Page 1

2002 Chevrolet Avalanche

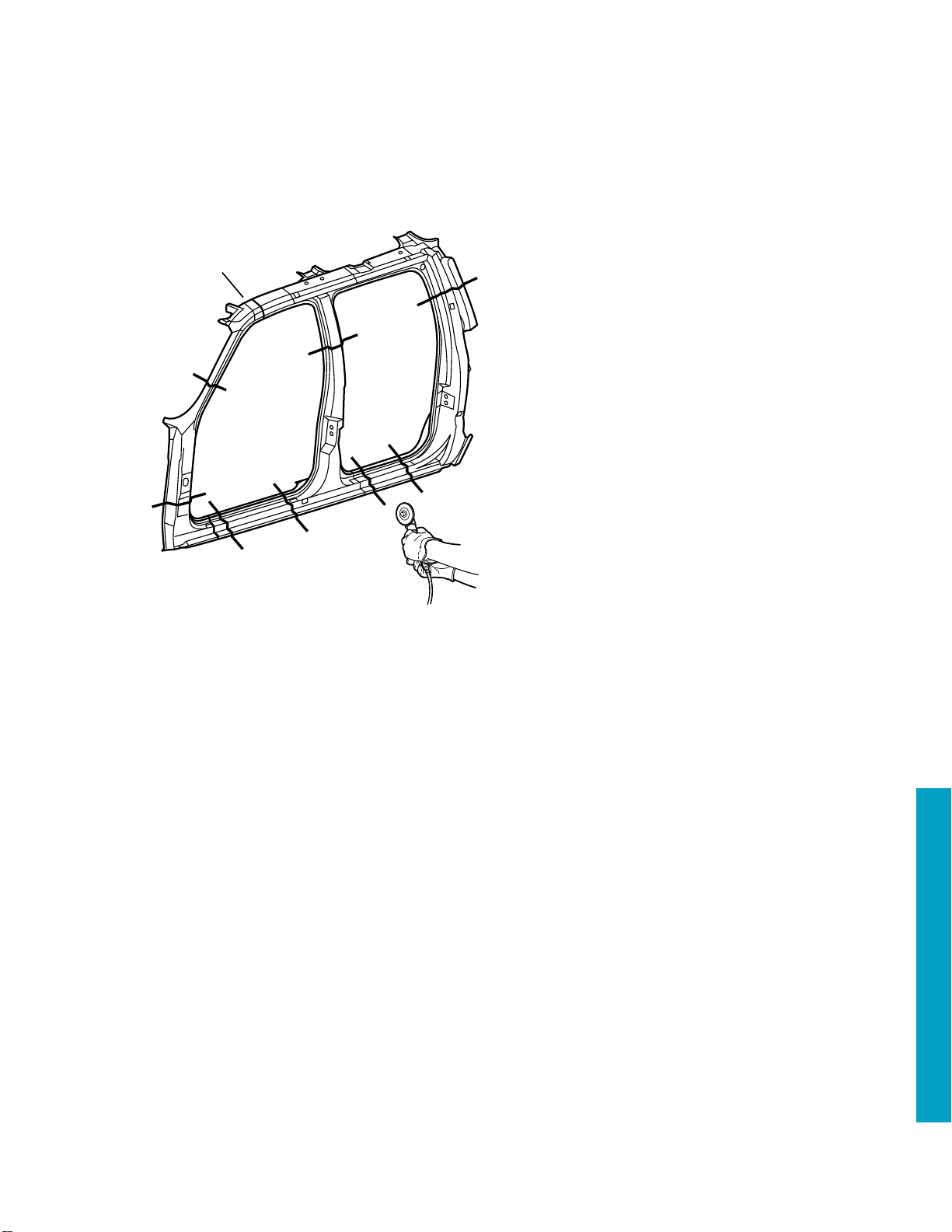

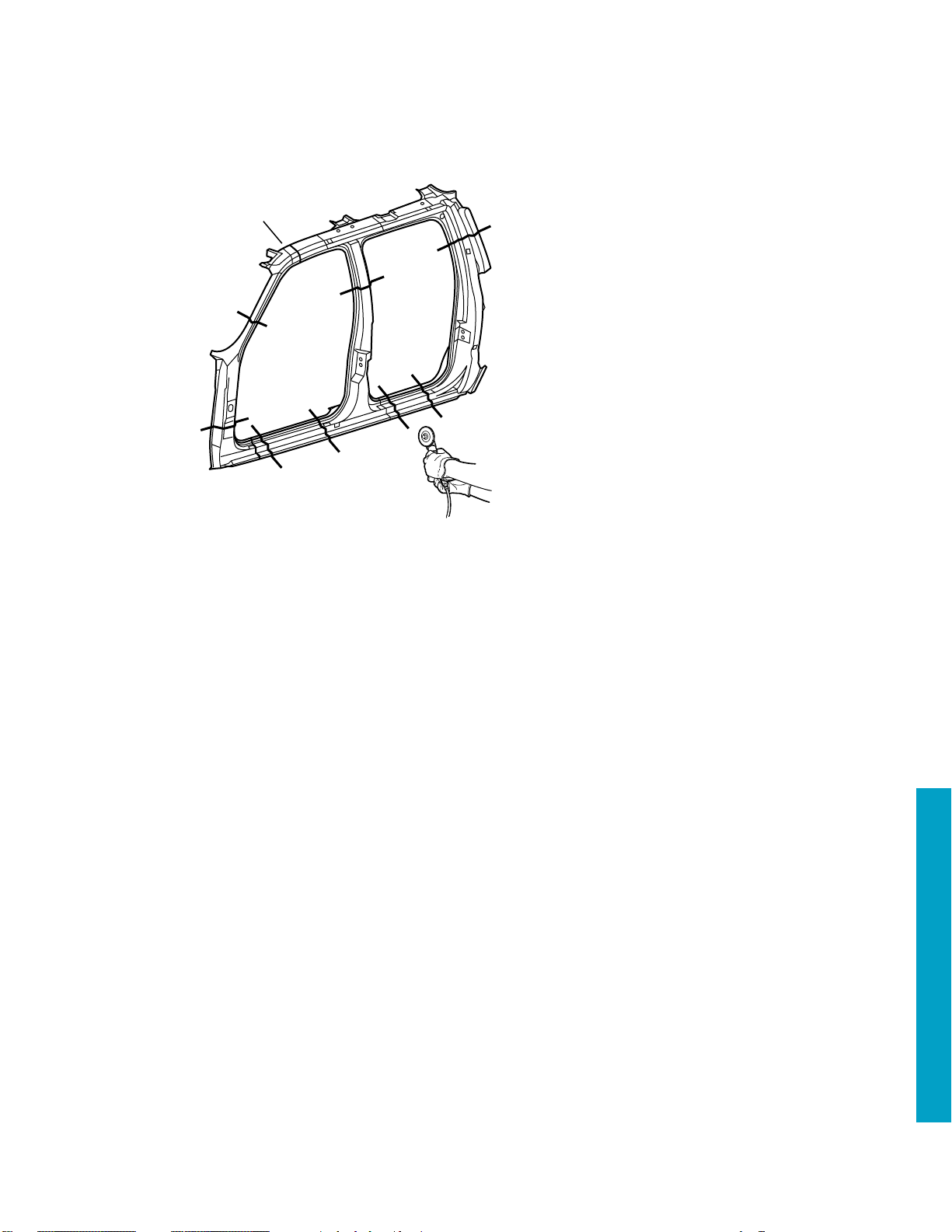

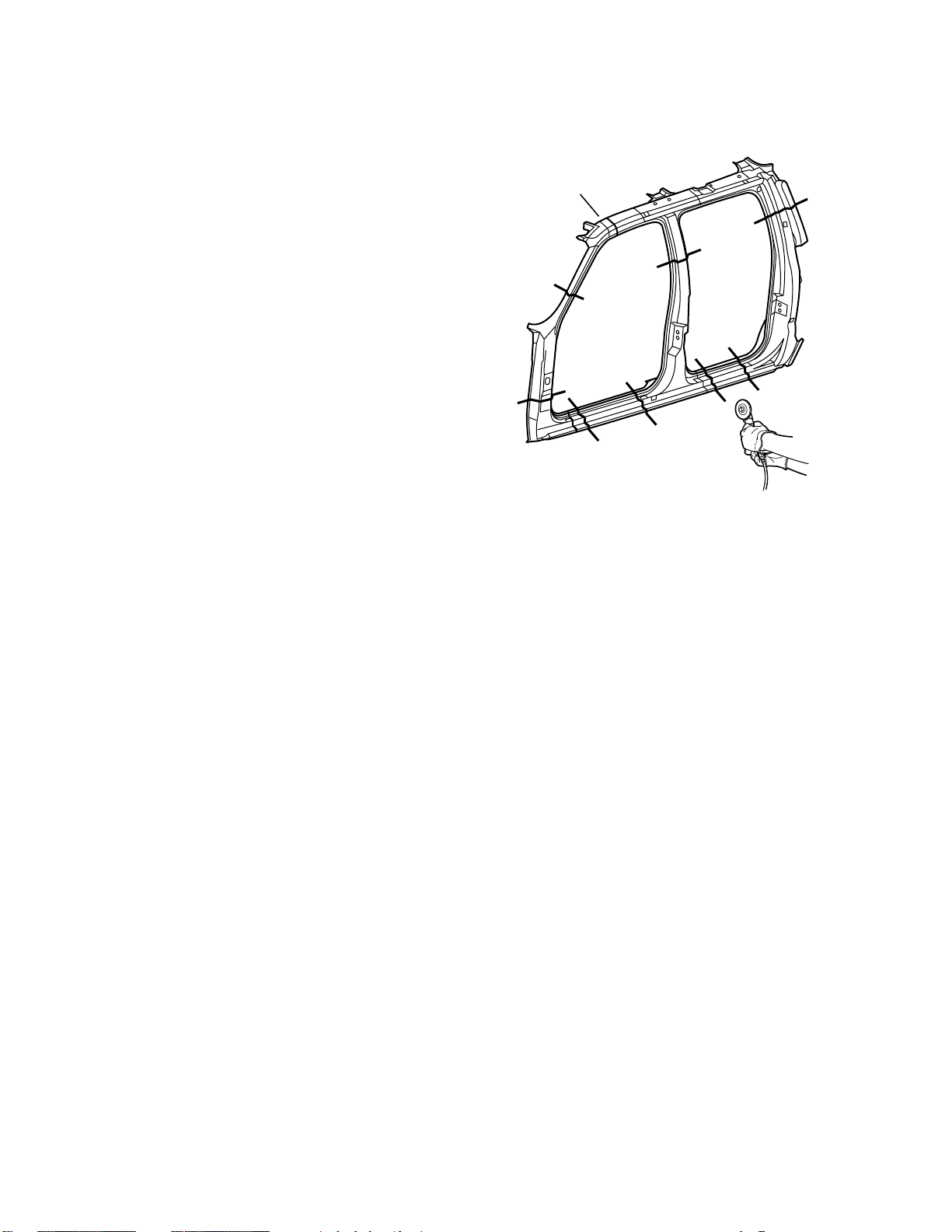

Door Frame

Sectioning

IMPORTANT: Section in specified areas

1

only. Sectioning outside of these areas

may compromise the structural integrity

of the vehicle. Do not section in laser

weld (1) areas of door frame sections.

The door frame opening is a unique

laser-weld design incorporating multiple

metal thicknesses to ensure the

structural integrity of the cab. The door

frame can be replaced at factory seams,

but requires the removal of the roof

panel, windshield and quarter panel.

Sectioning procedures have been

developed as a more cost-effective

alternative to complete replacement. The

specific area to be sectioned is

determined by the extent of the damage

to the vehicle.

2002 Avalanche 3-1

2002 Chevrolet Avalanche

Page 2

Windshield Pillar

Sectioning

Removal Procedure

1. Remove all related panels and

components.

2. Restore as much of the damage as

possible to factory specifications.

3. Note the location and remove the

following as necessary:

• Sealers

• Sound deadeners

• Anti-corrosion materials

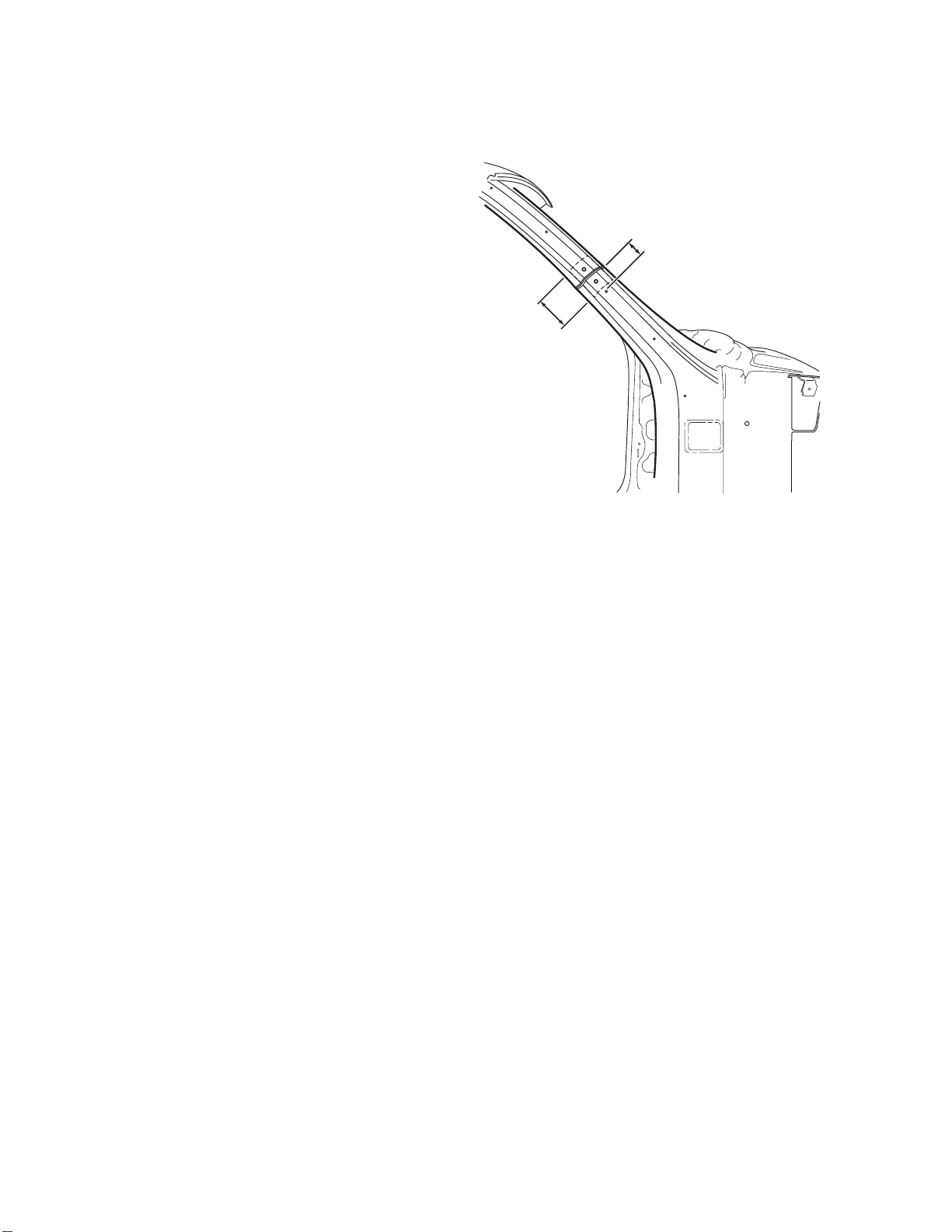

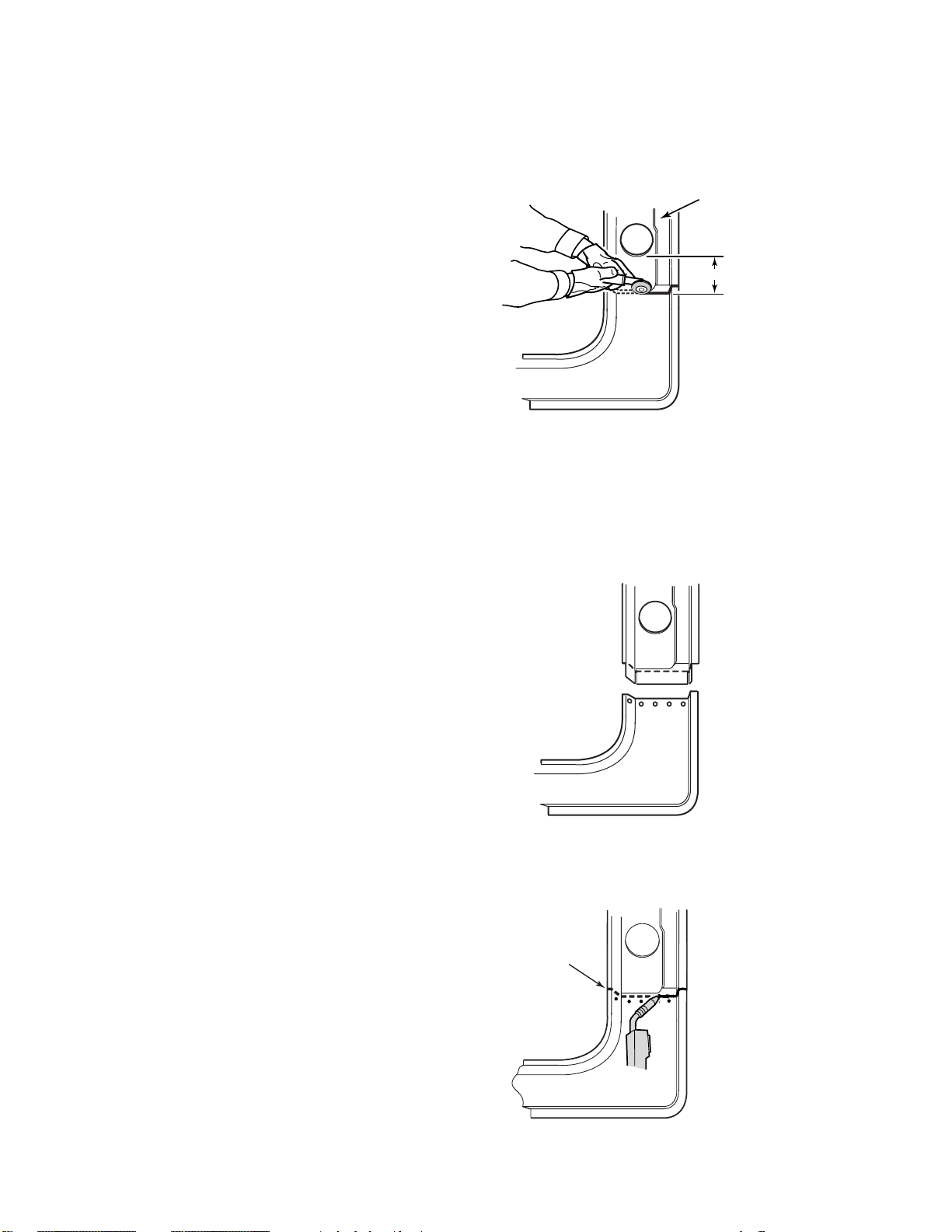

IMPORTANT: Perform sectioning

in the windshield area 30␣ mm

(1-3/16␣ in.) above the third trim

mounting hole.

IMPORTANT: Take care not to

damage the inner panels or

reinforcements.

4. Cut the pillar in the locations where

sectioning is to be performed.

5. Locate and drill out all factory

welds. Note the number and

location of the welds for installation

of the service part.

6. Remove the damaged Windshield

Pillar section.

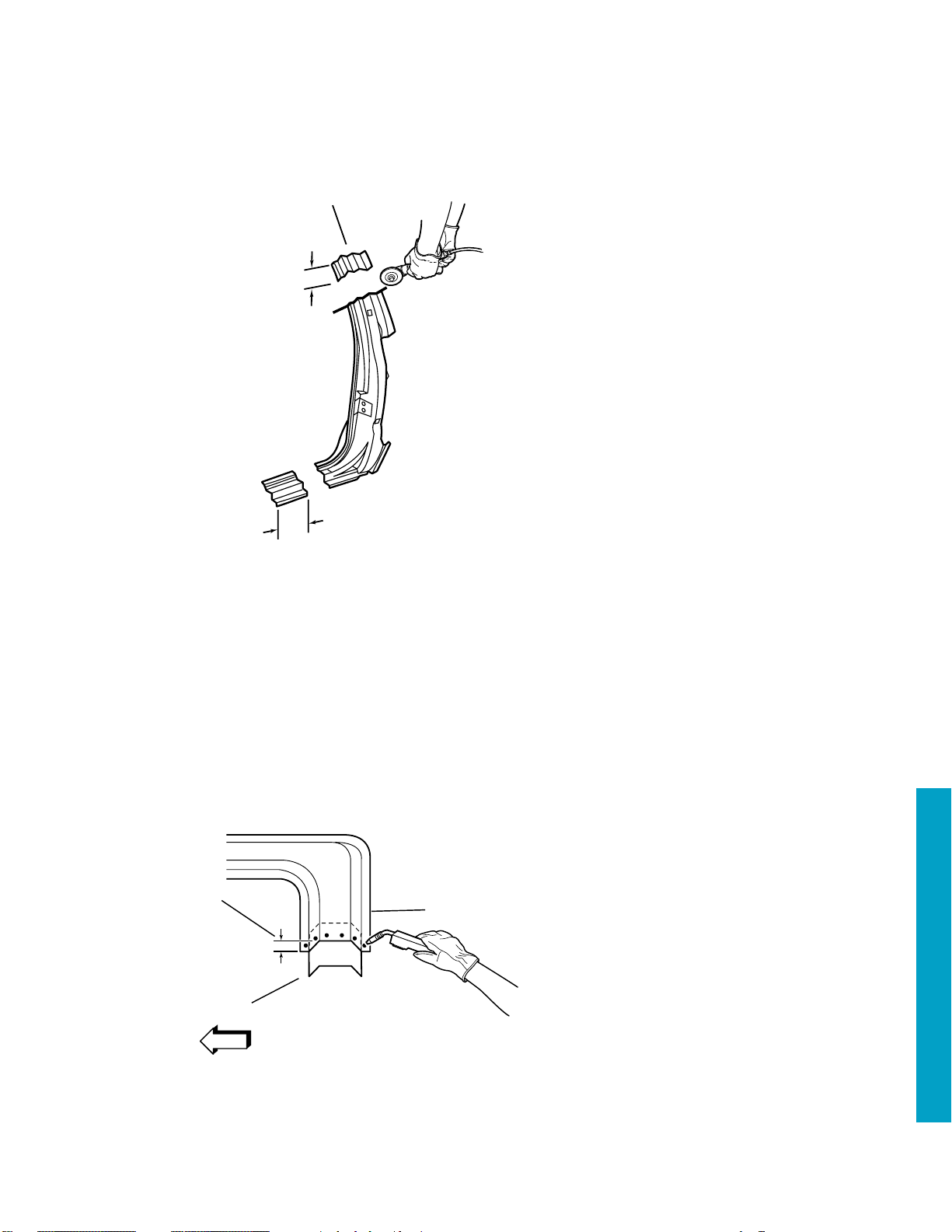

30 MM (1-3/16 IN)

50 MM (2 IN)

3-2 2002 Avalanche

Page 3

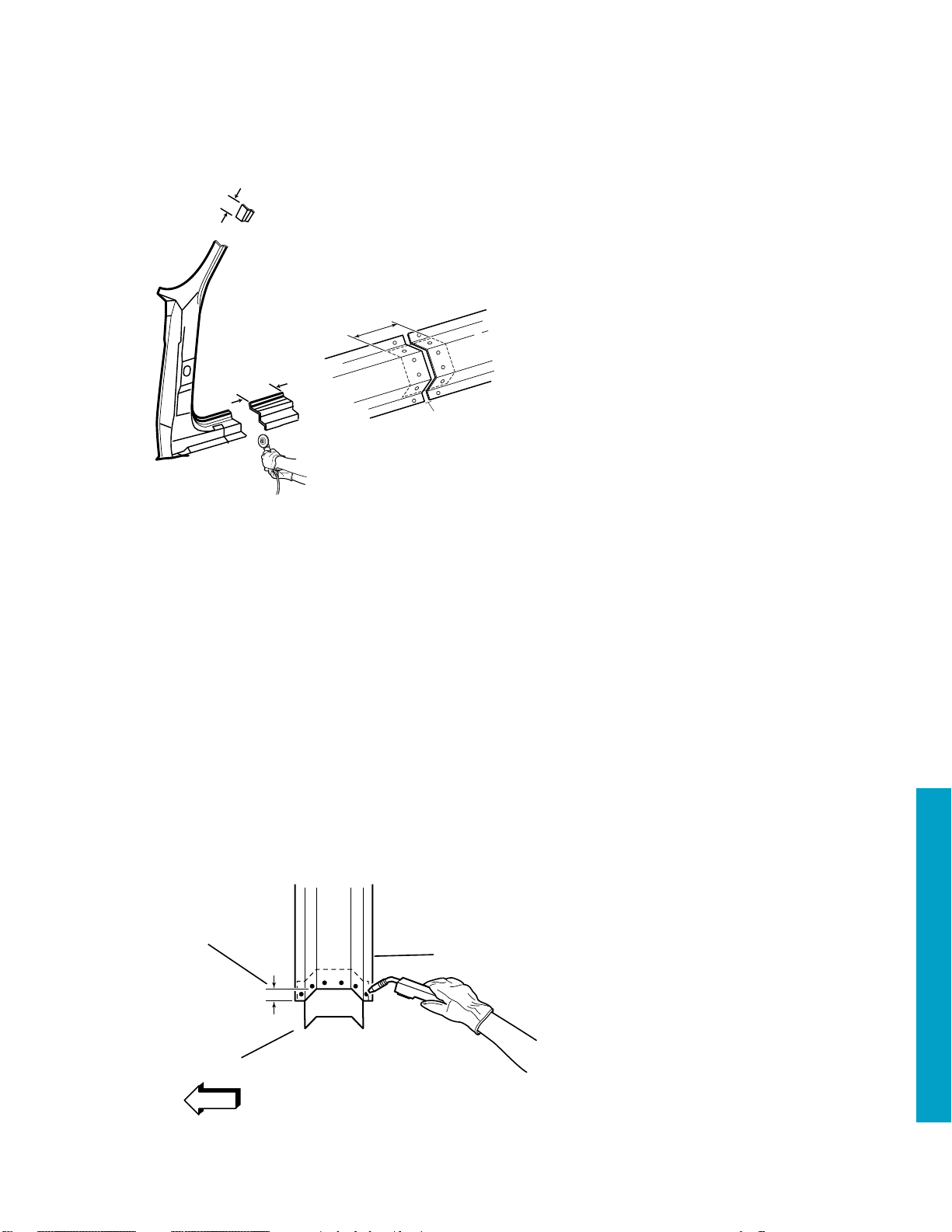

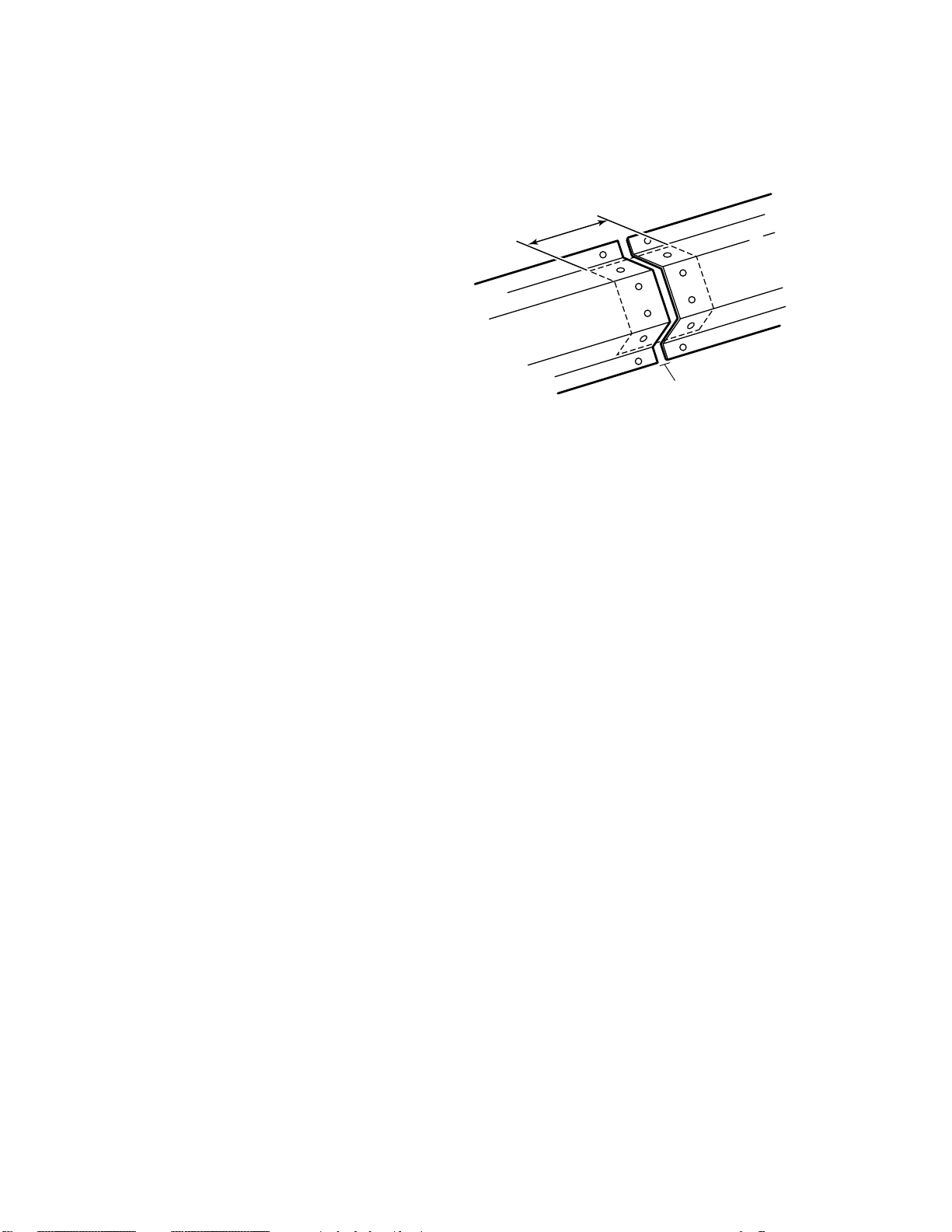

50 MM

(2 IN)

100 MM

(4 IN)

100MM

(4 IN)

BACKING PLATE

GAP = ONE AND ONE-HALF TIMES

THE THICKNESS OF THE METAL

Windshield Pillar

Sectioning

Installation Procedure

1. Cut the replacement pillar in

corresponding locations to fit the

remaining original panel. The

sectioning joint should be trimmed

to allow a gap of one and one-half

times the metal thickness at the

sectioning joint.

2. Create a 50␣ mm (2␣ in.) backing

plate from the unused portion of the

service part. Trim the backing plate

as necessary to fit behind the

sectioning joint.

3. Perform additional sectioning

procedures as necessary. Refer to

Center Pillar Sectioning; Front

Lower Pillar Sectioning; Rear Lock

Pillar Sectioning; and Rocker

Sectioning.

4. Drill 8␣ mm (5/16␣ in.) holes for plug

welding in the original part. Locate

these holes approximately 13␣ mm

(1/2␣ in.) from the edge of the

sectioning cuts and spaced 40␣ mm

(1-1/2␣ in.) apart.

5. Drill 8␣ mm (5/16␣ in.) plug weld

holes in the service panel as

necessary in the locations noted

from the original panel and along

the sectioning cut.

CAUTION: FOAM SEALERS ARE

FLAMMABLE AND SHOULD BE

REMOVED FROM ALL WELD

LOCATIONS.

6. Prepare the mating surfaces, as

necessary.

7. Apply weld-through primer to all

bare metal surfaces.

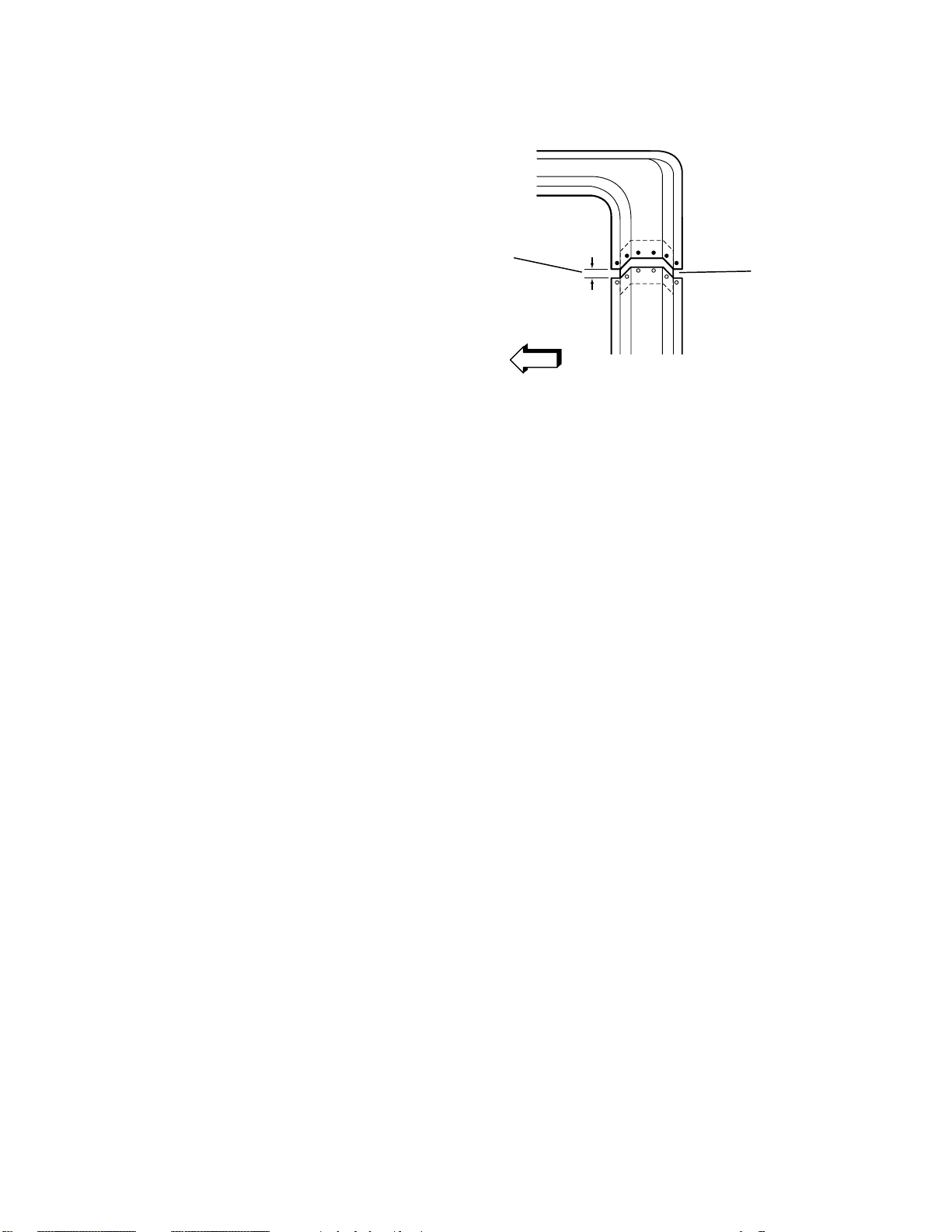

PLUG WELDS

13 MM

(1/2 IN)

BACKING PLATE

ORIGINAL PART

8. Fit the backing plate halfway into

the sectioning joint, clamp and plug

weld to the vehicle.

9. Align the Windshield Pillar to

adjacent panels using threedimensional measuring equipment.

10. Plug weld accordingly.

—continued

2002 Avalanche 3-3

Page 4

Windshield Pillar Sectioning

Installation Procedure con’t

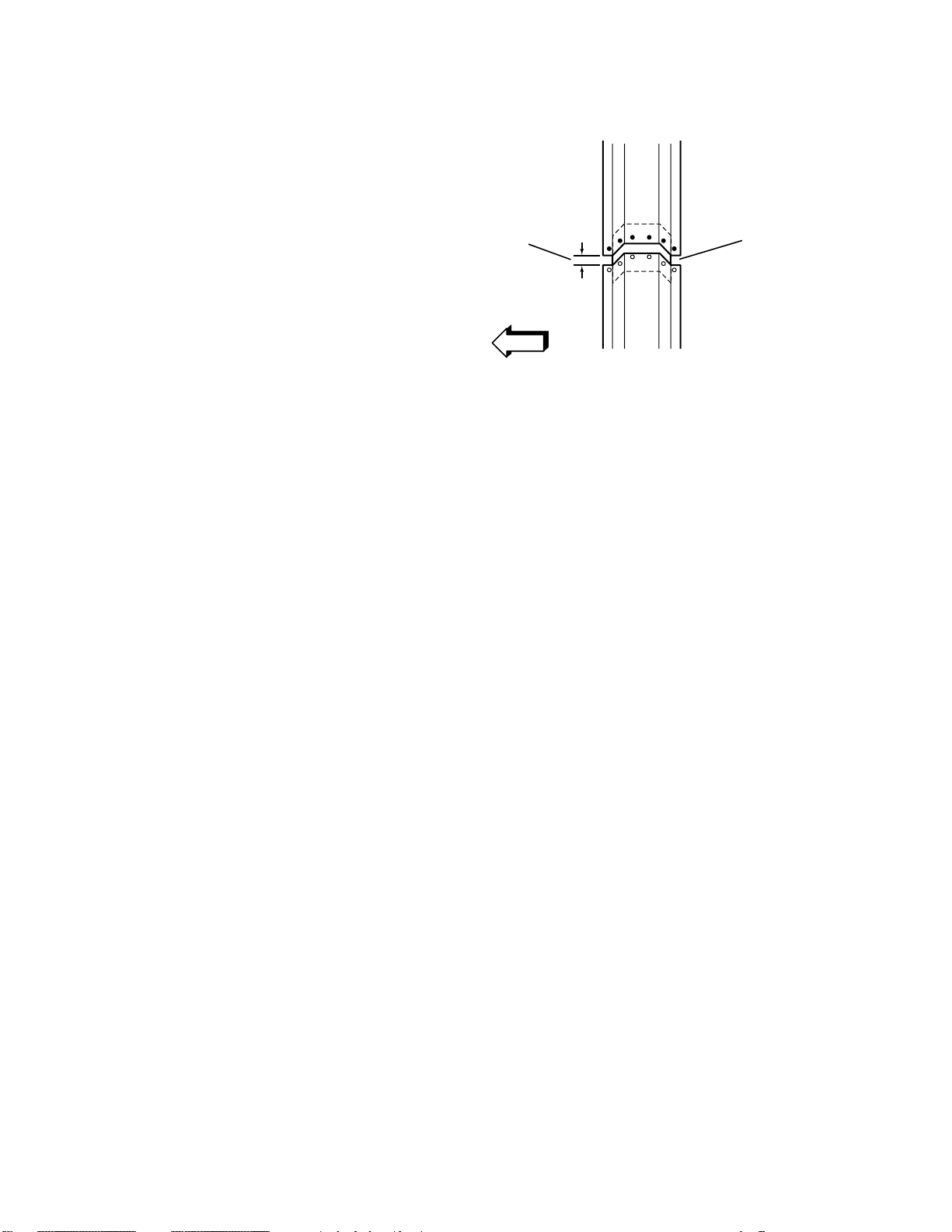

11. Make 25␣ mm (1␣ in.) stitch welds

along the seam with 25␣ mm (1␣ in.)

gaps between them, then go back

and complete the stitch weld. This

will create a solid joint with minimal

heat distortion.

12. Clean and prepare all welded

surfaces.

IMPORTANT: Prior to refinishing,

refer to the publication GM4901MD-01 GM Approved Refinish

Materials for recommended

products. Do not combine paint

systems. Refer to paint

manufacturer’s recommendations.

13. Apply an approved anti-corrosion

primer.

14. Apply sealers and refinish as

necessary.

15. Install all related panels and

components.

GAP =

ONE AND ONE-HALF TIMES

MET AL THICKNESS

STITCH WELD

3-4 2002 Avalanche

Page 5

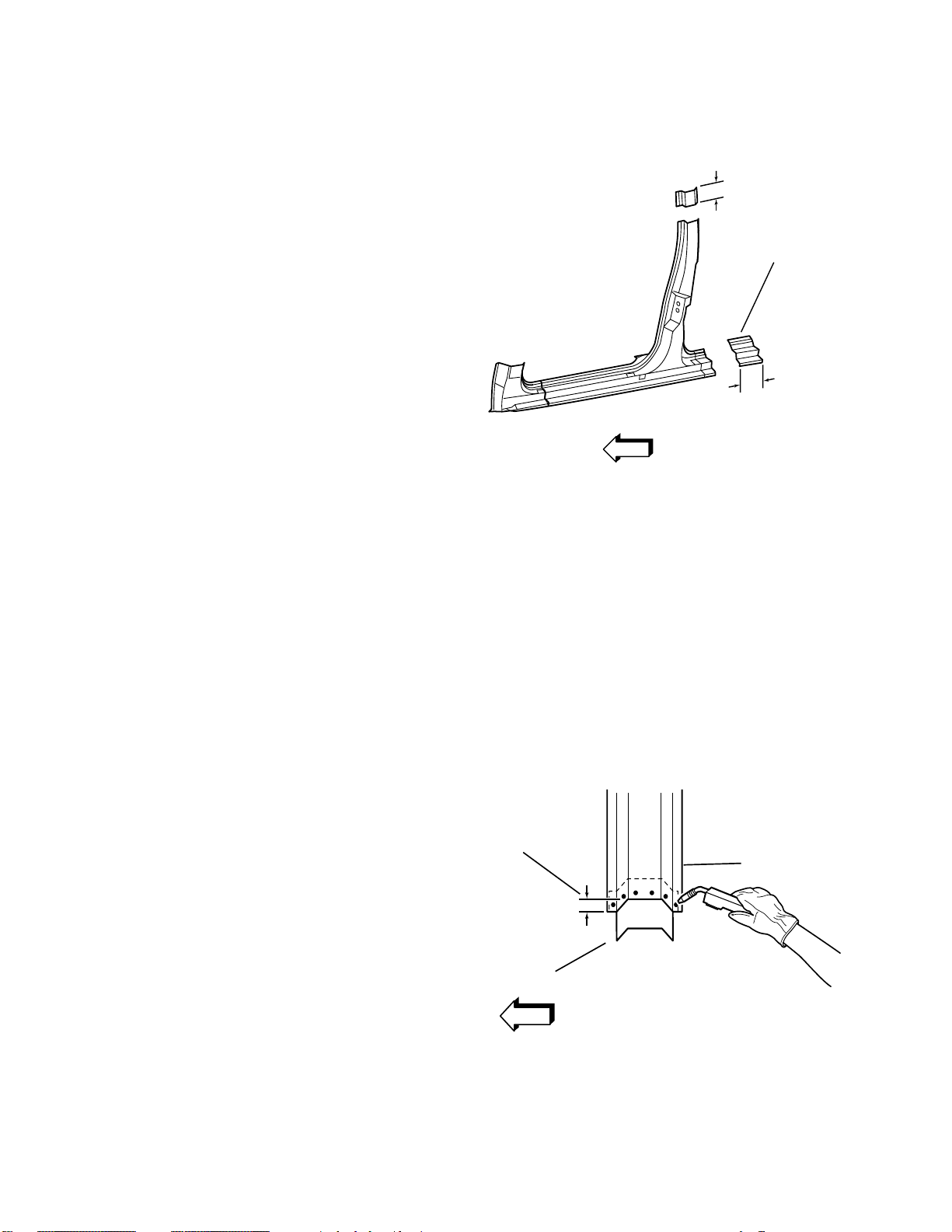

Front Lower Hinge

Pillar Sectioning

ORIGINAL

PANEL

80 MM (3-1/8 IN)

Removal Procedure

1. Visually inspect and restore as much of

the damage as possible to factory

specifications.

2. Remove all related panels and

components.

3. Note the location and remove the

following as necessary:

• Sealers

• Sound deadeners

• Anti-corrosion materials

4. Measure 80␣ mm (3-1/8 inches) down

from the large wiring harness hole in the

hinge pillar and mark a horizontal line.

5. Cut the pillar in the locations where

sectioning is to be performed.

IMPORTANT: Take care not to damage

the inner panel.

6. Locate, mark and drill out all necessary

factory welds. Note the number of welds

for the installation of the service section.

7. Remove the damaged section of the door

frame opening.

5 MM (3/16 IN)

IMPORTANT: The metal of the hinge

pillar is of a heavy gauge. However, the

tabs can be created using the appropriate

tools.

8. Cut and remove 30␣ mm (1-3/16 inches)

from the flanges on either side of the

remaining section of the original hinge

pillar to create 30␣ mm (1-3/16␣ in.) tabs.

Cut 5␣ mm (3/16␣ in.) wide gaps in the

bottom corners.

30 MM (1-3/16 IN)

9. Step the tabs inward to allow the door

frame opening service section to fit over

the original hinge pillar. Weld the tabs

together along the edges.

WELD TOGETHER

2002 Avalanche 3-5

Page 6

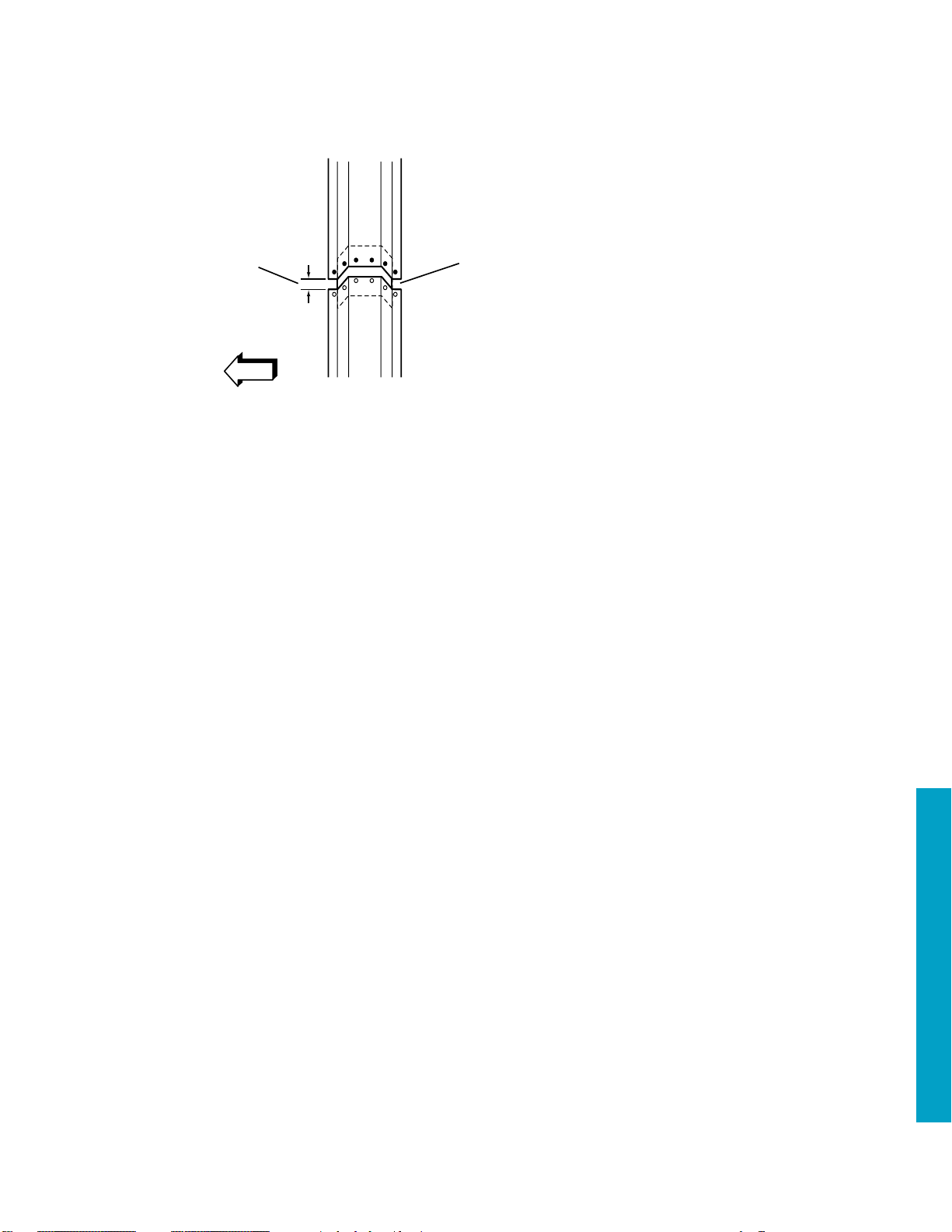

Front Lower Hinge

Pillar Sectioning

Installation Procedure

1. On the service part, measure 50␣ mm (2␣ in.)

down from the large wiring harness hole in

the hinge pillar and mark a horizontal line.

Cut the hinge pillar along this line.

2. Perform additional sectioning procedures as

necessary to remove the unused areas of

the service part. Refer to Windshield

Sectioning; Center Pillar, Rear Lock Pillar,

and Rocker Sectioning.

NOTICE: In any area damaged beyond

recognition, space plug weld holes every

40␣ mm (1-1/2␣ in.) apart.

3. Drill 8␣ mm (5/16␣ in.) plug weld holes as

necessary in the locations noted from the

original section. Also drill plug weld holes

along the hinge pillar sectioning cut of the

service part. These should be located

approximately 15␣ mm (9/16␣ in.) from the

edge of the cut.

CAUTION: FOAM SEALERS ARE

FLAMMABLE AND SHOULD BE

REMOVED FROM ALL WELD

LOCATIONS.

4. Prepare mating surfaces as necessary.

5. Apply weld-thru primer to all bare-metal

surfaces.

SERVICE

PANEL

50 MM (2 IN)

ORIGINAL

PANEL

6. Position the service section over the

stepped tab on the original hinge pillar,

allowing 30␣ mm (1-3/16 inches) of overlap.

Check fit using three-dimensional

measuring.

7. Plug weld service part in position.

8. Make 25␣ mm (1␣ in.) welds along the seam

with 25␣ mm (1␣ in.) gaps between. Then go

back and complete the stitch weld. This

will create a solid joint with minimal heat

distortion.

9. Clean and prepare all welded surfaces.

IMPORTANT: Prior to refinishing,

refer to the publication GM4901M-D-01

GM Approved Refinish Materials for

recommended products. Do not combine

paint systems. Refer to paint manufacturer’s

recommendations.

10. Apply an approved anti-corrosion primer.

11. Apply sealers and refinish as necessary.

12. Install all related panels and components.

30 MM (1-3/16 IN)

OF OVERLAP

NEW

SERVICE PANEL

ORIGINAL

PANEL

3-6 2002 Avalanche

Page 7

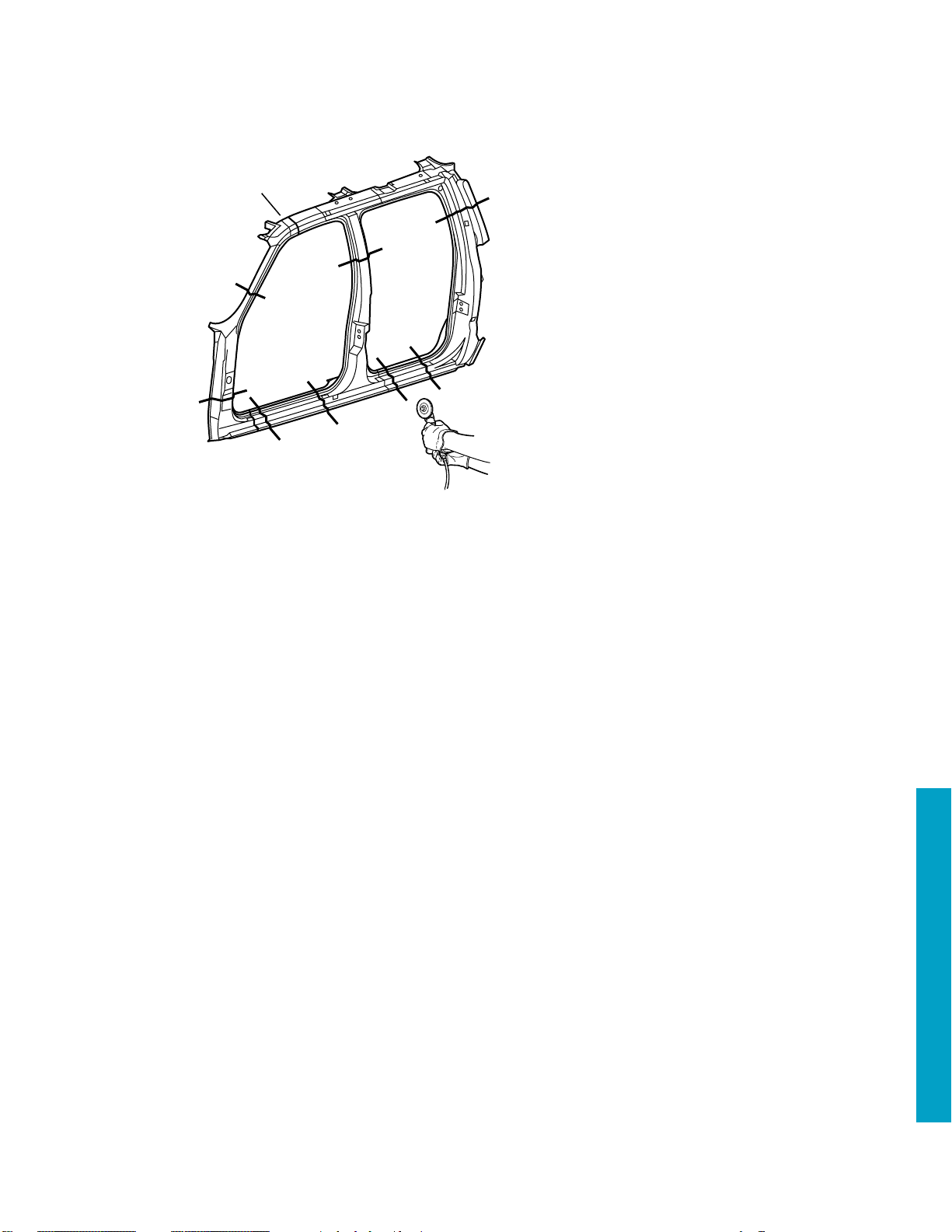

Center Pillar

Sectioning

Removal Procedure

1. Remove all related panels and

1

components.

2. Restore as much of the damage as

possible to factory specifications.

3. Note the location and remove the

following as necessary:

• Sealers

• Sound deadeners

• Anti-corrosion materials

IMPORTANT: Take care not to

damage the inner panels or

reinforcements.

4. Cut the Center Pillar in the location

where sectioning is to be performed.

5. Locate and drill out all factory

welds. Note the number and

location of the welds for installation

of the service part.

6. Remove the damaged Center Pillar

section.

2002 Avalanche 3-7

Page 8

Center Pillar

Sectioning

Installation Procedure

1. Cut the replacement Center Pillar in

corresponding locations to fit the

remaining original panel. The sectioning

joint should be trimmed to allow a gap of

one-and-one-half times the metal

thickness at the sectioning joint.

2. Create a 50␣ mm (2␣ in.) backing plate

from the unused portion of the service

part. Trim the backing plate as necessary

to fit behind the sectioning joint.

3. Perform additional sectioning procedures

as necessary. Refer to Windshield

Sectioning; Front Lower Pillar

Sectioning; Rear Lock Pillar Sectioning;

and Rocker Sectioning.

4. Drill 8␣ mm (5/16␣ in.) plug weld holes

along the sectioning cut on the

remaining original part.

5. Drill 8␣ mm (5/16␣ in.) plug weld holes in

the service panel as necessary in the

locations noted from the original panel

and along the sectioning cut.

CAUTION: FOAM SEALERS ARE

FLA␣ MMABLE AND SHOULD BE

REMOVED FROM ALL WELD

LOCATIONS.

6. Prepare the mating surfaces as necessary.

7. Apply weld-through primer to all bare

metal surfaces.

50MM

(2 IN)

1

100MM

(4 IN)

8. Fit the backing plate halfway into the

sectioning joint, clamp and plug weld to

the vehicle.

—continued

3-8 2002 Avalanche

PLUG WELDS

ORIGINAL PART

13 MM

(1/2 IN)

BACKING PLATE

Page 9

GAP =

ONE AND ONE-HALF TIMES

MET AL THICKNESS

STITCH WELD

Center Pillar Sectioning

Installation Procedure con’t

9. Align the Center Pillar to adjacent

panels using three-dimensional

measuring equipment.

10. Plug weld accordingly.

11. Make 25␣ mm (1␣ in.) stitch welds

along the seam with 25␣ mm (1␣ in.)

gaps between them, then go back

and complete the stitch weld. This

will create a solid joint with minimal

heat distortion.

12. Clean and prepare all welded

surfaces.

IMPORTANT: Prior to refinishing,

refer to the publication GM4901MD-01 GM Approved Refinish

Materials for recommended

products. Do not combine paint

systems. Refer to paint

manufacturer’s recommendations.

13. Apply an approved anti-corrosion

primer.

14. Apply sealers and refinish as

necessary.

15. Install all related panels and

components.

2002 Avalanche 3-9

Page 10

Rear Lock Pillar

Sectioning

Removal Procedure

1. Remove all related panels and components.

2. Restore as much of the damage as possible to

factory specifications.

3. Note the location and remove the following

as necessary:

• Sealers

• Sound deadeners

• Anti-corrosion materials

IMPORTANT: Take care not to damage the

inner panels or reinforcements.

4. Cut the Rear Lock Pillar in the locations

where sectioning is to be performed.

5. Locate and drill out all factory welds. Note

the number and location of the welds for

installation of the service part.

6. Remove the damaged Rear Lock Pillar

section.

1

3-10 2002 Avalanche

Page 11

BACKING PLATE

50 MM

(2 IN)

100 MM

(4 IN)

Rear Lock Pillar

Sectioning

Installation Procedure

1. Cut the replacement Rear Lock

Pillar in corresponding locations to

fit the remaining original panel. The

sectioning joint should be trimmed

to allow a gap of one-and-one-half

times the metal thickness at the

sectioning joint.

2. Create a 50␣ mm (2␣ in.) backing

plate from the unused portion of the

service part. Trim the backing plate

as necessary to fit behind the

sectioning joint.

3. Perform additional sectioning

procedures as necessary. Refer to

Windshield Sectioning; Front Lower

Pillar Sectioning; Center Pillar; and

Rocker Sectioning.

4. Drill 8 ␣ mm (5/16␣ in.) plug weld

holes along the sectioning cut on

the remaining original part.

5. Drill 8␣ mm (5/16␣ in.) plug weld

holes in the service panel as

necessary in the locations noted

from the original panel and along

the sectioning cut.

CAUTION: FOAM SEALERS ARE

FLAMMABLE AND SHOULD BE

REMOVED FROM ALL WELD

LOCATIONS.

6. Prepare the mating surfaces, as

necessary.

7. Apply weld-through primer to all

bare metal surfaces.

PLUG WELDS

13 MM

(1/2 IN)

BACKING PLATE

8. Fit the backing plate halfway into

the sectioning joint, clamp and plug

weld to the vehicle.

ORIGINAL PANEL

2002 Avalanche 3-11

Page 12

Rear Lock Pillar Sectioning

Installation Procedure con’t

9. Align the Rear Lock Pillar to

adjacent panels using threedimensional measuring equipment.

10. Plug weld accordingly.

11. Make 25␣ mm (1␣ in.) stitch welds

along the seam with 25␣ mm (1␣ in.)

gaps between them, then go back

and complete the stitch weld. This

will create a solid joint with minimal

heat distortion.

12. Clean and prepare all welded

surfaces.

IMPORTANT: Prior to refinishing,

refer to the publication GM4901MD-01 GM Approved Refinish

Materials for recommended

products. Do not combine paint

systems. Refer to paint

manufacturer’s recommendations.

13. Apply an approved anti-corrosion

primer.

14. Apply sealers and refinish as

necessary.

15. Install all related panels and

components.

GAP =

ONE AND ONE-HALF TIMES

THE METAL THICKNESS

STITCH WELD

3-12 2002 Avalanche

Page 13

Rocker Panel

Sectioning

Removal Procedure

1

1. Remove all related panels and

components.

2. Restore as much of the damage as

possible to factory specifications.

3. Note the location and remove the

following as necessary:

• Sealers

• Sound deadeners

• Anti-corrosion materials

IMPORTANT: Take care not to

damage the inner panels or

reinforcements.

4. Cut the Rocker Panel in the

locations where sectioning is to be

performed.

5. Locate and drill out all factory

welds. Note the number and

location of the welds for installation

of the service part.

6. Remove the damaged Rocker Panel

section.

2002 Avalanche 3-13

Page 14

Rocker Panel

Sectioning

Installation Procedure

1. Cut the replacement Rocker Panel in

corresponding locations to fit the

remaining original panel. The sectioning

joint should be trimmed to allow a gap of

one-and-one-half times the metal thickness

at the sectioning joint.

2. Create a 100␣ mm (4␣ in.) backing plate

from the unused portion of the service

part. Trim the backing plate as necessary

to fit behind the sectioning joint.

3. Perform additional sectioning procedures

as necessary. Refer to Windshield

Sectioning; Front Lower Pillar Sectioning;

Rear Lock Pillar Sectioning; and Center

Pillar sectioning.

4. Drill 8␣ mm (5/16␣ in.) plug weld holes along

the sectioning cut on the remaining

original part.

5. Drill 8␣ mm (5/16␣ in.) plug weld holes in

the service panel as necessary in the

locations noted from the original panel and

along the sectioning cut.

CAUTION: FOAM SEALERS ARE

FLAMMABLE AND SHOULD BE

REMOVED FROM ALL WELD

LOCATIONS.

6. Prepare the mating surfaces as necessary.

7. Apply weld-through primer to all bare

metal surfaces.

8. Fit the backing plate halfway into the

sectioning joint, clamp and plug weld to

the vehicle.

9. Align the Rocker Panel to adjacent panels

using three-dimensional measuring

equipment.

10. Plug weld service part in position.

11. Make 25␣ mm (1␣ in.) stitch welds along the

seam with 25␣ mm (1␣ in.) gaps between

them, then go back and complete the

stitch weld. This will create a solid joint

with minimal heat distortion.

12. Clean and prepare all welded surfaces.

IMPORTANT: Prior to refinishing, refer to

the publication GM4901M-D-2000 “GM

Approved Refinish Materials” for

recommended products. Do not combine

paint systems. Refer to paint manufacturer’s

recommendations.

13. Apply an approved anti-corrosion primer.

14. Apply sealers and refinish as necessary.

15. Install all related panels and components.

100 MM

(4 IN)

BACKING PLATE

GAP = ONE AND ONE-HALF TIMES

THE THICKNESS OF THE METAL

3-14 2002 Avalanche

Page 15

Front Body-Side

Hinge Replacement

Removal Procedure

1. Remove related panels and

component.

2. Remove any excess sealer

surrounding the existing hinge and

scribe the location of the hinge on

the hinge pillar.

3. Lightly hand-sand the existing hinge

with 100 grit or finer sandpaper in

order to locate the

4 welds that attach the hinge to the

pillar.

IMPORTANT: Punch the center of

the weld so that as much of the weld

as possible is removed during the

drilling.

4. Center punch each of the four weld

marks on the original hinge.

DRILL THROUGH HINGE ONLY

13 MM (1/2 IN)

ROTABROACH BIT

HINGE

PILLAR

HINGE REINFORCEMENT

TYPICAL MIG WELD

IMPORTANT: Do not drill into the

hinge pillar.

5. Drill through the hinge only, at each

punch location. Use a 13␣ mm (1/

2␣ in.) rotabroach hole saw or

equivalent.

6. Remove the hinge. If necessary, use

a chisel in order to separate the

hinge from the pillar.

7. Remove all of the remaining weld

from the pillar surface in order to

ensure a flush fit of the service

hinge.

2002 Avalanche 3-15

Page 16

Front Body-Side

Hinge Replacement

Installation Procedure

1. Repair any damage done to the pillar

during the drilling or the removal.

2. Position the service hinge within the

scribe marks on the pillar.

3. Center punch each stud location on

the hinge pillar according to the

service hinge.

4. Drill a 3 ␣ mm (1/8␣ in.) pilot hole at

each center punch location.

IMPORTANT: Drill must be exact size.

5. Drill an 11.5 mm (29/64␣ in.) hole at

the pilot locations for the studs.

IMPORTANT: Prior to refinishing,

refer to the publication GM4901M-D2000 “GM Approved Refinish

Materials” for recommended products.

Do not combine paint systems. Refer to

paint manufacturer’s

recommendations.

6. Clean and prepare all of the bare

metal surfaces.

7. Apply an approved anti-corrosion

primer.

3 MM (1/8 IN)

PILOT

11.5 MM (29/64 IN)

DRILL

8. Feed fish wire, GM P/N 15017229 or

the equivalent, through the hinge, the

hinge stud hole and out of the

conduit hole in the pillar.

9. Install the stud, GM P/N 15017230,

supplied with the service hinge into

the wire end. Pull the stud into

position.

10. Hold the stud in position with the

hinge and remove the fish wire.

11. Draw the stud tight through the

pillar. Use the nuts (GM P/N

11516746) supplied.

12. Repeat steps 7-10 on the remaining

stud locations.

13. Remove each service nut.

14. Apply a full-bodied caulk to the entire

hinge mounting surface in order to

ensure a proper seal.

3-16 2002 Avalanche

Page 17

Hinge

Nuts

Pillar

Hinge

Reinforcement

Studs

Front Body-Side Hinge

Replacement

Installation Procedure con’t

15. Install the hinge to the pillar. Use

the supplied nuts.

16. Torque the hinge to the pillar nuts

to 25␣ ␣ N·m (18 ft lb.).

17. Clean and prepare all of the

surfaces as necessary for refinishing.

18. Apply the sealers. Refinish the

surfaces as necessary.

19. Install and align all of the related

panels and the components.

2002 Avalanche 3-17

Page 18

Front Door-Side

13mm (1/2 inch)

Rotabroach Bit

Hinge

Door

Hinge Reinforcement

Typical Mig Weld

Drill through hinge only

Hinge Replacement

Removal Procedure

1. Remove related panels and

components.

2. Remove any excess sealer surrounding

the hinge and scribe the location of

the hinge on the door.

3. Lightly hand-sand the existing body

hinge with 100 grit or finer sandpaper

in order to locate the 4 welds that

attach the hinge to the door.

IMPORTANT: Punch the center of the

weld so that as much of the weld is

removed during the drilling as possible.

4. Center punch each of the four weld

marks on the original hinge base.

IMPORTANT: Do not drill into the

door.

5. Drill through hinge base only at the

punch location. Use a 13 mm (1/2␣ in.)

rotabroach hole saw, or the equivalent.

6. Remove hinge. If necessary, use a

chisel to separate the hinge from the

door.

7. Remove all of the remaining weld from

the door surface in order to ensure a

flush fit of the service hinge.

3-18 2002 Avalanche

Page 19

3 MM (1/8 IN)

PILOT

13 MM (1/2 IN)

DRILL

Front Door-Side

Hinge Replacement

Installation Procedure

1. Repair any damage done to door

during the drilling or the removal.

2. Clean and prepare the backing plate

mounting surfaces in order to

ensure a flush fit of the backing

plate.

3. Position the service hinge within the

scribe marks on the door.

4. Center punch each hole location on

the door according to the service

hinge.

5. Drill a 3 mm (1/8␣ in.) pilot hole at

each center punch location.

6. Drill a 13 mm (1/2␣ in.) hole at the

pilot locations.

IMPORTANT: Prior to refinishing,

refer to the publication GM4901MD-2000 “GM Approved Refinish

Materials” for recommended

products. Do not combine paint

systems. Refer to paint

manufacturer’s recommendations.

7. Clean and prepare all of the bare

metal surfaces.

8. Apply an approved anti-corrosion

primer.

9. Apply full-bodied caulk to the entire

hinge mounting surface in order to

ensure a proper seal.

HINGE

DOOR

BOLTS

BACKING

PLATE

10. Align the hinge and the backing

plate with the holes in the door

(Fig. 4-34).

11. Install the bolts. Tighten the bolts

to 25 ␣ N·m (18 ft lb).

12. Apply the sealers.

13. Refinish the metal surfaces as

necessary.

14. Install and align all of the related

panels and the components.

2002 Avalanche 3-19

Page 20

Rear Body-Side

Hinge Replacement

Removal Procedure

1. Remove related panels and

components.

2. Remove any excess sealer

surrounding the existing hinge and

scribe the location of the hinge on

the hinge pillar.

3. Lightly hand-sand the existing hinge

with 100 grit or finer sandpaper in

order to locate the

4 welds that attach the hinge to the

pillar.

IMPORTANT: Punch the center of

the weld so that as much of the weld

as possible is removed during the

drilling.

4. Center punch each of the 4 weld

marks on the original hinge.

IMPORTANT: Do not drill into the

hinge pillar.

5. Drill through the hinge only at each

punch location. Use a 13␣ mm

(1/2␣ in.) rotabroach hole saw or the

equivalent.

6. Remove the hinge. If necessary, use

a chisel in order to separate the

hinge from the pillar.

7. Remove all of the remaining weld

from the pillar surface in order to

ensure a flush fit of the service

hinge.

3-20 2002 Avalanche

DRILL THROUGH HINGE ONLY

13 MM (1/2 IN)

ROTABROACH BIT

HINGE

PILLAR

HINGE REINFORCEMENT

TYPICAL MIG WELD

Page 21

3 MM (1/8 IN)

PILOT

11.5 MM (29/64 IN)

DRILL

Rear Body-Side

Hinge Replacement

Installation Procedure

1. Repair any damage done to the

pillar during the drilling or the

removal.

2. Position the service hinge within the

scribe marks on the pillar.

3. Center punch each stud location on

the hinge pillar according to the

service hinge.

4. Drill a 3␣ mm (1/8␣ in.) pilot hole at

each center punch location.

IMPORTANT: Drill must be exact

size.

5. Drill an 11.5␣ mm (29/64␣ in.) hole at

the pilot locations for the studs.

IMPORTANT: Prior to refinishing,

refer to the publication GM4901MD-01 GM Approved Refinish

Materials for recommended

products. Do not combine paint

systems. Refer to paint

manufacturer’s recommendations.

6. Clean and prepare all of the bare

metal surfaces.

7. Apply an approved anti-corrosion

primer.

STUD

8. Feed fish wire, GM P/N 15017229

or the equivalent, through the

hinge, the hinge stud hole and out

of the conduit hole in the pillar

(Fig. 4-38).

9. Install the stud, GM P/N 15017230,

supplied with the service hinge, into

the wire end. Pull the stud into

position.

10. Hold the stud in position with the

hinge and remove the fish wire.

—continued

2002 Avalanche 3-21

Page 22

Rear Body-Side Hinge

Replacement Installation

Procedure cont’d

11. Draw the stud tight through the

pillar. Use the nuts GM P/N

11516746, supplied.

12. Repeat steps 7 through 10 on the

remaining stud locations.

13. Remove each service nut.

14. Apply a full-bodied caulk to the

entire hinge mounting surface in

order to ensure a proper seal.

15. Install the hinge to the pillar. Use

the supplied nuts.

16. Torque the hinge nuts to 25␣ N·m

(18 ft lb).

17. Clean and prepare all of the

surfaces as necessary for refinishing.

18. Apply the sealers. Refinish the

surfaces as necessary.

19. Install and align all of the related

panels and the components.

Hinge

Nuts

Pillar

Hinge

Reinforcement

Studs

3-22 2002 Avalanche

Page 23

Rear Door-Side

Hinge Replacement

Removal Procedure

1. Remove related panel and

components.

2. Remove any excess sealer

surrounding the existing hinge and

scribe the location of the hinge on

the door.

3. Lightly hand-sand the existing door

hinge with 100 grit or finer

sandpaper in order to locate the

four welds that attach the hinge to

the door.

IMPORTANT: Punch the center of

the weld so that as much of the weld

is removed during the drilling as

possible.

4. Center punch each of the 4 weld

marks on the original hinge base.

DRILL THROUGH HINGE ONLY

13 MM (1/2 IN)

ROTABROACH BIT

HINGE

PILLAR

HINGE REINFORCEMENT

TYPICAL MIG WELD

IMPORTANT: Do not drill into the

door.

5. Drill through the hinge base only at

the punch location. Use a 13␣ mm

(1/2␣ in.) rotabroach hole saw or the

equivalent.

6. Remove the hinge. If necessary, use

a chisel in order to separate the

hinge from the door.

7. Remove all of the remaining weld

from the door surface in order to

ensure a flush fit of the service

hinge.

2002 Avalanche 3-23

Page 24

Rear Door-Side

Hinge Replacement

Installation Procedure

1. Repair any damage done to the door

during the drilling or the removal.

2. Clean and prepare the backing plate

mounting surfaces in order to

ensure a flush fit of the backing

plate.

3. Position the service hinge within the

scribe marks on the door.

4. Center punch each hole location on

the door according to the service

hinge.

5. Drill a 3␣ mm (1/8␣ in.) pilot hole at

each center punch location.

6. Drill a 13␣ mm (1/2␣ in.) hole at the

pilot locations.

IMPORTANT: Prior to refinishing,

refer to the publication GM4901MD-01 GM Approved Refinish

Materials for recommended

products. Do not combine paint

systems. Refer to paint

manufacturer’s recommendations.

7. Clean and prepare all of the bare

metal surfaces.

8. Apply an approved anti-corrosion

primer.

9. Apply a full-bodied caulk to the

entire hinge mounting surface in

order to ensure a proper seal.

13 MM (1/2 IN)

3 MM (1/8 IN)

PILOT

DRILL

10. Align the hinge and the backing

plate with the holes in the door.

11. Install the bolts.

12. Torque the bolts to 25␣ N·m

(18 ft lb).

13. Apply the sealers.

14. Refinish the metal surfaces as

necessary.

15. Install and align all of the related

panels and the components.

3-24 2002 Avalanche

HINGE

DOOR

BOLTS

BACKING

PLATE

Page 25

Quarter Panel

Removal Procedure

1. Remove all related panels and

components.

2. Restore as much of the damage as

possible to factory specifications.

3. Note the location and remove the

following as necessary:

• Sealers

• Sound deadeners

• Anti-corrosion materials

4. Apply 25 mm (1 in.) wide tape (1)

along the upper edge of the Quarter

25mm

1

(1 IN)

Panel at the roof line.

IMPORTANT: Do not damage any

inner panels or reinforcements.

5. Cut the Quarter Panel at the

bottom edge of the tape.

—continued

2002 Avalanche 3-25

Page 26

Quarter Panel

Removal Procedure cont’d

6. Locate and drill out all factory

welds. Note the number and

location of welds for installation of

the service part.

7. Remove the damaged Quarter

Panel, leaving a 25 mm (1 in.)

flange attached to the roof.

25mm

(1 IN)

3-26 2002 Avalanche

Page 27

Quarter Panel

8mm

(5/16 IN)

40mm

(1 1/2 IN)

1

Installation Procedure

1. Trim and discard the upper mounting

flange on the service Quarter Panel so

that it will fit over the 25 mm (1 in.)

flange left from the original panel.

8mm

(5/16 IN)

40mm

(1 1/2 IN)

2. Drill 8 mm (5/16 in.) plug weld holes

along the sectioning cut on the service

1

part. Locate these holes 13 mm (1/2 in.)

from the edge and spaced 40 mm (1-1/2

in.) apart (1).

IMPORTANT: In any area damaged

beyond recognition, space plug weld holes

every 40 mm (1-1/2 in.) apart.

4. Drill 8 mm (5/16 in.) plug weld holes in

the service part as necessary in the

locations noted from the original panel

and along the sectioning cut.

5. Prepare all attachment surfaces as

necessary.

6. Apply weld-through primer to all bare

metal surfaces.

CAUTION: THE FUEL FILLER

OPENING MUST BE PROPERLY

SEALED PRIOR TO POSITIONING

THE QUARTER PANEL. FAILURE TO

PROPERLY SEAL THE QUARTER

PANEL COULD RESULT IN EXHAUST

GAS LEAKAGE INTO THE INTERIOR

OF THE VEHICLE CAUSING

PERSONAL INJURY.

7. Install GM P/N 12399117 Sealing Strip

between outer wheelhouse and quarter

panel gas door pocket.

8. Apply internal sealers (1) in the

locations noted from the removal

procedure.

—continued

1

2002 Avalanche 3-27

Page 28

Quarter Panel

Installation Procedure cont’d

9. Position the Quarter Panel to the

vehicle.

10. Plug weld accordingly.

11. To create a solid weld with minimum

heat distortion, make 25 mm (1 in.)

stitch welds along the seam with 25

mm (1␣ in.) gaps between them. Then

go back and complete the stitch weld.

12. Clean and prepare all welded surfaces.

IMPORTANT: Prior to refinishing,

refer to publication GM4901M-D-01

GM Approved Refinish Materials for

recommended products. Do not

combine paint systems. Refer to paint

manufacturer’s recommendations.

13. Apply the following as necessary:

• Anti-corrosion primer

• Sound deadeners

• Sealers

14. Refinish as necessary.

15. Install all related panels and

components.

3-28 2002 Avalanche

Page 29

GAP = ONE AND ONE-HALF TIMES

THE THICKNESS OF THE METAL

Front Bumper Bracket

Replacement—

1500 Series

1. Remove related panels and components.

2. Remove damaged bumper bracket.

IMPORTANT: Do not remove any material

from end of frame rail.

3. Position the service template on the end

of the frame rail; use 3M’s Repositionable

Adhesive or equivalent.

4. Drill three 13␣ mm (1/2␣ in.) holes at

locations indicated on template that is

supplied with part.

IMPORTANT: Prior to refinishing, refer to

the publication GM4901M-D-01 GM

Approved Refinish Materials for

recommended products. Do not combine

paint systems. Refer to paint

manufacturer’s recommendations.

5. Apply approved anti-corrosion primer to

bare metal surfaces.

6. Position replacement bumper bracket.

7. Install bolts, torque to 50 N·m (37 ft. lb.).

2002 Avalanche 3-29

Page 30

Front Bumper Bracket

Replacement—

2500 Series

1. Remove related panels and components.

2. Remove damaged bumper bracket.

3. Visually inspect frame and restore all

damage to factory specifications using

three-dimensional measuring.

IMPORTANT: If vehicle is equipped with

tow hooks, discard original fasteners.

4. Align replacement bracket lower bolt

holes with tow hook mounting locations

and install bolts supplied.

5. Align front edge of bracket with front

edge of frame and mark upper bolt

locations on frame.

DISCARD ORIGINAL

FASTENERS

MARK BOLT

LOCATIONS

6. Rotate bracket forward and drill 13␣ mm

(1/2␣ in.) holes in frame at upper bolt

locations.

7. Rotate bracket back into position.

8. Install fasteners supplied. Torque

bracket fasteners to 70 N·m (52 ft. lb.).

3-30 2002 Avalanche

Page 31

155 MM

(6 IN)

Rail End

Front Crush Cap

Replacement

Removal Procedure

1. Remove all of the related panels and the

components.

IMPORTANT: If the crush cap is bent or

damaged in any way you must replace the

crush cap.

2. Visually inspect the damage. Use threedimensional measuring in order to

restore all of the damage rearward of the

Crush Cap to the factory specifications.

IMPORTANT: Use care not to damage

the rail.

3. Remove the core support mounting

bracket.

4. Locate the brake line attachment hole

on the top of the rail. Measure forward

155 mm (6-1/8␣ in.). This is the cut line.

5. Scribe a line 360 degrees around the

frame rail and in front of the cross tube.

CAUTION: DO

CROSS TUBE

6. Remove the Crush Cap at the cut-line

and the forward edge of the cross tube.

NOT DAMAGE THE

7. Grind the remaining weld off of the

cross tube where you removed the

damaged Crush Cap.

2002 Avalanche 3-31

Page 32

Rail End

Front Crush Cap

Replacement

Installation Procedure

1. Drill 4 plug weld holes (2 at the top and

2 at the bottom), 13 mm (1/2␣ in.) from

the cut line and 50 mm (2␣ in.) apart on

the existing frame rail.

2. Prepare all of the bare metal surfaces

with a suitable weld through primer.

IMPORTANT: The replacement bumper

bracket is a bolt-on component that must

be ordered separately.

IMPORTANT: Retain a gap of one and

one-half times the metal thickness at the

butt joint when attaching the service part

to the vehicle.

3. Install and position the replacement

Crush Cap using three-dimensional

measuring.

4. Tack weld the part into position at the

initial plug weld holes.

5. Inspect the service part for proper

dimensions.

6. Stitch weld along the entire sectioning

joint. Make 25 mm (1␣ in.) welds along

the seam with 25 mm (1␣ in.) gaps

between.

7. Complete the stitch weld.

8. Position the new core support mounting

bracket and weld the bracket in place

according to the specified dimensions.

9. Clean and prepare the welded surfaces.

IMPORTANT: Prior to refinishing, refer

to the publication GM4901M-D-01 GM

Approved Refinish Materials for

recommended products. Do not combine

paint systems. Refer to paint

manufacturer’s recommendations.

10. Apply an approved anti-corrosion primer.

11. Apply the sealers.

12. Refinish the welded surfaces as

necessary.

13. Replace the related panels and the

components.

13mm

50mm

GAP = ONE AND ONE-HALF TIMES

THE THICKNESS OF THE METAL

3-32 2002 Avalanche

Page 33

Rear Module

Replacement

Removal Procedure

1. Remove all related panels and

components.

2. Restore as much of the damage as

possible to factory specifications.

3. Support the rear of the body at the

outer edges of the rear cross sill to

keep the vehicle stable while

performing rear module

replacement.

4. Locate the rear module factory

seams (1) in front of rear axle

trailing arm mounts.

1

PRELIMINARY

5. Cut each frame rail at the rear edge

of the factory weld.

6. Remove the damaged rear frame

module.

—continued

2002 Avalanche 3-33

Page 34

Rear Module Replacement

Removal Procedure con’t

7. Grind remaining portion of rear rails

back to middle section.

8. Remove the remaining section of

the rear rails from the inside of

middle section.

9. Remove the wax coating from inside

and outside surfaces of the middle

rails.

PRELIMINARY

3-34 2002 Avalanche

Page 35

Rear Module

Replacement

Installation Procedure

1. Prepare all bare metal surfaces as

necessary.

2. Install and position the replacement

module using three-dimensional

measuring. Refer to frame

dimensions.

3. Tack weld the rear module into

position.

PRELIMINARY

IMPORTANT: Check all

measurements three-dimensionally to

ensure proper position of the rear

module. Refer to frame dimensions.

4. Continuous-weld upper and lower

horizontal joints from corner to

corner.

5. Continuous-weld inner and outer

vertical joints from corner to corner.

6. Clean and prepare the welded

surfaces.

7. Apply suitable wax coating to the

inside and the outside of the rails at

the repair locations.

8. Install all related panels and

components.

2002 Avalanche 3-35

Page 36

SRIM Composite

Repair

The Avalanche midgate and tailgate, as

well as the Chevrolet Pro-tec

pickup box, can be repaired using SRIM

composite repair procedures.

®

composite

Repair Procedure

1. Remove all related panels and

components.

2. Clean front and back sides of area

to be repaired.

3. On both sides of the damaged area,

use an 80 grit disc on a D.A. sander

to feather out the area where repair

is to be performed.

4. Bevel the edges on both sides of the

damaged area with a 50 grit abrasive

disc.

5. Clean the repair area with a tack rag

and compressed air.

—continued

3-36 2002 Avalanche

Page 37

GLASS CLOTH MAT

BEVELED EDGE

EXISTING PANEL

GLASS CLOTH MAT

ADHESIVE

BEVELED EDGE

EXISTING PANEL

SRIM Composite Repair

Repair Procedure con’t

6. Create a multi-layered

reinforcement patch, as shown,

using the procedure outlined in

steps 7–27.

7. Cut one piece of glass cloth mat to

form a patch large enough to extend

38 to 50 mm (1-1/2 to 2␣ in.) beyond

the damaged area.

8. Apply an 8 mm (1/4␣ in.) layer of

repair material (contact SIA

Adhesives, Inc. customer service at

1-330-374-2468 for SRIM repair kit

P/N 30208030001) to a piece of

release paper, such as wax paper or

polyethlene film, covering an area as

large as the glass cloth mat patch.

9. Place the pre-cut piece of mat over

the pool of repair material.

—continued

2002 Avalanche 3-37

Page 38

SRIM Composite Repair

Repair Procedure con’t

10. Apply an 8 mm (1/4␣ in.) layer of

repair material over the glass cloth

mat.

12. Place a second sheet of release

paper over the repair patch.

12. Roll patch with saturation roller

until the mat is completely saturated

with repair material.

13. Separate the two sheets of release

paper.

14. Apply repair material over the

backside of the damage Use an

applicator to spread repair material

38 to 50 mm (1-1/2 in to 2␣ in.)

beyond the damaged area.

15. Place the repair patch over the

backside of the repair area, use an

applicator to smooth the patch out

and remove all trapped air.

16. Secure the release paper and patch

in place with tape.

—continued

3-38 2002 Avalanche

Page 39

SRIM Composite Repair

Repair Procedure con’t

17. Cut two pieces of glass cloth mat

large enough to cover the beveled

area on the front side of repair.

18. Mix and apply a layer of repair

material to the front of the repair,

repair material should be at a level

slightly above the surrounding area.

19. Lay a pre-cut piece of mat into the

repair material, use an applicator to

saturate the mat and remove all

trapped air.

20. Apply a second coat of repair

material and smooth out the surface

with an applicator.

—continued

2002 Avalanche 3-39

Page 40

SRIM Composite Repair

Repair Procedure cont’d

21. Place the second layer of pre-cut mat

over the repair material, smooth out

and remove all trapped air.

22. Apply a third coat of repair material

to the front of the repair, and place

a sheet of release paper over it. Use

a saturation roller to ensure full

saturation of repair material into the

mat.

23. Cure the repair material according

to the adhesive manufacturer’s

recommendations.

24. Rough out the repaired surface with

an 80 grit disc on a dual-action

sander.

25. Apply necessary skim coats of repair

material until surface contour is

achieved.

—continued

3-40 2002 Avalanche

Page 41

Composite Box

Repair Procedure cont’d

26. Finish contour sanding with a 220

grit abrasive or finer.

27. Refinish as necessary. Follow paint

manufacturer’s recommendations

for application instructions.

2002 Avalanche 3-41

Page 42

Avalanche Panel Identification (Metal)

1

3

1

1

1

2

1

2

1

3-42 2002 Avalanche

1. Two-Sided Glavanized Steel

2. Ultra High-Strength Steel

3. Mild Steel

Page 43

Avalanche Panel Identification (Plastic)

3

1

1

3

1

2

1

1

1

1

1

4

1

1

1. Thermoplastic Olefin (TPO)

2. Fiberglass Reinforced Polyester

3. Structural Reaction Injection Molded (SRIM)

4. Polyolefin

2002 Avalanche 3-43

Page 44

2000 and Newer Chevrolet Suburban/GMC Yukon XL

2002 Chevrolet Avalanche

Frame Dimensions

1459

1343

1632

1714

Ø

388 411 522 601 500

C

L

1829

1921

2145

2212

C

L

562

A

552 382 351 574

B

1441

1327

1827

C

Ø

D

3732

Description Location Length Width Height

13 mm hole A 1441 388 562

32 mm hole B 1327 411 552

22 x 19 mm slot zero line C 0 522 382

33 x 17 mm hole D 1827 601 351

19 mm hole E 3732 500 574

All dimensions are measured in millimeters, from a zero line, center line, and a common datum. All dimensions are symmetrical, unless otherwise specified.

3-44 2002 Avalanche

ØØ

E

Loading...

Loading...