Chicago Faucet 625-AB Installation Manual

Pedal Valve Installation Instructions

General Installation Instructions and Maintenance for 625-ABCP, 625-SLOABCP, 625-LPABCP, 625-LPSLOABCP,

628-ABCP, 806-ABCP, 834-ABCP and 910-GCP

Overview

Chicago Faucets pedal valves feature cast brass bodies and precision cartridges for years of reliable operation.

Notice to the Installer

• Read this entire instruction sheet before installing to ensure proper installation.

• Installation must comply with local codes and ordinances.

Pressurized plumbing fixtures shall be installed in accordance with manufacturer’s recommendations. The supply piping to these devices shall

be securely anchored to the building structure to prevent installed device from moving unnecessarily when operated by the user. Care shall be

exercised when installing the device to prevent marring the exposed surface.

NOTE: The information in this manual is subject to change without notice.

Please leave this manual with the facility manager after completing the faucet installation. This document contains information necessary for

routine maintenance and servicing.

NOTE: Before installation, turn off water supplies to existing faucet and remove faucet if replacing. Clean faucet basin and clear away debris.

Flush all supply lines before connecting to faucet. Failure to do so can result in debris clogging the inlets and/or cartridges.

NOTE: Before installing a replacement cartridge flush lines completely.

Installation Instructions

1. At the time of installation, it is recommended that all pipes to the pedal box be thoroughly flushed. Failure to do so may result in foreign matter such

as line sediment or plumbing compounds clogging the by-pass of the dashpot or embedding in the seat and impairing operation of the cartridge.

2. Chicago Faucets pedal boxes are fully assembled at the factory and ready for operation. Installation is simply a matter of securely mounting the

product and connecting the water supplies.

3. Remove contents from packaging and read instructions thoroughly before installation.

4. Chicago Faucets pedal boxes are available in wall, floor, and shelf mount configurations. These are heavy commercial faucets and must be

mounted securely to a solid surface to prevent movement. They are all designed with a 1/4˝ diameter through-hole that has a countersunk

chamfer to accept common wood screws. It is strongly recommended that a 2˝ x 4˝ wood backing be used to provide a solid surface for the

wood screws to secure the fitting to the mounting surface.

5. Once the pedal box is securely mounted, the water supplies can be connected. All pedal boxes are designed with 1/2˝ NPT threaded female

inlets as a standard supply connection. For the outlet connections the 628 and 806 also have a 1/2˝ NPT threaded female outlet, while the 625

and 834 are designed with a 3/8˝ NPT threaded female outlet.

6. Once all inlet and outlet supplies are securely connected, the water can be turned on to check for leaks. Activate one or both pedals, depending

on the design, several times to insure that the product is operating properly.

7. The pedals on all pedal boxes must have sufficient clearance between the bottom of the pedal and the floor so that the cartridge can be

depressed fully. The 806 and 834 models have an additional pedal height adjustment screw, due to their long pedals, to aid in installation. Refer

to the specification sheet for your specific model for dimensional requirements.

General Maintenance

1. Your Chicago Faucets foot pedal valve is chrome plated to protect the brass construction material. The same plating is used for our rough (RCF)

or polished (CP) surfaces. With either finish, mild soap and water or mild cleaners approved for chrome plated surfaces should only be used. Do

not use products with acid ingredients. Using acid based products can cause discoloration or other damage to the finish.

2. Chicago Faucets pedal boxes are supplied with one of two cartridge types. The standard version activates when your foot depresses the pedal

and deactivates immediately when your foot leaves the pedal. The alternative closing feature is the “SLO” or slow closing cartridges. With

these cartridges the same method is used to activate the water, but when you remove your foot the water will continue to dispense for a predetermined period of time. The timing duration can be set to run up to 20 seconds. Please refer to instructions below.

3. Routine maintenance may be required periodically after installation to insure that your pedal box continues to operate properly.

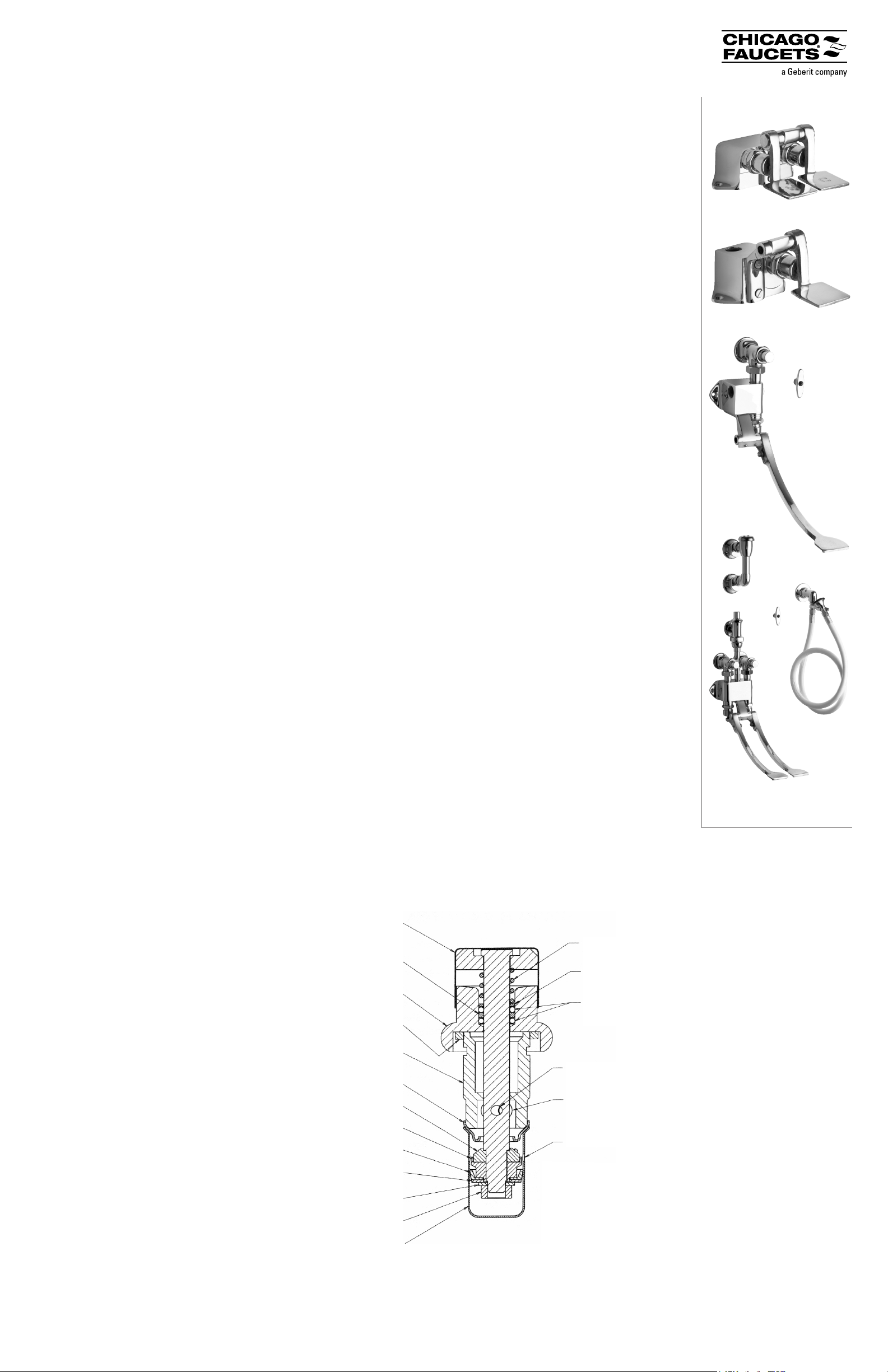

How to Repair a NAIAD Push Button

1. Loosen (319-003) Cap Nut with combination or flat wrench, remove cartridge. In some cases, the dashpot may remain in the body. When this

occurs, reach in the body cavity with your finger to remove.

2. Insert pin wrench (244-025) or 1/8˝ diameter pin through hole to keep stem from turning while removing or tightening (333-097) Stem Nut.

3. If leakage is occurring through spout, remove and replace (1-027) Seat or (244-006) Seat Washer. Also inspect (333-040) Cup Washer.

If leakage is around button assembly, remove button and stem sub-assembly from (319-003) Cap Nut and (433-042) or (433-046- one outlet

hole) Sleeve. Clean stem thoroughly and lubricate top half with light grease. Replace the packing arrangement of (2)-(319-140) O-Rings and

(1)-(319-035) Leather Washer.

4. To reassemble, place stem sub-assembly into (319-003) Cap Nut and (433-042) or (433-046) Sleeve. Then at lower end of cartridge starting

with (1-027) Seat, put remaining parts on, in order, as indicated in diagram below.

625-012K Button

and Stem Assembly

319-035 Leather Washer

395-018 Spring

319-012 Brass Washer

319-003 Cap Nut

1-043 Gasket

433-042 Sleeve/

433-046 Sleeve

1-027 Seat

244-006 Seat Washer

333-026 Retainer

333-040 Rubber Washer

333-039 Washer

1-031 Washer

333-097 Nut

333-075 Dashpot

319-140 O-Ring

Insert Pin in Hole to

Repair Unit

Outlet

Inlet

For additional technical assistance, call 800/TEC-TRUE (800-832-8783) or visit our website at chicagofaucets.com.

1

Pedal Valve Installation Instructions (continued)

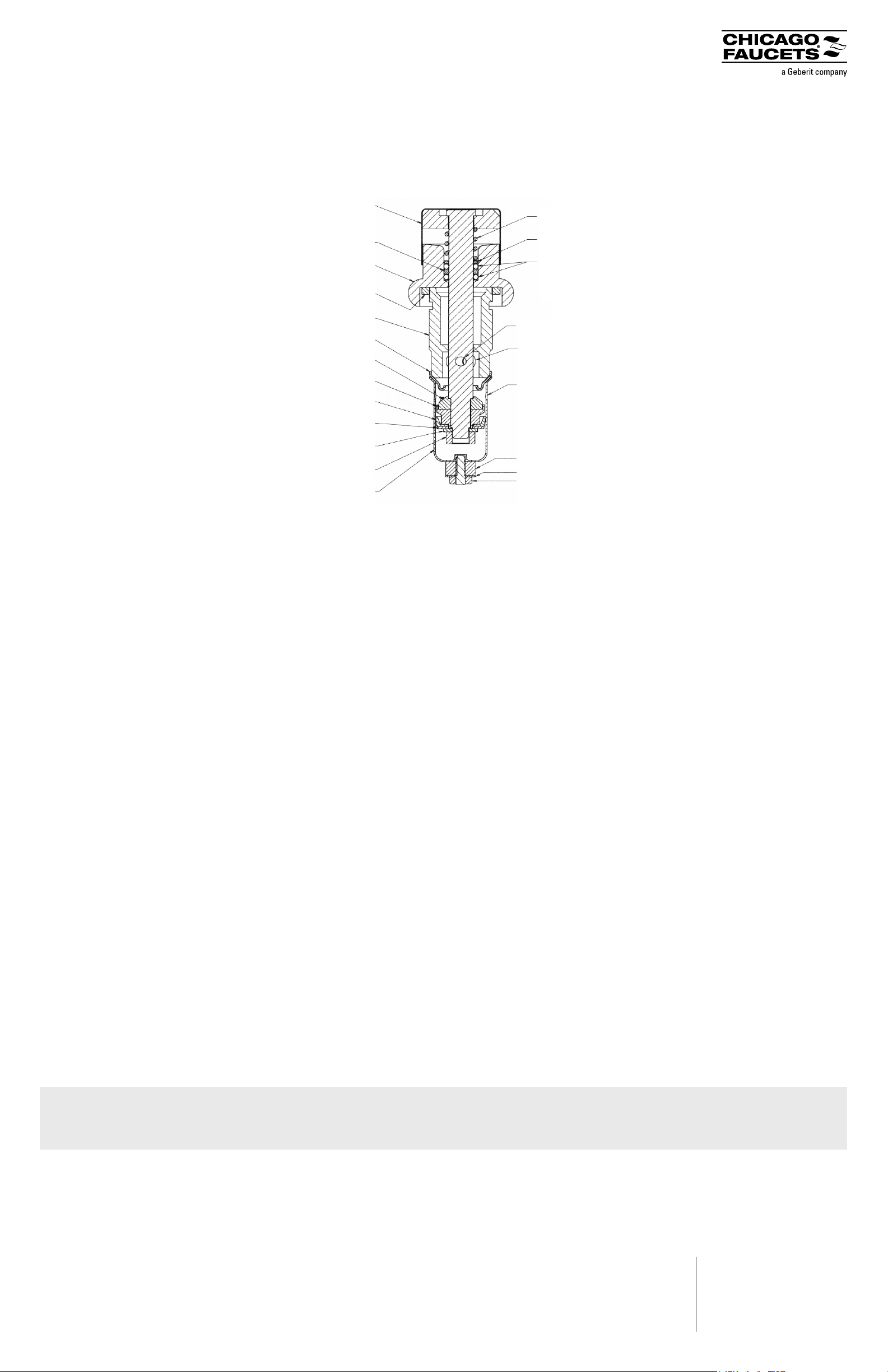

How to Adjust a NAIAD Cartridge Using a 333-073K Dashpot

1. On (333-073K) Dashpot used on pedal boxes where an adjustable closing feature is desired, this dashpot uses a black 333-027 Felt Washer,

333-028 Brass Washer and 333-052 Stainless Steel Nut on the lower end of dashpot, in lieu of the hole on other dashpots. Adjustment is

made by tightening the nut to increase the running time, or loosening nut to decrease running time.

2. After a period of service, variation may be noted in the flow time from the original setting. This indicates foreign matter has plugged the felt

washer and cleaning or replacing the washer is required, or (333-040) Cup Washer needs to be replaced.

625-012K Button

and Stem Assembly

395-018 Spring

319-035 Leather Washer

Cap Nut 319-003

319-012 Brass Washer

319-140 O-Ring

1-043 Gasket

433-042 Sleeve/

433-046 Sleeve

Insert Pin in Hole to Repair Unit

1-027 Seat

Outlet

244-006 Seat Washer

333-026 Retainer

Inlet

333-040 Rubber Washer

333-039 Washer

1-031 Washer

333-027 Felt Washer

333-097 Nut

333-028 Brass Washer

333-052 Stainless Steel Nut

333-073K Dashpot

Replacement Parts

1. Chicago Faucets has an extensive replacement parts program that promotes interchangeability and modularity for our products. For your convenience,

most parts are available individually or in an assembly. Refer to the specification sheet for your specific model for dimensional requirements.

Care and Maintenance

All Chicago Faucets ttings are designed and engineered to meet or exceed industry performance standards.

Care should be taken when cleaning this product. Do not use abrasive cleaners, chemicals, or solvents as they can result in surface damage.

2

© 2013 Chicago Faucet Company TAG-185 01/13

Use mild soap with warm water for cleaning and protecting the life of Chicago Faucets ttings.

For additional technical assistance, call 800/TEC-TRUE (800-832-8783) or visit our website at chicagofaucets.com.

CHICAGO FAUCETS LIMITED WARRANTY

TO WHOM DOES THIS WARRANTY APPLY? — The Company extends the following limited warranty to the original user only.

WHAT DOES THIS WARRANTY COVER AND HOW LONG DOES IT LAST?

This warranty covers the following Commercial Products:

LIFETIME FAUCET WARRANTY — The “Faucet,” dened as any metal cast, forged, stamped or formed portion of the Product, not including electronic or moving parts or other products separately covered by this Limited Warranty or water

restricting components or other components, is warranted against material manufacturing defects for the life of the Product.

FIVE YEAR FAUCET WARRANTY — Certain Products and portions of the Product are warranted against material manufacturing defects for a period of ve (5) years from the date of Product purchase. Products warranted against material

manufacturing defects for a period of ve (5) years from the date of Product purchase are referred to by the product numbers 42X, 43X, 15XX and E-Tronic™ - 4X, 5X, 6X, 7X, 8X and 9X. All zinc die cast portions of Product are warranted against

material manufacturing defects for a period of ve (5) years from the date of Product purchase.

THREE YEAR ELECTRONICS WARRANTY — Electronic components, including the solenoid, are warranted for three (3) years from the date of installation.

FIVE YEAR CARTRIDGE WARRANTY — The “Cartridge”, dened as the metal portion of any Product typically referred to by the product numbers containing

1-099, 1-100, 1-310, 377X, 217X and 274X, excluding any rubber or plastic components, is warranted against material manufacturing defects for a period of

ve (5) years from the date of Product purchase. All Cartridges included in the Company’s Single Control or Shower Products also are warranted against material manufacturing defects

for a period of ve (5) years from the date of Product purchase.

ONE YEAR FINISH WARRANTY – COMMERCIAL — For Products used in commercial applications, the nish of the Product is warranted against material manufacturing defects

for a period of one (1) year from the date of Product purchase.

OTHER WARRANTIES — All other Products not covered above are warranted against material manufacturing defects for a period of one (1) year from the date of Product purchase.

Other restrictions and limitations apply. For complete warranty details, call Chicago Faucets Customer Service at 847-803-5000 or visit chicagofaucets.com.

2

© 2013 Chicago Faucet Company TAG-625 06/13

The Chicago Faucet Company

2100 South Clearwater Drive

Des Plaines, IL 60018

Phone: 847/803-5000

Fax: 847/803-5454

Technical: 800/832-8783

www.chicagofaucets.com

Loading...

Loading...