Page 1

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 1

Contents

Document Use and Disclaimers ....................................................................................................................................................................................................... 12

Section A .......................................................................................................................................................................................................................................... 13

Body Control System Description and Operation ........................................................................................................................................................................ 13

Power Mode Master ................................................................................................................................................................................................................ 13

Gateway ................................................................................................................................................................................................................................... 13

Body Control ............................................................................................................................................................................................................................ 13

Power Mode Description and Operation ..................................................................................................................................................................................... 14

Serial Data Power Mode Master .............................................................................................................................................................................................. 14

Relay Controlled Power Mode ................................................................................................................................................................................................. 15

Battery Saver Mode (Transport Mode) ................................................................................................................................................................................... 15

BCM Awake/Sleep States ......................................................................................................................................................................................................... 15

Retained Accessory Power .......................................................................................................................................................................................................... 17

RAP Description and Operation ............................................................................................................................................................................................... 17

Relay Controlled Retained Accessory Power ........................................................................................................................................................................... 17

Serial Data Controlled Retained Accessory Power .................................................................................................................................................................. 18

Back-up Alarm and Camera ......................................................................................................................................................................................................... 19

Back-up Alarm and Camera relay installation schematic ........................................................................................................................................................ 20

Back-up Alarm, Camera and Lamps schematic ........................................................................................................................................................................ 21

Chassis Harness Routing .............................................................................................................................................................................................................. 22

Charging System Description of Operation ................................................................................................................................................................................. 23

Electrical Power Management Overview ................................................................................................................................................................................ 23

Charging System .......................................................................................................................................................................................................................... 24

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 2

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 2

Charging System Components ................................................................................................................................................................................................. 24

Charge Mode ........................................................................................................................................................................................................................... 27

Fuel Economy Mode ................................................................................................................................................................................................................ 27

Headlamp Mode ...................................................................................................................................................................................................................... 27

Start Up Mode ......................................................................................................................................................................................................................... 27

Voltage Reduction Mode ......................................................................................................................................................................................................... 28

Instrument Panel Cluster Operation ............................................................................................................................................................................................ 28

Charge Indicator Operation ..................................................................................................................................................................................................... 28

Display Message: ..................................................................................................................................................................................................................... 28

Charging System schematic ......................................................................................................................................................................................................... 29

Engine Idle Up .............................................................................................................................................................................................................................. 30

Elevated Idle ............................................................................................................................................................................................................................ 30

High Idle ................................................................................................................................................................................................................................... 30

PTO (power take-off) ............................................................................................................................................................................................................... 30

Vehicle Regular Production Option (RPO) Content ................................................................................................................................................................. 30

ADDING PTO OPTION TO A VEHICLE WITHOUT THE OPTION .................................................................................................................................................. 31

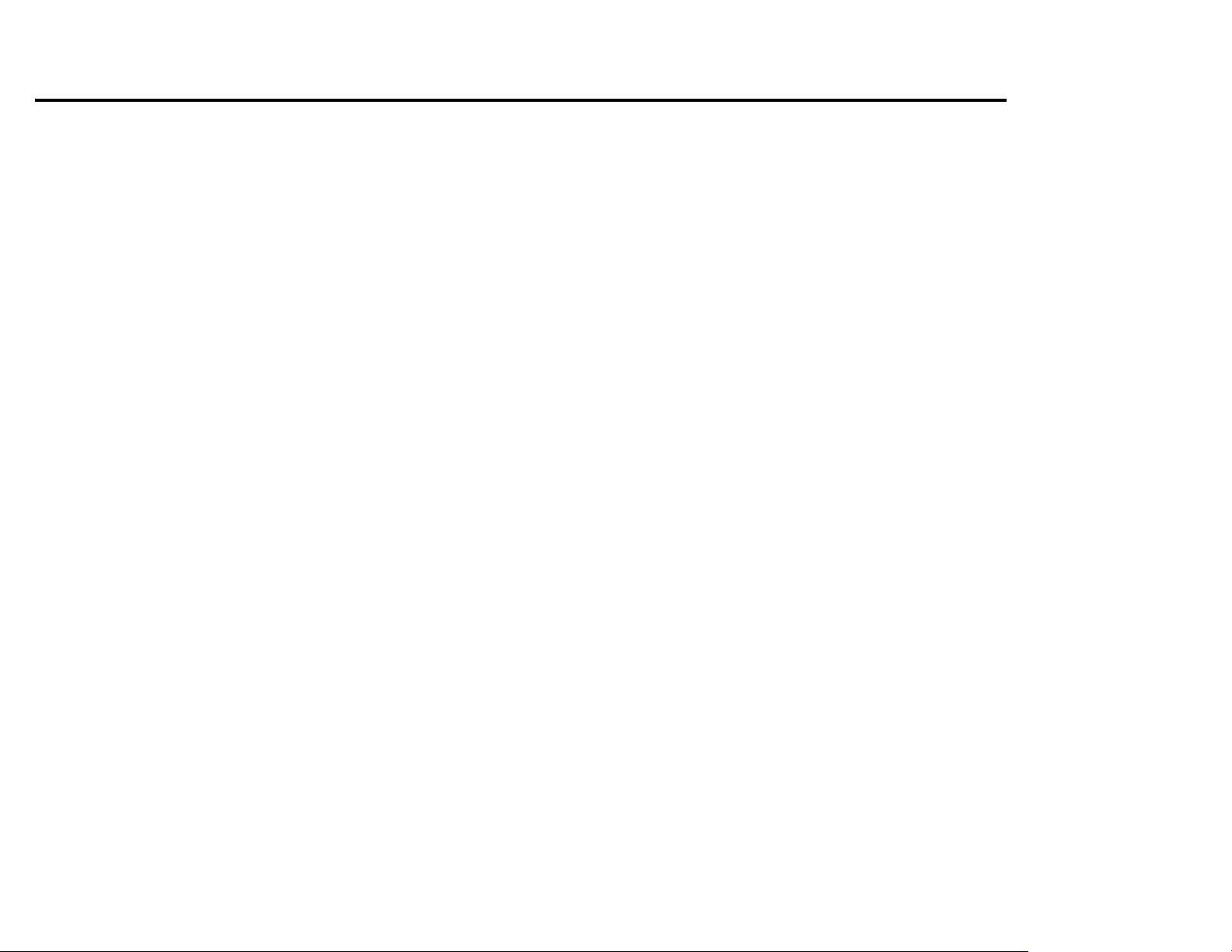

Installation of Electrical Aftermarket Accessories ...................................................................................................................................................................... 32

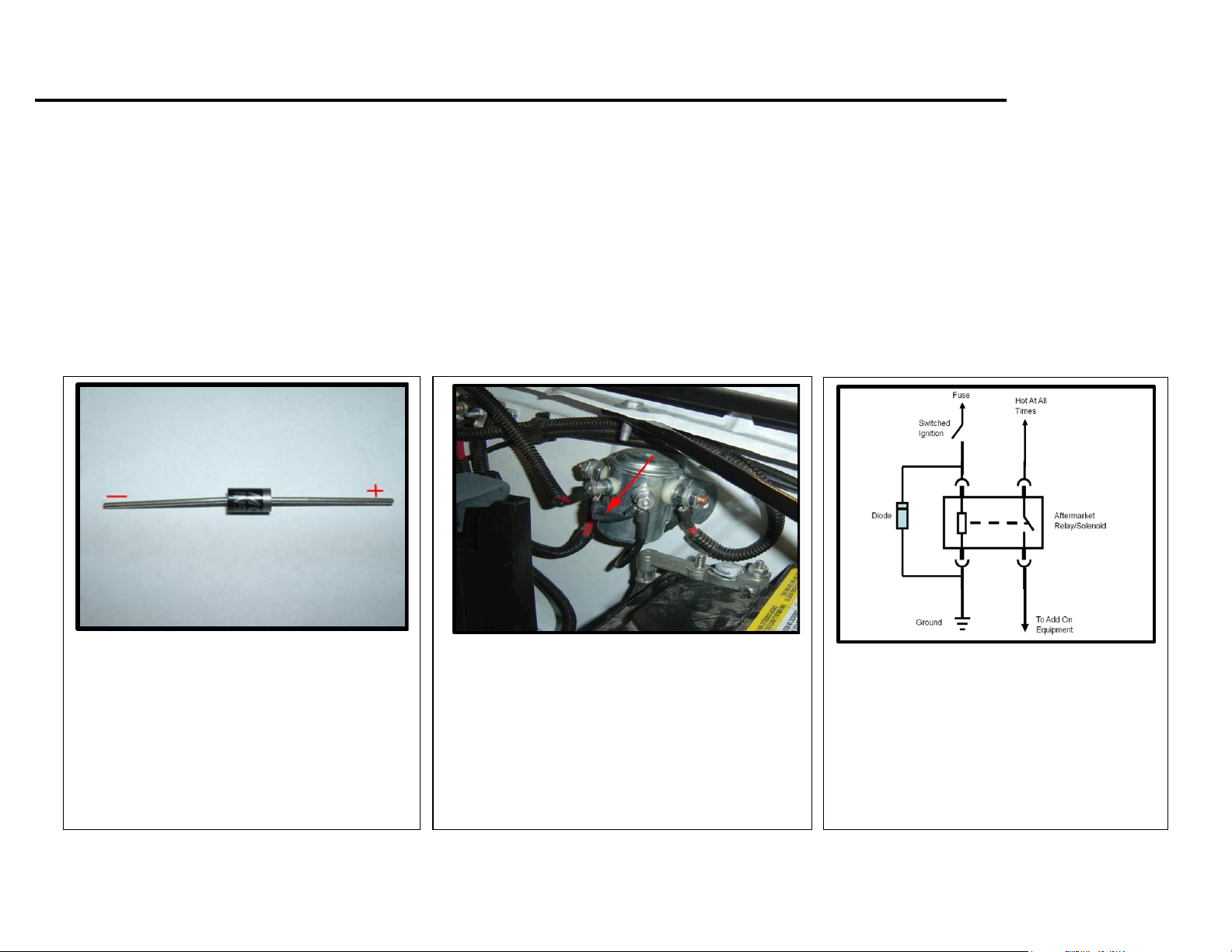

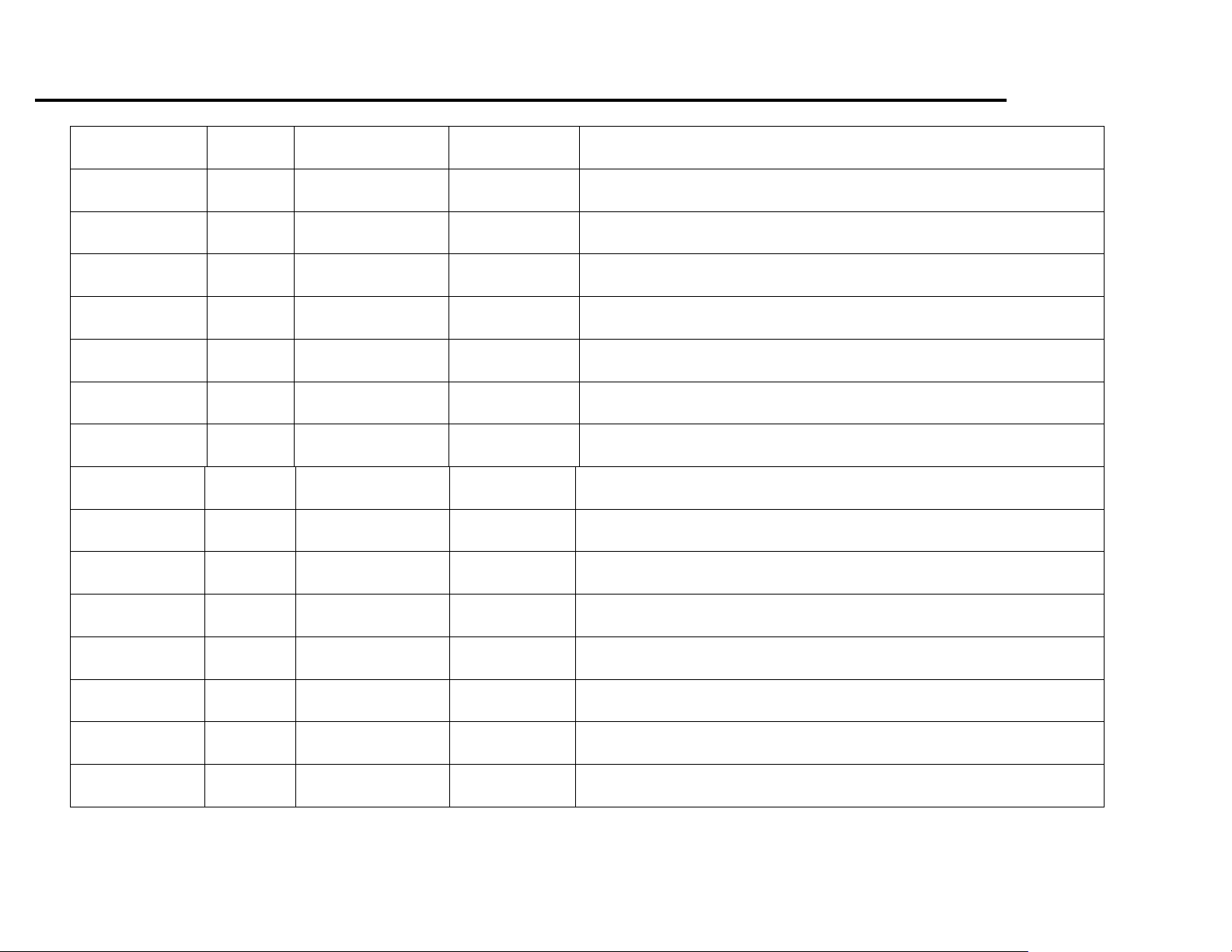

Installation of a Diode to Suppress Voltage Spikes ................................................................................................................................................................. 32

Remote Vehicle Immobilizer ........................................................................................................................................................................................................ 33

Exterior Lighting Systems Description and Operation ................................................................................................................................................................. 34

Low Beam Headlamps ............................................................................................................................................................................................................. 34

Run Up Of the Lamp................................................................................................................................................................................................................. 36

When to Change the HID Bulb ................................................................................................................................................................................................. 36

Light Color ................................................................................................................................................................................................................................ 37

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 3

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 3

High Beam Headlamps ............................................................................................................................................................................................................. 37

Adaptive Forward Lighting (AFL) .............................................................................................................................................................................................. 37

Automatic Headlamp Leveling ................................................................................................................................................................................................. 38

Daytime Running Lamps (DRL)................................................................................................................................................................................................. 39

Automatic Lamp Control .......................................................................................................................................................................................................... 39

Flash to Pass (FTP) ................................................................................................................................................................................................................... 40

Hazard Lamps ........................................................................................................................................................................................................................... 40

Park, Tail, and License Lamps .................................................................................................................................................................................................. 40

Stop Lamps ............................................................................................................................................................................................................................... 40

Turn Signal Lamps .................................................................................................................................................................................................................... 41

Backup Lamps .......................................................................................................................................................................................................................... 41

Battery Run Down Protection/Inadvertent Power .................................................................................................................................................................. 41

X110 Left Forward Lamp Harness to Headlamp - Connector End View and Pin-out .................................................................................................................. 42

X120 Right Forward Lamp Harness to Headlamp – Connector End View and Pin-out................................................................................................................ 44

Headlamp Replacement .............................................................................................................................................................................................................. 46

Under hood Harness Routing ...................................................................................................................................................................................................... 47

Tail lamp Replacement ................................................................................................................................................................................................................ 47

Chassis Harness Routing .............................................................................................................................................................................................................. 49

Rear Body Junction Block X63A –Connector X5........................................................................................................................................................................... 50

Rear Body Junction Block X63A –Connector X1........................................................................................................................................................................... 51

X63A Junction Block - Rear Body X1 Pin-outs .............................................................................................................................................................................. 52

Bulb Replacement ........................................................................................................................................................................................................................ 54

Rearward Lighting Separate Stop and Turn ................................................................................................................................................................................. 55

Rearward Lighting Separate Stop and Turn (continued) ............................................................................................................................................................. 56

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 4

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 4

Dome/Courtesy Lamps (-E29), DH6 ............................................................................................................................................................................................. 57

Dome/Courtesy Lamps E29 ......................................................................................................................................................................................................... 58

Roof Mounted Beacon ................................................................................................................................................................................................................. 59

Park Neutral Signal-Shift Lock Control ......................................................................................................................................................................................... 60

Shift Lock Control Schematic ....................................................................................................................................................................................................... 61

Trailer Brake Control System ....................................................................................................................................................................................................... 62

The Trailer Brake Control System is compatible with two types of Trailer Brake Systems as listed below: ........................................................................... 62

Trailer Brake Output versus Trailer Brake Type ....................................................................................................................................................................... 62

The vehicle is equipped with the following trailer braking components: ............................................................................................................................... 63

Chassis Control Module ........................................................................................................................................................................................................... 63

Trailer Brake Power Control Module ....................................................................................................................................................................................... 64

Trailer Brake Control Panel ...................................................................................................................................................................................................... 64

Trailer Gain Adjustment ........................................................................................................................................................................................................... 64

Trailer Gain Adjustment Procedure ......................................................................................................................................................................................... 65

Hill Start Assist ......................................................................................................................................................................................................................... 65

Trailer Sway Control ................................................................................................................................................................................................................. 65

Driver Information Center Indicators and Messages (Trailer Brake System) .............................................................................................................................. 66

Trailer Connected .................................................................................................................................................................................................................... 66

Check Trailer Wiring ................................................................................................................................................................................................................. 66

Service Trailer Brake System .................................................................................................................................................................................................... 67

Trailer Gain and Output Display .............................................................................................................................................................................................. 67

Trailer Brake Control System Schematic...................................................................................................................................................................................... 68

Chassis Control Module Connector ............................................................................................................................................................................................. 69

Trailer Connector 1 of 3 (Terminals A, B, D, E, F & G) ................................................................................................................................................................. 70

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 5

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 5

Trailer Connector 2 of 3 (Terminal C except E29) ........................................................................................................................................................................ 71

Trailer Connector 3 of 3 (Terminal C with E29) ........................................................................................................................................................................... 72

Trailer Connector Location .......................................................................................................................................................................................................... 73

Trailer Connector Pin Out ............................................................................................................................................................................................................ 74

Section B .......................................................................................................................................................................................................................................... 75

Understanding the Alpha Numeric Naming Convention ............................................................................................................................................................. 75

Fuse, Relay, and Block Names ................................................................................................................................................................................................. 75

Battery Fuse Block –Top View ..................................................................................................................................................................................................... 76

Fuse Block (X50) Under-hood - Label........................................................................................................................................................................................... 77

Fuse Block (X50) Under-hood - Top View .................................................................................................................................................................................... 78

Fuse Block (X50) Under-hood - Bottom View .............................................................................................................................................................................. 79

Fuse Block (X50A) Under-hood - Connector X1 ........................................................................................................................................................................... 86

Fuse Block (X50A) Under-hood - Connector X2 ........................................................................................................................................................................... 88

Fuse Block (X50A) Under-hood - Connector X3 ........................................................................................................................................................................... 90

Fuse Block (X50A) Under-hood - Connector X4 ........................................................................................................................................................................... 92

Fuse Block (X50A) Under-hood - Connector X5 ........................................................................................................................................................................... 94

Fuse Block (X51L) Instrument Panel Left - Label.......................................................................................................................................................................... 96

Fuse Block (X51L) Instrument Panel Left - Top View ................................................................................................................................................................... 97

Fuse Block (X51L) Instrument Panel Left - Bottom View ............................................................................................................................................................. 98

Fuse Block (X51L) Instrument Panel Left – Connector X1 ........................................................................................................................................................... 99

Fuse Block (X51L) Instrument Panel Left – Connector X1 Pin-out ............................................................................................................................................. 100

Fuse Block (X51L) Instrument Panel Left – Connector X2 ......................................................................................................................................................... 102

Fuse Block (X51L) Instrument Panel Left – Connector X2 Pin-out ............................................................................................................................................. 103

Fuse Block (X51L) Instrument Panel Left – Connector X3 ......................................................................................................................................................... 105

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 6

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 6

Fuse Block (X51L) Instrument Panel – Connector X3 Pin-out .................................................................................................................................................... 106

Fuse Block (X51R) Instrument Panel Right - Label ..................................................................................................................................................................... 107

Fuse Block (X51R) Instrument Panel Right - Top View .............................................................................................................................................................. 108

Fuse Block (X51R) Instrument Panel – Bottom View ................................................................................................................................................................. 109

Fuse Block (X51R) Instrument Panel - Connector X1 ................................................................................................................................................................. 110

Fuse Block (X51R) Instrument Panel - Connector X1 Pin-outs ................................................................................................................................................... 111

Fuse Block (X51R) Instrument Panel - Connector X2 ................................................................................................................................................................. 113

Fuse Block (X51R) Instrument Panel - Connector X2 Pin-outs ................................................................................................................................................... 114

Fuse Block (X51R) Instrument Panel - Connector X3 ................................................................................................................................................................. 116

Fuse Block (X51R) Instrument Panel - Connector X3 Pin-outs ................................................................................................................................................... 117

Junction Block (X61) Instrument Panel – Top View ................................................................................................................................................................... 118

Junction Block (X61) Instrument Panel – Bottom View ............................................................................................................................................................. 119

Junction Block (X61) Instrument Panel – Connector X1 ............................................................................................................................................................ 119

Junction Block (X61) Instrument Panel – Connector X1 Pin-outs .............................................................................................................................................. 121

Junction Block (X61) Instrument Panel – Connector X2 ............................................................................................................................................................ 123

Junction Block (X61) Instrument Panel – Connector X3 ............................................................................................................................................................ 126

Junction Block (X61) Instrument Panel – Connector X3 Pin-outs .............................................................................................................................................. 127

Junction Block (X61) Instrument Panel – Connector X4 ............................................................................................................................................................ 129

Junction Block (X61) Instrument Panel – Connector X4 Pin-outs .............................................................................................................................................. 129

Junction Block (X61) Instrument Panel – Connector X5 ............................................................................................................................................................ 132

Junction Block (X61) Instrument Panel – Connector X5 Pin-outs .............................................................................................................................................. 133

Junction Block (X61) Instrument Panel – Connector X6 ............................................................................................................................................................ 135

Junction Block (X61) Instrument Panel – Connector X6 Pin-outs .............................................................................................................................................. 135

Junction Block (X61) Instrument Panel – Connector X7 ............................................................................................................................................................ 136

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 7

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 7

Junction Block (X61) Instrument Panel – Connector X7 Pin-outs .............................................................................................................................................. 137

Junction Block (X61) Instrument Panel – Connector X8 ............................................................................................................................................................ 138

Junction Block (X61) Instrument Panel – Connector X8 Pin-outs .............................................................................................................................................. 139

Junction Block (X61) Instrument Panel – Connector X9 ............................................................................................................................................................ 140

Junction Block (X61) Instrument Panel – Connector X9 Pin-outs .............................................................................................................................................. 140

Section C......................................................................................................................................................................................................................................... 143

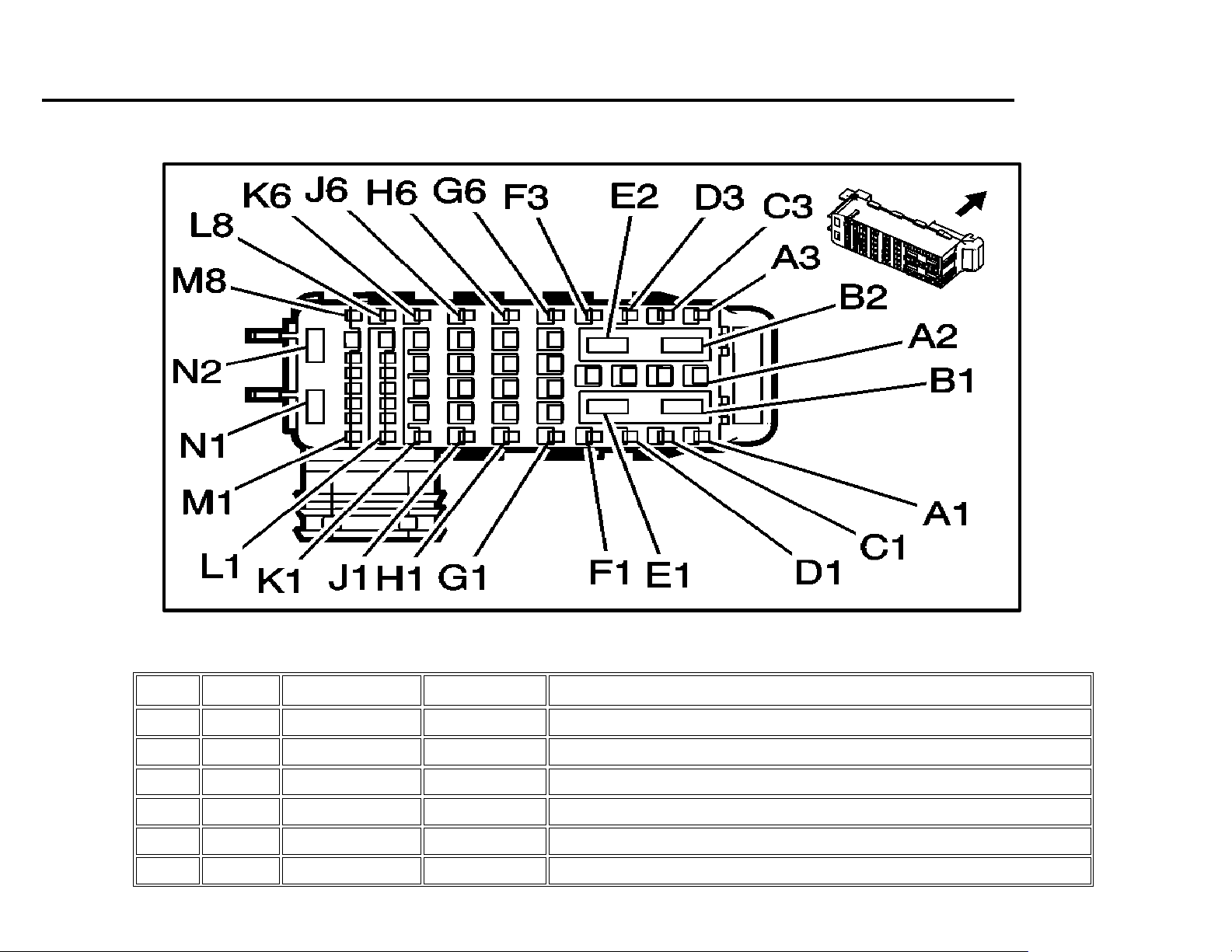

K9 Body Control Module ............................................................................................................................................................................................................ 143

K9 Body Control Module (BCM) – Connector X1 ................................................................................................................................................................... 143

K9 Body Control Module (BCM) – Connector X1 Pin-outs ..................................................................................................................................................... 144

K9 Body Control Module (BCM) – Connector X2 ................................................................................................................................................................... 146

K9 Body Control Module (BCM) – Connector X2 Pin-outs ..................................................................................................................................................... 147

K9 Body Control Module (BCM) – Connector X4 ................................................................................................................................................................... 149

K9 Body Control Module (BCM) – Connector X4 Pin-outs ..................................................................................................................................................... 150

K9 Body Control Module (BCM) – Connector X5 ................................................................................................................................................................... 152

K9 Body Control Module (BCM) – Connector X5 Pin-outs ..................................................................................................................................................... 153

Component Locations ................................................................................................................................................................................................................ 177

Front of Vehicle - Chevrolet ................................................................................................................................................................................................... 177

Front of Vehicle - GMC .......................................................................................................................................................................................................... 178

Right Side of Engine Compartment Components .................................................................................................................................................................. 179

Left Side of Engine Compartment Components .................................................................................................................................................................... 179

Underside of Engine Compartment & Cooling Fans .............................................................................................................................................................. 180

Engine Component Views (Top & Left Front) ........................................................................................................................................................................ 181

Engine Component Views (Right Rear, Manual Transmission & Transfer Case) ................................................................................................................... 182

Section D ........................................................................................................................................................................................................................................ 183

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 8

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 8

Electrical System - Vehicle Zoning Strategy ............................................................................................................................................................................... 183

Adjustable Pedals (With A45) .................................................................................................................................................................................................... 185

Adjustable Pedals (Without A45) ............................................................................................................................................................................................... 186

Fixed and Moveable Windows –Front Doors ............................................................................................................................................................................ 187

Fixed and Moveable Windows – Rear Doors & Rear Sliding Window ....................................................................................................................................... 188

Rear Defogger/Horns ................................................................................................................................................................................................................. 189

Exterior Lighting - Headlights/Daytime Running Lights (DRL) ................................................................................................................................................... 190

Exterior Lighting – Park Lamps and Controls ............................................................................................................................................................................. 191

Exterior Lighting – Outside Mirror Lamps and Controls ............................................................................................................................................................ 192

Exterior Lighting – Turn Signal Lamps ........................................................................................................................................................................................ 193

Exterior Lighting – Fog Lamps and Roof Lighting ....................................................................................................................................................................... 194

Exterior Lighting –Tail lamps ...................................................................................................................................................................................................... 194

Exterior Lighting – CHMSL and License Plate lamps .................................................................................................................................................................. 196

Interior Lighting – Controls (DD7) .............................................................................................................................................................................................. 197

Interior Lighting – Front Dome Lamps (-E29), DH6 ................................................................................................................................................................... 198

Interior Lighting – Front Dome Lamps (E29) .............................................................................................................................................................................. 199

Interior Lighting – Accent Lamps ............................................................................................................................................................................................... 200

Interior Lighting – Dimming (1 of 3) .......................................................................................................................................................................................... 201

Interior Lighting – Dimming (2 of 3) .......................................................................................................................................................................................... 202

Interior Lighting – Dimming (3 of 3) .......................................................................................................................................................................................... 203

Mirrors – Inside Rearview (DD8) ............................................................................................................................................................................................... 204

Mirrors – Outside Rearview Driver (with A45) .......................................................................................................................................................................... 205

Mirrors – Outside Rearview Passenger (with A45) .................................................................................................................................................................... 206

Mirrors – Outside Rearview Position Controls (without A45) ................................................................................................................................................... 207

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 9

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 9

Mirrors – Outside Rearview Heat (DL8, DL3 or DPN) ................................................................................................................................................................ 208

Vehicle Access - Front Switches and Indicators (1 of 2) ............................................................................................................................................................ 209

Vehicle Access - Front Switches and Indicators (2 of 2) ............................................................................................................................................................ 210

Vehicle Access - Rear Switches and Indicators .......................................................................................................................................................................... 211

Vehicle Access – Actuators ........................................................................................................................................................................................................ 212

Wipers and Washers – Controls ................................................................................................................................................................................................ 213

Wipers and Washers – Motor and Washers .............................................................................................................................................................................. 214

Cigar Lighter/Power Outlets – 12V DC ....................................................................................................................................................................................... 215

Cigar Lighter/Power Outlets – 110V AC ..................................................................................................................................................................................... 216

Cigar Lighter/Power Outlets – 220V AC ..................................................................................................................................................................................... 217

Power Moding Schematics - Ignition Off, Ignition I and Retained Accessory ............................................................................................................................ 218

Power Moding Schematics - Ignition II and Ignition III .............................................................................................................................................................. 219

Power Distribution Schematics - X50D Fuse Block - Battery ..................................................................................................................................................... 220

Power Distribution Schematics X50A Fuse Block – Under-hood Bussing .................................................................................................................................. 221

Power Distribution Schematics - F1UA, F2UA, F11UA, F12UA, F18UA, F20UA and F54UA ...................................................................................................... 222

Power Distribution Schematics - 4WD Fuse, F9UA, F35UA, F47UA and F53UA ........................................................................................................................ 223

Power Distribution Schematics - F14UA, F27UA and F57UA ..................................................................................................................................................... 224

Power Distribution Schematics - F13UA, F16U and F28UA ....................................................................................................................................................... 225

Power Distribution Schematics - F15UA, F32UA, F37UA and F48UA ........................................................................................................................................ 226

Power Distribution Schematics - F33UA, F39UA and F49UA ..................................................................................................................................................... 227

Power Distribution Schematics - F42UA, F44UA, F45UA and F50UA ........................................................................................................................................ 228

Power Distribution Schematics - F43UA .................................................................................................................................................................................... 229

Power Distribution Schematics - F3UA, F4UA, F7UA, F24UA and F56UA ................................................................................................................................. 230

Power Distribution Schematics - X51L Fuse Block - Instrument Panel Left Bussing .................................................................................................................. 231

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 10

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 10

Power Distribution Schematics - F6DL, F7DL, F9DL, F17DL, F25DL, F26DL, F34DL and F44DL ................................................................................................. 232

Power Distribution Schematics - F22DL, F23DL, F30DL, F31DL and F32DL ............................................................................................................................... 233

Power Distribution Schematics - F1DL, F2DL, F3DL, F10DL, F11DL, F12DL, F13DL, F40DL and F41DL...................................................................................... 234

Power Distribution Schematics - X51R Fuse Block - Instrument Panel Right Bussing ............................................................................................................... 235

Power Distribution Schematics - F7DR, F22DR, F31DR, F41DR, F44DR and F46DR .................................................................................................................. 236

Power Distribution Schematics - F18DR, F25DR and F38DR ..................................................................................................................................................... 237

Power Distribution Schematics - F6DR, F8DR, F27DR, F34DR, F35DR, F42DR and F43DR ........................................................................................................ 238

Ground Distribution Schematics - G101 and G102 .................................................................................................................................................................... 239

Ground Distribution Schematics - G108, G130, G140 and G327 ............................................................................................................................................... 240

Ground Distribution Schematics - G110 .................................................................................................................................................................................... 241

Ground Distribution Schematics - G121 and G400 .................................................................................................................................................................... 242

Ground Distribution Schematics - G210 (1 of 2) ........................................................................................................................................................................ 243

Ground Distribution Schematics - G210 (2 of 2) ........................................................................................................................................................................ 244

Ground Distribution Schematics - G218 (except E29) ............................................................................................................................................................... 245

Ground Distribution Schematics - G218 (E29) ........................................................................................................................................................................... 246

Ground Distribution Schematics - G311 .................................................................................................................................................................................... 247

Ground Distribution Schematics - G312 .................................................................................................................................................................................... 248

Ground Distribution Schematics - G325 .................................................................................................................................................................................... 249

Ground Location Views – G101 ................................................................................................................................................................................................. 250

Ground Location Views G102 .................................................................................................................................................................................................... 251

Ground Location Views G110 .................................................................................................................................................................................................... 252

Ground Location Views G120 .................................................................................................................................................................................................... 253

Ground Location Views G121 and G400 .................................................................................................................................................................................... 254

Ground Location Views G130 .................................................................................................................................................................................................... 255

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 11

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 11

Ground Location Views G140 .................................................................................................................................................................................................... 256

Ground Location Views G210 and G218 .................................................................................................................................................................................... 257

Ground Location Views G311 and G325 .................................................................................................................................................................................... 258

Ground Location Views G312 and G327 .................................................................................................................................................................................... 259

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 12

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 12

Document Use and Disclaimers

GM Upfitter Integration Body Builder Manuals and Technical Bulletins are intended for use by professional technicians,

NOT a "do-it-yourselfer". They are written to inform technicians of conditions that may occur on some vehicles and/or

models, or to provide information that could assist in the proper service and/or modification of a vehicle. Properly

trained technicians have the equipment, tools, safety instructions, and know-how to do a job properly and safely. If a

condition is described, DO NOT assume that the bulletin applies to the vehicle and/or model, Also do NOT assume that

every vehicle and/or model will have that condition.

Contact GM Upfitter Integration for information on whether the information is applicable your vehicle.

GM Upfitter Integration does not take responsibility for nor approve alterations to GM Commercial Chassis, Pickup &

Utility Vehicles.

If an Upfitter or Second Stage Manufacturer (SSM) or Individual chooses to modify a GM Chassis/Vehicle and/or its

components, liability and possible recertification responsibility for compliance with all related FMVSS/CMVSS and

regional standards lies with the Upfitter/SSM or Individual.

In addition liability for Non-OEM (aftermarket) installed components used in modifications to a GM Chassis/Vehicle

and/or its components is solely with the responsible aftermarket component manufacturer and the installer. If an

Upfitter/SSM or Individual chooses to modify a GM part/s design or function they risk voiding the GM warranty and

assume liability for the modification

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 13

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 13

Section A

Body Control System Description and Operation

The body control system consists of the body control module (BCM), communications, and various input and outputs. Some inputs, outputs and

messages require other modules to interact with the BCM. The BCM also has discrete input and output terminals to control the vehicle's body

functions. The BCM is wired to the high speed GMLAN serial data bus, low speed GMLAN serial data bus and Multiple LIN buses and acts as a

gateway between them.

Power Mode Master

This vehicle body control module (BCM) functions as the power mode master (PMM). The ignition switch is a low current switch with

multiple discrete ignition switch signals to the PMM for determining the power mode that will be sent over the serial data circuits to the

other modules that need this information; the PMM will activate relays and other direct outputs of the PMM as needed. Refer to Power

Mode Description and Operation for a complete description of power mode functions.

Gateway

The body control module (BCM) in this vehicle functions as a gateway or translator. The purpose of the gateway is to translate serial

data messages between the GMLAN high speed bus and the GMLAN low speed bus for communication between the various modules.

The gateway will interact with each network according to that network's transmission protocol.

All communication between the BCM and a scan tool is on the high speed GMLAN serial data circuits. A lost communication DTC

typically is set in modules other than the module with a communication failure.

Body Control

The various body control module (BCM) input and output circuits are illustrated in the corresponding functional areas on the BCM

electrical schematics. Refer to the Body Control System Schematics for more detailed information.

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 14

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 14

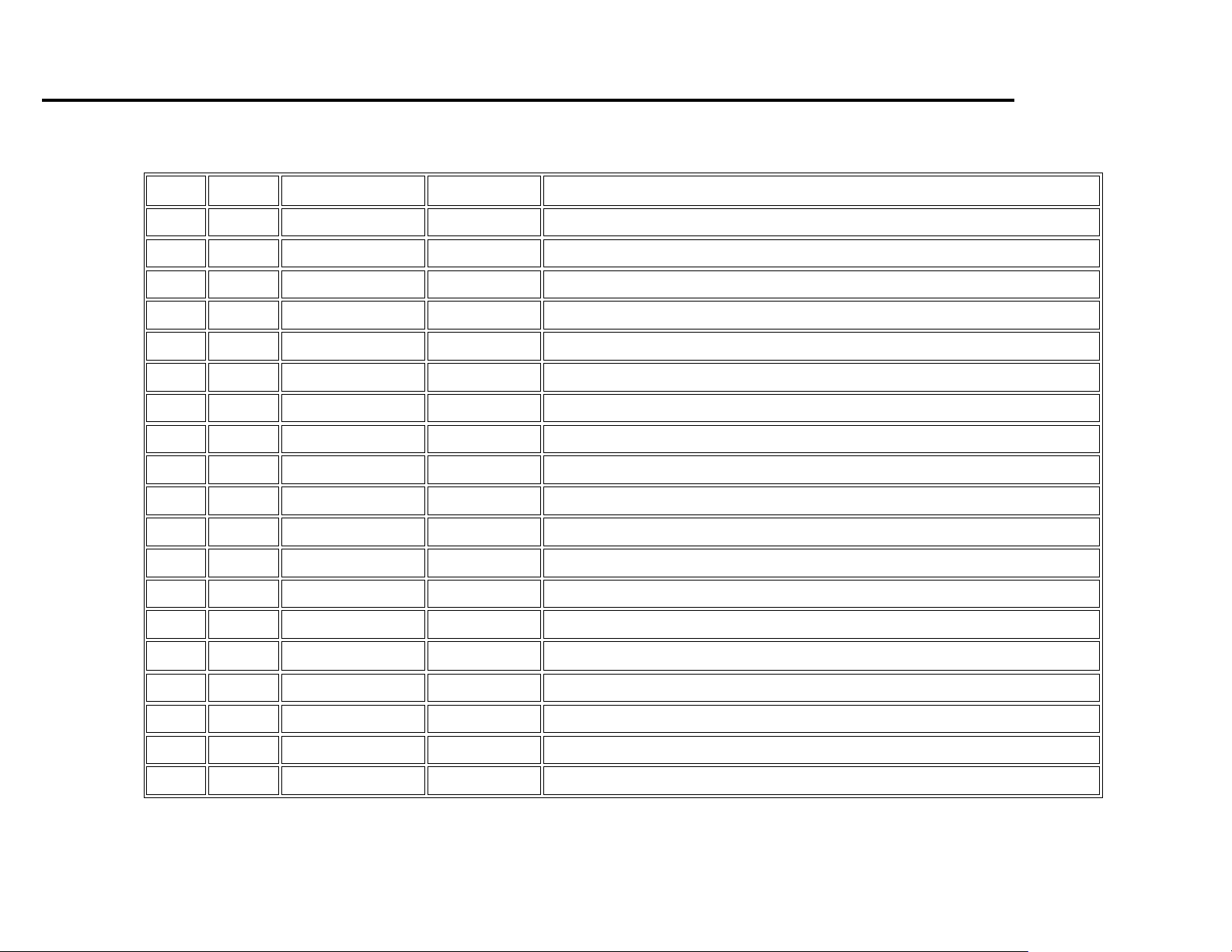

Power Mode Parameters

Ignition Switch Position

Power Mode Transmitted

Ign. Off/Run/Crank

(Off/Run Crank Voltage Circuit)

Ignition Accessory/Run

(Accessory Voltage Circuit)

Ignition Run/Crank

(Ignition 1 Voltage Circuit)

Off Key Out

Off

Key Out / ACC

Inactive

Inactive

Off Key IN

Off

Key In / Off

Inactive

Inactive

Accessory

Accessory

Key Out / ACC

Active

Inactive

Run

Run

Run

Active

Active

Start

Crank Request

Crank

Inactive

Active

Power Mode Description and Operation

Serial Data Power Mode Master

Power to many of this vehicles circuits is controlled by the module that is designated the power mode master. This vehicles power mode

master is the body control module (BCM). The BCM has multiple B+ circuits that feed into it. Each of those circuits are partitioned within

the controller to drive certain outputs of the vehicle’s body functions. An open or short in any one of the B+ circuits may induce multiple

codes/or a section of non-functionality within the BCM with the rest of the BCM functioning normally. In this case it is useful to refer to

the power distribution schematics to determine if the non-functional partition of the controller shares a common B+ circuit. The ignition

switch is a low current switch with multiple discrete ignition switch signals to the power mode master for determination of the power

mode that will be sent over the serial data circuits to the other modules that need this information. The power mode master will also

activate relays and other direct outputs of the power mode master as needed. The power mode master determines which power mode

(Off, Accessory, Run, Crank Request) is required, and reports this information to other modules via serial data. Modules which have

switched voltage inputs may operate in a default mode if the power mode serial data message does not match what the individual

module can see from its own connections.

The power mode master receives ignition switch signals to identify the operators desired power mode. The Power Mode Parameter

tables below illustrate the correct state of these input parameters (circuits) in correspondence to the ignition switch position:

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 15

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 15

Relay Controlled Power Mode

The BCM uses the discrete ignition switch inputs Off/Run/Crank Voltage, Accessory Voltage, and Ignition 1 Voltage, to distinguish the

correct power mode. The BCM, after determining the desired power mode, will activate the appropriate relays for that power mode.

The retained accessory power relay 1 and retained accessory power relay 2 remain on for a timed period after the Ignition key is

removed. Refer to Retained Accessory Power Description and Operation for more information on the retained accessory power

function.

Battery Saver Mode (Transport Mode)

Battery saver mode (transport mode) reduces the parasitic load of some modules during overseas shipment or during vehicle storage

conditions. This improves the drain time on the battery (up to 70 days without the battery going dead). When a vehicle is in

transport/storage, some features may have reduced functionality while in the battery saver mode, such as disabling keyless entry, afterblow, and content theft features. Battery saver mode is initiated by turning on the hazard flashers, applying the brake pedal, and then

turning the ignition key to the start position or pushing the ignition mode switch with the foot on the brake for greater than 15 seconds.

The mode is disengaged by repeating the previous process. The driver information center (if equipped) will display Transport Mode is On

when battery saver mode is enabled and Transport Mode is Off when battery saver mode is disabled. For vehicles not equipped with a

driver information center, the battery indicator light will constantly flash on the Instrument Cluster when battery saver mode is enabled.

This feature can be used as many times as necessary if the vehicle is to be stored for an extended period of time.

BCM Awake/Sleep States

The BCM is able to control or perform all of the BCM functions in the awake state. The BCM enters the sleep state when active control

or normal monitoring of system functions has stopped and a time limit has passed. The BCM must detect certain wake-up inputs before

entering the awake state. The BCM monitors for these inputs during the sleep state.

The BCM will enter the awake state if any of the following wake-up inputs are detected:

Activity on the serial data line

Detection of a battery reconnect

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 16

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 16

Any door open signal

Headlamps ON

Key-in-ignition

Ignition ON

Park lamps ON

Keyless entry or remote start message

The BCM will enter a sleep state when all of the following conditions exist:

The ignition switch is OFF, key out.

Ignition OFF, transmitter is out of range

No activity exists on the serial data line.

No outputs are commanded.

No delay timers are actively counting.

No wake-up inputs are present.

If all these conditions are met, the BCM will enter a low power or sleep condition.

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 17

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 17

Retained Accessory Power

RAP Description and Operation

The Body Control Module (BCM) monitors the ignition switch position, battery condition, and each door ajar/open switch status to

determine whether the retained accessory power should be initiated or terminated. Retained accessory power is controlled by two

different methods; relay control and serial data. Some modules receive a retained accessory power message from the BCM over the

serial data circuits. Serial data controlled retained accessory power is deactivated as required by their modules retained accessory

power mode operation. Other subsystems are activated directly by the BCM through a relay. Components and systems that are active in

retained accessory power are also activated anytime the ignition is any position other than OFF regardless of the door switch signals.

Relay Controlled Retained Accessory Power

The BCM keeps the retained accessory power relay 1 and retained accessory power relay 2 energized during all power modes, except

Off-Awake and Crank. The retained accessory power relay 1 and retained accessory power relay 2 are also energized for approximately

10 minutes after shutting the ignition OFF and removing the key, providing no door is opened.

Relay controlled retained accessory power will end when one of the following conditions is met:

The BCM receives an input from any door ajar or open switch indicating the opening of any door after the ignition key is out of

the ignition.

Note: If the BCM is receiving any door ajar or open signal from those switches when the ignition key is turned OFF, retained

accessory power will not initiate.

The BCM internal timer for the retained accessory power expires after approximately 10 minutes.

The BCM detects a decrease in battery capacity below a prescribed limit.

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 18

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 18

Relay Controlled Retained Accessory Power (continued)

Systems powered by the retained accessory power relay 1 and retained accessory power relay 2 during the retained accessory power

mode are as follows:

Note: The vehicle may not be equipped with all components as listed below.

Accessory Power Receptacle

Cigarette Lighter Receptacle

Sunroof Control Module

Sunroof Switch

Sliding Rear Window Switch

Mobile Device Wireless Charger Module

Serial Data Controlled Retained Accessory Power

Retained accessory power systems controlled by serial data are as follows:

Radio:

Radio retained accessory power activation / termination is the same as relay operation with one exception; the only door switch that

will turn off the radio during retained accessory power is the driver door open switch.

Vehicle Communication Interface Module (VCIM) (Onstar®) (If Equipped)

VCIM RAP activation/termination is the same as radio operation with 1 exception; if there is an active call when the ignition key is

turned off the VCIM will remain in RAP mode, and keep the radio in RAP mode until the call is terminated.

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 19

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 19

Back-up Alarm and Camera

For installation of a Back-up Alarm/Camera on vehicles not equipped with 8S3 (factory back-up alarm) connections can be made at the rear

body junction block (X63A).

In addition to when the vehicle is operated in reverse, the back-ups are illuminated during a lighted exit and as a key fob acknowledgement.

When using the back –lamps circuit to activate a back-up alarm, in which the perimeter lighting feature is set to ON for exiting, the back-up

alarm will be activated during the exit lighting event. To prevent this undesired alarm (or camera) activation during the exit lighting mode use

one of the two options listed below…

1. Have the vehicle’ BCM (Body Control Module) reprogramming with a new calibration that includes RPO (regular production Option)

code SFW. This option will suppress the activation of the Back-up lamps during the exit lighting mode operation.

OR

2. Install an ignition controlled relay to which only allows for the Back-up lamp signal to be provided to the alarm/camera if the ignition

is in the “RUN” mode, and the vehicle is being operated in reverse mode. (see sample schematic)

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 20

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 20

BACKUP LAMP WIRE

BACKUP ALARM

Relay

Ground

Back-up Alarm and Camera relay installation schematic

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 21

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 21

Back-up Alarm, Camera and Lamps schematic

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 22

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 22

Chassis Harness Routing

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 23

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 23

Charging System Description of Operation

Electrical Power Management Overview

The electrical power management system is designed to monitor and control the charging system and send diagnostic messages to alert

the driver of possible problems with the battery and generator. This electrical power management system primarily utilizes existing onboard computer capability to maximize the effectiveness of the generator, to manage the load, improve battery state-of-charge and life,

and minimize the system's impact on fuel economy. The electrical power management system performs 3 functions:

It monitors the battery voltage and estimates the battery condition.

It takes corrective actions by boosting idle speeds, and adjusting the regulated voltage.

It performs diagnostics and driver notification.

The battery condition is estimated during ignition-off and during ignition-on. During ignition-off the state-of-charge of the battery is

determined by measuring the open-circuit voltage. The state-of-charge is a function of the acid concentration and the internal resistance of

the battery, and is estimated by reading the battery open circuit voltage when the battery has been at rest for several hours.

The state-of-charge can be used as a diagnostic tool to tell the customer or the dealer the condition of the battery. Throughout ignition-on,

the algorithm continuously estimates state-of-charge based on adjusted net amp hours, battery capacity, initial state-of-charge, and

temperature.

While running, the battery degree of discharge is primarily determined by a battery current sensor, which is integrated to obtain net amp

hours.

In addition, the electrical power management function is designed to perform regulated voltage control to improve battery state-ofcharge, battery life, and fuel economy. This is accomplished by using knowledge of the battery state-of-charge and temperature to set the

charging voltage to an optimum battery voltage level for recharging without detriment to battery life.

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 24

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 24

Charging System

The Charging System Description and Operation is divided into 3 sections. The first section describes the charging system components and

their integration into the electrical power management. The second section describes charging system operation. The third section

describes the instrument panel cluster operation of the charge indicator, driver information center messages, and voltmeter operation.

Charging System Components

Generator

The generator is a serviceable component. If there is a diagnosed failure of the generator it must be replaced as an assembly. The engine

drive belt drives the generator. When the rotor is spun it induces an alternating current (AC) into the stator windings. The AC voltage is

then sent through a series of diodes for rectification. The rectified voltage has been converted into a direct current (DC) for use by the

vehicles electrical system to maintain electrical loads and the battery charge. The voltage regulator integral to the generator controls the

output of the generator. It is not serviceable. The voltage regulator controls the amount of current provided to the rotor. If the generator

has field control circuit failure, the generator defaults to an output voltage of 13.8 V.

Body Control Module (BCM)

The body control module (BCM) is a GMLAN device. It communicates with the engine control module (ECM) and the instrument panel

cluster for electrical power management (electrical power management) operation. The BCM determines the output of the generator and

sends the information to the ECM for control of the generator turn on signal circuit. It monitors the generator field duty cycle signal circuit

information sent from the ECM for control of the generator. It monitors a battery current sensor, the battery positive voltage circuit, and

estimated battery temperature to determine battery state of charge. The BCM performs idle boost.

Battery Current Sensor

The battery current sensor is a serviceable component that is connected to either the negative or positive battery cable at the battery. The

battery current sensor is a 3-wire Hall Effect current sensor. The battery current sensor monitors the battery current. It directly inputs to

the BCM. It creates a 5-volt pulse width modulation (PWM) signal of 128 Hz with a duty cycle of 0–100 percent. Normal duty cycle is

between 5–95 percent. Between 0–5 percent and 95–100 percent are for diagnostic purposes.

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 25

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 25

Engine Control Module (ECM)

When the engine is running, the generator turn-on signal is sent to the generator from the ECM, turning on the regulator. The generator's

voltage regulator controls current to the rotor, thereby controlling the output voltage. The rotor current is proportional to the electrical

pulse width supplied by the regulator. When the engine is started, the regulator senses generator rotation by detecting AC voltage at the

stator through an internal wire. Once the engine is running, the regulator varies the field current by controlling the pulse width. This

regulates the generator output voltage for proper battery charging and electrical system operation. The generator field duty terminal is

connected internally to the voltage regulator and externally to the ECM. When the voltage regulator detects a charging system problem, it

grounds this circuit to signal the ECM that a problem exists. The ECM monitors the generator field duty cycle signal circuit, and receives

control decisions based on information from the BCM.

Instrument Panel Cluster

The instrument panel cluster provides the customer notification in case a concern with the charging system. There are 2 means of

notification, a charge indicator and a driver information center message of SERVICE BATTERY CHARGING SYSTEM if equipped.

Charging System Operation

The purpose of the charging system is to maintain the battery charge and vehicle loads. There are 6 modes of operation and they include:

Battery Sulfation Mode

Charge Mode

Fuel Economy Mode

Headlamp Mode

Start Up Mode

Voltage Reduction Mode

The engine control module (ECM) controls the generator through the generator turn ON signal circuit. The ECM monitors the generator

performance though the generator field duty cycle signal circuit. The signal is a pulse width modulation (PWM) signal of 128 Hz with a duty

cycle of 0–100 percent. Normal duty cycle is between 5–95 percent. Between 0–5 percent and 95–100 percent are for diagnostic purposes.

The following table shows the commanded duty cycle and output voltage of the generator (see table next page):

Electrical Manual-2014 Light Duty Full Size C/K Trucks Revision Date 06/19/2013 (WIP)

Page 26

Electrical Manual-NEW 2014 Light Duty Full Size C/K Trucks Pg. 26

Commanded Duty Cycle

Generator Output Voltage

10%

11 V

20%

11.56 V

30%

12.12 V

40%

12.68 V

50%

13.25 V

Generator