Page 1

5,500 LB. CAPACITY 12 VOLT

WINCH WITH ROLLER FAIRLEAD

Model

91780

SET UP AND OPERATING INSTRUCTIONS

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2004 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork

contained herein may be reproduced in any shape or form without the express written consent of

Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein. Tools required for

assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

Manual Revised 10c

Page 2

SAVE THIS MANUAL

Keep this manual for the safety warnings

and precautions, assembly, operating,

inspection, maintenance and cleaning

procedures. Write the product’s serial number

in the back of the manual near the assembly

diagram (or month and year of purchase if

product has no number). Keep this manual

and the receipt in a safe and dry place for

future reference.

IMPORTANT SAFETY

INFORMATION

NOTICE is used to

address practices not

related to personal injury.

CAUTION, without the

safety alert symbol, is

used to address practices not

related to personal injury.

WARNING Read all safety warnings

and instructions. Failure to follow the

warnings and instructions may result

in electric shock, re and/or serious

injury.

Save all warnings and instructions

for future reference.

In this manual, on the labeling, and

all other information provided with

this product:

This is the safety alert

symbol. It is used to alert

you to potential personal

injury hazards. Obey all

safety messages that follow

this symbol to avoid possible

injury or death.

DANGER indicates a

hazardous situation

which, if not avoided, will result

in death or serious injury.

WARNING indicates a

hazardous situation

which, if not avoided, could

result in death or serious injury.

CAUTION, used with

the safety alert

symbol, indicates a hazardous

situation which, if not avoided,

could result in minor or moderate

injury.

The warnings, precautions, and

instructions discussed in this

instruction manual cannot cover all

possible conditions and situations that

may occur. It must be understood

by the operator that common sense

and caution are factors which cannot

be built into this product, but must be

supplied by the operator.

INSTALLATION PRECAUTIONS

1. Mounting location and hardware must

support winch and load.

2. Wear ANSI-approved safety goggles

during installation, operation and service.

3. Use supplied power cords and wire rope

listed in manual only. Do not use thinner/

longer cables or link multiple cables

together.

4. Always connect the Red wire to the

positive battery terminal and the Black

wire to the negative battery terminal.

5. Do not use a dirty, corroded or leaking

battery. You may suffer injury from acid

burns.

Page 2 For technical questions, please call 1-800-444-3353. SKU 91780

Page 3

6. Verify that the installation surface has no

hidden components or structural pieces

that will be damaged before drilling.

OPERATION PRECAUTIONS

1. Do not exceed load capacity. Be aware

of dynamic loading! Sudden load

movement may briey create excess

load causing product failure.

2. Wear ANSI-approved safety goggles and

heavy-duty leather work gloves during

operation.

3. Do not disengage clutch under load.

Engage clutch before starting.

10. Use as intended only. Do not lift items

vertically or use for aircraft purposes.

11. Prevent entanglement. Do not wear

loose clothing or jewelry, as they can

be caught in moving parts. Non-skid

footwear is recommended. Wear

restrictive hair covering to contain long

hair.

12. Inspect before every use; do not use if

damaged or if parts are loose. Examine

the winch for structural cracks, bends,

damage, frayed wire rope, and any

other condition that may affect the safe

operation of the winch. Do not use the

winch even if minor damage appears.

4. Keep clear of Fairlead when operating.

Do not try to guide wire rope.

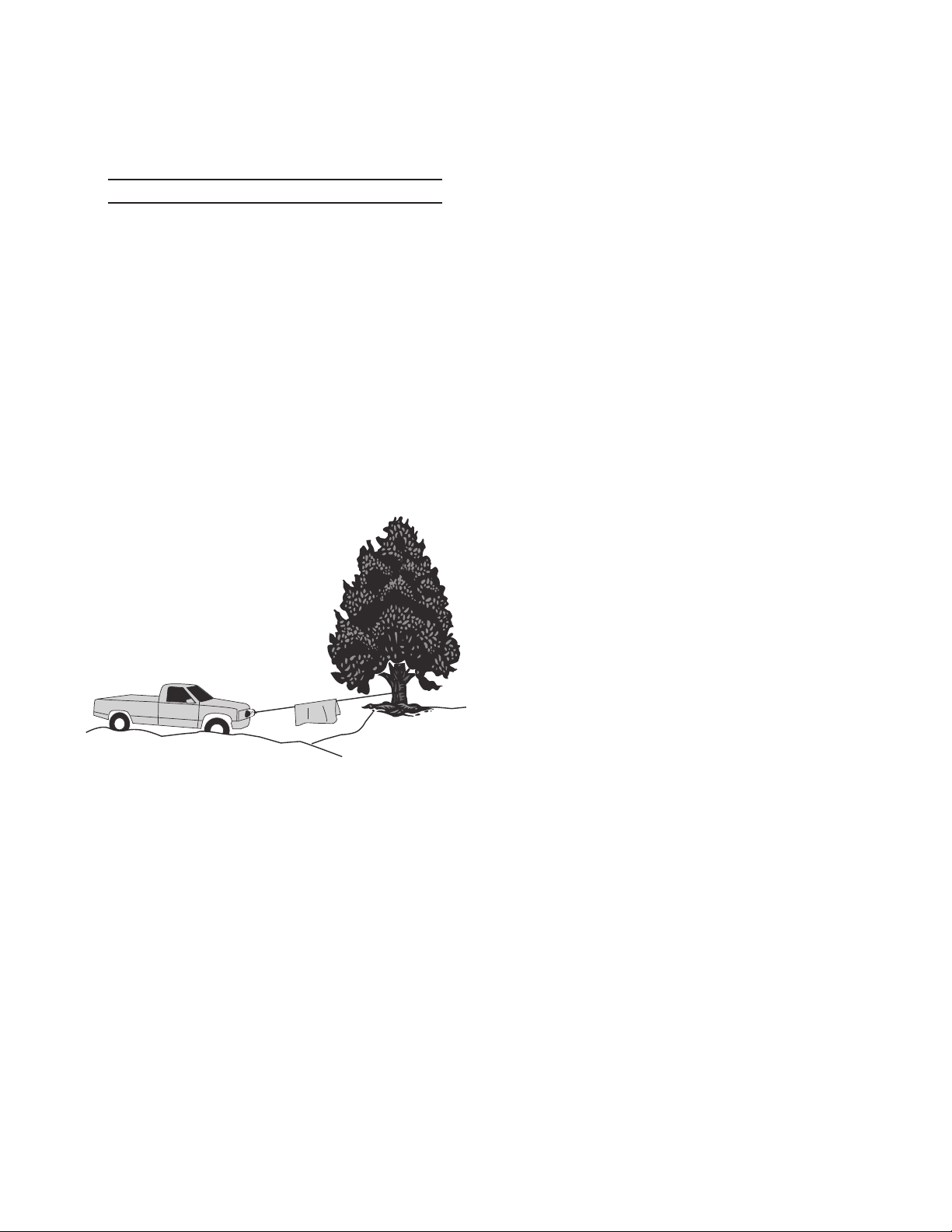

5. Place heavy rag or carpet

(not included) over wire

rope span 6 feet from

hook to help absorb

the force released if

the wire rope breaks.

6. Stay out of the direct line that the wire

rope is pulling. In case it slips or breaks,

it will “whiplash” along this line.

7. Do not winch a boat or other object with

anyone in or on it.

8. Use a spotter to assist you in assuring

that it is safe to operate the winch.

Make sure the spotter is out of the way

of the vehicle and the wire rope before

activating the winch.

13. Keep children and bystanders away

while operating. Distractions can cause

you to lose control.

14. Stay alert, watch what you are doing

and use common sense when operating.

Do not use a winch while you are tired

or under the inuence of drugs, alcohol

or medication. A moment of inattention

while operating winches may result in

serious personal injury.

15. Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the winch in unexpected

situations.

16. People with pacemakers should

consult their physician(s) before use.

Electromagnetic elds in close proximity

to heart pacemaker could cause

pacemaker interference or pacemaker

failure.

17. Do not power the hook all the way into

the fairlead or winch.

9. Do not use the hand crank, if equipped,

to “assist” the winch.

Page 3For technical questions, please call 1-800-444-3353.SKU 91780

Page 4

18. Hook onto the object using

a pulling point, tow strap or

chain. Do not wrap the

wire rope around the

object and hook onto the

wire rope itself. This can cause damage

to the object being pulled, and kink or

fray the wire rope.

19. Secure load after moving.

NO LOCKING MECHANISM.

20. Do not use a Recovery Strap while

winching. They are designed to stretch

and can suddenly whip back towards the

operator during a winching operation.

21. Keep at least 5 full turns of wire rope on

drum.

22. If wire rope begins to get entangled, stop

winch immediately and release wire rope

using switch.

thinner/longer cables or link multiple

cables together.

3. Have the winch serviced by a qualied

repair person using only identical

replacement parts. This will ensure that

the safety of the winch is maintained.

4. Maintain labels and nameplates on the

winch. These carry important safety

information. If unreadable or missing,

contact Harbor Freight Tools for a

replacement.

5. WARNING: Handling the cord on this

product will expose you to lead, a

chemical known to the State of California

to cause cancer, and birth defects or

other reproductive harm. Wash hands

after handling. (California Health &

Safety Code § 25249.5, et seq.)

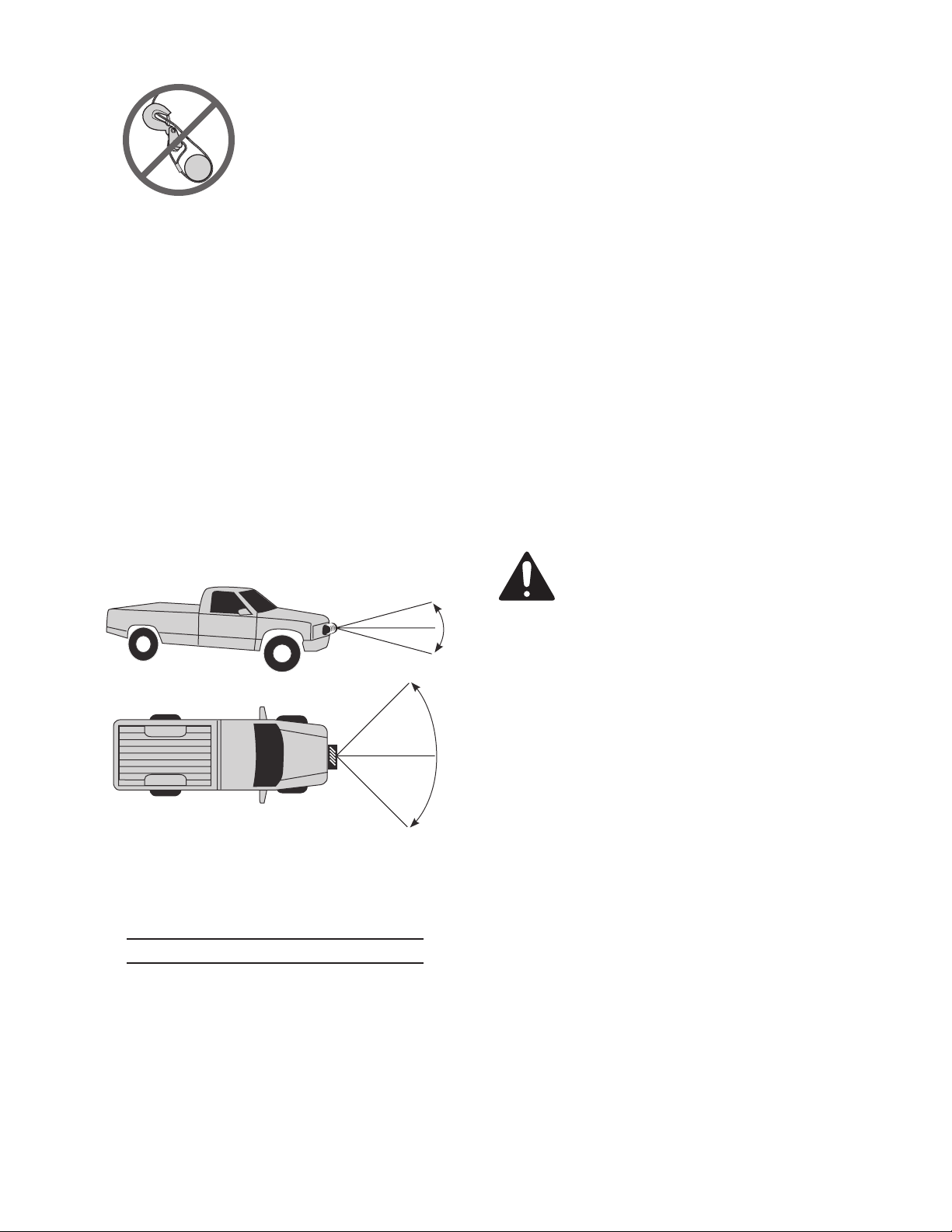

SAVE THESE

15°

15°

45°

45°

23.

Do not operate the winch at extreme

angles - do not exceed the angles shown

above.

SERVICE PRECAUTIONS

1. Wear ANSI-approved safety goggles

during installation, operation and service.

2. Use supplied power cords/wire rope or

cables listed in manual only. Do not use

INSTRUCTIONS.

Page 4 For technical questions, please call 1-800-444-3353. SKU 91780

Page 5

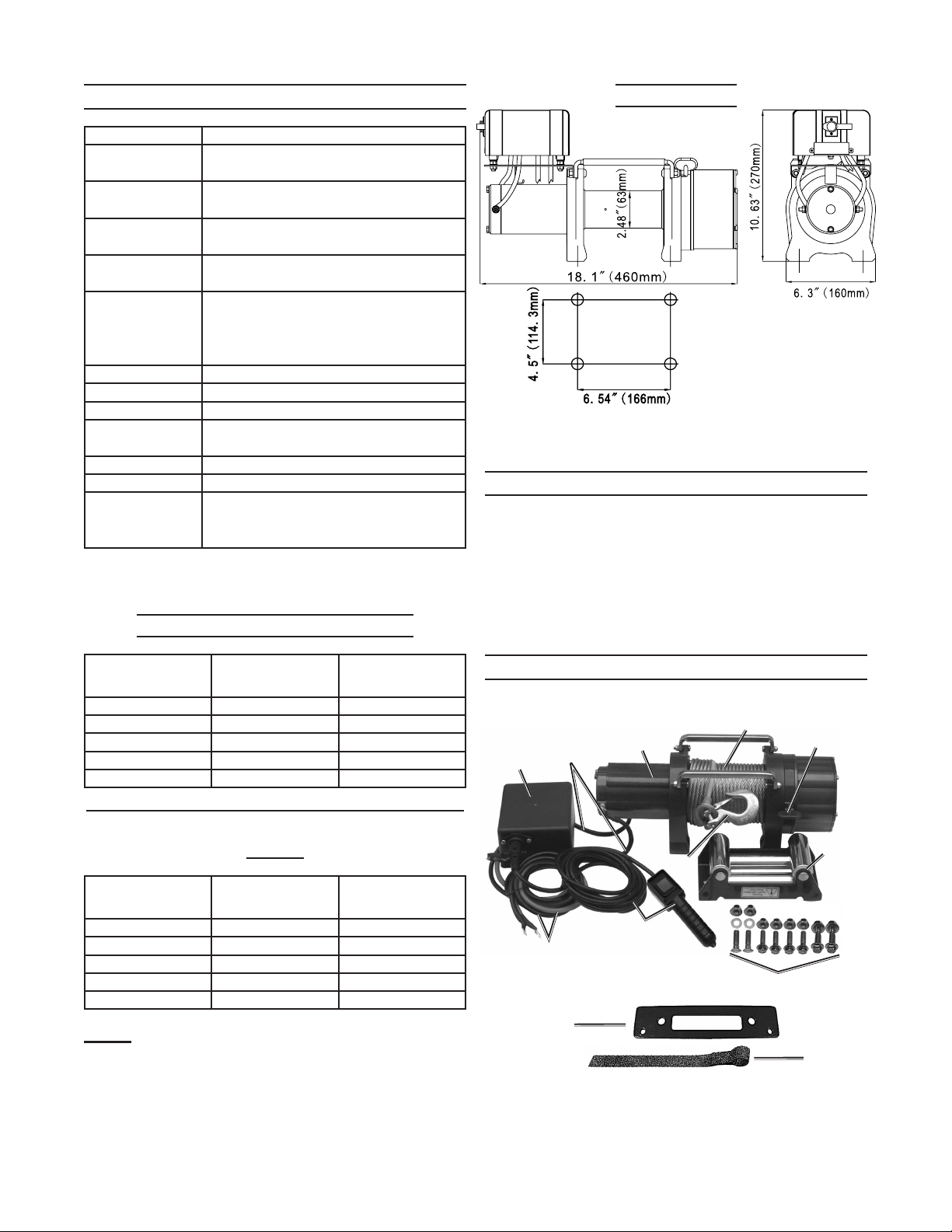

SPECIFICATIONS

Capacity 5,500 lb. Single Line Pull on Layer 1

Motor

Power Supply

Automatic Load

Holding Brake

Gear Train

Overall

Dimensions

Drum Size Ø2-1/2” Dia. x 5-1/2” W

Hook Opening 1/4”

Mounting Plate 6.54” x 4.5”

Mounting

Hardware

Power Cords 60”, 5 Gauge (AWG)

Remote Cable 12’ cord

Wire Rope

* “Aircraft” refers to the wire rope type, not the function

of the winch.

Performance of First Layer

Permanent Magnet

3.4 HP

12 VDC

650 CCA or larger battery

Yes

3-Stage Planetary

294:1 Ratio

- 17.24” L x 6.3” W x 6.30” H without

Solenoid over motor

- 18.1” L x 6.30” W x 10.63” H with

Solenoid over motor

6 Bolts (3w) M10 x 35 and Nuts M10

1/4” x 80’ Galvanized Steel

7,000 lb. Nominal Strength

(7 x 19 Aircraft* type)

Schematics

UNPACKING

When unpacking, make sure that the

item is intact and undamaged. If any parts

are missing or broken, please call Harbor

Freight Tools at 1-800-444-3353 as soon as

possible.

Line Pull

(lb.)

0 9.74 40

2,000 9.55 104

3,000 8.56 122

4,000 7.58 147

5,500 6.56 192

Line Speed

(ft./min)

Amp

Draw

Line Pull and Wire Rope Capacity by

Layer

Wire Rope

Layer

1 5500 15

2 4650 31.5

3 4000 50

4 3550 70

5 3180 78.7

Note: If a winch is to be used to pull a

vehicle, it should optimally be rated to a

single line pull at least twice the vehicle’s

weight.

Rated Line

Pull (lb.)

Wire Rope

Capacity (ft.)

Motor

Solenoid

(34w)

Battery Cables

Fairlead Mounting

Plate (45w)

Cables

(17s & 24s)

(13s & 16s)

Figure 1

COMPONENTS

Winch

(Cable Assembly (36w))

Motor

Hook

Switch

Assembly

(35w)

Mounting Hardware

Cam Ring (11)

Fairlead

(2w)

Hook

Strap

(46w)

REV 10c

Page 5For technical questions, please call 1-800-444-3353.SKU 91780

Page 6

INSTALLATION AND SETUP

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of this

manual including all text under

subheadings therein before set up

or use of this product.

Mounting the Winch

Mounting using the Mounting Frame

(Sold separately - SKU 90476):

Mounting Frame

(Sold Separately - SKU 90476)

Bolt (47w)

Washer

(5w)

Nut (6w)

1. Select a mounting site on the vehicle

bumper, truck bed, boat trailer, or other

suitable location, where the winch will

be perpendicular to the center line of the

vehicle.

NOTE: This winch can generate extreme

forces. Select a location that can

withstand the rated capacity without

damage or weakening. You may need to

use steel reinforcement plates, or weld

on additional bracing, depending on the

mounting location.

2. If the suggested mounting frame (SKU

90476 - sold separately) is not used, any

replacement mounting frame must be at

and rated to at least the winch’s capacity.

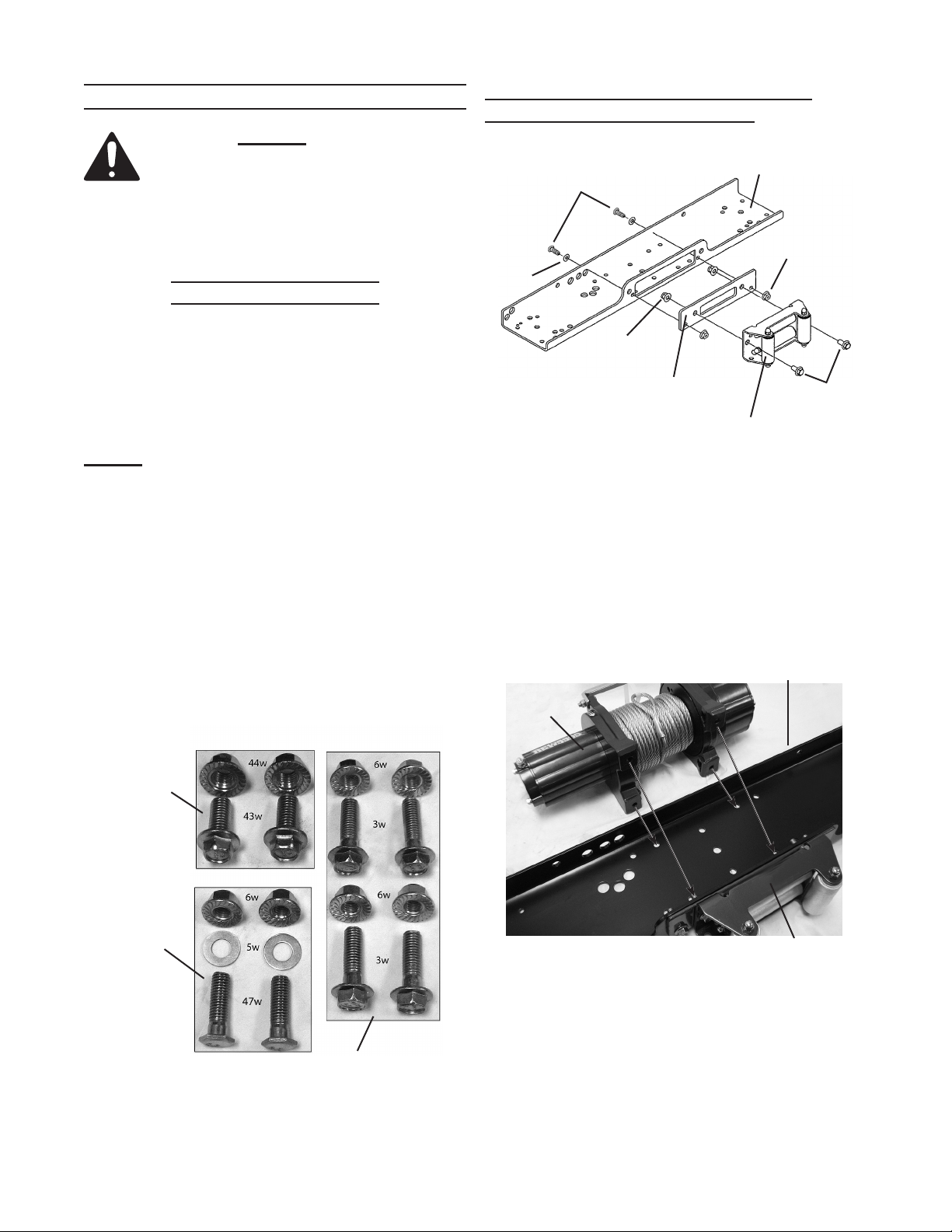

Hardware Identication:

Use to

attach

Fairlead

(2w)

to

Plate

(45w)

Flanged Nut

(44w)

Fairlead Mounting

Plate (45w)

Figure 2

1.

Mount the Fairlead (2w) to the Fairlead

Fairlead (2w)

Flanged Bolt

Mounting Plate (45w) using two Flanged

Bolts (43w) and Nuts (44w).

2. Mount the Fairlead/Mounting Plate

assembly to the Mounting Frame (sold

separately - SKU 90476) using two Bolts

(47w), Washers (5w) and Nuts (6w).

Mounting Frame

(Sold Separately

SKU 90476)

Winch

(43w)

Use to

attach

(45w) to

Frame

90476)

REV 10c

Plate

(SKU

Use to attach Winch to

Frame (SKU 90476)

Figure 3

3.

Mount the Winch to the Mounting Frame

using four Flanged Bolts (3w) and Nuts

(6w).

4. Mount the Solenoid Assembly (34w)

according to one of the options in the

Fairlead (2w)

Page 6 For technical questions, please call 1-800-444-3353. SKU 91780

Page 7

Solenoid Assembly Mounting instructions

in the following section.

Mounting the Solenoid Assembly

5. Place the Electric Winch assembly at

the location where it will be mounted.

Use the remaining holes in the Mounting

Frame as a template to mark holes for

mounting.

6. Verify that the installation surface has no

hidden components or structural pieces

that will be damaged before drilling.

7. Drill holes at the marked locations.

8. If the provided hardware does not

accommodate the installation, use

SAE grade 5 (Class 8.8) bolts (sold

separately), or higher, and torque to 35

ft-lb.

9. Attach the Hook to the loop at the end of

the Cable Assembly (36w).

Mounting using a different mounting plate:

Mounting Components

Solenoid Bracket (14s)

Solenoid

Assembly

(34w)

Figure 4

Motor

Motor Cables

(17s & 24s)

Battery Cables

(13s & 16s)

Mounting Option 1: Mounting the Solenoid

to the Mounting Frame

In this conguration, the Solenoid

Assembly (34w) is connected to the

Mounting Frame (sold separately), in line

with the Motor.

1. The plate must be rated to at least the

winch’s capacity.

2. Place the winch on the vehicle at the

desired location, and mark the mounting

holes. Decide how the Solenoid and

Fairlead will be mounted and mount

them in place.

3. Before drilling, verify that the installation

surface has no hidden components or

structural pieces that will be damaged or

that could cause structural weakening.

4. Install the winch using the hardware

specied on the Specication chart.

5. Attach the Hook to the loop at the end of

the Cable Assembly (36w).

Solenoid Assembly

(34w)

Motor

Cables

(17s & 24s)

Motor Terminals

Figure 5

1.

Line up the Solenoid Assembly with the

end of the Motor. Unthread one nut and

washer from each Motor Terminal and

attach the two Motor Cables (17s and

24s), securing in place with the nuts and

washers.

Page 7For technical questions, please call 1-800-444-3353.SKU 91780

Page 8

Solenoid Assembly

(34w)

Battery Cables

(13s & 16s)

Bracket

Mounting

Holes

Solenoid

Assembly

(34w)

Motor

Mounting Frame

Figure 6

2.

Unthread the nuts, spring washers and

(Sold Separately -

SKU 90476)

washers from the four bolts on the base

of the Solenoid. Insert the bolts on the

base of the Solenoid Assembly (34w)

through the holes in the Mounting Frame

and secure in place by replacing the

washers, spring washers and nuts.

Mounting Option 2: Mounting the Solenoid

to the Solenoid Bracket (40w)

In this conguration, the Solenoid is

rotated so that the two short cables

attached to the Motor Terminals are

crossed and Solenoid Assembly

(34w) and Solenoid Bracket (40w) are

positioned over, and attached to, the

Motor.

Solenoid

Bracket

(40w)

Bracket Tie-down

Figure 7

1.

To attach the Solenoid Assembly (34w)

Strap (41w)

Motor Cables

(17s & 24s)

to the Solenoid Bracket (40w):

a. Unthread the nuts, spring washers and

washers from the four bolts on the base

of the Solenoid Assembly.

b. Position the Solenoid Bracket so the

Bracket Mounting Holes face away

from the Motor Assembly and the Motor

Cables (17s & 24s) on the Solenoid

Assembly face the Motor Assembly.

c. Route the Cables through the openings

in the Solenoid Bracket, then slide the

Bolts on the Solenoid Assembly through

the holes in the bottom of the Solenoid

Bracket and secure the Solenoid

Assembly to the Solenoid Bracket by

replacing the washers, spring washers

and nuts.

d. Line up the Solenoid Assembly with the

end of the Motor Assembly and attach

the two Motor Cables (24s) to the motor

terminals.

Page 8 For technical questions, please call 1-800-444-3353. SKU 91780

Page 9

Solenoid

Assembly (34w)

Motor Cables

(17s & 24s)

Motor

Figure 8

2.

To attach the Solenoid Assembly/Bracket

Bracket mounted to

Tie Bar (10w) ends

Bracket

Tie-down

Strap (41w)

to the Motor Assembly:

a. Slide the Bracket Tie-down Strap (41w)

over the hook in the center of the

Solenoid Bracket (40w).

b. Unthread the two Bolts (12-1w) and

Nuts (13w) from the motor end of the

Tie Bars (10w).

c. Rotate the Solenoid Assembly/Bracket

so that the holes on the side of the

Bracket line up with the end of the Tie

Bars (10w).

d. Re-insert and tighten the Bolts (12-1w)

and Nuts (13w), securing the Solenoid

Bracket to the Tie Bar.

Turn the Power Switch of the

winch off and disconnect the

power and control cables before

making wiring connections.

TO PREVENT

SERIOUS INJURY

FROM LEAKING BATTERY ACID:

Do not use a dirty, corroded or

leaking battery. Only use a 12V

automotive (or equivalent)

battery, in good condition.

1. Plan a route for the wiring from the

point of the vehicle where the winch

will be mounted or used to the battery.

This route must be secure, out of the

way of moving parts, road debris, or

any possibility of being damaged by

operation or maintenance of the vehicle.

For example, you may wish to route

the wires under the vehicle, attaching

it to the frame using suitable fasteners.

Do not attach the wires to the exhaust

system, drive shaft, emergency brake

cable, fuel line, or any other components

which may damage wiring through heat

or motion, or create a re hazard.

2. If you drill through the bumper or any

part of the body to route the wires, be

sure to install a rubber grommet in the

hole to prevent fraying of the wires at

that point.

e. Secure the Solenoid Bracket to the

Motor by tightening the Bracket Tie

Down Strap (41w) around both the

Solenoid Bracket hook and the Motor

Assembly. Pull the Strap until secure.

Wiring

TO PREVENT

SERIOUS INJURY

FROM EXPLOSION DUE TO

SPARKING AT THE BATTERY

CONNECTION:

3. Route the Battery Cables (13s & 16s)

from the point the winch will be used to

the battery, following the precautions

discussed above.

4. Attach the red Battery Cable (13s) to the

positive terminal on the battery.

5. Attach the black Battery Cable (16s) to

the negative terminal of the battery.

Page 9For technical questions, please call 1-800-444-3353.SKU 91780

Page 10

Solenoid Assembly (34w)

OPERATION

Socket (6s)

Switch

Assembly

(35w)

Socket Cover (2s)

Figure 9

6.

Lift the Socket Cover (2s) on the

Solenoid Assembly (34w) and insert the

Switch Assembly (35w) connector into

the Socket (6s). Disconnect the Switch

Assembly when not in use.

Note: The attachment of the Motor Cables

(17s & 24s) determines the way the

toggle button on the Switch Assembly

(35w) operates. After the unit is mounted

and powered, check the direction of the

Power In and Power Out on the Switch

button. To change the direction on the

Switch, disconnect the Battery Cables

from the battery, switch the Motor Cable

connections on the Motor terminal, then

reconnect the Battery Cables.

Preparing the Wire Rope

BEFORE FIRST USE:

1. The wire rope must be properly coiled

under tension to be able to support a

load without damage.

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of this

manual including all text under

subheadings therein before set up

or use of this product.

The instructions that follow are

basic guidelines only and cannot

cover all situations encountered

during use. The operator and

assistants must carefully plan

usage to prevent accidents.

1. Examine the wire rope. Do not use the

winch if the wire rope is frayed, kinked or

damaged.

2. Fully charge the vehicle’s battery.

3. Check the winch’s electrical connections.

All connections must be tight and clean.

4. Put the vehicle’s transmission in Neutral.

5. If the vehicle where the winch is mounted

is not supposed to move, engage the

emergency brake and block the wheels

using wheel chocks.

6. To pull out the wire rope, move the Cam

Ring (11w) to the OUT position, slide the

loop of the Hook Strap (46w) over the

hook, then pull on the Hook Strap to pull

out the wire rope.

WARNING! Leave at least ve full

turns of wire rope on the drum.

2. Uncoil the wire rope, except for 5 full

wraps.

3. Recoil the wire rope back into the winch

under at least 500 lb. of tension.

Page 10 For technical questions, please call 1-800-444-3353. SKU 91780

Page 11

Double Line Rigging:

a. A double line system should be used

whenever possible.

It reduces the load on the winch, allowing

it to work longer with less heat buildup.

It reduces load on the winch in two ways:

• it utilizes the lower layers of wire rope

that have higher capacity, and

• it halves the load on the winch through

pulley action.

Stationary

Winching

Vehicle

(Chock tires, and

set parking brake)

Carpet

b.

Connect the wire rope for a double line

system as shown above. Use a pulley

block (not included) properly rated for

the load to be pulled and designed to be

operated with this winch’s wire rope.

c. Loop the wire rope around the pulley and

connect to another part of the vehicle’s

chassis or to a separate anchor point.

Do not anchor the cable back to the

winch or winch mount.

Load

Safety Clasp

7.

Hook onto the object using a pulling

point, tow strap, tree strap, or chain.

Make sure the hook’s safety clasp is fully

closed.

Do not wrap the wire

rope around the object

and hook onto the wire

rope itself. This can

damage the object being

pulled, and kink or fray the wire rope.

8. Do not use a Recovery Strap while

winching. They are designed to stretch

and can suddenly whip back towards the

operator during a winching operation.

9. Place heavy rag or carpet

(not included) over wire

rope span 6 feet from

hook to help absorb

the force released if

the wire rope breaks.

10. Re-engage the clutch by moving the

Cam Ring to the IN position.

11. WARNING! Do not allow anyone to

stand near the wire rope, or in line with

the wire rope behind the winch while it

is under power. If the wire rope should

slip or break, it can suddenly whip back

towards the winch, causing a hazard for

anyone in the area. Stand well to the

side while winching.

Page 11For technical questions, please call 1-800-444-3353.SKU 91780

Page 12

12. Attach the Switch Assembly (35w) to the

Socket (6s) on the Solenoid Assembly

(34w).

13. When it is safe to do so, use the button

on the Switch Assembly to retract the

wire rope, and winch the item as desired.

Do not power the hook all the way

into the fairlead to prevent damage.

15°

15°

45°

45°

14.

Do not operate the winch at extreme

angles - do not exceed the angles shown

above. Pay attention to how the wire

rope is coiling onto the drum. If it is

building up on one end of the drum, stop,

uncoil the wire rope and recoil it from a

less severe angle to prevent damage.

CAUTION Do not use the winch in a

constant duty application, it is

designed for INTERMITTENT USE

ONLY. Keep the duration of the

pulling job as short as possible. If the

motor becomes very hot to the touch,

stop and let it cool down for several

minutes. Do not pull for more than

one minute at or near the rated load.

Do not maintain power to the Winch if

the motor stalls. Double Line Rigging

will help prevent overloading and

should be used whenever practical.

17. When nished pulling the load, reverse

the direction of the winch just enough to

release tension on the Cable Assembly

(36w) so that you can unfasten the Hook

from the load and reel in the cable.

18. To prevent accidents, turn off the winch

and disconnect its power supply after

use. Clean, then store the winch indoors

out of children’s reach. If the cable is

wet, dry it then apply light oil right after

use.

If the object to be pulled must be pulled

at an angle in relation to the winch, use

a pulley and an anchor point directly in

front of the winch, as shown, to keep the

cable pull straight.

15. WARNING! Stop the winch and release

tension on the wire rope before moving

the rag or carpet placed on it.

16. Do not continue use of the winch until

the battery is completely run down. You

may wish to keep the engine running

while using this winch, to continually

recharge the battery. However, exercise

extreme caution when working around a

running vehicle.

Page 12 For technical questions, please call 1-800-444-3353. SKU 91780

Page 13

MAINTENANCE AND

SERVICING

Procedures not specically

explained in this manual must

be performed only by a qualied

technician.

TO PREVENT

SERIOUS INJURY

FROM ACCIDENTAL

OPERATION:

Unplug the Switch Assembly

(35w) connector from the Socket

(6s) on the Solenoid Assembly

(34w) and disconnect the Battery

Cables (13s & 16s) before

performing any inspection,

maintenance, or cleaning

procedures.

TO PREVENT SERIOUS INJURY

FROM WINCH FAILURE:

Do not use damaged equipment.

If abnormal noise or vibration

occurs, have the problem

corrected before further use.

4. The winch’s internal mechanism is

permanently lubricated. Do not open

the housing. However, if the winch is

submerged, it should be opened, dried,

and relubricated by a qualied technician

as soon as possible to prevent corrosion.

Cable Replacement

1. Move the Cam Ring (11w) to the OUT

position.

2. Manually pull the Cable out to it’s full

length. Note how the existing cable is

connected to the inside of the drum.

3. Remove the old Cable Assembly and

attach the new assembly.

CAUTION: Do not replace with inferior cable.

Always use an approved replacement

part from Harbor Freight Tools.

4. The cable must be rewound in the

direction shown on the winch. Retract

the Cable onto the cable drum being

careful not to allow kinking.

5. Coil the wire rope 5 full wraps.

Cleaning, Maintenance, and

Lubrication

1. BEFORE EACH USE, inspect the

general condition of the winch. Check

for loose hardware, misalignment or

binding of moving parts, cracked or

broken parts, damaged electrical wiring,

corroded or loose terminals, and any

other condition that may affect its safe

operation. Examine the wire rope. Do

not use the winch if the wire rope is

frayed, kinked or damaged.

2. AFTER USE, wipe the external surfaces

of the winch with a clean cloth.

3. Lubricate the wire rope occasionally with

a light oil.

6. Then, coil the wire rope into the winch

under at least 500 lb. of tension.

Page 13For technical questions, please call 1-800-444-3353.SKU 91780

Page 14

Troubleshooting

Problem Possible Causes Likely Solutions

Motor does not turn

on.

Motor runs but cable

drum does not turn.

Motor runs slowly

or without normal

power.

Motor runs in one

direction only.

Motor overheats. 1. Incorrect power cords.

1. Switch not connected properly.

2. Loose power cord connections.

3. Battery needs charging.

4. Solenoid malfunctioning.

5. Defective Switch.

6. Defective motor.

7. Water has entered motor.

8. Internal damage or wear.

Clutch not engaged. Move the Cam Ring to the In position. If

1. Insufcient current or voltage.

2. Loose or corroded battery cable

connections.

3. Incorrect power cords.

1. Defective or Stuck solenoid.

2. Defective Switch Assembly.

2. Winch running time too long.

1. Connect Switch properly.

2. Tighten all connections.

3. Fully charge battery.

4. Tap solenoid to loosen contacts. Briey

apply 12 volts directly to coil terminals.

Clicking indicates proper activation.

5. Replace Switch.

6. Check for voltage at armature port with

Switch pressed. If voltage is present, replace

motor.

7. Allow to drain and dry. Run in short bursts

without load until completely dry.

8. Have technician service winch.

problem persists, a qualied technician needs

to check and repair.

1. Battery weak, recharge. Run winch with

vehicle engine running.

2. Clean, tighten, or replace.

3. Use only supplied power cords.

1. Tap Solenoid to loosen contacts. Repair or

replace solenoid.

2. Replace Switch Assembly.

1. Use only supplied power cords.

2. Allow winch to cool down periodically.

Follow all safety precautions whenever diagnosing or servicing the winch.

Disconnect power supply before service.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE

OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED

TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR

EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY

CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK

AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT

PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Page 14 For technical questions, please call 1-800-444-3353. SKU 91780

Page 15

WINCH PARTS LIST & ASSEMBLY DIAGRAM

Part Description Qty

2w Fairlead 1

3w Bolt M10 x 34 4

5w Washer M10 2

6w Nut M10 6

7w End Bearing 1

8w Spring 6

9w Locking Ring 1

10w Tie Bar 2

11w Cam Ring 1

12w Bolt M8 x 30 4

13w Nut M8 4

14w Gear Ring 1

15w Gear Retainer Ring 1

16w Half Ring 2

17w Bolt M6 x 20 6

18w Gear - Output 1

20w Roll Pin Ø4 x 10 1

21w Cable Anchor 1

22w Bolt M6 x 12 1

23w Gear (Intermediate) 1

24w Gear (Input) 1

25w Thrust Disc 1

Part Description Qty

26w Thrust Washer 3

27w Bushing-Drum 2

28w Gasket 1

29w Cover Gear Housing 1

30w Screw M5 x 12 6

31w Drum 1

32w Break / Shaft Assembly 1

33w Motor End Bearing Assembly 1

34w Solenoid Assembly 1

35w Switch Assembly 1

36w Cable Assembly 80’ L x 1/4” D 1

37w Gear Carrier Assembly - Output 1

38w Gear Carrier Assembly - Intermediate 1

39w Gear Carrier Assembly - Input 1

40w Solenoid Bracket 1

41w Bracket Tie-Down Strap 1

42w Spring Washer 5 mm 6

43w Bolt M12 x 25 2

44w Nut M12 2

45w Fairlead Mounting Plate 1

46w Hook Strap 1

47w Bolt M10 x 34 (none standard) 2

Note: When ordering parts for Winch, include the sufx “w” after the part number.

5

REV 10c

Page 15For technical questions, please call 1-800-444-3353.SKU 91780

Page 16

SOLENOID PARTS LIST & ASSEMBLY DIAGRAM

Part Description Qty

1s Plastic Housing 1

2s Socket Cover 1

3s Flat Washer 6

4s Spring Washer 4

5s Screw M5 x 10 4

6s Socket 1

7s Screw M5 x 12 2

8s Copper Spacer 1

9s Screw M5 x 12 2

10s Solenoid 1

11s Ground Cable 1

12s Screw M6 x 30 4

Part Description Qty

13s Battery Cable (red) (+) 1

14s Solenoid Bracket 1

15s Nut M8 4

16s Battery Cable (Black) (-) 1

17s Motor Cable (Black) (-) 1

18s Nut M5 1

19s Spacer 3

20s Flat Washer 8

21s Spring Washer 8

22s Nut M6 8

23s Fiberglass Sleeve 1

24s Motor Cable (Black) (+) 1

REV 10c

Page 16 For technical questions, please call 1-800-444-3353. SKU 91780

Page 17

ROLLER FAIRLEAD PARTS LIST & ASSEMBLY DIAGRAM

Part Description Qty

1f Cap Nut 8

2f Lock Washer 8

3f Short Shaft 2

4f Nylon Bushing 8

Part Description Qty

5f Short Roller (Ø 3-3/8: x 1-3/8” 2

6f Long Shaft 2

7f Long Roller (Ø 4-3/4” x 1-3/8”) 2

8f Base 1

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not available

individually as replacement parts.

Page 17For technical questions, please call 1-800-444-3353.SKU 91780

Page 18

90 Day Warranty

Harbor Freight Tools Co. makes every effort to assure that its products meet high quality

and durability standards, and warrants to the original purchaser that this product is free from

defects in materials and workmanship for the period of 90 days from the date of purchase. This

warranty does not apply to damage due directly or indirectly, to misuse, abuse, negligence or

accidents, repairs or alterations outside our facilities, criminal activity, improper installation,

normal wear and tear, or to lack of maintenance. We shall in no event be liable for death,

injuries to persons or property, or for incidental, contingent, special or consequential damages

arising from the use of our product. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation of exclusion may not apply to

you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with

transportation charges prepaid. Proof of purchase date and an explanation of the complaint

must accompany the merchandise. If our inspection veries the defect, we will either repair or

replace the product at our election or we may elect to refund the purchase price if we cannot

readily and quickly provide you with a replacement. We will return repaired products at our

expense, but if we determine there is no defect, or that the defect resulted from causes not

within the scope of our warranty, then you must bear the cost of returning the product.

This warranty gives you specic legal rights and you may also have other rights which vary

from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

Page 18 For technical questions, please call 1-800-444-3353. SKU 91780

Loading...

Loading...