Chicago Electric 65712 User Manual

GARAGE DOOR OPENER

WITH DUAL REMOTES

65712

SET UP AND OPERATING INSTRUCTIONS

Distributed exclusively by Harbor Freight Tools®.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2008 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork

contained herein may be reproduced in any shape or form without the express written consent of

Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein. Tools required for

assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

CONTENTS

IMPORTANT SAFETY

INFORMATION ............................3

GENERAL SAFETY WARNINGS .......3

SPECIFIC SAFETY WARNINGS ........5

GROUNDING ................................. 6

DOUBLE INSULATED TOOLS:

TOOLS WITH TWO PRONG

PLUGS .............................................6

EXTENSION CORDS .........................7

SYMBOLOGY .....................................7

SPECIFICATIONS ..........................8

UNPACKING ..................................8

NOTE ..............................................8

ASSEMBLY INSTRUCTIONS ........8

ADJUSTMENT INSTRUCTIONS . 19

MAINTENANCE AND

SERVICING ...............................27

PLEASE READ THE

FOLLOWING CAREFULLY ....... 27

TROUBLESHOOTING .................28

PARTS LIST .................................29

ASSEMBLY DIAGRAM ................ 30

SKU 65712 For technical questions, please call 1-800-444-3353. Page 2

SAVE THIS MANUAL

Keep this manual for the safety warnings and precautions, assembly, operating,

inspection, maintenance and cleaning procedures. Write the product’s serial number

in the back of the manual (or month and

year of purchase if product has no number). Keep this manual and the receipt in

a safe and dry place for future reference.

NOTICE is used to

address practices

not related to personal injury.

CAUTION, without

the safety alert

symbol, is used to address

practices not related to

personal injury.

General Safety Warnings

IMPORTANT SAFETY

INFORMATION

In this manual, on the labeling,

and all other information provided with this product:

This is the safety alert

symbol. It is used to alert

you to potential personal

injury hazards. Obey all

safety messages that

follow this symbol to avoid

possible injury or death.

DANGER indicates

a hazardous

situation which, if not

avoided, will result in death or

serious injury.

WARNING

indicates a

hazardous situation which, if

not avoided, could result in

death or serious injury.

CAUTION, used

with the safety

alert symbol, indicates a

hazardous situation which, if

not avoided, could result in

minor or moderate injury.

WARNING Read all safety

warnings and instructions.

Failure to follow the warnings and

instructions may result in electric

shock, re and/or serious injury.

Save all warnings and

instructions for future reference.

Work area safety1.

Keep work area clean and well lit. a.

Cluttered or dark areas invite acci-

dents.

Do not operate the Garage Door b.

Opener in explosive atmospheres,

such as in the presence of ammable liquids, gases or dust. Power

equipment creates sparks which may

ignite the dust or fumes.

Keep children and bystanders c.

away while operating the Garage

Door Opener. Distractions can

cause you to lose control.

Electrical safety2.

The Garage Door Opener’s electri-a.

cal Plug must match the Outlet.

Never modify the Plug in any way.

Do not use any adapter Plugs with

grounded power equipment. Un-

modied Plugs and matching Outlets

will reduce risk of electric shock.

SKU 65712 For technical questions, please call 1-800-444-3353. Page 3

Avoid body contact with grounded b.

surfaces such as pipes, radiators,

ranges and refrigerators. There is

an increased risk of electric shock if

your body is grounded.

Do not expose the Garage Door c.

Opener to rain or wet conditions.

Water entering power equipment will

increase the risk of electric shock.

Do not abuse the Power Cord. d.

Never use the Cord for unplugging

the Garage Door Opener. Keep the

Cord away from heat, oil, sharp

edges or moving parts. Damaged

or entangled Cords increase the risk

of electric shock.

If operating the Garage Door Open-e.

er in a damp location is unavoidable, use a Ground Fault Circuit

Interrupter (GFCI) protected supply. Use of a GFCI reduces the risk

of electric shock.

Personal safety3.

Stay alert, watch what you are do-a.

ing and use common sense when

operating the Garage Door Opener.

Do not use power equipment while

you are tired or under the inuence

of drugs, alcohol or medication. A

moment of inattention while operating

power equipment may result in seri-

ous personal injury.

Use personal protective equipment b.

when assembling the Garage Door

Opener. Wear ANSI-approved

safety goggles. Safety equipment

such as dust mask, non-skid safety

shoes, hard hat, or hearing protection

used for appropriate conditions will

reduce personal injuries.

Do not overreach when assem-c.

bling the Garage Door Opener.

Keep proper footing and balance

at all times. This enables better

control of the power equipment in

unexpected situations.

Dress properly when assembling d.

the Garage Door Opener. Do

not wear loose clothing or jewelry. Keep your hair, clothing and

gloves away from moving parts.

Loose clothes, jewelry or long hair

can be caught in moving parts.

Power equipment use and care4.

Do not force the Garage Door a.

Opener. Use the correct power

equipment for your application.

The correct power equipment will do

the job better and safer at the rate for

which it was designed.

Do not use the Garage Door Open-b.

er if the Remote Controls do not

turn it on and off. Any power equip-

ment that cannot be controlled with

its Remote Control is dangerous and

must be repaired.

Disconnect the electrical Plug from c.

the power source before making

any adjustments, or changing accessories. Such preventive safety

measures reduce the risk of starting

the power equipment accidentally.

Store the Remote Controls out of d.

the reach of children and do not

allow persons unfamiliar with the

Garage Door Opener or these instructions to operate the product.

Power equipment is dangerous in the

hands of untrained users.

Maintain the Garage Door Opener. e.

Check for misalignment or binding of moving parts, breakage of

parts and any other condition that

may affect the power equipment’s

SKU 65712 For technical questions, please call 1-800-444-3353. Page 4

operation. If damaged, have the

power equipment repaired before

use. Many accidents are caused by

poorly maintained power equipment.

Service5.

Have your Garage Door Opener a.

serviced by a qualied repair person using only identical replacement parts. This will ensure that

the safety of the power equipment is

maintained.

Specic Safety Warnings

Maintain labels and nameplates on 1.

the Garage Door Opener. These

carry important safety information. If

unreadable or missing, contact Harbor Freight Tools for a replacement.

To avoid serious personal injury from 2.

entanglement, remove all ropes connected to the Garage Door Opener

before installing the unit. Installation

and wiring must be in compliance

with your local building and electrical codes. Connect the Power Cord

of this unit only to properly earthed

mains.

Keep the Garage Door Opener bal-3.

anced. Sticking or binding doors

must be repaired or replaced. Garage doors, door springs, cables, pulleys, brackets and their hardware are

under extreme tension and can cause

serious personal injury. Do not attempt to loosen, move or adjust them.

Instead, have a qualied service

technician perform the adjustments

and repairs.

The “safety reverse system test” is 4.

very important. The Garage Door

Opener MUST reverse on contact

with a 1-1/2” obstacle placed on the

oor. Failure to properly adjust the

Garage Door Opener may result in

serious personal injury from a closing

Garage Door. Repeat the test once a

month and make any needed adjustments.

The Garage Door Opener must not 5.

extend over a public byway during

operation.

Fasten the “CHILD WARNING” label 6.

adjacent to the lighted door control

button as a reminder of safe operating procedures. Disengage all existing garage door locks to avoid damage to the Garage Door Opener.

Any Garage Door Opener control 7.

buttons (if installed) MUST be located

where the Garage Door is visible,

but out of the reach of children. Do

not allow children to operate control

buttons or Remote Controls. Serious

personal injury from a closing Garage

Door may result from misuse of the

Opener.

Activate Remote Controls ONLY 8.

when the Garage Door Opener is

in full view, free of obstructions and

the Opener is properly adjusted. No

one should enter or leave the garage

while the Door is in motion. Do not

allow children to play near the Door.

Use the Manual Release only to 9.

disengage the Trolley and, if possible,

only when the Door is closed. Do not

use the red Handle to pull the Door

open or closed.

This product is provided with a Trans-10.

former and Power Supply Cord of

special design which, if damaged,

SKU 65712 For technical questions, please call 1-800-444-3353. Page 5

MUST be replaced by a qualied service technician.

People with pacemakers should 11.

consult their physician(s) before use.

Electromagnetic elds in close proximity to heart pacemaker could cause

pacemaker interference or pacemaker failure. In addition, people with

pacemakers should:

• Avoid operating alone.

• Do not use with power switch locked

on.

• Properly maintain and inspect to

avoid electrical shock.

• Any power cord must be properly

grounded. Ground Fault Circuit Interrupter (GFCI) should also be implemented – it prevents sustained electrical shock.

WARNING: Handling the Power Cord 12.

on this product will expose you to

lead, a chemical known to the State

of California to cause cancer, and

birth defects or other reproductive

harm. Wash hands after handling.

(California Health & Safety Code §

25249.5, et seq.)

GROUNDING

TO PREVENT

ELECTRIC SHOCK

AND DEATH FROM

INCORRECT GROUNDING

WIRE CONNECTION:

Check with a qualied

electrician if you are in doubt

as to whether the Outlet is

properly grounded. Do not

modify the Power Cord Plug

provided with the equipment.

Never remove the grounding

prong from the Plug. Do not

use the equipment if the

Power Cord or Plug is

damaged. If damaged, have it

repaired by a service facility

before use. If the Plug will not

t the Outlet, have a proper

Outlet installed by a qualied

electrician.

Double Insulated Tools: Tools

with Two Prong Plugs

The warnings, precautions, and in-13.

structions discussed in this instruction

manual cannot cover all possible conditions and situations that may occur.

It must be understood by the operator

that common sense and caution are

factors which cannot be built into this

product, but must be supplied by the

operator.

SAVE THESE

INSTRUCTIONS.

SKU 65712 For technical questions, please call 1-800-444-3353. Page 6

Equipment marked “Double Insu-1.

lated” do not require grounding. They

have a special double insulation

system which satises OSHA requirements and complies with the applicable standards of Underwriters Laboratories, Inc., the Canadian Standard

Association, and the National Electri-

cal Code. (See Outlets for 2-Prong

Plug.)

sharp objects, excessive heat, and

damp or wet areas.

Double insulated equipment may be 2.

used in either of the 120 volt Outlets

shown in the preceding illustration.

(See Outlets for 2-Prong Plug.)

Extension Cords

Double Insulated equipment can use 1.

either a two or three wire Extension

Cord.

As the distance from the supply Out-2.

let increases, you must use a heavier

gauge Extension Cord. Using Extension Cords with inadequately sized

wire causes a serious drop in voltage,

resulting in loss of power and possible equipment damage.

(See Table A.)

The smaller the gauge number of the 3.

wire, the greater the capacity of the

cord. For example, a 14 gauge Cord

can carry a higher current than a 16

gauge Cord. (See Table A.)

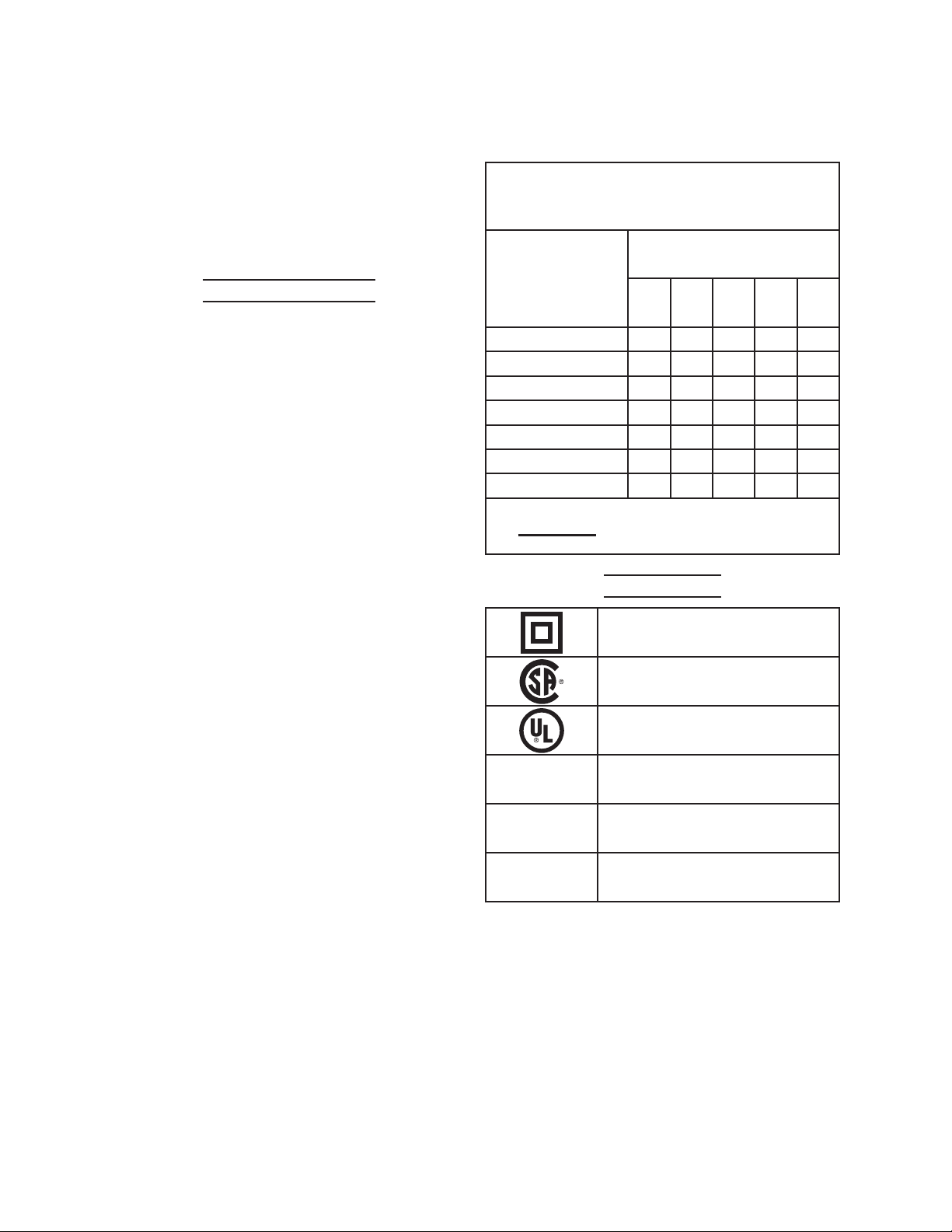

RECOMMENDED MINIMUM WIRE

GAUGE FOR EXTENSION CORDS*

(120/240 VOLT)

EXTENSION CORD

NAMEPLATE

LENGTH

AMPERES

(at full load)

0 – 2.0 18 18 18 18 16

2.1 – 3.4 18 18 18 16 14

3.5 – 5.0 18 18 16 14 12

5.1 – 7.0 18 16 14 12 12

7.1 – 12.0 18 14 12 10 -

12.1 – 16.0 14 12 10 - -

16.1 – 20.0 12 10 - - -

TABLE A

25’

50’

75’

100’

* Based on limiting the line

voltage drop to ve volts at

150% of the rated amperes.

Symbology

Double Insulated

Canadian Standards Association

150’

When using more than one Exten-4.

Underwriters Laboratories, Inc.

sion Cord to make up the total length,

make sure each Cord contains at

least the minimum wire size required.

(See Table A.)

V~

A

Volts Alternating Current

Amperes

If you are using one Extension Cord 5.

for more than one tool or equipment,

n0 xxxx/min.

No Load Revolutions per Minute

(RPM)

add the nameplate amperes and use

the sum to determine the required

minimum Cord size. (See Table A.)

Make sure the Extension Cord is 6.

properly wired and in good electrical

condition. Always replace a damaged

Extension Cord or have it repaired by

a qualied electrician before using it.

Protect the Extension Cords from 7.

SKU 65712 For technical questions, please call 1-800-444-3353. Page 7

SPECIFICATIONS

Fits One-Piece Doors with Horizontal Track

Product

Applications

Electrical

Requirements

Remote

Controls

Additional

Features

and Sectional Doors with Curved Track.

*Not for Use with One-Piece Doors with

Horizontal and Vertical Track, Double-Winged

Doors, or Canopy Doors.

120 V~ / 60 Hz / 120 Watts

1/2 HP, 24 VDC Motor Voltage

Power Plug: 2-Prong, Polarized

Power Cord: 18 AWG x 2C SVT

2 Remote Controls (Included)

100 Feet Remote Range

315 MHz Frequency

1 Button with Red L.E.D.’s (UP/DOWN)

1 A27-12 VDC Battery (Qty. 1 ea., Included)

Chrome Snap/Shut Keychain

Timed Light-Out/60 Watt Bulb (3 Min. Max.)

Adjustable Travel

Open & Closing Force Adjustment

Safety Reverse System

Adjustable Automatic Closing Time

UNPACKING

When unpacking, check to make sure

that the item is intact and undamaged. If

any parts are missing or broken, please

call Harbor Freight Tools at the number

shown on the cover of this manual as soon

as possible.

Note: For additional information regarding

the parts listed in the following pages,

refer to the Assembly Diagram near

the end of this manual.

FCC ID: VW5-CASAR

This device complies with Part 15

of the FCC Rules. Operation is subject

to the following two conditions: (1) this

device may not cause harmful interference, and (2) this device must accept

any interference received, including

interference that may cause undesired

operation.

REV 08j

SKU 65712 For technical questions, please call 1-800-444-3353. Page 8

ASSEMBLY

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the

beginning of this manual including all text under subheadings therein

before set up or use of this product.

TO PREVENT SERIOUS INJURY FROM ACCIDENTAL

OPERATION:

Unplug the Garage Door Opener from its electrical Outlet before

assembling or making any adjustments to the equipment.

IMPORTANT:1. This Garage Door Opener is designed to work with the follow-

ing types of garage doors:

One-piece doors with horizontal track only.a.

Sectional doors with curved tracks.b.

THIS GARAGE DOOR OPENER IS NOT DESIGNED TO WORK WITH:

One-piece doors with horizontal a. and vertical tracks, double-wing doors, or canopy

doors.

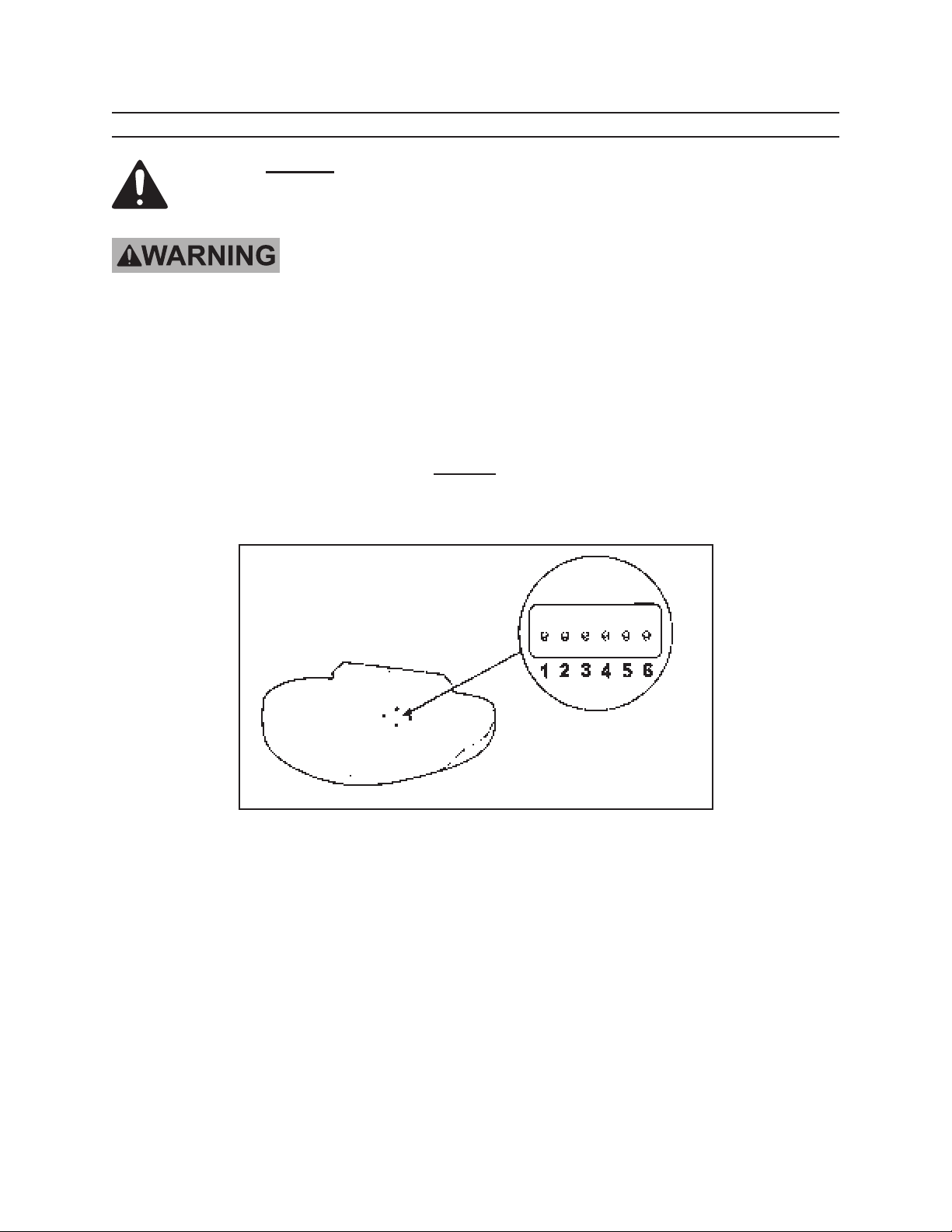

FIGURE B

2. There is a Connecting Wire Terminal in the unit’s Housing (31) which enables the

following accessories: (See Figure B.)

Terminal #1:• For Door Control Button (74) ground connection.

Terminal #2:• For Door Control Button (74).

Terminal #3:• For additional accessory (not included) ground connection.

Terminal #4:• For additional accessory (not included).

Terminal #5:• For additional 24 volt power source.

Terminal #6:• Additional terminal.

SKU 65712 For technical questions, please call 1-800-444-3353. Page 9

54

66

45

FIGURE C

35

59

28

9

54

50

46

49

43

34

31

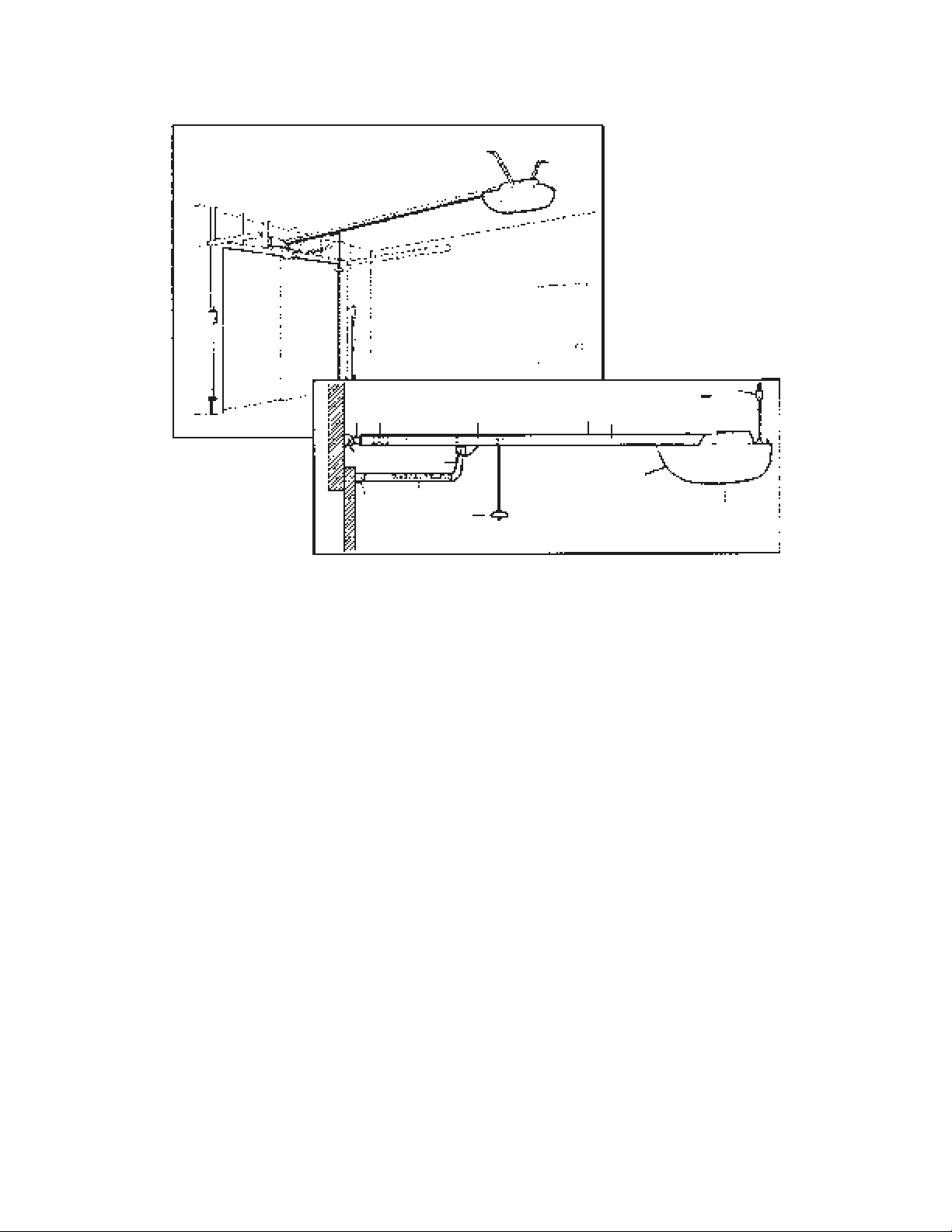

3. As you proceed with the assembly, installation, and adjustment steps in this manu-

al you may nd it helpful to refer back to this illustration of a completed installation.

(See Figure C.)

(54): Header Bracket (31): Housing

(66): Idler Pulley Seat (34): Light Cover

(45): Trolley (43): Manual Release Rope & Handle

(35): Rail (49): Curved Door Arm

(59): Chain (46): Straight Door Arm

(28): Hanging Bracket (50): Door Bracket

(9): Power Cord (54): Header Bracket

SKU 65712 For technical questions, please call 1-800-444-3353. Page 10

Loading...

Loading...