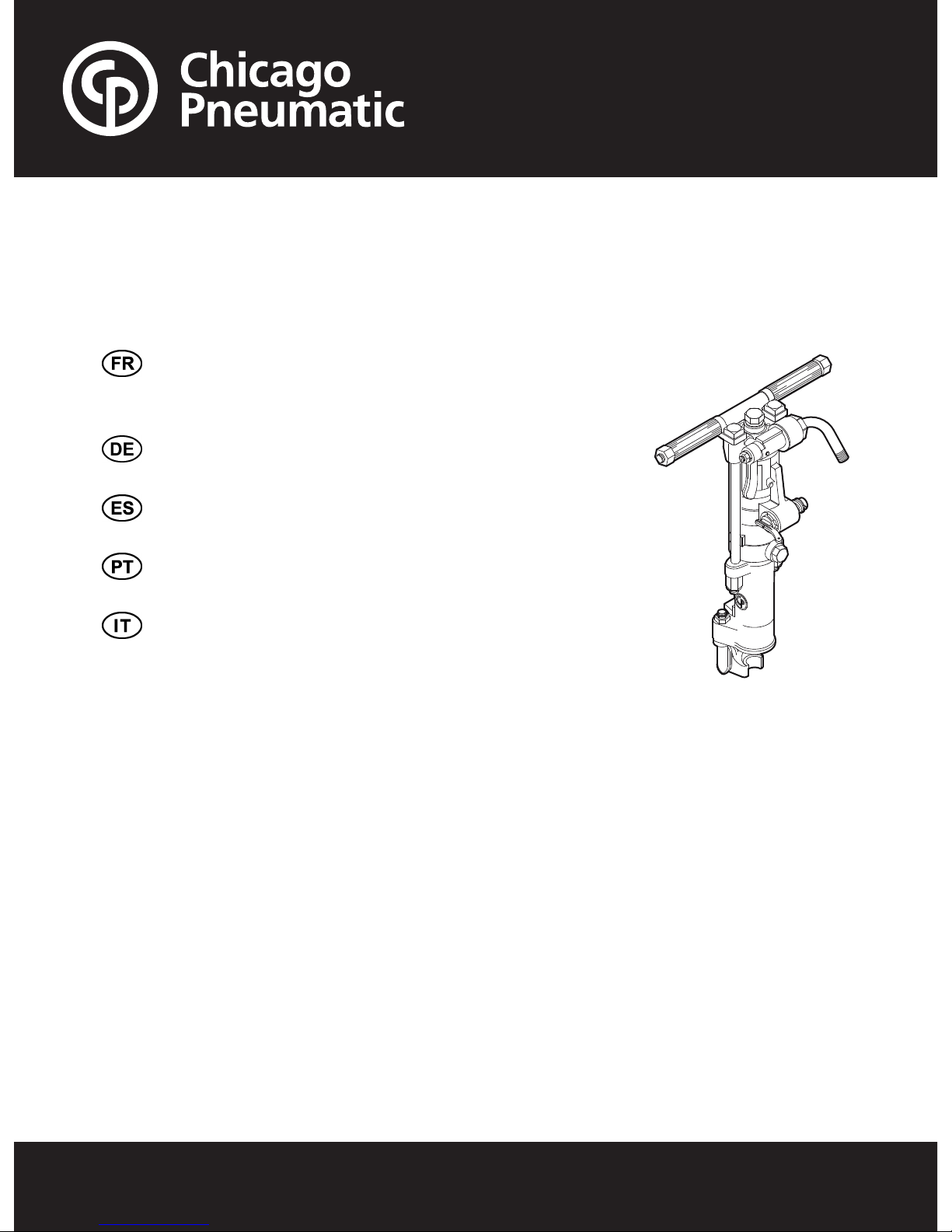

Chicago Pneumatic CP 0022, CP 0032, CP 0069 Safety And Operating Instructions Manual

Safety and operating instructions

Rock drills

CP 0022, CP 0032, CP 0069

Prescriptions de sécurité et instructions pour

l’opérateur

Perforateur

Sicherheits- und Betriebsanleitung

Bohrhämmer

Instrucciones de seguridad y de funcionamiento

Perforadoras

Instruções de segurança e operação

Perfuradores de rocha

Istruzioni per la sicurezza e per l'uso

Perforatrici

www.cp.com

9800 0901 90a | Original instructions2

CP 0022, CP 0032, CP 0069

Contents

ENGLISH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

FRANÇAIS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

DEUTSCH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

ESPAÑOL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

PORTUGUÊS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

ITALIANO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

39800 0901 90a | Original instructions

CP 0022, CP 0032, CP 0069

ENGLISH

Contents

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Safety and operating instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety signal words. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Personal precautions and qualifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation, precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operation, precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Maintenance, precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Storage, precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Design and function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Main parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Unpacking the drill. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Hoses and connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Methods to prevent freezing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connecting a water separator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Drill steel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wet drilling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Preparations before starting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Start and stop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Operating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

When taking a break. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Every day. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Periodic maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Tightening torque. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Damage patterns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

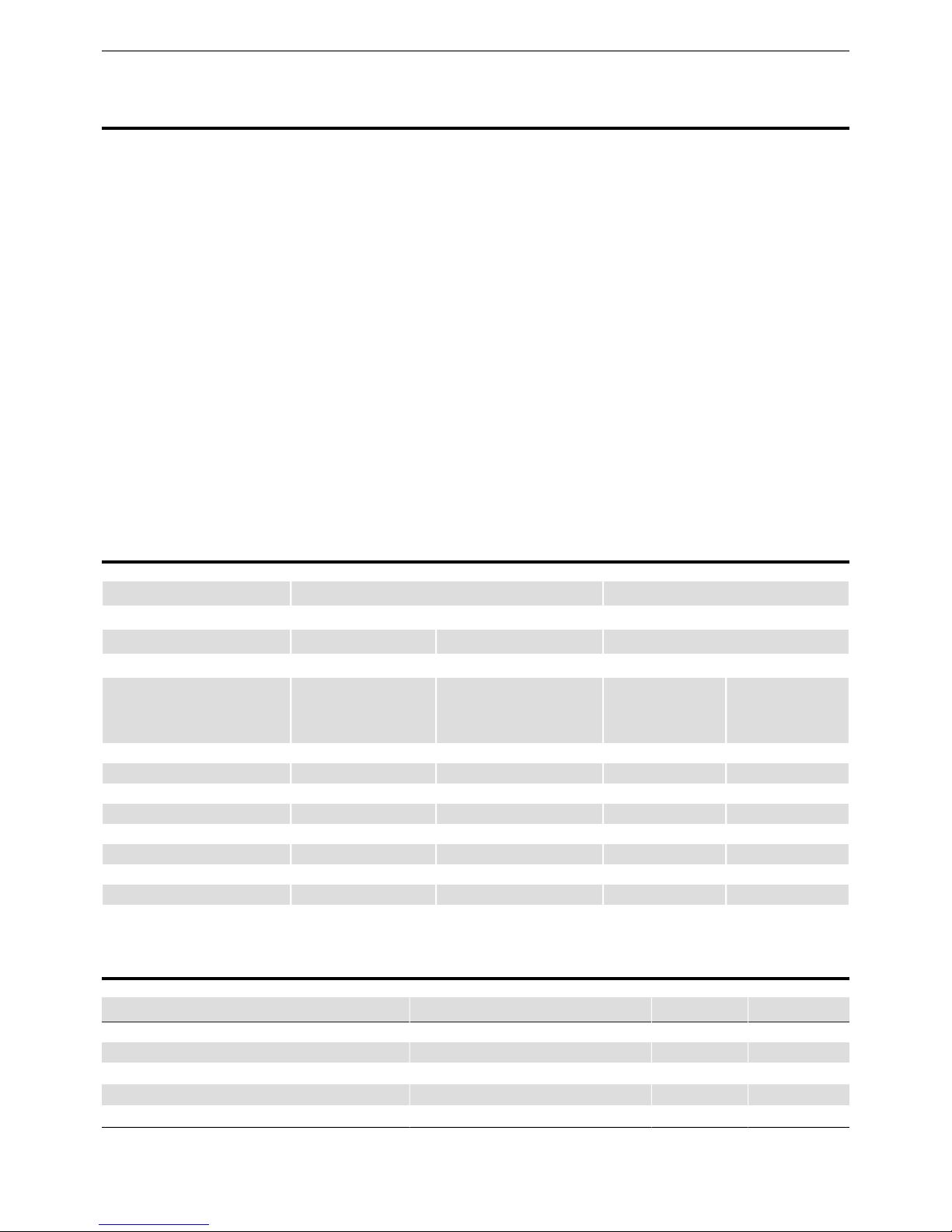

Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Machine data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Noise and vibration declaration statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Noise and vibration data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

EC Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

EC Declaration of Conformity (EC Directive 2006/42/EC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9800 0901 90a | Original instructions4

CP 0022, CP 0032, CP 0069Contents

Introduction

Thank you for choosing Chicago Pneumatic-brand products. For over a century, the

Chicago Pneumatic brand has represented performance and innovation in the

pneumatic tool industry.

Today the brand is found around the world on a range of pneumatic and hydraulic

tools that includes breakers, rock drills, chipping hammers, clay-diggers, picks and

busters, scabblers, pumps and a whole lot more.

The Chicago Pneumatic-brand is associated with powerful and reliable products that

are easy to maintain and that give good value for the money.

For more information please visit www.cp.com

Atlas Copco Construction Tools AB

105 23 Stockholm

Sweden

About the Safety and operating

instructions

The aim of the instructions is to provide you with knowledge of how to use the rock

drill in an efficient, safe way. The instructions also give you advice and tell you how

to perform regular maintenance on the rock drill.

Before using the rock drill for the first time you must read these instructions carefully

and understand all of them.

59800 0901 90a | Original instructions

Safety and operating instructionsCP 0022, CP 0032, CP 0069

Safety instructions

To reduce the risk of serious injury or death to

yourself or others, read and understand the Safety

and operating instruction before installing,

operating, repairing, maintaining, or changing

accessories on the machine.

Post this Safety and operating instruction at work

locations, provide copies to employees, and make

sure that everyone reads the Safety and operating

instruction before operating or servicing the

machine.

In addition, the operator or the operator's employer

must assess the specific risks that may be present as

a result of each use of the machine.

Safety signal words

The safety signal words Danger, Warning and

Caution have the following meanings:

Indicates a hazardous situation

which, if not avoided, will result

in death or serious injury.

DANGER

Indicates a hazardous situation

which, if not avoided, could

result in death or serious injury.

WARNING

Indicates a hazardous situation

which, if not avoided, could

result in minor or moderate

injury.

CAUTION

Personal precautions and

qualifications

Only qualified and trained persons may operate or

maintain the machine. They must be physically able

to handle the bulk, weight, and power of the tool.

Always use your common sense and good

judgement.

Personal protective equipment

Always use approved protective equipment.

Operators and all other persons in the working area

must wear protective equipment, including at a

minimum:

> Protective helmet

> Hearing protection

> Impact resistant eye protection with side

protection

> Respiratory protection when appropriate

> Protective gloves

> Proper protective boots

> Appropriate work overall or similar clothing (not

loose-fitting) that covers your arms and legs.

Drugs, alcohol or medication

WARNING Drugs, alcohol or medication

Drugs, alcohol or medication may impair your

judgment and powers of concentration. Poor

reactions and incorrect assessments can lead to

severe accidents or death.

► Never use the machine when you are tired or

under the influence of drugs, alcohol or

medication.

► No person who is under the influence of drugs,

alcohol or medication may operate the machine.

Installation, precautions

DANGER Whipping air hose

A compressed air hose that comes loose can lash

around and cause personal injury or death. To

reduce this risk:

► Check that the compressed air hose and the

connections are not damaged, replace if

necessary.

► Check that all compressed air connections are

properly attached.

► Never carry a pneumatic machine by the air hose.

► Never attempt to disconnect a compressed air

hose that is pressurized. First switch off the

compressed air at the compressor and then bleed

the machine by activating the start and stop

device.

► Never point a compressed air hose at yourself or

anyone else. To avoid the risk of getting injured,

never use compressed air to blow for example

dust, dirt etc. from your clothes.

► Do not use quick disconnect couplings at tool

inlet. Use hardened steel (or material with

comparable shock resistance) threaded hose

fittings.

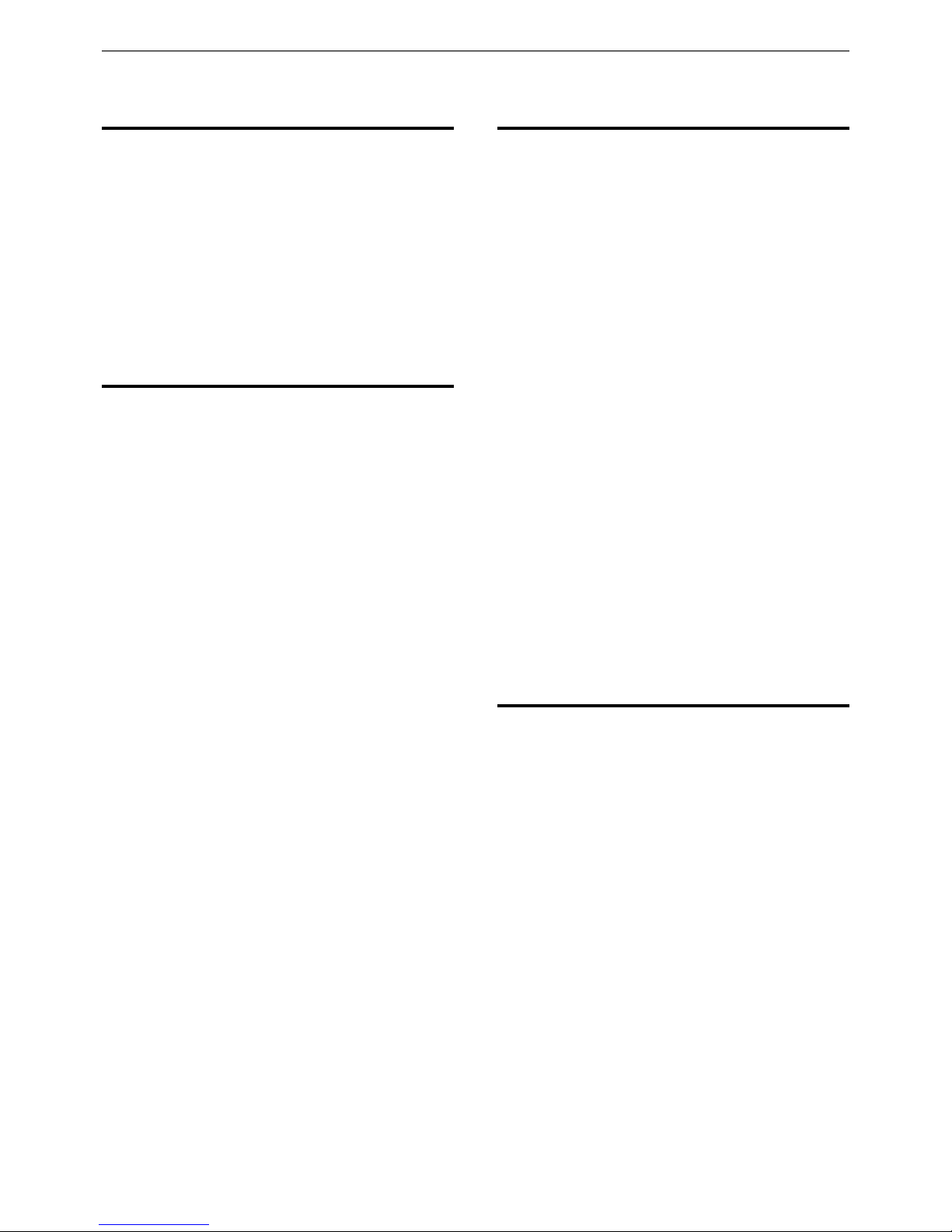

► Whenever universal twist couplings (claw

couplings) are used, we recommend that lock

pins are installed and whipcheck safety cables are

used to safeguard against possible hose to tool

and hose to hose connection failure.

9800 0901 90a | Original instructions6

CP 0022, CP 0032, CP 0069Safety and operating instructions

WARNING Ejected insertion tool

If the tool retainer on the machine is not in a locked

position, the inserted tool can be ejected with force,

which can cause personal injury.

► Never start the machine while changing the

insertion tool.

► Before changing the insertion tool or accessories,

stop the machine, switch off the power supply

and bleed the machine by activating the start and

stop device.

► Never point the inserted tool at yourself or anyone

else.

► Make sure that the insertion tool is fully inserted

and the tool retainer is in a locked position before

the machine is started.

► Check the locking function by pulling the inserted

tool outwards forcefully.

WARNING Moving or slipping insertion

tool

An incorrect dimension of the inserted tool’s shank

can result in that the inserted tool is lost or is slipping

out during operation. Risk of severe injury or crushed

hands and fingers.

► Check that the insertion tool has the shank length

and dimensions that the machine is intended for.

► Never use an insertion tool without a collar.

Operation, precautions

DANGER Explosion hazard

If a warm insertion tool comes into contact with

explosives, an explosion could occur. During

operation with certain materials as well as use of

certain materials in machine parts, sparks and

ignition can occur. Explosions will lead to severe

injuries or death.

► Never operate the machine in any explosive

environment.

► Never use the machine near flammable materials,

fumes or dust.

► Make sure that there are no undetected sources

of gas or explosives.

► Never drill in an old hole.

WARNING Unexpected movements

The inserted tool is exposed to heavy strains when

the machine is used. The inserted tool may break

due to fatigue after a certain amount of use. If the

inserted tool breaks or gets stuck, there may be

sudden and unexpected movement that can cause

injuries. Furthermore, losing your balance or slipping

may cause injury.

► Make sure that you always keep a stable position

with your feet as far apart as your shoulder width,

and keeping a balanced body weight.

► Always inspect the equipment prior to use. Never

use the equipment if you suspect that it is

damaged.

► Make sure that the handles are clean and free of

grease and oil.

► Keep your feet away from the inserted tool.

► Stand firmly and always hold on to the machine

with both hands.

► Never drill in an old hole.

► Never start the machine when it is lying on the

ground.

► Never ‘ride’ on the machine with one leg over the

handle.

► Never strike or abuse the equipment.

► Check regularly for wear on the insertion tool,

and check whether there are any signs of damage

or visible cracks.

► Pay attention an look at what you are doing.

WARNING Stalling hazard

If the insertion tool gets caught during operation,

the whole machine will start to rotate if you lose

your grip on it. This unexpected rotation of the entire

machine may cause serious injury or death.

► Stand firmly and always hold onto the machine

with both hands.

► Make sure that the handle or handles are clean

and free from grease and oil.

► Never drill in an old hole.

79800 0901 90a | Original instructions

Safety and operating instructionsCP 0022, CP 0032, CP 0069

WARNING Trapping hazard

There is risk of neck ware, hair, gloves and clothes

getting dragged into or caught by a rotating

insertion tool or accessories. This may cause choking,

scalping, lacerations or death. To reduce the risk:

► Never grab or touch a rotating drill steel.

► Avoid wearing clothing, neck ware or gloves that

may get caught.

► Cover long hair with a hair net.

WARNING Dust and fume hazard

Dusts and/or fumes generated or dispersed when

using the machine may cause serious and permanent

respiratory disease, illness, or other bodily injury (for

example, silicosis or other irreversible lung disease

that can be fatal, cancer, birth defects, and/or skin

inflammation).

Some dusts and fumes created by drilling, breaking,

hammering, sawing, grinding and other construction

activities contain substances known to the State of

California and other authorities to cause respiratory

disease, cancer, birth defects, or other reproductive

harm. Some examples of such substances are:

> Crystalline silica, cement, and other masonry

products.

> Arsenic and chromium from chemically-treated

rubber.

> Lead from lead-based paints.

Dust and fumes in the air can be invisible to the

naked eye, so do not rely on eye sight to determine

if there is dust or fumes in the air.

To reduce the risk of exposure to dust and fumes,

do all of the following:

► Perform site-specific risk assessment. The risk

assessment should include dust and fumes created

by the use of the machine and the potential for

disturbing existing dust.

► Use proper engineering controls to minimize the

amount of dust and fumes in the air and to

minimize build-up on equipment, surfaces,

clothing, and body parts. Examples of controls

include: exhaust ventilation and dust collection

systems, water sprays, and wet drilling. Control

dusts and fumes at the source where possible.

Make sure that controls are properly installed,

maintained and correctly used.

► Wear, maintain and correctly use respiratory

protection as instructed by your employer and as

required by occupational health and safety

regulations. The respiratory protection must be

effective for the type of substance at issue (and if

applicable, approved by relevant governmental

authority).

► Work in a well ventilated area.

► If the machine has an exhaust, direct the exhaust

so as to reduce disturbance of dust in a dust filled

environment.

► Operate and maintain the machine as

recommended in the operating and safety

instructions

9800 0901 90a | Original instructions8

CP 0022, CP 0032, CP 0069Safety and operating instructions

► Select, maintain and replace consumables/

inserted tools/ other accessory as recommended

in the operating and safety instructions. Incorrect

selection or lack of maintenance of consumables/

inserted tools/ other accessories may cause an

unnecessary increase in dust or fumes.

► Wear washable or disposable protective clothes

at the worksite, and shower and change into clean

clothes before leaving the worksite to reduce

exposure of dust and fumes to yourself, other

persons, cars, homes, and other areas.

► Avoid eating, drinking, and using tobacco

products in areas where there is dust or fumes.

► Wash your hands and face thoroughly as soon as

possible upon leaving the exposure area, and

always before eating, drinking, using tobacco

products, or making contact with other persons.

► Comply with all applicable laws and regulations,

including occupational health and safety

regulations.

► Participate in air monitoring, medical examination

programs, and health and safety training

programs provided by your employer or trade

organizations and in accordance with

occupational health and safety regulations and

recommendations. Consult with physicians

experienced with relevant occupational medicine.

► Work with your employer and trade organization

to reduce dust and fume exposure at the worksite

and to reduce the risks. Effective health and safety

programs, policies and procedures for protecting

workers and others against harmful exposure to

dust and fumes should be established and

implemented based on advice from health and

safety experts. Consult with experts.

WARNING Projectiles

Failure of the work piece, of accessories, or even of

the machine itself may generate high velocity

projectiles. During operating, splinters or other

particles from the working material may become

projectiles and cause personal injury by striking the

operator or other persons. To reduce these risk:

► Use approved personal protective equipment and

safety helmet, including impact resistant eye

protection with side protection.

► Make sure that no unauthorised persons trespass

into the working zone.

► Keep the workplace free from foreign objects.

► Ensure that the work piece is securely fixed.

WARNING Splinters hazard

Using the insertion tool as a hand struck tool can

result in splinters hitting the operator and can cause

personal injury.

► Never use a insertion tool as a hand struck tool.

They are specifically designed and heat-treated to

be used only in a machine.

WARNING Slipping, tripping and

falling hazards

There is a risk of slipping or tripping or falling, for

example tripping on the hoses or on other objects.

Slipping or tripping or falling can cause injury. To

reduce this risk:

► Always make sure that no hose or other object is

in your way or in any other person's way.

► Always make sure you are in a stable position with

your feet as far apart as your shoulders width and

keeping a balanced body weight.

WARNING Motion hazards

When using the machine to perform work-related

activities, you may experience discomfort in the

hands, arms, shoulders, neck, or other parts of the

body.

► Adopt a comfortable posture whilst maintaining

secure footing and avoiding awkward

off-balanced postures.

► Changing posture during extended tasks may

help avoid discomfort and fatigue.

► In case of persistent or recurring symptoms,

consult a qualified health professional.

99800 0901 90a | Original instructions

Safety and operating instructionsCP 0022, CP 0032, CP 0069

WARNING Vibration hazards

Normal and proper use of the machine exposes the

operator to vibration. Regular and frequent exposure

to vibration may cause, contribute to, or aggravate

injury or disorders to the operator’s fingers, hands,

wrists, arms, shoulders and/or nerves and blood

supply or other body parts, including debilitating

and/or permanent injuries or disorders that may

develop gradually over periods of weeks, months,

or years. Such injuries or disorders may include

damage to the blood circulatory system, damage to

the nervous system, damage to joints, and possibly

damage to other body structures.

If numbness, persistent recurring discomfort,

burning sensation, stiffness, throbbing, tingling,

pain, clumsiness, weakened grip, whitening of the

skin, or other symptoms occur at any time, when

operating the machine or when not operating the

machine, stop operating the machine, tell your

employer and seek medical attention. Continued

use of the machine after the occurrence of any such

symptom may increase the risk of symptoms

becoming more severe and/or permanent.

Operate and maintain the machine as recommended

in these instructions, to prevent an unnecessary

increase in vibration.

The following may help to reduce exposure to

vibration for the operator:

► Let the tool do the job. Use a minimum hand grip

consistent with proper control and safe operation.

► If the machine has vibration absorbing handles,

keep them in a central position, avoid pressing

the handles into the end stops.

► When the percussion mechanism is activated, the

only body contact with the machine you should

have are your hands on the handle or handles.

Avoid any other contact, for example supporting

any part of the body against the machine or

leaning onto the machine trying to increase the

feed force. It is also important not to keep the start

and stop device engaged while extracting the tool

from the broken work surface.

► Make sure that the inserted tool is well-maintained

(including sharpness, if a cutting tool), not worn

out, and of the proper size. Insertion tools that

are not well-maintained, or that are worn out, or

that are not of the proper size result in longer time

to complete a task (and a longer period of

exposure to vibration) and may result in or

contribute to higher levels of vibration exposure.

► Immediately stop working if the machine

suddenly starts to vibrate strongly. Before

resuming the work, find and remove the cause of

the increased vibrations.

► Never grab, hold or touch the inserted tool when

using the machine.

► Participate in health surveillance or monitoring,

medical exams and training programs offered by

your employer and when required by law.

► When working in cold conditions wear warm

clothing and keep hands warm and dry.

See the ”Noise and vibration declaration statement”

for the machine, including the declared vibration

values. This information can be found at the end of

these Safety and operating instructions.

♦

Comply with the recommended air-pressure when

operating the machine. Either higher or lower

air-pressure has the potential of resulting in higher

levels of vibration.

DANGER Electrical hazard

The machine is not electrically insulated. If the

machine comes into contact with electricity, serious

injuries or death may result.

► Never operate the machine near any electric wire

or other source of electricity.

► Make sure that there are no concealed wires or

other sources of electricity in the working area.

WARNING Concealed object hazard

During operating, concealed wires and pipes

constitute a danger that can result in serious injury.

► Check the composition of the material before

operating.

► Watch out for concealed cables and pipes for

example electricity, telephone, water, gas and

sewage lines etc.

► If the inserted tool seems to have hit a concealed

object, switch off the machine immediately.

► Make sure that there is no danger before

continuing.

9800 0901 90a | Original instructions10

CP 0022, CP 0032, CP 0069Safety and operating instructions

WARNING Involuntary start

Involuntary start of the machine may cause injury.

► Keep your hands away from the start and stop

device until you are ready to start the machine.

► Learn how the machine is switched off in the event

of an emergency.

► Release the start and stop device immediately in

all cases of power supply interruption.

► Whenever fitting or removing the insertion tool,

switch off the air supply, bleed the machine by

pressing the start and stop device and disconnect

the machine from the power source.

WARNING Noise hazard

High noise levels can cause permanent and disabling

hearing loss and other problems such as tinnitus

(ringing, buzzing, whistling or humming in the ears).

To reduce risk and prevent an unnecessary increase

in noise levels:

► Risk assessment of these hazards and

implementation of appropriate controls is

essential.

► Operate and maintain the machine as

recommended in these instructions.

► Select, maintain and replace the insertion tool as

recommended in these instructions.

► If the machine has a muffler, check that it is in

place and in good working condition.

► Always use hearing protection.

► Use damping material to prevent work pieces

from "ringing".

Maintenance, precautions

WARNING Machine modification

Any machine modification may result in bodily

injuries to yourself or others.

► Never modify the machine. Modified machines

are not covered by warranty or product liability.

► Always use original parts, insertion tools, and

accessories.

► Change damaged parts immediately.

► Replace worn components in good time.

CAUTION Hot insertion tool

The tip of the insertion tool can become hot and

sharp when used. Touching it can lead to burns and

cuts.

► Never touch a hot or sharp insertion tool.

► Wait until the insertion tool has cooled down

before carrying out maintenance work.

WARNING Insertion tool hazards

Accidental engagement of the start and stop device

during maintenance or installation can cause serious

injuries, when the power source is connected.

► Never inspect, clean, install, or remove the

insertion tool while the power source is

connected.

Storage, precautions

♦

Keep the machine and tools in a safe place, out

of the reach of children and locked up.

119800 0901 90a | Original instructions

Safety and operating instructionsCP 0022, CP 0032, CP 0069

Overview

To reduce the risk of serious injury or death

to yourself or others, read the Safety

instructions section found on the previous

pages of this manual before operating the

machine.

Design and function

CP 0022, CP 0032 and CP 0069 are pneumatic rock

drills designed for vertical drilling, plug hole drilling

and drilling in concrete for construction and mining

applications. No other uses are permitted.

To choose correct insertion tools, contact your local

Chicago Pneumatic dealer

Working principle of a rock drill

FlushingRotationFeed forceImpact

Control valve mechanism

The valve directs the air alternately from one side to

the other of the piston so that it moves up and

down. The piston transmits the energy through the

drill steel to the bottom of the hole.

Rotation mechanism

Return strokeImpact stroke

The drill steel is turned slightly with each blow by

the rifle bar rotation. The rotation is anti-clockwise

and is applied on the return stroke of the piston.

Flushing

Flushing is ducted through a hole in the piston. This

means that flushing air is provided as soon as the

compressed air is switched on.

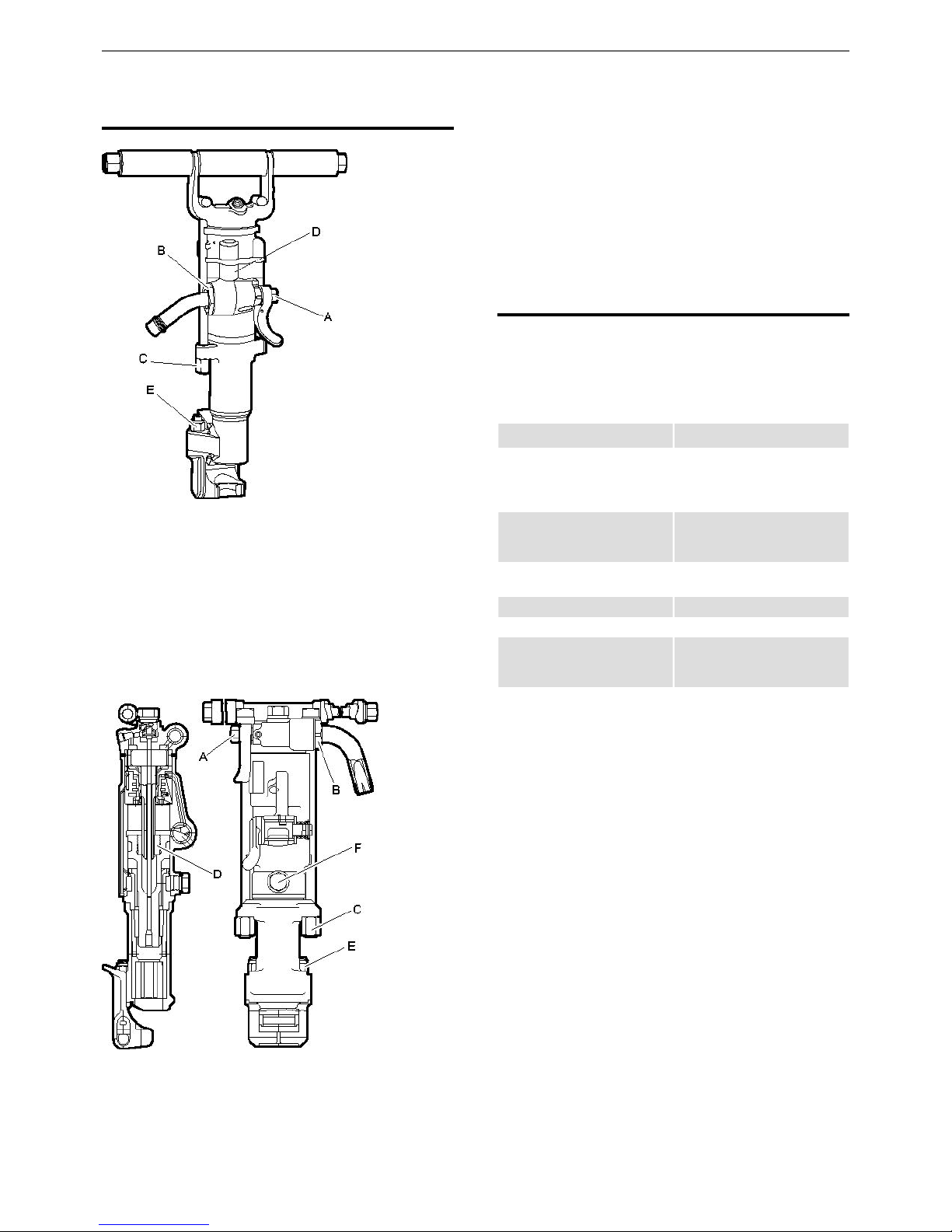

Main parts

9800 0901 90a | Original instructions12

CP 0022, CP 0032, CP 0069Safety and operating instructions

CP 0022 KL

CP 0032, CP 0069

A. Handle

B. Air inlet nipple

C. Drill steel retainer

D. Throttle lever

E. Extra blower lever

F. Muffler (optional)

Labels

The machine is fitted with labels containing

important information about personal safety and

machine maintenance. The labels shall be in such

condition that they are easy to read. New labels can

be ordered from the spare parts list.

Data plate

A. Machine type

B. Maximum permitted compressed air pressure

C. Serial number

D. The warning symbol together with the book

symbol means that the user must read the

safety and operating instructions before the

machine is used for the first time.

E. The CE symbol means that the machine is

EC-approved. See the EC declaration which is

delivered with the machine for more

information. If the CE symbol is missing, it

means that the machine is not EC-approved.

Safety label

To avoid injury, before using or servicing tool, read

and understand separately provided safety

instructions.

Installation

Unpacking the drill

Plastic guards

Before the drill is used for the first time remove all

the plastic guards from the hose nipples.

Lubricate

After unpacking and installing the tool, pour a liberal

amount of lubrication oil in the air connection.

139800 0901 90a | Original instructions

Safety and operating instructionsCP 0022, CP 0032, CP 0069

Hoses and connections

A. Compressed air source

B. Water separator (optional)

C. Oiler (optional)

D. Max. 10 feet (3 meter) compressed air hose

between the oiler and the machine.

♦

Check that you are using the correct

recommended operating pressure, 87 psig (6 bar

(e)).

♦

The maximum permissible air pressure, 90 psig

(6.2 bar (e)), must not be exceeded.

♦

Blow any impurities out of the compressed air

hose before connecting it to the machine.

♦

Select the correct dimension and length for the

compressed air hose. For hose lengths up to 100

feet (30 meters), a hose with a minimum internal

diameter of 3⁄4" (19 mm) should be used. If the

hose length is between 100 and 330 feet (30 and

100 meters), a hose with a minimum internal

diameter of 1" (25 mm) should be used.

Methods to prevent freezing

Ice formation in the muffler can occur when the

ambient air temperature is 0–10°C (32-50 °F) and

the relative humidity is high.

The machine is designed to avoid the formation of

ice in the muffler. Despite this, under extreme

conditions ice can form in the muffler.

Take the following actions to further counteract the

risk of ice formation:

♦

Use a rockdrill oil.

♦

Use a water separator.

Connecting a water

separator

The length of the air hose between the compressor

and the water separator must be such that the water

vapor is cooled and condenses in the hose before

reaching the water separator.

If the ambient temperature is below 32 °F (0 °C) the

hose must be short enough to prevent the water

from freezing before reaching the water separator.

Lubrication

The lubricant is important for the machine’s function

and has a great impact on the service life. In order

to supply the correct volume of oil, an oiler should

be connected to the air hose. The use of Chicago

Pneumatic air line oiler is recommended. To

guarantee good lubrication, the length of the air

hose between the oiler and the pneumatic tool

should not exceed 10 feet (3 m).

Too much lubrication can cause starting problems,

low power or uneven performance.

Recommended Lubricant: Rockdrill oil with a

viscosity of 100-150 SUS at 100°F (ISO VG 22–32).

Drill steel

WARNING Ejected insertion tool

If the tool retainer on the machine is not in a locked

position, the inserted tool can be ejected with force,

which can cause personal injury.

► Before changing the insertion tool, stop the

machine, switch off the compressed air supply

and bleed the machine by activating the start and

stop device.

Before fitting the drill steel

Check that the tool shank is of the correct size and

length for the chuck used. The shank must be clean

and the tool must be in good condition. Shanks

which are chipped, rounded, out of square or too

hard on the striking end will operate inefficiently

and cause premature piston failure.

Inspect the drill steel:

A dull drill steel will slow down the drilling speed

and overstrain the drill mechanism. When changing

drill steel make sure that the new one is the correct

size to follow your previous bore.

Before drilling, check that the flushing hole in the

drill steel is not blocked.

9800 0901 90a | Original instructions14

CP 0022, CP 0032, CP 0069Safety and operating instructions

CAUTION Hot insertion tool

The tip of the insertion tool can become hot and

sharp when used. Touching it can lead to burns and

cuts.

► Never touch a hot or sharp insertion tool.

► Wait until the insertion tool has cooled down

before carrying out maintenance work.

NOTICE Never cool a hot insertion tool in water,

it can result in brittleness and early failure.

Fitting the drill steel

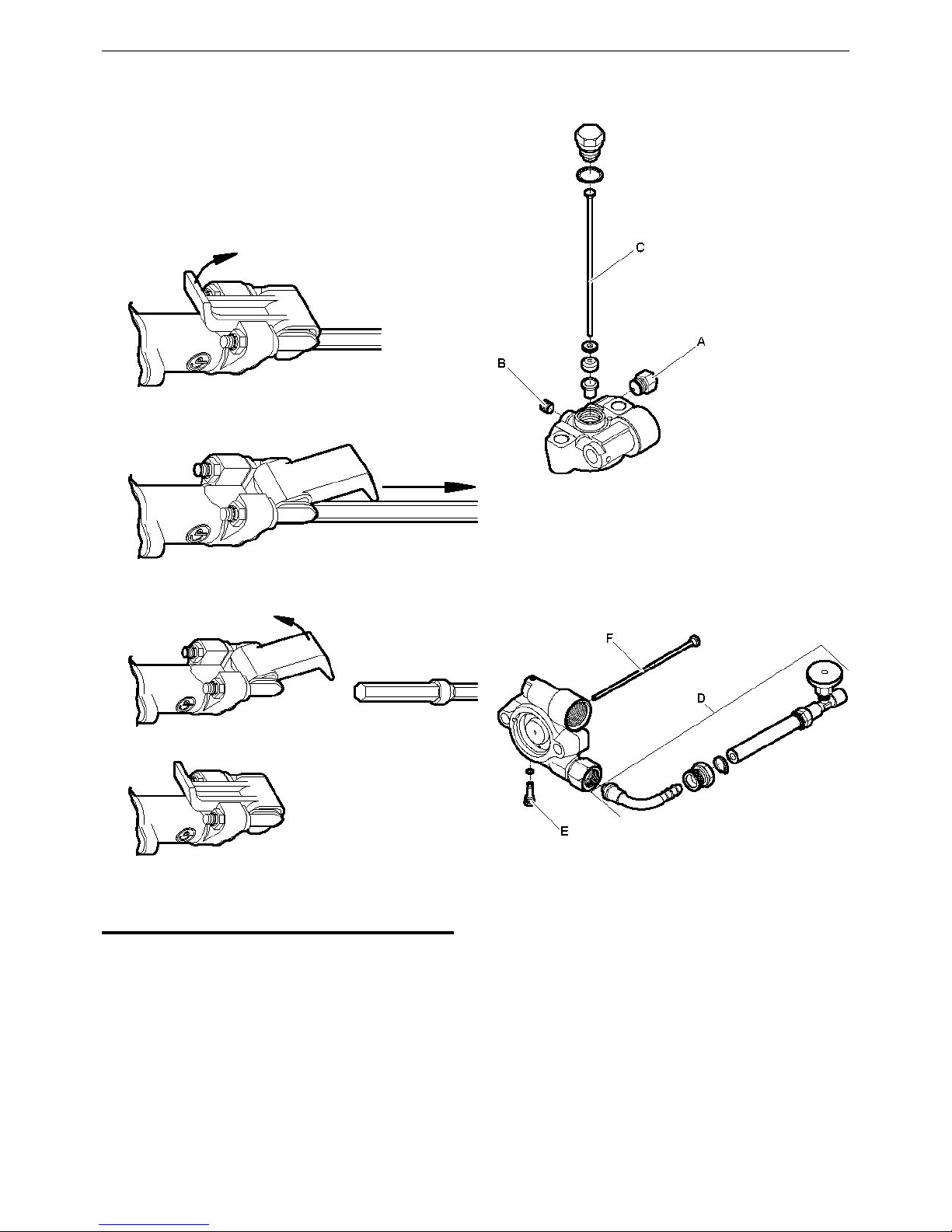

CP 0022 KL, CP 0032, CP 0069

Whenever fitting the drill steel the following

instructions must be observed:

1. Push the retainer inwards in the direction of the

arrow, until the front portion of the retainer is

able to accommodate the drill steel collar.

2. Insert the drill steel in the chuck.

3. When the drill bottoms, push back the retainer

to lock it

159800 0901 90a | Original instructions

Safety and operating instructionsCP 0022, CP 0032, CP 0069

Removing the drill steel

CP 0022 KL, CP 0032, CP 0069

Whenever removing the drill steel the following

instructions must be observed:

1. Push the retainer inwards in the direction of the

arrow until the drill steel collar disengages from

the front of the retainer.

2. Pull the drill steel out.

3. Push back the retainer.

Wet drilling

Before converting to wet drilling

Before converting the rock drill to wet drilling,

always switch off the air supply and bleed the

machine by depressing the throttle handle. Then

disconnect the air hose from the machine.

Converting to wet drilling

Only for CP 0032 and CP 0069

1. Unscrew plug (A) from the water connection.

2. Unscrew plug (B) from the back head.

3. Remove air tube (C) from the back head.

Only for CP 0032 and CP 0069

1. Assemble the water conversion kit (D) and

connect it to the water connection.

2. Screw in plug (E) into the back head.

3. Place water tube (F) into the back head.

9800 0901 90a | Original instructions16

CP 0022, CP 0032, CP 0069Safety and operating instructions

Operation

WARNING Involuntary start

Involuntary start of the machine may cause injury.

► Keep your hands away from the start and stop

device until you are ready to start the machine.

► Learn how the machine is switched off in the event

of an emergency.

► Stop the machine immediately in all cases of

power supply interruption.

Preparations before starting

Check the drilling equipment

♦

Check that all of the drilling equipment is in good

condition.

♦

Check that the impact surface of the drill steel

shank is flat, with no signs of wear.

♦

Make sure that the air inlet and exhaust ports are

free from obstructions.

♦

Check that the flushing holes in the drill steel and

drill bit are not blocked, and that the flushing air

and water flows through without obstruction.

♦

Make sure that the air filter (located in the air

nipple) is clean and not torn or distorted.

♦

Ensure that the fittings are tight and leak-proof.

DANGER Whipping air hose

A compressed air hose that comes loose can lash

around and cause personal injury or death

► Check that the compressed air hose and the

connections are not damaged.

► Check that all compressed air connections are

properly attached.

Blow out the air hose

♦

Every day before using the drill, blow out the air

hose to clear it of accumulated dirt and moisture.

Fill the lubricator with oil

♦

Check that the chuck and drill steel shank are

always covered with a film of oil.

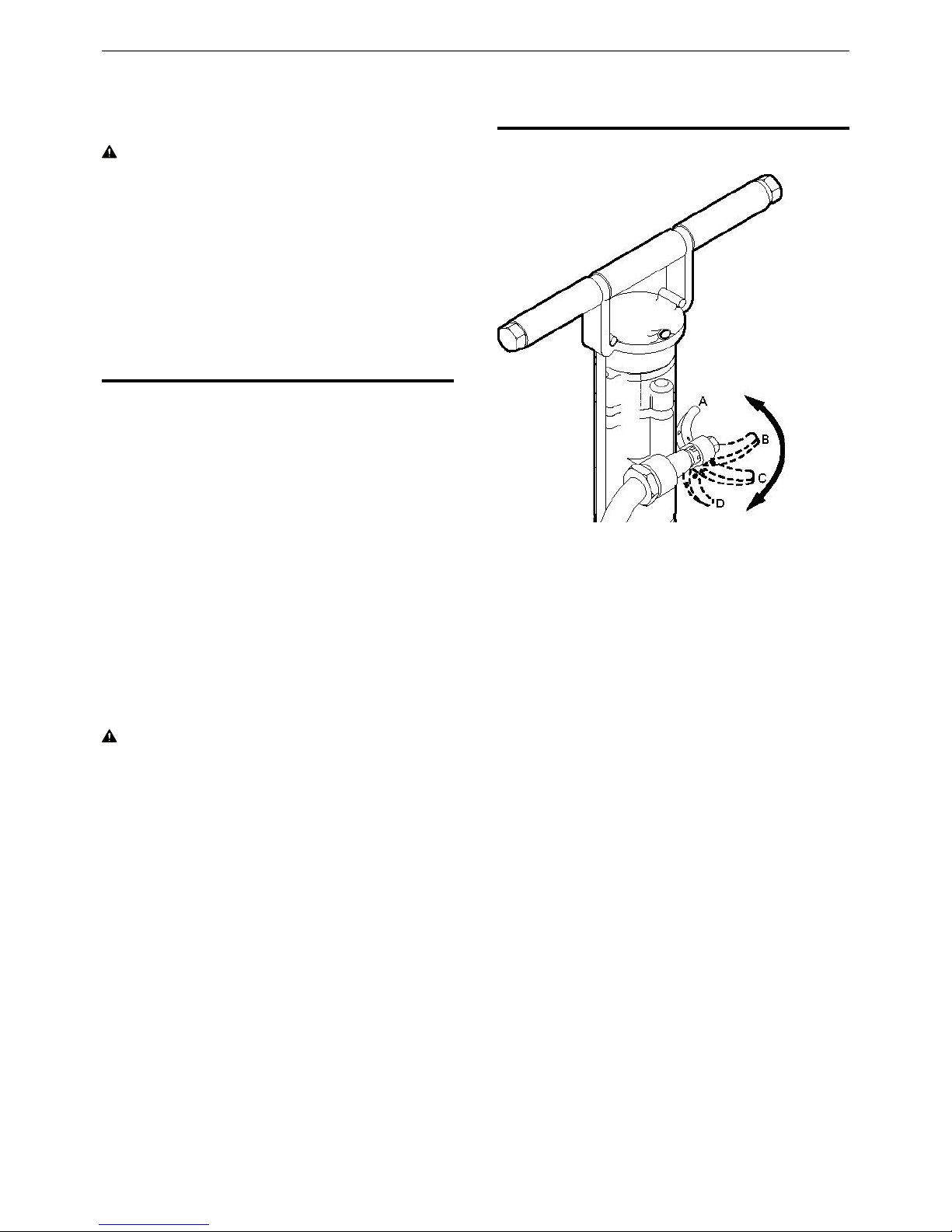

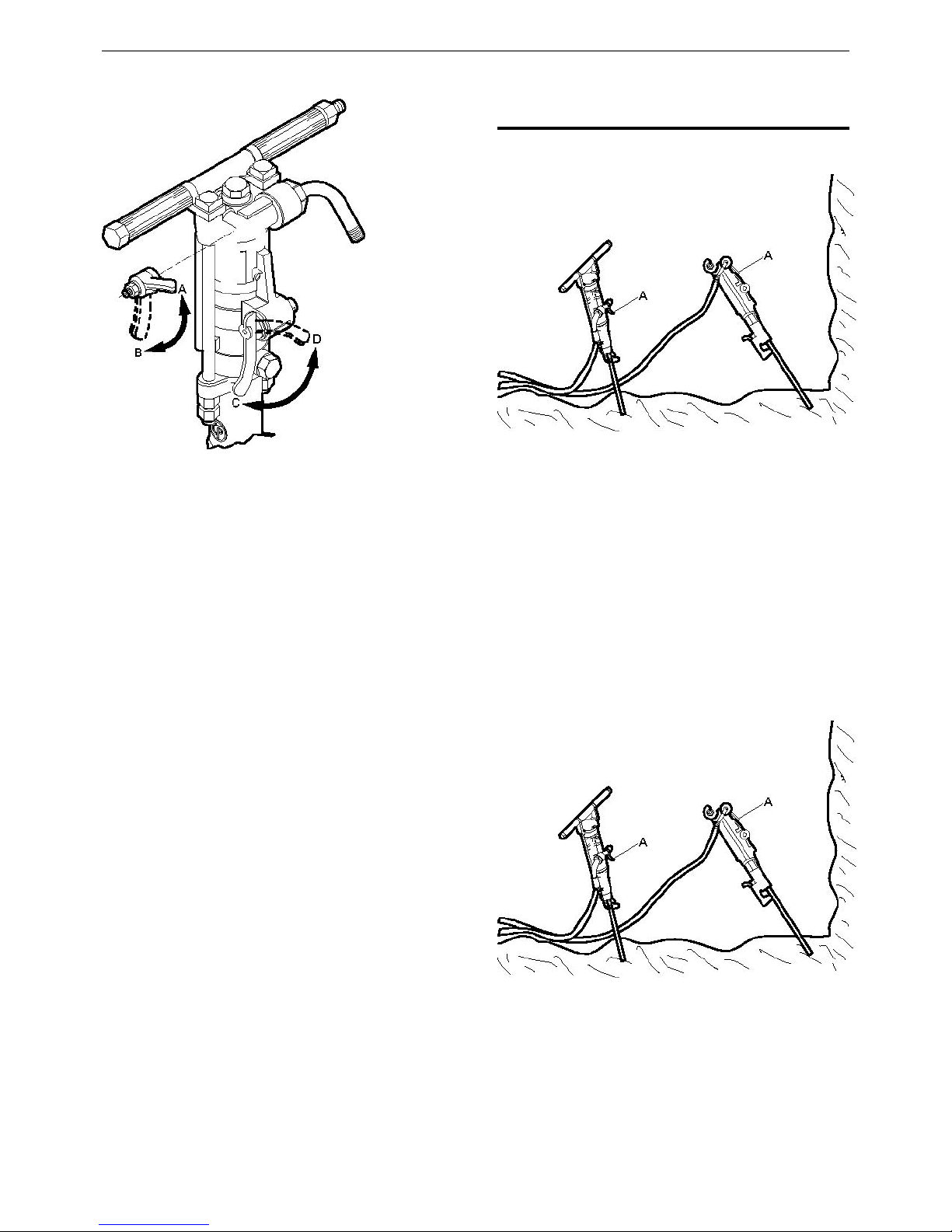

Controls

Throttle lever

CP 0022 KL

The rock drill is equipped with a throttle lever for

regulating compressed air to the percussion

mechanism.

♦

Throttle valve closed (stop position) (A).

♦

Blow-cleaning only (B).

♦

Throttle lever half open (C).

♦

Throttle lever fully open (D).

179800 0901 90a | Original instructions

Safety and operating instructionsCP 0022, CP 0032, CP 0069

CP 0032 and CP 0069

The rock drill is equipped with a throttle lever for

regulating compressed air to the percussion

mechanism and a blower lever for extra

blow-cleaning.

♦

Throttle valve closed (stop position) (A).

Blow-cleaning only.

♦

Throttle lever fully open (B).

♦

Blower valve closed (stop position) (C).

♦

Blower valve fully open (D).

Start and stop

Starting the rock drill

1. Open the main valve for compressed air.

2. Align the rock drill so that the drill steel touches

the required collaring point.

3. Move the throttle lever (A) forward a little, which

will start the percussion and rotation.

4. Collar the hole with reduced feed force.

5. Move the throttle lever (A) fully forward once

the drill steel has gained a secure footing in the

rock.

Stopping the rock drill

1. Pull the throttle lever (A) backwards to the closed

position, this will stop the percussion and

rotation.

9800 0901 90a | Original instructions18

CP 0022, CP 0032, CP 0069Safety and operating instructions

Operating

Drilling

♦

Use protective shoes, gloves, helmet, ear

protectors and impact resistant eye protection

with side protection.

♦

Stand firmly and always hold the machine with

both hands.

♦

Hold the inserted tool firmly against the work

surface before starting the machine.

When taking a break

♦

During all breaks you must place the machine in

such a way that there is no risk for it to be

unintentionally started. Make sure to place the

machine on the ground, so that it can not fall.

♦

In the event of a longer break or when leaving the

workplace: Switch off the power supply and then

bleed the machine by activating the start and stop

device.

Maintenance

Regular maintenance is a basic requirement for the

continued safe and efficient use of the machine.

Follow the maintenance instructions carefully.

♦

Before starting maintenance on the machine,

clean it in order to avoid exposure to hazard

substances. See “Dust and fume hazards”

♦

Use only authorised parts. Any damage or

malfunction caused by the use of unauthorised

parts is not covered by warranty or product

liability.

♦

When cleaning mechanical parts with solvent,

comply with appropriate health and safety

regulations and ensure there is satisfactory

ventilation.

♦

For major service to the machine, contact your

nearest authorised workshop.

♦

After each service, check that the machine's

vibration level is normal. If not, contact your

nearest authorised workshop.

Every day

Before undertaking any maintenance or changing

the insertion tool on pneumatic machines, always

switch off the air supply and bleed the machine by

depressing the start and stop device then disconnect

the air hose from the machine.

♦

Clean and inspect the machine and its functions

each day before the work commences.

♦

Conduct a general inspection for leaks and

damage.

♦

Check that the air inlet nipple is tightened and

that the claw coupling is free from damage.

♦

Check the function of the throttle handle. Make

sure that it moves freely up and down.

♦

Check the function of the retainer. Make sure that

it locks the drill steel.

♦

Change damaged parts immediately.

♦

Replace worn components in good time.

♦

Check the through bolts of the machine. Make

sure that they are tightened.

♦

If the machine is equipped with a muffler, check

for damage.

Periodic maintenance

After each operating period of approximately 100

working hours or three times a year the machine

must be dismantled and all parts be cleaned and

checked. This work must be performed by authorized

staff, trained for this task.

199800 0901 90a | Original instructions

Safety and operating instructionsCP 0022, CP 0032, CP 0069

Tightening torque

CP 0022 KL

A. Nut, 70-80 ft.lbf (95-108 Nm)

B. Air inlet nut, 110-120 ft.lbf (149-163 Nm)

C. Through bolt nut, 90-100 ft.lbf (122-136 Nm)

D. Rifle nut, 200-225 ft.lbf (271-305 Nm)

E. Nut, 100-110 ft.lbf (136-149 Nm)

CP 0032, CP 0069

A. Nut, 35-40 ft.lbf (47- 54 Nm)

B. Air inlet nut, 125-150 ft.lbf (169-203 Nm)

C. Through bolt nut, 110-120 ft.lbf (149-163 Nm)

D. Rifle nut, 200-225 ft.lbf (271-305 Nm)

E. Nut, 100-110 ft.lbf (136-149 Nm)

F. Oil plug, 90-100 ft.lbf (122-136 Nm)

Damage patterns

Worn or broken parts must always be studied

carefully before they are replaced. They can give

important information about the condition of the

drill and about the way it is used and maintained.

CauseProblem

The parts have been subjected

to excessive heat. This can be

caused by insufficient

lubrication or idling

Steel parts are a bluish colour

See aboveSteel parts have small almost

microscopic fissures on the

wear surfaces

See aboveIrregular cavities on the surface

of bronze parts

Secondary damageCutting marks

Dirt inside the drill

Interior misalignment due to

uneven tension of the side

bolts

Storage

> Always oil the rock drill well, before you put it

into storage.

> Always store the machine in a clean and dry place.

> Make sure that no foreign matter enters the

machine.

> Protect the chuck using the plastic plug provided

with the machine. Alternatively, use a wooden

plug or a clean piece of cotton waste.

> In the case of long-term storage, pour a quantity

of oil directly into the rock-drill's air intake and

then turn on the air briefly. This will protect the

machine from corrosion.

9800 0901 90a | Original instructions20

CP 0022, CP 0032, CP 0069Safety and operating instructions

Disposal

A used machine must be treated and disposed of in

such a way that the greatest possible portion of the

material can be recycled and any negative influence

on the environment is kept as low as possible, and

in respect to local restrictions.

219800 0901 90a | Original instructions

Safety and operating instructionsCP 0022, CP 0032, CP 0069

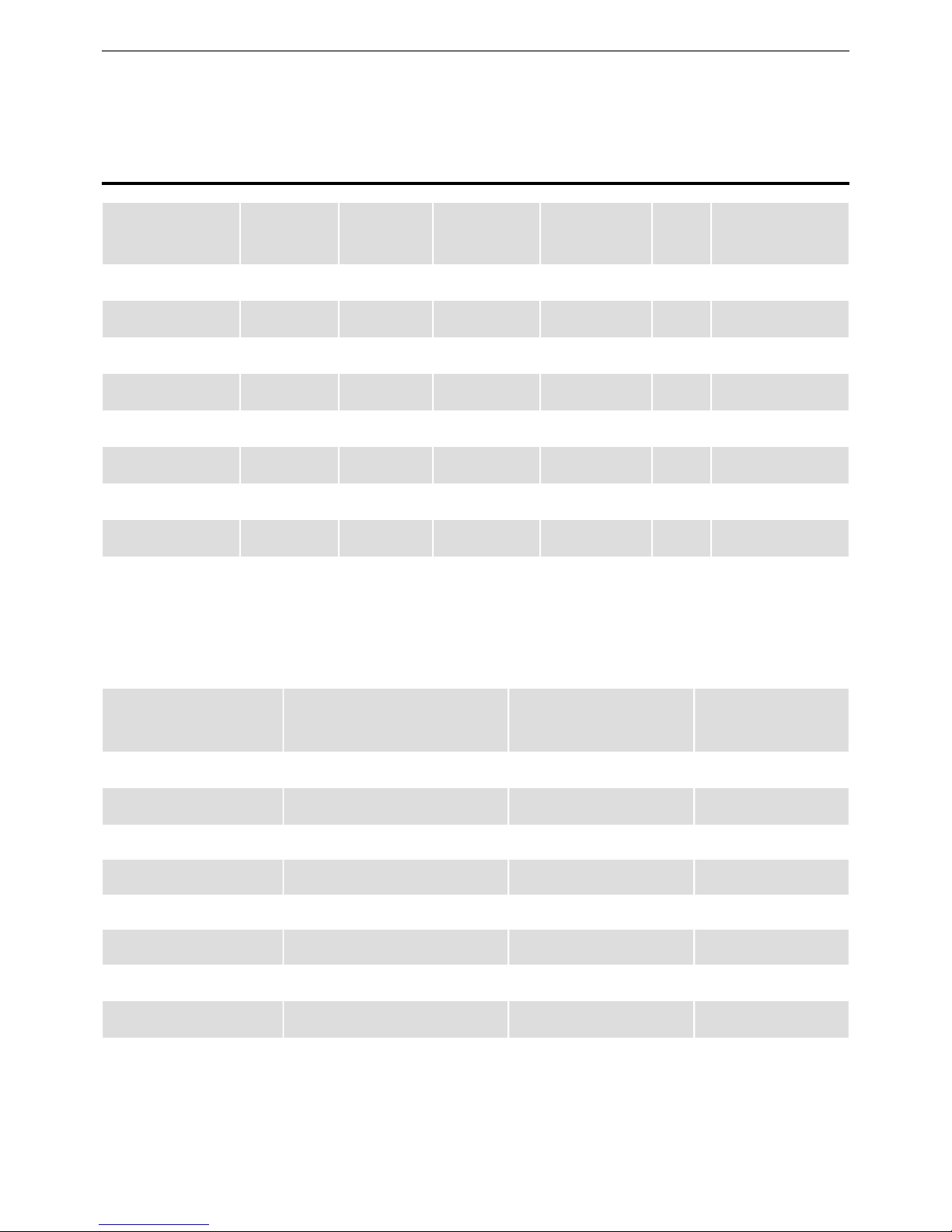

Technical data

Machine data

Shank dimension

in.

(mm)

Weight

lb

(kg)

Overall length

in.

(mm)

Stroke length

in.

(mm)

Piston bore

in.

(mm)Part numberModel

⅞ x 3¼

(22 X 82.5)

32

(14.7)

183⁄

4

(475)

13⁄

4

(44)

23⁄

8

(60)

8900 0020 01CP 0022 KL ⅞" x 3¼"

⅞ x 4¼

(22 x 108)

33

(14.9)

196⁄

8

(500)

13⁄

4

(44)

23⁄

8

(60)

8900 0020 02CP 0022 KL ⅞" x 4¼"

⅞ x 3¼

(22 X 82.5)

54

(24.5)

22

(559)

2

(51)

25⁄

8

(67)

T022318CP 0032 A ⅞" x 3¼"

⅞ x 4¼

(22 x 108)

54

(24.5)

23

(584)

2

(51)

25⁄

8

(67)

T022117CP 0032 A ⅞" x 4¼"

⅞ x 4¼

(22 x 108)

54

(24.5)

23

(584)

2

(51)

25⁄

8

(67)

T025431CP 0032 AS ⅞" x 4¼"

1 x 4¼

(25 x 108)

54

(24.5)

23

(584)

2

(51)

25⁄

8

(67)

T022319CP 0032 A 1" x 4¼"

⅞ x 4¼

(22 x 108)

64

(29.1)

241⁄

2

(622)

25⁄

8

(67)

23⁄

4

(70)

T006661CP 0069 ⅞" x 4¼"

1 x 4¼

(25 x 108)

64

(29.1)

241⁄

2

(622)

25⁄

8

(67)

23⁄

4

(70)

T022259CP 0069 1" x 4¼"

⅞ x 4¼

(22 x 108)

64

(29.1)

241⁄

2

(622)

25⁄

8

(67)

23⁄

4

(70)

T025423CP 0069 WET ⅞" x 4¼"

Hole diameter

in.

(mm)

Impact rate (6 bar)

Hz

Air consumption (6 bar)

foot3/min

(l/s)Model

≤11⁄

2

(≤38)

3756

(22)

CP 0022 KL ⅞" x 3¼"

≤11⁄

2

(≤38)

3756

(22)

CP 0022 KL ⅞" x 4¼"

≤2

(≤50)

37103

(48)

CP 0032 A ⅞" x 3¼"

≤2

(≤50)

37103

(48)

CP 0032 A ⅞" x 4¼"

≤2

(≤50)

37103

(48)

CP 0032 AS ⅞" x 4¼"

≤2

(≤50)

37103

(48)

CP 0032 A 1" x 4¼"

≤21⁄

2

(≤62.5)

32130

(61)

CP 0069 ⅞" x 4¼"

≤21⁄

2

(≤62.5)

32130

(61)

CP 0069 1" x 4¼"

≤21⁄

2

(≤62.5)

32130

(61)

CP 0069 WET ⅞" x 4¼"

9800 0901 90a | Original instructions22

CP 0022, CP 0032, CP 0069Safety and operating instructions

Noise and vibration declaration statement

Guaranteed sound power level Lw according to ISO 3744 in accordance with directive 2000/14/EC.

Sound pressure level Lp according to ISO 11203.

Vibration value A and uncertainty B determined according to ISO 20643. See table ”Noise and vibration data”

for the values of A, B, etc.

These declared values were obtained by laboratory type testing in accordance with the stated directive or

standards and are suitable for comparison with the declared values of other tools tested in accordance with

the same directive or standards. These declared values are not suitable for use in risk assessments and values

measured in individual work places may be higher. The actual exposure values and risk of harm experienced

by an individual user are unique and depend upon the way the user works, in what material the machine is

used, as well as upon the exposure time and the physical condition of the user, and the condition of the

machine.

We, Atlas Copco Construction Tools AB, cannot be held liable for the consequences of using the declared

values, instead of values reflecting the actual exposure, in an individual risk assessment in a work place situation

over which we have no control.

This tool may cause hand-arm vibration syndrome if its use is not adequately managed. An EU guide to

managing hand-arm vibration can be found at http://www.humanvibration.com/EU/VIBGUIDE.htm

We recommend a programme of health surveillance to detect early symptoms which may relate to vibration

exposure, so that management procedures can be modified to help prevent future impairment.

Noise and vibration data

VibrationNoise

Declared valuesDeclared values

Three axes valuesSound powerSound pressure

ISO 206432000/14/ECISO 11203

B

m/s2spreads

A

m/s2value

Lw

guaranteed dB(A) rel

1pW

Lp

r=1m dB(A) rel

20µPaModel

3.025.7116106CP 0022 KL ⅞" x 3¼"

3.025.7116106CP 0022 KL ⅞" x 4¼"

2.721.9122111CP 0032 A ⅞" x 3¼"

2.721.9122111CP 0032 A ⅞" x 4¼"

2.721.9114103CP 0032 AS ⅞" x 4¼"

2.721.9122111CP 0032 A 1" x 4¼"

3.429.0124113CP 0069 ⅞" x 4¼"

3.429.0124113CP 0069 1" x 4¼"

3.429.0124113CP 0069 WET ⅞" x 4¼"

Accessories

Part numberQuantityRemarkDescription

8900 0050 071For both mineral and synthetic oilLubricator 43, US type (NPT)

8900 0050 021For both mineral and synthetic oilLubricator 1300, European type (BSP)

8900 0050 011Airflow <130 ft3/min (60 l/s)Water separator, US type (NPT)

8900 0050 001Airflow <130 ft3/min (60 l/s)Water separator, European type (BSP)

8900 0050 10120 mm (3⁄4")RED-X air hose, 60 m

239800 0901 90a | Original instructions

Safety and operating instructionsCP 0022, CP 0032, CP 0069

EC Declaration of Conformity

EC Declaration of Conformity (EC Directive 2006/42/EC)

We, Atlas Copco Construction Tools AB, hereby declare that the machines listed below conform to the provisions

of EC Directive 2006/42/EC (Machinery Directive), and the harmonised standards mentioned below.

Pmax (bar)Part numberRock drills

6.28900 0020 01CP 0022 KL ⅞" x 3¼"

6.28900 0020 02CP 0022 KL ⅞" x 4¼"

6.2T022318CP 0032 A ⅞" x 3¼"

6.2T022117CP 0032 A ⅞" x 4¼"

6.2T025431CP 0032 AS ⅞" x 4¼"

6.2T022319CP 0032 A 1" x 4¼"

6.2T006661CP 0069 ⅞" x 4¼"

6.2T022259CP 0069 1" x 4¼"

6.2T025423CP 0069 WET ⅞" x 4¼"

Technical Documentation authorised representative:

Erik Sigfridsson

Atlas Copco Construction Tools AB

Dragonvägen 2

Kalmar

General Manager:

Erik Sigfridsson

Manufacturer:

Atlas Copco Construction Tools AB

105 23 Stockholm

Sweden

Place and date:

Kalmar, 2010-01-01

9800 0901 90a | Original instructions24

CP 0022, CP 0032, CP 0069Safety and operating instructions

259800 0901 90a | Instructions d’origine

SommaireCP 0022, CP 0032, CP 0069

FRANÇAIS

Sommaire

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

À propos des prescriptions de sécurité et des instructions pour l'opérateur. . . . . . 27

Consignes de sécurité. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Indications de sécurité. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Précautions et qualifications du personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Installation, précautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Fonctionnement, précautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Maintenance, précautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Stockage, précautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Vue d'ensemble. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Conception et fonctionnement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Pièces principales. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Étiquettes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Pose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Déballage du marteau perforateur. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Flexibles et connexions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Mesures de prévention du gel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Branchement d'un séparateur d'eau. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Lubrifiant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Fleuret. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Forage humide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Utilisation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Opérations à effectuer avant de démarrer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Commandes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Marche/arrêt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Utilisation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Lors des pauses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Chaque jour. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Maintenance périodique. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Couple de serrage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Types de dégâts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Stockage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Destruction d'une machine usagée. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Données techniques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Caractéristiques de la machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Énoncé déclaratif sur les vibrations et le bruit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Données relatives au bruit et aux vibrations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Accessoires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Déclaration CE de conformité. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Déclaration CE de conformité (Directive 2006/42/CE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9800 0901 90a | Instructions d’origine26

CP 0022, CP 0032, CP 0069Sommaire

Introduction

Nous vous remercions d'avoir choisi un produit Chicago Pneumatic. Depuis plus

d'un siècle, la marque Chicago Pneumatic est synonyme de performance et

d'innovation dans le secteur des outils pneumatiques.

Aujourd'hui, la société offre une vaste gamme d'outils pneumatiques et hydrauliques

comprenant brise-béton, trépans, marteaux burineurs, marteaux-bêches, pioches et

défricheuses, bouchardeuses, pompes et bien d'autres outils.

La marque Chicago Pneumatic est associée avec des produits puissants et fiables,

faciles à entretenir et ayant un bon rapport qualité-prix.

Pour plus d’informations, veuillez consulter le site Web www.cp.com

Atlas Copco Construction Tools AB

S-105 23 Stockholm

Suède

À propos des prescriptions de sécurité et

des instructions pour l'opérateur

Le but des instructions est de vous apprendre à utiliser le marteau perforateur d’une

manière efficace et en toute sécurité. Les instructions vous donnent également des

conseils et vous indiquent comment effectuer la maintenance de routine du marteau

perforateur.

Vous devez lire ces instructions attentivement et les comprendre avant d'utiliser le

marteau perforateur pour la première fois.

279800 0901 90a | Instructions d’origine

Prescriptions de sécurité et instructions pour

l’opérateur

CP 0022, CP 0032, CP 0069

Consignes de sécurité

Il convient de lire et d'assimiler les Prescriptions de

sécurité et des instructions pour l'opérateur avant

toute installation, utilisation, réparation, entretien

ou remplacement d'accessoire sur la machine, afin

de minimiser le risque de blessures graves ou de

dommages pouvant entraîner la mort.

Affichez les Prescriptions de sécurité et instructions

pour l'opérateur sur les différents sites de travail ;

faites en des copies pour les employés et

assurez-vous que chaque personne concernée a bien

lu les Prescriptions de sécurité et instructions pour

l'opérateur, avant d'utiliser ou d'intervenir sur la

machine.

En outre, l'opérateur ou l'employeur doit évaluer

les risques spécifiques pouvant survenir à la suite de

chaque utilisation de la machine.

Indications de sécurité

Les indications de sécurité Danger, Attention et

Prudence ont les sens suivants :

Indique une situation

dangereuse qui, si elle n'est

pas évitée, terminera par

provoquer la mort ou des

blessures graves.

DANGER

Indique une situation

dangereuse qui, si elle n'est

pas évitée, est de susceptible

de provoquer la mort ou des

blessures graves.

ATTENTION

Indique une situation

dangereuse qui, si elle n'est

pas évitée, est de susceptible

de provoquer des blessures

mineures à modérées.

PRUDENCE

Précautions et qualifications

du personnel

Seules des personnes qualifiées ou formées peuvent

utiliser ou procéder à l'entretien de la machine. Elles

doivent être physiquement aptes à manipuler le

volume, le poids et la puissance de l'outil. Utilisez

toujours votre jugement et votre bon sens.

Équipement de protection du personnel

Utilisez toujours un équipement de protection

individuelle homologué. Les opérateurs et toutes

autres personnes séjournant sur la zone de travail

doivent porter un équipement de protection

individuelle, incluant au minimum :

> Casque de protection

> Protections auditives

> Protecteurs des yeux résistants aux chocs avec

protection latérale

> Appareil de protection respiratoire, le cas échéant

> Gants de protection

> Bottes de protection adaptées

> Salopette de travail appropriée ou vêtement

similaire (serré) qui recouvre les bras et les jambes.

Drogues, alcool ou médicaments

AVERTISSEMENT Drogues, alcool ou

médicaments

Les drogues, l'alcool ou les médicaments risquent

d'avoir un effet négatif sur votre jugement et votre

capacité de concentration. De mauvaises réactions

et des évaluations incorrectes peuvent entraîner des

accidents graves, voire la mort.

► N'utilisez jamais la machine lorsque vous êtes

fatigué(e) ou sous l'influence de drogues, de

l'alcool ou de médicaments.

► L'utilisation de la machine par une personne sous

l'influence de drogues, de l'alcool ou de

médicaments est strictement interdite.

Installation, précautions

DANGER Coup de fouet d'un flexible

pneumatique

Un flexible d'air comprimé qui se détache risque de

fouetter dans tous les sens et de provoquer des

dommages corporels ou la mort. Pour réduire ce

risque :

► Vérifiez que le flexible d'air comprimé et les

raccords ne sont pas endommagés. Les remplacer

si nécessaire.

► Vérifiez que les raccords d'air comprimé sont

correctement fixés.

► Ne jamais porter une machine pneumatique par

le flexible d'air.

9800 0901 90a | Instructions d’origine28

CP 0022, CP 0032, CP 0069Prescriptions de sécurité et instructions pour

l’opérateur

► Ne jamais essayer de débrancher un flexible d'air

comprimé sous pression. D'abord, coupez

l'alimentation en air comprimé au niveau du

compresseur, puis purgez la machine en activant

le dispositif de marche/arrêt.

► Ne jamais pointer un flexible d'air comprimé sur

quelqu'un ou sur soi. Afin d'éviter tout risque de

blessure, ne jamais utiliser l'air comprimé pour

nettoyer la poussière, les salissures, etc., sur vos

vêtements.

► N'utilisez pas de raccords rapides à l'entrée de

l'outil. Utilisez des raccords filetés en acier trempé

(ou un matériau présentant une résistance aux

chocs comparable).

► Chaque fois que des raccords universels (raccords

à griffes) sont utilisés, nous recommandons de

monter des goupilles de verrouillage et d’utiliser

des câbles de sécurité pour tuyaux flexibles, afin

d’empêcher tout relâchement d’un accouplement

flexible - outil et tuyau - tuyau.

AVERTISSEMENT Outil d'insertion

éjecté

Si la sécurité de l'outil n'est pas verrouillée sur la

machine, l'outil d'insertion risque d'être éjecté avec

force, et de provoquer des dommages corporels.

► Ne démarrez jamais la machine au moment du

changement de l'outil d'insertion.

► Avant de changer l'outil d'insertion ou un

accessoire, arrêtez la machine, coupez

l'alimentation électrique et purgez la machine en

activant le dispositif de marche/arrêt.

► Ne jamais pointer l'outil inséré vers soi-même ni

vers autrui.

► Assurez-vous que l'outil d'insertion est

entièrement inséré et que la sécurité de l'outil est

en position verrouillée avant tout démarrage de

la machine.

► Vérifiez la fonction de verrouillage en tirant

énergiquement l'outil inséré vers l'extérieur.

AVERTISSEMENT Déplacement /

glissement d'outil d'insertion

Une dimension incorrecte de L'emmanchement de

l'outil inséré peut induire la perte ou le glissement

de ce dernier pendant le fonctionnement. Risque de

blessure grave ou d'écrasement des mains et des

doigts.

► Vérifiez que l'outil d'insertion utilisé possède la

bonne taille d'emmanchement et les dimensions

pour lesquelles la machine est prévue.

► Ne jamais utiliser un outil d'insertion sans collet.

Fonctionnement,

précautions

DANGER Danger d'explosion

Si un outil d'insertion chaud entre en contact avec

un explosif, cela pourrait provoquer une explosion.

Lors de travaux sur certains matériaux et lors

d'utilisation de certains matériaux dans les pièces

de la machine, des étincelles susceptibles

d'enflammer des gaz peuvent provoquer des

explosions. Les explosions peuvent provoquer des

dommages corporels voire la mort.

► Ne jamais utiliser la machine dans un

environnement explosif quelconque.

► N'utilisez jamais cette machine près de poussières,

d'émanations ou de matériaux inflammables.

► Assurez-vous qu'il n'y a aucune source de gaz

non identifiée ni explosifs dans les environs.

► Ne jamais forer dans un ancien trou.

AVERTISSEMENT Mouvements inopinés

L'outil inséré est soumis à des efforts importants lors

de l'utilisation de la machine. L'outil inséré peut se

rompre à cause de la fatigue après un certain temps

d'utilisation. En cas de rupture ou de blocage de

l'outil inséré, des mouvements soudains et imprévus

peuvent se produire et entraîner des blessures. Les

pertes d'équilibre ou les glissades peuvent

également provoquer des blessures.

► Assurez-vous de toujours adopter une position

stable, les pieds dans le prolongement de vos

épaules et votre poids bien réparti sur les deux

jambes.

► Vérifiez toujours l'équipement avant de l'utiliser.

Évitez d'utiliser l'équipement s'il vous semble

endommagé.

► Assurez-vous que les poignées sont toujours bien

propres, sans graisse ni huile.

299800 0901 90a | Instructions d’origine

Prescriptions de sécurité et instructions pour

l’opérateur

CP 0022, CP 0032, CP 0069

► Gardez vos pieds éloignés de l'outil inséré.

► Restez bien droit et tenez toujours la machine à

deux mains.

► Ne jamais forer dans un ancien trou.

► Ne mettez pas la machine en marche lorsqu'elle

est posée sur le sol.

► Ne 'chevauchez' jamais la machine, une jambe

passée sur la poignée.

► Ne maltraitez jamais l'équipement.

► Examinez régulièrement l'usure de l'outil

d'insertion et contrôlez la présence éventuelle de

signes de détérioration ou de fissures visibles.

► Soyez vigilant et concentrez-vous sur ce que vous

faites.

AVERTISSEMENT Danger de calage

Si l'outil d'insertion se bloque durant le

fonctionnement, la machine se mettra à tourner sur

elle-même si vous ne la tenez pas bien. Cette rotation

inattendue de la machine entière peut provoquer

des blessures graves, voire la mort.

► Restez bien droit et tenez toujours la machine

avec les deux mains.

► Assurez-vous que les poignées sont toujours bien

propres, sans graisse ni huile.

► Ne jamais forer dans un ancien trou.

AVERTISSEMENT Danger de piégeage

Les vêtements flottants, cheveux, gants, foulards ou

écharpes risquent de se prendre sur un outil à

insertion ou un accessoire en rotation. Ce type

d'incident peut provoquer un étouffement, un scalp,

des déchirures voire la mort. Pour réduire ce risque

:

► Évitez à tout prix d'agripper ou de toucher un

fleuret en rotation.

► Évitez de porter des vêtements amples, des gants,

des foulards ou écharpes susceptibles de se

prendre dans la pièce en rotation.

► Couvrez les cheveux à l'aide d'un filet.

AVERTISSEMENT Dangers liés aux

poussières et aux fumées

Les poussières et/ou de fumées générées ou

dispersées lors de l’utilisation de la machine peuvent

causer des maladies respiratoires graves et

permanentes, ou autre lésion corporelle (par

exemple, la silicose ou autre maladie pulmonaire

irréversible qui peut être mortelle, cancer,

malformations congénitales et/ou inflammation de

la peau).

Certaines poussières et fumées créées lors de

foration, casse, martelage, sciage, meulage et autres

activités de construction, contiennent des substances

connues dans l'État de Californie et par d’autres

autorités pour provoquer des maladies respiratoires,

le cancer, des malformations congénitales ou autres

problèmes de reproduction. Quelques exemples de

ces substances sont :

> Silice cristalline, ciment et autres produits de

maçonnerie.

> Arsenic et chrome provenant de caoutchouc traité

chimiquement.

> Plomb provenant de peintures à base de plomb.

Les poussières et fumées dans l’air peuvent être

invisibles à l’œil nu. Par conséquent, ne comptez

pas sur la vue oculaire pour déterminer s'il y a des

poussières ou des fumées dans l’air.

Pour réduire les risques d’exposition aux poussières

et fumées, effectuez tout ce qui suit :

► Effectuez une évaluation des risques spécifiques

au site. L’évaluation des risques devra inclure les

poussières et les vapeurs créées par l’utilisation

de la machine et les poussières susceptibles

d'incommoder le voisinage.

► Utilisez la sécurité intégrée appropriée pour

minimiser la quantité de poussières et de fumées

dans l’air et leur accumulation sur les

équipements, les surfaces, les vêtements et les

parties du corps. Exemples de mesures applicables

: systèmes de ventilation aspirante et de captage

des poussières, pulvérisation d'eau et forage

humide. Contrôlez si possible les poussières et les

fumées à la source. Assurez-vous que les

commandes sont correctement installées,

entretenues et utilisées.

► Portez, entretenez et utilisez de manière correcte

la protection respiratoire comme indiqué par votre

employeur, en respectant les normes de sécurité

et de santé au travail. La protection respiratoire

doit être efficace pour le type de substance en

cause (et le cas échéant, approuvée par l’autorité

gouvernementale pertinente).

9800 0901 90a | Instructions d’origine30

CP 0022, CP 0032, CP 0069Prescriptions de sécurité et instructions pour

l’opérateur

Loading...

Loading...