Page 1

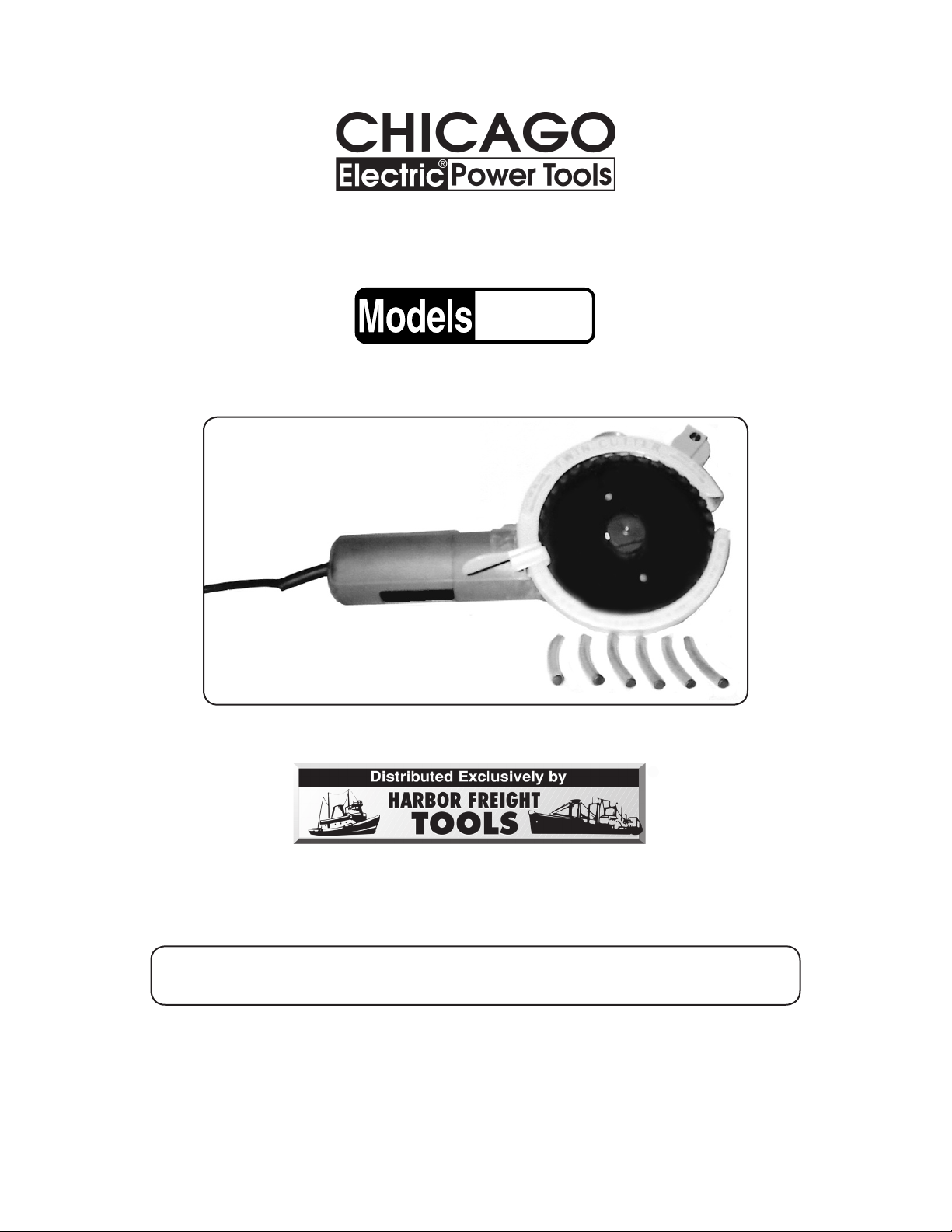

TWIN CUTTER SAW

®

94596 /

94896

ASSEMBLY AND OPERATION INSTRUCTIONS

Due to continuing improvements, actual product may differ slightly from the product described herein.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

TO PREVENT SERIOUS INJURY, READ AND UNDERSTAND

ALL WARNINGS AND INSTRUCTIONS BEFORE USE.

Copyright© 2006 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

For technical questions or replacement parts, please call 1-800-444-3353.

Page 2

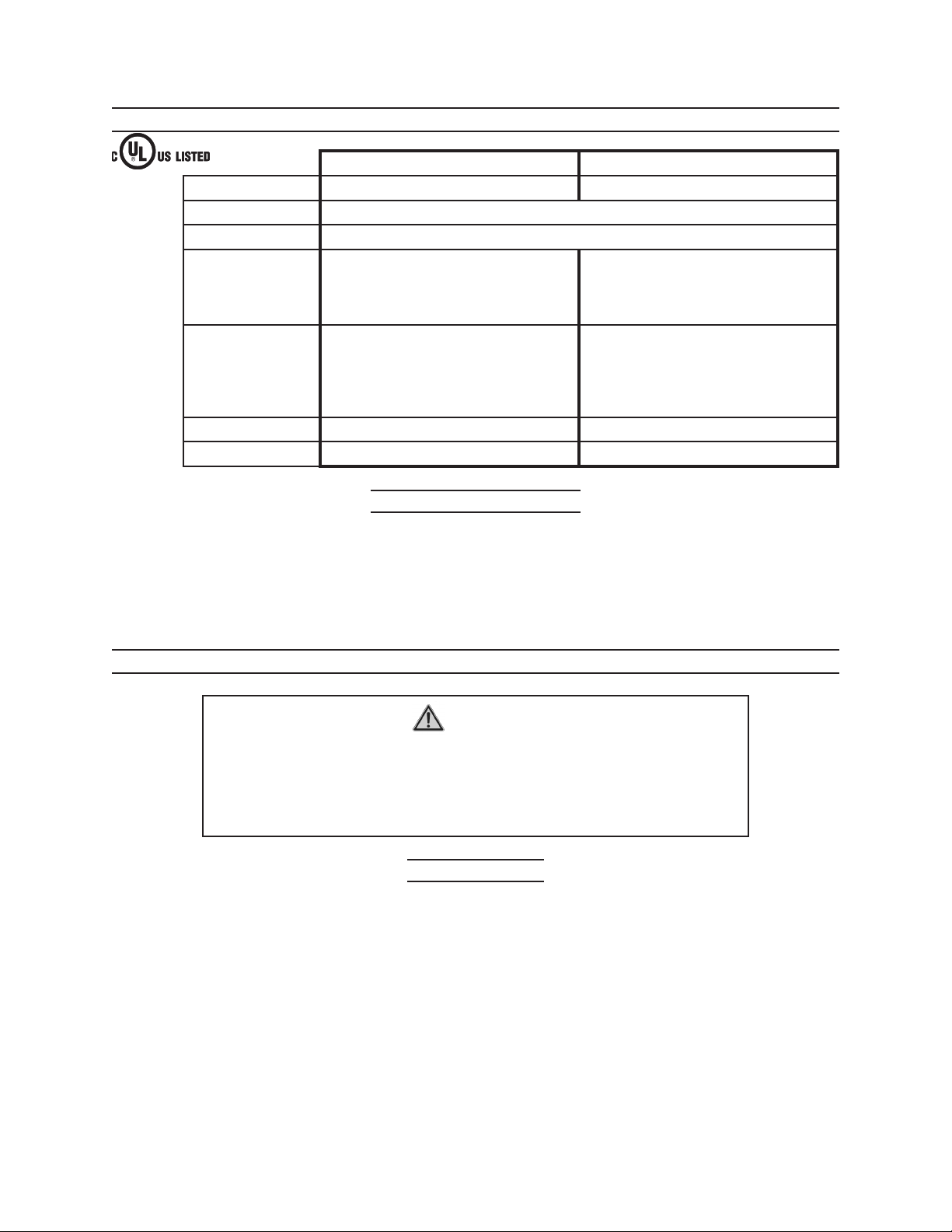

PRODUCT SPECIFICATIONS

E194601E194601

Motor 120 V~ / 60 Hz / 5.6 A / n0 5,500/min 120 V~ / 60 Hz / 7.8 A / n0 4,600/min

Power Switch Slider Button with Automatic Shut-Off

Power Cord 18 AWG x 2C SJT / 2-Prong Polarized Plug

Saw Blades

(Qty. 2, Included)

Maximum Cutting

Depth

Overall Dimensions 13” Long x 6” Wide x 73/8” High 13” Long x 61/2” Wide x 8” High

Unit Weight 7 lb. 11.2 lb.

MODEL 94896 - 5” Twin Cutter Saw MODEL 94596 - 61/8” Twin Cutter Saw

47/8” Diameter / 32 Teeth

0.05” Individual Thickness

Minimum 5,500 RPM Rating

Carbide Tipped / Teflon® Coated

11/8” Wood

1

/8” Mild Steel (Tubing & Sheets)

1

/8” Plastic (Tubing & Sheets)

1

/8” Copper, Stainless Steel,

Aluminum, Cast Iron (Tubing & Sheets)

61/8” Diameter / 36 Teeth

0.064” Individual Thickness

Minimum 4600 RPM Rating

Carbide Tipped / Teflon® Coated

11/2” Wood

1

/8” Mild Steel (Tubing & Sheets)

3

/16” Plastic (Tubing & Sheets)

1

/8” Copper, Stainless Steel,

Aluminum, Cast Iron (Tubing & Sheets)

SAVE THIS MANUAL

You will need this manual for the safety warnings and precautions, assembly, operating, inspection, maintenance and cleaning procedures, parts list and assembly diagram.

Keep your invoice with this manual. Write the invoice number on the inside of the front

cover. Keep this manual and invoice in a safe and dry place for future reference.

1.

2.

3.

GENERAL SAFETY RULES

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions listed below may result in

electric shock, fire, and/or serious injury.

SAVE THESE INSTRUCTIONS

WORK AREA

Keep your work area clean and well lit. Cluttered benches and dark areas invite

accidents.

Do not operate power tools in explosive atmospheres, such as in the pres-

ence of flammable liquids, gases, or dust. Power tools create sparks which may

ignite the dust or fumes.

Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control. Protect others in the work area from

debris such as chips and sparks. Provide barriers or shields as needed.

94596 &

94896

For technical questions, please call 1-800-444-3353.

Page 2SKUs

Page 3

ELECTRICAL SAFETY

1.

2.

3.

4.

5.

Grounded tools must be plugged into an outlet properly installed and grounded

in accordance with all codes and ordinances. Never remove the grounding

prong or modify the plug in any way. Do not use any adapter plugs. Check with

a qualified electrician if you are in doubt as to whether the outlet is properly

grounded. If the tools should electrically malfunction or break down, grounding

provides a low resistance path to carry electricity away from the user.

Double insulated tools are equipped with a polarized plug (one blade is wider

than the other). This plug will fit in a polarized outlet only one way. If the plug

does not fit fully in the outlet, reverse the plug. If it still does not fit, contact

a qualified electrician to install a polarized outlet. Do not change the plug

in any way. Double insulation eliminates the need for the three wire grounded

power cord and grounded power supply system.

Avoid body contact with grounded surfaces such as pipes, radiators, ranges,

and refrigerators. There is an increased risk of electric shock if your body is

grounded.

Do not expose power tools to rain or wet conditions. Water entering a power

tool will increase the risk of electric shock.

Do not abuse the Power Cord. Never use the Power Cord to carry the tools or

pull the Plug from an outlet. Keep the Power Cord away from heat, oil, sharp

edges, or moving parts. Replace damaged Power Cords immediately. Dam-

aged Power Cords increase the risk of electric shock.

6.

1.

2.

3.

When operating a power tool outside, use an outdoor extension cord marked

“W-A” or “W”. These extension cords are rated for outdoor use, and reduce the

risk of electric shock.

PERSONAL SAFETY

Stay alert. Watch what you are doing, and use common sense when operat-

ing a power tool. Do not use a power tool while tired or under the influence

of drugs, alcohol, or medication. A moment of inattention while operating power

tools may result in serious personal injury.

Dress properly. Do not wear loose clothing or jewelry. Contain long hair.

Keep your hair, clothing, and gloves away from moving parts. Loose clothes,

jewelry, or long hair can be caught in moving parts.

Avoid accidental starting. Be sure the Power Switch is off before plugging

in. Carrying power tools with your finger on the Power Switch, or plugging in power

tools with the Power Switch on, invites accidents.

94596 &

94896

For technical questions, please call 1-800-444-3353.

Page 3SKUs

Page 4

4.

Remove adjusting keys or wrenches before turning the power tool on. A

wrench or a key that is left attached to a rotating part of the power tool may result

in personal injury.

5.

6.

1.

2.

3.

4.

Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance enables better control of the power tool in unexpected situations.

Use safety equipment. Always wear eye protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must be used for appropriate conditions.

TOOL USE AND CARE

Use clamps (not included) or other practical ways to secure and support the

workpiece to a stable platform. Holding the work by hand or against your body

is unstable and may lead to loss of control.

Do not force the tool. Use the correct tool for your application. The correct

tool will do the job better and safer at the rate for which it is designed.

Do not use the power tool if the Power Switch does not turn it on or off. Any

tool that cannot be controlled with the Power Switch is dangerous and must be

replaced.

Disconnect the Power Cord Plug from the power source before making any

adjustments, changing accessories, or storing the tool. Such preventive safety

measures reduce the risk of starting the tool accidentally.

5.

6.

7.

8.

1.

2.

Store idle tools out of reach of children and other untrained persons. Tools

are dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting tools sharp and clean. Properly main-

tained tools with a sharp cutting edge are less likely to bind and are easier to control.

Do not use a damaged tool. Tag damaged tools “Do not use” until repaired.

Check for misalignment or binding of moving parts, breakage of parts, and any

other condition that may affect the tool’s operation. If damaged, have the tool

serviced before using. Many accidents are caused by poorly maintained tools.

Use only accessories that are recommended by the manufacturer for your

model. Accessories that may be suitable for one tool may become hazardous

when used on another tool.

SERVICE

Tool service must be performed only by qualified repair personnel. Service or

maintenance performed by unqualified personnel could result in a risk of injury.

When servicing a tool, use only identical replacement parts. Follow instruc-

tions in the “Inspection, Maintenance, And Cleaning” section of this manual.

94596 &

94896

For technical questions, please call 1-800-444-3353.

Page 4SKUs

Page 5

Use of unauthorized parts or failure to follow maintenance instructions may create

a risk of electric shock or injury.

SPECIFIC SAFETY RULES

1.

2.

3.

4.

5.

DANGER! Keep hands away from cutting area and blade. Keep your second

hand on auxiliary handle, or motor housing. If both hands are holding the saw,

they cannot be cut by the blade.

Keep your body positioned to either side of the saw blade, but not in line with

the saw blade. KICKBACK could cause the saw to jump backwards. (See “Causes

and Operator Prevention of Kickback.”)

Do not reach underneath the work. The guard can not protect you from the blade

below the work.

Check lower guard for proper closing before each use. Do not operate saw if

lower guard does not move freely and close instantly. Never clamp or tie the

lower guard into the open position. If saw is accidentally dropped, lower guard

may be bent. Raise the lower guard with the Retracting Handle and make sure

it moves freely and does not touch the blade or any other part, in all angles and

depths of cut.

Check the operation and condition of the lower guard spring. If the guard and

the spring are not operating properly, they must be serviced before use. Lower

guard may operate sluggishly due to damaged parts, gummy deposits, or a buildup

of debris.

6.

7.

8.

9.

10.

Lower guard should be retracted manually only for special cuts such as

“Pocket Cuts” and “Compound Cuts.” Raise lower guard by Retracting Handle.

As soon as blade enters the material, lower guard must be released. For all other

sawing, the lower guard should operate automatically.

Always observe that the lower guard is covering the blade before placing

saw down on bench or floor. An unprotected, coasting blade will cause the saw

to walk backwards, cutting whatever is in its path. Be aware of the time it takes for

the blade to stop after switch is released.

NEVER hold piece being cut in your hands or across your leg. It is important

to support the work properly to minimize body exposure, blade binding, or loss of

control.

Hold tool by insulated gripping surfaces when performing an operation where

the cutting tool may contact hidden wiring or its own cord. Contact with a “live”

wire will also make exposed metal parts of the tool “live” and shock the operator.

When ripping always use a rip fence or straight edge guide. This improves the

accuracy of cut and reduces the chance for blade binding.

94596 &

94896

For technical questions, please call 1-800-444-3353.

Page 5SKUs

Page 6

11.

Always use blades with correct size and shape (diamond vs. round) arbor

holes. Blades that do not match the mounting hardware of the saw will run eccen-

trically, causing loss of control.

12.

13.

14.

15.

16.

17.

Never use damaged or incorrect blade washers or bolts. The blade washers

and bolt were specially designed for your saw, for optimum performance and safety

of operation.

Always wear safety impact eye goggles when using the Twin Cutter

Saw. Always wear heavy duty work gloves when changing Saw Blades.

Using personal safety devices reduces the risk for injury. A leather apron

and arm protection may be advisable to protect from sparks created

when cutting metal.

Maintain a safe working environment. Keep the work area well lit. Make sure

there is adequate surrounding workspace. Always keep work area free of obstruc-

tions, grease, oil, trash, and other debris. Do not use a power tool in areas near

flammable chemicals, dusts, and vapors. Do not use in a damp or wet location.

Avoid unintentional starting. Make sure you are prepared to begin work before

turning on the Twin Cutter Saw.

Do not force the Twin Cutter Saw. This tool will do the work better and safer at

the speed and capacity for which it was designed. Do not force the Saw Blades

into the workpiece being cut.

Never leave the Twin Cutter Saw unattended when it is plugged into an electri-

cal outlet. Turn off the tool, and unplug it from its electrical outlet before leaving.

18.

19.

20.

21.

22.

23.

24.

Before using the Twin Cutter Saw, check to make sure the Saw Blades are

properly mounted on the Arbor Adapter. Make sure the Saw Blades are sharp,

and are not cracked or bent.

Industrial applications must follow OSHA guidelines.

When cutting a large workpiece, make sure its entire length is properly sup-

ported. If necessary, use a roller stand (not included).

To avoid electrical shock, do not handle the Twin Cutter Saw or its Power Cord

Plug with wet hands.

Make sure the workpiece is free from nails and any other foreign objects which

can damage the Saw Blades.

Always check to make sure there are no electrical wires or cables in the cut-

ting path of the Twin Cutter Saw.

Allow the Blades to run up to full speed before feeding them into a workpiece.

When turning off the Twin Cutter Saw, allow the Saw Blades to stop on their own.

94596 &

94896

For technical questions, please call 1-800-444-3353.

Page 6SKUs

Page 7

25.

Turn off the Twin Cutter Saw and allow the Saw Blades to completely stop if

the Saw Blades are to be backed out of an uncompleted cut.

26.

27.

28.

Never attempt to remove material stuck in the moving parts of the Twin Cutter

Saw while it is plugged in and running.

Always unplug the Twin Cutter Saw from its electrical outlet before performing

any inspection, maintenance, or cleaning procedures.

KICKBACK PRECAUTIONS

Causes and operator prevention of “KICKBACK”: Kickback is a sudden reaction

to pinched, bound, or misaligned Saw Blades, causing an uncontrolled Twin Cutter

Saw to lift up and out from the workpiece toward the operator. When the Saw Blades

are pinched or bound tightly by the kerf closing down, the Saw Blades stall and the

motor reaction drives the Twin Cutter Saw rapidly back toward the operator. If the

Saw Blades become twisted or misaligned in the cut, the teeth at the front edge of

the Saw Blades can raise the Twin Cutter Saw (walk up) toward the operator. Kick-

back is a result of tool misuse and/or incorrect operating procedures or conditions

and can be avoided by taking proper precautions as follows:

Maintain a firm grip with both hands on the saw and position your body

•

and arm to allow you to resist KICKBACK forces. KICKBACK forces can be

controlled by the operator, if proper precautions are taken.

When blade is binding, or when interrupting a cut for any reason, release the

•

trigger and hold the saw motionless in the material until the blade comes

to a complete stop. Never attempt to remove the saw from the work or pull the

saw backward while the blade is in motion or KICKBACK may occur. Investigate

and take corrective actions to eliminate the cause of blade binding.

When restarting the Twin Cutter Saw on a workpiece, center the Saw Blades

•

in the pre-cut kerf and check that the Saw Teeth are not engaged into the

workpiece. If the Saw Blades are binding, the Twin Cutter Saw may walk up or

kickback as the Saw is restarted.

When restarting a saw in the workpiece, center the saw blade in the kerf and

•

check that saw teeth are not engaged into the material. If saw blade is binding,

it may walk up or KICKBACK from the workpiece as the saw is restarted.

Support large panels to minimize the risk of blade pinching and KICKBACK.

•

Large panels tend to sag under their own weight. Supports must be placed under

the panel on both sides, near the line of cut and near the edge of the panel.

Do not use dull or damaged blades. Unsharpened or improperly set blades

•

produce narrow kerf causing excessive friction, blade binding and KICKBACK.

Blade depth and bevel adjusting locking levers must be tight and secure

•

before making cut. If blade adjustment shifts while cutting, it may cause binding

and KICKBACK.

94596 &

94896

For technical questions, please call 1-800-444-3353.

Page 7SKUs

Page 8

Use extra caution when making a “Pocket Cut” into existing walls or other

•

blind areas. The protruding blade may cut objects that can cause KICKBACK.

Push the Saw Blades past the workpiece prior to releasing the Power

•

Switch.

Make sure to check the Blade Guard for proper operation. Never disable the

•

Guard. Do not use the Twin Cutter Saw if the Guard assembly does not operate

properly. Before each use, make sure the Blade Guard does not touch the Saw

Blades.

Make sure the workpiece is free from nails, metal rebar, and any other foreign

•

objects that could damage the Saw Blades or cause “kickback”.

29.

30.

31.

32.

CAUTION! When cutting metal, the Twin Cutter Saw produces extremely hot

chips (rather than sparks). Use caution to avoid accidental fire and/or injury to the

operator.

WARNING! Some dust created by power sanding, sawing, grinding, drilling,

and other construction activities, contain chemicals known (to the State of California) to cause cancer, birth defects or other reproductive harm. Some examples of

these chemicals are: lead from lead-based paints, crystalline silica from bricks and

cement or other masonry products, arsenic and chromium from chemically treated

lumber. Your risk from these exposures varies, depending on how often you do this

type of work. To reduce your exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such as those dust masks that are

specially designed to filter out microscopic particles.

(California Health & Safety Code § 25249.5, et seq.)

WARNING! People with pacemakers should consult their physician(s) before

using this product. Electromagnetic fields in close proximity to a heart pacemaker

could cause interference to or failure of the pacemaker.

WARNING! The warnings and cautions discussed in this manual cannot cover

all possible conditions and situations that may occur. It must be understood by the

operator that common sense and caution are factors which cannot be built into this

product, but must be supplied by the operator.

94596 &

94896

SAVE THESE INSTRUCTIONS

For technical questions, please call 1-800-444-3353.

Page 8SKUs

Page 9

GROUNDING

WARNING!

Improperly connecting the grounding wire can result in the risk of electric shock.

Check with a qualified electrician if you are in doubt as to whether the outlet is

properly grounded. Do not modify the power cord plug provided with the tool.

Never remove the grounding prong from the plug. Do not use the tool if the

power cord or plug is damaged. If damaged, have it repaired by a service facility before use. If the plug will not fit the outlet, have a proper outlet installed by

a qualified electrician.

GROUNDED TOOLS: TOOLS WITH THREE PRONG PLUGS

1.

2.

3.

Tools marked “Grounding Required” have a three wire cord and three prong grounding plug. The plug must be connected to a properly grounded outlet. If tool should

electrically malfunction, grounding provides a low resistance path to carry electricity

away from the user, reducing risk of electric shock. (See Figure A.)

The grounding prong in the plug is connected through the green wire inside the

cord to the grounding system in the tool. The green wire in the cord must be the

only wire connected to the tool’s grounding system and must never be attached to

an electrically “live” terminal. (See Figure A.)

Your tool must be plugged into an appropriate outlet, properly installed and grounded

in accordance with all codes and ordinances. The plug and outlet should look like

those in the following illustration. (See Figure A.)

FIGURE A

FIGURE B

DOUBLE INSULATED TOOLS: TOOLS WITH TWO PRONG PLUGS

1.

2.

Tools marked “Double Insulated” do not require grounding. They have a special

double insulation system which satisfies OSHA requirements and complies with

the applicable standards of Underwriters Laboratories, Inc., the Canadian Standard

Association, and the National Electrical Code. (See Figure B.)

Double insulated tools may be used in either of the 120 volt outlets shown in the

preceding illustration. (See Figure B).

94596 &

94896

For technical questions, please call 1-800-444-3353.

Page 9SKUs

Page 10

EXTENSION CORDS

1.

2.

3.

4.

5.

6.

7.

Grounded tools require a three wire extension cord. Double Insulated tools can

use either a two or three wire extension cord.

As the distance from the supply outlet increases, you must use a heavier gauge

extension cord. Using extension cords with inadequately sized wire causes a serious drop in voltage, resulting in loss of power and possible tool damage.

(See Figure C, next page.)

The smaller the gauge number of the wire, the greater the capacity of the cord. For

example, a 14 gauge cord can carry a higher current than a 16 gauge cord.

(See Figure C.)

When using more than one extension cord to make up the total length, make sure

each cord contains at least the minimum wire size required. (See Figure C.)

If you are using one extension cord for more than one tool, add the nameplate am-

peres and use the sum to determine the required minimum cord size.

(See Figure C.)

If you are using an extension cord outdoors, make sure it is marked with the suffix

“W-A” (“W” in Canada) to indicate it is acceptable for outdoor use.

Make sure your extension cord is properly wired and in good electrical condition.

Always replace a damaged extension cord or have it repaired by a qualified electrician before using it.

8.

Protect extension cords from sharp objects, excessive heat, and damp or wet areas.

94596 &

94896

For technical questions, please call 1-800-444-3353.

Page 10SKUs

Page 11

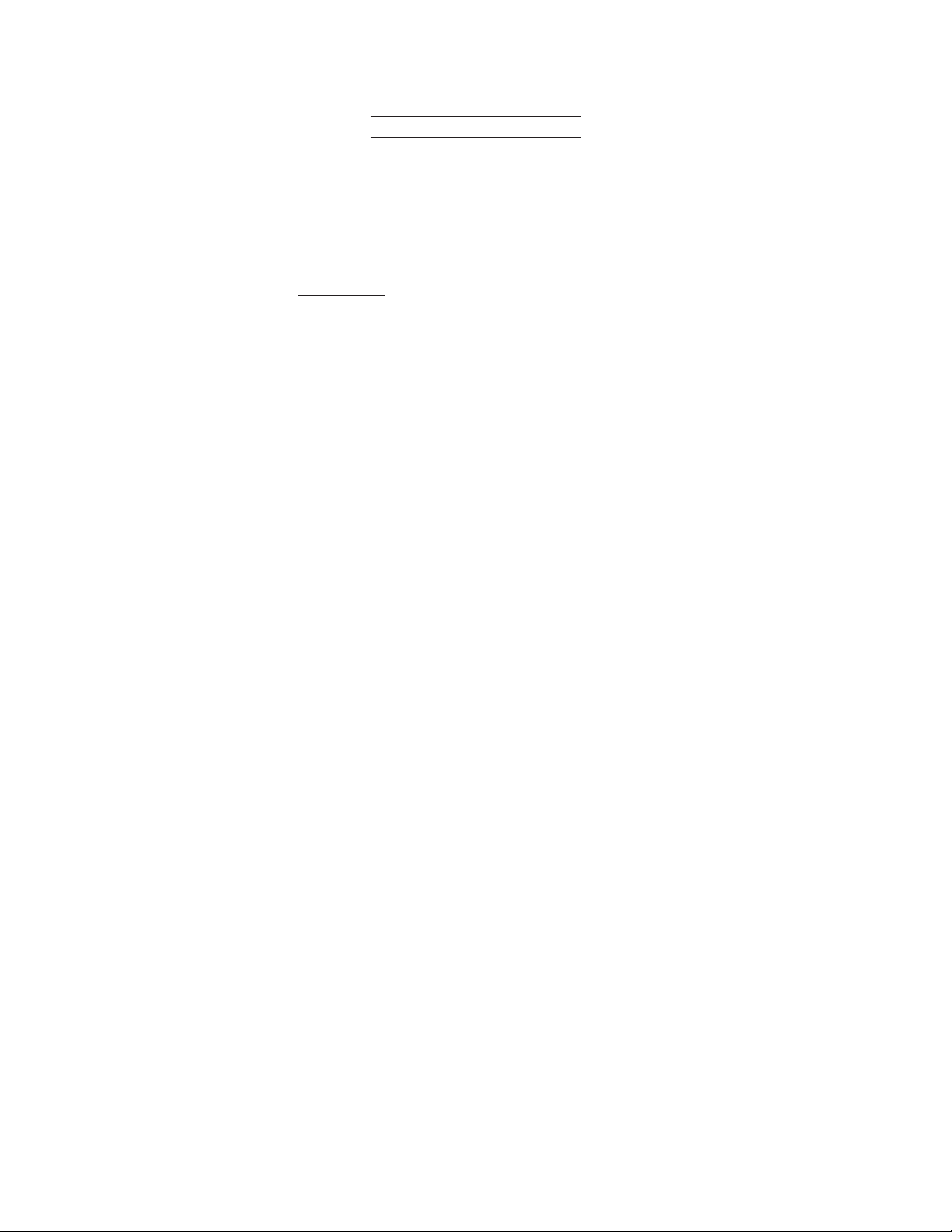

RECOMMENDED MINIMUM WIRE GAUGE FOR EXTENSION CORDS*

(120 OR 240 VOLT)

NAMEPLATE

AMPERES

(at full load)

0 – 2.0 18 18 18 18 16

2.1 – 3.4 18 18 18 16 14

3.5 – 5.0 18 18 16 14 12

5.1 – 7.0 18 16 14 12 12

7.1 – 12.0 18 14 12 10 -

12.1 – 16.0 14 12 10 - -

16.1 – 20.0 12 10 - - -

FIGURE C

25 Feet 50 Feet 75 Feet 100 Feet 150 Feet

* Based on limiting the line voltage drop to five volts at 150% of the rated amperes.

EXTENSION CORD LENGTH

SYMBOLOGY

Double Insulated

Canadian Standards Association

V~

A

n0 xxxx/min.

Underwriters Laboratories, Inc.

Volts Alternating Current

Amperes

No Load Revolutions per Minute

(RPM)

94596 &

94896

For technical questions, please call 1-800-444-3353.

Page 11SKUs

Page 12

UNPACKING

When unpacking, check to make sure all the parts shown on the Parts List on page

16 are included. If any parts are missing or broken, please call Harbor Freight Tools at the

number shown on the cover of this manual as soon as possible.

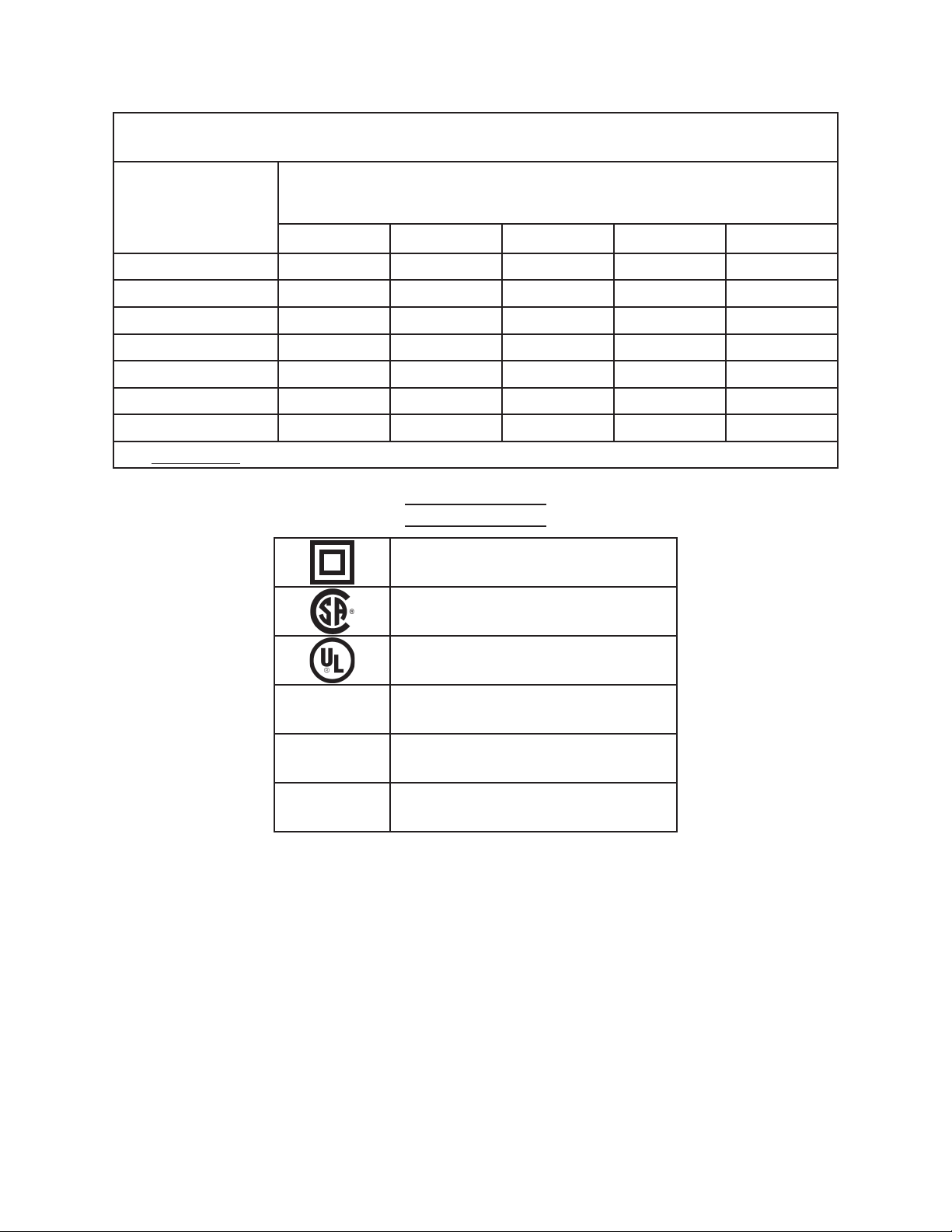

PRODUCT FEATURES

FIGURE E

POWER

CORD/PLUG

1.

2.

SIDE HANDLE

POWER SWITCH

HOUSING

UPPER GUARD

LUBRICATING

UNIT KNOB

WAX TUBE

LOWER GUARD

Power Switch: The Power Switch is a simple “slider” switch that when pressed

and held turns on the Twin Cutter Saw. To turn off the Saw, release pressure on the

Power Switch and the switch will automatically return up to its “OFF” position.

Power Cord/Plug: The Power Cord/Plug must only be connected to a 120 volt,

grounded, electrical outlet. Do not pull on the Cord to remove the Plug from its

electrical outlet.

3.

4.

5.

Side Handle and Housing: The Side Handle allows for increased control of the

Twin Cutter Saw and additional safety. When using the Saw, always maintain a firm

grip on the Side Handle and Housing.

Lower Guard and Upper Guard: Before each use of the Twin Cutter Saw, always

check to make sure the Lower Guard and Upper Guard are operating properly. Also,

make sure the Saw Blades do not touch either Guard.

Wax Tube and Lubricating Unit Knob: Always use a lubricating Wax Tube when

cutting aluminum, copper, stainless steel, and cast iron. When cutting, these materials tend to soften and adhere to the Saw Blades and can diminish the performance

of the Twin Cutter Saw. To use a Wax Tube, insert the Wax Tube into the Lubricating Unit Dispenser. Turn the Lubricating Unit Knob to apply lubricant to the Saw

94596 &

For technical questions, please call 1-800-444-3353.

Page 12SKUs

94896

Page 13

Blades. A 1/4 turn of the Lubricating Unit Knob will provide adequate lubrication

for several cuts.

6.

Saw Blades: The Saw Blades should always be kept clean, sharp, and properly

installed in the Twin Cutter Saw. Using dull Saw Blades will place an excessive

load on the Saw and increases the danger of kickback. It is recommended to keep

extra Saw Blades on hand so sharp Saw Blades are always available.

To install the Saw Blades:

Unplug the Twin Cutter Saw from its electrical outlet.

a.

To avoid accidental cuts, make sure to wear heavy duty work gloves while in-

b.

stalling the Saw Blades.

“INNER”

“OUTER” “OUTER”

PIN

FIGURE F

Lay the Twin Cutter Saw down with its Blade Lock Nut pointing upward.

c.

(See Figure F, above.)

Open the Lower Guard.

d.

Place the Saw Blade marked “INNER” onto the Flange of the Gear Box with

e.

the word “INNER” clearly visible. Then, align the holes in the Saw Blade with

the Pins on the Flange and securely fit the Saw Blade on the Flange.

Place the Saw Blade marked “OUTER” onto the Arbor Adapter with the word

f.

“OUTER” clearly visible. Then, thread (do not tighten) the Blade Lock Nut onto

the Flange of the Gear Box.

Turn the Saw Blades so that the holes in both Blades are aligned.

g.

Insert the Pin that is attached to the Wrench into the aligned holes in the Saw

h.

Blades.

Using the Wrench, tighten the Blade Lock Nut clockwise. Do not tighten ex-

i.

cessively. Then, remove the Pin from the Saw Blades. This will allow the Saw

Blades to turn freely.

Turn the Saw Blades with your gloved hand to ensure the Saw Blades easily

j.

turn in opposite directions.

94596 &

94896

For technical questions, please call 1-800-444-3353.

Page 13SKUs

Page 14

OPERATING INSTRUCTIONS

Note: Refer to Figure E on page 11 during the procedures shown below.

CAUTION! Always use safety equipment. Wear ANSI approved safety impact

eye goggles and heavy duty work gloves when operating the Twin Cutter Saw. Also,

a dust mask and hearing protection must be used for appropriate conditions.

CAUTION! Always check the Lower Guard for proper closing before each use.

Do not operate the Twin Cutter Saw if the Lower Guard does not move freely and

close instantly.

CAUTION! Always secure the workpiece in place, using a vise or clamps (not

included).

1.

2.

3.

4.

5.

6.

Make sure the Power Switch is in its “OFF” position and the Power Cord/ Plug is

unplugged from the electrical outlet.

Insert a Wax Tube into the Lubricating Unit Dispenser. Turn the Lubricating Unit

Knob to apply lubricant to the Saw Blades. A 1/4 turn of the Lubricating Unit Knob

will provide adequate lubrication for several cuts. If necessary to reapply more Wax,

first turn off the Twin Cutter Saw. Wait until the Saw Blades come to a complete stop.

Unplug the tool from its electrical outlet. Then, readjust the Wax Tube to continue

providing lubricant to the Saw Blades.

Plug the Power Cord/Plug into the nearest 120 volt, grounded, electrical outlet.

Position the Saw Blades of the Twin Cutter Saw about 1/2” from the beginning cut

line on the workpiece. Do not allow the Saw Blades to come in contact with the

workpiece. NOTE: The kerf (width of cut) of the two Saw Blades is approximately

1/8”. Always make sure to allow for this.

Grip the Twin Cutter Saw firmly with both hands. Then press the Power Switch to

turn on the tool.

Allow the Saw Blades to spin at full speed before slowly feeding them into the

workpiece.

7.

8.

When finished making the cut, release the Power Switch to stop the Twin Cutter Saw.

Wait until the Saw Blades stop completely. Remove the tool from the workpiece,

and unplug the Twin Cutter Saw from its electrical outlet.

Always make sure to store the Twin Cutter Saw in a clean, dry, safe location out of

reach of children and other unauthorized people.

94596 &

94896

For technical questions, please call 1-800-444-3353.

Page 14SKUs

Page 15

INSPECTION, MAINTENANCE, AND CLEANING

1.

2.

3.

4.

WARNING! Make sure the Power Switch of the Twin Cutter Saw is in its “OFF”

position and the tool is unplugged from its electrical outlet before performing any

inspection, maintenance, or cleaning procedures.

Before each use: Inspect the general condition of the Twin Cutter Saw. Check

for loose screws, misalignment or binding of moving parts, cracked or bent Saw

Blades, damaged electrical wiring, and any other condition that may affect its safe

operation. If abnormal noise or vibration occurs, have the problem corrected before

further use. Do not use damaged equipment.

Before each use: Inspect the Saw Blades. Using dull Saw Blades will cause excessive wear on the Motor of the Twin Cutter Saw and will not produce a satisfactory

cut. Replace with a new Saw Blade when needed. Replace both saw blades as

a set. (See Figure F.)

To replace or clean the Motor Carbon Brushes: It may become necessary at

sometime to replace or clean the two Carbon Brushes when the Motor performance

decreases, or stops working completely. The Carbon Brushes are located at the

rear of the Housing. (See Assy. Diagram.)

To replace or clean the Carbon Brushes:

Unscrew and remove the two Tapping Screws located on the Back Cover of the

a.

Housing.

5.

6.

Slowly pull the Back Cover out to expose the Carbon Brushes.

b.

Remove the two Carbon Brushes from the two Brush Holders.

c.

If either of the Carbon Brushes are worn down more than 1/2, replace both

d.

Carbon Brushes. If, however, the Carbon Brushes are just dirty they may be

cleaned by rubbing them with a pencil eraser.

When installing the Carbon Brushes, make sure the carbon portion of the Car-

e.

bon Brushes contact the Motor’s Stator and that the springs face away from the

Stator. Also, make sure the springs operate freely.

After replacement or cleaning, push the Back Cover back against the Housing.

f.

Then, replace the two Tapping Screws.

NOTE: New Carbon Brushes tend to arc or spark when first used until they wear

g.

and conform to the Motor’s Stator.

To clean the exterior parts of the Twin Cutter Saw, use only a clean cloth and

mild detergent to clean the outer body of the Saw. Do not immerse any electrical

part of the tool in any liquids.

WARNING! All maintenance, service, or repairs not mentioned in this

manual must only be performed by a qualified service technician.

94596 &

94896

For technical questions, please call 1-800-444-3353.

Page 15SKUs

Page 16

PARTS LIST - MODEL 94896

IMPORTANT

When ordering parts, reference which model you are ordering parts for. Parts are

not interchangeable.

Part Description Qty.

1 5” Saw Blades 1 Set

2 Guard Plate 1

3 Swing Guard 1

4 Guard Washer 1

5 Screw M4 x 14 1

6 Rubber Pin 1

7 Screw SA M4 x 12 1

8 Guard 1

10 Tap Screw ST 4.2 x 35 4

11 Gear Box 1

12 Side Handle 1

13 Cover 1

14 Pinion 1

15 Bearing 6000-2RS 1

16 Armature 1

17 Bearing 606zz 1

18 Logo Label 1

19 Cord Protector 1

20 Tap Screw ST 4.2 x 12 1

21 Cord Retainer 2

22 Lead IV 2

23 Spring 1

24 Switch Lever 1

25 Tap Screw ST 4.2 x 20 2

26 Power Switch 1

Part Description Qty.

27 Cover 1

28 Spring 1

30 Back Cover 1 1

31 Tap Screw ST 4.2 x 16 2

32 Warning Label 1

33 Switch 1

35 Housing 1

36 Stator 1

37 Tap Screw ST 4.2 x 14 2

38 Power Cord 1

39 Brush 2

40 Brush Holder 2

42 Lock Nut 1

43 Wrench and pin 1

44 Wax Tubes 6

45 Lubricating Unit 1

46 Tap Screw ST 4.8 x 10 1

47 Rotation label 1

48 Inductor Coil 2

49 Connector 1

50 Brush Cap 2

51 Bearing Insert 1

52 Guard Assembly* 1

53 Overload Protector 1

*Includes parts 2, 3, 4, & 8

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not available

individually as replacement parts.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER

OR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER

THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR

SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER

AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS

SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE

BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS

TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS

OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

94596 &

94896

For technical questions, please call 1-800-444-3353.

Page 16SKUs

Page 17

ASSEMBLY DIAGRAM - MODEL 94896

94596 &

94896

For technical questions, please call 1-800-444-3353.

Page 17SKUs

Page 18

PARTS LIST A - MODEL 94596

IMPORTANT

When ordering parts, reference which model you are ordering parts for. Parts are

not interchangeable.

Part Description Qty.

1a 61/8” Saw Blades 1 Set

2a Guard Plate 1

3a Lower Guard 1

4a Guard Washer 1

5a Screw (M4 x 14) 1

6a Rubber Pin 1

7a Screw (SA M4 x 12) 1

8a Upper Guard 1

10a Tapping Screw (ST 4.2 x 35) 4

11a Gear Box 1

12a Side Handle 1

13a Cover 1

14a Pinion 1

15a Bearing (6000 zz) 1

16a Armature 1

18a Rubber Ring 1

Part Description Qty.

30a Cover 1

31a Spring 1

33a Label 1

34a Back Cover 1

35a Tapping Screw (ST 4.2 x 16) 2

37a Surge Protector 1

38a Switch 1

39a Capacitor 1

40a Housing 1

41a Stator 1

42a Tapping Screw (ST 4.2 x 65) 2

43a Power Cord/Plug 1

47a Lead (VI) 1

48a Tapping Screw (ST 2.2 x 8.5) 4

49a Washer 4

50a Brush 2

19a Bearing (607 zz) 1

21a Cord Protector 1

22a Cord Platen 1

23a Tapping Screw (ST 4.2 x 12) 1

24a Lead (IV) 2

25a Spring 1

26a Spring Washer 1

27a Switch Lever 1

28a Tapping Screw ( ST 4.2 x 20) 1

29a Power Switch 1

51a Brush Holder 2

53a Blade Lock Nut 1

54a Wrench and Pin 1

55a Wax Tube 6

56a Lubrication Unit 1

57a Tapping Screw (ST 4.8 x 10) 1

58a Rotation Label 1

59a Guard Assembly 1

63a 14mm & 22mm Arbor Wrench 1

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not available

individually as replacement parts.

REV 09/06

94596 &

94896

For technical questions, please call 1-800-444-3353.

Page 18SKUs

Page 19

ASSEMBLY DIAGRAM A - MODEL 94596

19a

43a

47a

48a

49a

37a

35a

24a

50a

38a

51a

34a

39a

21a

40a

22a

41a

23a

33a

24a

25a

26a

27a

28a

29a

31a

18a

16a

15a

14a

13a

12a

30a

11a

10a

63a: Arbor Wrench not shown.

94596 &

94896

42a

7a

4a

5a

3a

2a

54a

53a

1a

57a

For technical questions, please call 1-800-444-3353.

8a

58a

6a

55a

REV 09/06

Page 19SKUs

Page 20

LIMITED 90 DAY

WARRANTY

Harbor Freight Tools Co. makes every effort to assure that its products meet high quality and durability standards,

and warrants to the original purchaser that this product is free from defects in materials and workmanship for

the period of ninety days from the date of purchase. This warranty does not apply to damage due directly or

indirectly, to misuse, abuse, negligence or accidents, repairs or alterations outside our facilities, or to lack of

maintenance. We shall in no event be liable for death, injuries to persons or property, or for incidental, contingent,

special or consequential damages arising from the use of our product. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation of exclusion may not apply to you. THIS

WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with transportation charges prepaid.

Proof of purchase date and an explanation of the complaint must accompany the merchandise. If our inspection

verifies the defect, we will either repair or replace the product at our election or we may elect to refund the purchase

price if we cannot readily and quickly provide you with a replacement. We will return repaired products at our

expense, but if we determine there is no defect, or that the defect resulted from causes not within the scope of

our warranty, then you must bear the cost of returning the product.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

94596 &

94896

For technical questions, please call 1-800-444-3353.

Page 20SKUs

Page 21

Modèles

94596 /

94896

INSTRUCTIONS D’INSTALLATION ET

®

FONCTIONNEMENT

IMPORTANT!

Cette édition de langue

française est une traduction

du manuel anglais original

accompagnant ce produit. Si

une partie du manuel anglais

original est inconsistante

avec cette traduction, le

manuel anglais original

gouvernera.

SCIE

En raison des améliorations continuantes, le produit réel peut différer légèrement du produit décrit ici.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visitez notre site Internet à http://www.harborfreight.com

POUR ÉVITER LA BLESSURE SÉRIEUSE, LISEZ

ET COMPRENEZ TOUS LES AVERTISSEMENTS

ET LES INSTRUCTIONS AVANT L’UTILISATION.

Le Copyright© 2007 par le Harbor Freight Tools®. Tous droits réservés. Aucune portion de

ce manuel ou de n’importe quel travail d’art contenu ici ne peut être reproduite dans aucune

forme ou forme sans le consentement écrit explicite de Harbor Freight Tools.

Pour les questions techniques et les pièces détachées,

appelez-vous s’il vous plaît 1-800-444-3353.

Page 22

CARACTÉRISTIQUES

E194601E194601

MODELE 94896 – 5 po Scie MODELE 94596 – 61\8 po Scie

Moteur 120 V~/60 Hz /5.6 A /no 5,500/min 120 V~/60 Hz /7.8 A/ no 4,600/min

Interrupteur Bouton à glisser avec Coupé Automatique

Cordon d’Alimentation 18 AWG x 2C SJT / 2- Fiche à deux broche polarisé

Lames (Qty. 2, incluses) 4 7/8 po en Diamètre /32 Dents

0.05 po Épaisseur Individu

RPM de 5,500 Caractéristiques

Assignées Minimum

Extrémité de Carbure/Enduit de Téflon

Profondeur de Coupe

Maximum (Bois)

Profondeur de Coupe

Maximum

(Tubage et Tôle d’Aérage)

Dimension Totale 13 po en longueur x 6 po largeur d’un

Poids 7 lb 11.2 lb

1 1/8 po 1 ½ po

1/8 po Acier Doux

1/8 Plastique

1/8 Cuivre, Acier Inoxydable,

Aluminium, Fonte

pouce x 7 3/8 po en hauteur

6 1/8 po en Diamètre / 36 Dents

0.064 po Épaisseur Individu

RPM de 4600 Caractéristiques

Assignées Minimum

1/8 po Acier Doux

3/16 po Plastique

1/8 po Cuivre, Acier Inoxydable,

Aluminium, Fonte

13 po en longueur x 6 ½ po en

largeur x 8 ½ en hauteur

GARDEZ CE GUIDE

Gardez ce guide pour les conseils de sécurités et précautions, installation, instructions d’utilisation, inspection, entretien, la liste des pièces et le schéma du produit. Gardez

votre facture avec ce guide. Inscrivez le numéro de facture à l’intérieur de la couverture.

Gardez ce guide et facture dans un endroit sécuritaire et sec pour pouvoir le consulter à

l’avenir.

1.

2.

RÈGLES DE SÉCURITÉ GÉNÉRALES

AVERTISSEMENT!

LISEZ ET ASSUREZ-VOUS DE BIEN COMPRENDRE TOUTES LES

INSTRUCTIONS.

Le non -respect des instructions ci -après peut entraîner un risque

de choc électrique d’incendie et/ou de blessures graves.

GARDEZ CES INSTRUCTIONS

ESPACE DE TRAVAIL

Assurez-vous que l’espace de travail est propre et bien éclairé. Un établi en-

combré ou un endroit sombre est propice aux accidents.

N’utilisez pas un outil électrique dans un environnement aux propriétés ex-

plosives, comme en présence de poussière, de liquides ou de gaz inflamma-

bles. Les outils électriques produisent des étincelles qui peuvent enflammer les

poussières ou les vapeurs.

94596 &

94896

Pour obtenir de l’assistance composez le 1-800-444-3353.

Page 2SKUs

Page 23

3.

Gardez les spectateurs, les enfants et les visiteurs à l’écart pendant que vous

utilisez l’outil. Une distraction pourrait vous faire perdre la maîtrise de l’outil. Vous

devez les protéger contre les blessures corporelles. Si nécessaire, construisez des

barrières.

SÉCURITÉ ÉLECTRIQUE

1.

2.

3.

4.

Les outils mis à la terre doivent être branchés dans une prise de courant cor-

rectement installée et mise à la terre conformément à tous les codes et règle-

ments pertinents. Ne modifiez jamais la fiche de quelque façon que ce soit, par

exemple en enlevant la broche de mise à la terre. N’utilisez pas d’adaptateur

de fiche. Si vous n’êtes pas certain que la prise de courant est correctement

mise à la terre, adressez-vous à un électricien qualifié. En cas de défaillance

ou de défectuosité électrique de l’outil une mise à la terre offre un trajet de faible

résistance à l’électricité qui autrement risquerait de traverser l’utilisateur.

Les outils à double isolation sont équipés d’une fiche polarisée (une des

broches est plus large que l’autre), qui ne peut se brancher que d’une seule

façon dans une prise polarisée. Si la fiche n’entre pas parfaitement dans la

prise, inversez sa position; si elle n’entre toujours pas bien, demandez à un

électricien qualifié d’installer une prise de courant polarisée. Ne modifiez pas

la fiche de l’outil. La double isolation élimine le besoin d’un cordon d’alimentation

à trois fils avec mise à la terre ainsi que d’une prise de courant mise à la terre.

Évitez tout contact du corps avec les surfaces reliées à la terre telles que

tuyaux, radiateurs, cuisinières et réfrigérateurs. Le risque de choc électrique

est accru lorsque le corps est mis à la terre.

N’exposez pas les outils électriques à la pluie ni à des conditions mouillées.des conditions mouillées.

Toute infiltration d’eau dans l’outil augmente les risques de choc électrique.

5.

6.

1.

Évitez l’emploi abusif du cordon. N’utilisez jamais le cordon pour transporter

l’outil ou pour le débrancher de la prise de courant en tirant dessus. Tenez

le cordon à l’écart de la chaleur, de l’huile, des arêtes vives et des pièces

mobiles. Remplacez sans tarder un cordon endommagé. Les risques de choc

électrique augmentent lorsqu’un cordon est endommagé.

Lorsque vous utilisez un outil électrique à l’extérieur, vous devez vous servir

d’une rallonge électrique portant le symbole « W-A » ou « W ». Ces cordons

ont une tolérance appropriée à un usage extérieur et réduisent les risques de choc

électrique.

SECURITE PERSONNELLE

Soyez vigilant, surveillez ce que vous faites et faites preuve de bon jugement

lorsque vous utilisez un outil électrique. Ne vous servez pas de l’outil lorsque

vous êtes fatigué ou sous l’influence de la drogue, de l’alcool ou de médi-

94596 &

94896

Pour obtenir de l’assistance composez le 1-800-444-3353.

Page 3SKUs

Page 24

caments. Lorsque vous utilisez un outil électrique un moment d’inattention peut

entraîner des blessures graves.

2.

3.

4.

5.

6.

Portez des vêtements appropriés. Ne portez pas de vêtements amples ni des

bijoux. Attachez-vous les cheveux s’ils sont longs. Gardez vos cheveux, vos

vêtements et vos gants éloignés des pièces mobiles. Des vêtements amples,

des bijoux, ou des cheveux longs non retenus peuvent rester coincés dans les

pièces mobiles.

Évitez les démarrages accidentels. Assurez-vous que l’interrupteur se trouve

à la position d’arrêt (OFF) avant de brancher l’outil. Le fait de transporter l’outil

en gardant le doigt sur l’interrupteur ou de le brancher alors que l’interrupteur est

en position de marche (ON) peut provoquer un accident.

Retirez les clés de réglage ou les autres clés avant de mettre l’outil en marche.

Le fait de laisser une clé quelconque en prise sur une pièce rotative de l’outil peut

causer des blessures.

Évitez tout état de déséquilibre. Tenez-vous de façon stable et maintenez votre

équilibre en tout temps pour vous permettre de garder la maîtrise de l’outil

en cas d’imprévu.

Utilisez l’équipement de sécurité. Portez toujours une protection oculaire.

Portez aussi un masque anti poussière, des chaussures de sécurité antidérapantes,

un casque de sécurité, ou un protecteur auditif, selon les conditions.

1.

2.

3.

4.

5.

UTILISATION ET ENTRETIEN DE L’OUTIL

Utilisez des serre-joints (pas fournis) ou un autre moyen pratique de retenir et

de soutenir la pièce à scier sur une plate-forme stable. Le fait de tenir la pièce

à travailler avec une main ou contre votre corps constitue une situation instable qui

pourrait vous faire perdre la maîtrise de l’outil.

Ne forcez pas l’outil. Utilisez l’outil qui convient au travail à effectuer. L’outil

approprié fonctionne mieux et de façon plus sécuritaire au régime pour lequel il a

été conçu. Ne forcez pas l’outil. Il fera un meilleur travail, de manière plus sécuritaire,

au rythme pour lequel il est conçu.

N’utilisez pas l’outil si son interrupteur ne fonctionne pas normalement. Un

outil qui ne peut être contrôlé au moyen de son interrupteur est dangereux et doit

être réparé.

Débranchez la fiche de sa source d’alimentation avant de faire des réglages,

de changer des accessoires ou de ranger l’outil. De telles mesures préventives

réduisent les risques de démarrage accidentel de l’outil.

Rangez les outils non utilisés hors de la portée des enfants et des person-

nes inexpérimentées. Les outils sont dangereux dans les mains d’un utilisateur

inexpérimenté.

94596 &

94896

Pour obtenir de l’assistance composez le 1-800-444-3353.

Page 4SKUs

Page 25

6.

Entretenez soigneusement les outils. Gardez les accessoires de coupe affû-

tes et propres. Des outils bien entretenus, dont les arêtes sont bien tranchantes,

sont moins susceptibles de se coincer et se maîtrisent plus facilement. N’utilisez

pas l’outil endommagé. Faites étiqueter l’outil endommagé « N’ UTILISEZ PAS »

jusqu’à ce que vous le répare.

7.

8.

1.

2.

Vérifiez si des pièces mobiles sont désalignées ou coincées, si des pièces sont

endommagées ou toute autre situation pouvant nuire au bon fonctionnement

de l’outil. Si l’outil est endommagé, faites-le réparer avant de vous en servir.

De nombreux accidents sont causés par des outils mal entretenus.

Utilisez uniquement les accessoires recommandés par le fabricant. Des acces-

soires convenant à un outil en particulier peuvent être dangereux s’ils sont utilisés

avec un autre outil.

ENTRETIEN

L’entretien de cet outil doit être effectué uniquement par une personne qua-

lifiée. Tout entretien réalisé par une personne non qualifiée peut entraîner des

risques de blessures.

Lors de l’entretien de l’outil, utilisez uniquement des pièces de rechange

identiques à celles d’origine. Suivez les directives fournies dans la section

« Inspection, Entretien et Nettoyage » de ce guide. L’utilisation de pièces non

autorisé ou le non-respect des consignes d’entretien peut entraîner des risques de

choc électrique ou de blessures.

1.

2.

3.

4.

5.

REGLES DE SECURITE SPECIFIQUES

Garder les mains éloignées de la lame et de la zone de coupe. Votre seconde

main doit se trouver sur la poignée auxiliaire en le carter du moteur. Si les deux mains

sont utilisées pour tenir la scie, elles n’entreront pas en contact avec la lame.

Placez-vous toujours de manière a ne pas vous trouver dans la trajectoire

de la lame de la scie. Les reculs peuvent faire violemment reculer la scie. (Voir :

Reculs, « Quelles en sont les causes et quels sont les moyens pour les éviter »

Ne passez pas les mains sous la pièce. Le protège lame ne vous protège pas

de la lame en dessous de la pièce.

Vérifiez toujours si le protège lame se ferme correctement avant chaque uti-

lisation. N’utilisez pas la scie, si le protège lame ne pivote librement pas (et ne se

referme pas instantanément). Assurez-vous qu’il se déplace librement et qu’il ne

touche pas la lame ni toute autre pièce, quels que soient son angle et la profondeur

de coupe.

Vérifiez toujours le fonctionnement et l’état du ressort du protège lame in-

férieur. Si le protège lame et le ressort ne fonctionne pas correctement, il faut les

94596 &

94896

Pour obtenir de l’assistance composez le 1-800-444-3353.

Page 5SKUs

Page 26

faire réparer avant d’employer la scie. La protège lame inférieur peut fonctionner

lentement si des pièces sont endommagées ou s’il y a des dépôts de gomme ou

des débris

6.

7.

8.

9.

10.

Le protège lame inférieur doit être rétracté manuellement seulement pour des

coupes spéciales comme coupes en cavité et coupes en angles combines. Re-

levez toujours le protège lame par la poignée de rétraction. Des que la lame pénètre

dans le matériau à couper le protège lame inférieur doit être relâche. Pour tous les

autres sciages le protège lame inférieur doit fonctionner automatiquement.

Assurez-vous toujours que la protège lame inférieur recouvre la lame avant

de poser la scie sur l’établi ou le sol. Une lame non protégée tournant encore

peut faire déplacer la scie vers l’arrière, et couper tout ce qui pourrait se trouver sur

son passage. Notez le temps nécessaire pour que la lame s’arrête complètement

une fois la détente relâchée.

Ne tenez jamais la pièce à couper avec les mains ou sur les genoux. Il est im-

portant de prévoir des appuis appropriés pour la pièce afin de minimiser l’exposition

du corps, le coincement de la lame, ou la perte de contrôle.

Tenez l’outil par les surfaces de préhension isolées pour effectuer une opéra-

tion dans laquelle l’outil de coupe peut entrer en contact de fils caches ou de

son propre cordon. Tout contact avec un fil sous tension met les parties métalliques

exposées de l’outil sous tension et transmet un choc électrique à l’operateur.

Lors de la refente, utilisez toujours un guide de bord ou de coupe parallèle.

Ceci améliore la précision de la coupe et réduit les possibilités de coincement de

la lame.

11.

12.

13.

14.

Utilisez toujours des lames de dimensions correctes. (Diamond vs. Ronde) avec

les trous arbre. Les lames que ne correspond pas à la ferrure de fixation de la scie

ne peut pas fonctionner bien.

N’utilisez jamais de boulons ou rondelles d’aube endommagées ou incorrec-

tes. Les rondelles d’aube et boulons a été conçu spécifiquement pour la scie, pour

des meilleures performances et sécurité.

Lorsque vous utilisez cet outil, portez toujours des lunettes protectrices.

Portez toujours des gants durs de protection lorsque vous changez Les Lames de

La Scie. L’utilisation de l’équipement de protection adéquat réduit les risques de

blessure. Pour vous protéger des étincelles, il est conseillé de porter un tablier enil est conseillé de porter un tablier en

cuir et une protection pour les bras lorsque vous coupez des métaux.

Maintenez l’aire de travail. Assurez – vous que l’espace de travail est bien éclairé.

Assurez-vous toujours que la surface de travail ne comporte pas de clous ou d’autres

corps étrangers. N’utilisez pas en présence de vapeurs explosives comme celles

dégagées par des liquides, des gaz ou des poussières inflammable. N’utilisez pasutilisez pas

l’outil dans un endroit mouillé ou humide.

94596 &

94896

Pour obtenir de l’assistance composez le 1-800-444-3353.

Page 6SKUs

Page 27

15.

Évitez les démarrages accidentels. Assurez-vous d’être entièrement prêt à ef-

fectuer une coupe avant de mettre en marche la scie.

16.

17.

18.

19.

20.

21.

22.

Ne forcez pas La Scie. L’outil approprié fonctionne mieux et de façon plus sécuri-

taire au régime pour lequel il a été conçu. Ne forcez pas Les Lames dans La pièce

à scier.

Lorsque l’outil est branché, ne laissez-le jamais sans surveillance. Mettez

l’interrupteur en position « arrêt » puis retirez la fiche de la prise de courant avant

de sortir.

Avant d’utiliser La Scie, assurez-vous que La Lame est bien fixé sur une sur-

face à plat, et qu’elle n’est pas fêlée ni endommagée.

Les applications d’industrie doivent se conformer aux exigences du NIOSH.

Lors de la coupe de une grande pièce à scier, assurez-vous de fournir un

appui convenable pour la longueur entière. Si nécessaire, utilisez un support

et carter du dispositif d’appel individuel du fil (pas fournie) avec des pièces à scier

plus grande.

Afin d’éviter le risque de choc électrique, ne touchez pas La Scie ou Le

Cordon d’Alimentation ou Fiche d’Alimentation Électrique avec les mains

mouillées.

Recherchez et enlevez toujours tous les clous se trouvant dans la pièce avant

de la couper. En observant cette règle de sécurité, le risque de blessures graves

est réduit.

23.

24.

25.

26.

27.

28.

Vérifiez toujours les murs, planchers et plafonds pour voir s’il n’y a pas de

tuyaux ou de fils d’alimentation dissimulés.

Laissez La lame atteindre sa vitesse maximale avant de l’enfoncer dans la

pièce à scier. Lorsque vous arrêtez La Scie, laissez La Lame s’arrêter complè-arrêtez La Scie, laissez La Lame s’arrêter complè-laissez La Lame s’arrêter complè-

tement.

Lors d’une interruption du sciage mettez l’interrupteur de La Scie en position d’une interruption du sciage mettez l’interrupteur de La Scie en position

« ARRÊT » et laissez La Lame s’arrêter complètement.ARRÊT » et laissez La Lame s’arrêter complètement.complètement.

N’essayez jamais de retirer des matériaux coincés dans les pièces mobiles

de La Scie pendant qu’elle est branchée et en marche.

Débranchez toujours La Scie de la prise de courant électrique avant d’y placer

ou d’en enlever des pièces ou avant un nettoyage.

MOYENS POUR ÉVITER LES RECULS

Les reculs consistent en un mouvement violent provenant d’un coincement,

d’un calage ou d’un mauvais alignement de la lame de la scie, et provoquant

un relèvement non contrôle de la scie hors de la pièce et vers l’utilisateur.

94596 &

94896

Pour obtenir de l’assistance composez le 1-800-444-3353.

Page 7SKUs

Page 28

Lorsque la lame est coincée ou calée par la fermeture du trait de scie, la lame se

bloque et la réaction du moteur est d’entrainer l’outil rapidement vers l’arrière donc

vers l’utilisateur. Si la lame se tord ou d’aligne mal lors de la coupe, les dents du bord

arrière de lame peuvent mordre dans la surface supérieure de la pièce entrainant

une sortie de la lame hors du trait de scie et un recul violent vers l’utilisateur. Le

recul est le résultat d’un mauvais emploi de l’outil d’un technique oud de conditions

inappropriées. Cela peut être évité en prenant les précautions nécessaires comme

il est indiqué ci-dessous.

Tenez toujours bien la scie avec les deux mains et placez-vous de manière

•

que vous puissiez, avec vos bras, résister à la force des reculs. La force des

Reculs peut être contrôlée par l’utilisateur si de bonnes précautions sont prises.

Lors de la remise en marche de la scie dans la pièce, pour éliminer le coin-

•

cement de la lame, centrez toujours la lame dans le trait de scie et vérifiez

que les dents de la lame ne touchent pas le matériau. Si la lame se coince,

celle-ci peut se déplacer ou un recul peut avoir lieu lors de la remise en marche

de la scie.

Lorsque la lame se coince ou lors d’une interruption du sciage, quelle que

•

soit la raison, relâchez toujours la détente de l’interrupteur et tenez la scie

sans la bouger dans le matériau jusqu’à ce que la lame s’arrête complètement. N’essayez jamais d’enlever la scie de la pièce ni de tirer la scie vers l’arrière

lorsque la lame tourne, sinon un recul peut avoir lieu. Faites toujours les vérifications nécessaires et soyez toujours prêt a prendre les mesures qui s’imposent

pour éliminer le coincement de la lame.

29.

Fournissez toujours un appui convenable lors de la manipulation des grands

•

panneaux pour minimiser le risque de coincement de lame et le recul. Les

grands panneaux ont tendance à se plier sous leur propre poids. Des chevalets

doivent être places sous le panneau et cela sur les deux côtés prés de la ligne

de coupe et près du bord du panneau.

N’utilisez pas de lame endommagée ou émoussée. Les lames qui ne sont

•

pas tranchantes ou dotées d’une mauvaise voie donnent un trait de scie étroit qui

entraine une friction excessive un coincement de lame et un recul.

Assurez-vous toujours que les leviers de verrouillage de réglage de la coupe

•

en biseau et de la profondeur de la lame sont bien montés et serrés avant

de scier. Si le réglage de la lame change pendant le sciage cela peut entrainer

un coincement ou un recul.

Faites toujours très attention lors d’une coupe d’ouverture dans des murs

•

ou d’autres endroits cachés. La lame dépassant de l’autre côté peut entrer en

contact avec des objets qui peuvent entrainer un recul.

AVERTISSEMENT! Certains outils, tels que les sableuses électriques, les scies,

les meules, les perceuses ou certains autres outils de construction, peuvent soulever de la poussière contenant des produits chimiques susceptibles (en Californie)

d’entraîner le cancer des malformations congénitales ou pouvant être nocifs pour

94596 &

94896

Pour obtenir de l’assistance composez le 1-800-444-3353.

Page 8SKUs

Page 29

le système reproductif. Parmi ces produits chimiques, on retrouve : le plomb dans

les peintures à base de plomb; la silice cristalline dans les briques et le ciment et

autres produits de maçonnerie; l’arsenic et le chrome dans le bois de sciage ayant

subi un traitement chimique. Le risque associé à telles expositions peut varier selon

la fréquence avec laquelle on effectue ces travaux. Pour réduire l’exposition à de

tels produits, il faut travailler dans un endroit bien ventilé et utiliser l’équipement de

sécurité approprié, tel un masque anti poussière spécialement conçu pour filtrer les

particules microscopique. (California Health & Safety Code § 25249.5, et seq.)California Health & Safety Code § 25249.5, et seq.) § 25249.5, et seq.)

30.

31.

Avertissement ! Consultez votre médecin avant d’utiliser cet outil si vous portez un

stimulateur cardiaque. Le champ magnétique à proximité d’un cœur peut causer

du brouillage ou s’affaiblir le fonctionnement du stimulateur.

Avertissement ! Les consignes de sécurité et précautions mentionnées dans ce

guide ne couvriront pas toutes les conditions et situations que peut arriver. Il vous

incombe d’utiliser en toute sécurité.

CONSERVEZ CES INSTRUCTIONS

MISE À LA TERRE

AVERTISSEMENT!

Une mauvaise connexion du fil de terre de l’outil peut entraîner un risque de choc

électrique. En cas de doutes, consultez un électricien qualifié ou une personne

affectée à l’entretien. Ne modifiez pas la fiche de l’outil. Ne modifiez pas la fiche

mise à la terre à trois broches. N’utilisez pas l’outil si le cordon d’alimentation

ou la fiche est endommagé. S’il est endommagé le faites réparer dans un centre

de service avant de l’utiliser.

LES OUTILS MISE À LA TERRE : LES OUTILS FICHE À TROIS BROCHES

1.

2.

Les outils étiquetés «Mise à la terre requis» sont munis d’un cordon tri filaire mise

à la terre et une prise de mise à la terre. La fiche doit être branché à un cordon mis

à la terre. En cas de fonctionnement défectueux ou de panne, la mise à la terre

assure un parcours sécuritaire de faible résistance pour le courant électrique, ce

qui réduit les risques de choc électrique. (Voir L’IMAGE A.)

La broche de mise à la terre à l’intérieur de la fiche est raccordée à travers le fil

vert à l’intérieur du cordon au conducteur de mise à la terre de l’outil. Le fil vert à

l’intérieur du cordon doit être le seul fil raccordé au conducteur de mise à la terre

de l’outil et ne devrait jamais être raccordé à une lame sous tension.

(Voir L’IMAGE A.)

94596 &

94896

Pour obtenir de l’assistance composez le 1-800-444-3353.

Page 9SKUs

Page 30

3.

L’outil doit être branché dans une prise de courant correctement installée et mise

à terre conformément à tous les codes et règlements locaux. La fiche et la prise de

courant semblable à celles l’illustrée ci-après. (Voir L’IMAGE A.)

1.

2.

1.

2.

L’IMAGE A

L’IMAGE B

LES OUTILS À DOUBLE ISOLATION: LES OUTILS AVEC

FICHE À DEUX BROCHES

La double isolation élimine le besoin d’un cordon tri filaire mis à la terre et d’un

système d’alimentation mise à la terre. Ils ont un système spécial double isolation

qui se conforme aux exigences de OSHA et conforme aux normes de Underwriters Laboratories, Inc., de L’Association Canadienne de Normalisation et du Code

Electrique National. (Voir L’IMAGE B.)

Les outils à double isolation peuvent être utilisé dans l’un ou l’autre de la prise de

courant d’un circuit de 120 volts comme le montre l’illustration ci-dessus.

(Voir L’IMAGE B.)

CORDONS DE RALLONGE

L’outil avec mise à la terre doit utiliser une rallonge à trois fils. Les outils a double

isolation peuvent utiliser une rallonge à deux ou trois fils.

L’utilisation d’un cordon de calibre inférieur occasionne une baisse de tension entraînant une perte de puissance et la surchauffe. (Voir L’IMAGE C.)

3.

4.

5.

Le calibre du fil est inversement proportionnel à sa grosseur. (Voir L’IMAGE C.)

Lorsque vous utilisez plus d’un cordon de rallonge pour longueur, assurez-vous

que le calibre des fils des cordons convient à l’intensité du courant consommé par

l’outil. (Voir L’IMAGE C.)

Si vous utilisez un cordon de rallonge pour multiples outils, mettez l’intensité nominale de la plaque signalétique et utiliser le somme de déterminer le calibre de

cordon minimum requis. (Voir L’IMAGE C.)

94596 &

94896

Pour obtenir de l’assistance composez le 1-800-444-3353.

Page 10SKUs

Page 31

6.

Lorsque vous utilisez un outil électrique à l’extérieur, vous devez vous servir d’une

rallonge électrique portant le symbole « W-A » ou « W ».au Canada. Ces cordons

ont une tolérance appropriée à un usage extérieur.

7.

8.

Assurez-vous que la rallonge est bien câblée et en bon état. Si la rallonge est endommagée, remplacez-la ou faites-la réparer par un électricien qualifié avant de

vous en servir.

La rallonge ne doit pas venir en contact avec des objets tranchants, être exposée

à de la chaleur excessive ni être utilisée dans un endroit mouillé ou humide.

CALIBRE MINIMUM DES RALLONGES *

(COURANT DE 120 OU 240 V SEULEMENT)

L’INTENSITÉ

Longueur de la rallonge en pieds

NOMINALE

(au maximum)

0 – 2.0 18 18 18 18 16

2.1 – 3.4 18 18 18 16 14

3.5 – 5.0 18 18 16 14 12

5.1 – 7.0 18 16 14 12 12

7.1 – 12.0 18 14 12 10 -

12.1 – 16.0 14 12 10 - -

16.1 – 20.0 12 10 - - -

L’IMAGE C

25 pieds 50 pieds 75 pieds 100 pieds 150 pieds

*Basé sur limitant le volt du cordon, baissez à cinq volts à

150 % de l’intensité nominale.

94596 &

94896

SYMBOLES

Construction de Classe 2

Association Canadienne de Normalisation

Underwriters Laboratories Inc.

V~

A

n0 xxxx/min.

Pour obtenir de l’assistance composez le 1-800-444-3353.

Volts

Ampères

Sous Vide xxxx/tours à la minute

Page 11SKUs

Page 32

DÉBALLER

Lorsque vous déballez, assurez-vous que toutes les pièces qui figurent à la page

16 sont incluses. S’il manque des pièces ou si des pièces sont endommagées, communiquez le plus vite possible avec Harbor Freight Tools au numéro qui figure sur la couverture

de ce guide.

CARACTÉRISTIQUES

L’IMAGE E

CORDON

D’ALIMENTATION

/ FICHE

D’ALIMENTATION

ÉLECTRIQUE

1.

L’Interrupteur:: L’outil est mis en marche en appuyant sur l’interrupteur. Relâchez

l’interrupteur d’arrêter la scie.

2.

Cordon D’alimentation / Fiche D’alimentation Électrique : Le Cordon d’Alimen-

tation/ Fiche d’Alimentation Électrique doit être branché seulement à une prise de

courant de 120 V et mise à la terre. Ne tirez pas sur le cordon de le débrancher de

la prise de courant électrique.

INTERRUPTEUR

BOÎTIER

POIGNÉE

LATÉRALE

PROTÈGE LAME

SUPERIEUR

POIGNÉE

D’APPAREIL À

LUBRIFICATION

TUBE À

CIRE

PROTÈGE

LAME

INFÉRIEUR

3.

4.

5.

Poignée et Boîtier : La Poignée Latérale permets au contrôle augmenté de la

scie et plus de sécurité. Lors de l’utilisation de la scie, tenez toujours fermement

La Poignée Latérale et Boîtier.

La Protège Lame Inferieur et La Protège Lame Supérieur : Avant chaque utilisa-

tion de La Scie, assurez-vous toujours que La Protège Lame Inferieur et La Protège

Lame Supérieur fonctionnent correctement. De plus, assurez-vous que Les Lames

de La Scie ne touche pas l’une ou l’autre des Protège Lames.

La Tube à Cire et La Poignée d’Appareil de Lubrification : Utilisez toujours une

tube de cire lubrification lorsque vous coupez des aluminiums, cuivre, acier inoxy-

dable, et fonte. Lors du sciage, ces matériaux ont tendance à adoucir et adhérer à

94596 &

Pour obtenir de l’assistance composez le 1-800-444-3353.

Page 12SKUs

94896

Page 33

la lame et peut diminuer la performance de La Scie. Pour utilisez une tube à cire

insérez La Tube à cire dans le distributeur de l’appareil de lubrification. Tournez La

Poignée de l’appareil de lubrification afin d’appliquer du graisse aux Lames.

6.

Lames: Conservez toujours les lames bien affutées, propres, et bien installées

dans La Scie. Des lames émoussées peuvent faire dévier la scie ou caler sous la

pression. Il est recommandé de gardez des lames supplémentaires.

Pour placer la lame dans La Scie:

Débranchez La Scie de La prise de courant électrique.

a.

Afin d’éviter des accidents, assurez-vous de portez des gants durs lors de l’ins-

b.

tallation des neuf lames.

“INNER”

“OUTER” “OUTER”

TIGE

L’IMAGE F

Posez La Scie avec La Contré Écrou de la lame vers le haut.

c.

(Voir L’Image F, ci-dessus)

Ouvrez Le Protège Lame Inferieur.

d.

Placez La Lame portant « INNER » SUR Le Collet de Boite à Engrenage avec

e.

le mot « INNER » bien évident. Puis, alignez les trous dans La Lame avec Les

Tiges sur Le Collet et fixez bien La Lame sur Le Collet.

Placez La Lame portant « OUTER » sur L’Adaptateur de l’Arbor avec le motAdaptateur de l’Arbor avec le motde l’Arbor avec le mot

f.

« OUTER » bien évident. Puis, filetez (ne serrez pas) Le Contre Écrou de La

Lame sur Le Collet de La Boîte à Engrenage.

Tournez Les Lames pour que les trous dans les deux lames soient alignés.

g.

Insérez La Tige qu’est attachée à La Clé dans les trous alignés de La Lame.

h.

En utilisant La Clé, serrez La Contre Écrou de La Lame vers la droite. Ne serrez

i.

pas excessivement. Puis, enlevez la tige de la lame. Ceci permet aux lames

de tourner librement.

Tournez Les Lames en portant des gants pour vous assurer que Les Lames

j.

tournent facilement vers la droite et la gauche.

94596 &

94896

Pour obtenir de l’assistance composez le 1-800-444-3353.

Page 13SKUs

Page 34

MODE D’EMPLOI

Remarque : Reportez-vous à l’Image E à la page 11 durant la procédure montré ci-après.

AVERTISSEMENT! Utilisez toujours l’équipement de sécurité. Portez toujours

des lunettes protectrices approuvées par ANSI et des gants d’électricien en caout-

chouc lors de l’utilisation et entretien. Portez aussi un masque anti poussière, et

un protecteur auditif, selon les conditions.

AVERTISSEMENT! Vérifiez toujours si le protège lame se ferme correctement

avant chaque utilisation. N’utilisez pas la scie, si le protège lame ne pivote libre-

ment pas (et ne se referme pas instantanément). Assurez-vous qu’il se déplace

librement et qu’il ne touche pas la lame ni toute autre pièce, quels que soient son

angle et la profondeur de coupe.

AVERTISSEMENT! Utilisez des serre-joints (pas fournis) de retenir et de soutenir

la pièce à scier.

1.

2.

3.

4.

5.

6.

Assurez-vous que L’Interrupteur se trouve à la position d’arrêt (OFF) et La Fiche

est débranchez de sa source d’alimentation.

Insérez un tube à cire dans le distributeur de l’appareil de lubrification. Tournez la

poignée de l’appareil de lubrification pour appliquer de la graisse aux lames. Un tour

de ¼ de la poignée de l’appareil de lubrification fournira de la lubrification adéquate

pour quelques coupes. Si nécessaire, de réappliquer plus de cire, arrêtez la scie.

Attendez que les lames s’arrêtent complètement. Débranchez l’outil de la prise de

courant électrique. Puis réajustez le tube à cire afin de continuer à appliquer de la

graisse aux lames.

Branchez Le Cordon d’Alimentation / La Fiche d’Alimentation Électrique dans une

prise de courant mise à la terre d’un circuit de 120 volts.

Placez Les Lames à ½ po du début de la ligne de coupe sur la pièce à scier. Ne

laissez pas Les Lames de toucher la pièce à scier. Remarque : La largeur du trait de

scie des deux lames est environ de 1/8 po. Assurez-vous toujours de tenir compte

de ca.

Tenez La Scie fermement à deux mains. Puis, appuyez sur L’Interrupteur pour

mettre en marche l’outil.

Laissez La lame atteindre sa vitesse maximale avant de l’enfoncer dans la

pièce à scier. Lorsque vous arrêtez La Scie, laissez La Lame s’arrêter complè-arrêtez La Scie, laissez La Lame s’arrêter complè-laissez La Lame s’arrêter complè-

tement. N’appuyez pas sur La Lame pour l’arrêter.

7.

8.

Une fois que vous avez fini de scier, relâchez L’Interrupteur et laissez la lame s’ar-

rêter complètement. Apres l’arrêt de la lame, retirez-la de la pièce et débranchez

La Scie de la prise de courant.

Assurez-vous toujours de ranger l’appareil dans un endroit sécuritaire, propre et

sec, hors de la portée des enfants et des personnes inexpérimentées.

94596 &

94896

Pour obtenir de l’assistance composez le 1-800-444-3353.

Page 14SKUs

Page 35

INSPECTION, ENTRETIEN, ET NETTOYAGE

1.

2.

3.

4.

ATTENTION ! Assurez – vous que L’Interrupteur est réglé à « OFF » et que l’outil

est débranché de la prise de courant électrique avant d’y placer ou d’en enlever

des pièces ou avant un nettoyage.

AVANT CHAQUE UTILISATION, vérifiez l’état de l’outil. Vérifiez si des pièces

mobiles sont désalignées ou coincées, si des pièces sont endommagées ou toute

autre situation pouvant nuire au bon fonctionnement de l’outil. Si une vibration anor-

male se fait sentir ou si un bruit inhabituel se fait entendre, fait corriger le problème

avant de réutiliser l’appareil.

N’utilisez pas votre outil si une pièce est endommagée.

Avant chaque utilisation : Vérifiez Les Lames de La Scie. Utiliser les lames

émoussées sévèrement usera Le Moteur de La Scie et ne peut plus fonctionner

bien. Si nécessaire, remplacez les lames. Lorsque vous remplacez Les Balais

de Carbone, remplacez toujours les deux brosses à la fois. (Voir L’Image F)

Remplacer ou Nettoyer Les Balais de Carbone: Il peut falloir de remplacer ou

nettoyer Les deux Balais de Carbone lorsqu’elles ne peuvent plus fonctionner bien.

Les Balais de Carbone se trouvent à l’arrière du Boitier.

(Voir Le Schéma du Produit.)

Pour remplacer ou nettoyer Les Balais de Carbone :

5.

Dévissez et retirez les deux Vis Auto Taraudeuse se trouvent sur Le Couvercle

a.

à l’arrière du Boîtier.

Enlevez lentement Le Couvercle à l’arrière pour exposer Les Balais de Car-

b.

bone.

Enlevez Les deux Balais de Carbone de les deux Support de Brosse.

c.

Si l’une ou l’autre des balais est écaillé ou endommagé les deux brosses doi-

d.

vent être remplacées. Si elles sont vernies, et la longueur est plus de 1\8 po,

le vernis peut être retiré avec une gomme.

Lorsque vous installez Les Balais de Carbone, assurez-vous que la partie car-

e.

bone des Balais de Carbone touche Le Stator du Moteur et que les ressorts