Chevrolet Light, Heavy Duty, Medium, Truck 1952 Operator's Manual

www.carburetor-manual.com

Would you like some Free Manuals?

http://carburetor-manual.com/free-shop-manual-club-t-13.html

Also visit http://freeshopmanual.com for more Free Manuals

Also Visit my website for 7 FREE Download Manuals starting

with this one.

"The ABC's of Carburetion"

Click Here Now

file:///C|/Documents%20and%20Settings/Tim/Desktop/carburetor-manual-welcome/index.htm[4/22/2009 3:30:28 PM]

IOrl9S2

OPERATOR'S

MANUAL

For 19

52

Chevrolet Light, Medium

and

Heavy

Duty

Trucks

SECOND EDITION

INTRODUCTION

This operator's

and

owner's

manual has

been

prepared

to fur-

nish

information

pertaining

to

the

driving, care

and

maintenance

of

Chevrolet

trucks as

well

as

to

pro-

vide te

chni

cal

data that

may be of

value

or

interest

to

truck

owners.

The

subject

index

at

the

right

is a r

eady reference

to

the

key

subjects and will assist in find

ing

any

subject

cove r

ed

in the booklet.

Chevrolet Motor Division

General

Mot

ors

Cor

porati

on

Detroit

2,

Michigan

SUBJECT

INDEX

Driver's Ope

ra

tine

Inform

ation

Page

Breaki

ng·inP

eriad......

3

Controls

and

Jnstrumen

ls ..•. 4

Prestarlinglnspection

.

14

SlarlingllleEn'ine

......

....

14

Gearshitting

....

...

...

....

15

Cold

Wealller

Operation

.....

17

tkllWeather

Operation.

19

Tirelnflati

on

...........

.

..

19

Description,

Ca

re a

nd

Maint

enance

Pr

evenliveMaintenance

. 21

E ngi~e

......................

22

Cooling

System

.

34

Clutch.

.

.........

.....

40

T

ransmission

. 41

Rear

Axle

.....

..

.. .

.....

43

F

rontAxle

...

.. ...

45

~~~r~n~y~te:~

..............

...

: ~

SpringsandSh

ackles .....

..

56

El

ectricalSyslem

. 57

Tires

.. .

.....

........

63

Lubr

ica tion

E

ngine_ ....

....

.. .

....

.....

70

Rear Axle

and Transmission

..

77

Universal Joint ...........

__

78

Fro

nt Whe

el

Bearings

.. .. . . ~ 80

R

ear Wheel

Bearings..

81

C

hassis..

81

Hints (or Loca

tin,

Road

Troubl

es

~~~rse_

............

::::::::::::

::

~

General .................

95

Gener

al

Information

Manufaclurer'sWarranly ..... 96

TireWarranty ....

..... ___

..

97

Owner's

Service P

olicy

.......

104

Tec

hnical

Data

UnitCapaci

lyChart.

...

_.

__

.98

lamp

Bulb

Chart .....

....

..

99

Specifi

cations

............

...

99

Adjustment

Specification

s

tOO

loadCapacilyChart .

....

102·103

F

ig.

I-Co"'1OI, ond

l"st,um."Is_'j,

o"d %

To"

CHAPTER I

DRIVER

'S

OPERATING

INFORMATION

BREAKING-IN PERIOD

The

crankcase

of

the

engine

in

this vehicle, as

rec

eived,

is filled

with

a

light

body

"breaking

-in"

oil.

Use

this

oil

only

during

the

breaking-in

schedule

shown

below.

It

shou

ld

not

be

used

after

completion of

the

breaking-in

schedule.

Check

the

oil

frequently

during

the

first

500 miles

and

at

the

end

of 500 miles,

drain

the

crankcase-while

hot-and

refill

using

the

grade

of

oil recommended

in

Lubrication section.

To

properly

break-in the

moving

parts

of

the

engine

do

not

drive faster than:

35

miles

per

hour

for

the

first

100

miles

45 miles

per

hour

for

the

next

200

miles

50 miles

per

hour

for

the

next

200 miles

f

ig.

2_Co,"I.o1o ond

''''',,,,,,.,,h-'

'h e ....

., 2

To

..

-3'

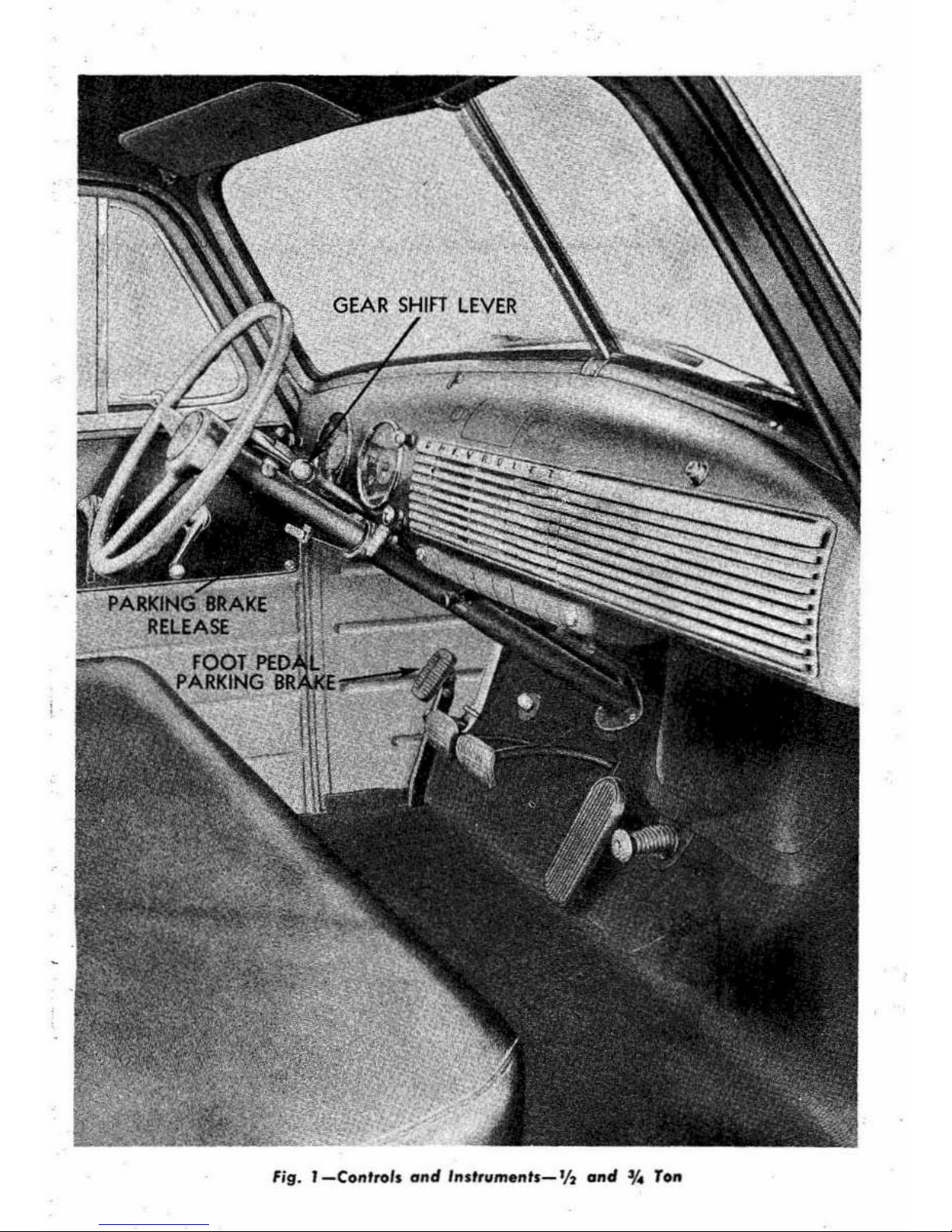

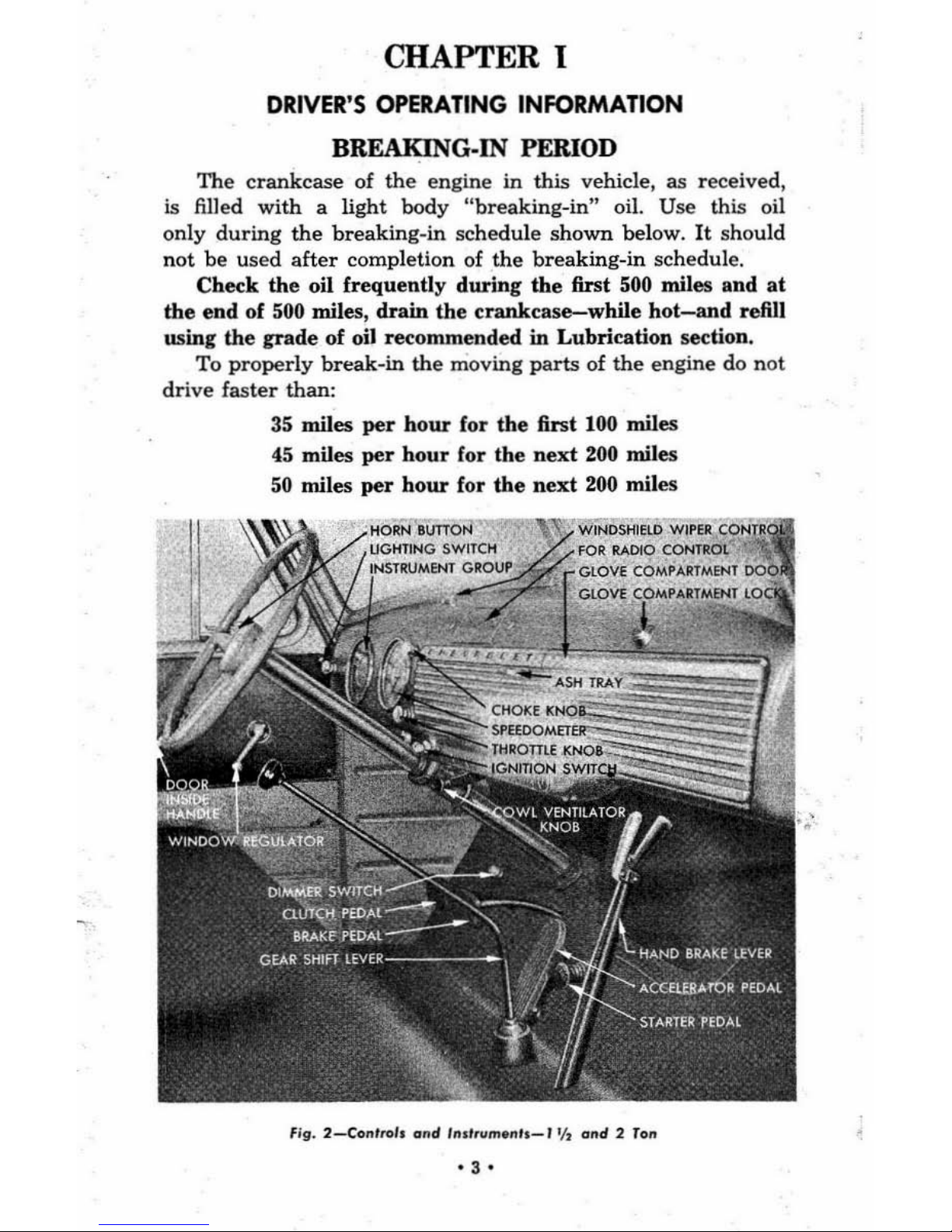

CONTROLS AND INSTRUMENTS

The

type,

location

and

operation

of

instruments

and

con-

trols

vary

on

different

models

and

makes

of

vehicles;

therefore,

regardless

of

the

experience

an

owner

or

driver

may

have

had

it

is

advisable

to

familiarize

one's

self

with

the

instruments

and

controls,

and

their

use

before

driving

this

new

truck.

The

locations

of

the

various

instruments

and

controls

are

shown

in

figures 1

and

2.

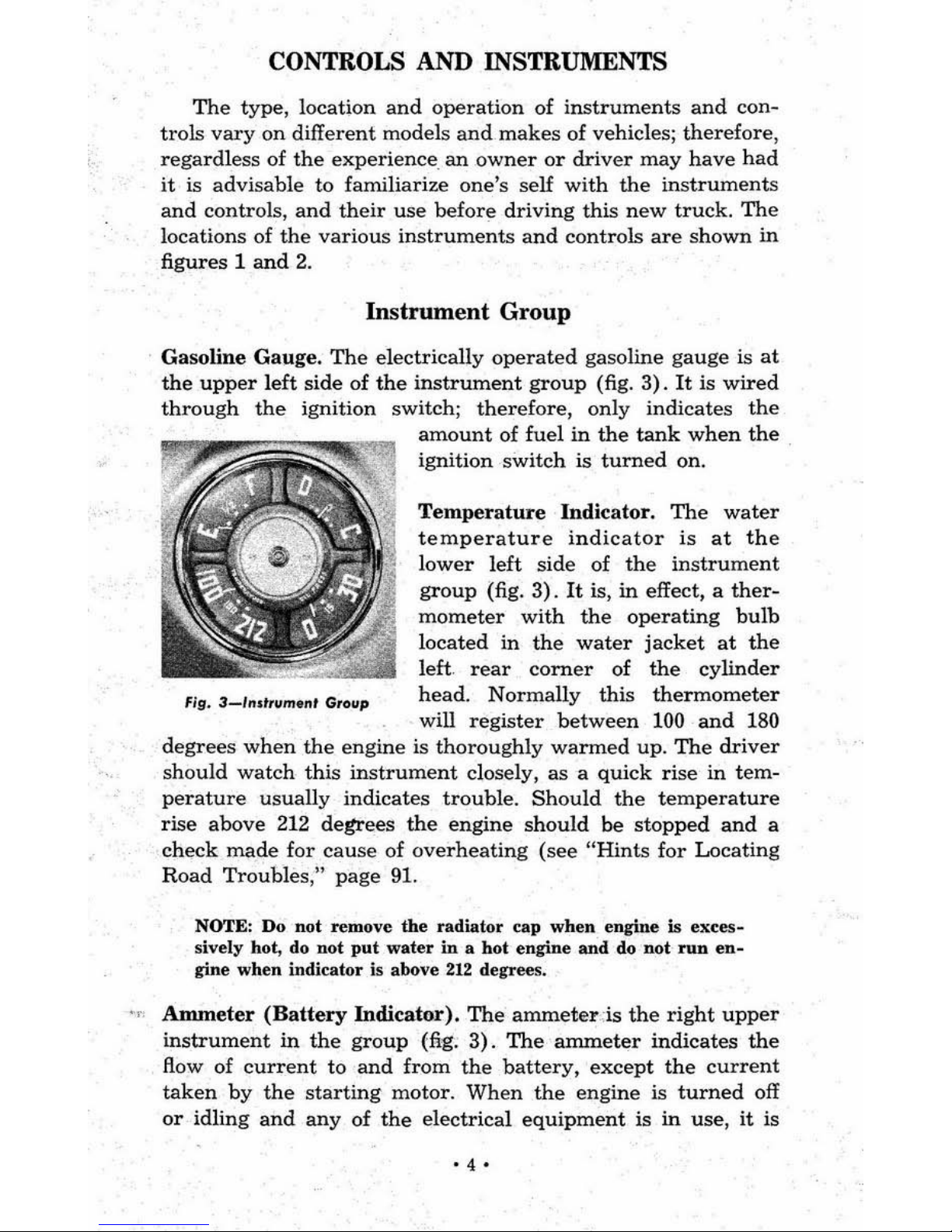

Instrument

Group

Gasoline

Gauge.

The

electrically

operated

gasoline

gauge

is

at

the

upper

left

side

of

the

instrument

group

(fig.

3).

It

is

wired

through

the

ignition

switch;

therefore,

only

indicates

the

fig.

3-J'''tfllmtnt

Grollp

amount

of

fuel

in

the

tank

when

the

ignition

switch

is

turned

on.

Temperature

Indicator.

The

water

temperature

indicator

is

at

the

lower

left

side

of

the

instrument

group

(fig.

3).

It

is,

in

effect, a

ther-

mometer

with

the

operating

bulb

located

in

the

water

jacket

at

the

left.

rear

corner

of

the

cylinder

head.

Normally

this

thermometer

will

register

between

100

and

180

degrees

when

the

engine

is

thoroughly

warmed

up.

The

driver

should

watch

this

instrument

closely,

as a quick

rise

in

tem-

perature

usually

indicates

trouble.

Should

the

temperature

rise

above

212

degrees

the

engine

should

be

stopped

and

a

check

made

for

cause

of

overheating

(see

"Hints

for

Locating

Road

Troubles

,"

page

91,

NOTE: Do not remove

the

radiator

cap

when

engine is

e"ces-

sively hot, do not

put

water

in a bot

engine

and

do Dot

run

en-

gine

when

indicator is above

212

degrees .

•• ' Anuneter

(Battery

Indicator).

The

ammeter

-is

the

right

upper

instrument

in

the

group

(fig.

3).

The

anuneter

indicates

the

flow

of

current

to

and

from

the

battery,

except

the

current

taken

by

the

starting

motor.

When

the

engine

is

turned

off

or

idling

and any

of

the

electrical

equipment

is

in

use,

it

is

'4'

natural

for

the

ammeter

to

show

discharge.

When

the

engine

is

running

at

medium

speed

and

most

of

the

electrical equip..

ment

is

turned

off

the

ammeter

should

show a slight

charge,

depending

on

the

state

of

charge

of

the

battery.

Should

the

ammeter

show

discharge

when

the

truck

is

being

driven

at

medium

speed,

trouble

is

indicated

in

the

charging

system

and

the

battery

will soon become discharged.

Oil

Pressure

Gauge.

This

instrument

is

in

the

lower

right

side

of

the

instrument

group

(fig.

3).

The

oU

pressure

gauge

indi-

cates

whether or-

not

the

oil

pump

is

working,

but

does

not

indicate

the

amount

of oil

in

the

crankcase.

The

pressure

gauge

reading

is

controlled

by

the

engine

speed

and

the

oil

being

used. A

low

reading

is

normal

at

idling

speeds

with

a

warm

engine

and

light

oil;

however,

as

the

engine

speed

is

increased

the

hand

should

move

over

near

the

"IS"

mark.

In

cold

weather

(especially

with

heavy

oil)

the

hand

may

move

over to'

the

"30"

mark

at

comparatively

low

engine

speeds. This indicates

that

the

oil is too

heavy

to

properly

lubricate

the

engine.

NOTE: Do

not

acce l

erate

the

engine

excessive

ly

until

the

oil

is

suffi.

dently

warm

to

permit

a l

ower

pres-

su~.

If

the

gauge

does

not

show

any

pressme,

stop

the

engine

im-

mediately

and

determine

the

cause.

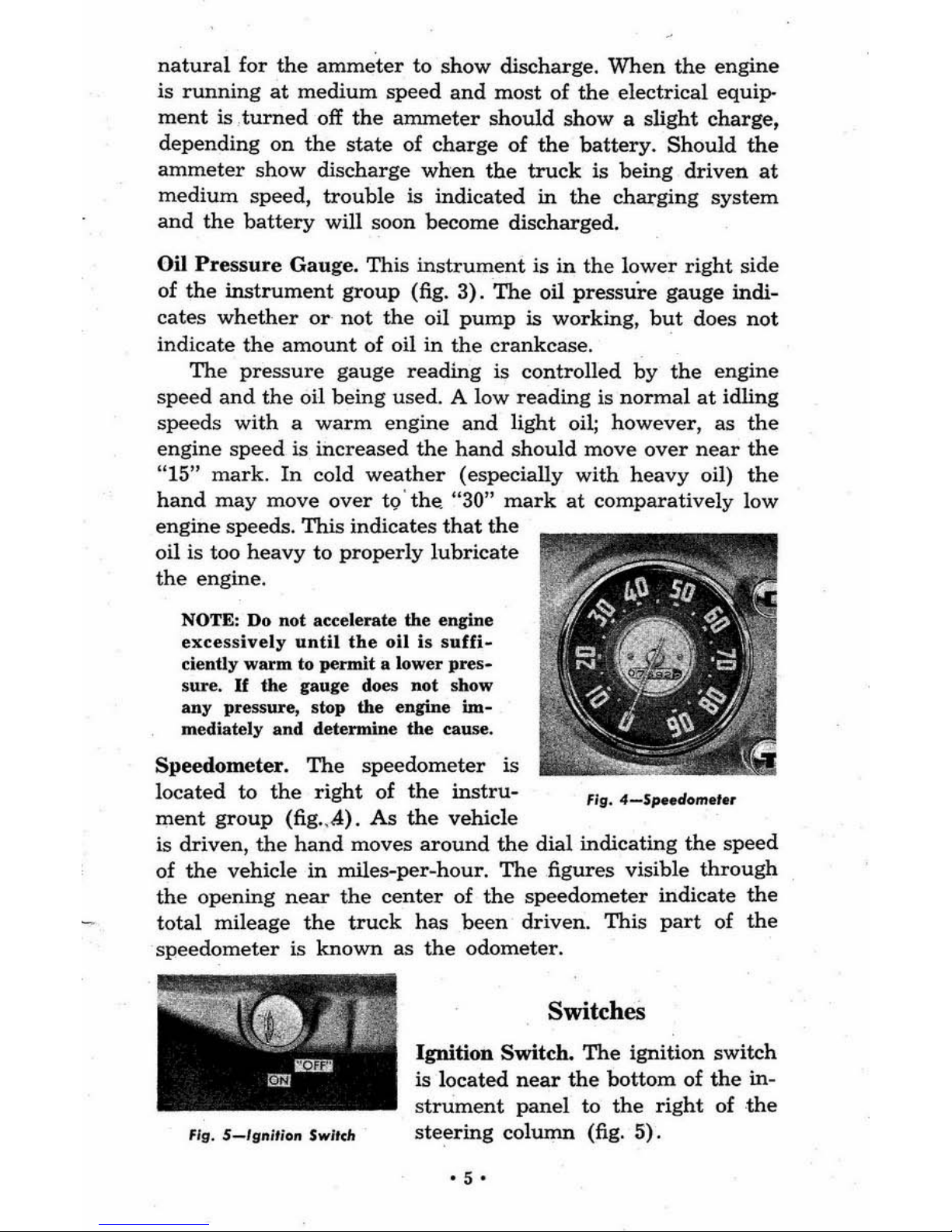

Speedometer.

The

speedometer

is

located

to

the

right

of

the

instru-

ment

group

(fig .. A).

As

the

vehicle

flg.4-Sp

..

dom.'.,

is

driven,

the

hand

moves

around

the

dial

indicating

the

speed

of

the

vehicle

in

miles-per-hour.

The

figures visible

through

the

opening

near

the

center

of

the

speedometer

indicate

the

total

mileage

the

truck

has

been

driven.

This

part

of

the

speedometer

is

known

as

the

odometer.

fIg.

S_/gnitionSwl'd.

Switches

Ignition

Switch.

'The ignition switch

is located

near

the

bottom

of

the

in-

strument

panel

to

the

right

of ·

the

steering

column

(fig. 5).

'5

'

The

ignition

switch

is

located

in

the

.low

tension

circuit

and

wired

between

the

battery

and

the

coil.

This

switch is

used

to

make

or

break

the

ignition

circuit

when

starting

or

stopping

the

engine.

The

key

is

turned

clockwise to

turn

the

switch

on

and

counterclockwise

to

turn

the

switch

off.

Fie·6-UllfltlllgSw

/ICh

Lighting

Switch.

The

lighting

switch,

located

to

the

left

of

the

in-

strument

group

(fig.

6),

controls

the

instrument

lamps,

headlamps,

park-

ing

lamps

and

tail

lamp.

When

this

switch

is

pulled

out

to

the

first

"on"

position

the

parking

lamps

and

tail

lamp

are

lighted.

When

the

switch

is

pulled

out

to

the

last

position

the

headlamps

and

tail

lamp

are

lighted.

Current

for

the

lighting

circuits

passes

through a thermal

circuit

breaker

located

on

the

light-

ing

switch

behind

the

instrument

panel.

In

case

all

lights fail

to

operate,

check

for

trouble

at

the

thermal

circuit

breaker.

The

instrument

lights

can

be

dimmed

or

turned

off

by

turning

the

light

switch

knob

clockwise.

Dimmer

Switch.

The

dimmer

switch

located

on

the

toe·board

to

the

left

of

clutch

pedal

(fig. 10) is

used

to

switch

the

head·

lamp

beam

from

"high"

to

"low"

or

"low"

to

"high".

Each

time

the

switch

is

depressed

the

light

beam

is

reversed.

A

headlamp

beam

indicator

is

located

between

the 0 and

80

at

the

bottom

of

spe~dometer.

When

the

lights

are

on

upper

beam

a

red

light

is visible

through

the

in-

dicator

opening. A void

use

of

upper

beam

when

meeting

other

vehicles

on

the

highway

or

in

city

traffic.

Dome

Lamp

Switch.

The

dome

lamp

switch

is

located

at

the

left

end

of

the

dome

lamp

assembly

directly

:::~g

~is

rse:tc:~:cok:a;:g~u!

fig.

1-~O':;~chUgh'

find

.

the

light

on

and

moving

it

forward

turns

the

light

off.

-6-

Horn

Button.

The

horn

button

is

conveniently

located

at

the

center

of

the

steering

wheel.

Depre

ssing

the

button

blows

the

horn.

Controls

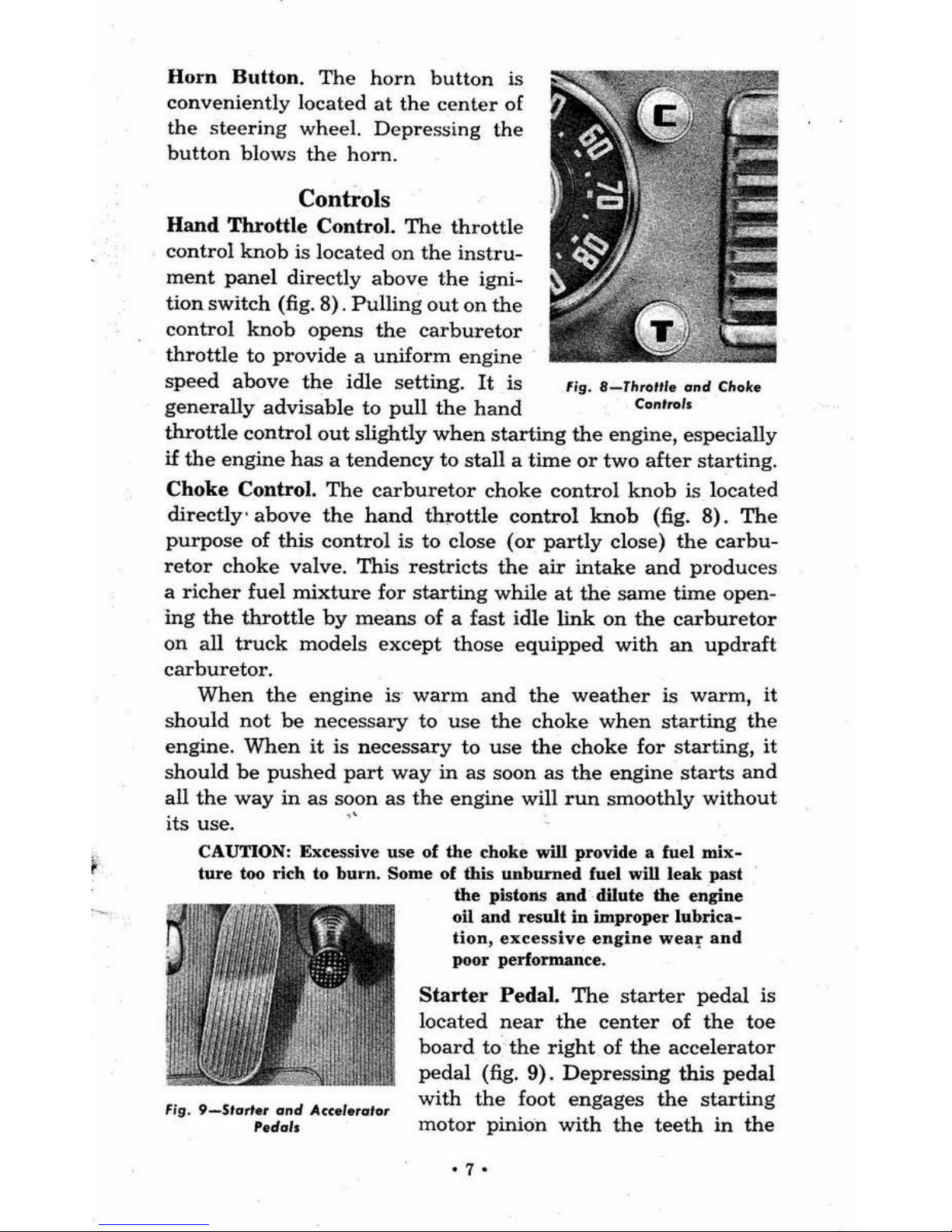

Hand

Throttle

Control.

The

throttle

control

knob

is located

on

the

instru

-

ment

panel

directly

above

the

igni-

tion

switch (fig.

8).

Pulling

out

on

the

control

knob

opens

the

carburetor

throttle

to

provide a uniform

engine

speed

above

the

idle

setting.

It

is

fig.

8_T"ro"'.

ond

Choke

generally

advisable

to

pull

the

hand

Control.

throttle

control

out

slightly

when

starting

the

engine, especially

if

the

engine

has a tendency

to

stall

a time

or

two

after

starting.

Choke

Control.

The

carburetor

choke

control

knob

is

located

directly'

above

the

hand

throttle

control

knob

(fig.

8).

The

purpose

of this

control

is to

dose

(or

partly

close)

the

carbu-

retor

choke

valve.

This

restricts

the

air

intake

and

produc

es

a

richer

fuel

mixture

for

starting

while

at

the

same

time open-

ing

the

throttle

by

means

of

a fast

idle

link

on

the

carburetor

on

all

truck

models

except

those

equipped

with

an

updraft

carburetor.

When

the

engine

is'

warm

and

the

weather

is

warm,

it

should

not

be

necessary

to

use

the

choke

when

starting

the

engine.

When

it

is

necessary

to

use

the

choke

for

starting,

it

should

be

pushed

part

way

in

as

soon as

the

engine

starts

and

all

the

way

in

as

~,on

as

the

engine

will

run

smoothly

without

its use.

CAUTION: Excessive use of

the

choke will provide a fuel

mix-

ture

too rich to

burn.

Some

of

this

unburned

fuel wiD leak past

fig.

9_Starte.

and

Acc.l.ralor

' e

dab

the

pistons

and

dilute

the

engine

oil and result

in

improper

lubrica-

tion,

excessive

engine

wea~

and

poor performance.

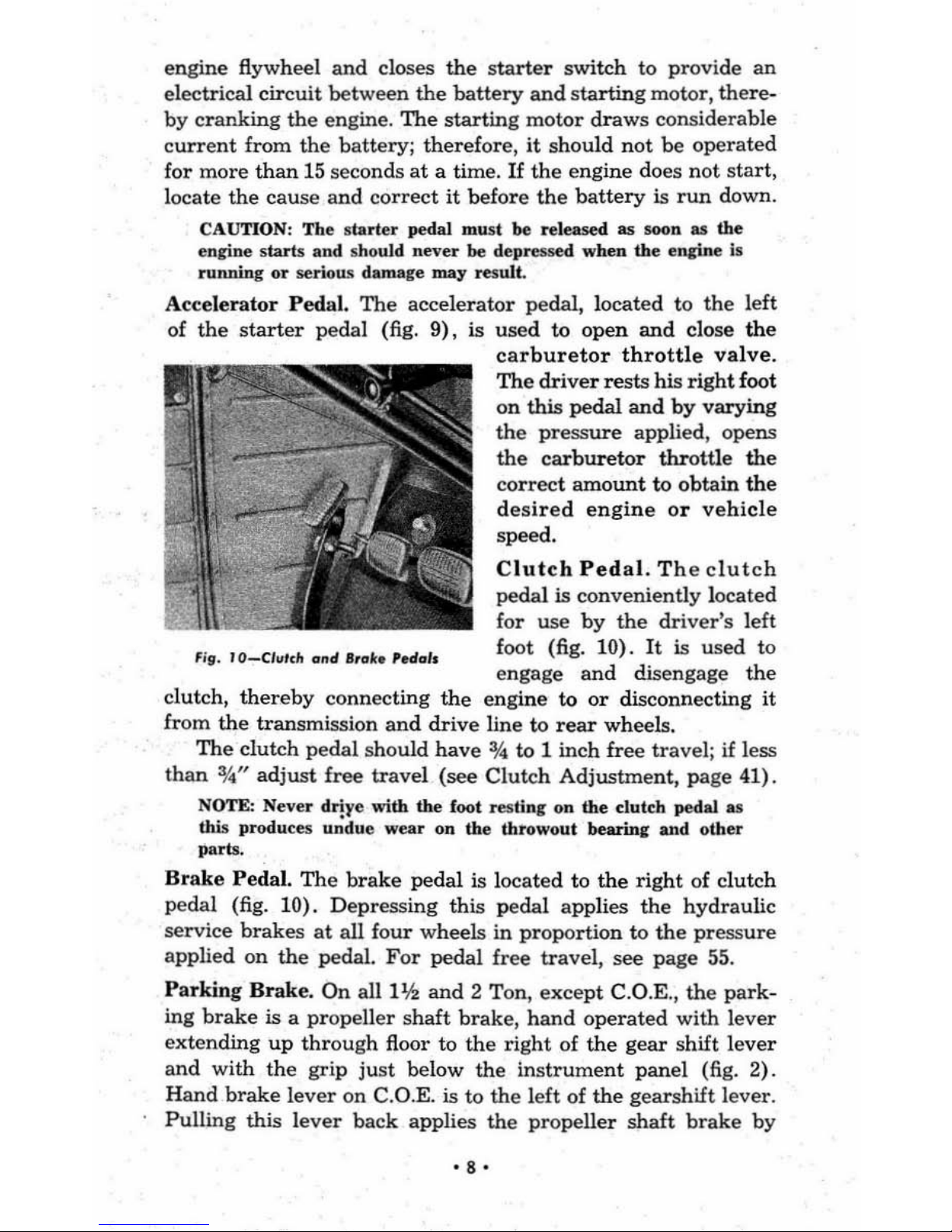

Starter

Pedal.

The

starter

pedal

is

located

near

the

center

of

the

toe

board

to

the

right

of

the

accelerator

pedal (fig.

9).

Depressing

this

pedal

with

the

foot

engages

the

starting

motor

pinion

with

the

teeth

in

the

'7'

engine flywheel

and

closes

the

starter

switch to provide

an

electrical

circuit

between

the

battery

and

starting

motor,

there-

by

cranking

the

engine.

The

starting

motor

draws

considerable

current

from

the

battery;

there

fore,

it

sho

uld

not

be

operated

for

more

than

15

seconds

at

a time.

If

the

engine does

not

star

t,

locate the

cause

and

correc

t it before

the

battery

is

run

down.

CAUTION:

The starter

pedal

must

be relellSed

til!

soon as

the

eneine

starts

and

should

never

be depressed

when

the engine is

running

or

serious damage

ma,.

result.

Accelerator

Pedal.

The

accel

erator

pedal, located

to

the

left

of

the

start

er

peda

l (fig.

9),

is

used

to open

and

close

the

Fill.

IO-C/",'(h

and

Itab

'adols

carburetor

throttle

valve.

The

driver

res

ts

his

right

foot

on

this pedal

and

by

varying

the

pressure

applied, opens

the

carburetor

throttle the

correct amount

to

obtain

the

desired

engine

or

vehicle

speed.

Clutch

Pedal.

The clutch

pedal

is

conveniently located

for

use

by

the

driver's

left

foot (fig.

10).

It

is used to

engage

and

disengage the

clutch,

thereby

connecting

the

eng

ine to

or

disconnecting it

from the transmission

and drive

line

to

rear

wheels.

The clutch

pedal should have

;'4

to

1 inch free travel; if less

than

%0"

adjust

free

travel (see

Clutch Adj

ustment, page 41).

NOTE: Never

d'iy

e with the foot

res

tin

l"

on

the

dutcl!

pedal

as

this produces

undue

wear

on the

throwout

bearln,

and

othe

r

pa

rts

.

Brake

Peda

l.

The

brake

pedal is located to

the

right of clutch

pedal (fig.

10).

Depressing

this

pedal

applies

the

hydraulic

service

brakes

at

all

four

wheels in

propertion

to

the

pressure

applied

on

the

pedal.

For

pedal free

trave

l,

see

page

55.

Parking

Brak

e.

On

all11h.

and

2 Ton,

except

C.O.E. ,

the

park-

ing

brake

is a

propeller

shaft

brake,

hand

operated

with lever

extending

up

through

floor

to

the

right

of

the

gear

shift lever

and

with

the

grip

just

below the

instrument

pan

el (fig.

2) .

Hand

brake

lever

on

C.O.E. is to the left of

the

gearshift

lever.

Pulling

this

lever

back

applies the

propeller

shaft

brake

by

• 8 ·

means of mechanical linkage. To release brakes,

grip

the

two

sections of

the

handle

and

pull

lever

back

slightly,

then

move

it forward.

Foot

Operated

Parking

Brake.

Parking

brakes

on

alllh,

%

and

1

ton

models

are

pedal operated.

The

operating pedal (fig. 10)

is located to

the

left

of

the

clutch

pedal

and

pressing down on

this pedal applies

the

rear

wheel

brakes

through

mechanical

linkage

entirely

independent

of

the

hydraulic system. To

release

the

brakes

a release lever is

mounted

on

the

instru-

ment

panel.

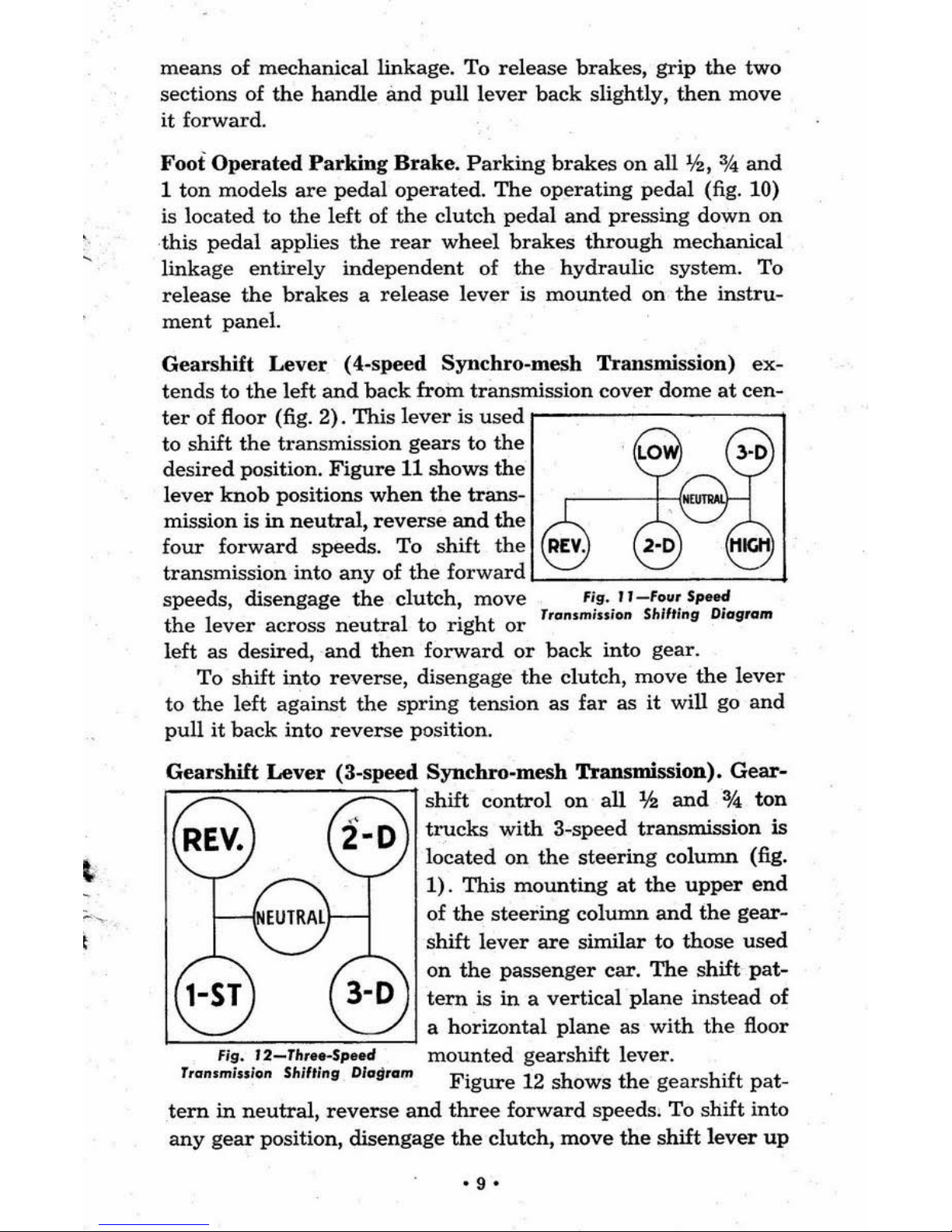

Gearshift

Lever

(4.speed Synchro-mesh Transmission) ex-

tends

to

the

left

and

back

from transmission

cover

dome

at

cen-

ter

of floor (fig. 2). This

lever

is

used

r--------,

to shift

the

tran

smission gears

to

the

desired

position.

Figure

11 shows

the

lever

knob

positions

when

the

trans-

mission is

in

neutral,

reverse

and

the

four

forward

speeds.

To

shift

the

transmission into

any

of

the

forward '-__

----'

___

-'

~~:e~:~e~::~~:;en!~a~l:~ig~to::

rrpn.!~;;i~~

S~~~'~n~a9ram

left as desired,

and

then

forward

or

back

into gear.

To

shift into reverse, disengage

the

clutch, move

the

lever

to

the

left

against

the

spring tension

as

far

as

it

will go and

pull

it

back

into

reverse

position.

Gearshift

Lever

(3-speed

Synchro-mesh

Transmission).

Gear-

shift control

on

all

lh

and

%

ton

trucks

with

3-speed transmission

is

located on

the

steering

column

(fig.

1).

This mounting

at

the

upper

end

of

the

steering

column

and

the

gear-

shift

lever

are

similar

to

those used

on

the

passenger car.

The

shift

pat-

tern

is

in

a vertical plane

instead

of

'-=:""".,....,,---0-==---' a horizontal plane as

with

the

floor

mounted

gearshift lever.

Figure

12 shows

the

gear

shift pat-

tern

in

neutral,

reverse

and

three

forward

speeds. To shift into

any

gear

position, disengage

the

clutch, move

the

shift

lever

up

'9'

or

down

from

neutral

position

and

then

forward

or ba'

ck

into

the

desired

gear.

Cowl

Ventilator

Control

Knob.

This

knob

located

below

the

in-

strument

panel

in

line

with

the

ignition switch (figs. 1

and

2) is

used

to

open

and

close

the

cowl ventilator.

When

the

knob

is

up

toward

the

instrument

panel

the

ventilator

is closed

and

locked.

By

pushing

the

lever

down

and

forward,

the

desired

FJg.I3-Alh

rrar

amount

of

air

circulation

can

be

obtained.

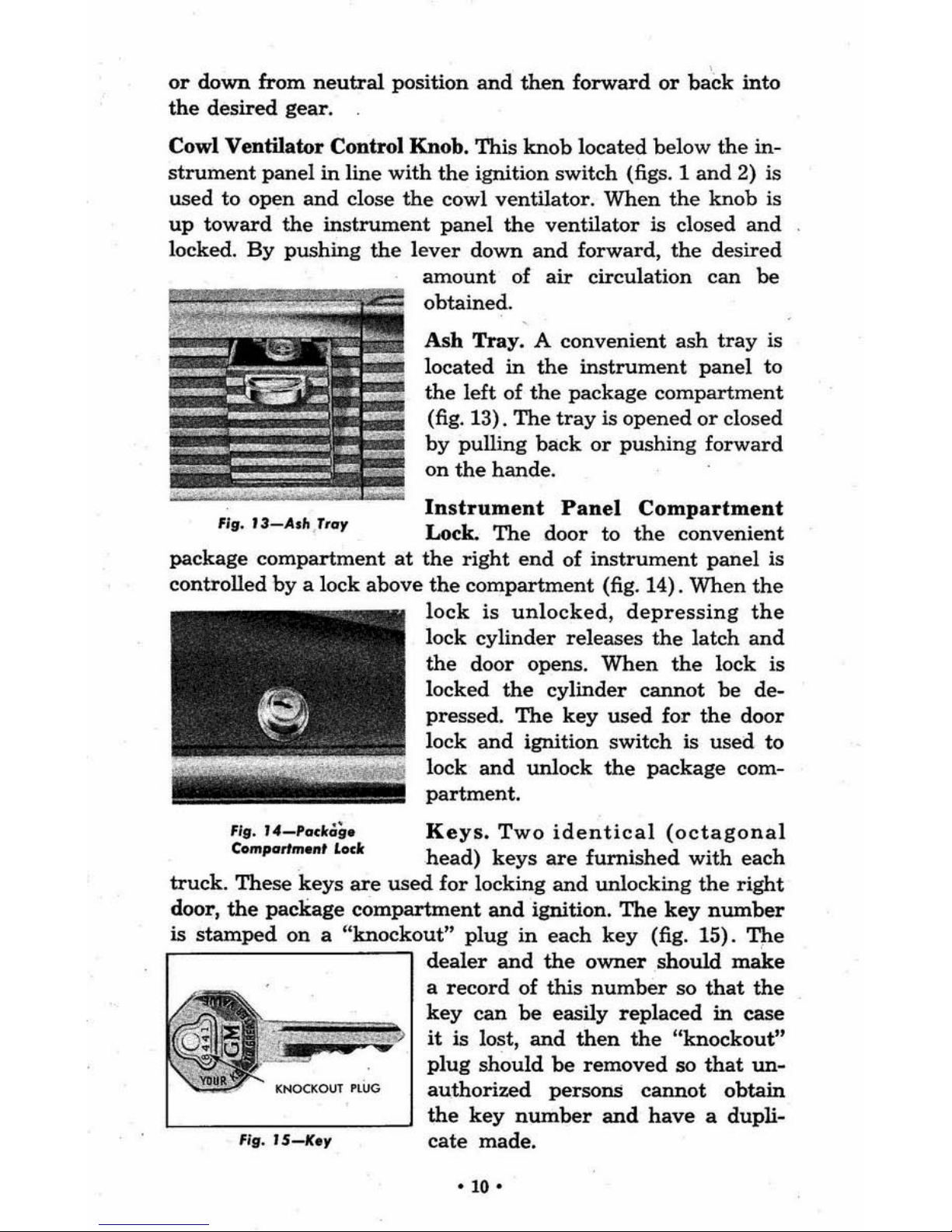

Ash

Tray. A convenient

ash

tray

is

located

in

the

instrument

panel

to

the

left of

the

package

compartment

(fig. 13).

The

tray

is opened

or

closed

by

pulling

back

or

pushing

forward

on

the

hande.

Instrument

Panel

Compartment

Lock.

The

door to

the

convenient

package

compartment

at

the

right

end

of

instrument

panel

is

controlled

by

a lock

above

the

compartment

(fig. 14). Wh en

the

lock

is

unlocked,

depressing

the

lock

cylinder

releases

the

latch

and

the

door

opens.

When

the

lock is

locked

the

cylinder

cannot

be de-

pressed.

The

key

used

for

the

door

lock

and

ignition switch is used

to

lock

and

unlock

the

package

com-

partment.

F/g.

'''-''adr,;;_

Camparlm_n' todr

Keys.

Two

identical

(octagonal

head)

keys

are

furnished

with

each

truck.

These

keys

are

used

for

locking

and

tmlocking

the

right

door,

the

package

compartment

and

ignition.

The

key

number

is

stamped

on a "knockout"

plug

in

each

key

(fig. 15).

T/:le

dealer

and

the

owner

should

make

a

record

of

this

number

so

that

the

"':

=~~

key

can be easily

replaced

in

case

~

j

~.

y

it

is

lost,

and

then

the

"knockout"

plug

should

be

removed

so

that

un-

authorized

personS

cannot

obtain

L-_--:,:-,

•. --:,-:-,_--:.:-.,----'

~~e

k:d:~ber

and

have

a dupli-

·10'

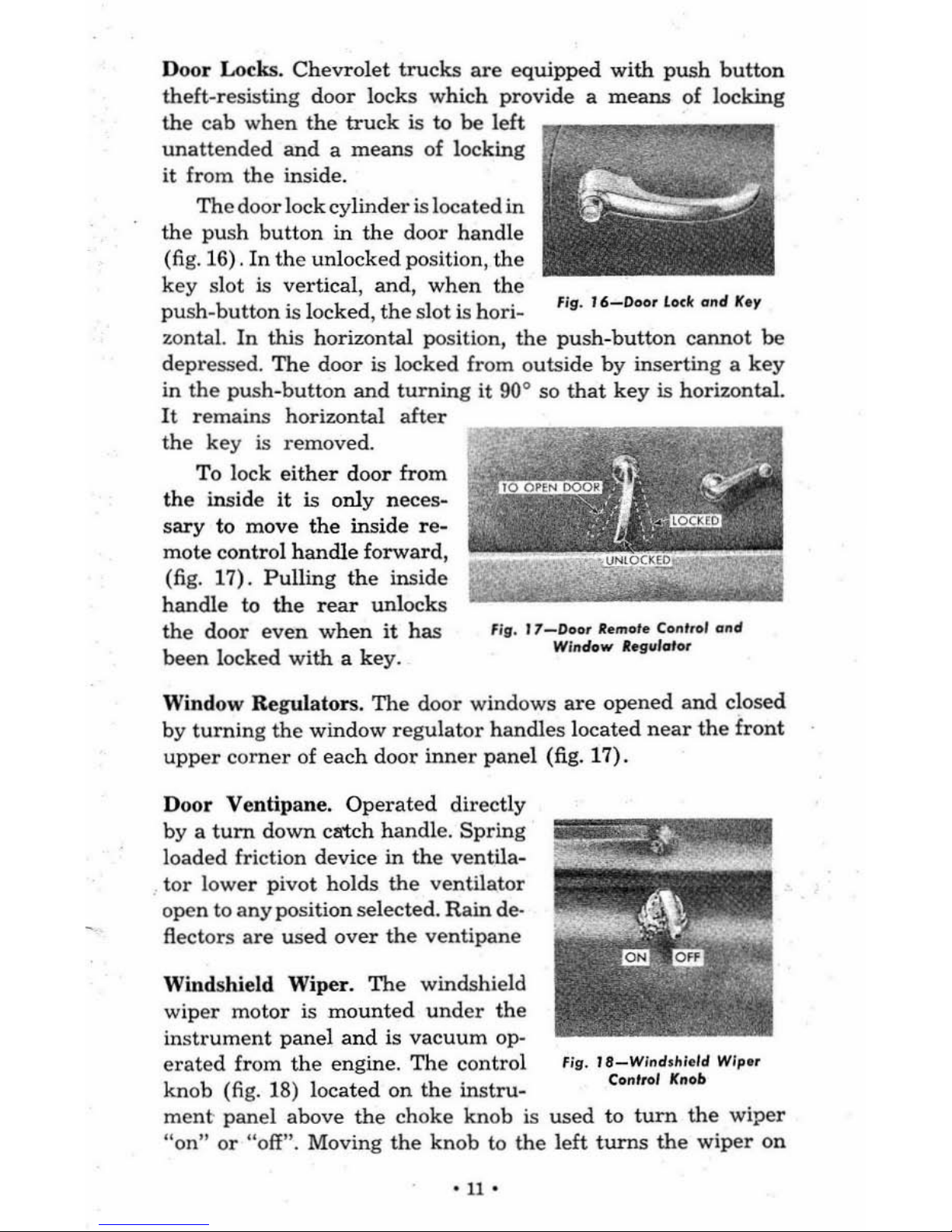

Door Locks.

Chevrolet

trucks

are

equipped

with

push

button

theft-resisting

door

locks which provide a

means

of locking

~n:;t

:

:d:~e:n~h:

~ue~

is

o~

l

~k:;;

""~I'l'!!I""''I''!!'IIIIIJI_

it from

the

inside.

The

door

lock cylinder is located in

the

push

button

in

the

door

handle

(

fig.

16) .

In

the

unlocked position,

the

key sl

ot

is vertical, and,

when

the

push-button

is locked ,

the

slot

is hori- Fig.

16-Doo.

lock

ond

Key

zontaL

In

this horizontal pos ition,

the

push-button

cannot

be

depre

ssed.

The

door

is locked from

outs

ide

by

inserting a

key

in

the pus

h-button

and

turning

it

900 so

that

key

is horizontal.

It

remains horizontal

ah

er

the key is removed.

To lock

either

door

from

the

inside

it

is only neces-

sary

to

move

the

inside

re-

mote control

handle

forward,

(fig. 17).

Pulling

the

inside

handle

to

the

rear

unlocks

the

door

even

when

it has

been locked

with a key.

Fig.

17-Door

lIemole Control

ond

Window IIlfg.,/o'

.....

Window Regulators.

The

door windows

are

opened

and

closed

by

turning

the

window

regulator

handles located

near

the

front

upper

corner

of each door

inner

panel (fig. 17).

Door Ventipane.

Operated

directly

by a

turn

down catch handle.

Spring

loaded friction device in

the

ventila-

tor

lower pivot holds

the

ventilator

open to

any

position sel

ecte

d. Rain de·

flectors

are used

over

the

venti

pane

Windshield Wiper.

The

windshield

wiper

motor

is

mounted

under

the

instrument

panel

and

is

vacuum

op-

erated

from

the

engine.

The

control Fig.

J8_Wind,IIleld

Wiplfr

knob

(fig. 18) located

on

the

instru-

Control Knob

ment

panel above

the

choke

knob is

used

to

turn

the

wiper

"on"

or "off

". Moving

the knob

to

the left

turns

the

wiper

on

'

11'

and moving

it

to

the

right

decrea

ses

wiper

speed

or

turns

it

off completely.

Rear

View Mirror.

An

adjustable

rear

view

mirror

is

mounted

on

the

left side of cowl

in

a position so

that

the

driver

can

get

a

clear

vision along

the

left side of

truck

by

looking

at

the

fIg

.

19-5.'"

Ad/II".'

mirror

through

the

ll!h

door

window.

Seat

Adjuster.

The

entire

seat

as-

sembly

can

be moved

forward

or

back

to

obtain

the

most comfortable

position

for

the

driver. As the

seat

is

moved

forward

it

raises

and

tips for-

ward

and

as

it

is moved

back

it

is

lowered

to

accommodate a tall person.

Moving

the

adjuster

handle

forwa

rd

(fig. 19) releases

the

seat

adjuster

lock so

that

the

seat

assembly

can

be moved for-

ward

or

back

as

desired. Two coil

spri

ngs assist

in

moving

the

seat

forward.

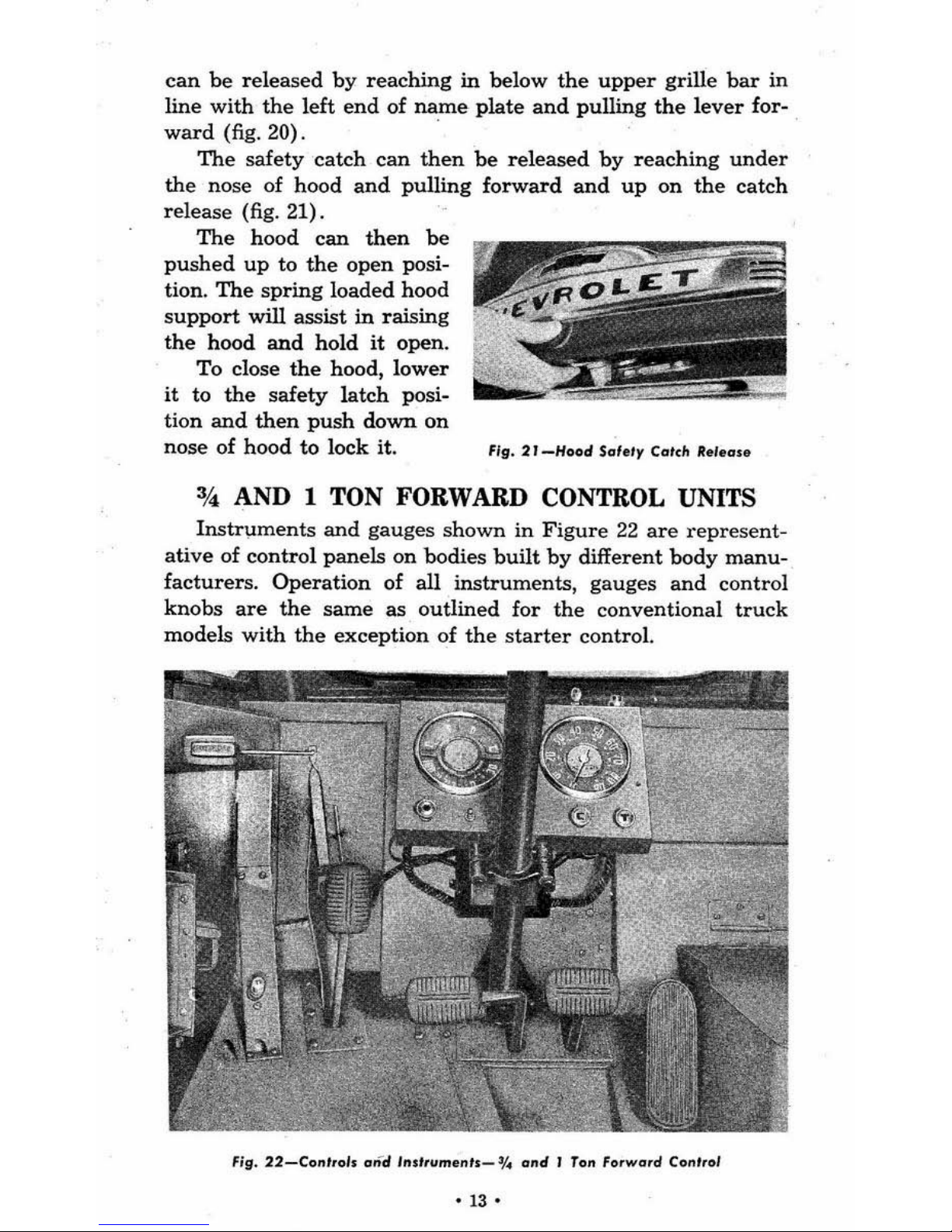

Hood

Lock

and

Safety

Catch.

Th

e hood

is

of

the

"alligator

j

aw"

type

and

is held closed

by

a lock

at

the

front. Thi s lock

"

12'

can

be

released

by

reaching

in

below

the

upper

grille

bar

in

line

with

the left

end

of

name

plate

and

pulling

the

lever

for-

ward

(fig. 20).

The

safety

catch

can

then

be

released

by

reaching

under

the nose of hood

and

pulling

forward

and

up

on

the

catch

release

(fig. 21).

The

hood

can

then

be

pushed

up

to

the

open

posi-

tion.

The

spring

loaded

hood

support

will assist

in

raising

the

hood

and

hold

it

open.

To

close

the

hood,

lower

it

to

the

safety

latch

posi-

tion

and

then

push

down

on

nose of

hood

to lock it. F

ig.

2'

-Hood

Saf.,y

COl." R. '.

all

34,

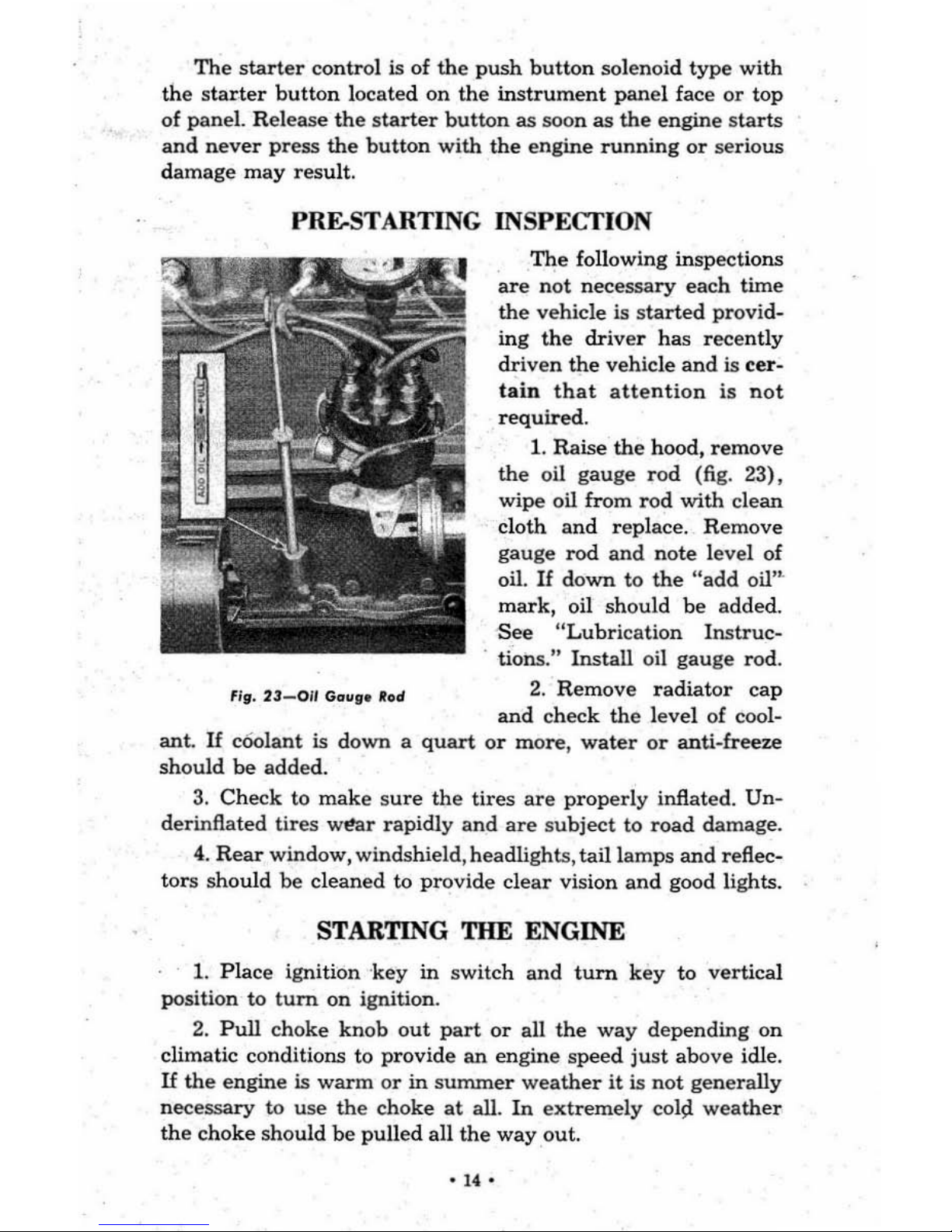

AND 1 TON FORWARD CONTROL UNITS

Instrl,lments

and

gauges

shown

in

Figure

22

are

represent-

ative

of

control

panels

on

bodies

built

by

different

body

manu-

facturers.

Operation

of

all

instruments,

gauges

and

control

knobs

are

the

same

as

outlined

for

the

conventional

truck

models

with

the

exception

of

the

starter

control.

Fig.

22-Co,,',ol.

and

I"II,ume,,'s_

0/.

a"d

,

Ton

fo,wa,d

Co

nl,ol

-13-

The

starter

control

is of

the

push

button

solenoid

type

with

the

star.ter

button

located

on

the

instrument

panel

face

or

top

of panel. Rel

ease

the

starter

button

as

soon

as

the

engine starts

and

never

press

the

button

with

the

engine

running

or

serious

damage

may

result.

PRE-STARTING

INSPECfION

~19.

23-011

Gaugelfod

The

following inspections

are

not

necessary

each

time

the

vehicle is

started

provi

d-

ing

the

driver

has

recently

driven

the

vehicle

and

is

cer-

tain

that

attention

is

not

required.

1.

Raise

the

hood,

remove

the

oil gauge r

od

(fig. 23),

wipe

oil

from

rod

with

clean

cloth

and

replace. Remove

gauge

rod

and

note

lev

el of

oil.

If

down

to

the

"add

oil'"

mark,

oil

should

be

added.

See "Lubri

cation

Instruc-

. tions." Install oil

gauge

rod.

2.

Remove

radiator

cap

and

check the level of cool-

ant.

U c60lant is down a

quart

or

more,

water

or

anti

-free

ze

should

be added.

3.

Check

to

make sure

the

tires

are

properly

inflated.

Un-

derinftated

tires

w~r

rapidly

and

are

subject

to

road

damage.

4.

Rear

window, windshield,headlights,

tail

lamps

and

reflec-

tors

should

be

cleaned

to

provide clear

vision

and

good lights.

STARTING THE ENGINE

1.

Plac

e ignition '

key

in

switch

and

turn

key

to

vertical

position

to

turn

on

ignition.

2.

Pull

choke

knob

out

part

or

all

the

way

depending

on

climatic conditions to provide

an

engine

speed

just

above

idle.

If

the

engine

is

warm

or

in

summer weather

it

is

not

generally

nec

essary

to

use

the

choke

at

all.

In

extremely

col9.

weather

the

choke

should

be

pulled

all

the

way

out.

'14'

3.

Make

sure

the

transmission shift

lever

is

in neutral. De-

press

the

clutch

pedal

to

relieve

the

load

in

the

transmission.

4.

Step

on

starter

pedal,

or

on

Forward

Control models press

button, to

crank

engine. Remove foot from

starter

pedal

or

finger

from

starter

button

as

soon

as

engine starts.

If

engine does

not

start

in

15 seconds, release

pedal

or

button

and check to see

that

the

above operations

have

been

performed

correctly.

5.

As

soon

as

engine starts,

push

choke

knob

in

part

way

and

adjust

throttle

for smooth idle.

6.

Note oil gauge

and

ammeter

readings. Amm

eter

sho uld

show some

charge

unless engine is idling slowly. Oil gauge

s

hould

show some

pre~ure.

In

unusually

cold

weather

the

oil

gauge

needle

may

go

over nearly

to 30.

If

so,

run

the

engine

ju

st above idling speed

until

the

pressure

drops to

around

15

before driving vehicle.

The

choke

knob

should

be

pushed

in

all

the

way

as

soon

as

the

engine is sufficiently

warmed

up.

GEARSHIFTING

Starting

the

Vehicle

1.

Push

clutch

pedal down to disengage

the

clutch.

2.

Move gearshift lever

into low

gear

position.

(If

4-speed

transmission

see

Figure

11

,

or

if

3-speed

transm

ission see

Figure

12.)

3.

Release ·

the

parking

brake.

4.

Push

down slightly

on

acce

lerator

pedal

and

at

the

same

time slowly engage

the

clutch.

Continue

to depress

the

accel-

er

ator

pedal

until

the

'Ve

hicle is moving.

Shifting

to

Highet

Gears.

1.

Depre

ss

clutch

pedal

and

release accelerator

at

the

same

time. Move

the

shift

lever

into

neutral

and

then

to

the

next

higher

gear.

See

shifting diagrams,

Figures

11

and

12.

2.

Accelerate

the

engine

slightly

and

slowly engage

the

clutch.

3.

Accelerate

the

engine

to

about % maximum

engine speed

before shifting to

the

next

high

er

gear

and

proceed

as outlined

above.

Shifting

to

Reverse

(4-speed

tran

smission)_

The

vehicle

must

not

be moving forward

when

shifting

to

-15'

1.

Depress

clutch

pedal

to

disengage

the

clutch

.

2. Move

shift lever

across

neutral

to left,

against

the

spr

ing

tension as

far

as

it

will go. Move

lever

back

into

reverse

(fig.

11).

3.

If. parking

brake

is on, release

the

brake.

4.

Push

down

slightly

on

accel

erator

pedal

and

at

the

same

time

slowly engage

the

clutch.

Control

the

vehicle

speed

with

the

accelerator.

Shift

ing to

Reverse

(3-speed transmission).

The

vehicle s

hould

not

be moving f

orward when

shifting

to

rev

erse

.

1.

Depre

ss

clutch

pedal to. disengage

the

clutch.

2.

Raise

shift lever

up

across ne

utral

and

forward

into

reverse

position. (fig. 1

2).

3.

If

parking

brake

is on,

rel

ease

the

brake.

4.

Push

down slig

htly on

accelerator

pedal

and

at

the

same

time

slowly engage

the

clutch.

Control

the

vehicle

speed

with

the

accele

rat

or. .

Shifting

to

Lower

Gears

To

obtain

more

pulling

power

for

negotiating

bad

roads

or

climbing hills,

or

to

travel

at

unusually slow

speed

it

is

sometimes

necessary

to

shift

to

lower

transm

ission gears.

The shift

from high to second

with

the

3-speed

synchro-me

sh

transmission

or

from

high

to

third

or

third

to second

with

the

4-speed

synchro-mesh

transmission

is

aeeomplished

in

the

same

manner

as un-shifting.

The

following

procedure should be

used

when

shifting

the

3-speed

or

4-speed

transmission

from

second

to

low.

1. Disengage

the

clutch

and shift

the

trans

mission

into

neutral

while

maintaining

enough

pressure

on

acce l

erator

to

noticeably

increa

se

engine

speed.

2.

Enga

ge

clutch

and

quickly

disengage

it

again.

3.

Shift

into

the

next

lower

gear

quickly

and

then

gradua

lly

engage clutch.

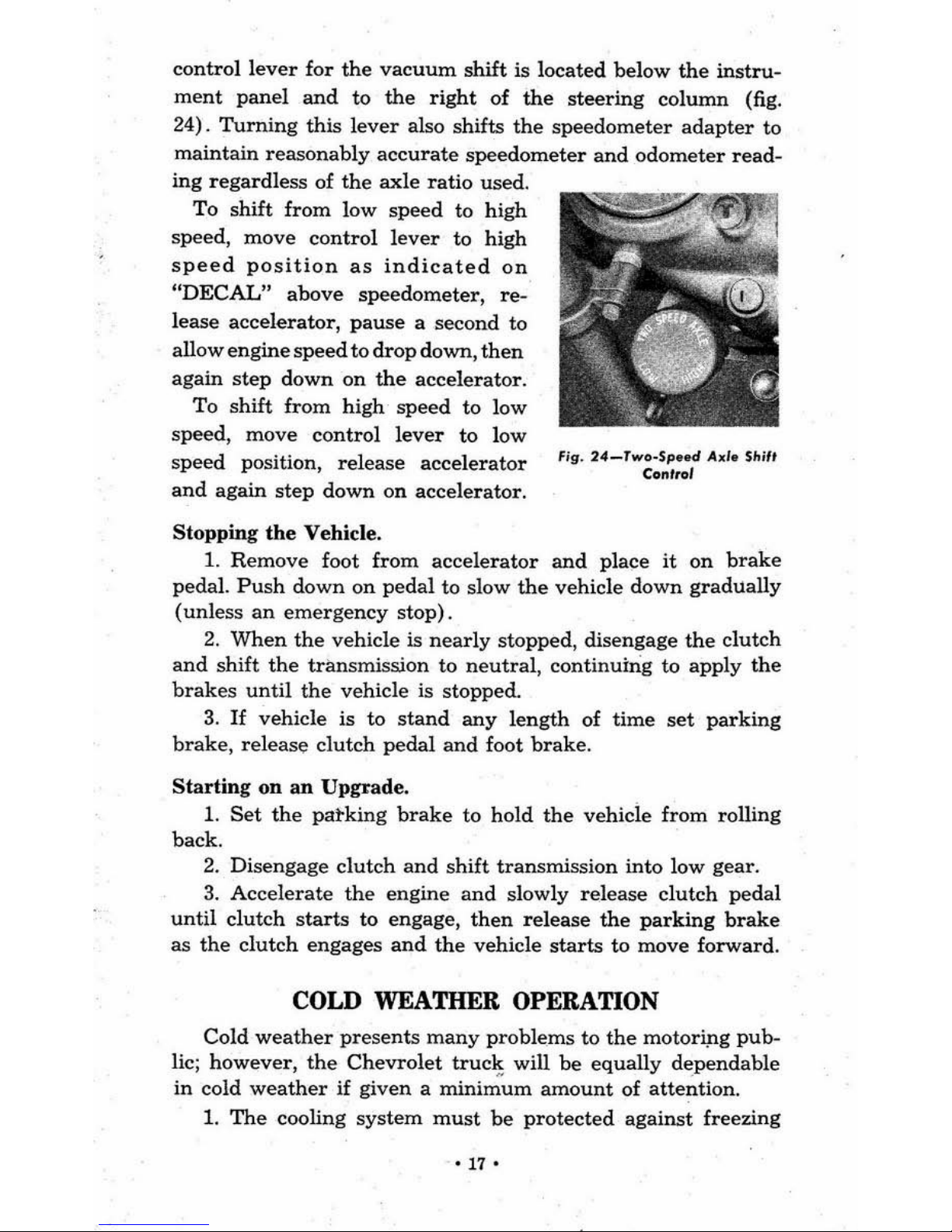

Shifting

Two-Speed

Rear

Ax

le

The

vacuum

shift

ma

kes this

operation

compar

atively

simple as

it

is

unnecessary

to declutch while shifting.

The

-I

S-

control

lever

for

the

vacuum

shift

is

located

below

the

instru-

ment

panel

and

to

the

right

of

the

steering

column

(fig.

24).

Turning

this

lever

also shifts

the

speedometer

adapter

to

maintain

reasonably

accurate

speedometer

and

odometer

read-

ing

regardless

of

the

axle

ratio

used.

To

shift

from

low

speed to high

speed,

move

control

lever

to high

speed

position

as

indicated

on

"DECAL"

above

speedometer,

re-

lease accelerator,

pause

a second to

allow

engine

speed

to

drop

down,

then

again

step

down

on

the

accelerator.

To

shift

from

high

speed

to

low

speed,

move

control

lever

to

low

speed

position,

release

accelerator

and

again

step

down

on

accelerator.

Stopping

the

Vehicle.

Fig.

24_Two_Sp

.. d Axi

.

Shi',

Con'tol

1.

Remove

foot

from

accelerator

and

place

it

on

brake

pedal.

Push

down

on

pedal

to slow

the

vehicle

down

gradually

(unless

an

emergency

stop).

2.

When

the

vehicle is

nearly

stopped, disengage

the

clutch

and

shift

the

transmission

to

neutral,

continuing

to

apply

the

brakes

until

the

vehicle is stopped.

3.

If

vehicle

is

to

stand

any

length

of

time

set

parking

brake,

release

clutch

pedal

and

foot

brake.

Starting

on

an

Upgrade.

1.

Set

the

pat-king

brake

to hold

the

vehicle from rolling

back.

2.

Disengage

clutch

and

shift

transmission

into

low

gear.

3.

Accelerate

the

engine

and

slowly

release

clutch

pedal

until

clutch

starts

to engage,

then

release

the

parking

brake

as

the

clutch

engages

and

the

vehicle

starts

to move

forward.

COLD WEATHER OPERATION

Cold

weather

presents

many

problems

to

the

motoripg

pub-

lic; however,

the

Chevrolet

truck

will

be

equally

dependable

in

cold

weather

if given a

mini~~m

amount

of

attention.

1.

The

cooling

system

must

be

protected

against

freezing

'17

-

by

the use of anti-freeze solutions (see "Cooling

System"

and

"Anti-Freeze")'

or

the system must be

drained

at

the lower

right

corner

of

radiator

and

the

left

rear

corner

of cylinder

block each time

the

vehicle is to

stand

any

length of time.

2.

Light oil should be

used

in

the

engine (see "Engine

Lubrication") .

3.

The

battery

should be

kept

fully charged to provide the

additional power necessary to

crank

a cold engine

and

furnish

a good spark. A discharged

battery

will freeze in extremely

cold

weather

which will

make

battery

replacement necessary.

4.

The

carburetor,

fuel

pump

and

fuel

tank

should

be

kept

free from

water

which will freeze

and

restrict

fuel flow.

5.

The ignition system should be

kept

in

good condition.

6.

Assuming

that

the

above items

have

been

given

normal

attention, the engine should

start

promptly, even in extremely

cold weather,

by

following this simple procedure:

a.

Turn

on ignition.

b.

Pull

choke knob

all

the

way

out.

c.

Depress foot accelerator slowly a few times.

d. Disengage

the

clutch.

e.

Step

on

starter

pedal

or

push

button

on

Forward

Control.

f.

Release

starter

as soon as engine

starts

and

push

choke

knob

in

slightly.

g.

Regulate choke to provide a fast idle and

gradually

push

choke knob

in

as engine warms up.

h. In

abnormal~

cold

weather

the

engine should be

run

slightly above idling speed for a few minutes to

warm

up

the oil before driving

the

truck.

NOTE: Never

race

the

e..,me

until

the

oil

pUle

needle wil l sta,.

.round

15.

7.

The

Chevrolet cooling system is designed to properly

cool

the

engine

under

most severe operating conditions in hot

weather. A

thermostat

is used

in

the system to

restrict

the

water

circulation until

the

engine

warms

up.

In

very

cold

weather

and

under

certain driving conditions such as house-

to-house delivery where

the

engine idles a lot

or

is stopped

·18·

and

started

frequently,

the

production

thermostat

does

not

maintain

high

enough

temperature

for best

economy

and

per-

formance.

In this

case a

higher

temperature

thermostat

should

be

us ed

or

part

of

the

radiator

area

covered.

HOT WEATHER OPERATION

Hot

weather

does

not

generally

present

as

many

problems

as cold

weather;

however, a little

special atte

ntion

will

pay

dividends

in

the

form

of

economy

and

convenience

.

1.

Check

the

radiator

regularly

for sufficient coolant as the

rate

of

evaporation

is

higher

in

hot

weather.

2.

Make

sure

the

fan

belt

is

in

good

condition

and

properly

adjusted.

3.

Keep the

radiator

area

free

of

bugs

and

other

things

that

restrict

air

circulation.

4.

Have the

water

level

in

the

battery

checked

at

lO-day

intervals

or

oftener,

if

necessary.

5.

Starting

a cool en

gine

in

hot

weather

does

not

present

a

problem

and

the

procedure

outlined

under

"Starting

the

Engine"

should

be followed.

_ A

hot engine

is easily flooded

and

may

start

hard.

If

the

carburetor

is

flooded

proceed

as follows:

a.

Turn

on

ignition.

b.

Pull

hand

throttle

knob

out

about

J.h".

c.

Do

not

pull

choke

knob

out

or

step

on

accelerator.

d.

Depress

sflarter

pedal

or

starter

button

without

depressing

accelerator.

e.

When

engine

starts,

release

starter,

but

do

not

accelerate

engine.

f.

Regulate

hand

throttle

knob

for

desired

engine

speed.

If

the

engine

still

does

not

start

look

for

trouble

in

the

fuel

pump

or

ignition

system.

.

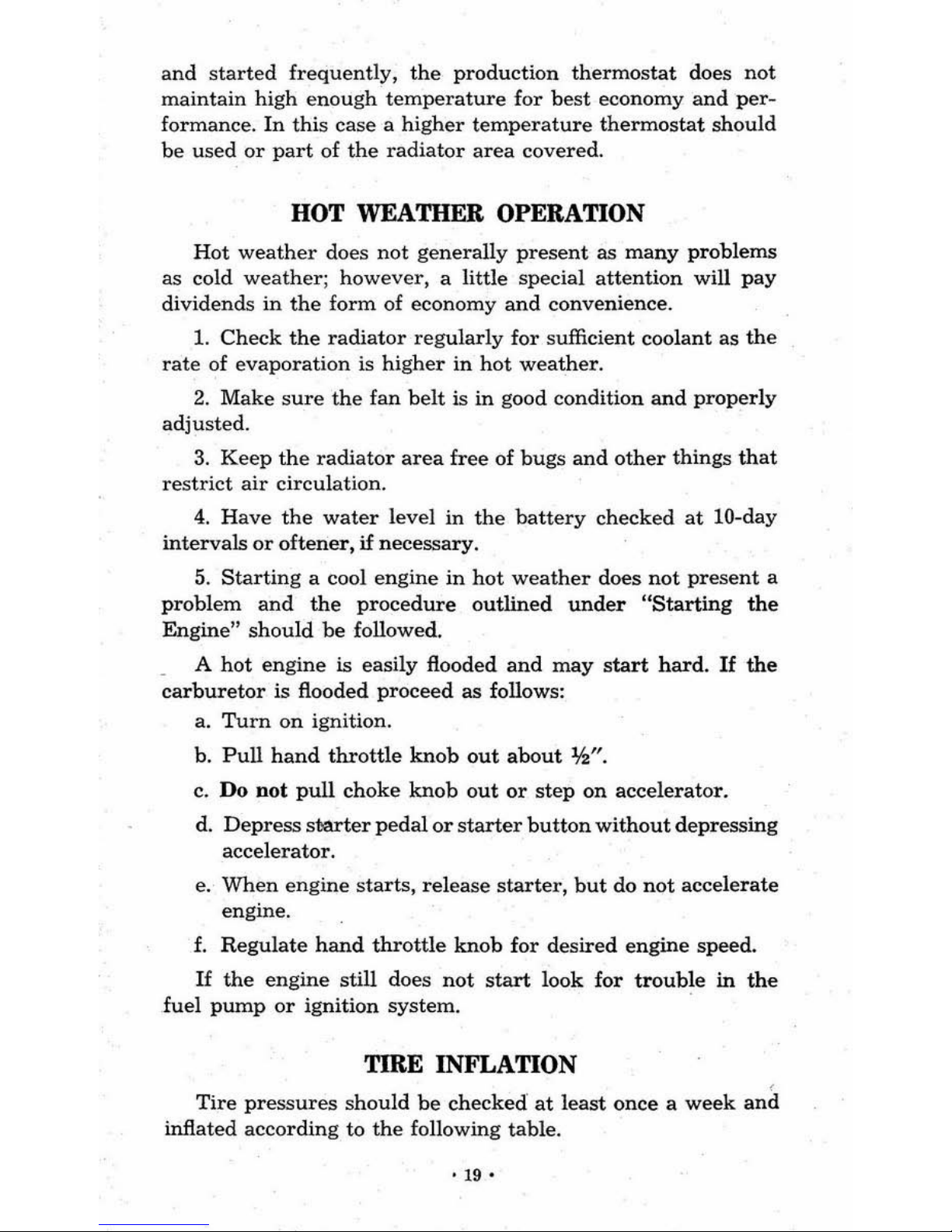

TIRE INFLATION

Tire

pressures

should

be checked"

at

least

once a week

and

inflated

according

to the following table.

-19-

Avoid underinftation to

prevent

pinched tubes,

rim

bruises,

excessive heat,

and

irregular

or

rapid

wear.

Avoid over inflation to

prevent

tire

ruptures, hard

riding,

irregular

or

rapid

wear

and

reduction of skid resistance.

Inflation Table

6.00-16 6-Ply

Rating..

. . front

30

pounds, r

ear

36 pounds

6.00-18 6-Ply

Rating

..........

front

30 pounds,

rear

36

pounds

6.50-16 6-Ply

Rating..

.

..

front

26

pounds, r

ear

36

pounds

6.50-20 6-Ply

Rating..

.

.front

40

pounds,

rear

50

pounds

6.50-20 8-Ply

Rating

.........

front

50

pounds,

rear

65

pounds

6.70-15 6-Ply Rating

.....

front

26

pounds,

rear

30

pounds

7.00-17 6-Ply Rating

.......

. .

front

40 pounds, r

ear

45

pounds

7.00-17 8-Ply

Rating

..........

front

40

pounds,

rear

55

pounds

7.00-18 8-Ply

Rating

.........

front

40

pounds,

rear

55

pounds

7.00-20 8-Ply

Rating

..........

front

40

pounds,

rear

55

pounds

7.00-20 10-Ply Rating

.........

front 45 pounds,

rear

70

pounds

7.50-17 8-Ply

Rating..

.

.front

40

pounds,

rear

60

pounds

7.50-17 10-Ply Rating

.........

front 40 pounds,

rear

75

poun

ds

7.50-20 8-Ply Rating. .

.front

40

pounds,

rear

60 pounds

7.50-20 10-Ply Rating

........

front

45 pounds,

rear

75

pounds

8.25-18

10-Ply

Rating.

.

rear

65 pounds

8.25-20 IO-Ply

Rating

........

front

40 pounds,

rear

65

pounds

8.25-20 12-Ply Rating

.........

front

60 pounds,

rear

75

pounds

9.00-18 10-Ply

Rating.

. .

rear

65

pounds

9.00-20 10-P

ly

Rating..

rear

65

pounds

10.00-18

l2-Ply

Rating

..

rear

70

pounds

15

Inch

Tires

Tire

Rotation.

Proper

inflation is the

prime

factor

in

satisfac-

tory

tire

life; however,

even

better

tire

service can be obtained

by

rotating

the

tires

every

3,000 to 5,000 miles.

·20·

CH

AP

TER n

DESCRIPT

ION,

CARE

AND

MAINTENANCE

PREVENTIVE MAINTENANCE

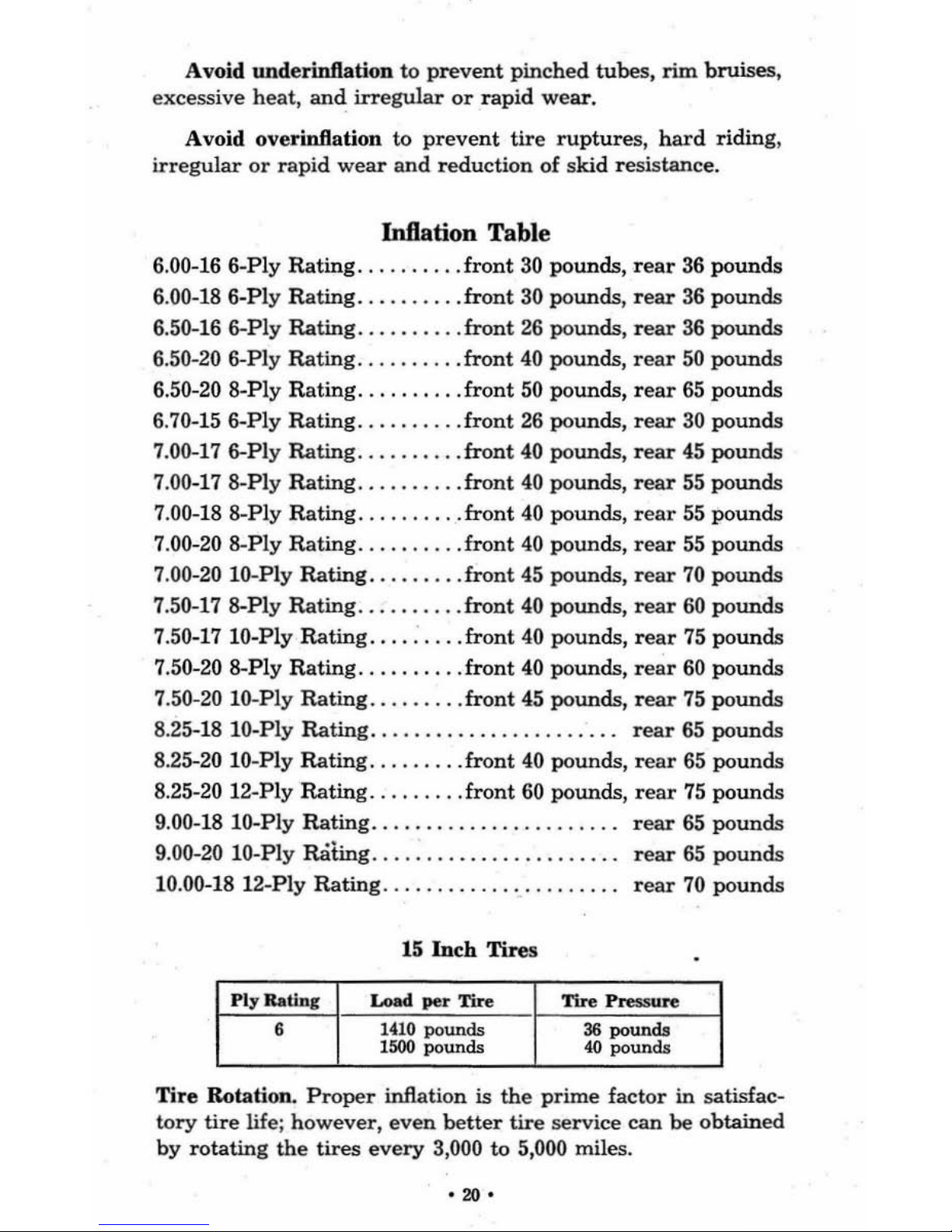

The

following table

will

indicate

som

e of

the

things

which

should be do

ne

at regular

mileage intervals to

assure

your

rec

eiving

the

maximum

, Dot only

in

perfonnance

. but

in

econ-

om

y.

M

U....

L~~.

Chan

a'

CI~n

i("

~~

8:~:-.

Tlln

. .

a.

r

~"n~

Ad •

.l~~

CII'.'''I

~

'

CI.~n

..

~"p

Tir ..

Enaln

t

~;

s:.~

,.-

------------

.1~

0

,.11.

___

_

~--

-_o_------

I-I-

___

_

~

_o_--------

I-I----'!...-

___

_

2000

000

~

°

===

:= 1-

==

~

_°

___

° ___ °

____

_

1--

-----

6000

_ 0

____

_

__ 0 ___ 0_1

-"-

_ 0 _

___

0 _

~

_o_-_o_-_o----I------

-

~~

_o_-------

-I-I-----

8000

_ 0

___ 0 ___ 0 ____

1-

-----

-

9000

_ 0

____

_____

1-

--

1--1--

1

0000

000000000

After 10000

miles,

repeat

above schedule

starting

with

1000

mile

operations.at

11000, 21000, 31000 miles,

etc

.

-For complete in .flru

cUotUl, see Charts

on pages 82 to 89.

tFor complete recommenda

Uon

a on changing oil and proper grade or

01

1 to u

se.

see

pag

es

70 to 75.

lAlso era nkease l'cotllator and hydrovac ai r cleane

rs

when aled.

The

following

operation

s sho

uld

be

done

as

indicated:

Fla

sh

CooIlnt

Add

a.

tt.

ry

in Ti

res

Syste

m

An

~·fr"l l

~

0 0

I-----=-

==

~~~

:n

g

1-

--

-

-+-

-0-

.".

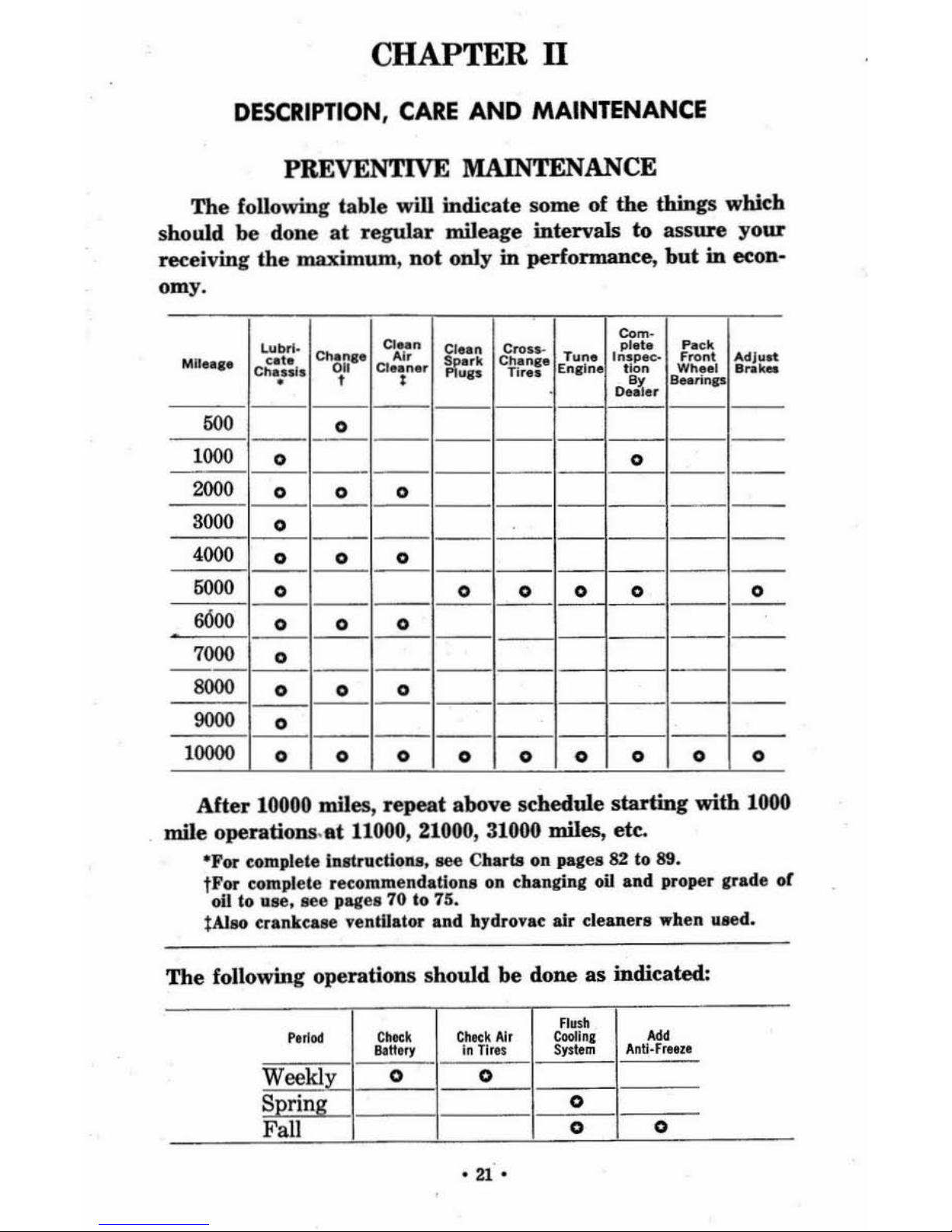

ENGINE

Description.

The

Chevrolet

six

cylinder

valve-in-head

truck

engines

are

the

prime

factor

in

Chevrolet's

outstanding

per-

formance

and

economy.

They

are

designed to give l

ong

trouble-

free life. Chevrolet's four-way engine lubrication system pro-

vides

the

correct

amount

of

lubr

ication

to

all

moving

parts

.

Full

stroke

length

water

jackets, surroundin

g

all

cylinders,

provide

uniform

cooling

and

prevent cylinder

distortion

which

wou

ld

cause

undue

wear

and

poor oil economy.

The

water

passages

in

the

cylinder block

and

cylinder

head

properly

direct

the flow of

water-to provide

unifonn

cooling of

the

engine

(fig. 25).

Care.

The

engine oil level s

hould

be

checked

each

time

fuel

is

purchased

and

oil

added when

necessary.

(See

Lubrication

Section.)

The

engine

should

be inspected occasionally for oil

and

water leaks

and

the

necessary

repairs

made.

Keep

the

engine

clean externally.

Valve

Tappet

Adjustment.

Valve

tappet

adjustment

shou

ld

be

c

hecked

when

the

engine is thoroughly

warmed

UP.

preferably

fI,

.

2S-Wot"

flow

""011,,,

Coo/in.

5,..1

....

•

22·

when

the

truck

comes

in

from a run

or

after

the

engine

has

been

run

at

a fast

idle

for

30

minutes.

1.

Remove

rocker

arm

cover

attaching

nuts

and

rocker

arm

cover.

2.

Lubricate

the

valve

stems

with

engine

oil

to

insure

free

movement

of

the val

ves

in

their

guides.

3.

Check

the

clearance

between

the

rocker

anus

and

the

valve

ste

ms

with a feeler

gauge

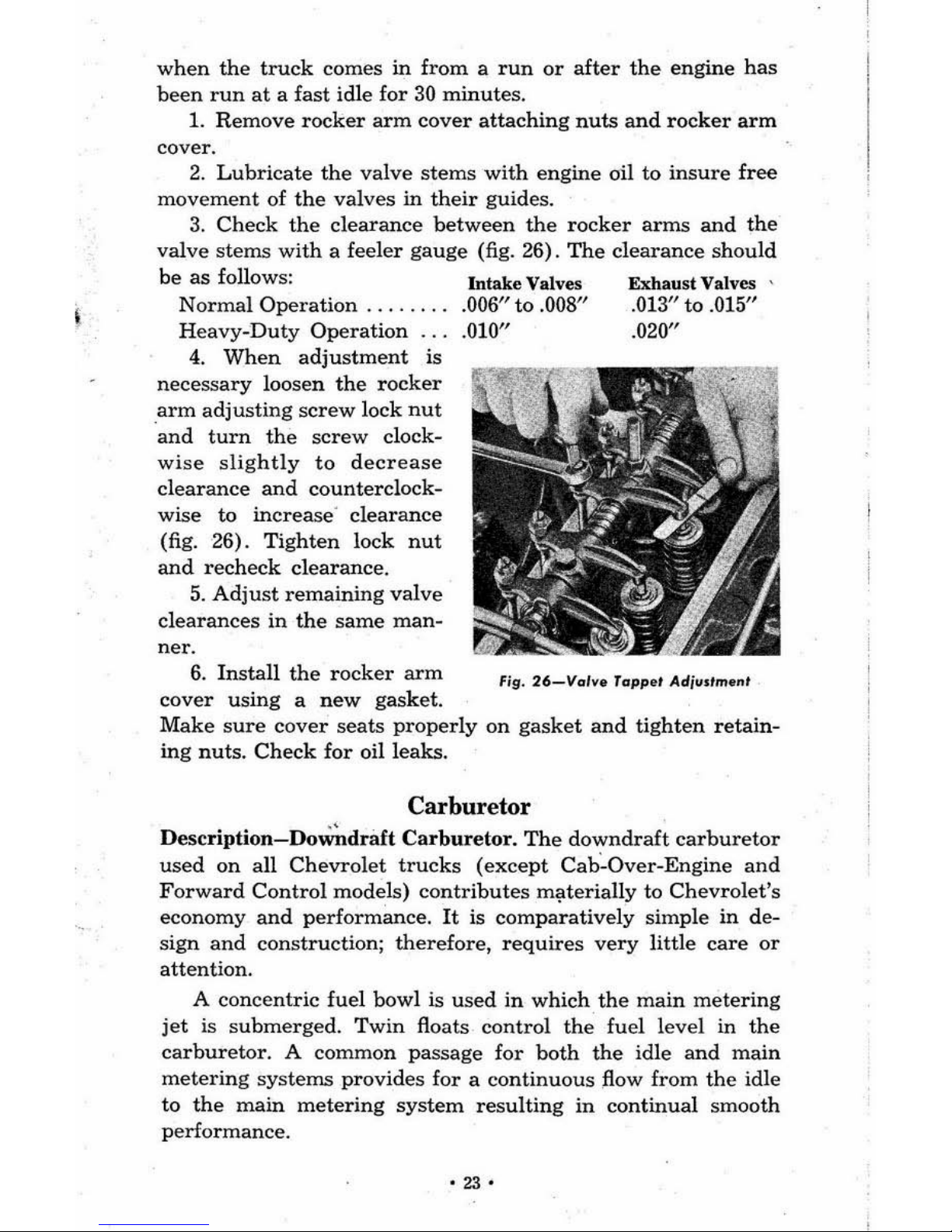

(fig. 26).

The

clearance

should

be

as

follows:

Normal Operation.

Heavy-Duty

Operation

.

4.

When

adjustment

is

necessary

loosen

the

rocker

arm

adjusting

screw

lock

nut

and

turn

the

screw

clock-

wise

slightly

to decrease

clearance

and

counterclock

-

wise to

increase' clearance

(fig. 26).

Tighten

lock

nut

and

recheck

clearance.

5.

Adjust

remain

ing

valve

clearances

in

the

same

man-

6.

Install

the

rocker

arm

cover

using

a

new

gasket.

Intak

e Valves

.006"

to

.008"

.010"

Exhaust

Valves '

.013"

to

.015"

.020"

Make

sure

cover

seats

properly

on

gasket

and

tighten

retain-

ing nuts.

Check

for

oil l

eaks.

Carburetor

Description-Do~draft

Carburetor.

The

downdraft

carburetor

used

on

all

Chevrolet

trucks

(except

Cab~Over-Engine

and

Forward

Control

mode

ls)

contributes

m~terially

to

Chevrolet's

economy and

performance.

It is

comparatively

simple

in

de-

sign

and

constructio

n;

therefore,

requires

very

little

care

or

attention.

A

concentric fuel bowl

is

used

in

which

the

main

metering

jet

is

submerged.

Twin

floats

control the

fuel

level in

the

carburetor.

A commo n

passage

for

both

the idle

and

main

metering

systems

provides

for a continuous

flow from

the

idle

to

the

main

metering

system

resulting

in

continua

l s

mooth

p

erfo

rmance.

'

23'

This

carburetor

has a vacuum

controlled

power

jet

and

a

throttle

operated

accelerator

pump

to

aid

in

pro

viding

the

desired

economy

and

performance.

Description-Updraft

Carburetor.

The

updraft

carburetor

used

on.

the

Cab-Over-Engine

and

Forward

Control

trucks

is

mounted

below

the

manifold.

It

is

equipped

with a vacuum

controlled

power jet

and a throttle

operated

accelerating

pump

to

aid

in

providing the

desired

economy

and

performance.

Care.

Tighten

the

carburetor

to

manifold

and

the

manifold

to

cylinder

head

stud

nuts

to

prevent

air

leaks.

Keep

the

car-

buretor

clean

externally

and

have

it

comple

tely

overhauled

at

regular

intervals

so

that

foreign

matter

in

the

carburetor

and

worn

parts

will

not

affect

correct

carburetion.

' Ig.

27_Downd,

.. f, C

..

,b

....

to,

Adj

..

.,men'

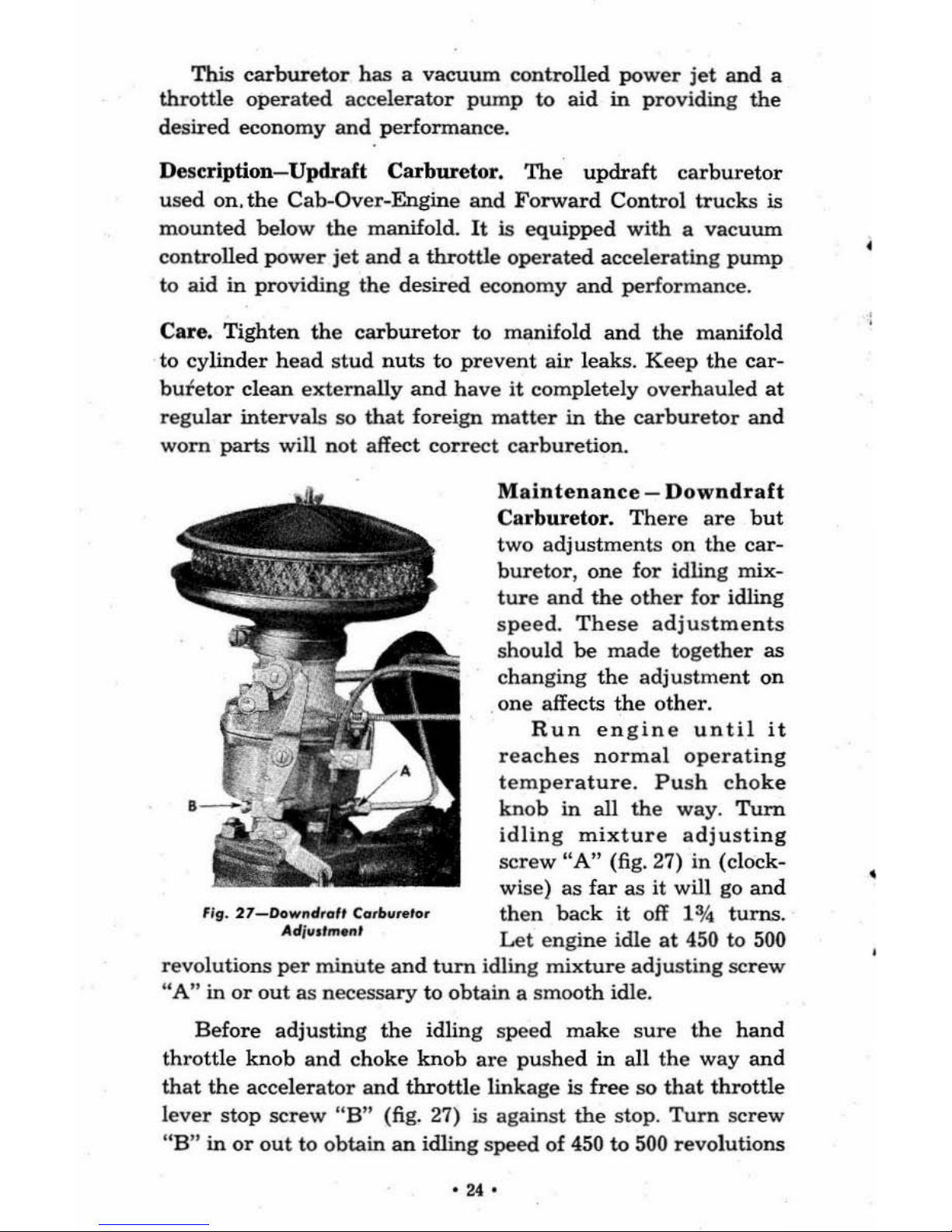

Maintenance

-

Downdraft

Carburetor.

There

are

but

two

adj

ustments

on

the

car-

buretor,

one

for

idling

mix-

ture and

the

other

for

idling

speed.

These

adjustments

sho

uld

be

made

together

as

changing

the

adjustment

on

one

affects

the

other.

Run

engine

until

it

reaches

normal

ope

rating

temperature.

Push

cho

ke

knob

in

all

the

way.

Turn

idling

mixture

adjusting

screw

"A"

(fig. 27) in (clock-

wise)

as

far

as

it will go

and

then

back

it

off 1

0/4

turns.

Let

engi

ne

idle

at

450 to 500

revolutions per

minute

and

turn

idling

mixture

adjusting

screw

"A"

in or

out

as

necessary

to

obtain

a smoo

th

idle.

Before

adjusting

the

idling speed

make

sure the

hand

throttle

knob

and

choke

knob

are

pushed

in

all

the

way

and

that

the

accelerator

and

throttle

linkage

is

free

so

that

throttle

l

ever

stop

screw

"B"

(fig. 27) is against

the

stop .

Turn

screw

"

B"

in

or

out

to

obtain

an

idling

speed

of 450

to

500 r

evo

lutions

.".

per

minute.

If

necessary

readjust

idling

mixture

screw

"A"

as

explained

above

to

obtain a smooth

idle.

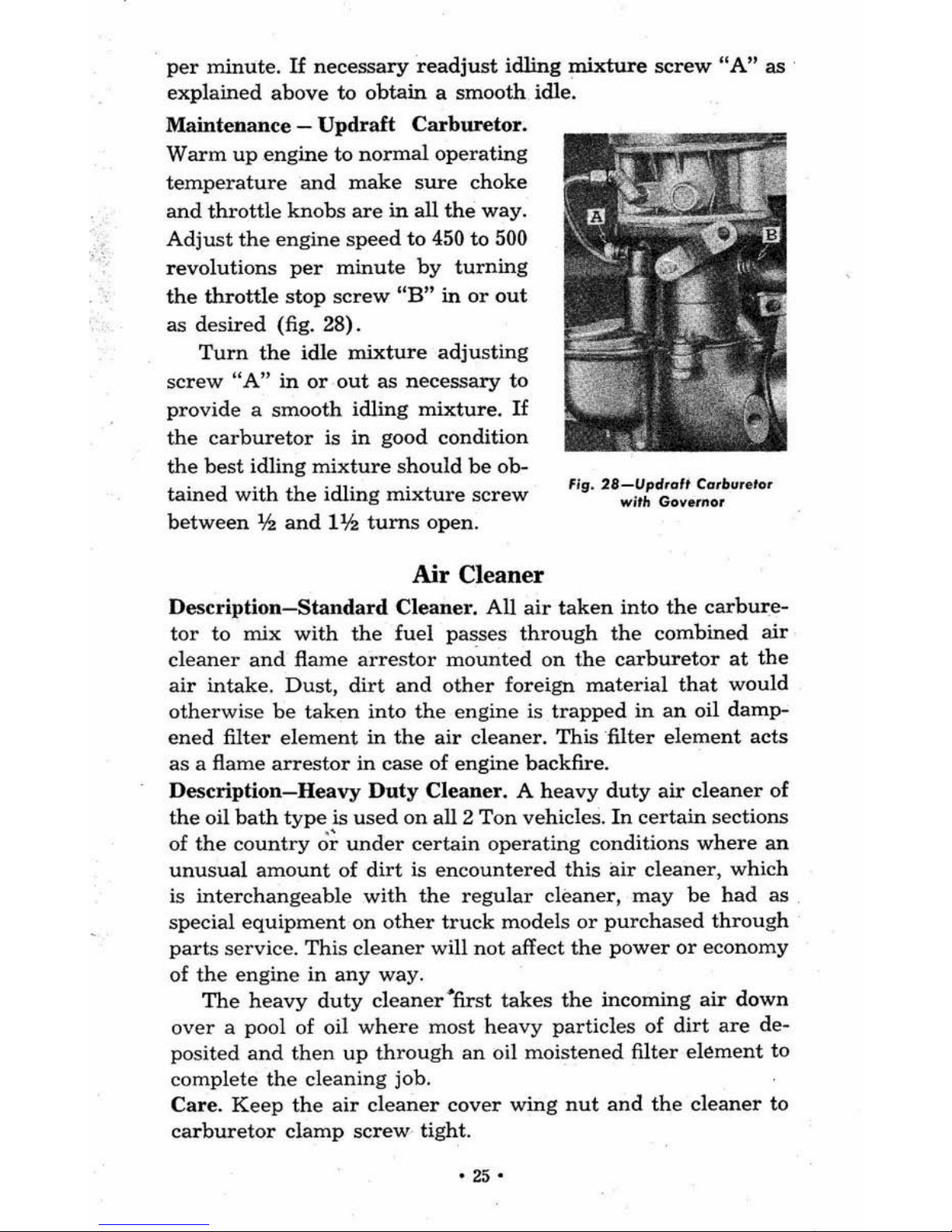

Maintenance -Updraft

Carburetor.

Warm

up

engine

to

normal

operating

temperature

and

make

sure

choke

and

throttle

knobs

are

in

aU

the

way.

Adjust

the

engine

speed

to

450 to 500

revolutions

per

minute

by

turning

the

throttle

stop

screw

"B"

in

or

out

as

desired

(fig. 28).

Turn

the

idle

mixture

adjusting

screw

"A"

in

or

out

as

necessary

to

provide a smooth

idling

mixture.

If

the

carburetor

is

in

good

condition

the

best

idling

mixture

should

be

ob-

tained

with

the

idling

mixture

screw

between

lh

and

Ilh

turns

open.

Air Cleaner

Fig.

28-Upd"./t

Ca,bIJ,eto,

wit" Gover/lot

Description-Standard

Cl

eaner.

AU

air

taken

into

the

carbure-

tor

to

mix

with

the

fuel

passes

through

the

combined

air

cleaner

and

flame

arrestor

mo·

unted

on

the

carburetor

at

the

air

intake.

Dust,

dirt

and

other

foreign

material

that

would

otherwise

be

taken

into

the

engine

is

trapped

in

an

oil

damp-

ened

filter

element

in

the

air

cleaner.

This

'filter

element

acts

as

a flame

arrestor

in

case

of

engine

backfire.

Description-Heavy

Duty

Cleaner. A heavy

duty

air

cleaner

of

the

oil

bath

type

is

used

on

all 2

Ton

vehicles.

In

certain

sections

of

the

country

o~

under

certain

operating

conditions

where

an

unusual

amount

of

dirt

is

encountered

this

air

cleaner,

which

is

interchangeable

with

the

regular

cleaner,

may

be

had

as

special

equipment

on

other

truck

models

or

purchased

through

parts

service.

This

cleaner

will

not

affect

the

power

or

economy

of

the

engine

in

any

way

.

The

heavy

duty

cleaner

"first

takes

the

incoming

air

down

over

a pool

of

oil

where

most

heavy

particles

of

dirt

are

de-

posited

and

then

up

through

an

oil

moistened

filter

element

to

complete

the

cleaning

job.

Care.

Keep

the

air

cleaner

cover

wing

nut

and

the

cleaner

to

carburetor

clamp

screw

tight.

-25

"

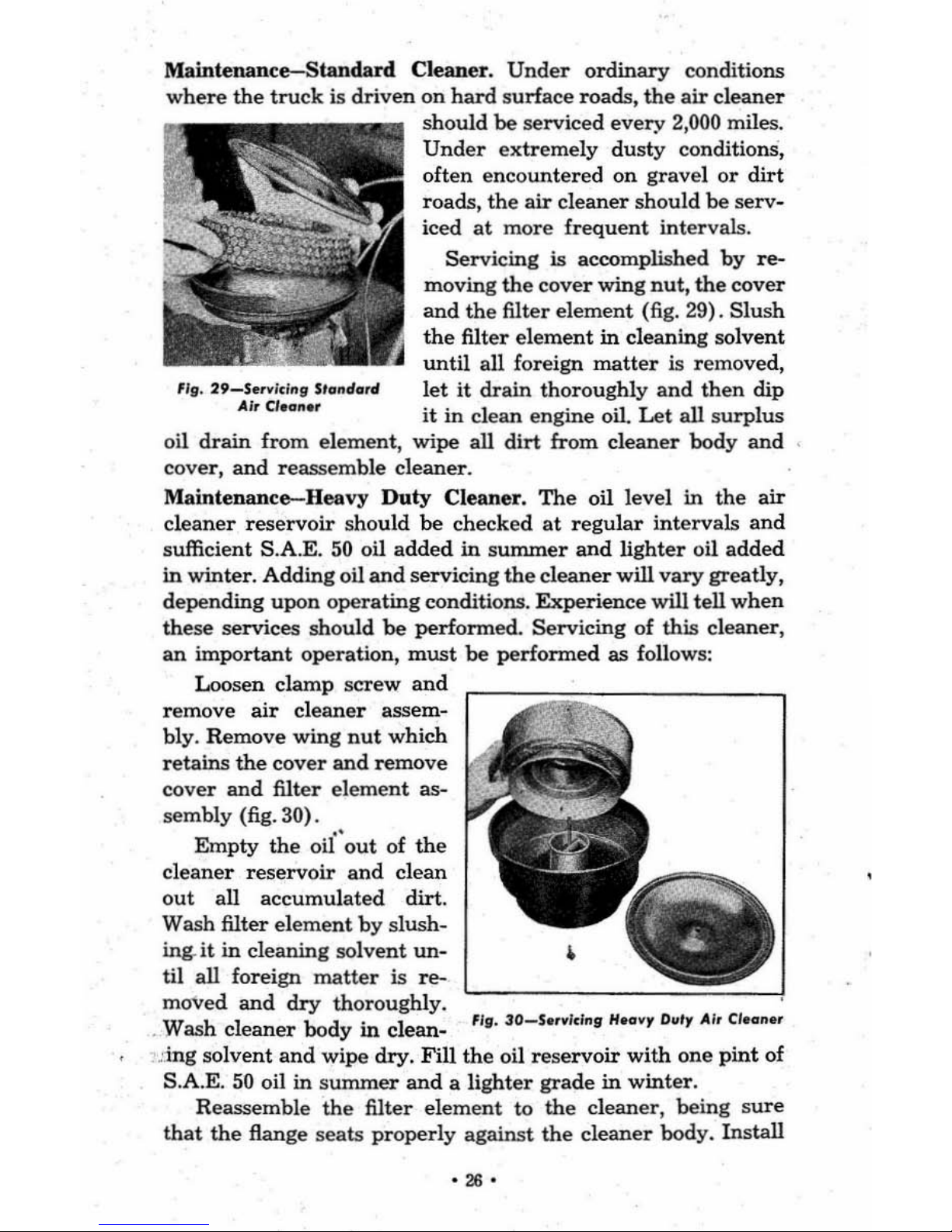

Maintenance-Standard

Cleaner.

Under

ordinary

conditions

where

the

tru

ck

is

driven

on

hard surface

roads,

the

air

cleaner

should

be

serviced

every

2,000 miles.

Under

extremely

dusty

conditions,

often encountered on gravel

or

dirt

roads,

the

air

cleaner

should

be

serv

-

iced

at

more frequent

intervals.

Servicing

is accomplished

by

re-

moving

the

cover

wing

nut,

the

cover

and

the

filter

element

(fig. 29). Sl

ush

the

filter

element

in

cleaning sol

vent

until

all foreign

matter

is removed,

fig. 29_Se,wld"g

Sto"dcm

'

let

it

drain thoroughly

and then

dip

AI,

CI.o".,

it

in

clean engine oil.

Let

all

surplus

oil

drain

from

element, wipe all

dirt

from

cleaner

body

and

'

cove

r,

and

reassemble cleaner.

Maintenance-Heavy

Duty

Cleaner,

The

oil level in

the

air

cleaner

reservoir

should

be

checked

at

regular

intervals

and

sufficient S.A.E.

50

oil

added

in

summer

and

lighter

oil

added

in

winter. Adding oil

and

servicing

the

cleaner

will

vary

greatly,

depending

upon

operating

conditions.

Experience

will tell

when

these

services should

be

performed.

Servicing

of

this cleaner,

an

important

operation,

must

be

performed

as

follows:

Loosen clamp screw

and

remove

air