Chicago Pneumatic Auto Feed Drills Tappers User Manual

Auto Feed Drills & TappersAuto Feed Drills & Tappers

Chicago

Pneumatic

TM

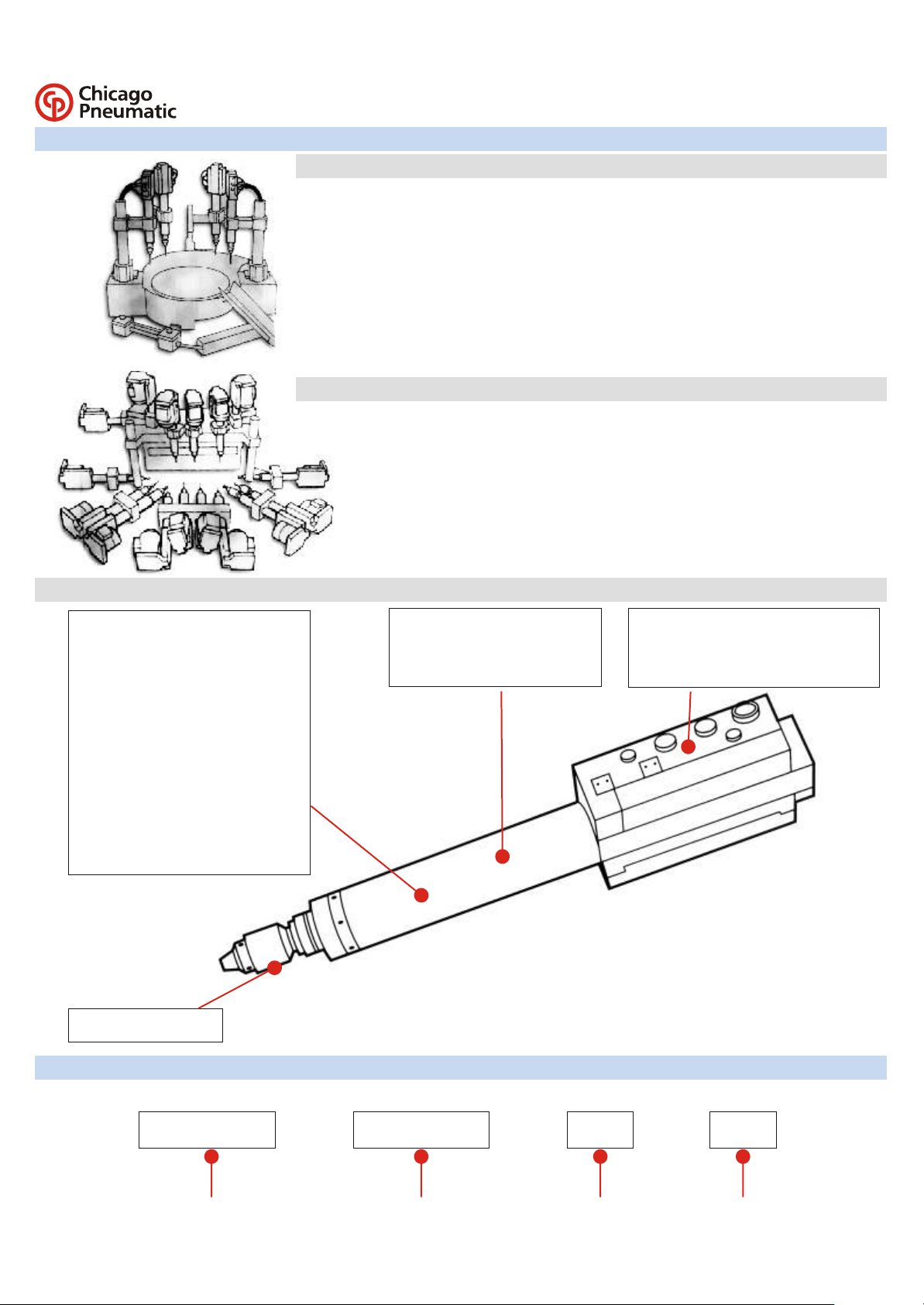

AFD Features

Desoutter Auto Feed Drill and Tapper Features

Rigid cast aluminium housing

Integral belt tensioner on

AFDE and AFTE models

Heavy duty belts and pulleys on AFDE

and AFTE models.

Modular Control Block Options

A1 - Full Feature Block

l Pneumatic signal ports for stop, start and

cycle complete

l Facility for using proximity switches to

sense depth and datum positions

l Control of feed and retract speed

A6 - Simple Control Block

l Forward and retract port for control via

remote valves

l Facility for using proximity switches to

sense depth and datum positions

Motor Powers up to 2.2kW(3.OHP)

Optional hydraulic control unit for fine

feed control and reduction of ‘break

through’ force

New crosshead design providing high

torque resistance

Dynamic thrusts up to 2670N (600lbf)

Front of tools

sealed to IP64**

Interchangeable modular output spindles including

multiple spindle and tapping heads

General Information

l All performance data is obtained at a line pressure of 6.3±0.15 bar in accordance with ISO2787 (1984).

l All speeds are nominal.

l Performance data is subject to alteration without prior notice.

l Unless stated otherwise dimensions are in mm.

l All imperial dimensions and performance data have been calculated from the measured metric values.

l Sound levels are ±2dB(A) measured using CAGI-PNEUROP test code.

l Before using an AFD always refer to the operating and warning instructions supplied with the tool.

l For AFD models maximum power is achieved at 50% of no load speed.

2

l Modular components for flexibility of

speed and function

l Simple interfaces for communicating to

other equipment

l Control options including peck feed, dwell

and skip feed

** AFD415, AFDE400/410 and AFDE600/610/62O tools only

AFD Applications

Ease of Incorporation into Machine or Process

l Extensive range of mounting clamps

l Control interfaces to link AFD(E) to other equipment through pneumatics or electrically

l Single signal required for AFD(E) to perform cycle

l Output signals at datum and depth

l Electric motor mounting on 200, 400 and 600 series can be rotated through 180º

Modular Design

l Flexibility of unit function and speed

l Common components in differing models reducing inventory

l Multiple spindle head options

l Drill and tapping options for all models

Model Type

Pneumatic Feed and Drive

AFD205, AFD215 0.22kW (0.29HP)

AFD415 0.38kW (0.50HP)

AFD/AFT60 0.52kW (0.70HP)

Pneumatic Feed, Electric Drive

AFDE200 0.25kW (0.33HP)

AFDE400, AFDE600 0.33kW (0.40HP)

AFDE410, AFDE610 0.75kW (1.00HP)

AFDE620 1.10kW (1.50HP)

AFDE700 1.50kW (2.00HP)

AFDE710 2.20kW (3.00HP)

Electric Feed and Drive via Leadscrew

AFTE270 0.18kW (0.24HP)

AFTE470 0.38kW (0.50HP)

AFTE480 0.75kW (1.00HP)

Output Spindle**

Output spindle to be supplied.

Model Codes

No Load Speed

The free output speed of the drill or tapper

with no drilling or tapping load applied.

Control Block

A1 – Full feature type* – Automatic cycle

A6 – Simple type** – Remote cycle control

A7 – Leadscrew type – PNP

A8 – Leadscrew type – NPN

* Not required on AFTE models.

** Does not apply for AFD60 and AFT60.

How to Order

AFDE400AFDE400 28502850

—— ——

A1A1 B24B24

++

Model Code Model Code No Load SpeedNo Load Speed Control BlockControl Block Output SpindleOutput Spindle

3

What is an AFD?

Drilling Pneumatic Drive

The Desoutter range of Auto Feed Drills and T appers are fixture mounted tools combining

linear feed and rotation for machining and tapping operations.

There are 3 basic model types:

l AFD/AFT – Pneumatic Feed and Drive

l AFDE – Pneumatic Feed with Electric Drive

l AFTE – Electric Drive and Feed via a Leadscrew

A wide range of accessories allow the tools to be configured to suit the application and

include mounting clamps, output spindles, multiple spindle heads and various control

options for interfacing with PLC’s or pneumatics.

AFD205/ AFD215 pneumatic drive

l Options of compact AFD205 or long stroke AFD215

l High thrust / size ratio

l Capacity up to 5mm (3/16”) in aluminium

l Modular output spindles

SPEED 650, 1000, 2700, 4350, 10000, 18700

TOOL TYPE POWER THRUST STROKE WEIGHT

HP N mm kg

AFD205 0.30 400 50 3.9

AFD215 0.30 400 90 4.2

AFD415 pneumatic drive

l Compact unit design

l Long working stroke of 100mm (3.94”)

l Spindle sealed to IP64 standard

l Capacity up to 8mm (5/16”) in mild steel, 10mm (3/8”) in aluminium

l Modular output spindles

SPEED 490, 790, 1250, 2100, 3400, 5400, 7000, 18000

TOOL TYPE POWER THRUST STROKE WEIGHT

HP N mm kg

AFD415 0.51 706 100 6.2

AFD60 pneumatic drive

l Heavy duty pneumatic unit

l Chuck supplied fitted to tool, 10mm (3/8”) for 1600-4300rpm and 13mm (1 / 2”) for

550-1000rpm

l Full feature control block fitted as standard

l Capacity up to 16mm (5/ 8”) in aluminium, 12mm(1 /2") in mild steel

SPEED 550, 700, 1000, 1600, 2100, 3000, 4300

TOOL TYPE POWER THRUST STROKE WEIGHT

HP N mm kg

AFD60 0.70 1200 95 8.1

4

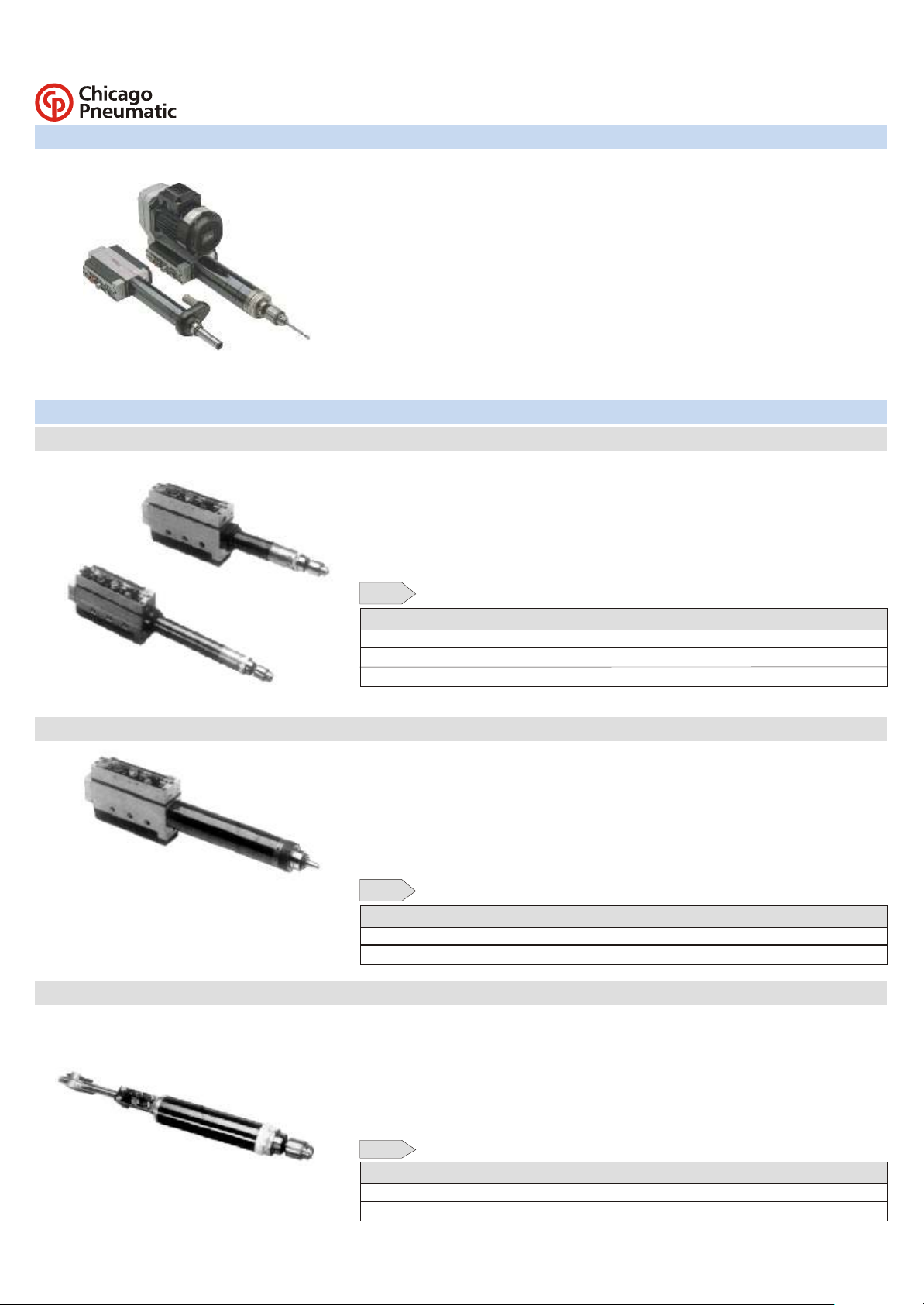

Drilling Electric Drive

AFDE200 electric drive

l Compact unit size

l High speed options up to 22400 rpm @ 50Hz, 26900 rpm @ 60Hz with K42 output

l Capacity up to 5mm (3/16”) in aluminium

l Modular output spindles

SPEED 850, 1200, 2350, 2850, 3750, 4600, 5250, 8000, 10000

TOOL TYPE POWER THRUST STROKE WEIGHT

HP N mm kg

AFDE200 0.34 320 90 10.1

AFDE400/ AFDE410 electric drive

l Comprehensive speed range 330-10000 rpm @ 50Hz, 400-11900 rpm @ 60Hz

l 0.33kW (0.44HP) and 0.75kW (1.00HP) options

l Capacity up to 10mm (3/8”) in aluminium or 8mm (5/16”) in mild steel

l Spindle sealed to IP64 standard

l Modular output spindles

SPEED 330, 550, 900, 1200, 1450, 1750, 2350, 2850, 3750, 4600, 5250, 8000, 10000

TOOL TYPE POWER THRUST STROKE WEIGHT

HP N mm kg

AFDE400 0.44 724 100 11.4

SPEED 330, 550, 900, 1200, 1450, 1750, 2350, 2850, 3750, 4600, 5250, 8000

AFDE410 1.00 724 100 12.4

AFDE600/ AFDE610/ AFDE620 electric drive

l 3 power ratings to give optimum power / thrust combination

l Heavy duty belts and pulley drive with integral belt tensioner

l Capacity up to 12mm (½”) in mild steel

l Spindle sealed to IP64 standard

l Modular output spindles

SPEED 330, 550, 900, 1200, 1450, 1750, 2350, 2850, 3750, 4600, 5250

TOOL TYPE POWER THRUST STROKE WEIGHT

HP N mm kg

AFDE600 0.44 1557 100 17.4

AFDE610 1.00 1557 100 18.4

AFDE620 1.47 1557 100 22

AFDE700/ AFDE710 electric drive

l Heavy duty drill unit

l Base mounted with cross key location

l Compact design

l Capacity up to 20mm (3/4”) in mild steel

l Hydraulic feed option available upon request to provide up to 7400N (1660 lbf) of thrust

SPEED 140, 280, 460, 950, 1400, 1900, 2850, 4750

TOOL TYPE POWER THRUST STROKE WEIGHT

HP N mm kg

AFDE700 2.00 2670 127 63

AFDE710 2.95 2670 127 63

5

Loading...

Loading...