INSTALLATION INSTRUCTIONS

TAG: T-183 DATE: 5/97

RETROFIT MVP™

METERING CARTRIDGES

THIS INSTALLATION INSTRUCTION SHEET APPLIES TO

EXPOSED PARTS FOR CONVERSION OF EXISTING

LAVATORY FITTING TO MVP™ METERING VALVE

THIS FITTING HAS BEEN SET TO COMPLY WITH THE U.S.

NATIONAL ENERGY POLICY ACT (1992) WHICH REQUIRES

METERING FAUCETS TO FLOW .25 GALLONS PER CYCLE

MAXIMUM AT 80 PSI. PRODUCTS CONFORM TO APPLICABLE ADA REQUIREMENTS (SEE TIMING ADJUSTMENTS).

IMPORTANT:

1. Read instructions carefully before installation.

2. Be sure supply lines are thoroughly flushed before

installation.

3. Clean chrome only with mild soap and water - no cleansers

or acids.

U.S. PATENT NO. 4,899,778 and NO. 4,991,819

CANADIAN PATENT NO. 2005319

1

2

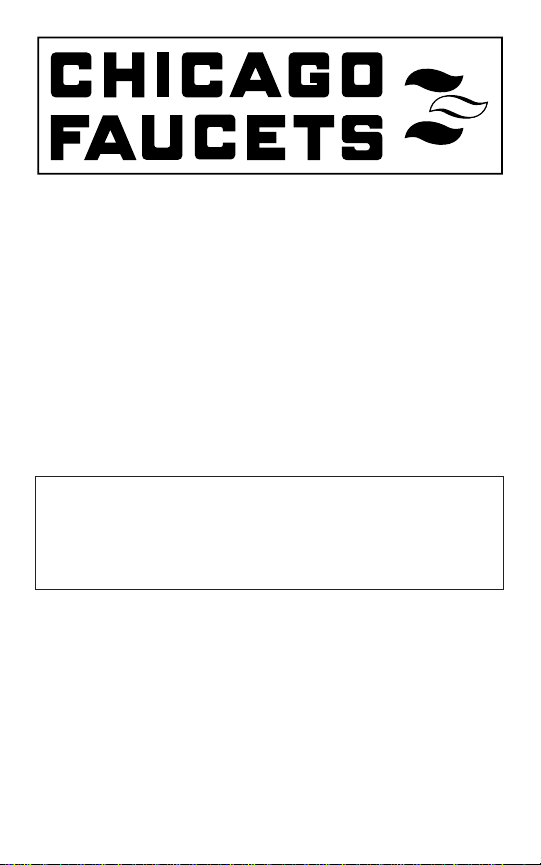

MOUNTING - FIT

RETROFIT FIT

(UNIT, ACTUATOR & HANDLE)

PART # 668-200K

ONE SET PER KIT

ONE SET PER KIT HANDLES INDEX KIT NO.

HOT 665 RKH

665 COLD 665 RKC

PUSH 665 RKP

HOT 669 RKH

669 COLD 669 RKC

PUSH 669 RKP

CHROME PLATED

FLANGE

#408-004 & RUBBER

WASHER #739-056.

THIS KIT IS REQUIRED

WHEN CONVERTING

TYPE I & II TO MVP

METERING UNITS.

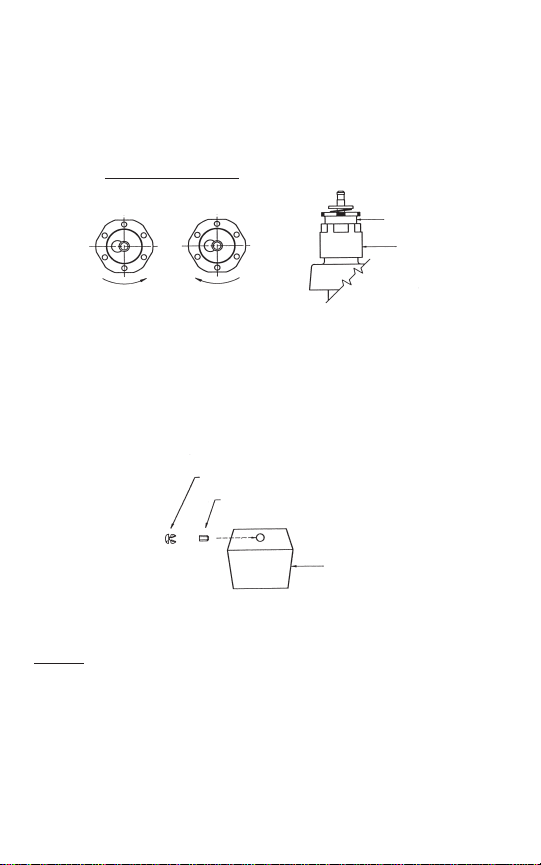

TYPE I

WIDESPREAD

TYPE II

WIDESPREAD

TYPE III

WIDESPREAD

CENTERSETS

BASIN COCKS

VALVE WITH EXPOSED

CAP NUT

VALVE WITH

SKIRTED HANDLE

VALVE WITH ESCUTCHEON

REQUIRES

REQUIRES

REQUIRES

MOUNTING

KIT

MOUNTING

KIT

UNIT

UNIT

UNIT

ACTUATOR

ACTUATOR

ACTUATOR

HANDLES

HANDLES

HANDLES

TYPE 665

TYPE 669

TYPE 665

TYPE 669

TYPE 665

TYPE 669

OR

OR

OR

FIGURE 1

TO INSTALL:

1. Turn off water at the supply stop(s).

2. Remove existing handles and units. Follow the chart on the

first page (Figure 1 ) to insure that the correct parts are being

used.

3. Flush supply lines to remove chips and dirt which can

become lodged in the seat washer and cause the faucet to

run on.

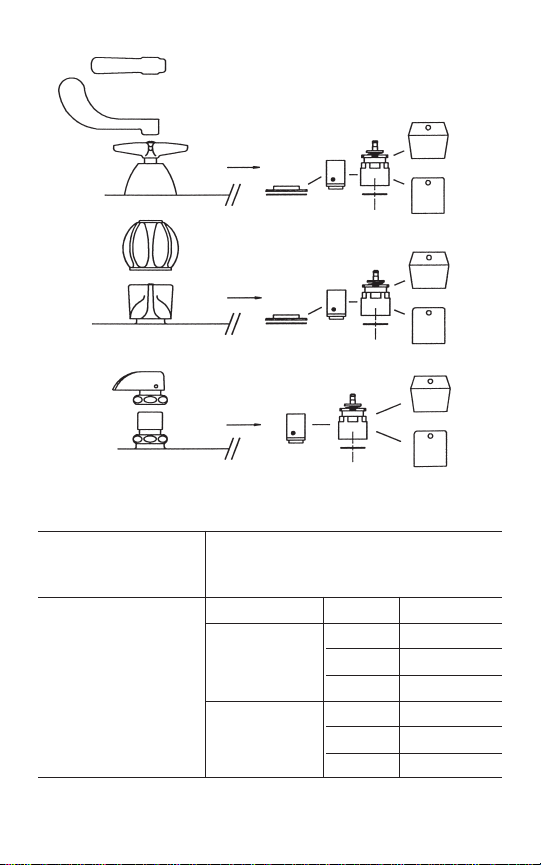

4. Inspect the seating surface inside the body and clean

thoroughly. If the seat is damaged (pitted or nicked) or if

heavy lime build-up has occurred, contact your nearest

Chicago Faucet representative for assistance. Failure to clean

up old seating surfaces can damage the new MVP™

cartridge and cause a dripping or

run-on situation. (Figure 2)

TROUBLE SHOOTING:

Accumulation of lime and/or dirt in

the cartridge can result in either short

or excessively long cycles. If either

occurs, remove cartridge and wash

with soap and water or a mild

solution of vinegar and water. If

continued problems are experienced,

contact your local representative for assistance.

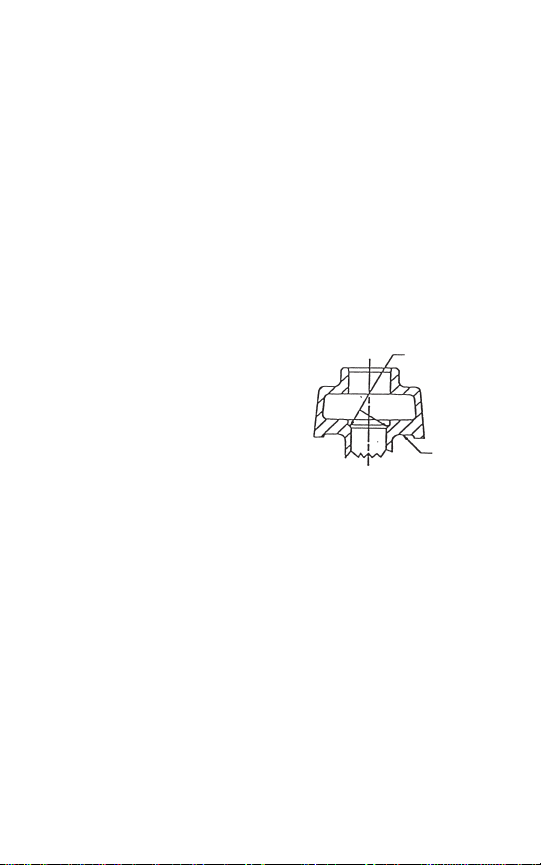

5. Insert the filter into the body and make sure it is completely

down and in place against the body seat. Then insert the

cartridge into the body. Make sure the cartridge is also

completely down and in place against the body seat

(Figure 3).

3

INSPECT

SEATING

AREA

TYPICAL

BODY

FIGURE 2

4

NOTE:

This cartridge is designed to be

used with the large filter enclosed. It is

possible when retrofitting existing fittings

that this filter cannot be used (especially

in type I and II fittings shown on Page

2). If no water flow occurs after Step

7, shut the stop off and disassemble

fitting to remove the larger drop-in style

filter. Replace it as shown with the small

filter enclosed.

IMPORTANT: NEVER USE BOTH FILTERS TOGETHER ON

THE SAME FITTING

6. Place the white cap sealing gasket into the actuator

assembly and screw the actuator assembly onto the body.

Tighten the actuator assembly onto the body to

approximately 20 ft. Ibs., (Hand tighten and give the actuator

assembly a 1/2 to 1 full turn with a wrench). (Figure 3)

7. Turn the water back on at the supply stop(s).

NOTE:

If leak occurs at cap gasket, remove gasket and inspect

it for damage and replace it if necessary. If the gasket is in good

condition, inspect the body surface for scratches or nicks and

clean up the surface by reaming if necessary.

TIMING ADJUSTMENT

:

These instructions are for the user to adjust the faucet to provide

a flow rate to meet the American Disability Act (ADA) regulations

which require 10 seconds running time for the water flow. For

ADA compliance follow these procedures:

NOTE:

Timing must be checked with the handle in place.

A) Purge the valve of air by pushing it completely open 4-8

times rapidly and then check the timing cycle .

B) Remove the handle with a 3/32” hex wrench.

ACTUATOR

ASSEMBLY

GASKET

CARTRIDGE

FILTER

TYPICAL BODY

OPTIONAL

(SEE NOTE)

FIGURE 3

5

E) Once cycle time is satisfactory, lock handle in place making

sure set screw is securely fastened on groove in stem.

(Figure 5) If a type 665 handle is used, remember to insert the

colored index button.

NOTE: A variation from cycle to cycle should be expected. It is

best to wait until hot water is available and the building as in use

before making final adjustments.

Some new installations may produce a slight closing noise. This

is normally the result of air trapped in the unit and the noise will

dissipate over time.

BUTTON

SET SCREW

665 HANDLE

FIGURE 5

DECREASE

TIME

INCREASE

TIME

FIGURE 4

HOW TO ADJUST

TOP VIEW

ADJUSTING NUT

ACTUATOR

C) Time is changed by rotating plastic serrated adjustment nut

with a pair of pliers. Raising nut (counter clockwise) shortens

time, lowering nut (clockwise) lengthens time.

(Figure 4)

D) After each adjustment, replace handle and check cycle time.

6

INSTRUCCIONES DE INSTALACION

ETIQUETA: T-183 FECHA: 5/97

CARTUCHOS DE MEDICION

DE MODIFICACION

RETROACTIVA MVP™

ESTE PLIEGO CON INSTRUCCIONES DE INSTALACION ES VALIDO

PARA LAS PIEZAS EXPUESTAS CON LA FINALIDAD DE EFECTUAR

LA CONVERSION DEL ACCESORIO EXISTENTE DE LAVABO A LA

VALVULA DE MEDICION MVP™

ESTE ACCESORIO HA SIDO AJUSTADO PARA CUMPLIR CON LA

LEY DE POLITICA ENERGETICA NACIONAL DE 1992 (NATIONAL

ENERGY POLICY ACT, 1992) QUE EXIGE QUE EL AGUA DE LOS

GRIFOS DE MEDICION FLUYA UN CUARTO DE GALON (0.94 LITRO)

POR CICLO MAXIMO A UNA PRESION DE 550 KPa (KILOPASCALS).

LOS PRODUCTOS CUMPLEN CON LOS REQUISITOS

CORRESPONDIENTES DE LA LEY DE CIUDADANOS INCAPACITADOS

(AMERICAN DISABILITY ACT, ADA) (VER LA SECCION "AJUSTE DE LA

TEMPORIZACION").

IMPORTANTE:

1. Lea cuidadosamente las instrucciones antes de la

instalación.

2. Asegúrese de que las tuberías de suministro sean lavadas

minuciosamente con abundancia de agua antes de la

instalación.

3. Limpie las piezas cromadas solamente con jabón suave y

agua - nunca con productos limpiadores o ácidos.

PATENTE ESTADOUNIDENSE No. 4.899.778 y No. 4.991.819

PATENTE CANADIENSE No. 2005319

7

KIT DE MONTAJE

KIT DE MODIFICACION RETROACTIVA

(UNIDAD, ACCIONADOR Y MANGO)

PIEZA # 668-200K

UN JUEGO POR CADA KIT

UN JUEGO POR MANGOS POSICIONADOR KIT No.

CADA KIT

CALIENTE

665 RKH

665 FRIO 665 RKC

EMPUJE 665 RKP

CALIENTE 669 RKH

669 FRIO 669 RKC

EMPUJE 669 RKP

REBORDE CROMADO

#408-004 & ARANDELA

DE CAUCHO #739-056.

ESTE KIT ES

NECESARIO CUANDO

SE CONVIERTEN

UNIDADES DEL TIPO I

& II EN UNIDADES DE

MEDICION MVP.

TIPO I

EXTENDIDO

TIPO II

EXTENDIDO

TIPO III LLAVES

EXTENDIDAS DE

PILETA CON

CENTROS

VALVULA CON

TUERCA TAPA

EXPUESTA

VALVULA CON MANGO

RIBETEADO

VALVULA CON ESCUDETE

REQUIERE

REQUIERE

REQUIERE

KIT DE

MONTAJE

KIT DE

MONTAJE

UNIDAD

UNIDAD

UNIDAD

ACCIONADOR

ACCIONADOR

ACCIONADOR

MANGOS

MANGOS

MANGOS

TIPO 665

TIPO 669

TIPO 665

TIPO 669

TIPO 665

TIPO 669

O

O

O

FIGURA 1

8

PARA INSTALAR:

1. Cierre el flujo de agua en la(s) llave(s) de paso del suministro.

2. Saque los mangos y las unidades existentes. Siga las indicaciones del

cuadro en la primera página (Figura 1) para asegurar que se estén

usando las piezas correctas.

3. Lave las tuberías de suministro con agua en abundancia para remover

los residuos y el sucio que puedan haberse alojado en la arandela del

asiento y que pueden hacer que el grifo bote agua continuamente.

4. Inspeccione la superficie de asentamiento dentro del cuerpo de la

válvula y límpiela minuciosamente. Si el asiento está dañado (corroído

o mellado) o si ha ocurrido una pesada acumulación de cal, póngase

en contacto con el representante de Chicago Faucet más cercano

para obtener asistencia. Si no se limpian completamente las viejas

superficies de asentamiento, es posible que se dañe el nuevo

cartucho MVP™ y se produzca una

situación de goteo o pérdida constante

de agua. (Figura 2)

CORRECCIÓN DE FALLAS:

La acumulación de cal y/o sucio en el

cartucho puede ocasionar ciclos cortos o

ciclos excesivamente largos. Si ocurre uno

de estos problemas en los ciclos, saque el

cartucho y lávelo con agua y jabón o una

solución suave de vinagre y agua. Si sigue

teniendo problemas continuamente, póngase en contacto con el

representante local de Chicago Faucet para obtener asistencia.

5. Inserte el filtro dentro del cuerpo y asegúrese de que el filtro esté

completamente abajo y en su sitio contra el asiento del cuerpo.

Seguidamente inserte el cartucho dentro del cuerpo. Asegúrese de

que el cartucho también esté

completamente abajo y en su sitio contra

el asiento del cuerpo (Figura 3).

NOT

A: Este cartucho está diseñado para ser

usado con el filtro grande que viene con la

unidad. Al retroadaptar los accesorios

existentes, es posible que no se pueda

usar este filtro (especialmente en los

accesorios del tipo I y del tipo II que se

muestran en la página 2). Si el agua no fluye

luego de completar el Paso 7, cierre la llave

de paso y desarme el accesorio para sacar

REVISE EL

AREA DEL

ASIENTO

CUERPO

TIPICO

FIGURA 2

CONJUNTO DEL

ACCIONADOR

EMPAQUETADURA

CARTUCHO

FILTRO

CUERPO TIPICO

OPCIONAL

(VER NOTA)

FIGURA 3

9

el filtro de mayor tamaño de estilo embutido. Reemplácelo como se

muestra con el filtro pequeño que viene con la unidad.

IMPORTANTE: NUNCA USE AMBOS FILTROS JUNTOS

EN EL MISMO ACCESORIO

6. Coloque la empaquetadura sellante de tapa blanca dentro del

conjunto del accionador y atornille el conjunto del accionador en el

cuerpo. Apriete el conjunto del accionador en el cuerpo a

aproximadamente 20 pies/libra (2.7 kilográmetros). (Apriete a mano y

déle al conjunto del accionador de media vuelta a una vuelta

completa con una llave.) (Figura 3)

7. Abra otra vez la(s) llave(s) de paso del suministro.

NOT

A: Si ocurre una fuga de agua en la empaquetadura de tapa, saque

la empaquetadura y revísela para detectar daños y reemplácela, de ser

necesario. Si la empaquetadura está en buen estado, revise la superficie

del cuerpo para detectar arañazos o mellas y limpie la superficie

escariándola, de ser necesario.

AJUSTE DE LA TEMPORIZACION:

El tiempo del ciclo viene

preajustado de la fábrica. Estas instrucciones tienen la finalidad de que el

usuario ajuste el grifo de tal manera que éste suministre un caudal de

agua que cumpla con las disposiciones reglamentarias de la Ley de

ciudadanos incapacitados (American Disability Act, ADA) que exigen un

tiempo de servicio (10) para el flujo de agua. Para cumplir con los

requisitos de la ADA, siga estos procedimientos:

NOT

A: La temporización debe revisarse con el mango en su lugar.

A) Elimine el aire que pueda haber en la válvula abriéndola

completamente 4-8 veces con rapidez y comprobando seguidamente

el ciclo de temporización.

B) Saque el mango con una llave hexagonal de 3/32”.

C) El tiempo se cambia girando la tuerca dentada plástica de ajuste de

color blanco con unas tenazas. Levantando la tuerca (haciéndola girar

en el sentido de rotación contrario al de las manecillas del reloj) se

acorta el tiempo; bajando la tuerca (haciéndola girar en el sentido de

las manecillas del reloj) se alarga el tiempo. (Figura 4)

10

D) Después de cada ajuste, vuelva a colocar el mango y compruebe el

tiempo del ciclo.

E) Una vez que el tiempo del ciclo sea satisfactorio, trabe el mango en

su sitio asegurándose de que el tornillo prisionero esté fijado

firmemente en la muesca en el vástago. (Figura 5) Si se usa un mango

de tipo 665, recuerde insertar el botón de posicionamiento de color.

NOTA: Cabe esperar que ocurra una variación de ciclo a ciclo. Es mejor

aguardar hasta que haya agua caliente disponible y el edificio esté

ocupado antes de efectuar los ajustes finales.

Algunas instalaciones nuevas pueden producir un ligero ruido al cerrar.

Esto es causado normalmente por el aire que quedó atrapado en la

unidad y este ruido desaparecerá con el paso del tiempo.

BOTON

TORNILLO PRISIONERO

MANGO 665

FIGURA 5

DISMINUIR

EL TIEMPO

AUMENTAR

EL TIEMPO

FIGURA 4

COMO AJUSTAR EL TIEMPO

VISTO DESDE ARRIBA

TUERCA DE

ACCIONADOR

INSTRUCTIONS D'INSTALLATION

NUMÉRO: T-183 DATE: 5/97

CARTOUCHES À AUTO-

FERMETURE MPV POUR

CONVERSION

LES INSTRUCTIONS D'INSTALLATION CI-APRÈS

S'APPLIQUENT À LA CONVERSION D'UNE ROBINETTERIE

DE LAVABO DÉJÀ EN PLACE AU

MOYEN D'UNE CARTOUCHE MVP™.

CETTE CARTOUCHE EST CONFORME À LA NATIONAL

ENERGY POLICY ACT (LOI AMÉRICAINE SUR LES

ÉCONOMIES D'ÉNERGIE) DE 1992, QUI STIPULE QUE LES

ROBINETS DOIVENT DÉBITER AU MAXIMUM 0,25 GALLON

PAR CYCLE À UNE PRESSION DE 550 KPa (KILOPASCALS).

CE PRODUIT EST CONFORME AUX EXIGENCES PERTINENTES DE L'AMERICAN DISABILITY ACT (LOI AMÉRI-CAINE

SUR LES INSTALLATIONS POUR PERSONNES HANDICAPÉES); VOIR LE RÉGLAGE DE DURÉE D'ÉCOULEMENT.

IMPORTANT:

1. Lire attentivement les instructions avant de procéder à

l'installation.

2. Rincer à fond toute la tuyauterie d'arrivée d'eau avant de

procéder à l'installation.

3. Utiliser uniquement un savon doux et de l'eau pour nettoyer

les surfaces chromées; ne pas utiliser de produits de

récurage ou d'acides.

BREVETS U.S Nos 4,899,778 ET 4,991,819

BREVET CANADIEN No 2005319

11

12

NÉCESSAIRE Nécessaire de conversion

DE MONTAGE (cartouche, actionneur et manette)

No CAT. 668-200K UN JEU PAR NÉCESSAIRE

Manettes Marquage No de catalogue

CHAUD 665 RKH

665 FROID 665 RKC

POUSSER 665 RKP

CHAUD 669 RKH

669 FROID 669 RKC

POUSSER 669 RKP

UN JEU PAR NÉCESSAIRE

BRIDE CHROMÉE

No 408-004

ET RONDELLE DE

CAOUTCHOUC No 739-056

CE NÉCESSAIRE EST

REQUIS POUR CONVERTIR

LES ROBINETS DE TYPE I

ET II EN ROBINETS À

AUTO-FERMETURE MVP.

ROBINETTERIE

DE TYPE I

GRANDE

LARGEUR

ROBINETTERIE

DE TYPE II

GRANDE

LARGEUR

ROBINETTERIE

DE TYPE III

GRANDE

LARGEUR À

MONTAGE

CENTRAL,

POUR LAVABO

ROBINET À

ÉCROU-CHAPEAU À

DÉCOUVERT

ROBINET AVEC

MANETTE À JUPE

ROBINET À ROSACE

ÉLÉMENTS

REQUIS:

ÉLÉMENTS

REQUIS:

ÉLÉMENTS

REQUIS:

NÉCESSAIRE

DE MONTAGE

NÉCESSAIRE

DE MONTAGE

CARTOUCHE

CARTOUCHE

CARTOUCHE

ACTIONNEUR

ACTIONNEUR

ACTIONNEUR

MANETTES

MANETTES

MANETTES

TYPE 665

TYPE 669

TYPE 665

TYPE 669

TYPE 665

TYPE 669

OU

OU

OU

FIGURE 1

POUR INSTALLER:

1. Fermer les robinets d'arrivée d'eau.

2. Enlever les manettes et autres pièces internes. Consulter le

tableau de la première page (Figure 1) pour être certain d'utiliser

les bonnes pièces.

3. Rincer la tuyauterie afin de chasser les débris et autres saletés

qui pourraient venir se loger sur le siège du robinet et l'empêcher

de bien fermer.

4. Examiner la surface d’assise à l'intérieur du corps de robinet et

la nettoyer méticuleusement. Si l’assise s’avère endommagée

(piqûres ou écailles), ou si elle présente une accumulation

excessive de calcaire, contacter le représentant Chicago Faucet

le plus proche pour lui demander son aide. Une assise

encrassée peut endommager la nouvelle cartouche MVP™ et

provoquer une fuite ou empêcher

la fermeture du robinet (Figure 2).

DEPANNAGE:

Toute accumulation de calcaire et/ou

de saletés dans la cartouche peut

écourter les cycles ou les prolonger

de façon excessive. Dans l’un et

l’autre cas, retirer la cartouche et la

laver a l’eau savonneuse, ou

additionnée d’une petite quantité de vinaigre. Si le problème

persiste, demander l’aide du représentant le plus proche.

5. Insérer bien à fond le filtre dans le

robinet; s'assurer qu'il est bien

appuyé sur le siège. Ensuite,

introduire la cartouche dans le

robinet; elle aussi doit être bien

appuyée sur le siège du robinet

(Figure 3).

Verifier la

surface

du siege

Corps de

robinet

(représentatif)

FIGURE 2

Actionneur

Joint d'étanchéité

Cartouche

Filtre

Corps de robinet

(représentatif)

Facultatif

(Voir la

remarque)

FIGURE 3

13

14

NOTE: Normalement, on utilise le plus grand des deux filtres fournis

avec la cartouche. Toutefois, dans le cas de certains robinets (surtout

de types I et II, voir page 2), il est possible que le grand filtre ne soit

pas utilisable. Si l'eau ne coule pas après l'étape 7, fermer les

robinets d'arrêt et démonter le robinet; retirer le grand filtre et le

remplacer par le petit filtre (Figure 3).

IMPORTANT: NE JAMAIS UTILISER LES DEUX FILTRES DANS LE

MÊME ROBINET.

6. Insérer le joint de chapeau blanc dans l'actionneur, puis visser

l'actionneur dans le robinet. Serrer l'actionneur à environ 20 lb-pi

(serrer d'abord à la main, puis visser de 1/2 à 1 tour à l'aide d'une

clé) (Figure 3).

7. Rétablir l'arrivée d'eau en ouvrant les robinets d'arrêt.

NOTE:

S'il y a une fuite au joint de chapeau, enlever le joint pour voir

s'il est endommagé et le remplacer si nécessaire. Si le joint est en

bon état, vérifier si la portée du corps du robinet est rayée ou

entaillée; rectifier la surface au besoin.

RÉGLAGE DE LA DURÉE D'ÉCOULEMENT

: La durée d'écoulement

est préréglée à l'usine. Les instructions suivantes permettent à

l'utilisateur d'obtenir une durée d'écoulement conforme à l'American

Disability Act (Loi américaine sur les installations pour personnes

handicapées), qui prescrit un écoulement de 10 secondes.

NOTE:

La manette doit être en place lorsqu'on vérifie la durée

d'écoulement.

A) Purger l'air de la cartouche en l'enfonçant complètement à

plusieurs reprises (de 4 à 8 fois). Vérifier ensuite le cycle

d'écoulement.

B) Enlever la manette à l'aide d'une clé hexagonal 3/32 po.

C) Pour modifier la durée d'écoulement, tourner l'écrou moleté de

réglage en plastique à l'aide d'une pince. En desserrant l'écrou

(sens anti-horaire), on réduit la durée d'écoulement; en serrant

l'écrou (sens horaire), on augmente la durée d'écoulement

(Figure 4).

15

D) Après chaque réglage, remettre la manette en place et vérifier la

durée d'écoulement.

E) Lorsque le réglage est satisfaisant, bloquer la manette en serrant

bien la vis de pression dans la rainure de la tige du robinet (Figure

5). Dans le cas d'une manette de type 665, ne pas oublier de

poser la coiffe indicatrice colorée.

NOTE: Des variations d'un cycle à l'autre sont possibles. Il est

préférable d'effectuer les derniers réglages lorsque l'eau chaude est

disponible et que le bâtiment est en service.

Un appareil neuf peut émettre un léger bruit à la fermeture, à cause

de l'air piégé dans la cartouche; ce bruit disparaîtra avec le temps.

COIFFE

VIS DE PRESSION

MANETTE 665

FIGURE 5

Pour diminuer

la durée

Pour augmenter

la durée

FIGURE 4

Réglage de durée d'écoulement -

Vue de dessus

Écrou de réglage

Actionneur

Loading...

Loading...