Chicago Pneumatic CPS 750 Instruction Manual

Instruction Manual for Portable Compressors

English

CPS 750

Instruction Manual

for Portable Compressors

CPS 750

CHICAGO PNEUMATIC - COMPRESSORS LLC

Printed matter N°

1310 3012 02

01/2009

CPS 750

4

CPS

Warranty and Liability Limitation

Use only authorized parts.

Any damage or malfunction caused by the use of unauthorized parts is not covered

by Warranty or Product Liability.

The manufacturer does not accept any liability for any damage arising for

modifications, additions or conversions made without the manufacturer's approval

in writing.

Copyright 2008, Chicago Pneumatic Compressors LLC, RockHill SC USA.

Any unauthorized use or copying of the contents or any part thereof is prohibited.

This applies in particular to trademarks, model denominations, part numbers and

drawings.

Instruction Manual

1310 3012 02 5

CPS

Table of contents

1 SAFETY PRECAUTIONS ...................................................................................... 9

1.1 Introduction ....................................................................................................... 9

1.2 General safety precautions ................................................................................ 10

1.3 Safety during transport and installation ............................................................... 12

1.4 Safety during use and operation ......................................................................... 13

1.5 Safety during maintenance and repair.................................................................. 15

1.6 Tool applications safety..................................................................................... 16

1.7 Specific safety precautions ................................................................................ 16

2 LEADING PARTICULARS ................................................................................... 18

2.1 General description ........................................................................................... 18

2.2 Markings and information labels ......................................................................... 20

2.3 Main parts ....................................................................................................... 22

2.4 Regulating system ............................................................................................ 24

2.4.1 Overview .................................................................................................... 24

2.4.2 Air flow ...................................................................................................... 26

2.4.3 Oil system ................................................................................................... 27

2.4.4 Continuous regulating system ........................................................................ 28

2.5 Electric system................................................................................................. 30

3 OPERATING INSTRUCTIONS.............................................................................. 32

3.1 Parking, towing and lifting instructions ................................................................ 32

3.1.1 Parking instructions ...................................................................................... 33

3.1.2 Towing instructions ...................................................................................... 34

3.1.3 Lifting instructions........................................................................................ 35

3.2 Before starting ................................................................................................. 36

3.3 Starting / Stopping ........................................................................................... 37

3.3.1 Control panel ............................................................................................... 38

3.3.2 During operation .......................................................................................... 39

3.3.3 Power ON/OFF............................................................................................. 40

3.3.4 Starting....................................................................................................... 41

3.3.5 Warming up................................................................................................. 42

3.3.6 Loading....................................................................................................... 43

3.3.7 Stopping ..................................................................................................... 44

3.3.8 Shut downs................................................................................................. 45

3.3.9 Emergency stop ........................................................................................... 46

3.3.10 Warnings .................................................................................................... 46

4 MAINTENANCE ................................................................................................ 47

4.1 Liability ........................................................................................................... 47

4.2 Service paks .................................................................................................... 47

4.3 Service kits...................................................................................................... 47

4.4 Storage ........................................................................................................... 48

4.5 Preventive maintenance schedule for the compressor ............................................ 48

4.6 Oil specifications .............................................................................................. 51

4.6.1 Compressor oil............................................................................................. 51

CPS 750

6 1310 3012 02

CPS

4.6.2 Engine oil .................................................................................................... 52

4.7 Oil level check ................................................................................................. 53

4.7.1 Check engine oil level ................................................................................... 53

4.7.2 Check compressor oil level ........................................................................... 53

4.8 Oil and oil filter change ..................................................................................... 54

4.8.1 Engine oil and oil filter change ....................................................................... 54

4.8.2 Compressor oil and oil filter change ................................................................ 54

4.8.3 Topping up the compressor oil ....................................................................... 55

4.9 Coolant specifications ....................................................................................... 56

4.9.1 GENCOOL EG .............................................................................................. 57

4.9.2 Handling GENCOOL EG ................................................................................. 58

4.10 Coolant check.................................................................................................. 59

4.11 Topping up/replacing coolant ............................................................................. 60

4.11.1 Topping up without draining from the cooling system ....................................... 61

4.11.2 Topping up after limited quantity draining from the cooling system..................... 62

4.11.3 Replacing the coolant ................................................................................... 63

4.12 Cleaning coolers............................................................................................... 64

4.13 Battery care..................................................................................................... 64

4.13.1 Electrolyte................................................................................................... 65

4.13.2 Activating a dry-charged battery .................................................................... 65

4.13.3 Recharging a battery .................................................................................... 65

4.13.4 Battery maintenance..................................................................................... 65

5 ADJUSTMENTS AND SERVICING PROCEDURES .................................................. 66

5.1 Adjustment of the continuous regulating system .................................................. 66

5.2 Air filters engine / compressor............................................................................ 67

5.2.1 Main parts................................................................................................... 67

5.2.2 Cleaning the dust trap .................................................................................. 68

5.2.3 Replacing the filter element and the safety cartridge......................................... 68

5.2.4 Air receiver ................................................................................................. 69

5.3 Fuel system ..................................................................................................... 70

5.3.1 Fuel system - Drain ...................................................................................... 70

5.3.2 Fuel system - Prime ...................................................................................... 71

5.3.3 Replacing filter elements .............................................................................. 73

5.4 Safety valve .................................................................................................... 74

5.5 Brake adjustment ............................................................................................. 75

5.5.1 Brake shoe adjustment.................................................................................. 75

6 PROBLEM SOLVING ......................................................................................... 77

7 AVAILABLE OPTIONS ....................................................................................... 80

8 TECHNICAL SPECIFICATIONS ........................................................................... 82

8.1 Torque values .................................................................................................. 82

8.1.1 For general applications ................................................................................ 82

8.1.2 For important assemblies .............................................................................. 83

8.2 Settings of shutdown switches and safety valves................................................. 84

8.3 Compressor / engine specifications ..................................................................... 84

8.3.1 Reference conditions .................................................................................... 84

8.3.2 Limitations .................................................................................................. 85

8.3.3 Performance data ......................................................................................... 87

Instruction Manual

1310 3012 02 7

CPS

8.3.4 Design data ................................................................................................. 88

9 DATAPLATE .................................................................................................... 90

10 LEGISLATION .................................................................................................. 91

10.1 Parts, subjected to Pressure Equipment Directive 97/23/EC, cat. II and above .......... 91

10.2 Parts, subjected to Simple Pressure Vessel Directive87/404/EC.............................. 91

10.3 Parts, subjected to cat. I and covered by the Machine Directive 89/392/EC ............. 91

10.4 Parts, subjected to art. I, paragraph 3.3 .............................................................. 91

CPS 750

8 1310 3012 02

CPS

.

Instruction Manual

1310 3012 02 9

CPS

Preface

Please read the following instructions carefully before starting to use your compressor. It is a solid, safe

and reliable machine, built according to the latest technology. Follow the instructions in this booklet and

we guarantee you years of troublefree operation.

Always keep the manual available near the machine.

In all correspondence always mention the compressor type and serial number, shown on the data plate.

The company reserves the right to make changes without prior notice.

1 Safety precautions

1.1 Introduction

The policy of Chicago Pneumatic is to provide the users of their equipment with safe, reliable and efficient

products. Factors taken into account are among others:

• the intended and predictable future use of the products, and the environments in which they are

expected to operate,

• applicable rules, codes and regulations,

• the expected useful product life, assuming proper service and maintenance,

• providing the manual with up-to-date information.

Before handling any product, take time to read the relevant instruction manual. Besides giving detailed

operating instructions, it also gives specific information about safety, preventive maintenance, etc.

Keep the manual always at the unit location, easy accessible to the operating personnel.

See also the safety precautions of the engine and possible other equipment, which are separately sent

along or are mentioned on the equipment or parts of the unit.

These safety precautions are general and some statements will therefore not always apply to a particular

unit.

Only people that have the right skills should be allowed to operate, adjust, perform maintenance or repair

on Chicago Pneumatic equipment. It is the responsibility of management to appoint operators with the

appropriate training and skill for each category of job.

Skill level 1: Operator

An operator is trained in all aspects of operating the unit with the push-buttons, and is trained to know the

safety aspects.

To be read attentively and acted accordingly before towing, lifting, operating,

performing maintenance or repairing the compressor

CPS 750

10 1310 3012 02

CPS

Skill level 2: Mechanical technician

A mechanical technician is trained to operate the unit the same as the operator. In addition, the

mechanical technician is also trained to perform maintenance and repair, as described in the instruction

manual, and is allowed to change settings of the control and safety system. A mechanical technician

does not work on live electrical components.

Skill level 3: Electrical technician

An electrical technician is trained and has the same qualifications as both the operator and the

mechanical technician. In addition, the electrical technician may carry out electrical repairs within the

various enclosures of the unit. This includes work on live electrical components.

Skill level 4: Specialist from the manufacturer

This is a skilled specialist sent by the manufacturer or its agent to perform complex repairs or

modifications to the equipment.

In general it is recommended that not more than two people operate the unit, more operators could lead

to unsafe operating conditions. Take necessary steps to keep unauthorized persons away from the unit

and eliminate all possible sources of danger at the unit.

When handling, operating, overhauling and/or performing maintenance or repair on Chicago Pneumatic

equipment, the mechanics are expected to use safe engineering practices and to observe all relevant

local safety requirements and ordinances. The following list is a reminder of special safety directives and

precautions mainly applicable to Chicago Pneumatic equipment.

These safety precautions apply to machinery processing or consuming air. Processing of any other gas

requires additional safety precautions typical to the application and are not included herein.

Neglecting the safety precautions may endanger people as well as environment and machinery:

• endanger people due to electrical, mechanical or chemical influences,

• endanger the environment due to leakage of oil, solvents or other substances,

• endanger the machinery due to function failures.

All responsibility for any damage or injury resulting from neglecting these precautions or by nonobservance of ordinary caution and due care required in handling, operating, maintenance or repair, also

if not expressly mentioned in this instruction manual, is disclaimed by Chicago Pneumatic.

The manufacturer does not accept any liability for any damage arising from the use of non-original parts

and for modifications, additions or conversions made without the manufacturer’s approval in writing.

If any statement in this manual does not comply with local legislation, the stricter of the two shall be

applied.

Statements in these safety precautions should not be interpreted as suggestions, recommendations or

inducements that it should be used in violation of any applicable laws or regulations.

1.2 General safety precautions

1 The owner is responsible for maintaining the unit in a safe operating condition. Unit parts and

accessories must be replaced if missing or unsuitable for safe operation.

Instruction Manual

1310 3012 02 11

CPS

2 The supervisor, or the responsible person, shall at all times make sure that all instructions regarding

machinery and equipment operation and maintenance are strictly followed and that the machines with

all accessories and safety devices, as well as the consuming devices, are in good repair, free of

abnormal wear or abuse, and are not tampered with.

3 Whenever there is an indication or any suspicion that an internal part of a machine is overheated, the

machine shall be stopped but no inspection covers shall be opened before sufficient cooling time has

elapsed; this to avoid the risk of spontaneous ignition of oil vapour when air is admitted.

4 Normal ratings (pressures, temperatures, speeds, etc.) shall be durably marked.

5 Operate the unit only for the intended purpose and within its rated limits (pressure, temperature,

speeds, etc.).

6 The machinery and equipment shall be kept clean, i.e. as free as possible from oil, dust or other

deposits.

7 To prevent an increase in working temperature, inspect and clean heat transfer surfaces (cooler fins,

intercoolers, water jackets, etc.) regularly. See the 4.5 Preventive maintenance schedule for the

compressor.

8 All regulating and safety devices shall be maintained with due care to ensure that they function

properly. They may not be put out of action.

9 Care shall be taken to avoid damage to safety valves and other pressure-relief devices, especially to

avoid plugging by paint, oil coke or dirt accumulation, which could interfere with the functioning of the

device.

10 Pressure and temperature gauges shall be checked regularly with regard to their accuracy. They shall

be replaced whenever outside acceptable tolerances.

11 Safety devices shall be tested as described in the maintenance schedule of the instruction manual to

determine that they are in good operating condition. See the 4.5 Preventive maintenance schedule

for the compressor.

12 Mind the markings and information labels on the unit.

13 In the event the safety labels are damaged or destroyed, they must be replaced to ensure operator

safety.

14 Keep the work area neet. Lack of order will increase the risk of accidents.

15 When working on the unit, wear safety clothing. Depending on the kind of activities these are: safety

glasses, ear protection, safety helmet (including visor), safety gloves, protective clothing, safety

shoes. Do not wear the hair long and loose (protect long hair with a hairnet), or wear loose clothing or

jewelry.

16 Take precautions against fire. Handle fuel, oil and anti-freeze with care because they are inflammable

substances. Do not smoke or approach with naked flame when handling such substances. Keep a

fire-extinguisher in the vicinity.

CPS 750

12 1310 3012 02

CPS

1.3 Safety during transport and installation

To lift a unit, all loose or pivoting parts, e.g. doors and towbar, shall first be securely fastened.

Do not attach cables, chains or ropes directly to the lifting eye; apply a crane hook or lifting shackle

meeting local safety regulations. Never allow sharp bends in lifting cables, chains or ropes.

Helicopter lifting is not allowed.

It is strictly forbidden to dwell or stay in the risk zone under a lifted load. Never lift the unit over people or

residential areas. Lifting acceleration and retardation shall be kept within safe limits.

1 Before towing the unit:

• ascertain that the pressure vessel(s) is (are) depressurized,

• check the towbar, the brake system and the towing eye. Also check the coupling of the towing

vehicle,

• check the towing and brake capability of the towing vehicle,

• check that the towbar, jockey wheel or stand leg is safely locked in the raised position,

• ascertain that the towing eye can swivel freely on the hook,

• check that the wheels are secure and that the tyres are in good condition and inflated correctly,

• connect the signalisation cable, check all lights and connect the pneumatic brake couplers,

• attach the safety break-away cable or safety chain to the towing vehicle,

• remove wheel chocks, if applied, and disengage the parking brake.

2 To tow a unit use a towing vehicle of ample capacity. Refer to the documentation of the towing

vehicle.

3 If the unit is to be backed up by the towing vehicle, disengage the overrun brake mechanism (if it is

not an automatic mechanism).

4 Never exceed the maximum towing speed of the unit (mind the local regulations).

5 Place the unit on level ground and apply the parking brake before disconnecting the unit from the

towing vehicle. Unclip the safety break-away cable or safety chain. If the unit has no parking brake or

jockey wheel, immobilize the unit by placing chocks in front of and/or behind the wheels. When the

towbar can be positioned vertically, the locking device must be applied and kept in good order.

6 To lift heavy parts, a hoist of ample capacity, tested and approved according to local safety

regulations, shall be used.

7 Lifting hooks, eyes, shackles, etc., shall never be bent and shall only have stress in line with their

design load axis. The capacity of a lifting device diminishes when the lifting force is applied at an

angle to its load axis.

8 For maximum safety and efficiency of the lifting apparatus all lifting members shall be applied as near

to perpendicular as possible. If required, a lifting beam shall be applied between hoist and load.

9 Never leave a load hanging on a hoist.

10 A hoist has to be installed in such a way that the object will be lifted perpendicular. If that is not

possible, the necessary precautions must be taken to prevent load-swinging, e.g. by using two hoists,

each at approximately the same angle not exceeding 30° from the vertical.

Instruction Manual

1310 3012 02 13

CPS

11 Locate the unit away from walls. Take all precautions to ensure that hot air exhausted from the engine

and driven machine cooling systems cannot be recirculated. If such hot air is taken in by the engine or

driven machine cooling fan, this may cause overheating of the unit; if taken in for combustion, the

engine power will be reduced.

12 Before moving the compressor, switch it off.

1.4 Safety during use and operation

1 When the unit has to operate in a fire-hazardous environment, each engine exhaust has to be

provided with a spark arrestor to trap incendiary sparks.

2 The exhaust contains carbon monoxide which is a lethal gas. When the unit is used in a confined

space, conduct the engine exhaust to the outside atmosphere by a pipe of sufficient diameter; do this

in such a way that no extra back pressure is created for the engine. If necessary, install an extractor.

Observe any existing local regulations. Make sure that the unit has sufficient air intake for operation.

If necessary, install extra air intake ducts.

3 When operating in a dust-laden atmosphere, place the unit so that dust is not carried towards it by the

wind. Operation in clean surroundings considerably extends the intervals for cleaning the air intake

filters and the cores of the coolers.

4 Close the compressor air outlet valve before connecting or disconnecting a hose. Ascertain that a

hose is fully depressurized before disconnecting it. Before blowing compressed air through a hose or

air line, ensure that the open end is held securely, so that it cannot whip and cause injury.

5 The air line end connected to the outlet valve must be safeguarded with a safety cable, attached next

to the valve.

6 No external force may be exerted on the air outlet valves, e.g. by pulling on hoses or by installing

auxiliary equipment directly to a valve, e.g. a water separator, a lubricator, etc. Do not step on the air

outlet valves.

7 Never move a unit when external lines or hoses are connected to the outlet valves, to avoid damage

to valves, manifold and hoses.

8 Do not use compressed air from any type of compressor, without taking extra measures, for breathing

purposes as this may result in injury or death. For breathing air quality, the compressed air must be

adequately purified according to local legislation and standards. Breathing air must always be

supplied at stable, suitable pressure.

9 Distribution pipework and air hoses must be of correct diameter and suitable for the working

pressure. Never use frayed, damaged or deteriorated hoses. Replace hoses and flexibles before the

lifetime expires. Use only the correct type and size of hose end fittings and connections.

10 If the compressor is to be used for sand-blasting or will be connected to a common compressed-air

system, fit an appropriate non-return valve (check valve) between compressor outlet and the

connected sand-blasting or compressed-air system. Observe the right mounting position/direction.

11 Before removing the oil filler plug, ensure that the pressure is released by opening an air outlet valve.

12 Never remove a filler cap of the cooling water system of a hot engine. Wait until the engine has

sufficiently cooled down.

13 Never refill fuel while the unit is running, unless otherwise stated in the Chicago Pneumatic

Instruction Book (AIB). Keep fuel away from hot parts such as air outlet pipes or the engine exhaust.

Do not smoke when fuelling. When fuelling from an automatic pump, an earthing cable should be

connected to the unit to discharge static electricity. Never spill nor leave oil, fuel, coolant or cleansing

agent in or around the unit.

CPS 750

14 1310 3012 02

CPS

14 All doors shall be shut during operation so as not to disturb the cooling air flow inside the bodywork

and/or render the silencing less effective. A door should be kept open for a short period only e.g. for

inspection or adjustment.

15 Periodically carry out maintenance works according to the maintenance schedule.

16 Stationary housing guards are provided on all rotating or reciprocating parts not otherwise protected

and which may be hazardous to personnel. Machinery shall never be put into operation, when such

guards have been removed, before the guards are securely reinstalled.

17 Noise, even at reasonable levels, can cause irritation and disturbance which, over a long period of

time, may cause severe injuries to the nervous system of human beings. When the sound pressure

level, at any point where personnel normally has to attend, is:

• below 70 dB(A): no action needs to be taken,

• above 70 dB(A): noise-protective devices should be provided for people continuously being present

in the room,

• below 85 dB(A): no action needs to be taken for occasional visitors staying a limited time only,

• above 85 dB(A): room to be classified as a noise-hazardous area and an obvious warning shall be

placed permanently at each entrance to alert people entering the room, for even relatively short

times, about the need to wear ear protectors,

• above 95 dB(A): the warning(s) at the entrance(s) shall be completed with the recommendation

that also occasional visitors shall wear ear protectors,

• above 105 dB(A): special ear protectors that are adequate for this noise level and the spectral

composition of the noise shall be provided and a special warning to that effect shall be placed at

each entrance.

18 The unit has parts, which may be accidentally touched by personnel, of which the temperature can be

in exess of 80 °C (176 °F). The insulation or safety guard, protecting these parts shall not be removed

before the parts have cooled down to room temperature.

19 Never operate the unit in surroundings where there is a possibility of taking in flammable or toxic

fumes.

20 If the working process produces fumes, dust or vibration hazards, etc., take the necessary steps to

eliminate the risk of personnel injury.

21 When using compressed air or inert gas to clean down equipment, do so with caution and use the

appropriate protection, at least safety glasses, for the operator as well as for any bystander. Do not

apply compressed air or inert gas to your skin or direct an air or gas stream at people. Never use it to

clean dirt from your clothes.

22 When washing parts in or with a cleaning solvent, provide the required ventilation and use

appropriate protection such as a breathing filter, safety glasses, rubber apron and gloves, etc.

23 Safety shoes should be compulsory in any workshop and if there is a risk, however small, of falling

objects, wearing of a safety helmet should be included.

24 If there is a risk of inhaling hazardous gases, fumes or dust, the respiratory organs must be protected

and depending on the nature of the hazard, so must the eyes and skin.

25 Remember that where there is visible dust, the finer, invisible particles will almost certainly be present

too; but the fact that no dust can be seen is not a reliable indication that dangerous, invisible dust is

not present in the air.

26 Never operate the unit at pressures or speeds below or in excess of its limits as indicated in the

technical specifications.

Instruction Manual

1310 3012 02 15

CPS

1.5 Safety during maintenance and repair

Maintenance, overhaul and repair work shall only be carried out by adequately trained personnel; if

required, under supervision of someone qualified for the job.

1 Use only the correct tools for maintenance and repair work, and only tools which are in good

condition.

2 Parts shall only be replaced by genuine Chicago Pneumatic replacement parts.

3 All maintenance work, other than routine attention, shall only be undertaken when the unit is stopped.

Steps shall be taken to prevent inadvertent starting. In addition, a warning sign bearing a legend such

as ”work in progress; do not start” shall be attached to the starting equipment. On engine-driven units

the battery shall be disconnected and removed or the terminals covered by insulating caps. On

electrically driven units the main switch shall be locked in open position and the fuses shall be taken

out. A warning sign bearing a legend such as ”work in progress; do not supply voltage” shall be

attached to the fuse box or main switch.

4 Before dismantling any pressurized component, the compressor or equipment shall be effectively

isolated from all sources of pressure and the entire system shall be relieved of pressure. Do not rely

on non-return valves (check valves) to isolate pressure systems. In addition, a warning sign bearing a

legend such as ”work in progress; do not open” shall be attached to each of the outlet valves.

5 Prior to stripping an engine or other machine or undertaking major overhaul on it, prevent all movable

parts from rolling over or moving.

6 Make sure that no tools, loose parts or rags are left in or on the machine. Never leave rags or loose

clothing near the engine air intake.

7 Never use flammable solvents for cleaning (fire-risk).

8 Take safety precautions against toxic vapours of cleaning liquids.

9 Never use machine parts as a climbing aid.

10 Observe scrupulous cleanliness during maintenance and repair. Keep away dirt, cover the parts and

exposed openings with a clean cloth, paper or tape.

11 Never weld on or perform any operation involving heat near the fuel or oil systems. Fuel and oil tanks

must be completely purged, e.g. by steam-cleaning, before carrying out such operations. Never weld

on, or in any way modify, pressure vessels. Disconnect the alternator cables during arc welding on

the unit.

12 Support the towbar and the axle(s) securely if working underneath the unit or when removing a wheel.

Do not rely on jacks.

13 Do not remove any of, or tamper with, the sound-damping material. Keep the material free of dirt and

liquids such as fuel, oil and cleansing agents. If any sound-damping material is damaged, replace it to

prevent the sound pressure level from increasing.

14 Use only lubricating oils and greases recommended or approved by Chicago Pneumatic or the

machine manufacturer. Ascertain that the selected lubricants comply with all applicable safety

regulations, especially with regard to explosion or fire-risk and the possibility of decomposition or

generation of hazardous gases. Never mix synthetic with mineral oil.

15 Protect the engine, alternator, air intake filter, electrical and regulating components, etc., to prevent

moisture ingress, e.g. when steam-cleaning.

16 When performing any operation involving heat, flames or sparks on a machine, the surrounding

components shall first be screened with non-flammable material.

17 Never use a light source with open flame for inspecting the interior of a machine.

CPS 750

16 1310 3012 02

CPS

18 Disconnect –battery-clamp before starting electrical servicing or welding (evt. turn battery-switch in

“off” position).

19 When repair has been completed, the machine shall be barred over at least one revolution for

reciprocating machines, several revolutions for rotary ones to ensure that there is no mechanical

interference within the machine or driver. Check the direction of rotation of electric motors when

starting up the machine initially and after any alteration to the electrical connection(s) or switch gear,

to check that the oil pump and the fan function properly

20 Maintenance and repair work should be recorded in an operator’s logbook for all machinery.

Frequency and nature of repairs can reveal unsafe conditions.

21 When hot parts have to be handled, e.g. shrink fitting, special heat-resistant gloves shall be used and,

if required, other body protection shall be applied.

22 When using cartridge type breathing filter equipment, ascertain that the correct type of cartridge is

used and that its useful service life is not surpassed.

23 Make sure that oil, solvents and other substances likely to pollute the environment are properly

disposed of.

24 Before clearing the unit for use after maintenance or overhaul, check that operating pressures,

temperatures and speeds are correct and that the control and shutdown devices function correctly.

1.6 Tool applications safety

Apply the proper tool for each job. With the knowledge of correct tool use and knowing the limitations of

tools, along with some common sense, many accidents can be prevented.

Special service tools are available for specific jobs and should be used when recommended. The use of

these tools will save time and prevent damage to parts.

1.7 Specific safety precautions

Batteries

When servicing batteries, always wear protecting clothing and glasses.

1 The electrolyte in batteries is a sulphuric acid solution which is fatal if it hits your eyes, and which can

cause burns if it contacts your skin. Therefore, be careful when handling batteries, e.g. when

checking the charge condition.

2 Install a sign prohibiting fire, open flame and smoking at the post where batteries are being charged.

3 When batteries are being charged, an explosive gas mixture forms in the cells and might escape

through the vent holes in the plugs. Thus an explosive atmosphere may form around the battery if

ventilation is poor, and can remain in and around the battery for several hours after it has been

charged. Therefore:

• never smoke near batteries being, or having recently been, charged,

• never break live circuits at battery terminals, because a spark usually occurs.

4 When connecting an auxiliary battery (AB) in parallel to the unit battery (CB) with booster cables:

connect the + pole of AB to the + pole of CB, then connect the - pole of CB to the mass of the unit.

Disconnect in the reverse order.

Instruction Manual

1310 3012 02 17

CPS

Pressure vessels (according to directive 87/404/EEC annex II § 2)

Maintenance/installation requirements:

1 The vessel can be used as pressure vessel or as separator and is designed to hold compressed air

for the following application:

• pressure vessel for compressor,

• medium AIR/OIL,

• and operates as detailed on the data plate of the vessel:

• the maximum working pressure ps in bar(psi),

• the maximum working temperature Tmax in °C (°F),

• the minimum working temperature Tmin in °C (°F),

• the capacity of the vessel V in l (US gal, Imp gal, cu.ft.)

2 The pressure vessel is only to be used for the applications as specified above and in accordance with

the technical specifications. Safety reasons prohibit any other applications.

3 National legislation requirements with respect to re-inspection must be complied with.

4 No welding or heat treatment of any kind is permitted to those vessel walls which are exposed to

pressure.

5 The vessel is provided and may only be used with the required safety equipment such as manometer,

overpressure control devices, safety valve, etc.

6 Draining of condensate shall be performed regularly when vessel is in use.

7 Installation, design and connections should not be changed.

8 Bolts of cover and flanges may not be used for extra fixation.

Safety valves

All adjustments or repairs are to be done by an authorized representative of the valve supplier (see

4.5 Preventive maintenance schedule for the compressor).

CPS 750

18 1310 3012 02

CPS

2 Leading particulars

2.1 General description

The CPS 750 is a silenced, single-stage, oil-injected screw compressor, built for a nominal effective

working pressure of 7.0 bar (102 psi).

• Engine

The compressor is driven by a liquid-cooled diesel engine.

The engine’s power is transmitted to the compressor element through a heavy-duty coupling.

• Compressor

The compressor casing houses two screw-type rotors, mounted on ball and roller bearings. The male

rotor, driven by the engine, drives the female rotor. The compressor delivers pulsation-free air.

Injected oil is used for sealing, cooling and lubricating purposes.

• Compressor oil system

The oil is boosted by air pressure. The system has no oil pump.

The oil is removed from the air, in the air/oil vessel at first by centrifugal force, secondly through the oil

separator element.

The vessel is provided with an oil level indicator.

• Regulation

The compressor is provided with a continuous regulating system and a blow-off valve which is

integrated in the unloader assembly. The valve is closed during operation by air receiver pressure and

opens by air receiver pressure via the compressor element when the compressor is stopped.

When the air consumption increases, the air receiver pressure will decrease and vice versa.

This receiver pressure variation is sensed by the regulating valve which, by means of control air to the

unloader and an electronic engine speed regulator, matches the air output to the air consumption. The

air receiver pressure is maintained between the pre-selected working pressure and the corresponding

unloading pressure.

• Cooling system

The engine is provided with a liquid-cooler and intercooler and the compressor is provided with an oil

cooler. (For available options see chapter 7 Available options.)

The cooling air is generated by a fan, driven by the engine.

• Safety devices

A thermal shut-down sensor protects the compressor against overheating. The air receiver is provided

with a safety valve.

The engine is equipped with low oil pressure and high coolant temperature shut-down sensors.

• Frame and axles

The compressor/engine unit is supported by rubber buffers in the frame.

The standard compressor has an adjustable or fixed towbar with brakes.

The braking system consists of an integrated parking brake and overrunbrake. When driving

backwards the overrunbrake is not engaged automatically. (For available options see chapter

7 Available options.)

Instruction Manual

1310 3012 02 19

CPS

• Toolbox

For the basic unit the max. allowed weight in the toolbox is 90 kg (198 lb). For the full option unit (incl.

aftercooler, reheater, etc.) the max. allowed weight in the toolbox is 20 kg (44 lb).

• Bodywork

The bodywork has openings at the shaped front and rear end for the intake and outlet of cooling air

and hinged doors for maintenance and service operations. The bodywork is internally lined with

sound-absorbing material.

• Lifting eye

A lifting eye is accessible when a small door at the top of the unit is unlocked.

• Control panel

The control panel grouping the air pressure gauge, control switch etc., is placed at the left hand/ rear

end corner.

• Data plate

The compressor is furnished with a data plate showing the product code, the unit serial number and

the working pressure (see chapter 9Dataplate).

• Serial number

The serial number is located on the right-hand side towards the front on the upper edge of the frame.

CPS 750

20 1310 3012 02

CPS

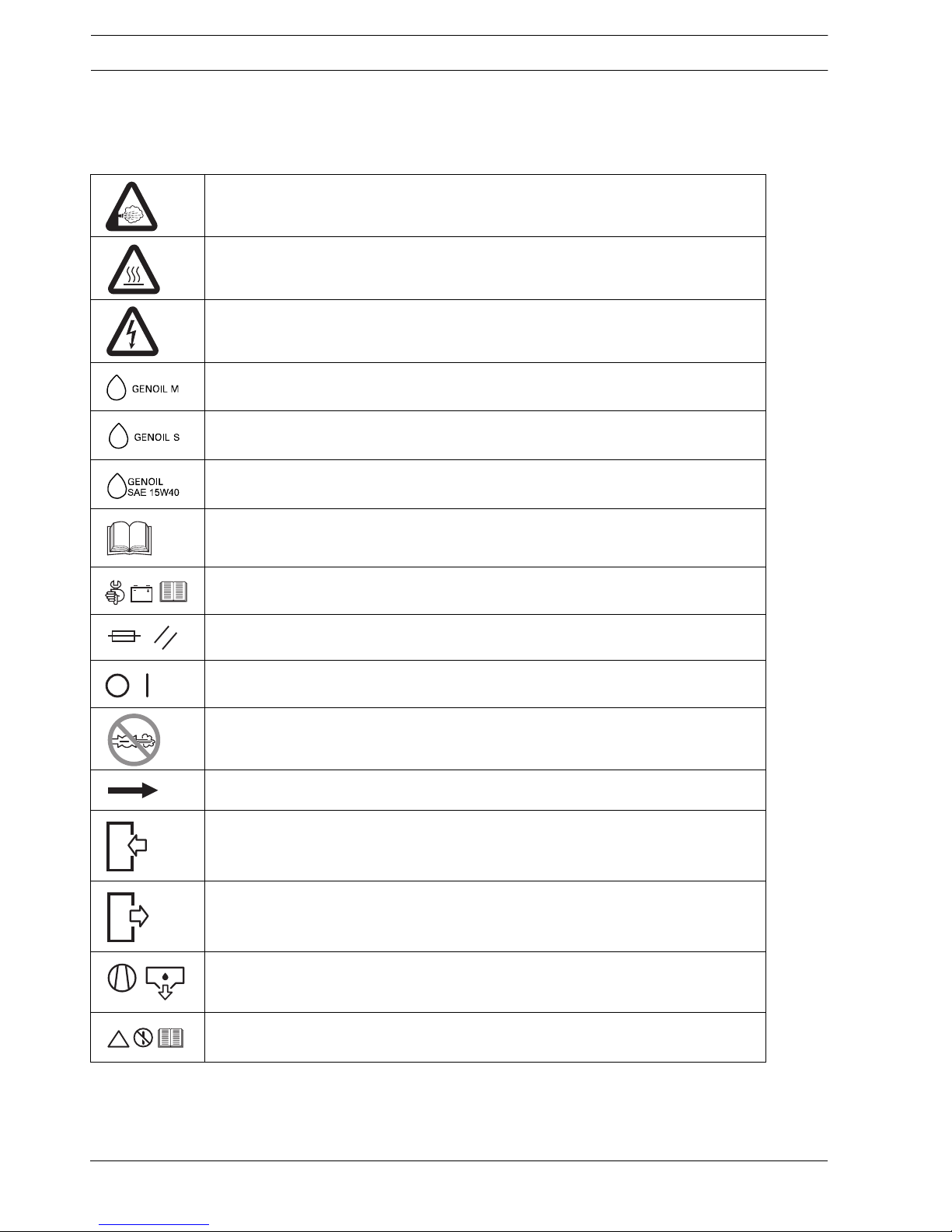

2.2 Markings and information labels

Dangerous outlet gases.

Danger, heat flat.

Electrocution hazard.

Chicago Pneumatic mineral compressor oil.

Chicago Pneumatic synthetic compressor oil.

Chicago Pneumatic mineral engine oil.

Manual.

Read the instruction manual before working on the battery.

Reset fuse.

On / off button.

Prohibition to open air valves without connected hoses.

Rotation direction.

Inlet.

Outlet.

Compressor oil drain.

Read the instruction manual before starting.

Instruction Manual

1310 3012 02 21

CPS

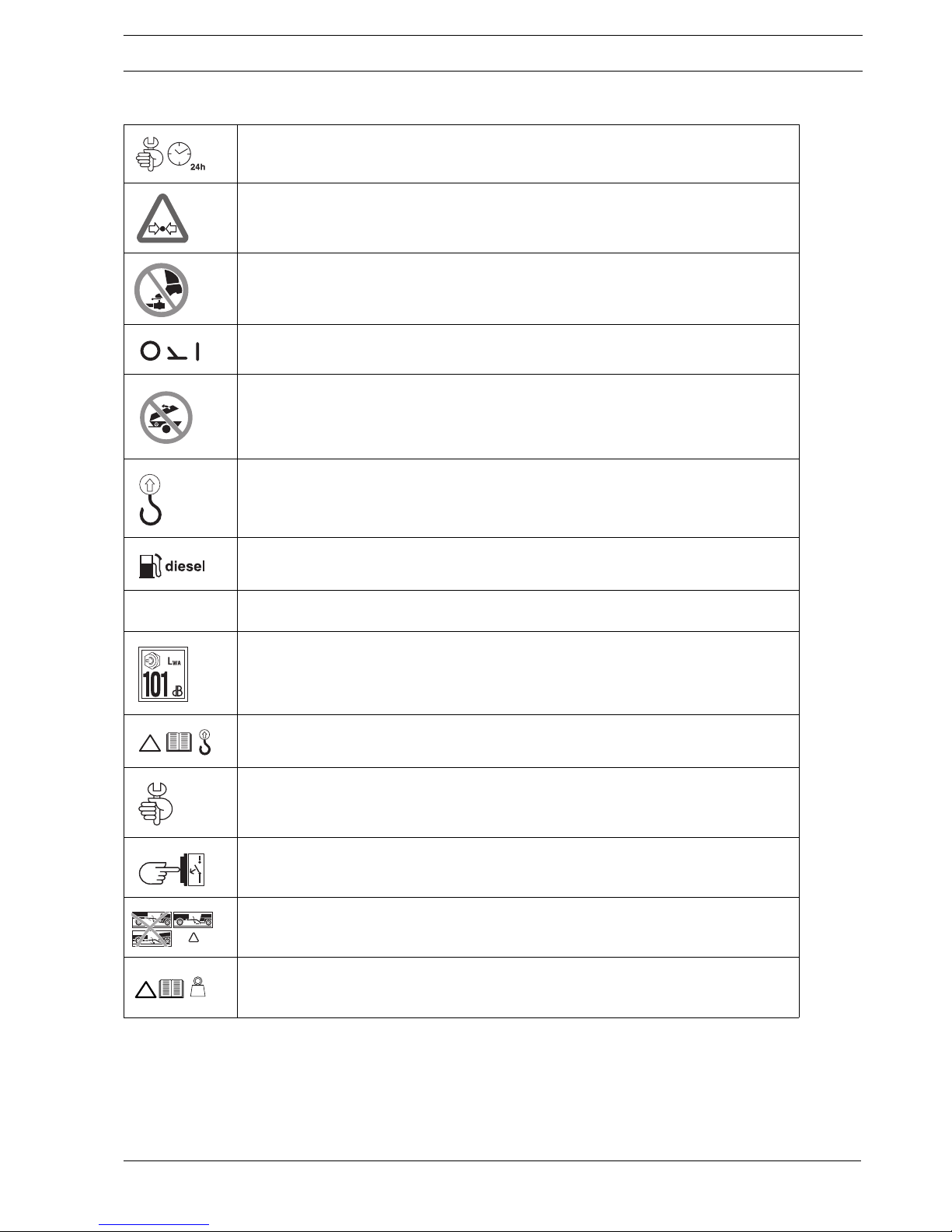

Service every 24 hours.

Warning! Part under pressure.

Do not stand on outlet valves.

Start-Stop indication of switch.

Do not run the compressor with open doors.

Lifting permitted.

Use diesel fuel only.

5.75 bar

(83 psi)

Tyre pressure.

Sound power level in accordance with Directive 2000/14/EEC

(expressed in dB (A)).

Read the instruction manual before lifting.

Service point.

Circuit breaker.

Horizontal towbar position required in case of coupling.

Max. load toolbox.

CPS 750

22 1310 3012 02

CPS

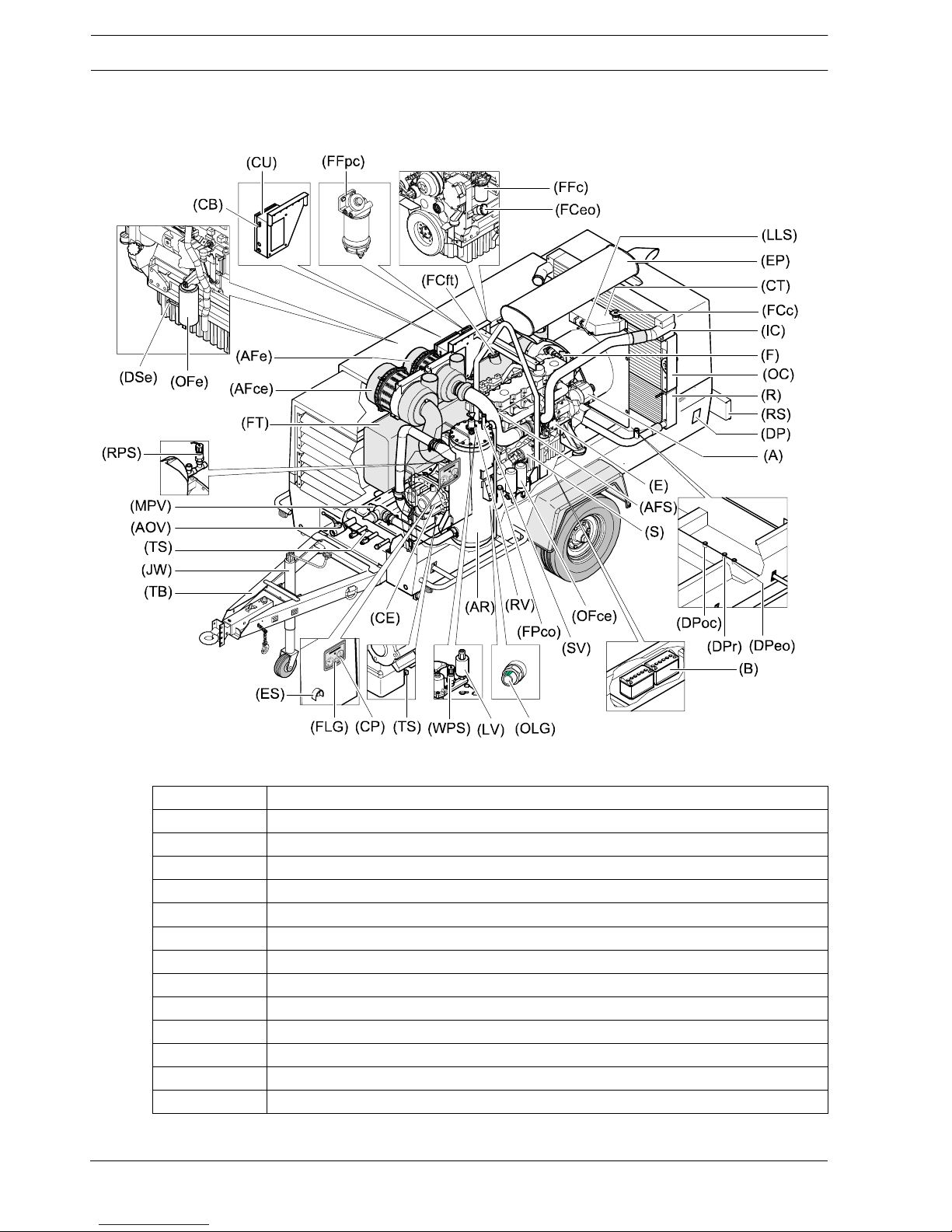

2.3 Main parts

Reference Name

A Alternator

AFce Air Filter (compressor element)

AFe Air Filter (engine)

AFS Air Filter Sensor

AOV Air Outlet Valves

AR Air Receiver

BBattery

CB Circuit Breaker

CE Compressor Element

CP Control Panel

CT Coolant Tank

CU Control Unit

DP Data Plate

Instruction Manual

1310 3012 02 23

CPS

DPeo Drain Plug Engine Oil

DPoc Drain Plug Oil Cooler

DPr Drain Plug Radiator

DSe Engine Oil Level Dipstick

EEngine

EP Exhaust Pipe

ES Emergency Stop

FFan

FCeo Filler Cap (engine oil)

FCft Filler Cap (fuel tank)

FCc Filler Cap (coolant)

FFc Fuel Filter Caterpillar

FFpc Fuel Prefilter Caterpillar

FLG Fuel Level Gauge

FPco Filler Plug (oil compressor element)

FT Fuel Tank

IC Intercooler

JW Jockey wheel

LLS Liquid Level Switch

LV Loading Valve

MPV Minimum Pressure Valve

OC Oil Cooler

OFce Oil Filter (compressor element)

OFe Oil Filter (engine)

OLG Oil Level Gauge

RRadiator

RPS Regulating Pressure Sensor

RS Roadsignalisation

RV Regulating Valve

SStarting Motor

SV Safety Valve

TB Towbar

TS Temperature Sensor

WPS Working Pressure Sensor

Reference Name

CPS 750

24 1310 3012 02

CPS

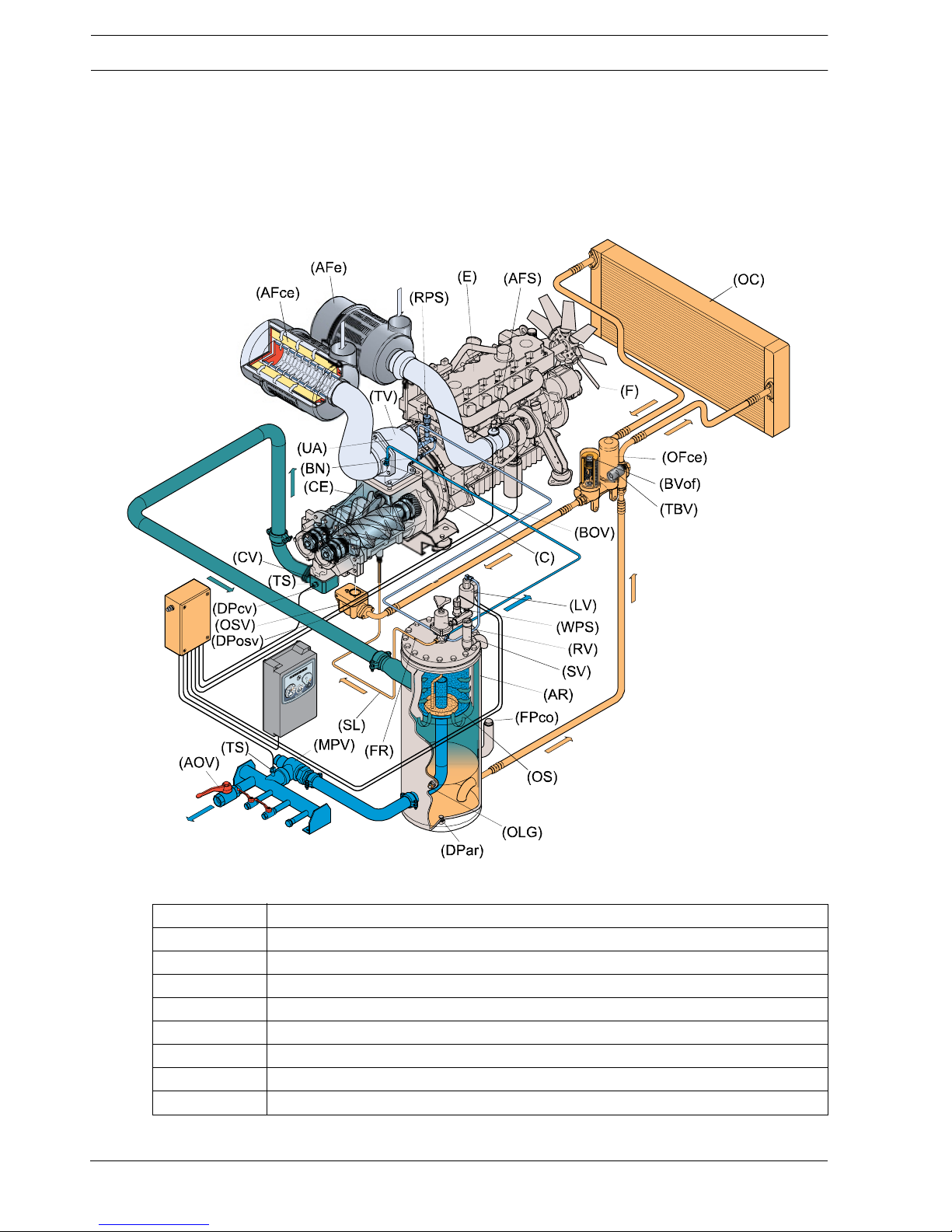

2.4 Regulating system

2.4.1 Overview

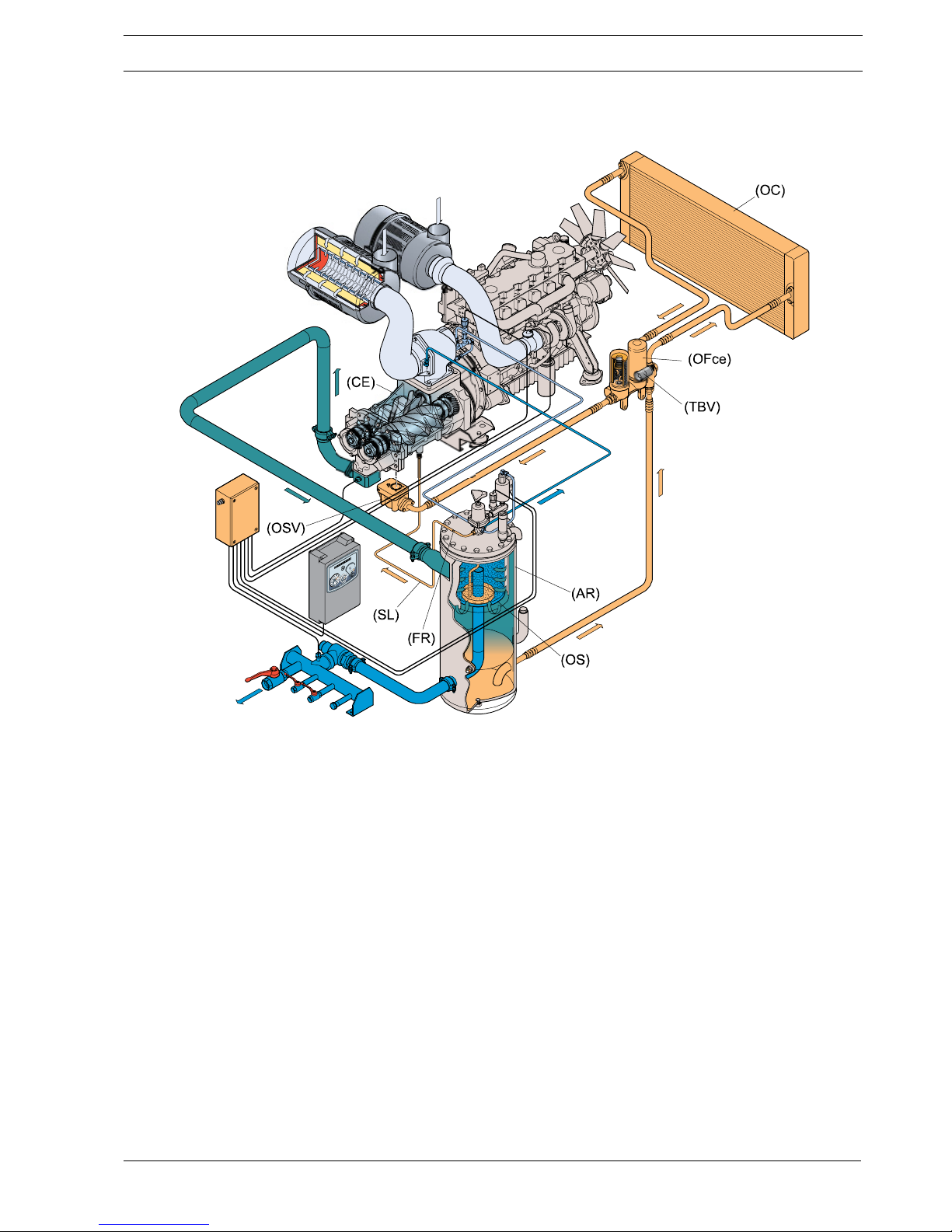

Reference Name

AFce Air Filter (compr. element)

AFe Air Filter (engine)

AFS Air Filter Sensor

AOV Air Outlet Valves

AR Air Receiver

BN Breather Nozzle

BOV Blow Off Valve

BVof By-pass Valve (oil filter)

Instruction Manual

1310 3012 02 25

CPS

C Coupling

CE Compressor Element

CV Check Valve

DPar Drain Plug (air receiver)

DPcv Drain Plug (check valve)

DPosv Drain Plug (oil stop valve)

EEngine

FFan

FPco Filler Plug (oil compressor element)

FR Flow Restrictor

LV Loading Valve

MPV Minimum Pressure Valve

OC Oil Cooler

OFce Oil Filter (compressor element)

OLG Oil Level Gauge

OS Oil Separator

OSV Oil Stop Valve

RPS Regulating Pressure Sensor

RV Regulating Valve

SL Scavenge Line

SV Safety Valve

TBV Thermostatic Bypass Valve

TS Temperature Sensor

TV Throttle Valve

UA Unloader Assembly

WPS Working Pressure Sensor

Reference Name

CPS 750

26 1310 3012 02

CPS

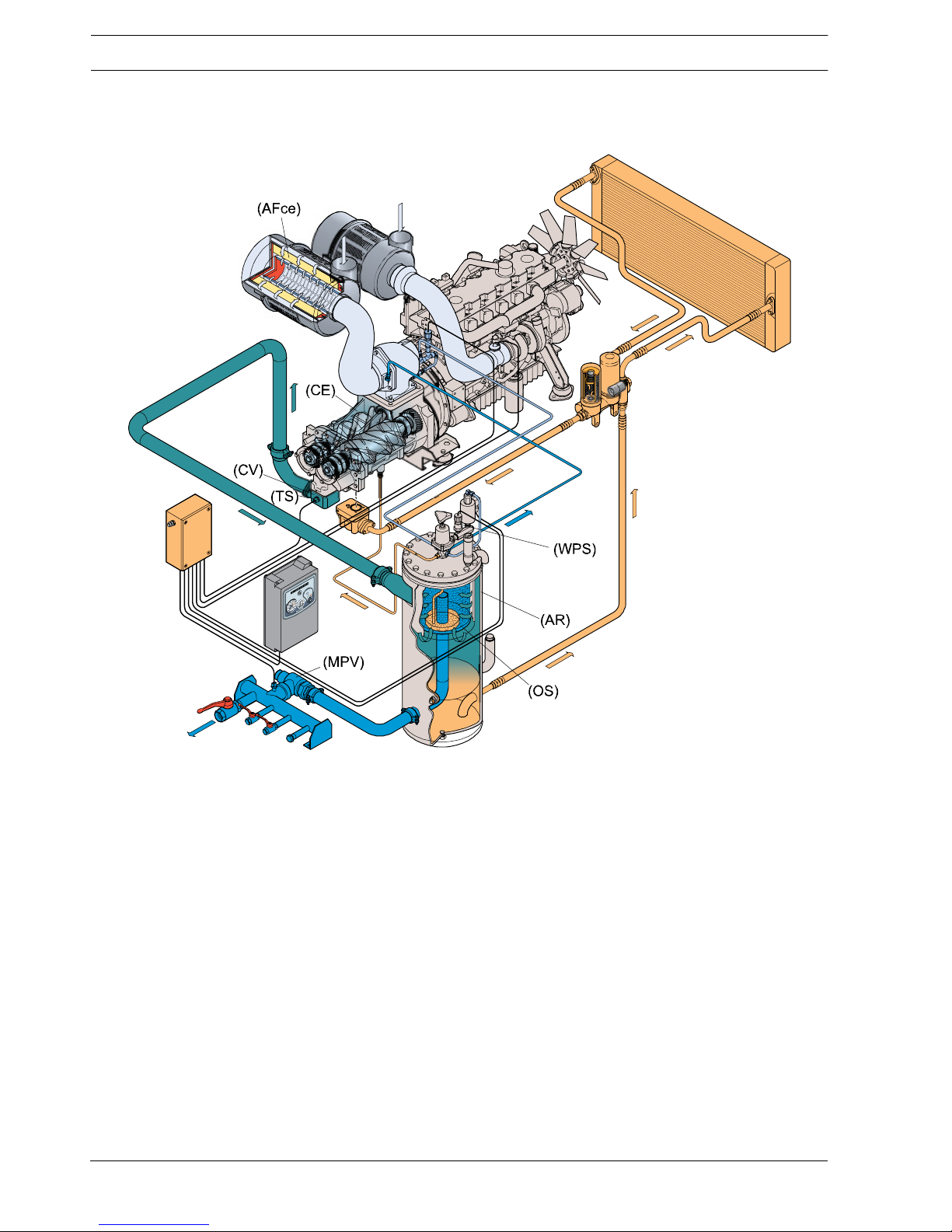

2.4.2 Air flow

Air drawn through the airfilter (AFce) into the compressor element (CE) is compressed. At the element

outlet, compressed air and oil pass into the air receiver/oil separator (AR/OS).

The check valve (CV) prevents blow-back of compressed air when the compressor is stopped. In the air

receiver/oil separator (AR/OS), most of the oil is removed from the air/oil mixture; the remaining oil is

removed by the separator element.

The oil collects in the receiver and on the bottom of the separator element.

The air leaves the receiver via a minimum pressure valve (MPV) which prevents the receiver pressure

from dropping below the minimum working pressure, even when the air outlet valves are open (specified

in section 8.3.2 Limitations). This ensures adequate oil injection and prevents oil consumption.

A temperature sensor (TS) and a working pressure sensor (WPS) are comprised in the system.

Instruction Manual

1310 3012 02 27

CPS

2.4.3 Oil system

The lower part of the air receiver (AR) serves as oil tank.

Air pressure forces the oil from the air receiver/oil separator (AR/OS) through the oil cooler (OC), the oil

filters (OFce) and the oil stop valve (OSV) to the compressor element (CE).

When the compressor is stopped and / or there is no pressure in the system, the oil stop valve (OSV)

prevents the oil from flowing back into the compressor element.

The thermostatic by-pass valve (TBV) opens when the oil temperature is above 70 °C (158 °F).

The compressor element has an oil gallery in the bottom of its casing. The oil for rotor lubrication, cooling

and sealing is injected through holes in the gallery.

Lubrication of the bearings is ensured by oil injected into the bearing housings.

The injected oil, mixed with the compressed air, leaves the compressor element and re-enters the air

receiver, where it is separated from the air as described in section 2.4.2 Air flow. The oil that collects in

the bottom of the oil separator element is returned to the system through a scavenging line (SL), which is

provided with a flow restrictor (FR).

The oil filter by-pass valve opens when the pressure drop over the filter is above normal because of a

clogged filter. The oil then by-passes the filter without being filtered. For this reason, the oil filter must be

replaced at regular intervals (see section 4.5 Preventive maintenance schedule for the compressor).

CPS 750

28 1310 3012 02

CPS

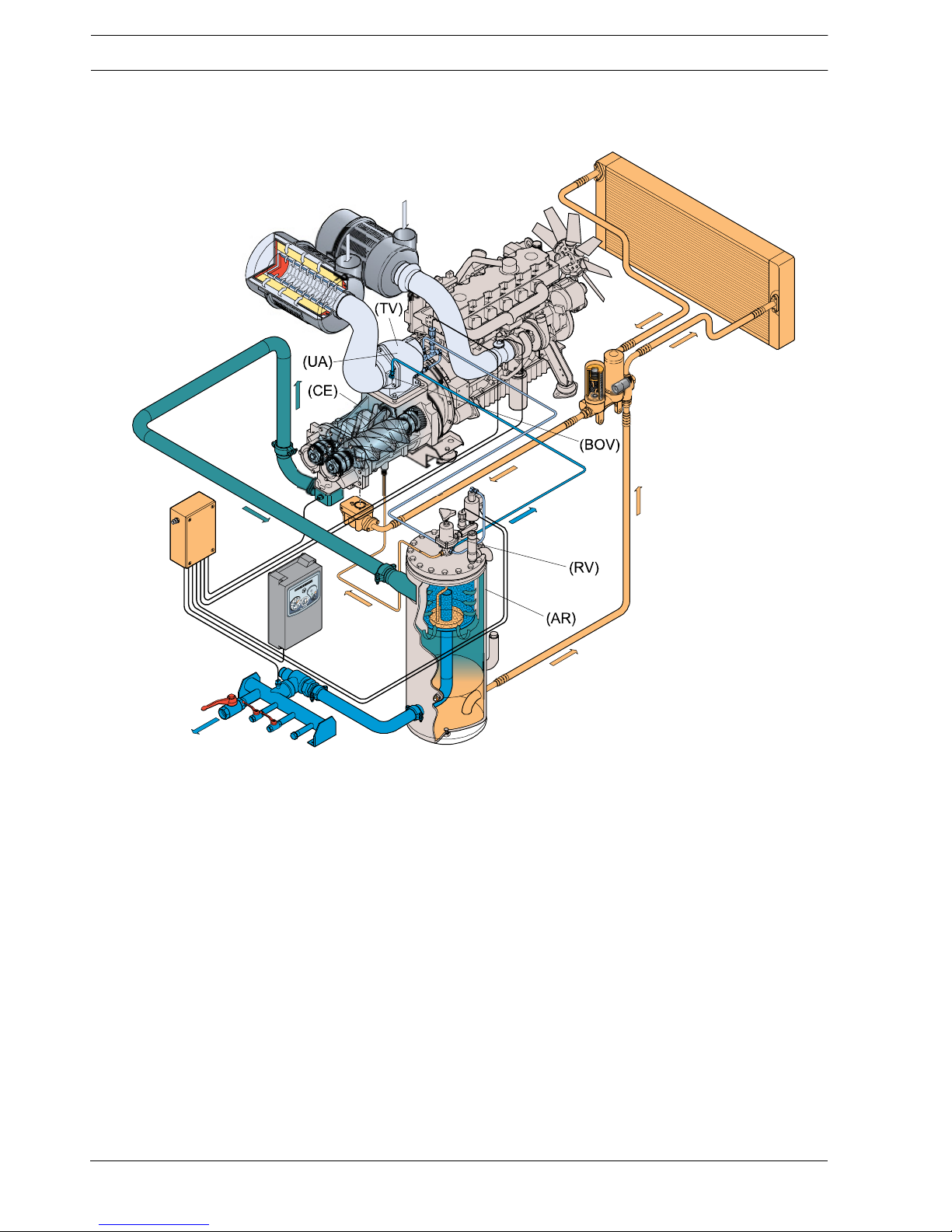

2.4.4 Continuous regulating system

The compressor is provided with a continuous regulating system and a blow-off valve (BOV) which is

integrated in the unloader assembly (UA). The valve is closed during operation by outlet pressure of the

compressor element and opens by air receiver pressure when the compressor is stopped.

When the air consumption increases, the air receiver pressure will decrease and vice versa. This receiver

pressure variation is sensed by the regulating valve (RV) which, by means of control air to the unloader

assembly (UA), matches the air output to the air consumption. The air receiver pressure is maintained

between the pre-selected working pressure and the corresponding unloading pressure.

When starting the compressor, the throttle valve (TV) is kept closed via receiver pressure. The

compressor element (CE) takes in air and pressure builds up in the receiver (AR). The throttle valve (TV)

is closed. The air output is controlled from maximum output (100%) to no output (0%) by:

1 Speed control of the engine between maximum load speed and unloading speed (the output of a

screw compressor is proportional to the rotating speed).

2 Air inlet throttling.

Instruction Manual

1310 3012 02 29

CPS

If the air consumption is equal to or exceeds the maximum air output, the engine speed is held at

maximum load speed and the throttle valve (TV) is fully open.

If the air consumption is less than the maximum air output, air receiver pressure increases and the

regulating valve supplies control air to throttle valve (TV) to reduce the air output and holds air receiver

pressure between the normal working pressure and the corresponding unloading pressure. Unloading

pressure = normal working pressure + 1 bar (14.504 psi).

When the air consumption is resumed, the blow off valve (BOV) closes and the throttle valve (TV)

gradually opens the air intake and the electronic speed regulator increases the engine speed.

The construction of the regulating valve (RV) is such that any increase (decrease) of the air receiver

pressure above the pre-set valve opening pressure results in a proportional increase (decrease) of the

control pressure to the throttle valve and the electronic speed regulator.

Part of the control air is vented to atmosphere, and any condensate discharged, through the vent holes.

Loading...

Loading...