Chicago Faucet 116.600.21.1 Installation Manual

Printed in USA © 0704

Tag # 317

Geberit V

Geberit V

ortex & V

ortex & V

ortex Max Diaphragm Flushometer V

ortex Max Diaphragm Flushometer V

alves

alves

INST

INST

ALLA

ALLA

TION INSTRUCTIONS

TION INSTRUCTIONS

Geberit Manufacturing, Inc.

1100 Boone Drive, Michigan City, IN 46360

Phone: (847) 803-5000 • Fax: (847) 298-3101

For Technical Assistance (800) TEC-TRUE (800-832-8783)

www.chicagofaucets.com

NOTE

Pressurized plumbing fixture flushing devices

(flushometers) shall be installed in accordance

with manufacturer’s recommendations. The

supply piping to these devices shall be securely

anchored to the building structure to prevent

installed device from unnecessary movement

when operated by the user. Care shall be exercised when installing the device to prevent marring the exposed significant surface.

Copyrights

© 2004 Geberit. All rights reserved. The information in this manual is subject to change without notice.

Notice to Installers

Please leave this manual with the facility manager after completing the flushometer installation. This document contains information necessary for routine maintenance and servicing.

TABLE OF CONTENTS

Product Overview...............................2

Vortex Flushometer Features............2

Vortex Max Flushometer Features....3

Prior to Installation.............................4

Tools Required for Installation..........4

Water Pressure and Volume..............4

Chrome Plating...................................4

Technical Support ..............................4

Safety Information..............................4

Rough-In Dimensions ........................5

Component Identification ..................6

Installation .......................................7-9

Service Procedures..........................10

Troubleshooting ..........................11-13

Warranty.......................................13-15

Las instrucciones en espanol ........17

Les instructions en francais ...........31

ADA Compliant

®

In compliance with ASSE 1037

U

P

C

C

Geberit Vortex Diaphragm Flushometer Valves

Installation & Maintenance Instructions

Printed in USA © 0704

Tag # 317

2

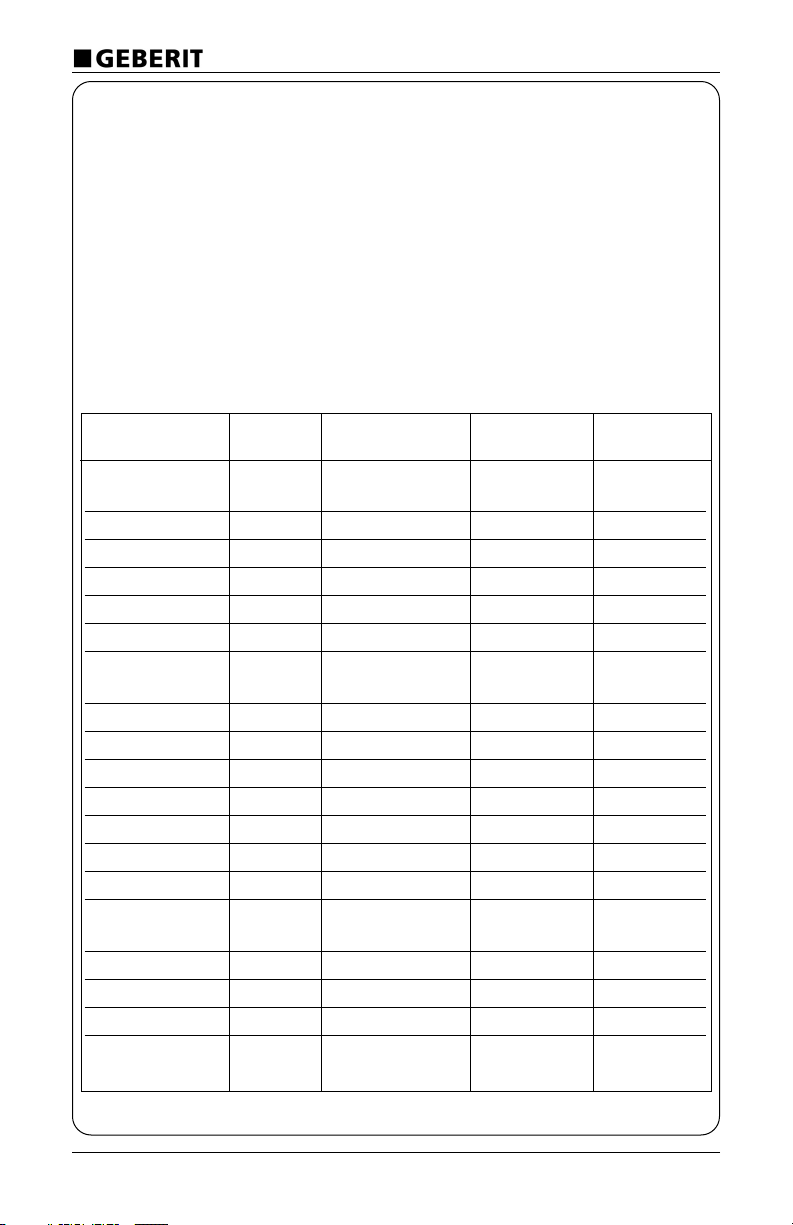

Vortex Diaphragm Flushometer Features

• Durable, proven diaphragm performance

• Accurate, low consumption flushing performance

• Vandal resistance built in, including set screw on stop cap

• Adjustable slip joint tailpiece

• Non-hold open handle

• ADA compliant

• Renewable main valve seat

• Available in a wide variety of configurations to meet most installation needs.

* Rough-in dimension is the vertical distance from CL of rough-in to top of china.

Product Overview

Geberit Vortex Flushometers are reliable, competitively priced manual flushometer valves

backed by a trusted name in plumbing products with a wealth of experience and excellent customer service.

Model Number Flush Rough-In Spud Type Stop Valve

Volume Dimension (in.)*

Urinal

116.600.21.1 1.0 GPF 11½ ¾ Top ¾ I.P.S.

116.601.21.1 1.0 GPF 11½ 1¼ Top 1 I.P.S.

116.602.21.1 1.5 GPF 11½ ¾ Top ¾ I.P.S.

116.603.21.1 1.0 GPF 11½ 1¼ Top 1 I.P.S.

116.604.21.1 1.0 GPF Valve Only None None

116.605.21.1 1.0 GPF Valve Only None None

Water Closet

116.620.21.1 1.6 GPF 11½ 1½ Top 1 I.P.S.

116.621.21.1 3.5 GPF 11½ 1½ Top 1 I.P.S.

116.622.21.1 1.6 GPF 24 1½ Top 1 I.P.S.

116.623.21.1 3.5 GPF 24 1½ Top 1 I.P.S.

116.624.21.1 1.6 GPF 11½ 1½ Back 1 I.P.S.

116.625.21.1 3.5 GPF 11½ 1½ Back 1 I.P.S.

116.626.21.1 1.6 GPF Valve Only None None

116.627.21.1 3.5 GPF Valve Only None None

Bedpan Washers

116.640.21.1 1.6 GPF 34 1½ Top 1 I.P.S.

116.641.21.1 3.5 GPF 34 1½ Top 1 I.P.S.

116.642.21.1 1.6 GPF Retrofit 1½ Top 1 I.P.S.

116.643.21.1 3.5 GPF Retrofit 1½ Top 1 I.P.S.

Service Sink

116.660.21.1 4.5 GPF 24 1½ Top 1 I.P.S.

Geberit Vortex Diaphragm Flushometer Valves

Installation & Maintenance Instructions

Printed in USA © 0704

Tag # 317

3

* Rough-in dimension is the vertical distance from CL of rough-in to top of china.

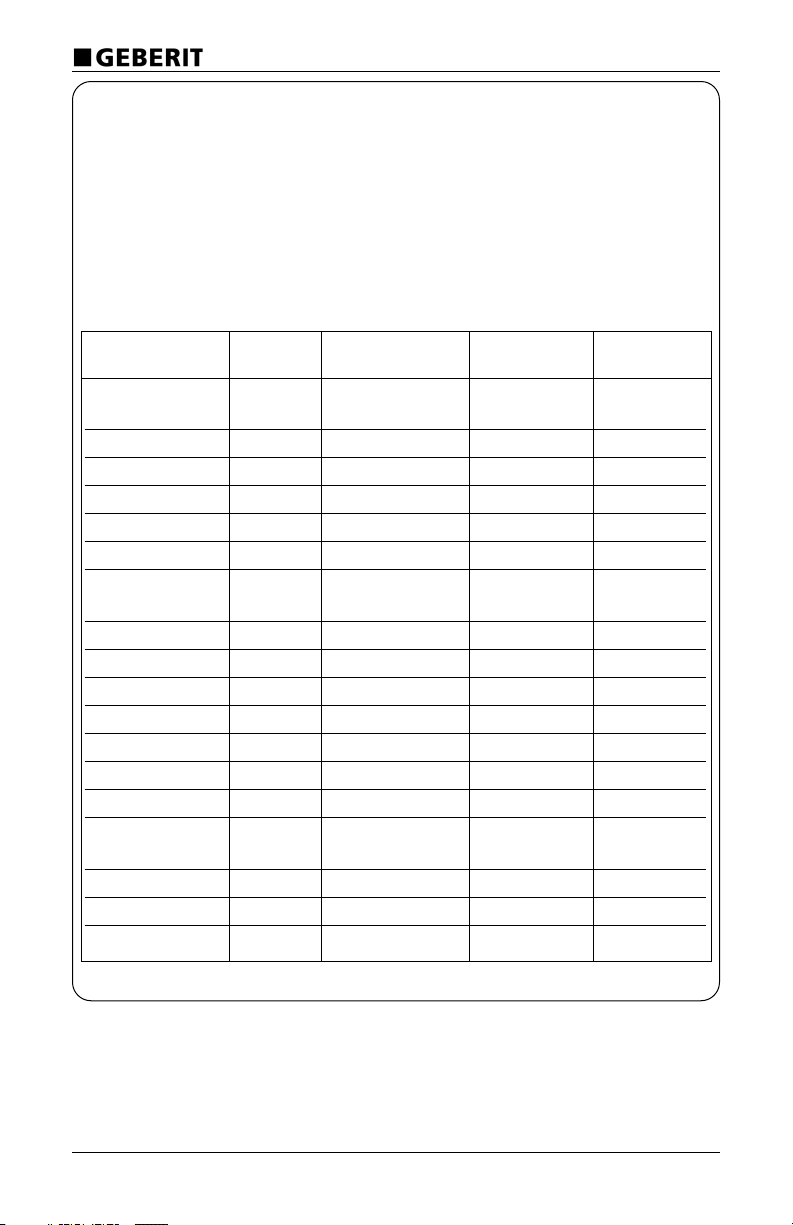

Vortex Max Diaphragm Flushometer Features

• High performance diaphragm performance with self cleaning orifice

• Stainless steel particulate filter at inlet

• Accurate, low consumption flushing performance

• Vandal resistance built in, including set screw on stop cap

• Adjustable slip joint tailpiece

• Non-hold open handle

• ADA compliant

• Renewable main valve seat

• Available in a wide variety of configurations to meet most installation needs

Model Number Flush Rough-In Spud Type Stop Valve

Volume Dimension (in.)*

Urinal

116.800.21.1 1.0 GPF 11½ ¾ Top ¾ I.P.S.

116.801.21.1 1.0 GPF 11½ 1¼ Top 1 I.P.S.

116.802.21.1 1.5 GPF 11½ ¾ Top ¾ I.P.S.

116.803.21.1 1.5 GPF 11½ 1¼ Top 1 I.P.S.

116.804.21.1 1.0 GPF Valve Only None None

116.805.21.1 1.5 GPF Valve Only None None

Water Closet

116.820.21.1 1.6 GPF 11½ 1½ Top 1 I.P.S.

116.821.21.1 3.5 GPF 11½ 1½ Top 1 I.P.S.

116.822.21.1 1.6 GPF 24 1½ Top 1 I.P.S.

116.823.21.1 3.5 GPF 24 1½ Top 1 I.P.S.

116.824.21.1 1.6 GPF 11½ 1½ Back 1 I.P.S.

116.825.21.1 3.5 GPF 11½ 1½ Back 1 I.P.S.

116.826.21.1 1.6 GPF Valve Only None None

116.827.21.1 3.5 GPF Valve Only None None

Bedpan Washers

116.840.21.1 1.6 GPF 34 1½ Top 1 I.P.S.

116.841.21.1 3.5 GPF 34 1½ Top 1 I.P.S.

116.842.21.1 1.6 GPF Retrofit 1½ Top 1 I.P.S.

116.843.21.1 3.5 GPF Retrofit 1½ Top 1 I.P.S.

Geberit Vortex Diaphragm Flushometer Valves

Installation & Maintenance Instructions

Printed in USA © 0704

Tag # 317

4

Prior To Installation

Before installing the flushometer, be sure

the following items are properly installed:

• Urinal fixture

• Drain line

• Water supply line

Tools Required for Installation

• Slotted screwdriver

• Standard box wrenches

• Smooth jawed adjustable wrench or

Chicago Faucet Quaturn wrench.

Water Pressure and Volume

Geberit valves require a minimum operating pressure of 10 psi while flushing. All

plumbing fixtures demand at least 10 psi,

so if this minimum requirement is met, the

valve should function properly.

In addition to pressure, volume requirements must be met to secure an adequate

syphon. Most toilets require a

minimum flow rate of 30 gpm. The lower

the pressure, the larger the piping must be

to supply the minimum flow.

Geberit valves are designed to operate at

water pressure up to 100 psi. Ideally, pressures should range between 30-60 psi. At

pressures of 80 psi and above, we recommend the use of pressure reducing valves

in supply lines. At higher pressures,

splashing is inevitable, noise is increased

and the life span of all plumbing brass is

reduced.

It is recommended that air chambers

and/or water hammer arrestors be

installed with flush valves. They should be

installed as close to the fixture as possible.

Air chambers are helpful in supplying a

reservoir of water in the event of sudden

pressure drops.

Chrome Plating

If installation is into new construction, we

recommend protecting all chrome surfaces from acid or cleaning fluid that can

discolor chrome, until the building is occupied. This will help to protect the surface

from damage.

Do not use serrated-jaw wrenches

on chrome surfaces. Use a smoothjawed adjustable wrench or Chicago

Faucet Quaturn wrench.

Technical Support

For additional technical assistance, visit

our website at: www.us.geberit.com, or

call:

1-800-TEC-TRUE (1-800-832-8783)

IMPORTANT! Installations may be performed at different times of construction by different individuals. For this

reason, these instructions should be

left on-site with the facility or maintenance manager.

Safety Information

• Read this entire instruction sheet to

ensure proper installation.

• Compliance and conformity to local

codes and ordinances is the

responsibility of the installer.

Flush all the water supply lines

before making connections.

CAUTION indicates a practice or

condition that MAY result in damage to

the equipment if the instruction or

notice is ignored.

Geberit Vortex Diaphragm Flushometer Valves

Installation & Maintenance Instructions

Printed in USA © 0704

Tag # 317

5

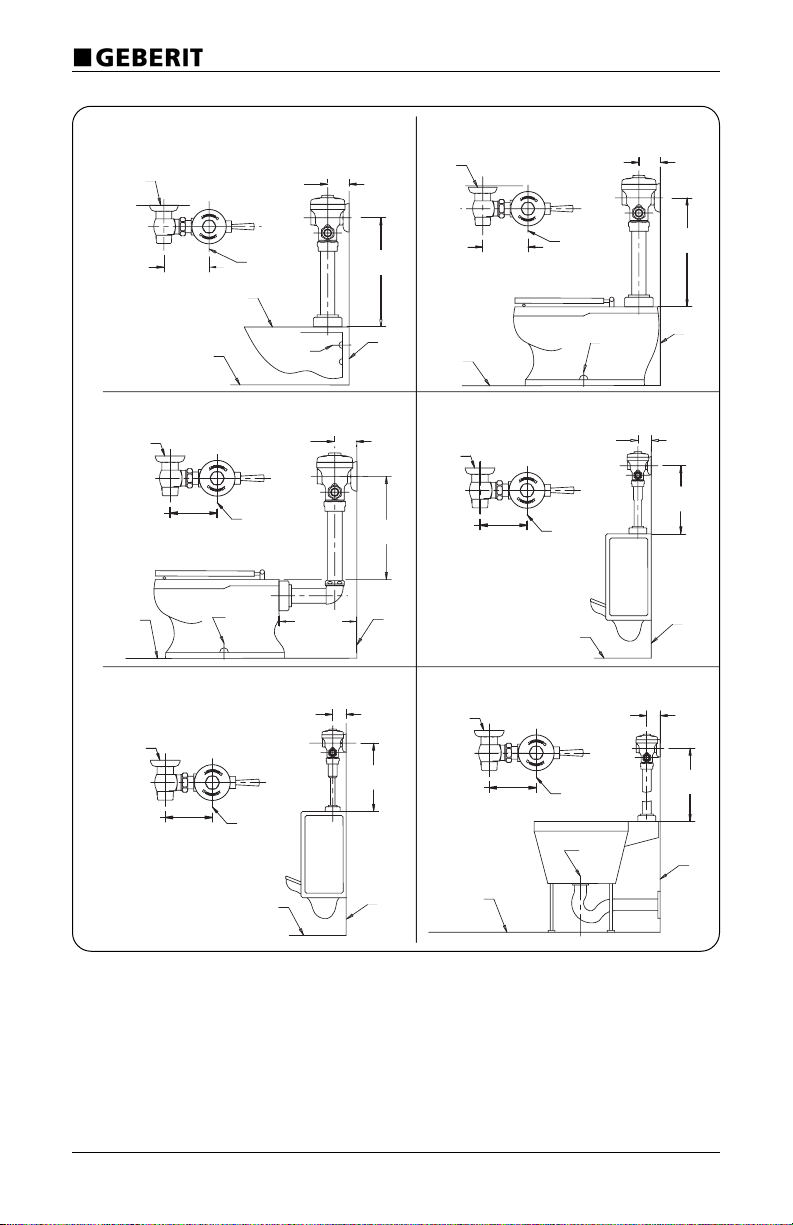

po MIN.

[57mm]

2-1/4

" MIN.

[57mm]

2-1/4

MIN.

[57mm]

2-1/4 po

MIN.

[57mm]

2-1/4 po

11-1/2 po

[292mm]

6-1/2 po

MIN.

[165mm]

po

[292mm]

11-1/2

[121mm]

4-3/4 po

[121mm]

4-3/4"

24"

[610mm]

"

[292mm]

11-1/2

" MIN.

[57mm]

2-1/4

[292mm]

11-1/2 po

[121mm]

4-3/4 po

" MIN.

[57mm]

2-1/4

24 "

[610mm]

MODÈLE 116.620.21.1, 116.820.21.1 - 1.6 GPF (6.0 LPF)

MODÈLE 116.621.21.1, 116.821.21.1 - 3.5 GPF (13.2 LPF)

MODEL 116.622.21.1, 116.822.21.1 - 1.6 GPF (6.0 LPF)

MODEL 116.623.21.1, 116.823.21.1 - 3.5 GPF (13.2 LPF)

MODÈLE 116.624.21.1, 116.824.21.1 - 1.6 GPF (6.0 LPF)

MODÈLE 116.625.21.1, 116.825.21.1 - 3.5 GPF (13.2 LPF)

MODEL 116.601.21.1, 116.801.21.1 - 1.0 GPF (3.8 LPF)

MODEL 116.603.21.1, 116.803.21.1 - 1.5 GPF (5.7 LPF)

MODÈLE 116.600.21.1, 116.800.21.1 - 1.0 GPF (3.8 LPF)

MODÈLE 116.602.21.1, 116.802.21.1 - 1.5 GPF (5.7 LPF)

MODEL 116.660.21.1 - 4.5 GPF (17.0 LPF)

N.C. DE

L'APPAREIL

SANITAIRE

C/L OF

FIXTURE

FIN.

FLOOR

C/L OF

WASTE

MUR FINI

SOL FINI

SOL FINI

N.C. DE

VIDANGE

N.C. DE L'APPAREIL

SANITAIRE

VIDANGE À FIXATION MURALE

MUR FINI

SOL FINI

ALIMENTATION

1" IPS

FIN.

WALL

1" IPS

SUPPLY

FIN.

WALL

FIN.

FLOOR

MUR

FINI

ALIMENTATION

1" IPS

FIN.

WALL

FIN.

FLOOR

C/L OF

WASTE

"

[121mm]

4-3/4

C/L

OF FIXTURE

1" IPS

SUPPLY

[121mm]

4-3/4 po

N.C. DE

VIDANGE

3/4" IPS

SUPPLY

"

[121mm]

4-3/4

C/L

OF FIXTURE

1" IPS

SUPPLY

N.C. DE

VIDANGE

ROUGH-IN DIMENSIONS (INCHES/MILLIMETERS)