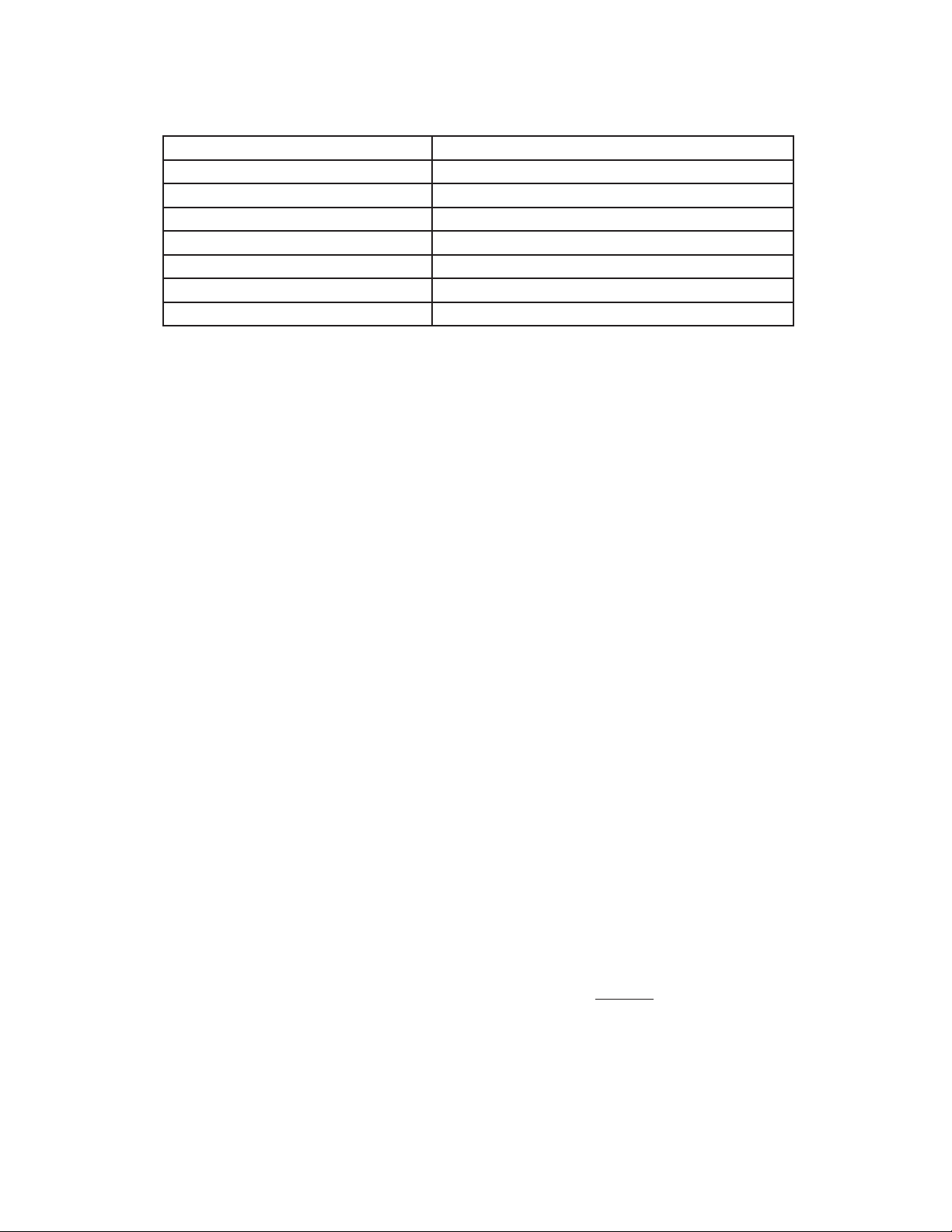

Chicago Electric 45690 User Manual

SPOT WELDER

230 VOLT

Model

45690

ASSEMBLY AND OPERATING INSTRUCTIONS

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2001 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork

contained herein may be reproduced in any shape or form without the express written consent of Harbor

Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing improve-

ments, actual product may differ slightly from the product described herein. Tools required for assembly

and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

Revised Manual 02b, 09l

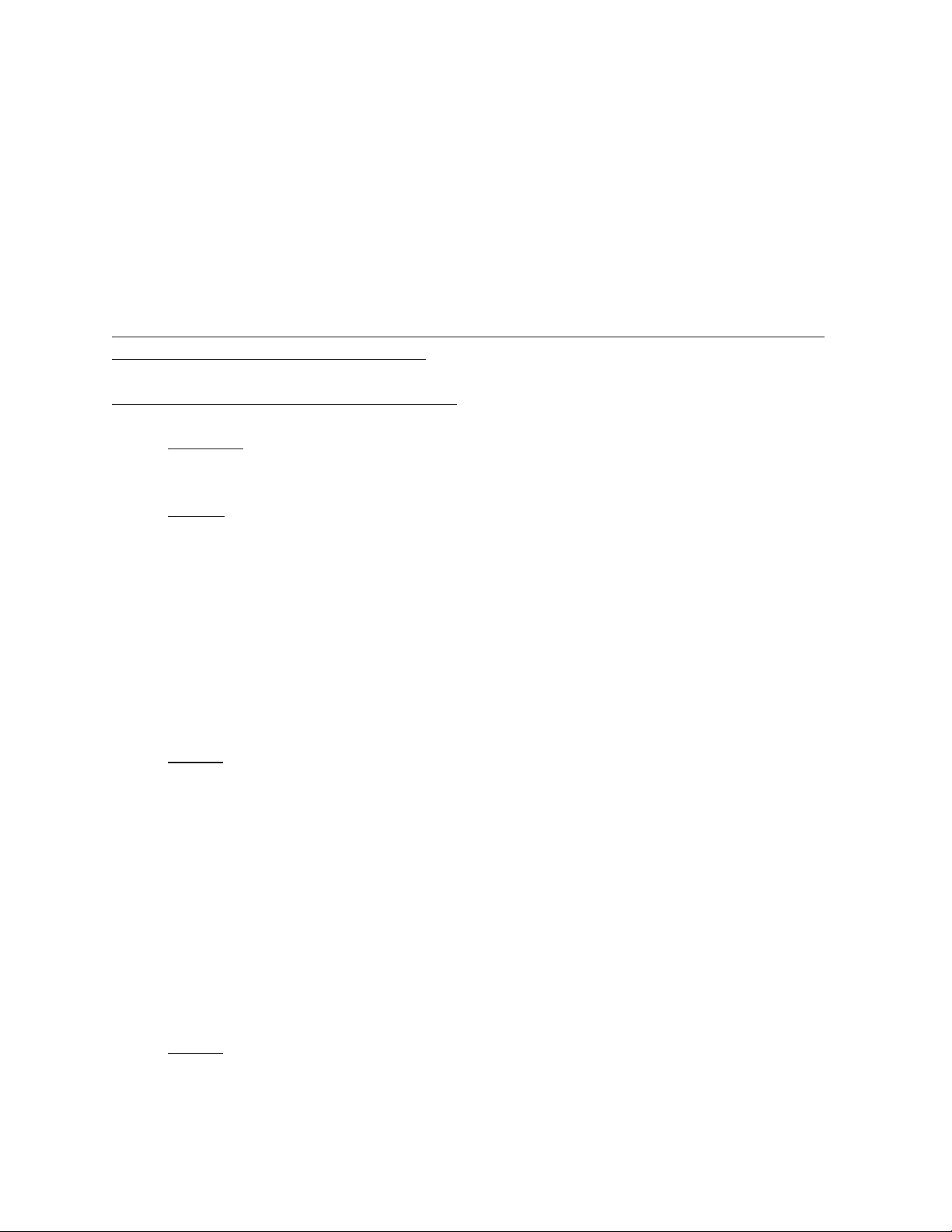

SPECIFICATIONS TABLE

ITEM DESCRIPTION

Electrical Input Requirements 230 Volt

Rated Output 1.5 KVA @ 50% Duty Cycle

Output Amps 5,500 +/- 10%

Material Capacity 1/8” Thick, Mild Steet

Tong Length 6”

Overall Dimensions 13” x 6” x 4.5”

Net Weight 23.5 Lbs.

SAVE THIS MANUAL

You will need this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance, and cleaning procedures, parts list and assembly

diagram. Keep your invoice with this manual. Write the invoice number on the inside

of the front cover. Keep this manual and invoice in a safe and dry place for future

reference.

GENERAL SAFETY WARNINGS AND PRECAUTIONS

1. KEEP WORK AREA CLEAN AND DRY. Cluttered, damp or wet work areas invite

injuries.

2. KEEP CHILDREN AWAY FROM WORK AREA. Do not allow children to handle this

product.

3. STORE IDLE EQUIPMENT. When not in use, tools and equipment should be stored

in a dry location to inhibit rust. Always lock up tools and equipment and keep out of

reach of children.

4. DO NOT USE THIS PRODUCT IF UNDER THE INFLUENCE OF ALCOHOL OR

DRUGS. Read warning labels on prescriptions to determine if your judgment or

reflexes are impaired while taking drugs. If there is any doubt, do not attempt to use

this product.

5. USE EYE, HEARING, BREATHING, AND HAND PROTECTION. Wear an ANSI

approved welding helmet/goggles with shaded lens, hearing protectors, breathing

respirator, and welding gloves when using this product. ANSI approved welding

helmet/goggles with shaded lens, hearing protectors, breathing respirators,and

welding gloves are available from Harbor Freight Tools.

6. DRESS SAFELY. Sparks and hot metal can injure. Always wear body protection.

Non-skid footwear or safety shoes should be used when working with this product.

Do not wear loose clothing or jewelry as they can become caught in moving parts.

Wear a protective hair covering to prevent long hair from becoming caught in moving

parts. If wearing a long-sleeve shirt, roll sleeves up above elbows.

7. INDUSTRIAL APPLICATIONS MUST FOLLOW OSHA REQUIREMENTS.

Rev 02b, 03h, 09l

SKU 45690 PAGE 2

8. DO NOT OVERREACH. Keep proper footing and balance at all times to prevent

tripping, falling, back injury, etcetera.

9. STAY ALERT. Watch what you are doing at all times. Use common sense. Do not

use this product when you are tired or distracted from the job at hand.

10. CHECK FOR DAMAGED PARTS. Before using this product, carefully check that it

will operate properly and perform its intended function. Check for damaged parts

and any other conditions that may affect the operation of this product. Replace or

repair damaged or worn parts immediately.

11. REPLACEMENT PARTS AND ACCESSORIES. When servicing, use only identical

replacement parts. Only use accessories intended for use with this product. Approved

accessories are available from Harbor Freight Tools.

12. MAINTAIN THIS PRODUCT WITH CARE. Keep this tool clean and dry.

13. MAINTENANCE: For your safety, service and maintenance should be performed

regularly by a qualified technician.

14. USE THE RIGHT PRODUCT FOR THE RIGHT JOB. There are certain applications for

which this product was designed. Do not use small equipment, tools or attachments

to do the work of larger industrial equipment, tools or attachments. Do not use this

product for a purpose for which it was not intended.

SPECIFIC PRODUCT WARNINGS AND PRECAUTIONS

1. GROUND THIS PRODUCT. The required electrical Power Cord Plug for this

product is a grounded, 230 Volt, 3-Prong Plug (not included). It is recommended

that only a qualified technician connect a Power Cord Plug to the Power Cord. Never

remove the grounding prong or modify the Plug in any way. Do not use adapter

plugs with this product. When in use, make sure this product is always plugged into

a grounded, 230 Volt, 3-hole electrical receptacle with an appropriate breaker switch

inline.

2. MAKE SURE THE CONTROL SWITCH (part #25) IS IN THE “OFF” POSITION

BEFORE PLUGGING IN THE POWER CORD. (See Figure D, and Assy.

Diagram.)

3. DO NOT ABUSE THE POWER CORD. Do not use the Cord to pull the 3-Prong Plug

from a power outlet. Keep Cord away from heat, oil, sharp edges, and moving parts.

Replace damaged Cord immediately. Route the Power Cord safely. Protect it from

being damaged by other equipment in the shop. Do not route the Cord where it can

be walked on or tripped over.

4. MAINTAIN A SAFE WORK ENVIRONMENT. Do not use this product in or near

damp or wet areas. Do not expose this product to rain. Keep work area well lit.

Make sure there is adequate surrounding work space. Use this product in a well

ventilated area. (Read Material Safety Data Sheets/MSDS for metals, coatings, and

cleaners.) Do not operate this product in the presence of flammable liquids, gases,

or dust. To avoid accidental electric shock, do not let your body come in contact with

grounded surfaces such as pipes, radiators, ranges and refrigerators. Always keep

a fire extinguisher nearby.

SKU 45690 PAGE 3

Rev 02b

5. DO NOT FORCE THE EQUIPMENT. This Spot Welder will do the work better and

safer at the speed and capacity for which it was designed.

6. AVOID UNINTENTIONAL STARTING. Make sure you are prepared to begin work

before turning the Control Switch (part #25) “ON”.

7. Caution: Never touch the Upper and Lower Tongs (parts #46, #47) when welding a

workpiece. Allow the Tong Tips (part #48) and the workpiece to cool before handling.

(See Figures A, B, E, and Assy. Diagram.)

8. MAKE SURE THE WORKPIECE IS SECURED AT ALL TIMES DURING OPERATION.

Use a vise, clamps, etcetera (not provided).

9. OVERUSE CAN CAUSE OVERHEATING. After continuous use, allow the Spot

Welder adequate time to cool before the next use.

10. BEFORE TRYING NEW OR COMPLICATED TECHNIQUES, STUDY THE

PROCEDURE, AND PRACTICE WITH SCRAP METAL.

11. ALWAYS DISCONNECT THE SPOT WELDER FROM ITS ELEC TRICAL

SUPPLY SOURCE BEFORE ASSEMLING, PERFORMING ANY SERVICES OR

MAINTENANCE always disconnect the electrical cord before leaving the work area,

moving the tool from one location to another, handing the tool to another person,

changing Tong Tips (part #48), cleaning the unit, etcetera.

12. WARNING: This product, when used for welding and similar applications, produces

chemicals known to the State of California to cause cancer and birth defects (or other

reproductive harm). (California Health & Safety Code 25249.5 et seq.)

13. WARNING: Operation of equipment in close proximity to a heart pacemaker could

cause interference or failure of the pacemaker.

SKU 45690 PAGE 4

REV 04e

UNPACKING

When unpacking, check to make sure all parts shown on the Parts List (page 12) are included. If any parts are missing or broken, please call Harbor Freight Tools at the number

shown on the cover of this manual as soon as possible.

ASSEMBLY INSTRUCTIONS

NOTE: For additional references to the parts listed below, refer to the Assembly

Diagram on page 13 of this manual.

To Attach The Upper And Lower Tongs:

1. Caution: Prior to attaching the Upper and Lower Tongs (parts #46, #47), make

sure the Spot Welder is disconnected from its electrical power source.

2. NOTE: Make sure the Upper and Lower Tongs (parts #46, #47) are clean and not

corroded before installing. If necessary, clean the Tongs with steel wool.

3. To attach the Lower Tong (part #47) to the Spot Welder, loosen the four Cap

Screws (part #3) located at the bottom/front of the tool. (See Figure A, and Assy.

Diagram.)

4. Slide the Lower Tong (part #47) between the Tong Insulator (part #33) and Lower

Tong Clamp (part #35), and position the Lower Tong so that the Tong Tip (part #48)

faces up.

5. NOTE: Check to make sure the Lower Tong (part #47) will align with the Upper

Tong (part #46) when fully assembled. (See Figure B, and Assy. Diagram.)

6. Re-tighten the four Cap Screws (part #3).

7. To attach the Upper Tong (part #46) to the Spot Welder, loosen the four Cap Screws

(parts #3, #11) located at the top/front of the tool. (See Figure A, and Assy.

Diagram.)

8. Slide the Upper Tong (part #46) between the Tong Tip Holder (part #12) and Upper

Tong Clamp (part #13), and position the Upper Tong so that the Tong Tip (part #48)

faces down.

9. NOTE: Check to make sure the Upper Tong (part #46) will align with the Lower

Tong (part #47) when fully assembled. (See Figure B, and Assy. Diagram)

SKU 45690 PAGE 5

Loading...

Loading...