric circuits in

your working area.

99800 1050 90 | Original instructions

RX 2, 3, 4, 6, 8Safety and operating instructions

Maintenance, precautions

WARNING Involuntary start

An involuntary start of the hydraulic breaker can lead

to severe injuries.

► Follow the instructions in the carrier manual to

prevent involuntary start of the hydraulic breaker.

► Installation of a start circuit on the hydraulic

breaker must be made in a way that avoids any

unintentional starts.

► A foot pedal on the carrier must be equipped with

a protection cover.

WARNING Hydraulic system under high

pressure

Maintenance work on a hydraulic breaker under

pressure can lead to severe injuries. Connections

can loosen suddenly, parts can suddenly move and

hydraulic oil can be ejected.

► Depressurise the hydraulic system before

performing maintenance on the hydraulic breaker

or the carrier.

Storage, precautions

WARNING Hydraulic breaker and

insertion tool are heavy

► Store the hydraulic breaker and the insertion tool

so that falling or rolling down is prevented.

WARNING Machine modification

Any machine modification may result in bodily

injuries to yourself or others.

► Never modify the machine. Modified machines

are not covered by warranty or product liability.

► Always use original parts, insertion tools, and

accessories.

► Change damaged parts immediately.

► Replace worn components in good time.

CAUTION Hot insertion tool

The tip of the insertion tool can become hot and

sharp when used. Touching it can lead to burns and

cuts.

► Never touch a hot or sharp insertion tool.

► Wait until the insertion tool has cooled down

before carrying out maintenance work.

WARNING Insertion tool hazards

Accidental engagement of the start and stop device

during maintenance or installation can cause serious

injuries, when the power source is connected.

► Never inspect, clean, install, or remove the

insertion tool while the power source is

connected.

9800 1050 90 | Original instructions10

Overview

To reduce the risk of serious injury or death

to yourself or others, read the Safety

instructions section found on the previous

pages of this manual before operating the

machine.

Design and function

RX is a range of rigmounted hydraulic breakers

designed for all kinds of demolition works. No other

use is permitted.

The hydraulic breaker is operated from the driver's

cab of the carrier using the carrier's hydraulic system.

The breaker frequency is controlled by the oil flow

from the carrier.

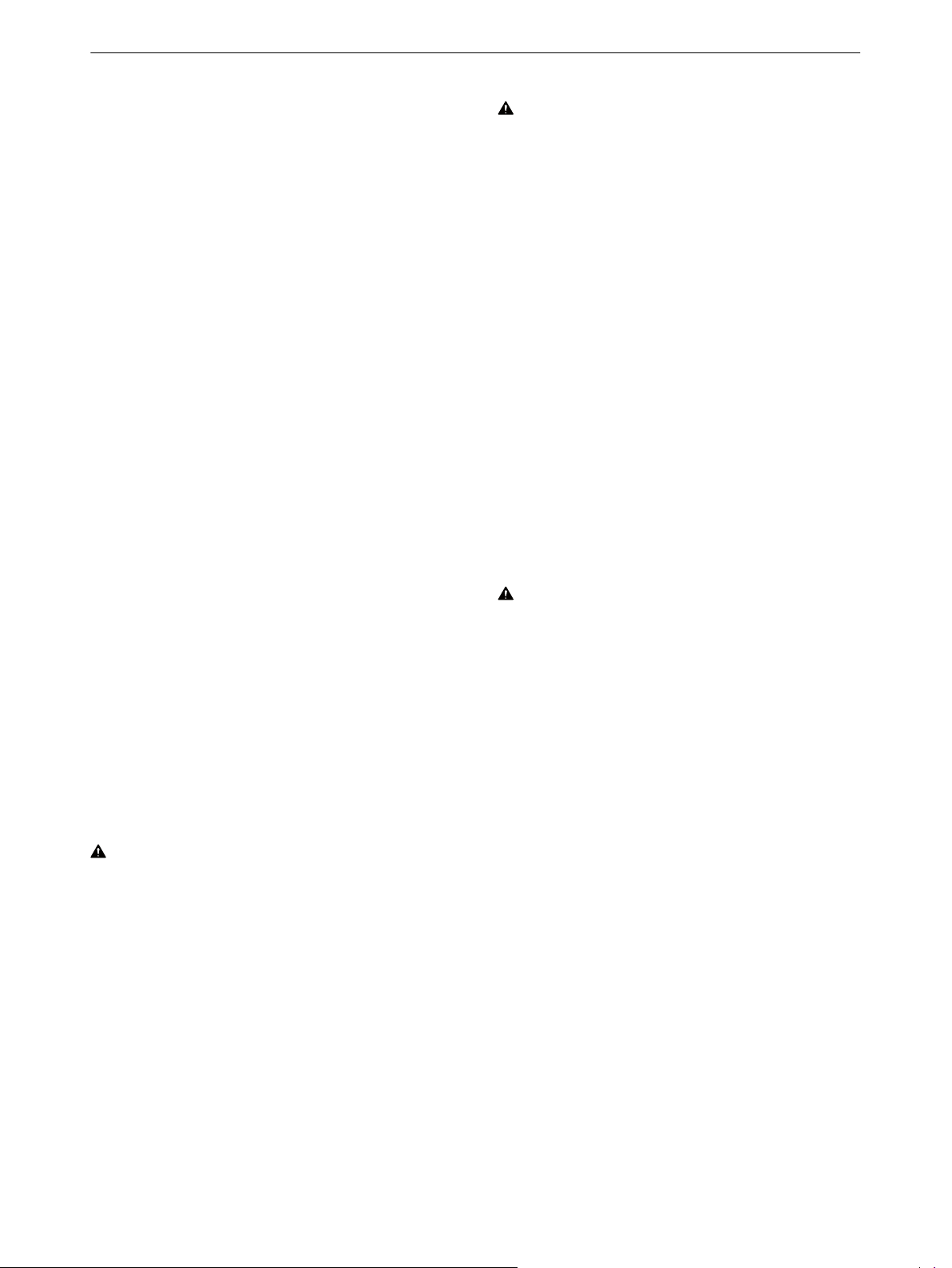

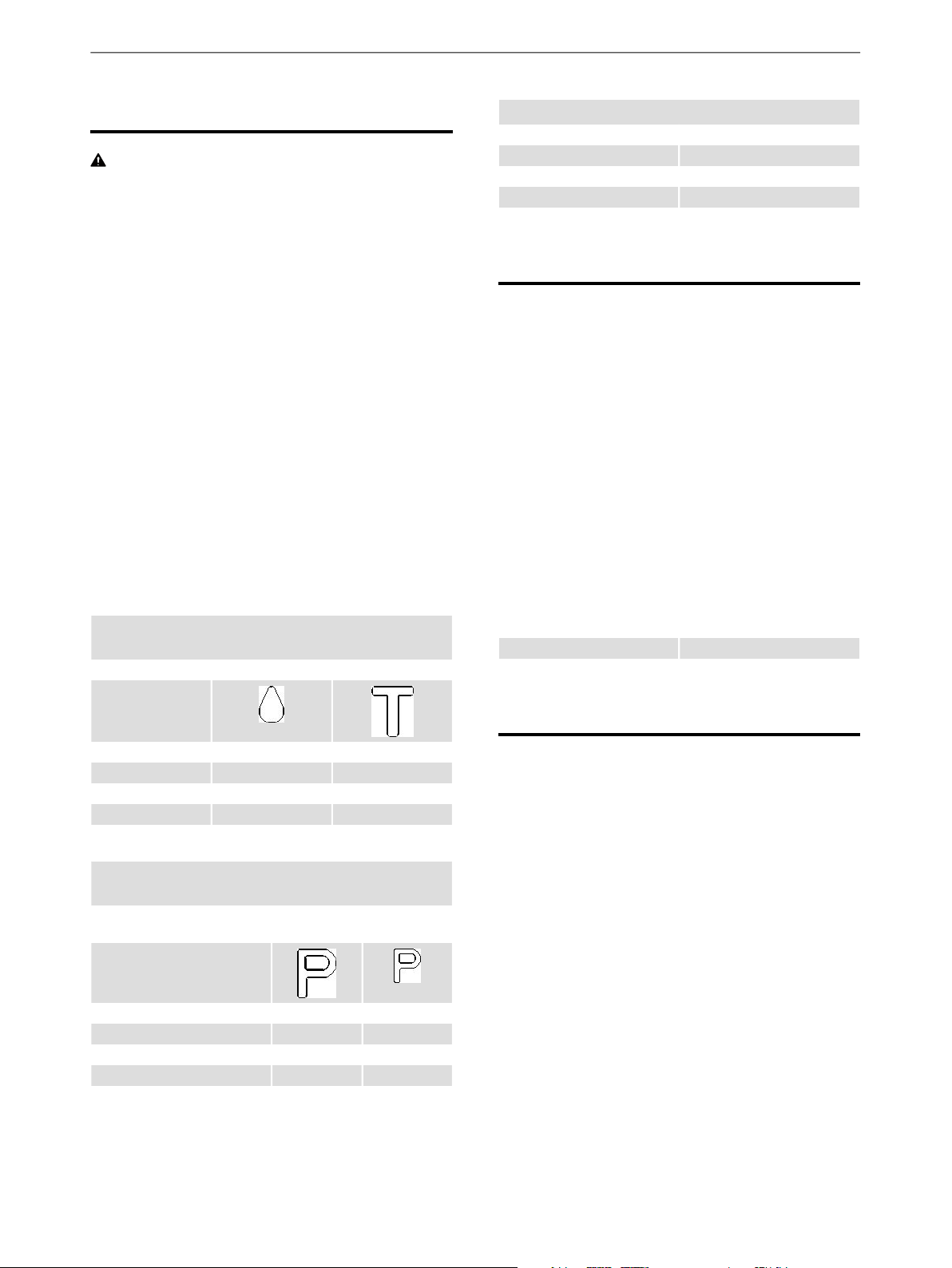

Main parts

Safety and operating instructionsRX 2, 3, 4, 6, 8

A. Hammer box

B. Percussion unit

C. Gasfilling valve

D. Tool retainer

E. Split pin

Labels

The machine is fitted with labels containing

important information about personal safety and

machine maintenance. The labels must be in such

condition that they are easy to read. New labels can

be ordered from the spare parts list.

119800 1050 90 | Original instructions

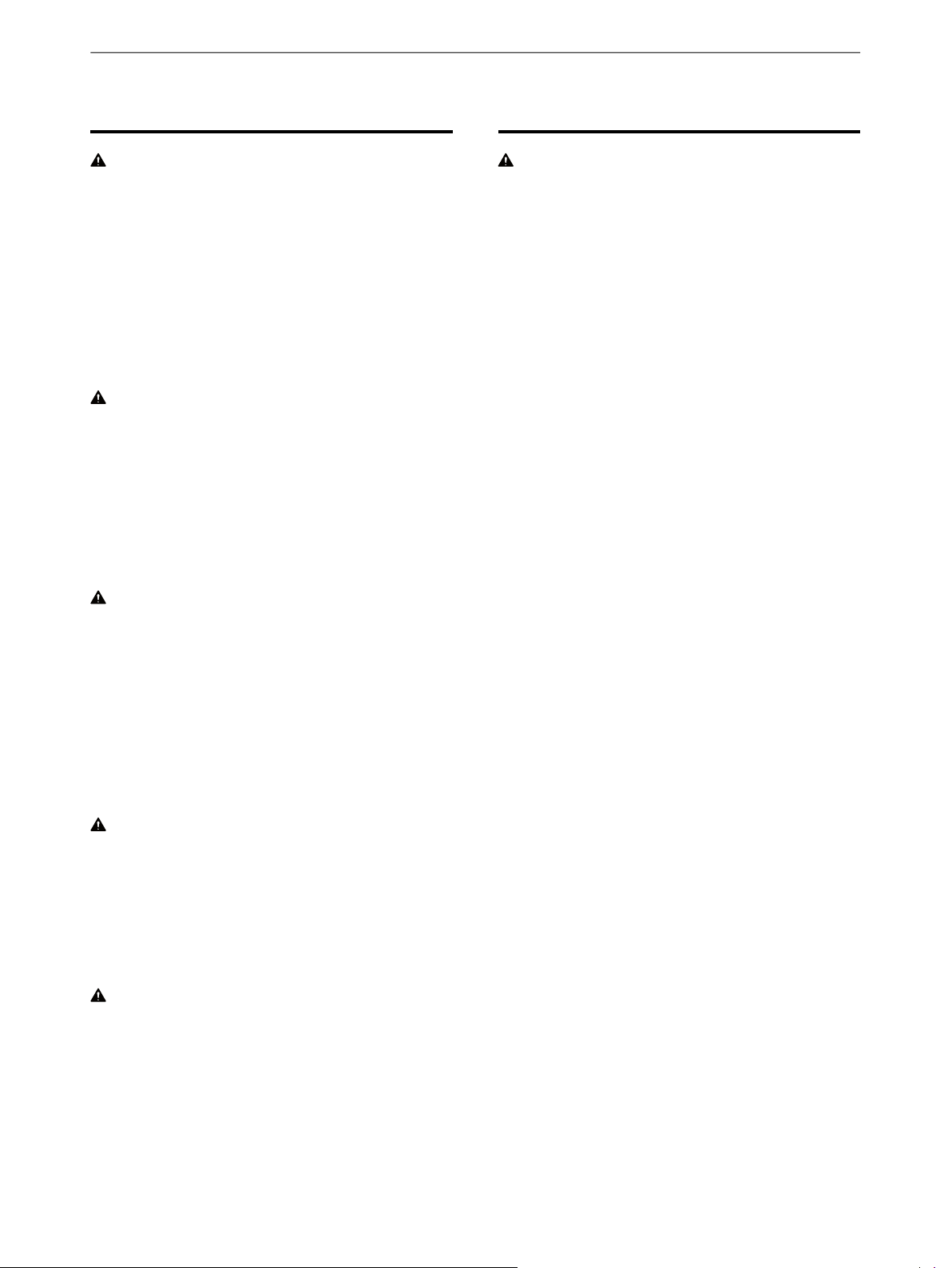

Data plate

A. Machine type

B. Maximum hydraulic pressure

C. Serial number

D. The warning symbol together with the book

symbol means that the user must read the

safety and operating instructions before the

machine is used for the first time.

E. The CE symbol means that the machine is

EC-approved. See the EC Declaration of

Conformity which is delivered with the

machine for more information.

Noise level label

RX 2, 3, 4, 6, 8Safety and operating instructions

The accumulator must only be charged with

Nitrogen.

NOTICE Only certified personnel are allowed to

work with the accumulator.

Transport

WARNING Falling breaker can cause

injuries

► Place the hydraulic breaker in a safe position

where it can not fall over and cause damage.

Carefully check that the carrier is stable enough

when transporting or performing maintenance or

other kind of work on the hydraulic breaker. The

hydraulic breaker is delivered in a box. To lift out the

hydraulic breaker in a safe way, use the lifting eye.

The label indicates the guaranteed noise level

corresponding to EC-directive 2000/14/EC. See

"Technical data" for accurate noise level.

Labels on the accumulator

Installation

Before installing the hydraulic breaker on the carrier

or operating it, read the operation manual and safety

instructions provided by the carrier manufacturer.

Follow all instructions.

The carrier must have the appropriate hydraulic

system for operation of the breaker.

If the carrier is too large for the hydraulic breaker it

may lead to broken insertion tools and increased

wear. See "Technical data" for choosing suitable

carrier.

The safety equipment in the hydraulic system must

be checked for quality (CE mark, etc.), suitability and

functionability by a professional or authorised

supervisor before use.

Read through the overhaul instructions carefully

before servicing or charging.

9800 1050 90 | Original instructions12

Safety and operating instructionsRX 2, 3, 4, 6, 8

Hoses and connections

WARNING Whipping hydraulic hose

Hydraulic hoses under pressure can whip

uncontrollably if screws loosen or are loosened. A

whipping hydraulic hose can cause severe injuries.

► Depressurize the hydraulic system before

loosening the connection of a hydraulic hose.

► Tighten the nuts on the connections of the

hydraulic hoses to the required torque.

Type of nipple: Chicago Pneumatic JIC standard

nipple. The nipple dimensions can be found in the

Spare parts list.

The quality of the hydraulic hoses should be 2SC

(according to EN 857) or better when connecting

the breaker to the carrier. If quick couplings are to

be used, we recommend using the "Flat Face" quick

coupling. This type is sturdy and easy to clean. The

quick couplings pressure class must agree with the

carrier's working pressure.

Always clean the quick couplings before mounting

or dismounting. Always plug hoses and hose nipples

with tight and clean plugs when dismounting.

Hose connections

Right side (As seen from operator’s seat)

Tank, return lineCentral lubrication

Symbol

Tightening torque for pressure and return hose

150 NmRX 2

150 NmRX 3

150 NmRX 4

150 NmRX 6

210 NmRX 8

Hydraulic oil

Normally the type of hydraulic oil the carrier is using

also works for the hydraulic breaker. When a

hydraulic breaker is connected to the carrier, the

hydraulic oil will get contaminated faster. Check and

follow the carrier's instructions for changing oil and

oil filter.

It is common to change the oil filter more frequently

when a hydraulic breaker is installed.

NOTICE When the machine is delivered it contains

some mineral based hydraulic oil. Before connecting

to the carrier's hydraulic system, check which type

of hydraulic oil the carrier is using. Mixing different

types of hydraulic oil may destroy the lubrication

quality which can lead to machine damage.

In order to protect the environment we recommend

the use of biologically degradable hydraulic oil.

Viscosity

15-100 cStViscosity (permitted)

M22 x 1.5G ¼”RX 2

M26 x 1.5G ¼”RX 3

M26 x 1.5G ¼”RX 4

M26 x 1.5G ¼”RX 6

M26 x 1.5G ¼”RX 8

Hose connections

Left side (As seen from operator's seat)

Pressure to

breaker

Symbol

Pressure for

ContiLube©II

M14 x 1.5M26RX 4

M14 x 1.5M26RX 6

M14 x 1.5M26RX 8

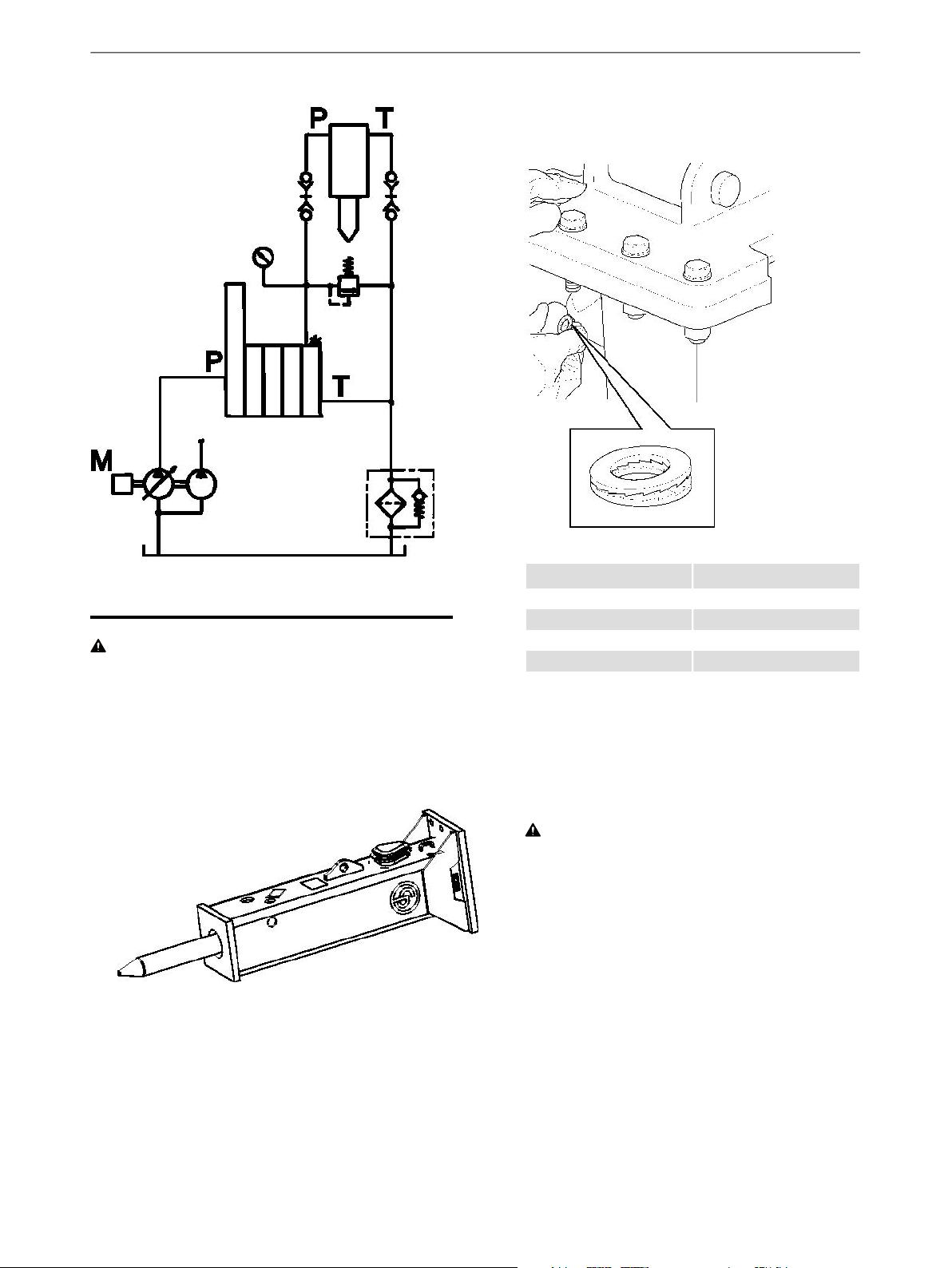

Pressure adjustment

To ensure that the accumulator and hammer are not

overloaded, a separate pressure relief valve should

be installed, see picture below. It is set at a value of

30 bar over the hammer’s maximum operating

pressure. If the carrier’s breaker circuit is already

equipped with a pressure limiting valve, no extra

valve is necessary.

-M22RX 2

-M26RX 3

139800 1050 90 | Original instructions

RX 2, 3, 4, 6, 8Safety and operating instructions

4. Always use NORDLOCK™ washers under bolt

and nut (NORDLOCK™ is a registered trademark

of Nord-Lock AB).

Assembly

WARNING Falling breaker can cause

injuries

► Place the breaker in a safe position where it can

not fall over and cause damage.

Preparation

1. Place the breaker in a position where it is easy

and safe to mount the adapter plate.

Mounting the adapter plate

2. Place a locking washer pair on each screw.

3. Tighten the screws with an spanner.

5.

Tightening torqueAdapter plate

200 NmRX 2

200 NmRX 3

390 NmRX 4

390 NmRX 6

390 NmRX 8

Connecting the breaker to the carrier

6. Place the breaker in a safe way at installation.

7. Carefully lower the stick of the boom into the

adapter.

WARNING Moving parts can crush

and cut

► Never check bores or passages with hands or

fingers.

An assistant should direct the movement of the

dipper arm until the bores in the dipper arm are

flush with those in the adapter.

Agree with the assistant on clear hand signals

for use during the mounting procedure.

8. Insert the pin and lock

9. Lift up the hydraulic breaker using the boom.

10. Extend the bucket cylinder until the bore in the

toggle is flush with those in the adapter. Insert

toggle pin and lock.

9800 1050 90 | Original instructions14

Safety and operating instructionsRX 2, 3, 4, 6, 8

11. After mounting the breaker, carefully extend and

retract the bucket cylinder to its full extent in

each direction. It is important that the cylinder

can be fully extended and retracted without any

difficulty.

Connecting the hydraulic hose

12. Circulate the hydraulic oil before connecting the

hydraulic breaker. This is to make sure that the

hydraulic oil is clean. Use the same routine when

changing the hydraulic oil hose. For further

information see "The hydraulic oil".

13. Connect the pressure and return hose.

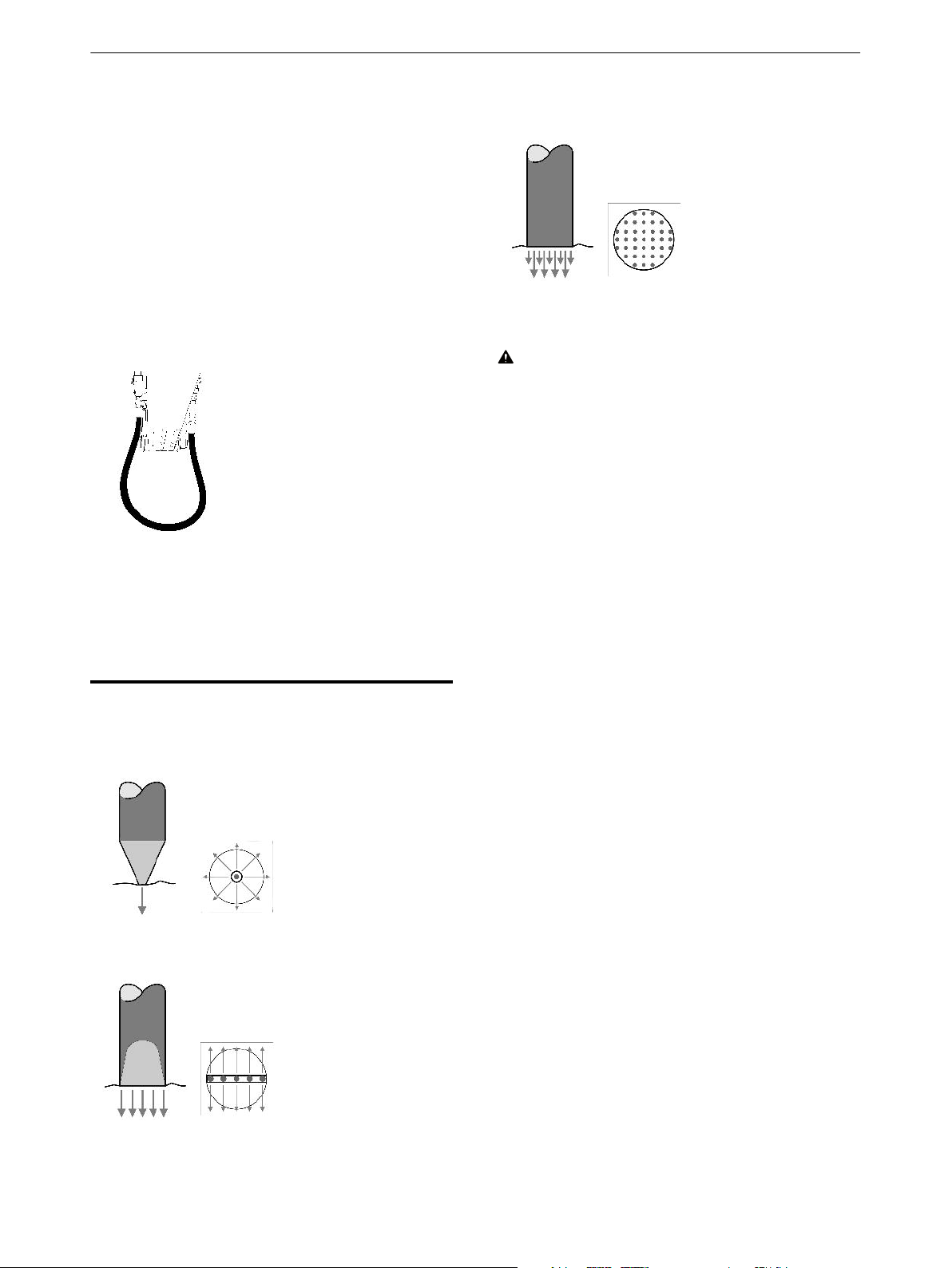

Blunt tool

> Very good energy

application

> Optimum breaking effect

> No torsion effect

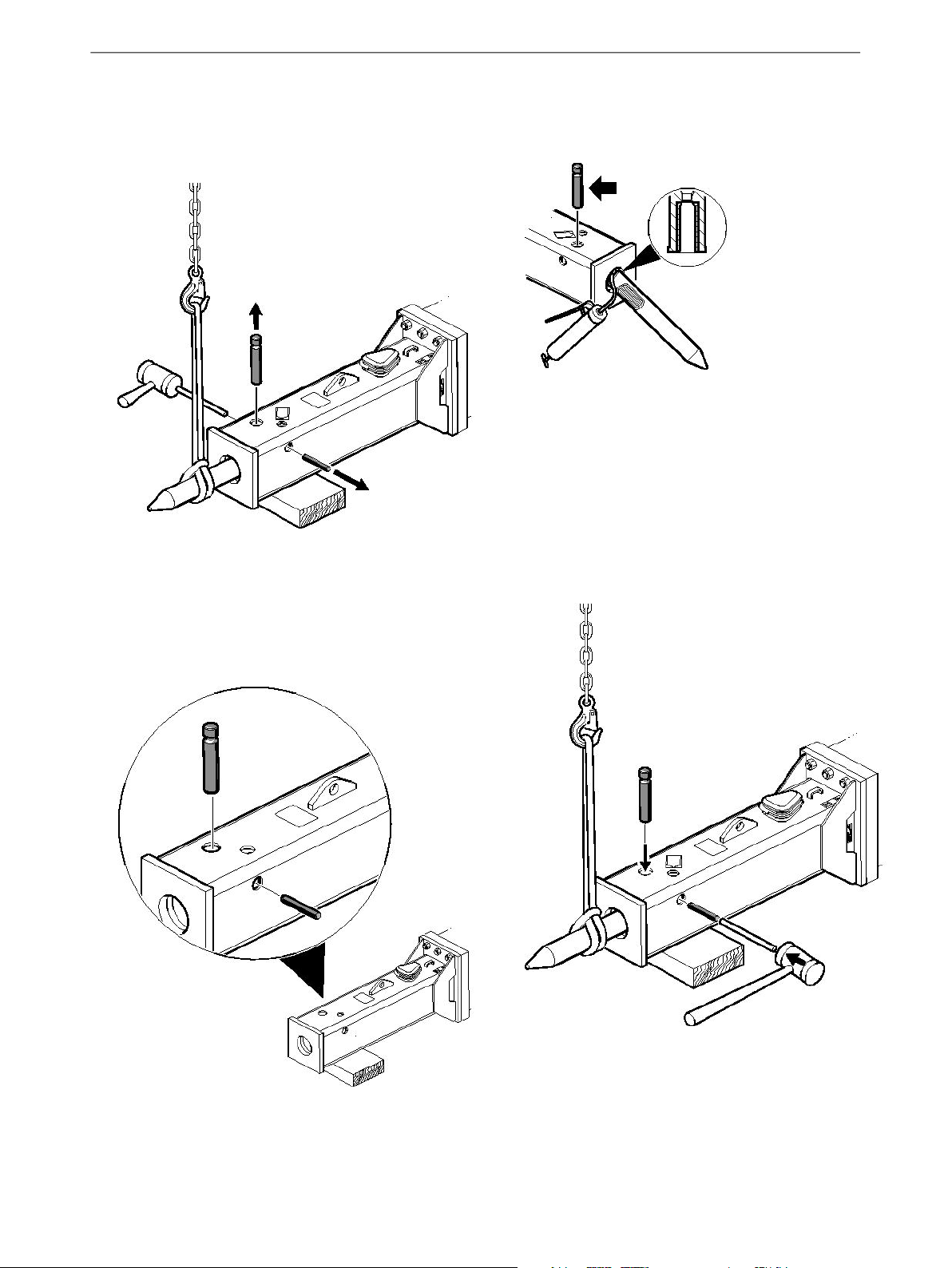

Mounting and dismounting the insertion

tool

WARNING Running engine

Changing the inserted tool or accessories while the

carrier's engine is running can cause serious injury.

► Secure the carrier against involuntary activation.

Before you start mounting or dismounting the

insertion tool, do the following:

1. Place the hydraulic breaker on timber support

blocks. The boring on the back side of the

hydraulic breaker has to remain free.

14. Run the hydraulic oil through the carrier's oil

filter for approximately 3 minutes to make sure

that the hoses are clean.

Insertion tool

Selecting the right insertion tool

Conical moil point

> Very good penetration

> Regular spread of wedge

action

> No torsion effect

Chisels and spades

> Very good spread of wedge

action

> Good penetration

> Torsion effect

2. Shut off the carrier's engine.

3. Remove two plugs from the hammer box, the

first at the split pin and the second at the retainer

pin.

Dismounting the insertion tool:

159800 1050 90 | Original instructions

RX 2, 3, 4, 6, 8Safety and operating instructions

1. Drive out the spring pin by using a break pin

punch and a hammer. Press the retainer pin out

from the hole at the back upwards until you can

remove it through the hole on the front side.

NOTICE Dismount the insertion tool with a

lifting strap to reduce the risk of crushed body

parts. Some insertion tools are heavy, therefore

lift out the insertion tool in a safe way.

1. Clean and lubricate the bushing plentifully. This

is especially important when mounting a new

insertion tool.

2. Mount the insertion tool.

3. Rotate the insertion tool to spread the grease.

4. Mount the retainer pin, and make sure it remains

in position so it not falls through the boring at

the back.

5. Drive in the spring pin by using a break pin

punch and a hammer, until it is flushed with the

percussion unit.

2. Check that the spring pin is not worn out or

damaged. Change if necessary.

Mounting the insertion tool

9800 1050 90 | Original instructions16

Safety and operating instructionsRX 2, 3, 4, 6, 8

Operation

NOTICE The hydraulic breaker or the inserted tool

is not to be used as a lifting device. When lifting

heavy components use the hook on the carrier arm.

Preparation before breaking

Operating temperatures

The operating temperatures of the hydraulic breaker

are between – 20 ºC and + 80 ºC.

CAUTION Temperature hazard

The hydraulic breaker and the hydraulic oil system

of the carrier can be damaged if the hydraulic breaker

is used at higher or lower temperatures.

► Only start the hydraulic breaker when the

hydraulic oil has reached the proper operating

temperature.

► If the ambient temperature is below – 20 ºC, you

should warm up the insertion tool and the

hydraulic breaker before use.

Breaking

CAUTION Machine and tool hazard

Continuous operation at full extension and/or

retraction can result in damage to the hydraulic

cylinders.

► Always avoid operating the breaker with the

cylinders fully extended or retracted.

► Reposition the carrier and/or boom to avoid fully

extended or retracted cylinders.

► Pay attention and look at what you are doing.

Never start the hydraulic breaker until both carrier

and the hydraulic breaker are in the correct position.

► If the oil temperature exceeds + 80 ºC, you must

not use the hydraulic breaker as the oil quality

becomes inadequate which severely shortens the

life time of seals and O-rings.

Engine rpm

Too high engine rpm only results in increased fuel

consumption and increased oil temperature. Adapt

the engine rpm to the recommended value to give

the correct operating oil flow.

Operating

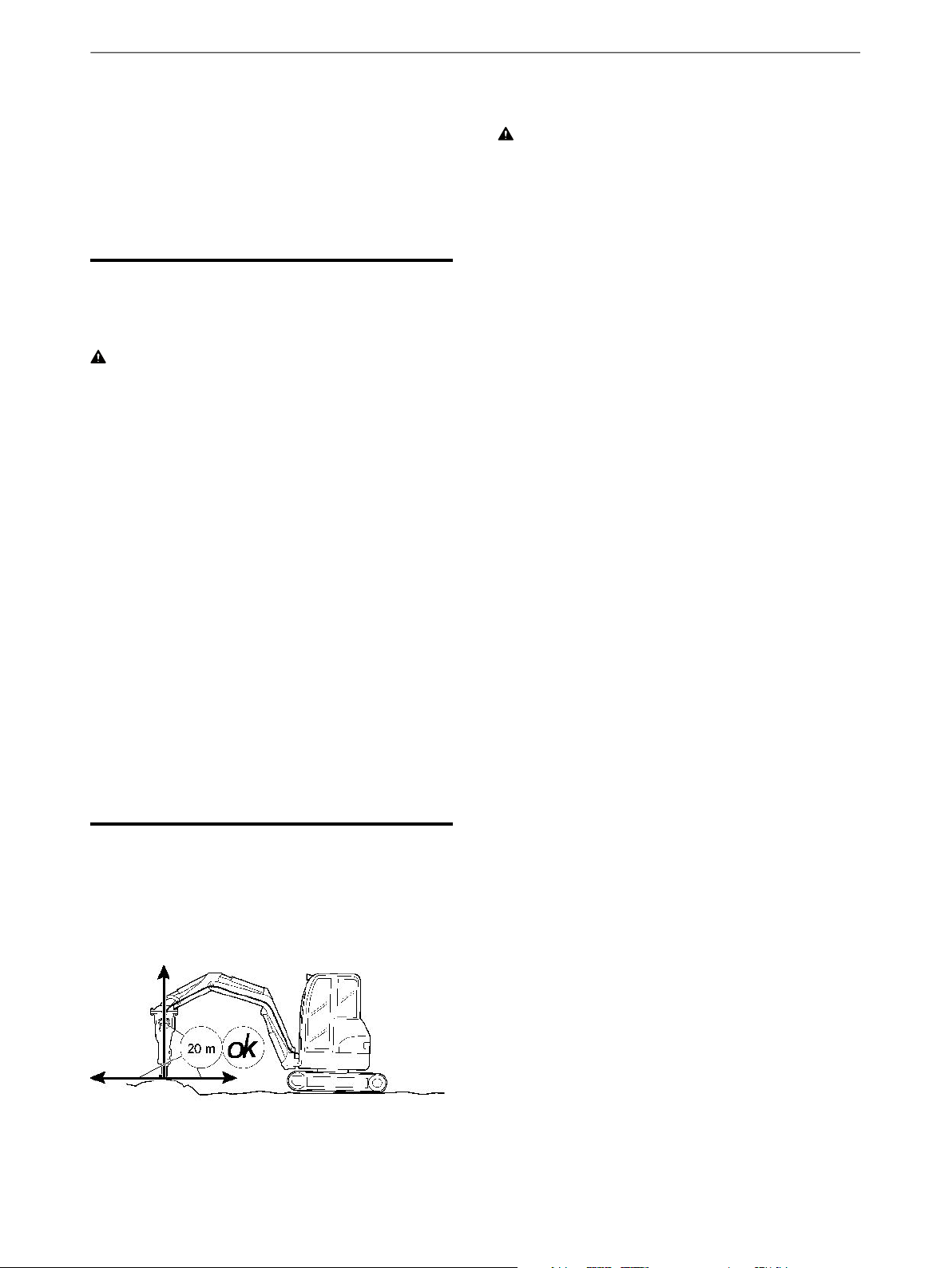

Risk area

Before starting the hydraulic breaker, make sure that

no persons are in the risk area, 20 meters both

horizontally and vertically from the hydraulic

breaker.

179800 1050 90 | Original instructions

RX 2, 3, 4, 6, 8Safety and operating instructions

♦

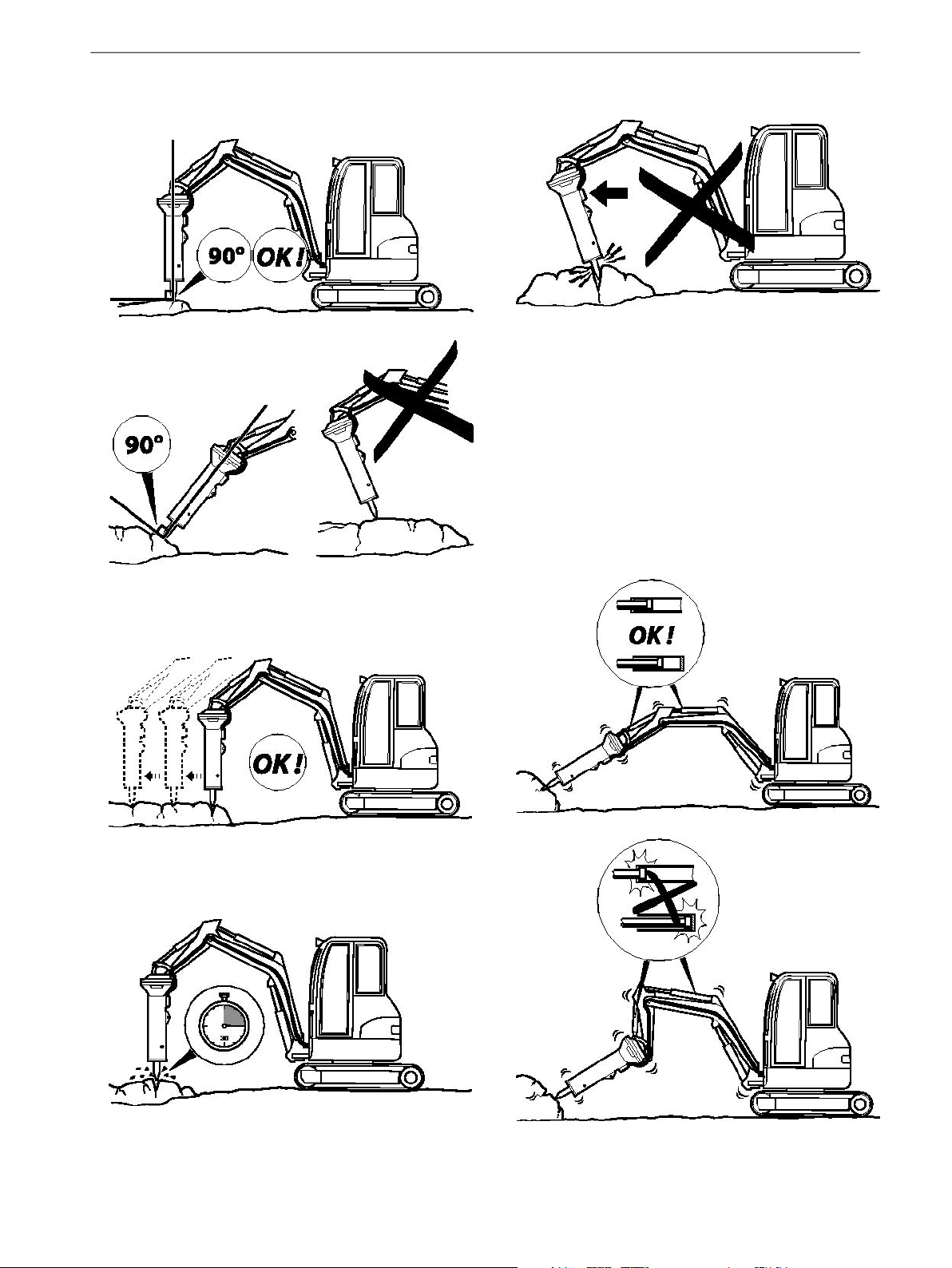

Direct the hydraulic breaker in a position 90°

towards the object.

♦

Never bend with the insertion tool.

♦

Use the correct feed pressure. When the feed

pressure is correct the hydraulic breaker is working

at its best and the vibrations are at a minimum.

Also the wear on the bushing and inserted tool is

kept to a minimum.

♦

Listen to the sound from the hydraulic breaker.

The sound changes if there is any bending

between the inserted tool and bushing.

♦

Never run the breaker with the boom cylinders at

their end positions. It may cause damage to the

carrier.

♦

Start near the edge and work your way in towards

the middle. Never start in the middle of large

objects.

♦

Never run the hydraulic breaker longer then 15

seconds on the same spot. Move the inserted tool

to a new position if the object does not break.

9800 1050 90 | Original instructions18

♦

Avoid idling strokes; it causes wear on both

inserted tool and tool retainers.

Safety and operating instructionsRX 2, 3, 4, 6, 8

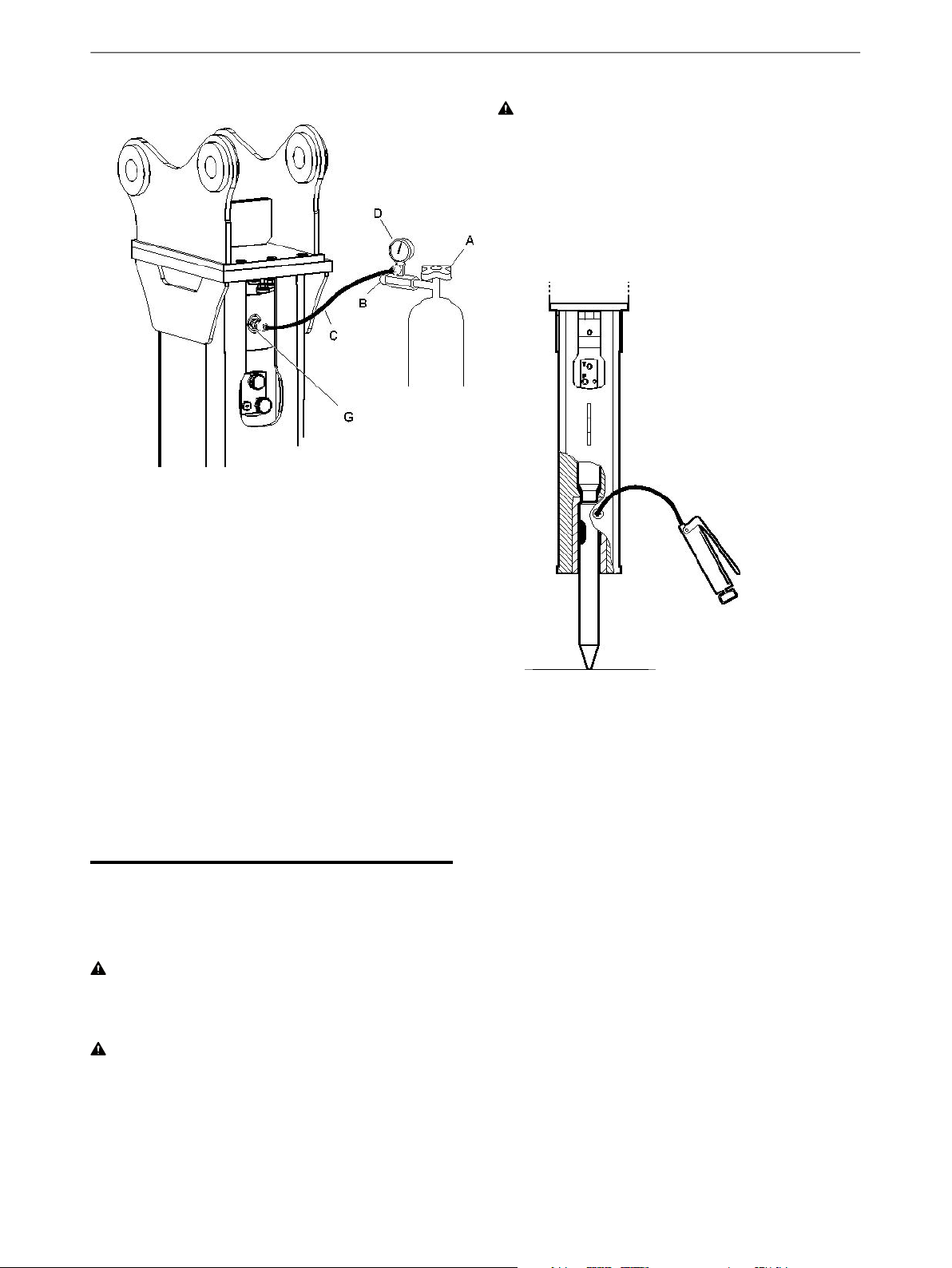

WARNING Explosion hazard

Use of other gases than Nitrogen (N2) can cause an

explosion.

► Charge the accumulator with Nitrogen (N2) only!

CP supplies a service box containing all necessary

tools and parts required to service the piston

accumulator. See the Spare parts list.

If the hammer's performance begins to deteriorate,

we recommend that you check the pressure in the

piston accumulator.

NOTICE The pressure must be checked with the

hammer at a working temperature of 60º-70ºC.

To measure the pressure, bring down the hammer

with no pressure on the chisel. Detach the plug from

the charge valve (G) and connect the test pressure

gauge.

The piston accumulator only needs to be filled if the

pressure falls below the minimum level.

Maintenance

It is essential that regular maintenance is performed

to maintain the breakers maximum efficiency.

Equipment that is insufficiently maintained can be

dangerous for both the operator and persons near

the breaker. Make sure that regular maintenance

routines with lubrication are followed to keep the

equipment safe and efficient.

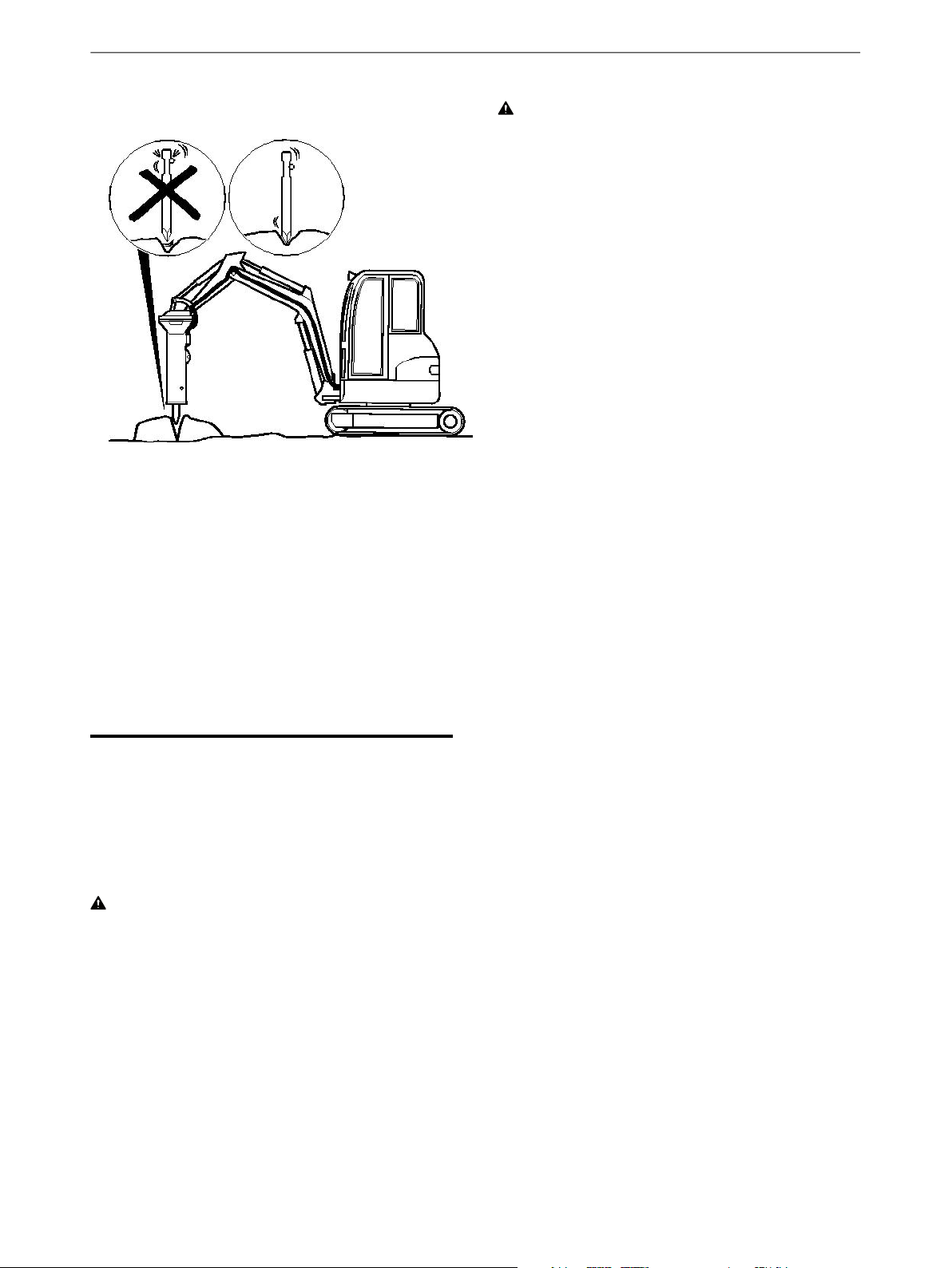

Lubrication

Lubricate the chisel shank thoroughly every two

hours using high-temperature grease such as

genuine chisel grease from your supplier. This also

lubricates the bushing and the tool holder; 5-10

pumps of the grease gun is sufficient. Stop when

the grease starts to emerge at the chisel holder or

between the chisel and the bushing.

WARNING Running engine

If the carrier's engine is running when lubricating

the chisel by hand there is a risk of severe accidents.

► Always switch off the carrier's engine to avoid

accidents.

Filling

1. Connect pressure relief valve (B) to gas bottle

valve (A).

2. Connect gas hose (C) to pressure relief valve (B)

as shown in figure.

3. Close pressure relief valve (B).

4. Open gas bottle valve (A).

5. Remove the plug from the charge valve (G).

6. Guide the nozzle of the hose (C) into the charge

valve.

7. Carefully open the relief valve (B).

8. Fill the piston accumulator.

9. Read the pressure on the pressure gauge (D).

10. Close the pressure relief valve when the desired

pressure has been reached.

Pull the gas hose out of the charge valve (G) and

fit the plug.

During lubrication, the chisel must be pressed

against the hammer piston so that the space

between piston and the chisel does not fill with

grease.

199800 1050 90 | Original instructions

RX 2, 3, 4, 6, 8Safety and operating instructions

11. Close gas bottle valve (A).

Checking and reducing the gas pressure

1. Always use the gas hose (C) and the pressure

gauge (D) when checking the gas pressure.

CAUTION Skin eczema

Grease can cause eczema when it comes in contact

with the skin.

► Avoid getting grease on your hands. Wash

thoroughly after contact.

1. Press the insertion tool against the piston so that

the space between the piston and the insertion

tool does not fill with grease.

2. Connect the gas hose to the pressure gauge.

3. Remove the plug from the charge valve (G).

4. Press the nozzle of the gas hose into the charge

valve and read the pressure.

5. Reduce the pressure by repeatedly inserting and

removing the nozzle.

NOTICE Only the nozzle may be used to reduce

the pressure. Never use pins, screwdrivers etc. as

these can damage the charge valve.

Every second hour

Regularly lubricate the insertion tool, the tool

retainer and the bushings.

Lubricating with a grease gun

WARNING Hot insertion tool during

operation and a period of time after use.

► Avoid contact with the insertion tool.

WARNING Hot hydralic breaker during

operation and a period of time after use.

► Avoid contact with the hydralic breaker.

2. Lubricate the insertion tool's shank plentifully

while pressing the insertion tool against the

surface to avoid filling the cavity with grease. If

the cavity is filled with grease when the hydraulic

breaker is started, the lower seals may be

damaged.

When the insertion tool shank is exposed to high

pressure and high temperatures a standard type of

grease will melt and run. To avoid this always use a

genuine insertion tool grease from your supplier.

Central lubrication system

We recommend Chicago Pneumatic's central

lubrication system. When this system is fitted on the

carrier, grease is pumped continuosly from a

lubrication container on the carrier to the breaker

when the breaker is activated. This increases the life

of the tool bushings and insertion tools considerably.

9800 1050 90 | Original instructions20

Safety and operating instructionsRX 2, 3, 4, 6, 8

Every day

♦

Check the tool retainer and split pin.

♦

Check that hoses, couplings and accumulator are

in a good condition.

♦

Check that bolts and connections are free from

damage and properly tightened. See tightening

torques in the spare parts list.

Every week

♦

Clean the hydraulic breaker carefully.

♦

Check the wear bushings wear and maximum

inner wear limits.

Wear limits

B (mm)A (mm)

3945RX 2

4955RX 3

5965RX 4

6773RX 6

7783RX 8

Replacing the insertion tool bushing

The insertion tool bushing is kept in place by the

tool retainer. A new bushing has a slip fit.

1. If a worn out bushing is stuck, use a sliding

hammer to remove it.

The wear bushing must be replaced when the

inner diameter (A) has reached its maximum wear

limit, see "Wear limits" and "Replacing the

insertion tool bushing".

♦

Check the insertion tool for wear.

The insertion tool must be replaced when the

outer diameter (B) has reached its minimum wear

limit. See "Wear limits".

Too large clearance can make the insertion tool

break and the piston can be damaged.

♦

Check the hammer and the adapter plate for

cracks and wear.

♦

Check that the accumulator screws are properly

tightened. The correct tightening torque is found

in the spare parts list.

The insertion tool may never be sharpened by

forging. Sharpening should only be performed by

milling, grinding, or turning.

2. Carefully clean the bore and the bushing seat

area.

3. Lubricate and mount the bushing.

4. Use a plastic sledgehammer to insert the

bushing.

5. Keep the bushing in position with help of the

tool retainer.

219800 1050 90 | Original instructions

Every year

Overhauling should be done after 1 year of

continuous operation. Overhauling should for safety

reasons be performed by authorised personnel at

an authorised workshop.

Storage

WARNING Falling breaker can cause

injuries

► Place the hydraulic breaker in a safe position

where it can not fall over and cause damage.

If the hydraulic breaker is not used for a long time,

the following points have to be considered to protect

the hydraulic breaker from corrosion:

1. Clean the hydraulic breaker carefully.

RX 2, 3, 4, 6, 8Safety and operating instructions

2. Dismount the insertion tool and lubricate the

front part of the piston, wear bushing, and the

retainer pin.

3. Store the hydraulic breaker in a dry place.

Always keep the breaker in an upright position, if

stored for a long time.

Disposal

A used machine must be treated and scrapped in

such a way that the greatest possible portion of the

material can be recycled and any negative influence

on the environment is kept as low as possible.

Before a used machine is scrapped it must be

emptied and cleaned from all hydraulic oil. The

remaining hydraulic oil must be deposited and any

negative influence on the environment is to be kept

as low as possible.

9800 1050 90 | Original instructions22

Technical data

Machine data

(kg)

(kg)

in. (mm)

Capacities

min-max tonnes

(blows/min)

(bar)

pressure (bar)

Safety and operating instructionsRX 2, 3, 4, 6, 8

RX 8RX 6RX 4RX 3RX 2

8460 0500 428460 0500 418460 0500 408460 0500 398460 0500 38Part number

838 (380)626 (284)514 (233)366 (166)258 (117)Operating weight lb

661 (300)472 (214)370 (168)265 (120)165 (75)Delivery weight lb

3.15 (80)2.76 (70)2.44 (62)2.05 (52)1.65 (42)Tool shank diameter

RX 8RX 6RX 4RX 3RX 2

7 - 125 - 9.02.5 - 62.0 - 4.51.2 - 3Suitable excavators

60–9045–7535–6030–5015–35Oil flow (l/min)

530–1050530–1150520–1150670–1450560–1700Impact rate

120–150100–140110–140110–140110–130Operating pressure

12 - 16.511 - 1514 - 1916 - 20.514 - 18.5Accumulator

Noise declaration statement

RX 8RX 6RX 4RX 3RX 2

1

dB(A)

1

Sound pressure level according to EN ISO 3744 in accordance with directive 2000/14/EC at 10 metres distance.

2

Guaranteed sound power according to EN ISO 3744 in accordance with directive 2000/14/EC inclusive spread

in production.

These declared values were obtained by laboratory type testing in accordance with the stated directive or

standards and are suitable for comparison with the declared values of other tools tested in accordance with

the same directive or standards. These declared values are not adequate for use in risk assessments and values

measured in individual work places may be higher. The actual exposure values and risk of harm experienced

by an individual user are unique and depend upon the way the user works, in what material the breaker is

used, as well as upon the exposure time and the physical condition of the user, and the condition of the

breaker.

We, Atlas Copco, cannot be held liable for the consequences of using the declared values, instead of values

reflecting the actual exposure, in an individual risk assessment in a work place situation over which we have

no control.

8786858381Sound pressure

115114113111109Sound power2dB(A)

239800 1050 90 | Original instructions

RX 2, 3, 4, 6, 8Safety and operating instructions

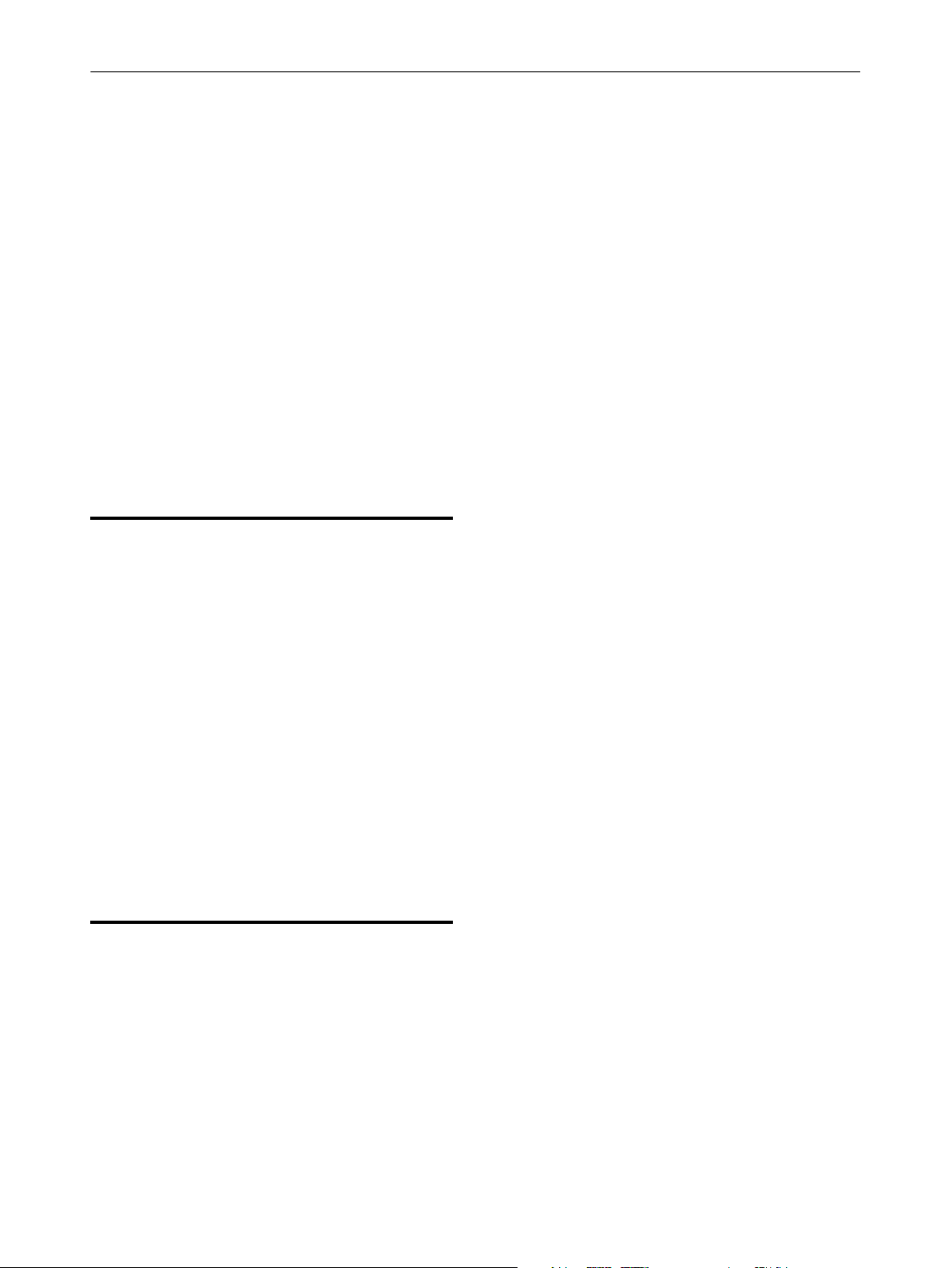

EC Declaration of Conformity

EC Declaration of Conformity (EC Directive 2006/42/EC)

We, Atlas Copco Construction Tools AB, hereby declare that the machines listed below conform to the provisions

of EC Directive 2006/42/EC (Machinery Directive) and 2000/14/EC (Noise Directive).

Guaranteed sound

power level [dB(A)]Hydraulic breaker

Technical Documentation authorised representative:

Erik Sigfridsson

Atlas Copco Constructions Tools AB

Dragonvägen 2

Kalmar

General Manager:

Erik Sigfridsson

Manufacturer:

Atlas Copco Constructions Tools AB

105 23 Stockholm

Sweden

Place and date:

Kalmar, 2010-03-16

Measured sound

power level [dB(A)]

Weight (kg)Pmax (bar)

75130108109RX 2

120140110111RX 3

168140112113RX 4

214140113114RX 6

300150114115RX 8

9800 1050 90 | Original instructions24

SommaireRX 2, 3, 4, 6, 8

259800 1050 90 | Instructions d’origine

RX 2, 3, 4, 6, 8Sommaire

FRANÇAIS

Sommaire

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

À propos des prescriptions de sécurité et des instructions pour l'opérateur. . . . . . 27

Consignes de sécurité. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Indications de sécurité. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Précautions et qualifications du personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Engins porteurs, précautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installation, précautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Fonctionnement, précautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Maintenance, précautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Stockage, précautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Vue d'ensemble. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Conception et fonctionnement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Pièces principales. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Étiquettes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Transport. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Flexibles et connexions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

L'huile hydraulique. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Réglage de pression. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Assemblage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Outil d'insertion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Commande. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Préparatifs avant de commencer le travail de démolition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Utilisation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Lubrification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Toutes les deux heures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Chaque jour. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Chaque semaine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Chaque année. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Stockage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Destruction d'une machine usagée. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Caractéristiques techniques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Caractéristiques de la machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Capacités. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Énoncé déclaratif sur le bruit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Déclaration CE de conformité. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Déclaration CE de conformité (Directive 2006/42/CE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9800 1050 90 | Instructions d’origine26

RX 2, 3, 4, 6, 8

Introduction

Nous vous remercions d'avoir choisi un produit Chicago Pneumatic. Depuis plus

d'un siècle, la marque Chicago Pneumatic est synonyme de performance et

d'innovation dans le secteur des outils pneumatiques.

Aujourd'hui, la société offre une vaste gamme d'outils pneumatiques et hydrauliques

comprenant brise-béton, trépans, marteaux burineurs, marteaux-bêches, pioches et

défricheuses, bouchardeuses, pompes et bien d'autres outils.

La marque Chicago Pneumatic est associée avec des produits puissants et fiables,

faciles à entretenir et ayant un bon rapport qualité-prix.

Pour plus d’informations, veuillez consulter le site Web www.cp.com

Atlas Copco Construction Tools AB

S-105 23 Stockholm

Suède

Prescriptions de sécurité et instructions pour

l’opérateur

À propos des prescriptions de sécurité et

des instructions pour l'opérateur

Le but des instructions est de vous apprendre à utiliser le brise-roche hydraulique

d’une manière efficace et en toute sécurité. Les instructions vous donnent également

des conseils et vous indiquent comment effectuer la maintenance de routine du

brise-roche hydraulique.

Vous devez lire ces instructions attentivement et les comprendre avant d'utiliser le

brise-roche hydraulique pour la première fois.

279800 1050 90 | Instructions d’origine

l’opérateur

RX 2, 3, 4, 6, 8Prescriptions de sécurité et instructions pour

Consignes de sécurité

Il convient de lire et d'assimiler les Prescriptions de

sécurité et des instructions pour l'opérateur avant

toute installation, utilisation, réparation, entretien

ou remplacement d'accessoire sur la machine, afin

de minimiser le risque de blessures graves ou de

dommages pouvant entraîner la mort.

Affichez les Prescriptions de sécurité et instructions

pour l'opérateur sur les différents sites de travail ;

faites en des copies pour les employés et

assurez-vous que chaque personne concernée a bien

lu les Prescriptions de sécurité et instructions pour

l'opérateur, avant d'utiliser ou d'intervenir sur la

machine.

En outre, l'opérateur ou l'employeur doit évaluer

les risques spécifiques pouvant survenir à la suite de

chaque utilisation de la machine.

Indications de sécurité

Les indications de sécurité Danger, Attention et

Prudence ont les sens suivants :

DANGER

AVERTISSEMENT

ATTENTION

Indique une situation

dangereuse qui, si elle n'est

pas évitée, terminera par

provoquer la mort ou des

blessures graves.

Indique une situation

dangereuse qui, si elle n'est

pas évitée, est de susceptible

de provoquer la mort ou des

blessures graves.

Indique une situation

dangereuse qui, si elle n'est

pas évitée, est de susceptible

de provoquer des blessures

mineures à modérées.

> sont qualifiées pour conduire une grue ou un

chariot élévateur conformément aux directives

nationales en vigueur,

> sont informées sur les prescriptions nationales de

sécurité pertinentes et les instructions de

prévention d’accidents

> et ont lu et compris les chapitres relatifs à la

sécurité et au transport contenus dans le présent

manuel.

Installation, stockage, maintenance et

mise au rebut

L'installation, le stockage, la maintenance et la mise

au rebut peuvent uniquement être entrepris par des

personnes qui :

> sont informés sur les prescriptions nationales de

sécurité pertinentes et les instructions de

prévention d’accidents

> et ont lu et compris les Prescriptions de sécurité

et instructions pour l'opérateur.

Fonctionnement

L'utilisation du brise-roche hydraulique est

uniquement réservée à des opérateurs d'engin

porteur qualifiés. Les opérateurs d'engin porteur

sont qualifiés s'ils :

> sont qualifiés pour conduire un engin porteur

conformément aux directives nationales en

vigueur,

> sont informées sur les prescriptions nationales de

sécurité pertinentes et les instructions de

prévention d’accidents

> et ont lu et compris les Prescriptions de sécurité

et instructions pour l'opérateur.

Précautions et qualifications

du personnel

Seules des personnes qualifiées ou formées peuvent

utiliser ou procéder à l'entretien de la machine. Elles

doivent être physiquement aptes à manipuler le

volume, le poids et la puissance de l'outil. Utilisez

toujours votre jugement et votre bon sens.

Transport

Le transport du brise-roche hydraulique peut

uniquement être entrepris par des personnes qui :

Procédure de test

La procédure de test de l'installation hydraulique

devra uniquement être entreprise par des techniciens

qualifiés. Les techniciens doivent être qualifiés pour

homologuer une installation hydraulique

conformément aux directives nationales.

9800 1050 90 | Instructions d’origine28

RX 2, 3, 4, 6, 8

Prescriptions de sécurité et instructions pour

l’opérateur

Équipement de protection du personnel

Utilisez toujours un équipement de protection

individuelle homologué. Les opérateurs et toutes

autres personnes séjournant sur la zone de travail

doivent porter un équipement de protection

individuelle, incluant au minimum :

> Casque de protection

> Protections auditives

> Protecteurs des yeux résistants aux chocs avec

protection latérale

> Appareil de protection respiratoire, le cas échéant

> Gants de protection

> Bottes de protection adaptées

> Salopette de travail appropriée ou vêtement

similaire (serré) qui recouvre les bras et les jambes.

Drogues, alcool ou médicaments

AVERTISSEMENT Drogues, alcool ou

médicaments

Les drogues, l'alcool ou les médicaments risquent

d'avoir un effet négatif sur votre jugement et votre

capacité de concentration. De mauvaises réactions

et des évaluations incorrectes peuvent entraîner des

accidents graves, voire la mort.

► N'utilisez jamais la machine lorsque vous êtes

fatigué(e) ou sous l'influence de drogues, de

l'alcool ou de médicaments.

► L'utilisation de la machine par une personne sous

l'influence de drogues, de l'alcool ou de

médicaments est strictement interdite.

Installation, précautions

Circuit hydraulique

DANGER Gaz comprimé, risque

d'explosion

L'accumulateur au-dessus du piston reste pressurisé

même lorsque le système hydraulique est coupé. Le

démontage de l'accumulateur sans libérer d'abord

l’azote peut provoquer des blessures graves ou la

mort.

► Remplir uniquement l'accumulateur au-dessus

du piston avec de l'azote (N2).

AVERTISSEMENT Huile hydraulique

sous haute pression

Les jets fins d'huile hydraulique sous haute pression

peuvent pénétrer la peau et provoquer des

dommages permanents.

► Consultez immédiatement un médecin en cas de

pénétration de l'huile hydraulique dans votre

peau.

► Ne jamais contrôler une fuite de liquide

hydraulique avec les doigts.

► Éloignez votre visage de toute fuite éventuelle.

AVERTISSEMENT Huile hydraulique

L'huile hydraulique renversée peut causer des

brûlures, des accidents par glissade et nuit

également à l'environnement.

► Soyez particulièrement prudent en cas d'huile

renversée et traitez celle-ci conformément aux

réglementations locales de sécurité et

d'environnement.

Engins porteurs, précautions

Avant d'utiliser ou de transporter l'engin porteur

avec le brise-roche hydraulique monté, lisez

soigneusement les prescriptions de sécurité et

instructions pour l'opérateur du fabricant de l'engin

porteur.

Assurez-vous que l'engin porteur est équipé de

dispositifs de protection adéquats, y compris un

écran de protection devant l'opérateur.

Le brise-roche hydraulique ne devrait être installé

que sur un engin porteur ayant une capacité de

charge suffisante.

Les engins porteurs sans capacité de charge

suffisante ne fournissent pas le niveau de stabilité

nécessaire et peuvent se renverser pendant

l’utilisation du brise-roche hydraulique en

provoquant des blessures et des dommages.

► Ne démontez jamais la machine hydraulique

lorsque l'huile hydraulique est chaude.

► Ne jamais faire passer des canalisations

hydrauliques pour l'attache de la machine

hydraulique à travers la cabine de conduite.

ATTENTION Eczéma de contact

L'huile hydraulique peut provoquer de l'eczéma en

cas de contact avec la peau.

► Évitez d’avoir de l'huile hydraulique sur vos mains.

► Portez toujours les gants de protection lorsque

vous manipulez de l'huile hydraulique.

► Lavez-vous les mains après tout contact avec de

l'huile hydraulique.

299800 1050 90 | Instructions d’origine

l’opérateur

RX 2, 3, 4, 6, 8Prescriptions de sécurité et instructions pour

Assemblage / Désassemblage

AVERTISSEMENT Pièces mobiles

Risque de fuites d'huile et de dommages corporels,

comme le pincement des mains et des doigts.

► Ne contrôlez jamais les orifices ou les canaux avec

les mains ou les doigts.

► Tous les mouvements de la flèche seront effectués

uniquement en coopération avec le personnel

d’installation du brise-roche hydraulique.

► Si le brise-roche hydraulique est installé avec une

attache rapide, assurez-vous qu'il est bien

verrouillé et que tous risques de desserrage soit

éliminés.

Fonctionnement,

précautions

DANGER Danger d'explosion

Si un outil d'insertion chaud entre en contact avec

un explosif ou avec des gaz explosifs, cela pourrait

provoquer une explosion. Lors de travaux sur

certains matériaux et lors d'utilisation de certains

matériaux dans les pièces de la machine, des

étincelles susceptibles d'enflammer des gaz peuvent

provoquer des explosions. Les explosions peuvent

provoquer des dommages corporels voire la mort.

► Ne jamais utiliser la machine dans un

environnement explosif quelconque.

► N'utilisez jamais cette machine près de poussières,

d'émanations ou de matériaux inflammables.

► Assurez-vous qu'il n'y a aucune source de gaz

non identifiée ni explosifs dans les environs.

AVERTISSEMENT Pression d'utilisation

Si la pression de fonctionnement maximale de la

machine hydraulique est dépassée, l'accumulateur

peut être surchargé, ce qui risque de provoquer des

dommages matériels et corporels.

► Faites toujours fonctionner la machine

hydraulique à la bonne pression de service. Voir

« Caractéristiques techniques ».

AVERTISSEMENT Dangers liés aux

poussières et aux fumées

Les poussières et/ou de fumées générées ou

dispersées lors de l’utilisation de la machine peuvent

causer des maladies respiratoires graves et

permanentes, ou autre lésion corporelle (par

exemple, la silicose ou autre maladie pulmonaire

irréversible qui peut être mortelle, cancer,

malformations congénitales et/ou inflammation de

la peau).

Certaines poussières et fumées créées lors de

foration, casse, martelage, sciage, meulage et autres

activités de construction, contiennent des substances

connues dans l'État de Californie et par d’autres

autorités pour provoquer des maladies respiratoires,

le cancer, des malformations congénitales ou autres

problèmes de reproduction. Quelques exemples de

ces substances sont :

> Silice cristalline, ciment et autres produits de

maçonnerie.

> Arsenic et chrome provenant de caoutchouc traité

chimiquement.

> Plomb provenant de peintures à base de plomb.

Les poussières et fumées dans l’air peuvent être

invisibles à l’œil nu. Par conséquent, ne comptez

pas sur la vue oculaire pour déterminer s'il y a des

poussières ou des fumées dans l’air.

Pour réduire les risques d’exposition aux poussières

et fumées, effectuez tout ce qui suit :

► Effectuez une évaluation des risques spécifiques

au site. L’évaluation des risques devra inclure les

poussières et les vapeurs créées par l’utilisation

de la machine et les poussières susceptibles

d'incommoder le voisinage.

► Utilisez la sécurité intégrée appropriée pour

minimiser la quantité de poussières et de fumées

dans l’air et leur accumulation sur les

équipements, les surfaces, les vêtements et les

parties du corps. Exemples de mesures applicables

: systèmes de ventilation aspirante et de captage

des poussières, pulvérisation d'eau et forage

humide. Contrôlez si possible les poussières et les

fumées à la source. Assurez-vous que les

commandes sont correctement installées,

entretenues et utilisées.

► Portez, entretenez et utilisez de manière correcte

la protection respiratoire comme indiqué par votre

employeur, en respectant les normes de sécurité

et de santé au travail. La protection respiratoire

doit être efficace pour le type de substance en

cause (et le cas échéant, approuvée par l’autorité

gouvernementale pertinente).

9800 1050 90 | Instructions d’origine30

Loading...

Loading...