Chicago Pneumatic CP7215 series, CP7225series, CP7255 Series Operator's Manual

Operator’s Manual

To reduce risk of injury, everyone using, installing, repairing, maintaining,

changing accessories on, or working near this tool must read and

understand these instructions before performing any such task.

CP7215, CP7225, CP7255 Series

Random Orbital Sander

13325 Carowinds Blvd. Charlotte NC 28273 USA

8940163475 Rev. C

Printed in Taiwan

KEK 01/08

http://www.cp.com

Visit our website:

UNITED STATES FRANCE SOUTH AMERICA

Chicago Pneumatic Tool Co. LLC Contact Chicago Pneumatic/USA

Espace Lumière

13325 Carowinds Blvd. for names of CP Authorized

Bâtiment S

Charlotte, NC 28273 • USA Distributors in this area

57, Boulevard de la République

Telephone: 1-803-817-7000

78403 Chatou Cédex. France

1-800-367-2442 (USA only)

Telephone: (0) 1 30 09 60 00

SOUTHEAST ASIA

Fax: 1-800-228-9096

Fax: (0) 1 30 71 96 70

Chicago Pneumatic Tool Company

Regional Office

AUSTRALIA

P.O. Box 1516

GERMANY

Unit 2103 - Citimark

Atlas Copco Tools Australia

Desoutter GMBH

28 Yuen Shun Circuit

3 Bessemer Street

Vehicle Service

Shatin

Blacktown • Australia

Edmund-Seng-Strasse 3-5

New Territories, Hong Kong

Telephone: 02-621-9482

D-63477 Maintal • Germany

Telephone: (8522) 3570963

Fax: 02-671-5915

Telephone: 49-0611-270120/22

Fax: 852-763-1875

Fax: 49-0611-270140

BELGIQUE

SPAIN

INDIA

Chicago Pneumatic Rep. Office

Desoutter S.A.

Avenue Sluysmans 10-4030

Chicago Pneumatic Sales

C. Serrano, 120

Liege • Belgium

Chemtex House, First Floor

28006 Madrid • Spain

Tel/Fax: 04-343 8150

Main Street

Telephone: 91 590 31 52

Hiranadani Gardens

Fax: 91 590 31 61

BRASIL

Powai, Mumbai 400076, India

Telephone: (22)25704907

Chicago Pneumatic Brasil

(22)25708984

SWEDEN

Av. Mascote 159 V. Sta. Catarina

Fax: (22)25705042

Chicago Pneumatic

04363-000

Distributor Markets

Sao Paulo/SP • Brasil

Sickla Industriväg 7

ITALY

Telefone: (011) 562-7314

S-131 34 Nacka • Sweden

Fax: (011) 563-9208

Desoutter Italiana S.R.L.

Telephone: 46 8743 9329

Viale Della Repubblica, 65

Fax: 46-8743 9427

CANADA

20035 Lisson (Milano)

Chicago Pneumatic Tool Co. LLC

UNITED KINGDOM

MEXICO

Automotive Division

Chicago Pneumatic Tool Company, Ltd.

13325 Carowinds Blvd.

Chicago Pneumatic Tool

P.O. Box 241

Charlotte, NC 28273

Company Mexico

Eaton Road

Telephone: 1-803-817-7000

San Francisco #223

Hemel Hempstead, Herts HP2 7DR

Fax: 1-800-228-9096

Valle Dorado, Tlalnepantla

England

C.P. 54020 • Mexico

Domestic: 01442-847703/06

CENTRAL AMERICA

Telephone: 525-378-0754

Export: 01442-232420/17

Fax: 525-378-0753

Contact Chicago Pneumatic/USA

Fax: 01442-2847723

for names of CP Authorized

SOUTH AFRICA

Distributors in this area

Chicago Pneumatic Tool Company, S.A.

20 Anvil Road

PO Box 105

Isando 1600, Transvaal • South Africa

Telephone: 011-9746761

Fax: 011-974-2324

FOR DETAILED INFORMATION ABOUT CHICAGO

PNEUMATIC AIR TOOLS AND EQUIPMENT CONTACT:

CP7215, CP7225, CP7255 Series

Random Orbital Sander

Copyright 2008, Chicago Pneumatic Tool Co. LLC

All rights reserved. Any unauthorized use or copying of the contents or part thereof is prohibited. This applies in particular to trademarks,

model denominations, part numbers and drawings. Use only authorized parts. Any damage or malfunction caused by the use of

unauthorized parts is not covered by Warranty or Product Liability.

EC DECLARATION OF CONFORMITY

We, Chicago Pneumatic Tool Co. LLC, 13325

Carowinds Blvd., Charlotte, NC 28273 USA, declare

under our sole responsibility that the product to which

this declaration relates, is in conformity with the

requirements of the Council Directive of June 1998 on

the approximation of the laws of the Member States

relating to machinery (98/37/EC).

Machine Name CP7215, CP7225, CP7255 Series

Random Orbital Sander

Machine Type Power tool equipped with flexible disc

fitted with abrasive paper for sanding - No other use

is permitted.

Serial No. Tools with No. 00000-001-P or higher

Technical Data

Pad diameter 6 in. (150 mm)

Free Speed 12,000 RPM

Air pressure 90 psi (6.2 bar)

Spindle size 5/16”-24

Harmonized Standards Applied EN792-8

National Standards Applied ISO 8662-8, EN ISO

15744

Name And Position Of Issuer Bruno Blanchet,

General Manager

Signature Of Issuer

Date Of Issue February 15, 2008

Noise & Vibration Declaration*

Sound pressure level 81 dB(A) uncertainty 3 dB(A), in

accordance with EN ISO 15744. For sound power,

add 11 dB(A).

2

Vibration value <2.5 m/s , re. ISO 8662-8.

*

These declared values were obtained by laboratory type

testing in compliance with the stated standards and are not

adequate for use in risk assessments. Values measured in

individual work places may be higher than the declared

values. The actual exposure values and risk of harm

experienced by an individual user are unique and depend

upon the way the user works, the workpiece and the

workstation design, as well as upon the exposure time and

the physical condition of the user. We, Chicago Pneumatic,

cannot be held liable for the consequences of using the

declared values, instead of values reflecting the actual

exposure, in an individual risk assessment in a work place

situation over which we have no control.

INSTRUCTION MANUAL

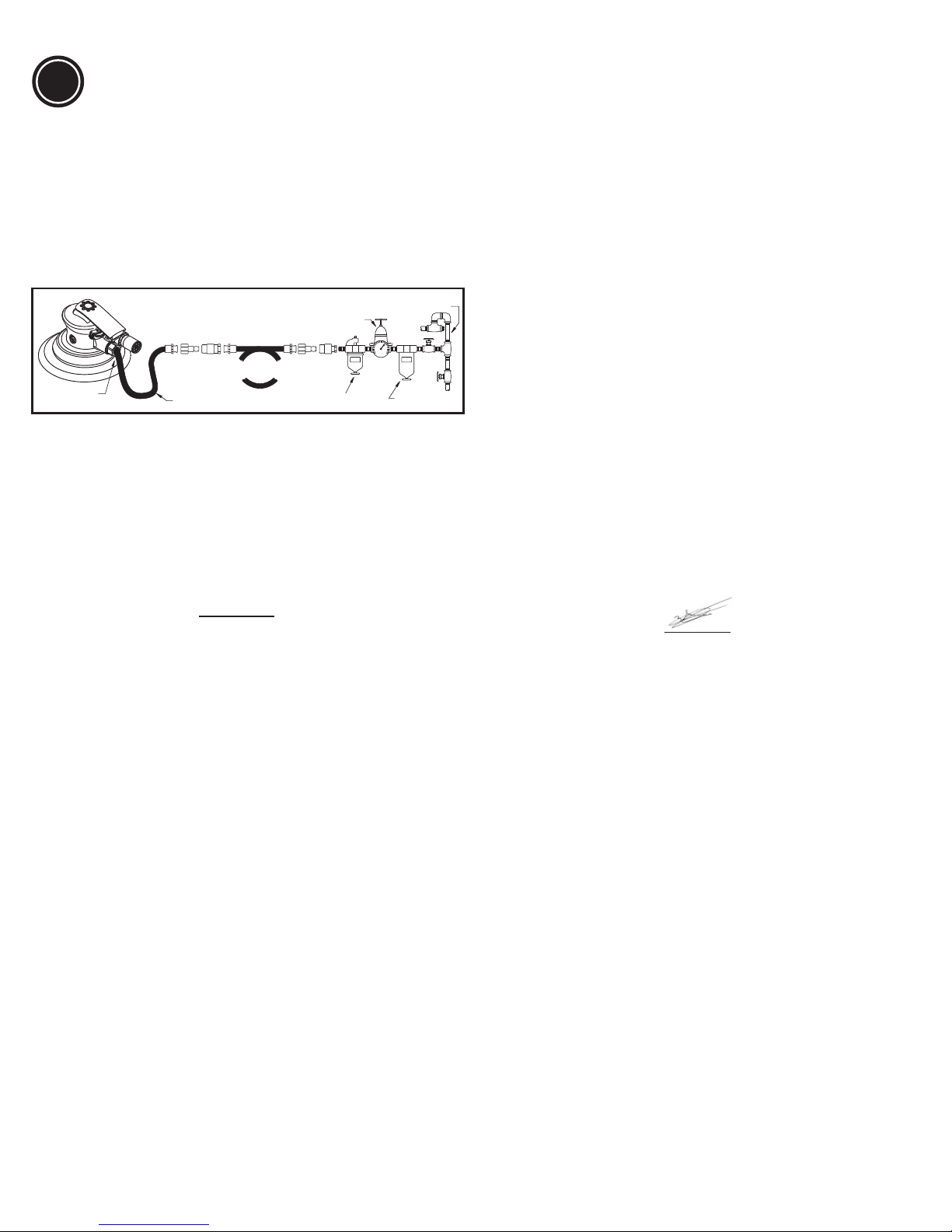

Air Supply Requirements

1. Supply tool with 90 psig (6.2 bar) of clean, dry air. Higher

pressure drastically reduces tool life.

2. Connect tool to air line using pipe, hose, and fitting sizes

shown in the diagram.

3. Do not install a quick coupler directly into the sander

throttle handle.

Lubrication

Use an air line lubricator with SAE #10 oil, adjusted to

two (2) drops per minute. If an air line lubricator cannot

be used, add air motor oil to the inlet once a day.

Maintenance

1. Disassemble and inspect air motor and orbital assembly

every three (3) months if the tool is used every day.

Replace damaged or worn parts.

2. High wear parts are underlined in the parts list.

3. To keep downtime to a minimum, the following service

kits are recommended:

Tune-Up Kit

8940163459 (Incl: 7, 17, 19, 20, 23, 26, 33)

Maintenance Kit

8940163460 (Incl: Wrenches for Pad, Motor Kit and Lock Ring)

Dust Extraction Kit

8940163461 (Incl: 1 Dust Bag and its Dust Hose for SV)

Dust Bag Set

8940163496 (Incl: 5 pcs. Dust Bag for SV)

Hose Adaptators for CV Palm Sanders

6153501170 (Incl: Vacuum Hose Adaptator ø25 (1”) / ø32 (1 1/4”)

6158044480 (Incl: Vacuum Hose Adaptator ø25 (1”) / ø28 (1 1/8”)

English

EN

1/2" (12mm)

LUBRICATOR

REGULATOR

1/4"NPT

FILTER

1/2" (12mm)

3/8" (10mm)

130

90

0

Loading...

Loading...