Chicago Pneumatic CP 550, CP 750, CP 1650, CP 2250, CP 3050 Operating Instructions Manual

...

Operating instructions

for hydraulic breaker

TM

CP 550

CP 750

CP 1150

CP 1650

CP 2250

CP 3050

CP 4250

© Copyright 2007

www.chicagopneumatic.com

AIB

2007−05−04

No. 3390 5053 01

Operating instructions for hydraulic breaker

CP 550

CP 750

CP 1150

CP 1650

CP 2250

CP 3050

CP 4250

E Chicago Pneumatic

Any unauthorized use or copying of contents or any part thereof is

prohibited.This applies in particular to to trademarks, model denominations,

part numbers and drawings.

3

Table of contents

1 Foreword 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Accident prevention regulations 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3CE markings EC machinery directive 98/37/EC 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1CE sticker product groups A 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 CE sticker product groups B 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Sticker for guaranteed sound level power11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 General informations 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Applications 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Scope of supply 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Main components 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Main components or assemblies CP 550 and CP 750 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Main components or assemblies CP 1150 and CP 1650 13 . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Main components or assemblies, CP 2250, CP3050 and CP 4250 14 . . . . . . . . . . . . . . . .

6 Installation 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Media/consumables 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.1 Mineral hydraulic oil 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2 Non−mineral hydraulic oil 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.3 Grease 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.4 Gas 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Attaching the adapter to the hydraulic breaker16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Mounting the hydraulic breaker on the excavatormechanical aspects 17 . . . . . . . . . . . . . .

6.4 Mounting the hydraulic breaker on the excavator−hydraulic aspects 18 . . . . . . . . . . . . . . . .

6.5 Switching the hydraulic breaker on/off from the carrier19 . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6Dismounting the hydraulic breaker from the excavator for short or

lengthy periods of nonuse 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.1Dismounting from excavator19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Storage 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1Hydraulic breaker 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1Short storage 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Long storage 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.3 How to proceed after more than twelve months’ storage 20 . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.4 Working tool 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Fitting/removing the working tool 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1Selecting the right working tool 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.1Working tools for hydraulic breakers CP 550 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.2 Working tools for hydraulic breakers CP 750 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.3 Working tools for hydraulic breakers CP 1150 CP 4250 23 . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Fitting the tool (After breaker delivery to the site) 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1CP 550 and CP 750 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2 CP 1150 CP 4250 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Removing the tool 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Operating the hydraulic breaker 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1Starting up the hydraulic breaker 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Advance 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Angle of attack 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 Breaker rocking 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5 Never drive the working tool into the ground 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6Never lever with the breaker 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . .

4

9.7 Never use as a sledgehammer 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.8Never use for transport purposes 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.9Using the hydraulic breaker in or under water 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10 Hydraulic breaker used in tunnelling 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.11 Working in high outside temperatures 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.12 Working in low outside temperatures 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13 Operating the breaker with the cylinders fully extended or retracted 29 . . . . . . . . . . . . . . . .

10 Maintenance work to be performed by the excavator driver 30 . . . . . . . . . . . . . . . . . . . .

10.1 Manual lubricating of the working tool for CP550 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Automatic lubrication using of the hydraulic breaker 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.1 Automatic lubrication using CP−Lube 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.2 Changing the lubricant cartridge 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.3 Operating the CP−Lube 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3 Manual lubrication without or upon failure of CP−Lube 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3.1 Filling device for the chisel paste 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4 Care and maintenance timetable33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5 Check 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5.1Checking the working tool for wear 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5.2 Checking the wear bushes 35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5.3 Checking the retaining pin for wear (CP 550 and CP 750) 36 . . . . . . . . . . . . . . . . . . . . . . . .

10.5.4 Checking the retainer bars (CP 1150 CP 4250) 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5.5 Checking the impact face of the percussion piston 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5.6Checking the breaker box for wear and cracks and checking the

adapter for cracks 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5.7 Screw couplings CP 550 and CP 750 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5.8Screw couplings CP 1150 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5.9Screw couplings CP 1650 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5.10 Screw couplings CP 2250, CP 3050 and CP 4250 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5.11 Checking pressure in piston accumulator and refilling if required 42 . . . . . . . . . . . . . . . . . . .

10.5.12 Checking that the highpressure accumulator is in perfect working order 44 . . . . . . . . . . . .

10.5.13 Checking the hydraulic lines before starting work44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5.14 Checking the adapter bolts for wear 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5.15 Checking and cleaning the hydraulic oil filter 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 Troubleshooting 45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 Breaker does not start45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 Impact rate of hydraulic breaker too low 46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 Impact force too low 47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4 Impact rate too high and impact force too low 47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.5 Oil leaks from ports »P« and »T« 47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.6 Oil leaks between cylinder cover and cylinder 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.7 Oil leaks from parts of hydraulic system for breaker (Screw couplings, hoses etc.) 48 . . .

11.8 Oil leaks from working tool 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.9 Oil leaks from high−pressure accumulator 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.10 Oil or grease leaks from CP−Lube 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.11 Operating temperature too high 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 Disposal 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 Technical specifications 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 52 . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

5

1 Foreword

Please read this operating manual before using

your Atlas Copco hydraulic breaker for the first

time so as to avoid errors and breakdowns through

incorrect usage.

These oper

H important safety regulations

H operating instructions for the hydraulic breaker

H maintenance instructions for the hydraulic

breaker

H aids to troubleshooting

operating instructions describe how to use the

The

hydraulic breaker on site and should therefore be

kept in the document compartment of the exca

vator cab.

Please pay careful attention to the safety regula

tions which are listed at the beginning of this man

ual and repeated in the relevant sections.

ating instructions contain:

Responsibility for the observation of these safety

regulations lies at all times with the operator.

All safety regulations listed in this manual comply

with the laws and regulations of the European

Union. Additional national regulations have also

been taken into consideration wherever applicable.

Hydraulic breaker operation outside the European

Union is subject to the laws and regulations valid in

the country of use. More specific national regula

tions and laws that apply in your country must be

observed.

Please note that reliable operation of the hydraulic

breaker can only be guaranteed if genuine spare

parts are used.

We wish you every success with your hydraulic

breaker.

6

2 Accident prevention regulations

To avoid the risk of injury, please observe the fol

lowing instructions.

Familiarise yourself with the operating manual and

the applicable regulations before starting work with

the hydraulic breaker.

When using hydraulic breaker in states of the Euro

pean Union, the regulations contained in the EC

machinery directive 98/37/EC must be observed

and followed, as must all applicable national acci

dent prevention regulations. In countries outside the

European Union, the valid local statutes and regula

tions shall apply. Please observe any other, more

stringent national/regional regulations and legisla

tion.

Explanation of the symbols used in this operating instructions

To emphasise their importance, certain points in the

operating instructions are marked with symbols,

The marked text provides instructions

Note

on the correct use of the hydraulic tool

aimed at avoiding incorrect operation or

errors during work.

which are described below.

CAUTION!

DANGER!

The marked text provides safety regula

tions and instructions aimed at avoiding

damage to equipment.

The marked text provides safety regula

tions and instructions aimed at avoiding

accidents and possible injuries.

7

Before the first installation:

Fitting and removing the working tool:

Before mounting/dismounting the hydraulic tool

and/or any maintenance work on the hydraulics of

the hydraulic tool/carrier the hydraulic system must

be depressurized!

When using or transporting the carrier with the hy

draulic breakers attached, the instructions included in

the operating manual supplied by the carrier manu

facturer must also be observed.

Do not run any hydraulic lines for attachment of the hy

draulic breaker through the driver’s cab! Hydraulic lines

may spring a leak or even burst! During operations, the

hydraulic oil becomes very hot.

Mounting the hydraulic breaker:

Mounting the hydraulic breaker requires the pres

ence of an assistant, who must be instructed by the

carrier driver. The carrier driver and assistant should

agree beforehand on clear hand signals.

For transport purposes, use only the lugs provided

and hoisting equipment of sufficient capacity.

The hydraulic breaker should only be mounted on an

excavator with sufficient load capacity. The carriers

specified under Section 13, Technical specifications

are needed to install the hydraulic breaker.

Carriers below this weight class will not provide the

required degree of stability and could even fall over

during hydraulic breaker use, causing injury and

damage.

Carriers above this weight class may apply excess

ively high mechanical loads to the attachment.

When attaching the adapter use only the special

steel screws included in supply.

Check the nominal width of the hydraulic lines on

existing hydraulic systems. It is important that supply

and return lines for the hydraulic oil are adequately

dimensioned.

Keep your hands away from bores and fitting sur

faces when mounting the hydraulic breaker, es

pecially when the carrier boom is moving.

Collect any oil which runs out and dispose of it in ac

cordance with the applicable statutory provisions to

avoid environmental hazards.

When putting into use hydraulic breakers with

high−pressure accumulators the applicable

national requirements are to be observed, e.g. in

Germany an authorized person/inspection body is

to inspect and certify the system on site before put

ting it into use.

Always wear protective glasses when fitting or re

moving the working tool, since metal splinters may fly

off when hammering out the locking bolts.

The working tool should only be fitted in the way de

scribed in this operating manual.

Never use your fingers to check whether the re

cesses on the working tool shaft are aligned to the

slots for

Operating the hydraulic breaker:

Close the front screen/splinter guard on the driver’s

cab to protect the driver from flying rock splinters

during breaker operations.

Wear ear protectors

The national regulations of the country of use as re

gards excavator operations with percussive tools

shall apply.

Guaranteed

The LWA guaranteed sound power level is an upper

limit, indication of which is mandatory under EU di

rective 2000/14/EC. The guaranteed sound power

levels are listed in section 13, Technical Specifica

tions.

Do not start up the hydraulic breaker until both carrier

and hydraulic breaker are in the correct position.

Stop the hydraulic breaker immediately as soon as

persons are in the danger zone. The danger zone

during the breaker operation is considerably greater

than during the excavation operation − on account of

fractions of stones and pieces of steel flying around −

and for this reason, the danger zone must, depend

ing on the type of material to be worked on, be en

larged correspondingly, or the danger zone must be

secured in a suitable manner through corresponding

measures.

Do not touch any hot parts

The hydraulic breaker heats up during operation.

Monitor the oil temperature

The temperature of the hydraulic oil must never ex

ceed 80°C. If higher temperatures are measured in

the tank, the hydraulic system and/or the pressure−

relief valve have to be checked.

Observe the excavator manufacturer’s safety regula

tions.

CAUTION!

With regard to excavator operation when working

with an attached hydraulic breaker, please refer to

Section 6.5.

the retainer bars.

sound power level

The hydraulic breaker is only to be used for the ap

plications described.

8

Maintenance and repairs:

The piston accumulator integrated in the hydraulic

breaker is pressurised. Before dismantling the hy

draulic breaker it is essential that all gas be bled off.

The same applies to removal of the filling valve »G«

(see Section 10.5.11).

When filling the piston accumulator, ensure noone is

in the vicinity of the working tool. If the tool has

jammed, the increase in pressure in the piston accu

mulator may cause it to spring out suddenly.

DANGER: risk of injury!

The piston accumulator should only be filled with ni

trogen from the green nitrogen cylinder. Ensure that

no other gas, e.g. air or oxygen, gets into the piston

accumulator.

DANGER: risk of explosion!

Pressure accumulator

Before replacing the pressure accumulator, the hy

draulic system must be fully depressurised.

If any significant changes are made to the hy

draulic system, a new acceptance inspection is

to be carried out in accordance with the relevant

national safety provisions.

Note

Check the pressure accumulator in accordance with

the national safety provisions. We recommend five−

yearly maintenance intervals.

Dismounting the hydraulic breaker:

Dismounting the hydraulic breaker from the carrier

requires the presence of an additional assistant who

must be instructed by the carrier driver. The carrier

driver and assistant should agree beforehand on

clear hand signals.

When using the excavator or putting it out of oper

ation, the safety instructions of the excavator manu

facturer must be observed.

Keep your hands away from bores and fitting sur

faces when dismounting the hydraulic breaker, es

pecially when the carrier boom is moving.

If one of the expansion bolts on the highpressure

accumulator should break, it is imperative that all

bolts be replaced.

Collect any oil which runs out and dispose of it in ac

cordance with the applicable statutory provisions to

avoid environmental hazards.

Secure the hydraulic breaker after dismounting so

that it cannot fall over.

9

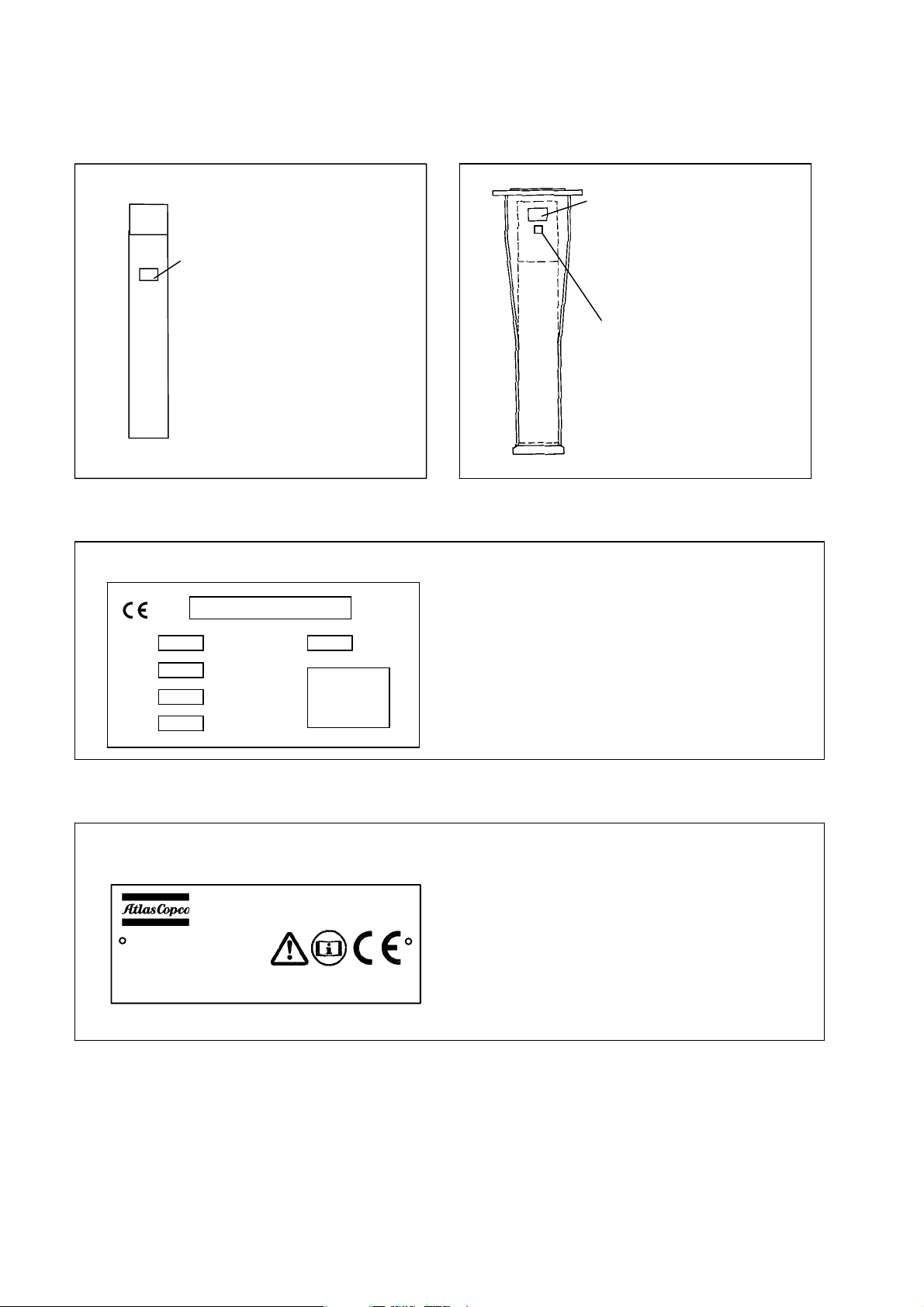

3CE markings EC machinery directive 98/37/EC

A Product group: Hydraulic breaker

(without guide system)

Location of CE sticker

3.1 CE sticker product groups A

B Product group: Hydraulic breaker with

breaker box

Location of CE sticker

LWA sticker

rear side of

breaker box,

below upper

flange

1

2

4

3

7

5

6

3.2 CE sticker product groups B

Atlas Copco Construction Tools

Essen Germany

Type

Ser. No.

Deliv. wt

P max

Year

Made in Germany

1. Name and address of manufacturer

2. Model

3. Serial no.

4. Part ident. no.

5. max. operating pressure

6. Year of construction of product group

7. Weight of product group

Name and address of manufacturer

Model

Serial no.

Weight of product group

max. operating pressure

Year of construction of product group

The CE nameplate contains information on the unit

"breaker and breaker box". All weights indicated refer

to the weight of this unit.

When selecting hoists and suspension aids for trans

porting the unit, the weights of the working tool and

adapter may also have to be considered.

10

In according with EC directives CE nameplates must

be affixed firmly and in a clearly visible position.

Should these nameplates be lost or defaced, repla

cements can be ordered from your dealer/from Chi

cago Pneumatic.

The following information must be provided:

Part ident. no. of the tool/ser. no. and date of delivery

(from the delivery note).

3.3 Sticker for guaranteed sound level power

In accordance with EU directive 2000/14/EC, hy

draulic breakers used within the EU must bear a

marking legible from the outside stating the sound

power level guaranteed by the manufacture.

4 General informations

4.1 Applications

The hydraulic breaker is an attachment suitable for

mounting on hydraulicpowered excavators.

The hydraulic breaker has been suited for the follow

ing operations:

Construction:

Demolition, tearing up, trenching, foundation work

4.2 Scope of supply

The scope of supply of a hydraulic breaker generally

includes:

Hydraulic breaker, operating instructions, spare parts

list and EC declaration of conformity.

Accessories: Mounting tool, hoses and service box

according to the order.

Special accessories: e. g. adapter, hydraulic adapter

kit for the excavator according to the order.

Mining and quarrying:

Primary breaking, bench leveling, reducing mineral

raw materials and rocks, tunnel construction

Under normal circumstances the hydraulic breaker is

operated from the driver’s cab of the carrier.

Please refer to Sections 2 and 6.5.

11

5 Main components

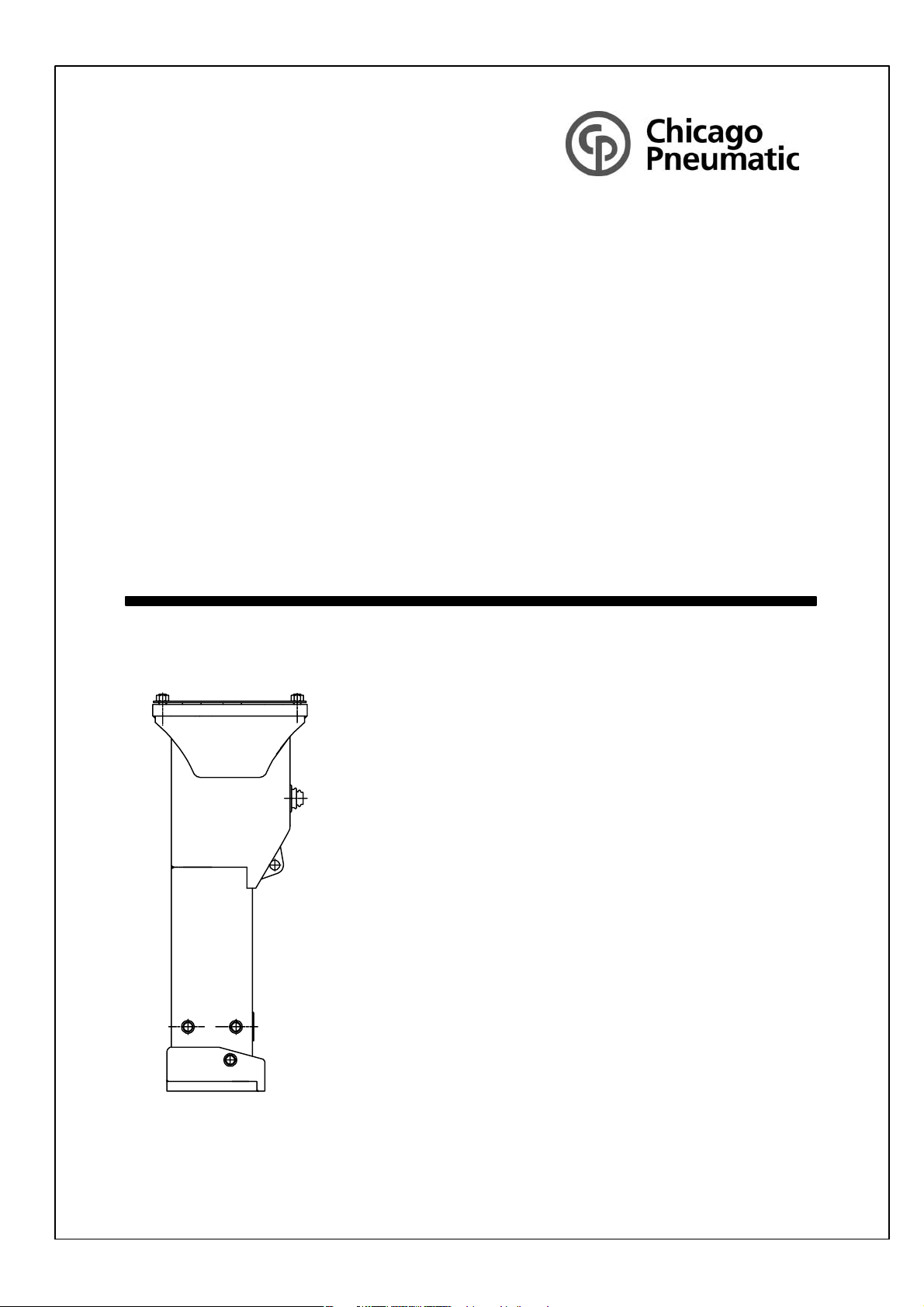

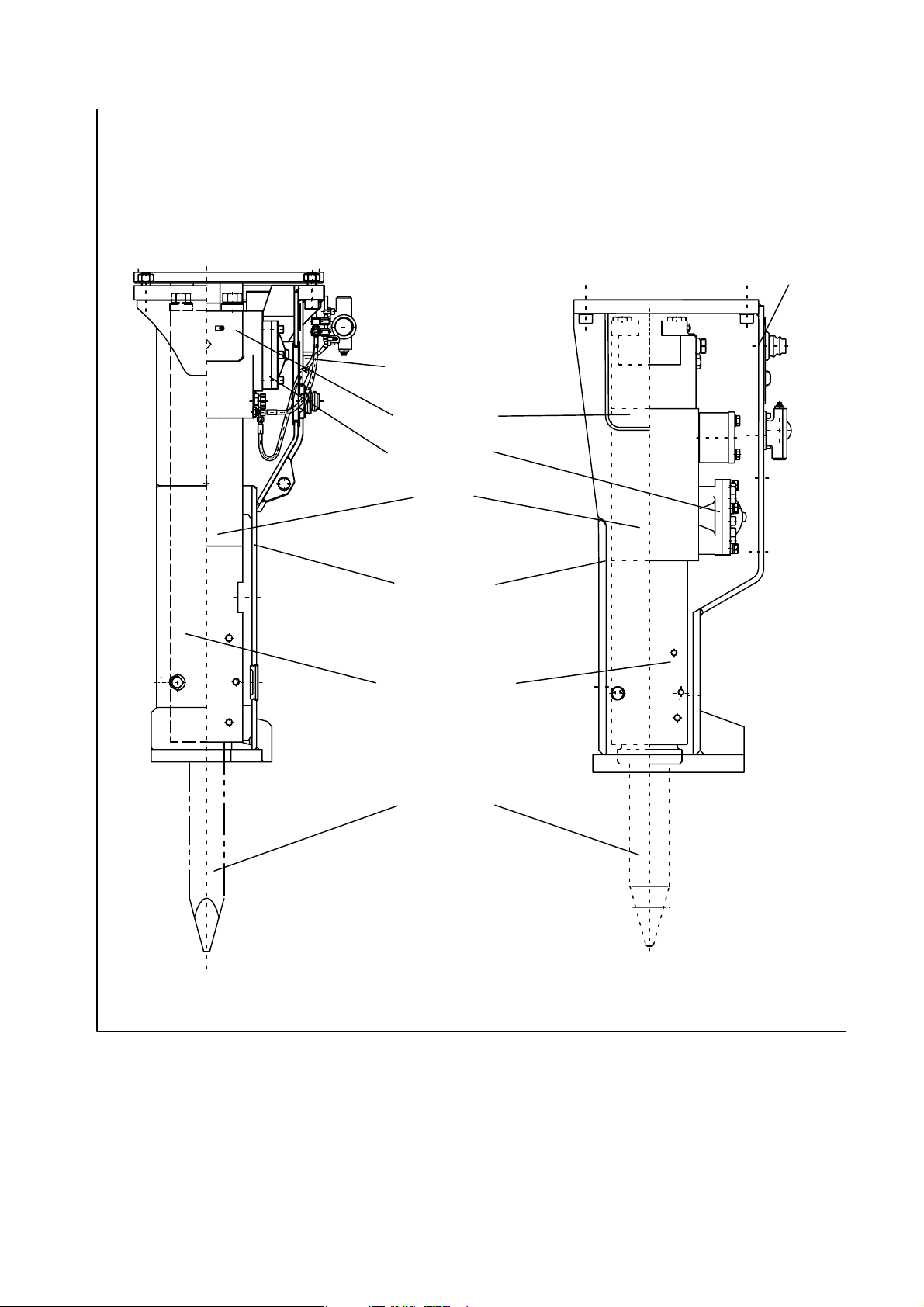

5.1 Main components or assemblies CP 550 and CP 750

CP 550 CP 750

CEnameplate

cylindercover

cylinder

CEname

plate

lower hammer part

hammerbox

working tool

The graphic shows only a general view of the main components.

Details may vary on different breaker models

12

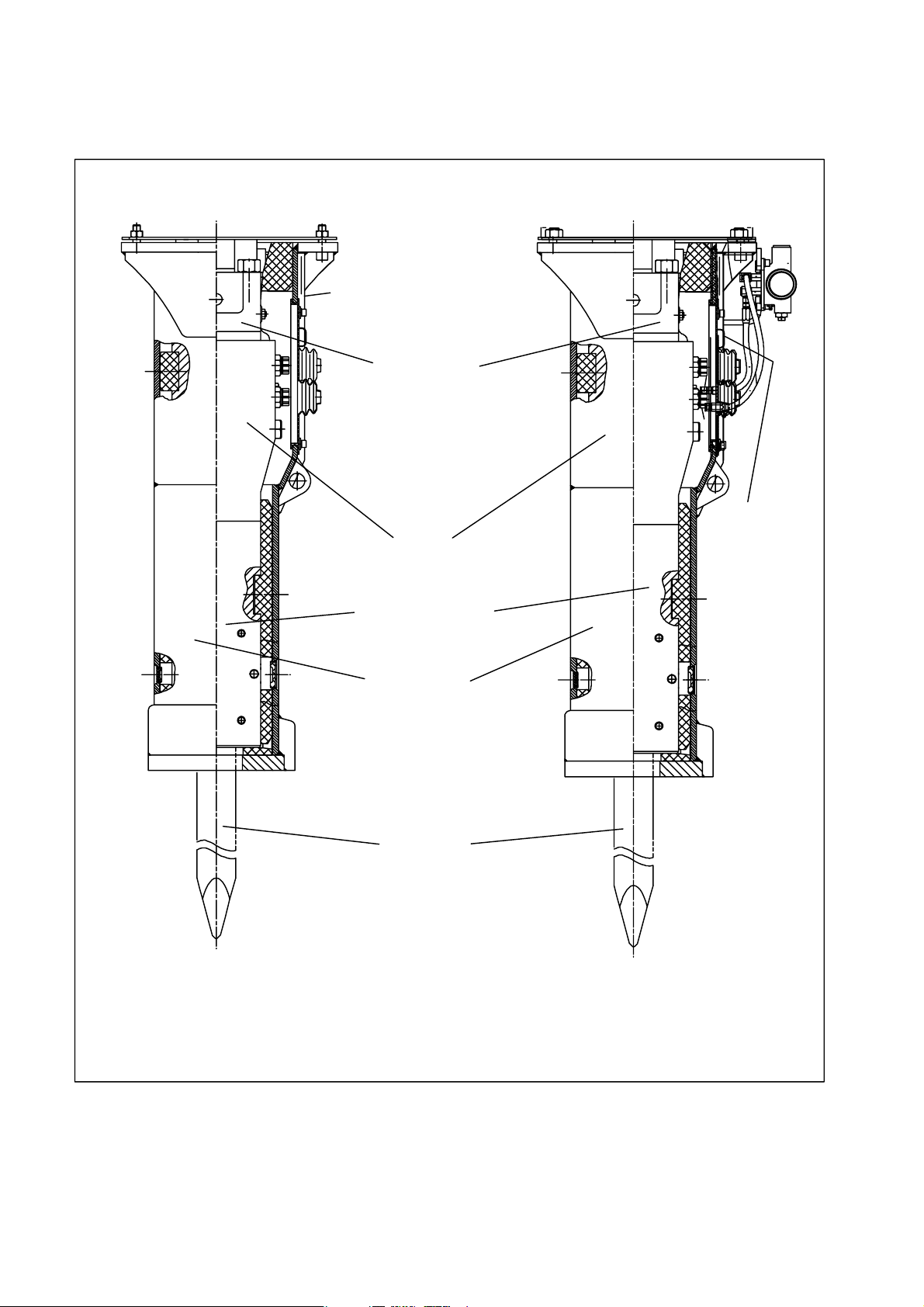

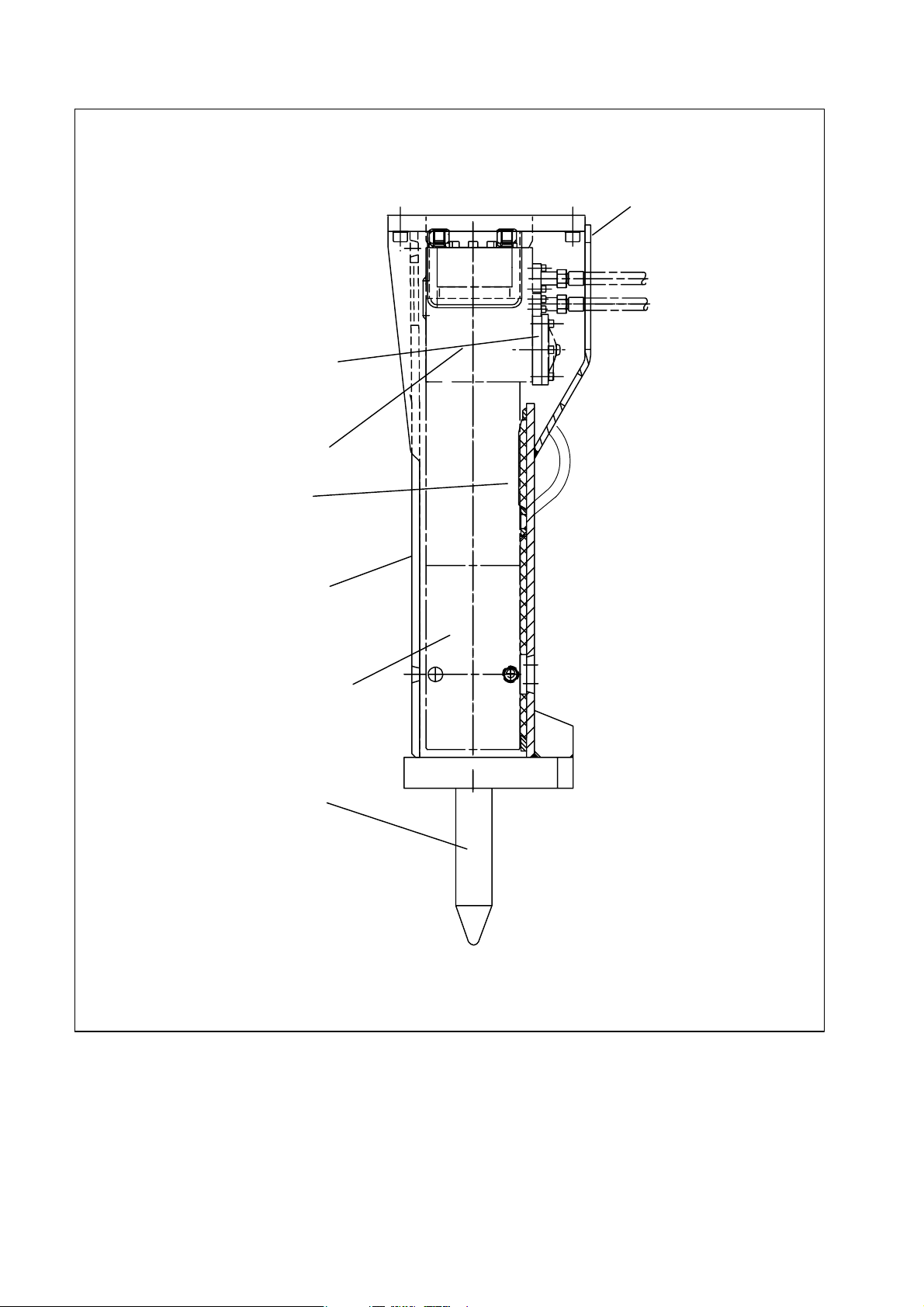

5.2 Main components or assemblies CP 1150 and CP 1650

CP 1150

CP 1650

CEname

plate

CEnameplate

cylinder cover

High−pressure

accumulator

cylinder

hammer box

lower hammer part

working tool

The graphic shows only a general view of the main components.

Details may vary on different breaker models.

13

5.3 Main components or assemblies, CP 2250, CP3050 and CP 4250

CP 2250,

CP 3050,

CP 4250

High−pressure

accumulator

cylinder cover

cylinder

CEname

plate

hammer box

Sealing flange

lower hammer part

working tool

The graphic shows only a general view of the main components.

Details may vary on different breaker models.

14

6 Installation

Â

Â

6.1 Media/consumables

The following media/consumables are required to operate the hydraulic breaker:

6.1.1 Mineral hydraulic oil

All hydraulic oil brands prescribed by the carrier

manufacturer are suitable for hydraulic breakers.

The oil should however correspond to viscosity class

HLP 32 or higher.

In summer and in hotter climates, oils of viscosity

class HLP 68 or higher should be used.

In all other respects the regulations of the carrier

manufacturer are to be considered.

Optimum viscosity range = 30 60 cSt

Max. initial viscosity = 2.000 cSt

Max. oil temperature = 80°C

Please refer to Section 9.12 for lowtemperature hy

draulic breaker applications.

Check the oil filter in the return line to the hydraulic

system.

6.1.2 Non−mineral hydraulic oil

In order to protect the environment or on technical

grounds, hydraulic oils are currently being used

which are not classified as HLP mineral oils.

Before using hydraulic oils of this kind it is imperative

to ask the carrier manufacturer whether operations

with such hydraulic oils are possible.

Our tools are basically designed for use with mineral

oils. Before using other hydraulic oil types which

have been approved by the carrier manufacturer,

Chicago Pneumatic Customer Center / dealer in your

region must always be consulted. Following initial

assembly and after any workshop repairs, our tools

are subjected to a test run on a test bed powered by

mineral oil.

The return line to the hydraulic system must be fittet

with an oil filter with a mesh no greater than 50

micrometers and equipped with a magnetic sparator.

CAUTION!

Monitor the oil temperature.

The temperature of the hydraulic oil must never ex

ceed 80°C. If higher temperatures are measured in

the tank, the hydraulic system and/or the pressure−

relief valve have to be checked.

CAUTION!

Never mix mineral and non−mineral hydraulic oils! Even

small traces of mineral oil mixed in with non−mineral hy

draulic oil can result in damage to both hydraulic attach

ment and carrier.

CAUTION!

Note

When returning tools for repair, it is imperative that

the name of the oil in use be indicated if you are

using non−mineral oil.

6.1.3 Grease

Grease type

ВВВВВВ

ВВВВВВВ

Chisel paste 3363 0949 10

Pt.−Id.−No.

Non−mineral oil is no longer biodegradable if it is con

taminated with mineral oil. Contaminated non−mineral

oil must be disposed of as special waste in accordance

with the applicable statutory regulations for environ

mental protection.

Always observe the relevant safety regulations when

handling oils and greases.

15

6.1.4 Gas

Normal nitrogen, 99.8% pure.

Use only nitrogen to fill the piston accumulator and

ensure that no other gas, e.g. air, oxygen, is used.

Risk of explosion!

The nitrogen for the piston accumulator is in the

green gas cylinder. Use of other gases could result in

an explosion.

DANGER!

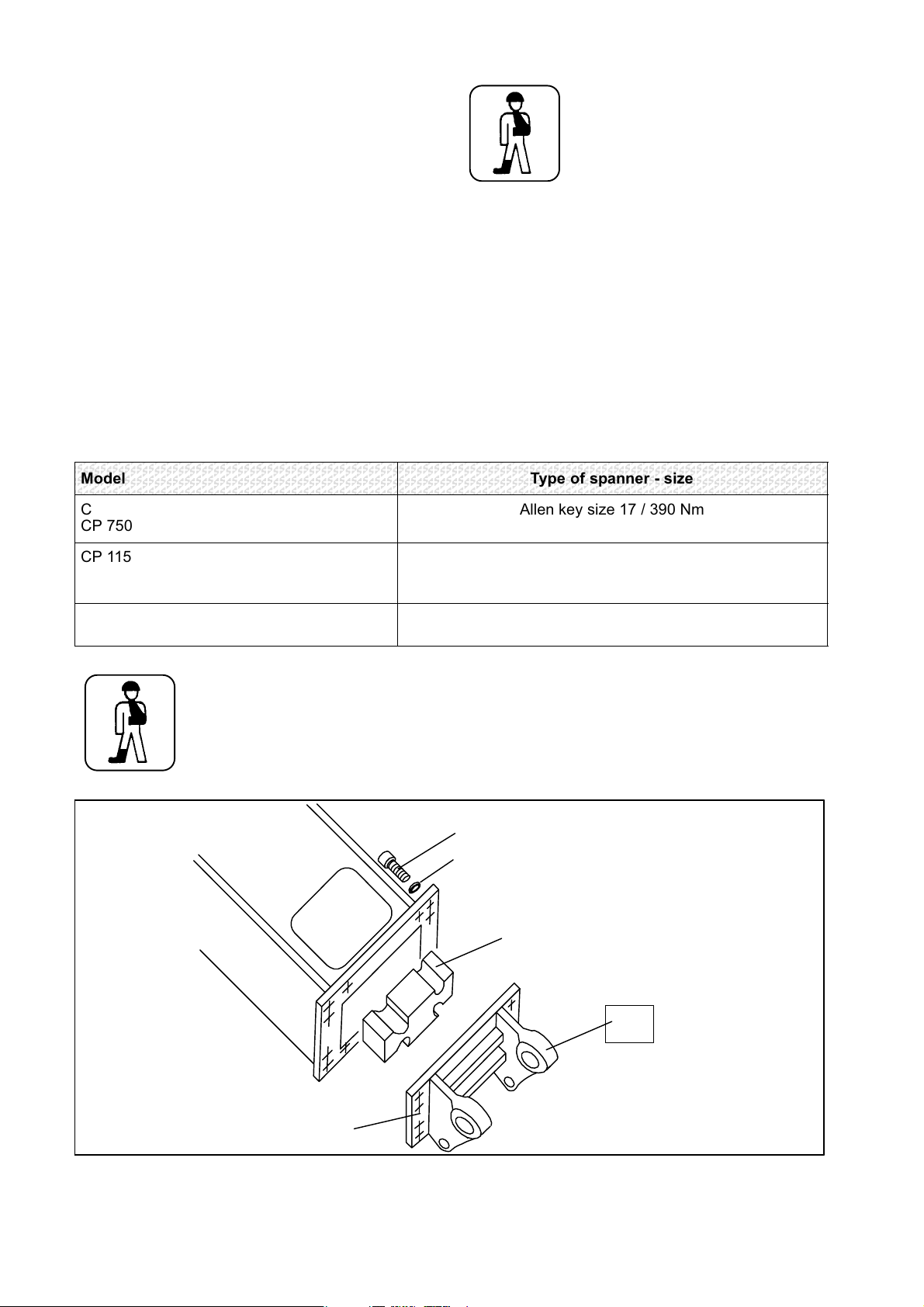

6.2 Attaching the adapter to the hydraulic breaker

Lay the hydraulic breaker on squared beams or a

pallet within reach of the excavator boom with the

service window of the breaker box facing upwards.

Insert the elastic pad in the breaker box, ensuring it

is the right way round, and fix the adapter to the

breaker box with two screws (referring to Sec

tion6.3)

Model

CP 550

CP 750

CP 1150

CP 1650

CP 2250

CP 3050

CP 4250

DANGER!

Then fit all screws. The required sizes for the Allen

keys are shown below.

Apply anti−seize to the threads of the cylindrical bolts

before screwing them in.

The contact face of the bolt head and the locking

rings must be free of lubricant.

Type of spanner − size

Allen key size 17 / 390 Nm

Allen key size 22 / 1500 Nm

Allen key size 27 / 2300 Nm

Only the specialsteel Allen screws included in sup

ply should be used to attach the adapter.

For transport purposes use only the lug(s) provided.

Note the weight (name plate, section 3.2).

16

Adapter

Screw

Pair of locking rings

Elastic pad

Marking:

Stiel

Stick

= Stiel

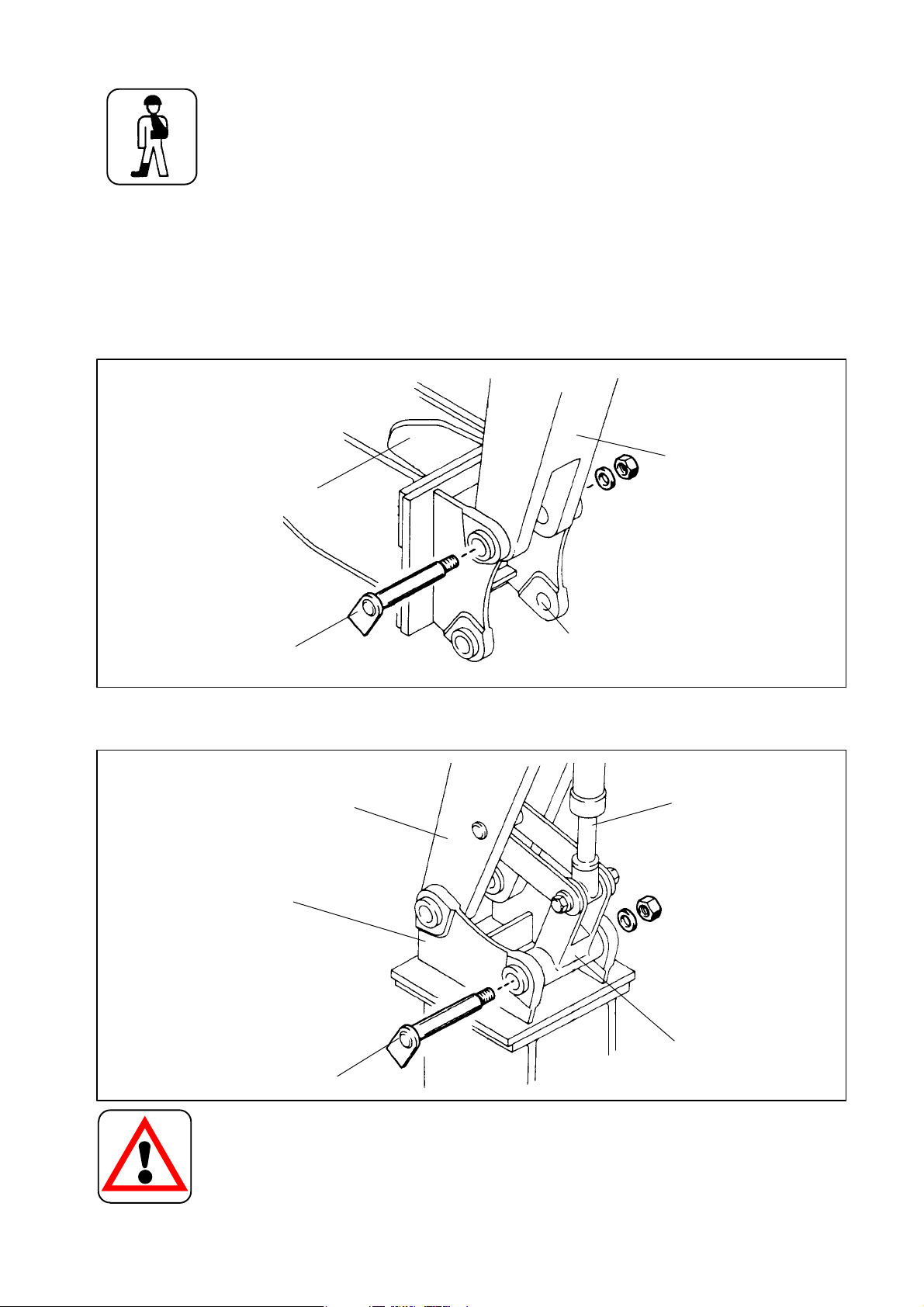

6.3 Mounting the hydraulic breaker on the excavatormechanical aspects

Keep your hands away from bores and fitting surfa

ces when mounting the hydraulic breaker.

DANGER!

Only mount the hydraulic breaker on an excavator

with sufficient load capacity. If the excavator is too

light it may become unstable and fall over.

During breaker mounting, the carrier should only be

operated from the driver’s cab.

Agree with the assistant on clear hand signals.

The assistant must be instructed by the excavator

driver.

Hydraulic breaker

Do not touch any parts when the boom is moving.

Never use your fingers to check whether the bores

are flush.

To mount the hydraulic breaker, carefully lower the

stick of the boom into the adapter. An assistant di

rects the movement of the stick until the bores in the

stick are flush with those in the adapter. Then insert

the stick pin and lock.

Stick

AdapterStick pin

Lift up the hydraulic breaker. Extend the shovel cylinder until the bore in the toggle is flush with those in the

adapter. Insert toggle pin and lock.

Stick

Adapter

Toggle pin

Shovel cylinder

Toggle

CAUTION!

After mounting the breaker, carefully extend and re

tract the shovel cylinder to its full extent in each

case. It is important that the cylinder can be fully ex

tended and retracted without any difficult. If problems

are encountered, please consult our Aftermarket de

partment.

17

Loading...

Loading...