Chicago Faucet 404-V1000E66AB, 1003 Repair Guide

Cartridge

Maintenance/Repair Guide

Introduction

hank you for choosing Chicago Faucets! All Chicago Faucet products are carefully assembled and tested to

T

insure the highest quality in the plumbing industry. We are proud to offer you a product that will provide years of

dependable, reliable service.

The Maintenance and Repair Guide is intended to provide you, as a customer, with a step-by-step procedure for

replacing or renewing our most popular cartridges. These procedures are limited to minor problems that are the

result of normal wear and not intended to cover repairs that are the result of damage caused by abuse or vandalism.

Ceramic Cartridge Replacement 3

Renewing Quaturn™and Slow Compression Operating Cartridges 4

Renewing KLO-SELF Cartridges 5

Timing Adjustment of MVP™Metering Valves 6

Renewing MVP Metering Valves 7

NAIAD™Push Button Adjustment 8

Renewing NAIAD Cartridges 9

NAIAD Oscillating Cartridge Adjustment 10

Repair NAIAD Oscillating and Dashpot Cartridges 11

Replacement Cartridge Model Numbers 12

Replacement Cartridges for ECAST®Products 13

Repair Kits 14 - 15

2

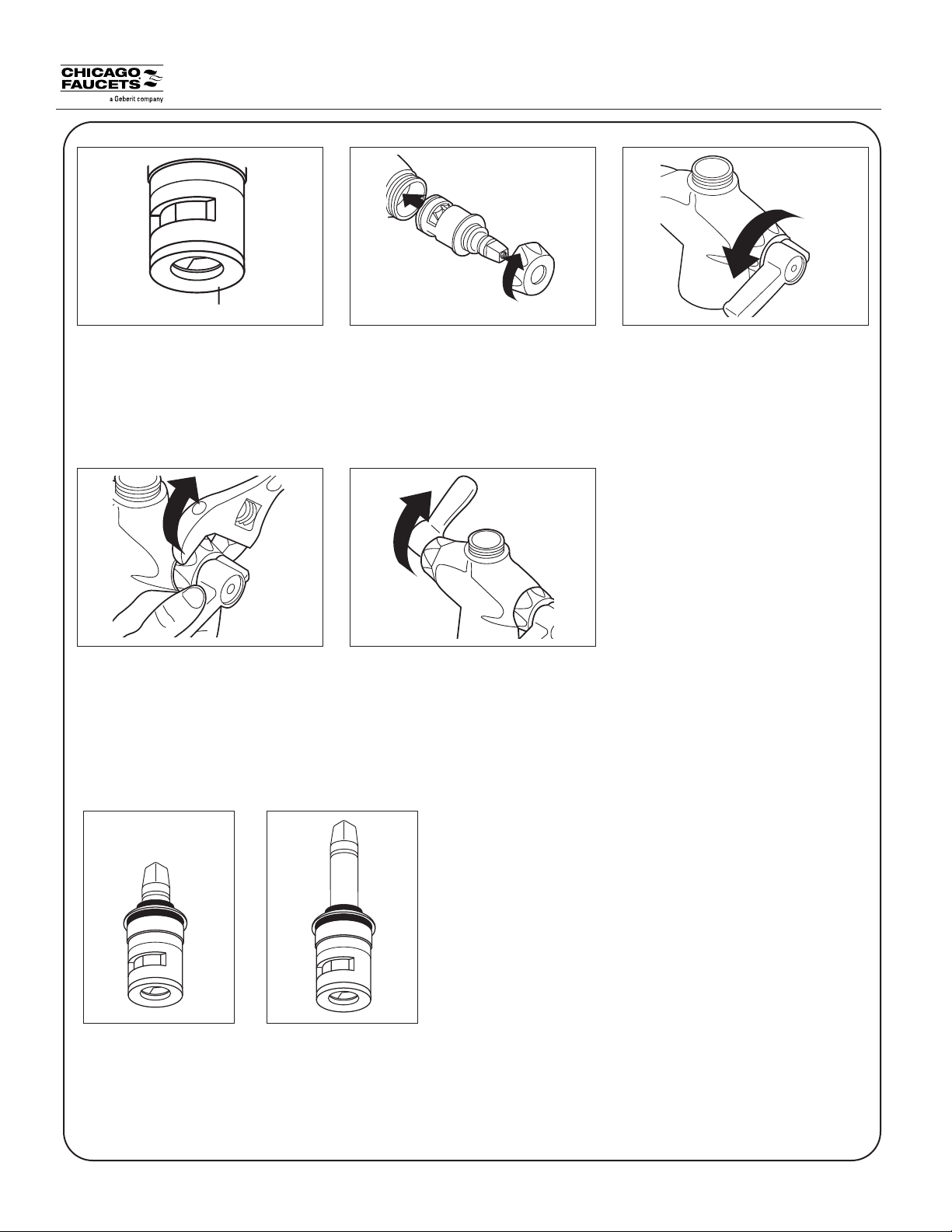

Stem Identification

olor-coded seat

C

Installation of Ceramic Cartridge

Ensure cartridges are in the closed

position before installing into valve body.

Cartridges feature color-coded seats.

Blue seat on cold cartridge, red seat on

hot cartridge.

Step 3 Using handle to maintain stem

position, fully tighten right cap nut to 20

to 27 ft. lb. torque.

Ceramic Operating Cartridges

Step 1 Push each cartridge into valve

body until it seats. Add cap nuts and

hand tighten. Add handles.

Step 4 Move LEFT handle (without

moving cartridge) to the open position

and fully tighten right cap nut to 20 to

27 ft. lb. torque. Return handle to

closed position.

Step 2 Rotate RIGHT handle (and

cartridge) counter clockwise to the

desired closed position.

Short Stem

No. 1-100XKJKNF

Left Hand Cartridge

No. 1-099XKJKNF

Right Hand Cartridge

Long Stem

No. 377-XKLHJKNF

Left Hand Cartridge

No. 377-XKRHJKNF

Right Hand Cartridge

Note: No replacement parts for ceramic cartridges,

sold only as complete assembly.

3

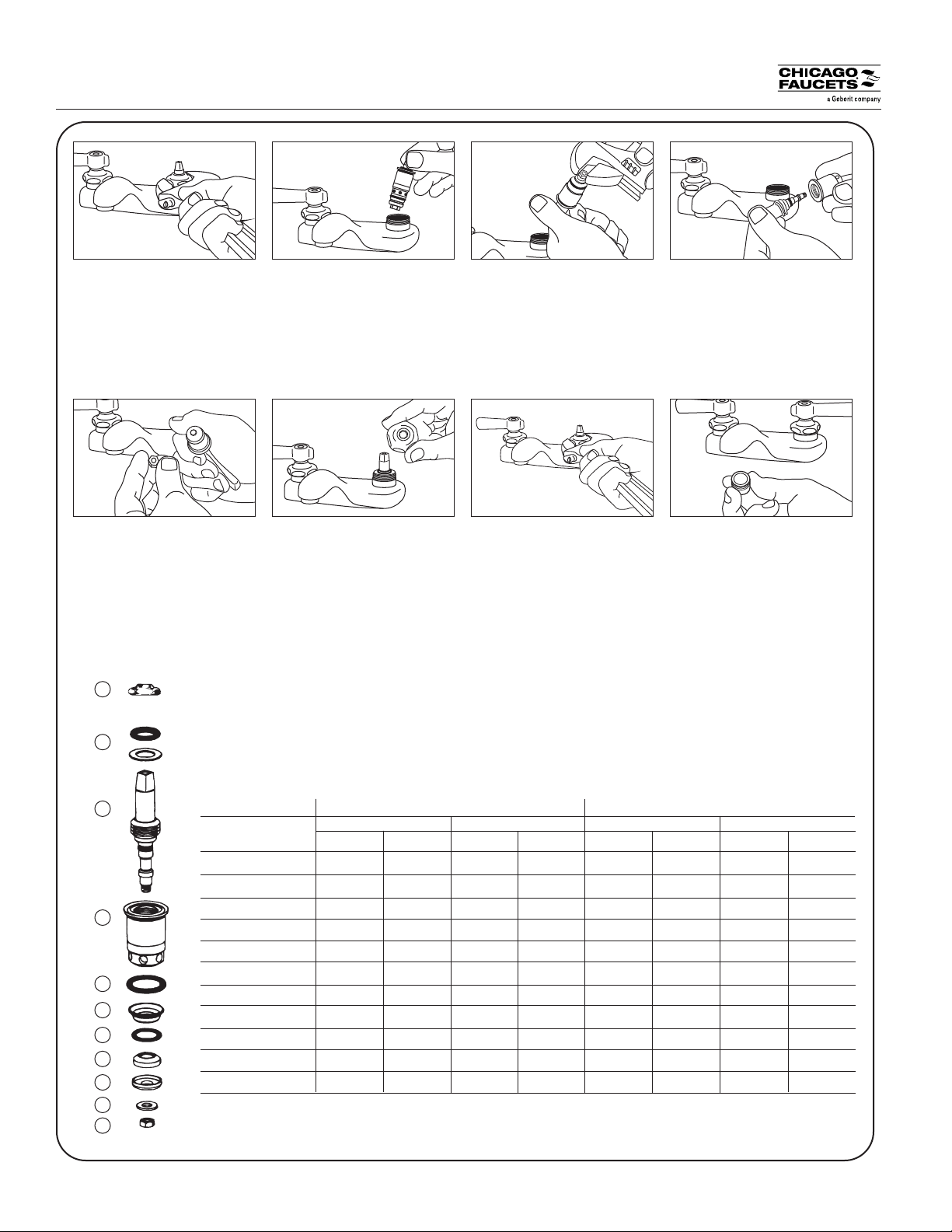

Renewing "XT" Quaturn™or Slow Compression Cartridges

STEP 1 - Turn off water at stop

or main valve. Remove handle

assembly and with flat face

wrench, remove cap nut (A).

STEP 5 - Reassemble sleeve

(D) on lightly lubricated stem (C).

With new parts add seat (F)

O-Ring (G) seat washer (H)

retainer (I) and washer (J) on

stem (C) and screw nut tightly

on stem.

A

“XT” TYPE CARTRIDGES

STEP 2 - Remove cartridge

from faucet. Flush out any rust

or chips that may be in body.

DO NOT use file or abrasives to

clean out body.

STEP 6 - Reposition washer

and O-Ring (B) on stem (C) add

to sleeve (D). Replace cartridge

in faucet.

STEP 3 - Unscrew stem nut (K)

at the bottom of the cartridge

with a flat wrench using a handle

as lever to assist removal.

STEP 7 - Replace Cap Nut (A)

and partially tighten. Replace

handle and rotate cartridge in

the direction of closing until the

cartridge is in the desired position

for convenient operation. Remove

handle. Lock cartridge in place

by securely tightening Cap Nut

(A) to 20 - 27 ft. lbs torque.

STEP 4 - Turn sleeve (D) off

stem (C) by holding handle and

turn sleeve by hand. As sleeve

is removed from stem, seat (F)

O-Ring (G) seat washer (H)

retainer (I) and washer (J) will be

forced off the stem.

STEP 8 - Turn water on at main

valve or stop. Remove aerator.

Turn faucet on to “full” allowing

sediment to flush from lines and

replace aerator cartridge.

B

PARTS LIST - Those parts listed in the “Description” column below that are marked with an asterisk (*) are parts that are

recommended for replacement when renewing these operating cartridges. Other parts not marked may require replacement

depending on the amount of wear they have received and their condition when examined.

C

Exposed Cap Concealed Cap Exposed Cap Concealed Cap

Description 1-009XTJKNF 1-100XTJKNF 377-XTRHJKNF 377-XTLHJKNF 217-XTLHJKNF 217-XTRHJKNF 274-XTLHJKNF 274-XTRHJKNF

A. Cap

B. Packing Assembly* 93-131JKNF 93-131JKNF 93-131JKNF 93-131JKNF 93-131JKNF 93-131JKNF 93-131JKNF 93-131JKNF

D

E

F

G

H

I

C. Stem Assy. w/ O-Ring 1-311KJKBNF 1-310KJKBNF 274-110KJKBNF 274-111KJKBNF 1-314KJKBNF 1-315KJKBNF 274-112KJKBNF 274-115KJKBNF

D. Sleeve 2-329JKRBF 2-328JKRBF 2-329JKRBF 2-328JKRBF 317-102JKRBF 317-103JKRBF 317-102JKRBF 317-103JKRBF

E. O-Ring 2-043JKNF 2-043JKNF 2-043JKNF 2-043JKNF 2-043JKNF 2-043JKNF 2-043JKNF 2-043JKNF

F. Seat* 1-327JKNF 1-327JKNF 1-327JKNF 1-327JKNF 1-327JKNF 1-327JKNF 1-327JKNF 1-327JKNF

G. O-Ring 1-328JKNF 1-328JKNF 1-328JKNF 1-328JKNF 1-328JKNF 1-328JKNF 1-328JKNF 1-328JKNF

H. Seat Washer* 1-021JKNF 1-021JKNF 1-021JKNF 1-021JKNF 1-021JKNF 1-021JKNF 1-021JKNF 1-021JKNF

I. Retainer 1-022JKNF 1-022JKNF 1-022JKNF 1-022JKNF 1-022JKNF 1-022JKNF 1-022JKNF 1-022JKNF

J. Washer 1-031JKNF 1-031JKNF 1-031JKNF 1-031JKNF 1-031JKNF 1-031JKNF 1-031JKNF 1-031JKNF

K. Nut 333-097JKNF 333-097JKNF 333-097JKNF 333-097JKNF 333-097JKNF 333-097JKNF 333-097JKNF 333-097JKNF

1-214JKCP 1-214JKCP

Quaturn Cartridges Slow Compression Cartridges

274-004JKRBF 274-004JKRBF 1-214JKCP 1-214JKCP 274-004JKRBF 274-004JKRBF

J

K

4

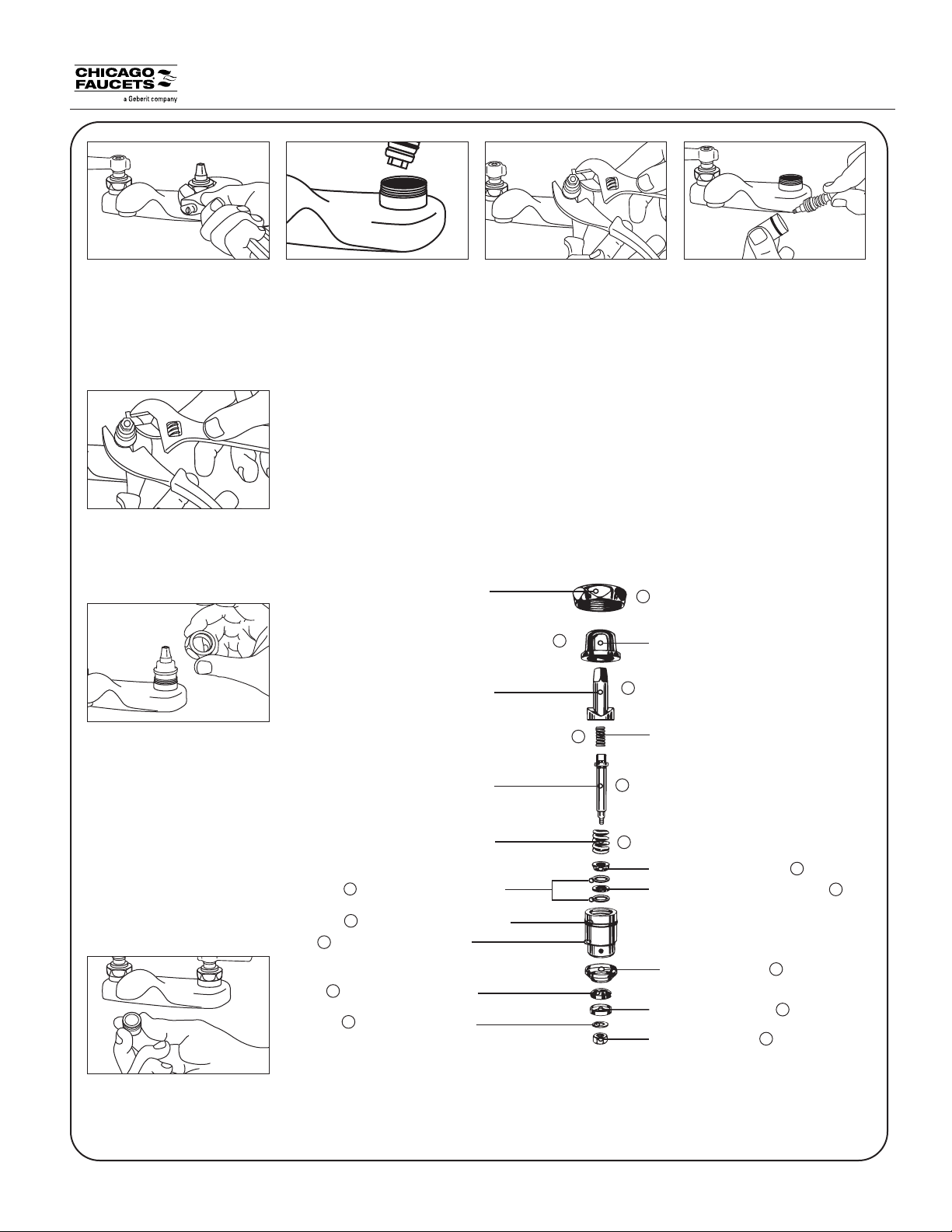

STEP 1 - Turn off water at stop

or main valve. Remove handle,

loosen cap nut (A) with flat faced

wrench and remove upper parts

of cartridge consisting of stem

(C), bonnet (B) and spring (D).

STEP 5 - Replace Monel seat

(L), seat washer (M), retainer (N),

cup washer (O), and tighten nut

(P) securely.

STEP 2 - With pliers, grab the

cartridge stem and pull up,

removing it from the body.

Renewing KLO-SELF Cartridges

TE

STEP 3 - Holding the flat portion

of plunger (E) remove stem nut

(P). After stem nut is removed,

remove washer (O), retainer (N)

seat washer (M) and Monel seat

(L) by tapping bottom of plunger

until parts are loosened. Now,

remove O-Rings (H), leather

packing (I), gland (G) and spring

(F) from sleeve (K).

826-XJKNF Parts Overview

S

n

a

ma

u

L

n

a

(G

-R

O

e

h

t

be

n

a

u

pl

a

e

l

ease b

r

g

inser

y

b

d

) o

t

d

y h

w

n

t

l

r

p

l

l

h

4

P

me

i

a

a

c

i

a

l

p

n

s (H) ma

g

n

i

h

t

a

e

n

e

e

a

e

.

r

ge

p

r

e

ted

- T

o

ve

e

t

e

c

u

l

e

h

t

L

a

into

b

p

n

r

h

t

e

u

efo

e

r

o

e

r

fo

r

-u

t

l

i

u

g

n

u

l

n

i

r

sp

.

r

e

g

k

c

pa

m.

e

c

pa

r

a

c

i

br

g

n

i

k

c

e the p

r

the sleev

a

ma

n

g

i

n

o

p

r

su

r

e

) a

(F

g

a

l

p

e

R

su

g

n

i

k

s

i

g

n

i

O

e

d

i

l

S

on

g

n

i

k

-R

O

e

t

a

h

t

i

w

lung

t

a

h

t

r

e

t

t

s.

t

r

a

p

(E)

e

c

fa

d

n

a

l

g

d

n

)

(2

e

h

t

e

c

t

a

h

t

e

r

d

e

c

a

pl

s

g

n

i

-R

e

h

t

d

n

s a

g

n

i

t

h

g

i

l

is

er

n

a

e

l

c

,

e

l

mb

sse

e (K).

STEP 6 - Replace O-Ring (J) with

new O-Ring, inserting into groove

on the sleeve (K). Lubricate outside

of O-Ring, stem (C) and inside of

bonnet (B). Lubricate spring (D)

and insert into stem. Assemble

upper parts of cartridge (B,C,D)

and tighten nut (A) to faucet body

sufficiently (25 - 32 ft. lbs.) to

insure that metal to metal contact

of lower seat (L) in faucet body.

Bonnet and sleeve must also

make metal to metal contact.

Replace handle.

823-004JKCP - Nut

585-001JKBNF - Stem

823-001JKNF - Plunger

823-010JKNF - Spring

H

319-140JKNF - “O” Rings

J

823-015JKNF - “O” Ring

K

823-002JKRBF - Sleeve

M

244-006JKNF - Washer

O

1-031JKNF - Washer

A

B

D

826-101JKRCF - Bonnet

C

823-013JKNF - Spring

E

F

711-007JKRBF - Gland

319-035JKNF - Leather Packing

1-027JKNF - Seat

1-022JKNF - Retainer

333-97JKNF - Nut

G

I

L

N

P

STEP 7 - Turn water on at stop

or main valve. Remove aerator.

Turn faucet on to “full” allowing

sediment to flush from lines and

replace aerator cartridge.

5

Loading...

Loading...