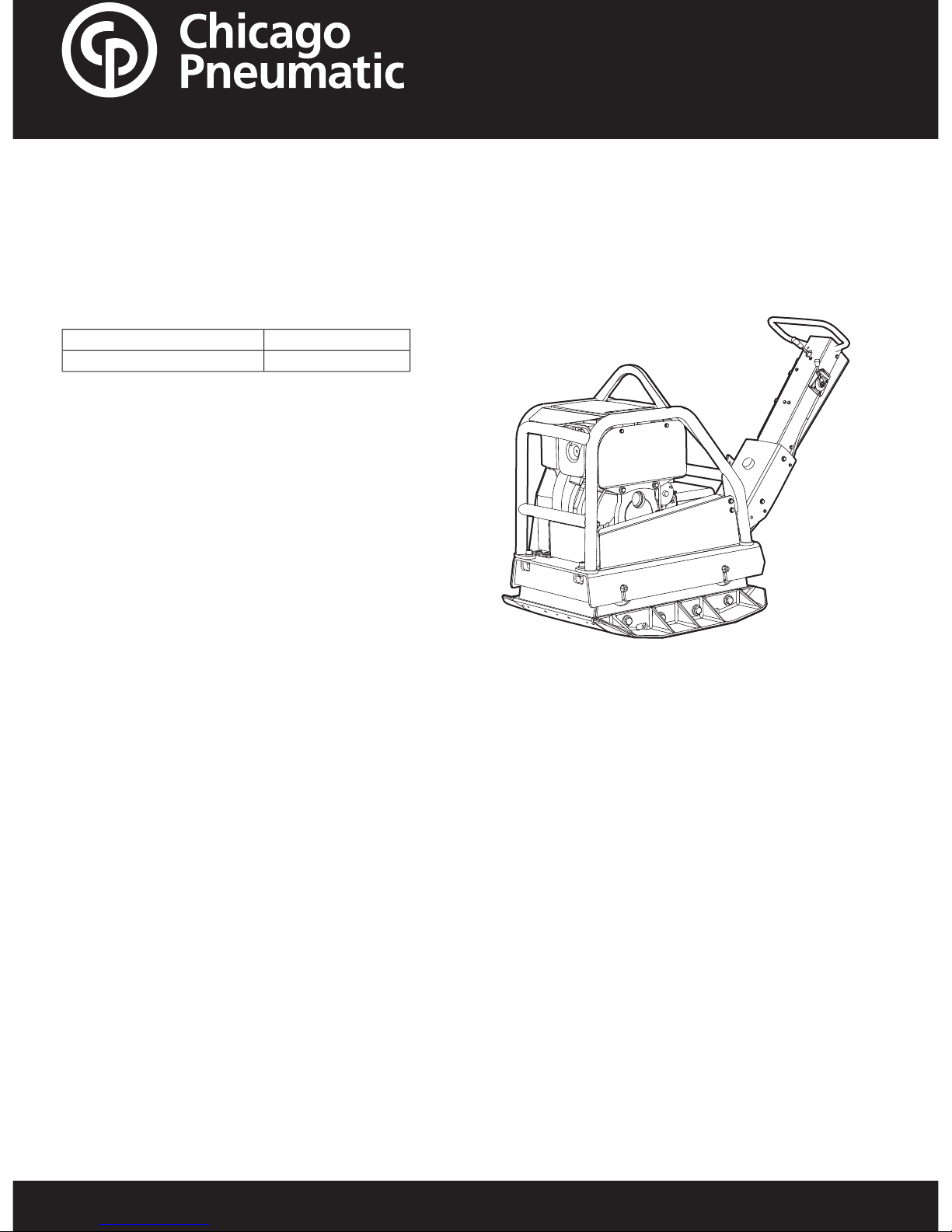

Chicago Pneumatic MV 500 Safety And Operating Instructions Manual

Safety and operating instructions

Forward and reversible plate

MV 500

Valid from serial number

BGF0002700MV 500 Hatz Electric start 850 mm

www.CrowderSupply.com • Toll Free: 888-883-5144

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

MV 500

www.CrowderSupply.com • Toll Free: 888-883-5144

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

Contents

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Safety and operating instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety signal words. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Personal precautions and qualifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operation, precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Transport, precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Maintenance, precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Storage, precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Design and function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Main parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Transport. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Lifting the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Secure transport. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fu el. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operating near edges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operating on slopes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Start and stop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

When taking a break. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Every 10 hours of operation (daily). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

After the first 20 hours of operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Every 100 hours of operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Every 250 hours of operation (every month). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Every 500 hours of operation (yearly). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Machine data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Noise and vibration declaration statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Noise and vibration data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Uncertainties, sound value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Dimensions (without extensions). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Dimensions (with extensions). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

EC Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

EC Declaration of Conformity (EC Directive 2006/42/EC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

ContentsMV 500

www.CrowderSupply.com • Toll Free: 888-883-5144

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

MV 500Safety and operating instructions

www.CrowderSupply.com • Toll Free: 888-883-5144

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

Introduction

Thank you for choosing Chicago Pneumatic brand products. For over a century, the

Chicago Pneumatic brand has represented performance and innovation in the

pneumatic tool industry.

Today the brand is found around the world on a range of pneumatic and hydraulic

tools that includes breakers, rock drills, chipping hammers, clay-diggers, picks and

busters, scabblers, pumps and a whole lot more.

The Chicago Pneumatic brand is associated with powerful and reliable products that

are easy to maintain and that give good value for the money.

For more information please visit www.cp.com

Atlas Copco Construction Tools AB

105 23 Stockholm

Sweden

About the Safety and operating

instructions

The aim of the instructions is to provide you with knowledge of how to use the

machine in an efficient, safe way. The instructions also give you advice and tell you

how to perform regular maintenance on the machine.

Before using the

machine for the first time you must read these instructions carefully

and understand all of them.

Safety and operating instructionsMV 500

www.CrowderSupply.com • Toll Free: 888-883-5144

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

Safety instructions

To reduce the risk of serious injury or death to

yourself or others, read and understand the Safety

and operating instruction before installing,

operating, repairing, maintaining, or changing

accessories on the machine.

Post this Safety and operating instruction at work

locations, provide copies to employees, and make

sure that everyone reads the Safety and operating

instruction before operating or servicing the

machine.

In addition, the operator or the operator's employer

must assess the specific risks that may be present as

a result of each use of the machine.

Additional instructions for the engine can be found

in the manufacturer's engine manual.

Safety signal words

The safety signal words Danger, Warning and

Caution have the following meanings:

Indicates a hazardous situation

which, if not avoided, will result

in death or serious injury.

DANGER

Indicates a hazardous situation

which, if not avoided, could

result in death or serious injury.

WARNING

Indicates a hazardous situation

which, if not avoided, could

result in minor or moderate

injury.

CAUTION

Personal precautions and

qualifications

Only qualified and trained persons may operate or

maintain the machine. They must be physically able

to handle the bulk, weight, and power of the

machine. Always use your common sense and good

judgement.

Personal protective equipment

Always use approved protective equipment.

Operators and all other persons in the working area

must wear protective equipment, including at a

minimum:

> Protective helmet

> Hearing protection

> Impact resistant eye protection with side

protection

> Respiratory protection when appropriate

> Protective gloves

> Proper protective boots

> Appropriate work overall or similar clothing (not

loose-fitting) that covers your arms and legs.

Drugs, alcohol or medication

WARNING Drugs, alcohol or medication

Drugs, alcohol or medication may impair your

judgment and powers of concentration. Poor

reactions and incorrect assessments can lead to

severe accidents or death.

► Never use the machine when you are tired or

under the influence of drugs, alcohol or

medication.

► No person who is under the influence of drugs,

alcohol or medication

may operate the machine.

Operation, precautions

DANGER Explosion hazard

If a warm machine or exhaust pipe comes into

contact with explosives, an explosion could occur.

During operating with certain materials, sparks and

ignition can occur. Explosions will lead to severe

injuries or death.

► Never operate the machine in any explosive

environment.

► Never use the machine near flammable materials,

fumes or dust.

► Make sure that there are no undetected sources

of gas or explosives.

► Avoid contact with the warm exhaust pipe or the

bottom of the machine.

DANGER Fire hazard

If a fire starts in the machine, it can cause injury.

► If possible use an ABE-class powder extinguisher,

otherwise use a BE-type carbon dioxide fire

extinguisher.

DANGER Fuel hazard

The fuel is flammable and fuel fumes can explode

when ignited, causing serious injury or death.

► Protect your skin from contact with the fuel. If fuel

has penetrated the skin, consult a qualified health

professional.

► Never remove the filler cap, or fill the fuel tank

when the machine is hot.

► Fill the fuel tank outdoors or in a clean and well

ventilated place, free from sparks and open

flames. Fill the fuel tank at least ten meters (30

feet) from the place where the machine is to be

used.

► Release the filler cap slowly to let pressure escape.

MV 500Safety and operating instructions

www.CrowderSupply.com • Toll Free: 888-883-5144

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

► Never overfill the fuel tank.

► Make sure the filler cap is screwed on when the

machine is used.

► Avoid spilling fuel on the machine, wipe off any

spilled fuel.

► Check regularly for fuel leaks. Never use the

machine if it is leaking fuel.

► Never use the machine in the proximity of material

that can generate sparks. Remove all hot or

spark-generating devices before starting the

machine.

► Never smoke when filling the fuel tank or when

working with the machine or servicing it.

► Only store fuel in a container that is specially

constructed and approved for the purpose.

► Consumed fuel and oil containers must be taken

care of and returned to the retailer.

► Never use your fingers to check for fluid leaks.

WARNING Unexpected movements

The machine is exposed to heavy strains during

operation. If the machine breaks or gets stuck, there

may be sudden and unexpected movement that can

cause injuries.

► Always inspect the machine prior to use. Never

use the machine if you suspect that it is damaged.

► Make sure that the handle is clean and free of

grease and oil.

► Keep your feet away from the machine.

► Never sit on the machine.

► Never strike or abuse the machine.

► Pay attention and look at what you are doing.

WARNING Dust and fume hazard

Dusts and/or fumes generated or dispersed when

using the machine may cause serious and permanent

respiratory disease, illness, or other bodily injury (for

example, silicosis or other irreversible lung disease

that can be fatal, cancer, birth defects, and/or skin

inflammation).

Some dusts and fumes created by compaction work

contain substances known to the State of California

and other authorities to cause respiratory disease,

cancer, birth defects, or other reproductive harm.

Some examples of such substances are:

> Crystalline silica, cement, and other masonry

products.

> Arsenic and chromium from chemically-treated

rubber.

> Lead from lead-based paints.

Dust and fumes in the air can be invisible to the

naked eye, so

do not rely on eye sight to determine

if there is dust or fumes are the air.

To reduce the risk of exposure to dust and fumes,

do all of the following:

► Perform site-specific risk assessment. The risk

assessment should include dust and fumes created

by the use of the machine and the potential for

disturbing existing dust.

► Use proper engineering controls to minimize the

amount of dust and fumes in the air and to

minimize build-up on equipment, surfaces,

clothing, and body parts. Examples of controls

include: exhaust ventilation and dust collection

systems, water sprays, and wet drilling. Control

dusts and fumes at the source where possible.

Make sure that controls are properly installed,

maintained and correctly used.

► Wear, maintain and correctly use respiratory

protection as instructed

by your employer and as

required by occupational health and safety

regulations. The respiratory protection must be

effective for the type of substance at issue (and if

applicable, approved by relevant governmental

authority).

► Work in a well ventilated area.

► If the machine has an exhaust, direct the exhaust

so as to reduce disturbance of dust in a dust filled

environment.

► Operate and maintain the machine as

recommended in the operating and safety

instructions

► Wear washable or disposable protective clothes

a

t

the worksite, and shower and change into clean

clothes before leaving the worksite to reduce

exposure of dust and fumes to yourself, other

persons, cars, homes, and other areas.

Safety and operating instructionsMV 500

www.CrowderSupply.com • Toll Free: 888-883-5144

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

► Avoid eating, drinking, and using tobacco

products in areas where there is dust or fumes.

► Wash your hands and face thoroughly as soon as

possible upon leaving the exposure area, and

always before eating, drinking, using tobacco

products, or making contact with other persons.

► Comply with all applicable laws and regulations,

including occupational health and safety

regulations.

► Participate in air monitoring, medical examination

programs, and health and safety training

programs provided by your employer or trade

organizations and in accordance with

occupational health and safety regulations and

recommendations. Consult with physicians

experienced in relevant occupational medicine.

► Work with your employer and trade organization

to reduce dust

and fume exposure at the worksite

and to reduce the risks. Effective health and safety

programs, policies and procedures for protecting

workers and others against harmful exposure to

dust and fumes should be established and

implemented based on advice from health and

safety experts. Consult with experts.

DANGER Exhaust gas hazard

The exhaust gas from the machine’s combustion

engine contains carbon monoxide which is

poisonous, and chemicals known to the State of

California and other authorities to cause cancer, birth

defects, or other reproductive harm. Inhalation of

exhaust fumes can cause serious injury, illness, or

death.

► Never inhale exhaust fumes.

► Ensure good ventilation (extraction of air by fan

if necessary).

WARNING Battery hazard

The battery contains poisonous and corrosive

sulphuric acid and can explode, this can cause injury.

► Never expose the battery to naked flames, sparks,

strong heat, or anything else where there is a risk

of explosion.

► Avoid getting acid on your skin, clothes or on the

machine.

► Wear protective glasses to avoid getting acid in

your eyes, if you get acid in your eyes rinse them

with water for at least 15 minutes and seek

immediate medical treatment.

► Never short-circuit the battery poles when fitting

or replacing the battery.

WARNING Projectiles

Failure of the work piece, of accessories, or even of

the machine itself may generate high velocity

projectiles. During operating, splinters or other

particles from the compacted material may become

projectiles and cause personal injury by striking the

operator or other persons. To reduce these risk:

► Use approved personal protective equipment and

safety helmet, including impact resistant eye

protection with side protection.

► Make sure that no unauthorised persons trespass

into the working zone.

► Keep the workplace free from foreign objects.

WARNING Hydraulic system hazard

Hydraulic hoses are made of rubber and can

deteriorate with age, with the consequent risk of

splitting. This can cause injuries.

► Maintain the hydraulic system regularly.

► Whenever there are uncertainties as to durability

and wear, replace hoses with new original hoses.

WARNING Slope hazards

During operation, secure the machine so it can not

fall if it is placed on a sloping ground. A fall can lead

to severe accidents and result in personal injury.

► Always ensure that all personnel in the working

area are higher up the slope than the machine.

► Always operate the machine straight up and down

when placed on slopes.

► Never exceed the maximum recommended slope

angle when operating the machine. Follow the

recommendations.

WARNING Motion hazards

When using the machine to perform work-related

activities, you may experience discomfort in the

hands, arms, shoulders, neck, or other parts of the

body.

► Adopt a comfortable posture whilst maintaining

secure footing and avoiding awkward

off-balanced postures.

► Changing posture during extended tasks may

help avoid discomfort and fatigue.

► In case of persistent or recurring symptoms,

consult a qualified health professional.

MV 500Safety and operating instructions

www.CrowderSupply.com • Toll Free: 888-883-5144

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

WARNING Vibration hazards

Normal and proper use of the machine exposes the

operator to vibration. Regular and frequent exposure

to vibration may cause, contribute to, or aggravate

injury or disorders to the operator’s fingers, hands,

wrists, arms, shoulders and/or nerves and blood

supply or other body parts, including debilitating

and/or permanent injuries or disorders that may

develop gradually over periods of weeks, months,

or years. Such injuries or disorders may include

damage to the blood circulatory system, damage to

the nervous system, damage to joints, and possibly

damage to other body structures.

If numbness, persistent recurring discomfort,

burning sensation, stiffness, throbbing, tingling,

pain, clumsiness, weakened grip, whitening of the

skin, or other symptoms occur at any time, when

operating the machine or when not operating the

machine, stop operating the machine, tell your

employer and seek medical attention. Continued

use of the machine after the occurrence of any such

symptom may increase the risk of symptoms

becoming more severe and/or permanent.

Operate and maintain the machine as recommended

in these instructions, to prevent an unnecessary

increase in vibration.

The following may help to reduce exposure to

vibration for the operator:

► If the machine has vibration absorbing handles,

keep them in a central position, avoid pressing

the handles into the end stops.

► When the percussion mechanism is activated, the

only body contact with the machine you should

have are your hands on the handle or handles.

Avoid any other

contact, for example supporting

any part of the body against the machine or

leaning onto the machine trying to increase the

feed force.

► Make sure that the machine is well-maintained

and not worn out.

► Immediately stop working if the machine

suddenly starts to vibrate strongly. Before

resuming the work, find and remove the cause of

the increased vibrations.

► Participate in health surveillance or monitoring,

medical exams and training programs offered by

your employer and when required by law.

► When working in cold conditions wear warm

clothing and keep hands warm and dry.

See the ”Noise and vibration declaration statement”

for the machine, including the declared vibration

values. This information can be found at the end of

these Safety and operating instructions.

WARNING Trapping hazard

There is a risk of neck ware, hair, gloves, and clothes

getting dragged into or caught by rotating machine

parts. This may cause choking, scalping, lacerations,

or death. To reduce the risk:

► Never grab or touch a rotating machine part.

► Avoid wearing clothing, neck ware or gloves that

may get caught.

► Cover long hair with a hair net.

DANGER Electrical hazard

The machine is not electrically insulated. If the

machine comes into contact with electricity, serious

injuries or death may result.

► Never operate the machine near any electric wire

or other source of electricity.

► Make sure that there are no concealed wires or

other sources of electricity in the working area.

WARNING Concealed object hazard

During operating, concealed wires and pipes

constitute a danger that can result in serious injury.

► Check the composition of the material before

operating.

► Watch out for concealed cables and pipes for

example electricity, telephone, water, gas, and

sewage lines.

► If the machine seems to have hit a concealed

object, switch off the machine immediately.

► Make sure that there is no danger before

continuing.

WARNING Involuntary start

Involuntary start of the machine may cause injury.

► Keep your hands away from the start and stop

device until you are ready to start the machine.

► Learn how the machine is switched off in the event

of an emergency.

WARNING Noise hazard

High noise levels can cause permanent and disabling

hearing loss and other problems such as tinnitus

(ringing, buzzing, whistling, or humming in the

ears). To reduce risks and prevent an unnecessary

increase in noise levels:

► Risk assessment of these hazards and

implementation of appropriate controls is

essential.

► Operate and maintain the machine as

recommended in these instructions.

► If the machine has a silencer, check that it is in

place and in good working condition.

► Always use hearing protection.

Safety and operating instructionsMV 500

www.CrowderSupply.com • Toll Free: 888-883-5144

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

Transport, precautions

WARNING Loading and unloading

hazard

When the machine is lifted by a crane and similar

appliance, this can lead to injury.

► Use marked lifting points.

► Make sure that all lifting devices are dimensioned

for the weight of the machine.

► Never remain under or in the immediate vicinity

of the machine.

Maintenance, precautions

WARNING Machine modification

Any machine modification may result in bodily

injuries to yourself or others.

► Never modify the machine. Modified machines

are not covered by warranty or product liability.

► Always use original parts, insertion tools, and

accessories.

► Change damaged parts immediately.

► Replace worn components in good time.

WARNING Hot oil hazard

When changing the oil, oil filter or hydraulic oil on

a hot machine, there is a risk of burns.

► Wait until the machine has cooled down before

changing the oil.

CAUTION High temperature

The machine's front cover, exhaust pipe, and

hydraulic system become hot during operation.

Touching them can lead to burns.

► Never touch a hot front cover.

► Never touch the hot exhaust pipe.

► Never touch the hydraulic system.

► Wait until the front cover, exhaust pipe, and

bottom of the machine has cooled down before

carrying out maintenance work.

NOTICE Any use of a quick-charger to charge the

battery can shorten the life time of the battery.

Storage, precautions

♦

Keep the machine in a safe place, out of the reach

of children and locked up.

MV 500Safety and operating instructions

www.CrowderSupply.com • Toll Free: 888-883-5144

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

Loading...

Loading...