Chesney's Beaumont 8SGS, Alpine 6SGS, Belgravia 8SGS, Beaumont 6SGS, Salisbury 8SGS User And Installation Instructions Manual

...Page 1

0

Page 2

1

Technical Manual

PIN: 0558CM1311

User and Installation Instructions

Model No. 8SGS – 6SGS

Model Names

8 Series Gas Stoves

6 Series Gas Stoves

Beaumont 8SGS

Alpine 6SGS

Belgravia 8SGS

Beaumont 6SGS

Salisbury 8SGS

Belgravia 6SGS

Shipton 8SGS

Salisbury 6SGS

Shoreditch 8SGS

Shipton 6SGS

Shoreditch 6SGS

Available in Natural Gas.

IMPORTANT:

Please read these instructions carefully before installation or use.

This appliance must be installed and serviced by a qualified person in

accordance with local and national regulations.

The flue system must be installed and inspected by a qualified person in

accordance with local and national regulations.

Page 3

2

Contents

Section

Pages

1

Unpacking

3 2 Technical data

4-7

3

Installation parameters

8-9

4

Balanced flue configurations / information

10-14

5

Appliance setup information

15-22

6

Control system information

23-34

7

Injector information

35 8 Placement of fibre logs and embers

36-38

9

Commissioning the fire unit

39 - 40

10

Briefing and handover to the customer

40

11

Servicing and maintenance

41-56

12

Fault finding

57

13

User Instructions

58-63

Fireguards

58

Lighting the appliance

60-61

Changing the batteries

62

Cleaning

63

14

Installer checklist

64

15

Dealer and Installer Information

64

16

Annual Service Record

65

Page 4

3

1. Unpacking

Remove the appliance from its packaging, and check that it is complete and

undamaged.

If satisfied by the condition and the contents is as specified, proceed with the

installation.

The installation should only be carried out by a competent person and all gas work

must be carried out by a Gas Safe Registered person in accordance with national

and local regulations for both gas and electricity (If required).

The installation must comply with local and national building regulations.

For the Republic of Ireland, reference should be made to IS813 and ICP3 and any

guidance notes from Bord Gais.

Failure to comply with the regulations nullifies ALL guarantees.

Parts

Gas Stove Appliance 3 Piece log set

Embers Installation Manual

Page 5

4

2. Technical Data

Chesney’s gas stove specifications

Gas Connection Size

8.0mm O.D. tubing

Pilot Assembly

SIT NG 9029

Control System

Mertik Maxitrol GV60 (Radio Frequency)

Appliance Mass Range (kilograms)

65.5-91.0

Gas

Type

Gas Category, Type

and Supply Pressure

Countries of Destination

AT

BG

BE

CH

CZ

DE

DK

EE

ES

FI

FR

GB

GR

HR

IE

IT

LT

NG

I

2H

- G20 at 20mbar

Gas

Type

Gas Category, Type

and Supply Pressure

Countries of Destination

LU

LV

NO

PL

PT

RO

SE

Sl

SK

TR

NG

I

2H

- G20 at 20mbar

Gas

Type

Gas Category, Type

and Supply Pressure

Injector

(1 per appliance)

Nominal Heat Input

kW, Gross/Net

Gas Rate

m3/h

Burner

Pressure (mbar)

Full / Reduced

Efficiency

Class

NOx

Class

Marking

Size

(single)

NG

I

2H

- G20 at

20mbar

1.80

1.8mm

5.6 / 5.0

0.533

19.7 / 14.6

(±0.3)

2

5

Efficiency and Heat Output

Efficiency

%, Net

Heat Output

kW, Net

76.7-81.2

3.8-4.1

Page 6

5

8 Series

Model

Overall dimensions (mm)

Approx.

weight

Balanced

flue

Log

fire

Back and Top

Flue Exits

Flue System

(mm)

W H D (kg)

Alpine 6

460

686

390

91

External 150 (6”)

Internal 100 (4”)

Beaumont 8

642

704

395

76

External 150 (6”)

Internal 100 (4”)

Beaumont 6

522

704

395

68

External 150 (6”)

Internal 100 (4”)

Belgravia 8

642

704

395

77

External 150 (6”)

Internal 100 (4”)

Belgravia 6

522

704

395

69.5

External 150 (6”)

Internal 100 (4”)

Salisbury 8

570

653

428

80

External 150 (6”)

Internal 100 (4”)

Salisbury 6

450

653

428

69

External 150 (6”)

Internal 100 (4”)

Shoreditch 8

568

685

378

72.5

External 150 (6”)

Internal 100 (4”)

Shoreditch 6

448

485

378

66

External 150 (6”)

Internal 100 (4”)

Shipton 8

608

634

378

73

External 150 (6”)

Internal 100 (4”)

Shipton 6

488

634

378

65.5

External 150 (6”)

Internal 100 (4”)

SALISBURY SHIPTON BEAUMONT SHOREDITCH BELGRAVIA

Page 7

6

6 Series

SALISBURY SHIPTON BEAUMONT SHOREDITCH ALPINE BELGRAVIA

Page 8

7

Clearances

The minimum distances between the appliance and any walls and/or shelves are

marked below.

Shelf = 250mm

Wall (side) = 100mm

Wall (rear) = 50mm

It is also advised against placing combustible materials or soft furnishings directly

in front of the appliance.

Main Balanced Flue Parts

Product Code for Stainless Steel

Air Intake Collar

CH 150

Emissions Exit Collar

CH 100

Air Intake Gasket

CH 150G

Emissions Exit Gasket

CH 100G

Blanking Plate Gasket for Air Intake

CH 100G

Wall Terminal Style 1

CH USDHC2 10

Wall Terminal Style 2

CH USDHC3 10

Roof Terminal

CH USDVC2 10

15° Bend

CH USB1510

30° Bend

CH USB3010

45° Bend

CH USB4510

90° Bend

CH USB9010

200mm Straight

CH US2010

500mm Straight

CH US5010

1000mm Straight

CH US10010

Locking Band

CH USKB

Flexi Tube

CH XE/XD

Flue Brackets

CH USMB

Renovation Set

CH USSAN

Renovation Set Top

CH USSAN1 10

Renovation Set Bottom

CH USSAN2 10

Wall Terminal Guard Style 1

CH TG18161 for CH USDHC2 10 Terminal

Wall Terminal Guard Style 2

CH TG11116 for CH USDHC3 10 Terminal

Page 9

8

3. Installation Parameters

This appliance must be installed in accordance with the rules in force, and used

only in a sufficiently ventilated space. Consult instructions before installation and

use of this appliance.

NOTE – This appliance is heavy, care must be taken when installing or servicing to

avoid personal injury.

Wear protective clothing when fitting or carrying works out on the appliance.

For your safety it is law that all gas appliances must be installed by a competent

person, in accordance with the current gas safety regulations applicable in the

country of use.

The installation must be carried out in accordance with the relevant local and

national specifications and comply with current building regulations.

If there is any conflict between these instructions and the current regulations, then

the current regulations are to be followed.

Hearths

The area where the appliance is to be fitted must have a suitable load-bearing

capacity for both hearth and appliance and must stand on a non-combustible

hearth. Check building regulations.

If you are using an existing hearth check it complies with the relevant construction

regulations and is at least the minimum sizes specified.

Hearth and clearance dimensions must comply with the requirements and satisfy

Building Regulations – Approved Document J.

NOTE - The flue must not be shared with any other appliance.

Before installation, ensure that the local distribution conditions (identification of the

type of gas and pressure) and the adjustment of the appliance are compatible.

Before the appliance is installed, the flue must be inspected to ensure that it is

structurally sound and free from obstructions.

Before the appliance is installed ensure the correct restrictor plate is fitted and the

aeration is set for the type of flue installation.

For opening the door please read instructions on page 43.

The flue must be fitted in accordance with Local and National regulations.

The flue system must be in good condition, meet all regulations and work correctly.

The flue must be inspected by a competent person and passed for use with the

appliance.

It is advised that flue specialist inspect the flue system on an annual basis to

ensure that the flue system is sound and the combustion products outlet (terminal)

is clear of obstruction.

Page 10

9

It is advised that provisions be made for the removal of the appliance without the

need to dismantle the flue system.

The gas connection must be in accordance with Local and National regulations.

This appliance is intended for use on a gas installation with a governed meter.

The pilot fitted to this appliance is not to be adjusted or put out of action. If the pilot

is damaged or faulty it should be replaced only with the original identical unit

supplied by Chesney’s Limited.

The appliance is not fitted with an integral guard. It is recommended that a guard

be used for the protection of young children, the elderly or infirm and also for

normal use conforming to BS8423:2002, such that access to the hot appliance is

minimised.

Do not place combustible materials directly in front of the appliance. Floor

coverings, such as carpets, are considered to be acceptable.

All parts of the appliance are hot so can be considered to be a working surface.

Due to the newness of materials, the fire may give off a slight smell for a period of

time after commissioning and that a window or door to the outside can be opened

to ventilate the odours. This is quite normal due to the curing of paints and

materials avoid touching the paintwork during this curing process, any odours

should disappear within a few hours of operation.

Page 11

10

4. Balanced flue configurations / information

Positioning of balanced flue outlets.

Minimum Distances for terminals

1) 1500mm from a structure on the roof.

2) 600mm above the highest point of intersection with the roof.

3) Flue must not penetrate the shaded area (separation distance of 600mm).

4) Flue must not penetrate the shaded area (separation distance of 2000mm).

5) 300mm below gutters, soil pipes or drain pipes.

6) 300mm below the eaves.

7) 300mm above the ground, roof or balcony level.

8) 300mm below an opening.

9) 300mm horizontally from a terminal on the same wall.

10) 600mm from an internal or external corner or to a boundary alongside the

terminal.

11) 1200mm vertically from a terminal on the same wall.

12) *300mm above an opening.

13) 600mm below a balcony or car port roof.

14) 1200mm from an opening in the car port into the building.

15) 600mm from a surface or boundary facing the terminal.

16) *300mm horizontally to an opening.

17) 300mm from a vertical drain pipe or soil pipe.

18) 600mm from a terminal facing the terminal.

Note * An opening – meaning an openable element e.g. an openable window,

a fixed opening such as air vents.

In addition the terminal should not be nearer than 300mm (natural draught) to

an opening in the building fabric formed for the purpose of accommodating a

built-in element such as a window frame.

Page 12

11

Types of chimney or flue

Chesney’s Gas stoves are Balanced Flue appliances this means they vent directly

outside through a co-axial tube (one tube within a larger tube). The outer tube

draws air in from the outside and the inner tube expels the combustion gases.

These appliances can be routed through an existing chimney, a pre-fabricated flue

or where a room has no chimney.

Below are flue systems available for all 8 series and 6 series gas stove

models.

Balanced Flue

A Balanced Flue consists of a tube inside a larger

tube that emits products of combustion and an

outer tube feeds outside air into the stove for

combustion.

If the room has no chimney a balanced flue option

can be used.

Options

1. Top flue exit /up and out :

Vertical - 1m minimum, Horizontal –

475mm maximum (length of wall terminal

piece)

or

Vertical - 1.5m minimum, Horizontal –

1m minimum / 7m maximum plus length of

wall terminal

2. Top flue exit :

Vertical 1m minimum / 8m plus length of

terminal

3. Top flue exit / offset vertical :

1m minimum to first bend / 8m maximum

flue length.

4. Rear flue exit vertical :

Horizontal - 0.5m minimum / 1m

maximum, Vertical – 1.0m minimum

Page 13

12

Vertical Terminal

Vertical terminal – CH/USDVC2 10 Full

flue restrictor fitted

The appliance is usable with:

1. 1.0m minimum vertical height up to

a height of 8.0m plus length of

terminal.

Other combinations are possible provided

the vertical height is not below the

minimum.

Page 14

13

Up and out the wall Terminal

Wall terminals – CH/USDHC2 10

/ CH/USDHC3 10

No flue restrictor fitted

The appliance is usable with:

1. a 1.0m minimum vertical with

a maximum horizontal length of

0.475m (length of wall terminal

piece).

2. a 1.5m minimum vertical with

a maximum horizontal length of

7.475m (length of flue sections

and wall terminal piece).

Other combinations are possible

provided the vertical height is not

below the minimum and the

maximum horizontal length is not

exceeded.

Vertical Terminal rear flue exit

Vertical Terminal – CH/USDVC2 10

Part flue restrictor fitted

The appliance is usable with:

1. a 0.5m to 1.0m (maximum)

horizontal length with a minimum

vertical length of 1.0m and a

maximum of 8.0m plus terminal.

Page 15

14

Terminal Guards

The flue outlet should be protected with a terminal guard if persons could come into

contact with it, or if it could become damaged or if a flue outlet is in a vulnerable

position such as where the flue discharges is within reach from the ground (less

than 2 meters), balcony, veranda or an opening window.

Sealing the flue to the appliance

The flue must be sealed to the appliance to ensure the products of combustion do

not enter the room.

A suitable heat proof sealant that can withstand temperatures of up to 1200°C is

recommended.

Apply a bead of sealant to the inner face of the outer flue collar and the outer face

of the inner flue pipe then attach the flue to the collars.

Page 16

15

5. Appliance setup information

Chesney’s Alpine

WARNING – This appliance is heavy

Lifting this appliance requires 2 persons.

Handle the appliance with care to avoid damage.

Page 17

16

The images below are of the Salisbury – Appliances Shoreditch, Shipton,

Beaumont, and Belgravia have the same controls, body and internals, only the top

panel, legs and door have differences.

All appliances are supplied with a metal data plate attached to it and must remain

with the appliance for annual services.

Image of the data plate shown below:-

Page 18

17

Changing the flue opening

For opening the door please read instructions on page 43.

If the flue is to be changed to run through the rear of the appliance follow these

steps.

Step 1

Alpine model

Remove the door by taking the weight of the door at 90° remove the hex socket

bolts circled to release the door clear from the hinges and remove the controls

access door.

Other models remove the stove top.

Step 2

Remove the rear exit panel by cutting off the lugs to access the rear blanking

plates.

Step 3

Remove both blanking plates.

Page 19

18

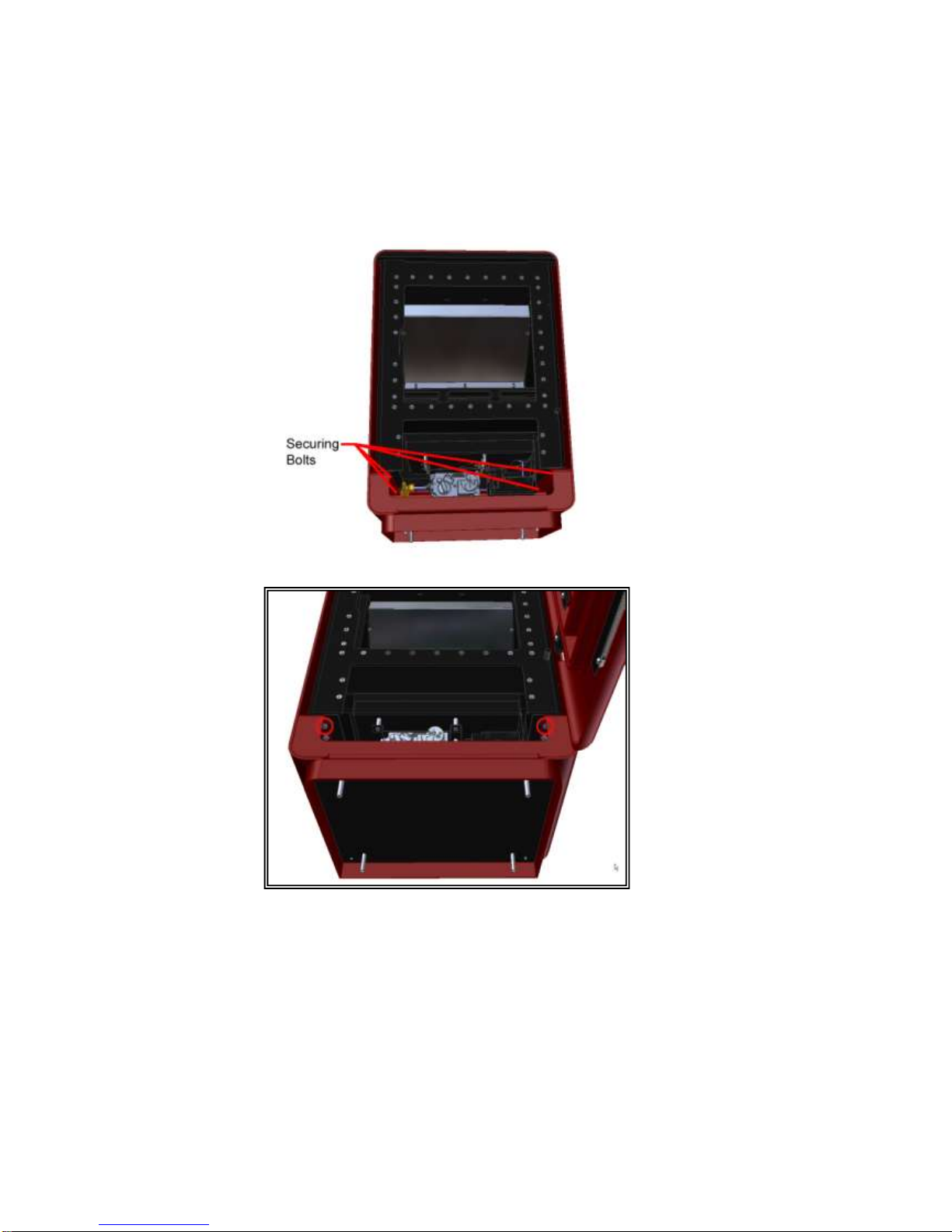

Step 4

(Alpine model only)

Remove the 4 securing bolts shown below to allow the movement of the gas cube

in the cladding.

Step 5

(Alpine model only)

Remove the inner flue collar then unscrew the outer flue collar by moving the gas

cube slightly within the cladding to access all the screws.

Step 6

(Alpine model only)

Lift the gas fire cube clear from the Alpine cladding to release the outer flue collar.

Page 20

19

Step 7

Swap over the flue collars and blanking plates and ensure all parts are sealed then

refit the fire cube.

Step 8

Refit the door and adjust the box within the Alpine cladding to re-line up the door

then re-tighten up the bolts then fit the blanking plate over the opening.

Page 21

20

Fitting the restrictor plate

Important

Before fitting the appliance check the flue setting to see if a flue restrictor plate is

required.

All wall terminals (CH/USDHC2 10 / CH/USDHC3 10) do not require a restrictor

plate.

Both restrictor plates are fitted as standard, if they are to be adjusted or removed,

access is made by removing the baffle plate via the 5 screws circled below.

NOTE: The baffle plate must be refitted.

(Below shows image behind the baffle plate)

The appliance is supplied with restrictor plates and are attached to either the

opening or the blanked off opening via 2 x 7mm nuts.

Only certain configurations use restrictor plates and these are listed in the table

below (also refer to pages 12-13):

Restrictor

Configuration

Vertical Terminal [CH USDVC2 10]

Top Flue Connection

Up and Out Wall Terminal

[CH USDHC2 10 or CH USDHC3 10]

Vertical Terminal [CH USDVC2 10]

Rear Flue Connection

Part Restrictor X X

Full Restrictor X

X

Full Restrictor Plate shown below

Part Restrictor Plate shown below

Page 22

21

IMPORTANT NOTE

Setting up the aeration.

The appliance aeration must also be set according to how the flue is set.

Under the appliance is a screw located next to the injector, when screwed fully out

the aeration is closed and when screwed fully in the aeration is open.

Only adjust the aeration when the appliance is cool.

Using a mirror can help locate the adjustment screw.

The screw can be adjusted by using a short cross headed screw driver.

The appliance aeration should be set when the particular flue configuration has

been chosen and before the appliance has been operated for the first time.

If the appliance is fitted with:

- the vertical roof terminal [CH USDVC2 10] configuration, the aeration must be

adjusted so that the aeration is at the Minimum setting;

- the Up and Out wall terminal [CH USDHC2 10 or CH USDHC3 10]

configuration, the aeration must be adjusted so that the aeration is at the

Maximum setting;

- the vertical roof terminal [CH USDVC2 10], rear flue configuration, the aeration

must be adjusted so that the aeration is at the Maximum setting;

A summary of the allowable aeration/restrictor and flue configurations is given in

the table below as follows:

Restrictor

Configuration

Vertical Terminal [CH USDVC2 10]

Top Flue Connection

Up and Out Wall Terminal

[CH USDHC2 10 & CH USDHC3 10]

Vertical Terminal [CH USDVC2 10]

Rear Flue Connection

Part Restrictor X X

Full Restrictor X

X

Aeration Setting

Minimum (fully closed)

Maximum (fully open)

Maximum (fully open)

IMPORTANT NOTE – THE AERATION SCREW IS FACTORY SET & SEALED IN THE FULLY

CLOSED POSITION if the aeration is to be adjusted the screw must be re-sealed after setting. (Paint

is to be used to seal the threads).

Alpine model Other models

Page 23

22

All Chesney’s appliances have been tested to ensure safety.

NOTE – All gas work must be carried out by a qualified gas installer to all relevant

regulations.

Ensure that the gas supply is capable of delivering the required amount of gas, and

is in accordance with the rules in force.

Lay the appliance in the desired area to note where the appliance’s gas inlet

location to ensure a smooth run.

An isolation valve or valves must be fitted near to the appliance in accordance with

national regulations to allow the complete removal for maintenance or repair.

Before connecting the fire unit purge the pipes from air and debris.

Page 24

23

6. Control system information

Features and Options

No external electrical power required.

Used with standard thermocouple and standard ODS pilot

Flame height adjustment with remote control or switch

Compact design with large capacity

Thermoelectric flame failure device

Safety interlock

Pressure regulator or throttle

Minimum rate selling with fixed or adjustable orifices

Pilot gas adjustment screw

GV60 models require no external electrical power to operate. The batterypowered motor allows main gas adjustment via an electric switch or remote.

The thermoelectric flame failure device functions with all standard

thermocouple and ODS pilot burners (no powerpile necessary).

Page 25

24

WARNING

Fire or explosion hazard. Attempted disassembly or repair of controls can cause property damage,

severe injury or death. Do not disassemble the gas valve; it contains no serviceable components.

For your safety, read the user instructions before attempting to light the appliance.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this control or other

appliances.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your building.

Immediately call the gas supplier from a neighbour’s phone. Follow the gas supplier’s instructions.

If you cannot reach the gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

The installation must conform with local codes or in the absence of local codes, with the National Fuel

Gas Code, ANSI Z223.1/NFPA 54 or The International Fuel Gas Code or B149.1 in Canada.

All piping and tubing must comply with local codes and ordinances.

Do not use this control or any gas appliance if any part has been under water or in contact with water.

Immediately call a qualified service technician to replace the control system and any gas control which

has been under water or in contact with water.

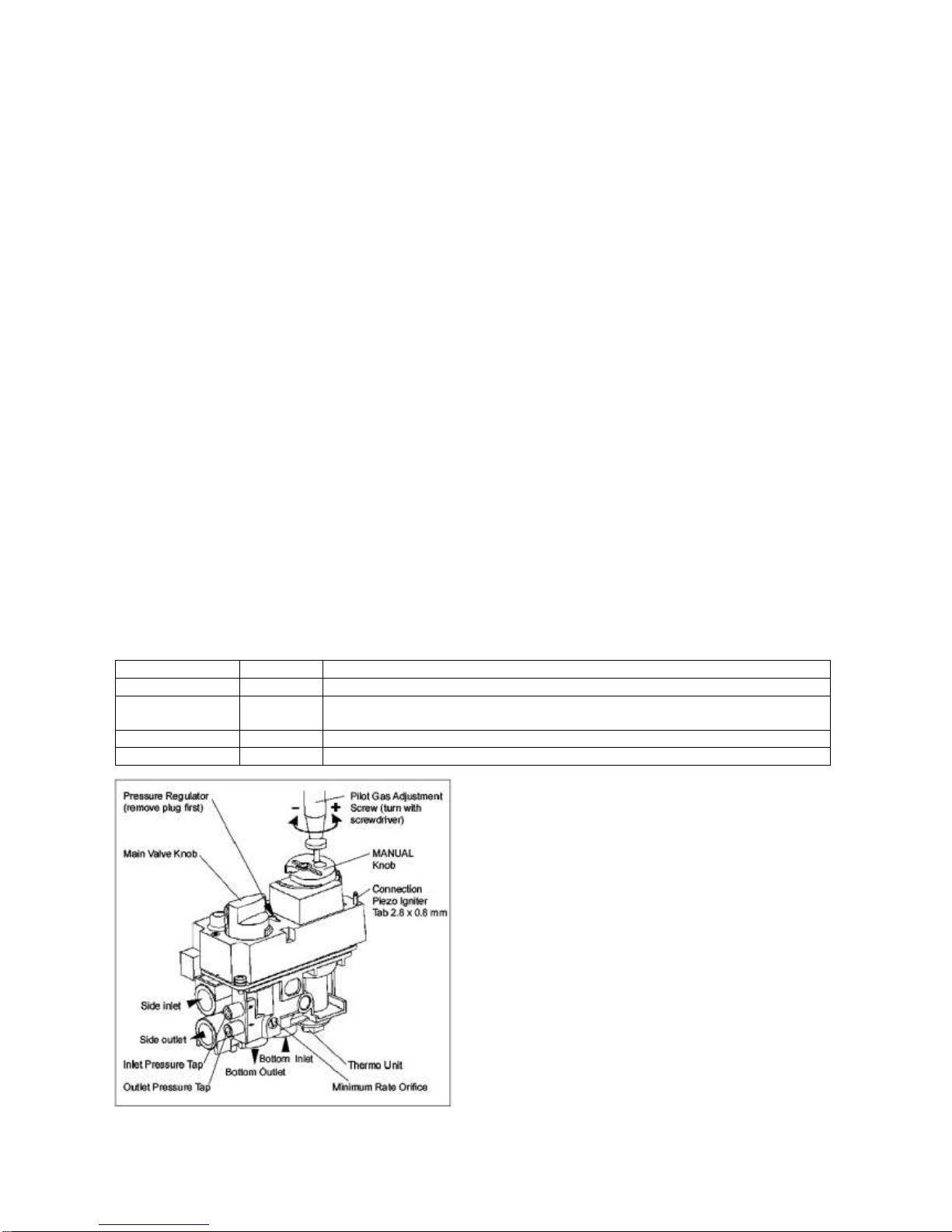

COMPONENTS

The standard GV60 system consists of the

following components (see figure 1).

Gas Combination Control (GV60 Series)

with:

ON/OFF switch with soldered cable or

Thermo current cable #2 interrupter –

receiver

Thermo current cable #1 interrupter –

receiver

Thermo current interrupter block

Ignition cable

Remote Control

Remote handset

Receiver

8 wire cable (connects valve to receiver

Figure 1; GV60 components

Page 26

25

TECHNICAL SPECIFICATIONS

Gas combination control according to CSA or CE approval (see label for certification)

Fuels:

CSA: Suitable for use with natural, manufactured, mixed and propane (LP) gases and LP gas-air

mixtures.

CE: Suitable for use with gases of EN 437 gas family 1,2, and 3.

Approvals:

ANSI Z21.78/CSA 6.20 FOR U.S. & Canada.

CE: Gas Appliances Directive 90/396/EEC and EN126

Pressure Drop/Capasity:

CSA : 1’’ W.C. at 65,000 BTU/hr.

CE: 2,5 mbar at 1,2m³/h air

Range of Regulation:

CSA: 10,000 to 85,000 BTU/hr.

CE: Class C according EN88

Regulator Adjustment:

CSA:3” W.C. to 5” W.C. (7.5 to 12 mbar); 8” W.C. to 12” W.C. (20 to 30 mbar); 3” W.C. to 12” W.C. (7.5

to 30 mbar)

CE: 5 to 40 mbar; 7,5 to 30 mbar

Max. Ambient Temperature:

32°F to 176°F (0°C to 80°C)

Mounting Position:

Mount valve 0° to 90° in any direction (Including vertically) from the upright position of the gas control knob.

Max. Inlet Pressure:

CSA: ½ psi (34.5 mbar)

CE: 50 mbar (20”W.C.)

Main Gas Connection:

CSA: 3/8 in. NPT; Rp 3/8 ISO 7-1 internal thread for 12mm, 10mm, 8mm, 6mm outside diameter tube.

CE: Rp 3/8 ISO 7-1 internal thread for 12mm, 10mm, 8mm, 6mm outside diameter tube

Inlet and Outlet Connection:

At side or bottom

Pilot Gas Connection:

CSA: 7/16-24 UNS for 1/4” or 3/16” tubing

CE: M10x1 for 4mm or 6mm tubing

Thermocouple:

11/32 UNS, M10x1, M9x1, M8x1

Maximum allowed torque inlet and outlet:

CSA: 280 inch-pounds

CE: 35 Nm

Page 27

26

Remote

NOTE: These remote handsets, receiver, wall switches, switch panels and touch pads are not

interchangeable with previous versions.

Approvals:

ANSI Z21.20/CSA 6.20 for U.S. & Canada.

CE: Gas Appliances Directive 90/396/EEC and EN298-2003

Max. Ambient Temperature:

Remote Handset and Receiver: 140°F (60°C)

Wall Switch/Touch Pad: 176°F (80°C)

Switch Panel: 221°F (105°C)

8 Wire Connecting Cable, Thermo Current Cable: 221°F (105°C)

Ignition Cable: 302°F (150°C)

Batteries – Remote Handset:

1 x 9V Block (quality alkaline recommended)

Batteries – Receiver:

4 x 1.5V “AA” (quality alkaline recommended)

An AC Mains Adapter may be used instead of batteries (only the Mertik Maxitrol AC Mains Adapter or one

approved by Mertik Maxitrol can be used).

NOTE: During a power outage the AC Mains Adapter must be unplugged from the receiver to

operate in the battery mode.

INSTALLATION INSTRUCTIONS

Read these instructions carefully. Failure to follow them could damage the product or cause a hazardous

condition. These instructions are not to supersede the appliance manufacturer’s instructions.

WARNING

It is the appliance manufacturer’s responsibility to determine GV60’s suitability for a specific application.

WARNING

Do not remove screws from the gas valve. Do not adjust and/or alter any components marked with

tamper indicating paint; Motor knob is not to be removed.

WARNING

Oxygen Depletion is a hazard and can cause injury or death due to asphyxiation. Use only components

intended for vented gas appliances on vented appliances and unvented gas components on unvented

gas appliances.

1. Turn off gas supply at the appliance service valve before starting installation, and perform a Gas Leak

Test after the installation is complete.

2. Install the sediment trap (where required) in the gas supply line to prevent contamination of the gas

valve.

3. Use only your hand to push in or turn the gas control knobs. Never use tools. If a knob will not push

in or turn by hand, don’t try to repair it, call a qualified service technician. Force or attempted repair

will void warranty and can result in a fire or explosion.

Location

Locate the combination gas valve where it is not exposed to steam cleaning, high humidity,

dripping water, corrosive chemicals, dust or grease accumulation or excessive heat. To

assure proper operation, follow these guidelines:

Locate combination gas valve in a well-ventilated area.

Mount combination gas valve high enough to avoid exposure to flooding or splashing water.

Page 28

27

Make sure the ambient temperature does not exceed the ambient temperature ratings for each component.

WARNING

GV60 standard version is suitable for indoor use only.

CONNECTIONS – MAIN AND PILOT GAS

WARNING

Fire or Explosion Hazard. Can cause property damage, severe injury or death. Do not bend tubing at

gas valve connection point after compression fitting has been tightened. This can result in gas leakage at the

connection.

All piping must comply with local codes and ordinances or with the National Fuel Gas Code, ANSI Z223.1/NFPA

54 or The International Fuel Gas Code or B149.1 in Canada. Tubing installation must comply with approved

standards and practices.

1. Use new, properly reamed pipe free from metal or material chips. When tubing is used, assure that the ends

are square, deburred and clean. All tubing bends must be smooth and free of distortion.

2. Run pipe or tubing to the valve.

3. Install a sediment trap (where required) in the supply line to the gas valve (see figure 2)

Figure 2: Sediment Trap (where required)

WARNING

The main gas valve must be disconnected from the gas supply piping system during any pressure testing of

the gas supply piping system at test pressures in excess of ½ psi (3.5 kPa CSA; 50 mbar CE).

Connection Main Gas (Tubing Connections)

1. Mount valve 0° to 90° any direction (including vertically) from the upright position of the gas control knob.

2. Slip nut and ferrule over tubing.

3. Insert tubing into inlet/outlet connection until it bottoms, slide ferrule and gland into place and turn finger tight.

Do not use pipe joint compound.

4. Use a wrench to tighten gland about 1 turn beyond finger tight.

Connection Main Gas (Pipe Connections)

1. Mount valve 0° to 90° any direction (including vertically) from the upright position of the gas control knob.

2. Pipe to be inserted into the valve must be the proper thread length and to gauge. Thread that is cut too long

can cause distortion or malfunction if inserted too deeply.

3. Apply a moderate amount of approved pipe sealant to the pipe only, leaving the two end threads bare.

(Do not use Teflon® tape.)

Connect pipe to valve inlet and outlet. When threads are tightened, the valve must be held at the designated

points (see figure 3). Do not apply pressure to top casting or plastic cover. Check all connections for leaks

Page 29

28

Connection Pilot Gas (Tubing Connections)

1. Ensure tubing end is square and free from burrs.

2. Insert pilot tubing into pilot outlet using fitting provided until it bottoms, and turn finger tight. Do not use

pipe joint compound.

3. Turn with wrench until you shear off the ferrule. Turn an additional ¾ turn to make a gastight seal.

4. Connect other end of tubing to pilot burner according to the manufacturer’s instructions.

Figure 3: S=Clamp Areas, B=Mounting Points

PERFORM GAS LEAK TEST

WARNING

Do not overtighten connections. Overtightening can damage the control body resulting in leakage or control

malfunction.

1. Using a clean brush, apply an approved leak test solution to the pipe connections. Bubbles indicate a leak.

2. If a leak is detected, tighten pipe connections.

3. Light the main burner.

4. With the main burner in operation, apply an approved leak test solution to all pipe connections (including

adapters) and the valve inlet and outlet. Bubbles indicate a leak.

5. If a leak is detected, tighten pipe connections (including adapters).

6. Replace parts if the leak cannot be stopped.

WIRING CONNECTIONS

WARNING

Wiring of valve and receiver must be completed before starting ignition. Failure to do so could damage

electronics.

Total resistance of the thermocouple circuit should be minimised to assure proper operation.

When GV60 components are installed, make sure they are not exposed to dirt, oil, grease or other

chemical agents.

Do not permit foreign particles under plastic cover.

Wiring must comply with diagram.

Place ON/OFF switch (if equipped) where it is easily accessible for the User.

Thermo Circuit

NOTE: The use of the Mertik Maxitrol interrupter block is recommended with the following connections.

Keep connection of Interrupter Block and Thermocouple clean and dry. Avoid severe bending of the

Thermocouple tubing during installation (min. 1” radius; 2.5cm) as this may cause it to fail.

Fasten ring terminals from Thermo Current Cable #1 and Thermo Current Cable #2 (or optional ON/OFF

Switch with soldered cable) tightly on the receiver with screws provided.

Install the interrupter block ¼ turn more than hand tight into the valve. Insert the spade connectors in the slots

(possible from both sides). Screw thermocouple hand tight into the interrupter block and tighten ¼ turn to

ensure a good electrical connection. Tighten only the thermocouple not the interrupter block.

Page 30

29

Ignition Cable

NOTE: Do not damage the ignition cable while attaching it to the ignition electrode. When the cable is in

place, avoid contact with sharp objects or edges.

Cables longer than 900mm, avoid contact with metal parts, as this could decrease spark.

Attach ignition cable to receiver tab 2.8 x 0.8mm (SPARK), and connect other side to ignition electrode.

Receiver

NOTE: To keep the receiver free from debris and dirt, Do not remove the receiver from the plastic bag until all

construction is complete. During a power outage the AC Mains Adapter must be unplugged from the

receiver to operate in battery mode.

Snap the plug of the 8 wire cable in the receptacle on the valve and receiver.

Insert batteries. Do not use metal tools. Using a metal tool could cause a short that may damage the

receiver.

Place ON/OFF switch (if equipped) to ON position.

Check the reception. If necessary, correct position of antenna by moving the antenna cable to a position that

allows for good reception.

When the RF-receiver is placed in the appliance, the surrounding metal can reduce reception considerably.

The position of the antenna on the receiver also influences reception.

The antenna must not come in contact or cross the ignition wire, this may render the receiver

inoperable.

GAS CONTROL KNOB SETTINGS

Gas control knobs function as follows (see figure 4):

KNOB

POSITION

FUNCTION

Main Valve

OFF

Prevents main gas flow through valve.

Main Valve

ON

Permits main gas flow through valve if the pilot is lit and thermocouple is

generating sufficient power.

MANUAL knob

MAN

Allows the pilot to be manually ignited and prevents main gas flow.

MANUAL knob

ON

Allows for automatic ignition.

Figure 4: Combination Control GV60, Connections and Adjustment Options

Page 31

30

ADJUSTMENT

WARNING

Do not adjust ODS (vent free) pilot.

WARNING

It is the appliance manufacturer’s responsibility to determine GV60’s suitability for a specific application.

WARNING

Do not attempt to remove screws from the top of the gas valve. Do not change any adjustments marked

with tamper indicating paint; Motor knob is not to be removed.

WARNING

Oxygen Depletion is a hazard and can cause injury or death due to asphyxiation. Use only components

intended for vented gas appliances on vented appliances and unvented gas components on unvented gas

appliances.

Pilot Flame adjustment

The pilot flow adjustment is pre-set to maximum at the factory. The pilot flame should envelope 3/8” to 1/2" of

the thermocouple – vented only (see figure 5).

1. The adjustment screw can be reached through a hole in the MANUAL knob (figures 4 and 8).

2. Turn the MANUAL knob to the ON position.

3. It is now possible to pierce through the film on the cover with a screw driver to reach the adjustment

screw beneath.

4. Turn the adjustment screw clockwise to decrease or counterclockwise to increase pilot flame.

Figure 5: Proper Flame Impingement on thermocouple

Outlet Pressure Adjustment

Pressure regulator or throttle are located under the cover and can be reached by removing the plug (see

figures 4 and 6).

WARNING

Do not exceed the input rating stamped on the appliance nameplate, or the manufacturer’s recommended

burner orifice pressure for size orifice(s) used.

WARNING

For complete combustion, be sure the primary air supply to the main burner is adjusted properly. Following

the instructions of the appliance manufacturer.

1. Connect a pressure manometer to the valve outlet pressure tap. Pressure tap is opened by turning the

screw counterclockwise .

2. To access regulator adjustment remove plug first (figures 4 and 6).

3. Turn MANUAL knob and main valve knob to the ON position.

4. Turn pressure regulator adjustment screw, accessible through opening in top of cover, to set required

burner pressure (high fire). Pressure is increased by turning clockwise (pressure regulator models),

or decreased by turning counterclockwise .

NOTE: Throttle models pressure is increased by turning counterclockwise ; or decreased by turning

clockwise .

5. After adjustment, replace the plug.

6. If no other adjustments are required, close pressure tap(s) by turning the screw(s) full clockwise .

Check all connections/pressure tap(s) for leaks.

Page 32

31

7. If the desired outlet pressure or flow cannot be achieved by adjusting the gas valve, check the gas valve

inlet pressure using a manometer at the valve inlet pressure tap. If the inlet pressure is in the normal

range, replace the gas valve; otherwise take the necessary steps to assure proper gas pressure to the

valve.

Minimum Gas Flow Adjustment (for CE Use only) (See figure 4)

1. Set the control into low fire setting by turning the motor knob in OFF-position and back until the valve

opens.

2. The minimum rate can be set either by screwing in a calibrated minimum rate screw (fixed orifice) or an

adjustable minimum rate screw. Controls with adjustable screws without a customer specific setting are

factory set at maximum flow.

3. Turn the screw clockwise to decrease the minimum flow.

4. Care should be taken to screw the fixed orifice until it stops.

5. Close pressure tap(s) by turning the screw(s) full clockwise . Check all connections/pressure tap(s)

for leaks.

Figure 6: Combination Control GV60, Cover

FINAL CHECK

Observe several complete cycles to ensure proper operation. During these cycles the electronics will

determine the optimum ignition sequence timing.

1. STOP! Read the safety information included before proceeding.

2. Turn main valve knob to the OFF, full clockwise position.

3. Place ON/OFF switch (if equipped) to the O (OFF position).

4. Wait five (5) minutes to clear out any gas. Verify that no gas is in the area around the appliance,

including near the floor. If you detect gas STOP! Follow “A” in the safety information of the

Operating Instructions. If no gas is present, proceed according to the Mertik Maxitrol Operating

Instructions GV60-OI-EN.

WARNING

Fire or explosion hazard. Attempted disassembly or repair can cause property damage, severe injury or

death. Do not disassemble the gas valve; it contains no serviceable components.

Page 33

32

OPERATING INSTRUCTIONS - FOR OEM USE ONLY

WARNING

Fire or explosion hazard. Attempted disassembly or repair of controls can cause property damage, severe

injury or death. Do not disassemble the gas valve; it contains no serviceable components.

If the information in this manual is not followed exactly, a fire or explosion may result causing property

damage, personal injury or loss of life

A. BEFORE OPERATING verify that no gas is in the area around the appliance, including near the floor.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your building.

Immediately call the gas supplier from a neighbour’s phone. Follow the gas supplier’s instructions.

If you cannot reach the gas supplier, call the fire department.

B. Use only your hand to push in or turn the gas control knobs. Never use tools. If a knob will not push in

or turn by hand, don’t try to repair it, call a qualified service technician. Force or attempted repair may

result in a fire or explosion.

C. Do not use this control or any gas appliance if any part has been under water or in contact with water.

Immediately call a qualified service technician to replace the control system and any gas control which

has been under water or in contact with water.

D. These instructions are to be referenced as a user guide, and do not supersede appliance

manufacturer’s lighting instructions.

APPLICATION

GV60 is a battery-powered electronic remote ignition and control system for gas appliances with

pilot burners and ODS systems

Figure 8 Combination Control GV60

Figure 7 Combination Control GV60

Page 34

33

GENERAL NOTES

Batteries – Remote Handset:

1 x 9V Block (quality alkaline recommended)

Batteries – Receiver:

4 x 1.5V “AA” (quality alkaline recommended)

An AC Mains Adapter may be used instead of batteries (only the Mertik Maxitrol AC Mains Adapter or one

approved by Mertik Maxitrol can be used).

NOTE: During a power outage the AC Mains Adapter must be unplugged from the receiver to operate in the

battery mode.

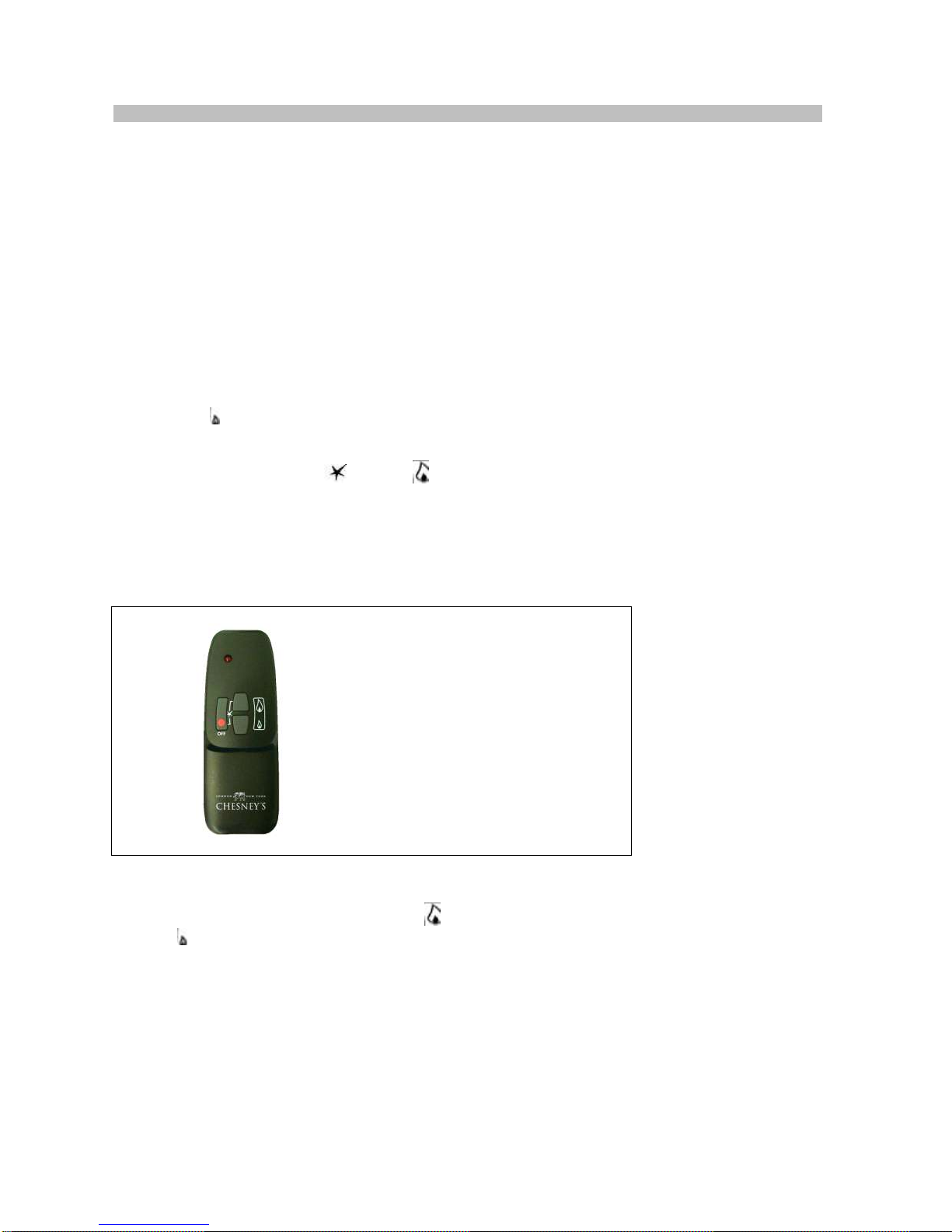

TO TURN OFF APPLIANCE

Press OFF button on remote handset.

NOTE: Press (small flame) to turn main gas to pilot gas.

Remote Handset (see figure 9)

Simultaneously press and hold (star) and (large flame) until a short acoustic signal confirms the start

sequence has begun; release buttons.

Continuing signals confirm the ignition is in process.

Once pilot ignition is confirmed, there is main gas flow.

NOTE: If the pilot does not stay lit after several tries, turn the main valve knob to OFF and follow the

instructions “Turn Off Gas to Appliance”.

WARNING – The appliance will get

hot whilst running; do not place the

remote handset on the appliance.

Figure 9 Remote Handset

Remote Handset (see figure 9)

To increase flame height press and hold the (large flame) button simultaneously.

Press (small flame) to decrease flame height or to set appliance at pilot flame.

For fine adjustment tap the large flame or small flame. There is a separate OFF button

NOTE: If the appliance will not operate, follow the instructions “TURN OFF GAS TO APPLIANCE”.

With very low battery the GV60 system shuts off the fire completely. This will not happen if the

power supply is interrupted.

Battery replacement

Battery replacement is recommended at the beginning of each heating season. Do not use metal tools to

remove batteries. Using a metal tool could cause a short that may damage the receiver.

Page 35

34

Page 36

35

Back log retaining bracket / pilot shield

The back log retaining bracket / pilot shield is located above the pilot and is

attached to the pilot bracket.

The back log sits on top of the bracket to ensure the log is in the correct area and

the bracket also improves pilot flame stability.

7. Injector information

NG Elbow Injector – Single hole drilled at 1.8mm

Only use genuine Chesney’s parts

Page 37

36

8. Placement of fibre logs and embers

Logs and glow embers are only available from Chesney’s stockists.

Important notes:

The placement of fibre logs and embers must be installed in accordance with these

instructions; any deviation may cause poor combustion.

If any of the components of the log effect burner are broken DO NOT INSTALL.

Do not to add more fibre logs onto the fire bed than specified.

This appliance is supplied with 3 fibre logs, and embers these must be placed in

the appliance as specified in this manual.

Log Placement

Log 1 must be fitted so that the mesh is located in the slot on the back of the log

pushing the log so that the location point is against the location pin.

Slot on the back of log 1 Location Point

Location Point Mesh Log behind this screw

Log 2

Log 2 has a location hole on the right side of the log.

Page 38

37

Locate the hole on the pin attached to the perforated bed laying the log against the

back wall of the appliance.

Embers

Place the embers all around log 1 ensuring there are no embers under log 2.

Log 3

Place log 3 so that the end of the log sits on the ledge of the bracket circled below

Page 39

38

On the underside of log 3 is a raised area this is to locate in the groove on Log 1

Lay the log at a 45 degree angle so that the log locates in the groove on log 1.

Fit the log retainer.

Page 40

39

9. Commissioning the fire unit

Turn on the gas supply.

Check the gas supply and gas appliance for soundness.

The appliance must be fully fitted, the door and glass on the appliance must be

sealed. Check areas around the door for gaps and that the rope seal is tightly

sandwiched between the door and enclosure. Check the glass for movement or

gaps and that there is no damage to the gaskets.

Lighting the appliance for the first time.

IMPORTANT NOTE - Ensure the door is firmly closed and locked before

turning on the appliance. Do not run the appliance if the is door open or if the

door glass has been removed or damaged.

When lighting the appliance for the first time, the materials (i.e. paint, sealants etc.)

may give off an unpleasant odour. This is quite normal and will disappear after a

few lightings. During this period, keep the room well ventilated.

Light the appliance and check that all available functions work correctly.

(See ‘Lighting the appliance’ in User Instructions for information).

Flame stability

The appliance should always be observed when lighting.

On starting the appliance an acoustic signal confirms the ignition is in process

IMPORTANT NOTE - The pilot will light soon after the acoustic signal has been

activated observations can be made by looking through the glass on the right side

under the back log.

If the pilot flame is extinguished either intentionally or unintentionally, allow 5

minutes before attempting to relight the appliance.

Once the acoustic signal stops the main valve opens to ‘High rate’ to allow gas

through to the main burner. All of the main burner should light within 6 seconds

lighting the whole burner area.

IF THIS DOES NOT HAPPEN THEN THE APPLIANCE SHOULD BE TURNED

OFF ALLOWING 5 MINUTES BEFORE ATTEMPTING TO RELIGHT.

Check the stability of the flame by turning to low rate then back to high rate then to

low rate doing this around three times whilst observing both pilot and main burner

flame, there should be no problems lighting the main burner.

Light the fire on maximum and run for at least 30mins or until the logs start to glow

before turning the appliance to low rate.

NOTE – The flames will start off blue until the appliance has heated properly before

turning more yellow.

With the appliance door closed check that all the products of combustion are

entering the flue and that no products of combustion are entering the building.

IMPORTANT- The door must be locked once the appliance has been commissioned.

Page 41

40

Alpine models - Lock the door using a hex key Other models – Lock the door using a

castle nut spanner clockwise to tighten

10. Briefing and handover to the customer

Instruct the customer on the full operation of the appliance.

Warn the customer that the fire unit may give off a temporary odour; this is normal

running in of the unit, and will disappear after a short period of use.

Inform the user that the appliance door is only to be opened when servicing, and

not to disturb the fibre logs as this may disturb the combustion.

Inform the customer that it is recommended that a full service on the fire unit and

flue checks be carried out annually by competent person/s.

Inform the user to always observe the appliance when lighting, once the acoustic

signal stops the main valve then opens to ‘High rate’ allowing gas through to the

main burner. The main burner should then light within 6 seconds IF THIS DOES

NOT HAPPEN THEN THE APPLIANCE SHOULD BE TURNED OFF ALLOWING

5 MINUTES BEFORE ATTEMPTING TO RELIGHT.

Instruct the customer that the pilot and flame sensing device fitted to the unit is

designed to shut off the appliance if the evacuation of the products of combustion

is interrupted.

If the appliance cuts off repeatedly then a qualified person is to be informed.

Warn the user that all parts of the appliance will become hot while the appliance is

running, so it is recommended that a guard conforming to BS8423: 2002 be used

for the protection of young children, aged or infirm persons.

Ensure the battery compartment is easily accessible so that the batteries can be

changed without the need to open the door and inform the user where it is placed.

Also advise the user not to stand too close to the appliance for prolonged periods

of time; loose clothing is particularly at risk of burning, and that rubbish cannot be

burned in the unit.

Advise the user against placing combustible material directly in front of the

appliance. Floor coverings, such as carpets, are considered to be acceptable.

Ensure the installer details are filled in.

Handover the installation manual to the customer.

Page 42

41

11. Servicing and maintenance

It is advised that the appliance is serviced annually by a qualified person to

Local and National Regulations.

Only carry out maintenance work when the appliance is cool.

Exchangeable components list

Pilot unit (natural gas) SIT-NG9029

Gas Injector (Natural Gas) Single hole / dia.1.8mm

Control Valve GV60

Controls Box Radio Frequency

Logs

Glow Fibre

Embers

Annual maintenance.

Safety precautions must be taken when cleaning the appliance.

Ensure the appliance is cool before carrying out a service.

Isolate the appliance and disconnect the unit.

Always test for gas soundness and spillage after refitting the appliance.

Check all logs, pilot burner/ignition unit, for soot or debris deposits.

Replace all misplaced logs and retest.

On the failure of pilot burner/ignition, or control valve have repairs carried out by a

competent person.

Paintwork

It is generally accepted that stove paintwork may need a light re-spray occasionally

after a seasons use, stoves painted in a lighter colour are more likely to require

this.

Touch-up spray is available from most Chesney’s stockists.

Wear appropriate safety equipment.

Ensure that there is adequate ventilation and that areas to be sprayed are clean and

dry. Make sure that all parts and the surrounding area that do not require paint are

properly masked up.

NOTE – Only re-spray when the appliance is off and cool following the safety

guidelines when carrying out such work.

Page 43

42

Door Handle information

Alpine model

To remove the handle unscrew the door locking grub screw then turn the

handle180° and remove the screw on the door handle boss.

On the underside of the handle boss is an opening, the handle must be facing

upwards to access the grub screw.

Using a 3mm Hexagon Key unscrew (counterclockwise) the grub screw to loosen

the handle and pull the handle and door boss from the mechanism.

Other models

Using a 3mm Hexagon Key unscrew (counterclockwise) the grub screws to loosen

the handle and pull the handle from the mechanism.

Page 44

43

Opening the door should only be carried out by a Gas Safe Registered

person

Important note - The door must only to be opened when servicing the appliance.

Only open the door when the appliance is off and cool.

Alpine model

On the Alpine the door is fitted with a grub screw to stop the door from being

opened (shown below). To open the door unscrew the grub screw using a 3mm

Hexagon key this releases the door mechanism to allow the handle to be turned.

When the service has been carried out close the door and refit the grub screw.

Other models.

Using the Castle nut spanner (provided) undo the castle nut to allow the handle to

open the door.

When the service has been carried out close the door then refit the locking nut and

door handle.

Page 45

44

Changing the door glass

Note attention must be paid to the curing time and temperature rating of the

silicone used with the glass and door seals.

Replacement glass is only available from Chesney’s stockists.

Only carry out a service or repair when the appliance is cool.

If the glass is damaged such as cracks or breaks do not use the fire until the glass

is replaced.

Wear appropriate safety equipment and take care when removing the glass panel.

On changing the glass the glass seal must also be renewed to ensure a good seal.

Remove the glass retaining brackets via the two screws on each side and gently

push the glass out.

Fit the seal using high temperature sealant and then re-fit the glass.

Check the glass panel has no movement within holder and is properly sealed to the

door.

Replacing the door rope

The door rope is a perishable item and at some point may need changing.

If the door rope is frayed and starting to leak emissions then it must be replaced.

The stove rope and rope adhesive are only available from most Chesney’s

suppliers.

Remove the old seal and clean off any dirt and old adhesive from around and in the

seal channel.

Dry fit the seal and cut off any overlapping excess.

Add a small bead of adhesive around the channel and then fit the seal into the

channel, wiping off any excess glue.

Close the door to press the seal in place and allow the glue to dry, before re-using

the appliance all replacement parts should be checked for leakage of combustion

products

Page 46

45

Adjusting the door seal

Important note - The door should only be opened when switched off and only if

the appliance requires maintenance.

Ensure the door is properly sealed.

To adjust the seal on the left hand side for Beaumont, Salisbury, Shipton, and

Belgravia firstly undo the grub screw to allow the handle to turn fully (Shoreditch

and Alpine models do not have the grub screw fitted).

Turn the door handle 360° counter clockwise turns to pull the door in or turn 360°

clockwise turns to adjust out.

Door seal adjustment on the left side

Door seal adjustment on the right side

To adjust the seal on the right hand side remove the door then turn the hinge 360°

clockwise to pull the door in or turn 360° counterclockwise to adjust out.

Refit the door.

Page 47

46

Aligning the door (Alpine models)

To align the Alpine door with the cladding

Undo the 4 securing bolts - 2 at the front and 2 at the back of the appliance.

Move the gas fire cube within the cladding until the door lines up then tighten up

the bolts.

Page 48

47

Removal of the gas cube

Alpine model

Remove all the gas logs and embers from the appliance.

Remove the door by taking the weight of the door at 90° remove the hex socket

bolts circled and lift the door clear from the hinges.

Remove the 4 securing bolts - 2 at the front and 2 at the back of the appliance.

Remove the back panel and if the flue collars exit the top then they also must be

removed.

Lift the gas fire cube clear from the Alpine cladding.

Page 49

48

Removal of the gas cube

All other models

The gas logs and embers must be removed from the appliance.

Remove the top cover.

Open the door and lift the door clear from the hinge pins then remove the controls

cover.

Remove the bolts holding the legs to the gas fire cube a lift away from the legs.

Page 50

49

Pilot Removal

Work should only be carried out by a competent person and all gas work be carried

out by a Gas Safe Registered person in accordance with national and local

regulations.

The pilot to be exchanged must be a genuine like for like part.

Part - SIT Pilot NG9029

Page 51

50

Pilot removal

NOTE – Before removing the pilot ensure you have a seal set. (Only supplied

by Chesney’s).

Isolate the appliance.

Remove the logs and embers.

Remove the log base to access the pilot.

Remove the white heat protective fibre then pull the spark lead from the pilot.

Undo the 4mm tube nut and release from the pilot then remove the pilot shield and

pilot bracket from the enclosure.

Remove pilot exit plate via screws shown below.

Pilot Shield

Pilot Bracket

Page 52

51

Remove the 2 gasket seals and assess for damage and replace if required.

NOTE- One of the gaskets is fitted so that the slots are pointing upwards and the

other fitted downwards to ensure a good seal.

Remove the pilot nut from the valve then pull the pilot free from the appliance.

Replace with genuine parts refitting in the reverse order.

NOTE- The position of the pilot is essential.

Commission the appliance.

Page 53

52

Replacing the pilot spark lead

Isolate the appliance.

Remove the logs and embers.

Remove the log base to access the pilot.

Remove the white heat protective fibre then pull the spark lead from the pilot.

Pull the spark lead from the controls box then pull the lead through the appliance.

Assess for damage to the protective sleeve and replace if required.

NOTE – Protective sleeve are only available from Chesney’s

Replace with genuine parts refitting in the reverse order.

Commission the appliance.

Page 54

53

Control Valve Removal – Mertik GV60 (Fully remote controlled)

Page 55

54

Removing the gas valve

Isolate the appliance.

Release the front panel via the four screws

Remove the cover plate (Beaumont / Belgravia / Shipton) by unscrewing the bolts

at each end using the hexagon key.

Undo the 2 screws holding the valve bracket assembly then slide the bracket

forward to drop the assembly.

Page 56

55

The valve assembly can be turned to access the connections to the injector, pilot

4mm OD tube nut and thermocouple nut.

Undo the screws to release the valve from the bracket.

IMPORTANT – Only use a Chesney’s factory set valve.

Fit the new factory set valve and refit the interrupter block, tube and wiring

connections.

Fit the valve assembly by sliding the bracket tabs in-between the fixing plate on the

underside of the appliance.

Page 57

56

Pairing the handset

The handset has been paired with the appliance at the factory.

If the handset is to be exchanged or is not responding with the appliance then the

control box RF receiver will require setting to allow communication.

The control box RF receiver has to learn the handset code:

Press and hold the control box RF receiver’s reset button until you hear two (2)

beeps. After the second longer beep release the reset button. Within the

subsequent 20 seconds press the small flame (circled) button on the remote

handset until you hear an additional long beep confirming the code is set.

NOTE: This is one time setting only, and is not required when changing the

batteries in the remote receiver.

Page 58

57

12. Fault finding

Symptom

Check List

Unit does not respond.

Check Remote is working properly

Check Battery power supply.

Check wiring is correct.

Remote does not work.

Check Battery Power.

Check Remote eye is visible and facing in the correct position.

Hardwire switch does

not work. (If fitted)

Check Switch is wired properly.

Unit clicks but no spark

or weak spark.

Check spark lead is connected properly.

Check spark electrode is in the correct area and the gap correctly

distanced.

Unit sparks but does not

light pilot.

Check for a good spark.

Check the spark is in the correct area.

Check if the ventilation is not too strong.

Check if there is gas running through.

If there is no gas.

Check isolation tap/shut off valves are free from grease.

Check isolation tap/shut off valve/s are on.

Check for blockages

If there is gas but pilot

does not light

Check pressure is correct.

Check for blockages.

Check for draughts.

Check the pilot gas slots are clear.

Pilot lights but does not

light main burner

Check the pilot flame is heating the thermocouple.

Check the thermocouple nut is properly tightened into the interrupter block.

Check that the pilot lights early on ignition clicks.

Check ventilation is not too strong.

Burner lights but turns

off after a few minutes

Check thermocouple nut is properly secured to the interrupter block.

Check ventilation is not too strong and the flame is not blowing off the

thermocouple.

Check gas pressure is correct.

The GV60 fully remote controlled system has audible beeps to indicate a

problem with the system.

Reason

No Beep

Impulse magnet not operating properly – Replace gas valve

1 Long Beep

ON (1)/OFF(0) Switch is on OFF position – Switch to ON (1)

3 Short Beeps

Low Batteries – Replace receiver batteries with 4x1.5V “AA” quality alkaline

batteries

Page 59

58

13. User Instructions

General

The flue must be fitted in accordance with Local and National Regulations.

The flue must not be shared with any other appliance.

It is advised that flue specialist inspect the flue system on an annual basis to

ensure that the flue system is sound and the combustion products outlet

(terminal) is clear of obstruction.

It is highly recommended that a full service on the appliance be carried out

annually by competent person/s.

The gas connection must be in accordance with Local and National

Regulations.

Installation and servicing must be carried out by a competent person in line with

relevant regulations.

WARNING – Do not use the appliance if the glass front door is broken, removed or

is open.

WARNING – The appliance will get hot whilst running; do not place the remote

handset on the appliance.

All parts of the appliance will become hot while the appliance is running, so it is

recommended that a guard conforming to BS8423: 2002 be used for the protection

of young children (i.e. in nurseries), aged or infirm persons.

Allow adequate clearances for curtains, pictures, soft furnishings, electrical

appliances or any items that may get damaged through heat.

Curtains should not be positioned above the appliance at a distance less than

250mm.

All parts of the appliance are hot so can be considered to be a working

surface.

It is also advised against placing combustible materials or soft furnishings directly

in front or above the appliance. Floor coverings, such as carpets (up to the hearth),

are considered to be acceptable.

Do not throw rubbish in the appliance or otherwise disturb the fuel bed. Debris from

any source, or soot formed, should be removed from time to time.

The pilot light and flame sensing device fitted to this fire shuts off both the main

burner and pilot if evacuation of the combustion products is interrupted.

The pilot is not to be adjusted or put out of action. If the pilot is damaged or

faulty it should be replaced by a qualified person and only with an original

identical unit.

The appliance when lit from cold will start off with a blue flame and will gradually

turn more yellow as the flue, logs and appliance heat up.

Page 60

59

Important notes

The appliance door must only to be opened when servicing the

appliance.

The appliance must not be operated with the door open.

The appliance must not be operated if the appliance glass front is damaged

or has been removed.

The appliance should always be observed when lighting.

Improper installation, service, maintenance, adjustment or

alterations may cause injury or property damage

Do not disturb, add extra fibre logs or embers as this will affect the

combustion.

Do not operate the appliance if the fibre logs are damaged

The appliance must be installed and maintained by a suitably qualified

heating engineer.

Ensure this manual remains with the appliance.

The products of combustion can cause white deposits to appear.

The white deposits are in the gas mixture and can be more noticeable in certain

areas. When burning off the residue it can adhere to moisture, e.g. the glass. It is

advised to remove the residue during a service. NOTE - The longer it stays on the

harder it is to remove.

Use a suitable cleaner such as 'White Off', ‘Brasso’ or a metal polish.

IMPORTANT – Do not use abrasive materials to remove the residue from the glass

as it could etch the glass and make future cleaning harder.

Page 61

60

Lighting the appliance

The GV60 is fully remote controlled.

IMPORTANT NOTE - The appliance should always be observed when lighting.

If the appliance makes a long beep when starting the appliance then the on/off

switch is set on the OFF (0) position, switch the unit to the ON (1) position.

Note - If the handset is out of action or is not obtainable the appliance can be

turned off by pressing the ON/OFF switch to the OFF (0) position (located on the

left side of the appliance). Care must be taken when doing this as the appliance will

be hot.

To light the fire unit you must press and hold both buttons red circle and large

flame button until a short acoustic signal is heard, this confirms that the starting

sequence has begun; release the buttons. Continuing signals confirms the ignition

is in process.

The pilot will light soon after the appliance has been activated observations can be

made by looking through the glass on the right side under the back log.

If the pilot flame is extinguished either intentionally or unintentionally, allow 5

minutes before attempting to relight the appliance.

Page 62

61

When the acoustic signal stops the main valve opens to ‘High rate’ to allow gas

through to the main burner. All of the main burner should light within 6 seconds

lighting the whole burner area.

IF THIS DOES NOT HAPPEN THEN THE APPLIANCE SHOULD BE TURNED

OFF ALLOWING 5 MINUTES BEFORE ATTEMPTING TO RELIGHT.

If lit from cold it is advised to leave the burner on high rate for at least 30 minutes to

warm up the flue before turning between the ‘High’ and ‘Low’ rates.

When the fire has warmed the flame height can be adjusted between ‘High and

Low’ by pressing and holding the large flame button to increase flame height, or

pressing and holding the small flame button to decrease flame height.

The pilot can just remain lit this is done by holding the small flame button until the

fire unit turns off the main burner.

To go from the lit pilot to main press and hold both the red circle and the large

flame button. All of the main burner should then light within 6 seconds lighting the

whole burner area.

If this does not happen then the appliance should be turned off allowing 5 minutes

before attempting to relight.

To turn off the fire unit completely press the off button.

Restarting the appliance

If the fire is extinguished or goes out in use, allow 5 minutes before attempting to

restart following the lighting sequence.

If the fire shuts itself off repeatedly, do not use the fire, and have the flue and fire

checked by a suitably qualified person.

Page 63

62

Changing the batteries

The batteries will require changing yearly (based on the average usage) this may

differ depending on usage and on the quality of battery, the battery change is best

done on the annual service of the appliance.

However if the appliance is showing signs of diminishing signal or during the

lighting sequence then the batteries may need changing.

Firstly replace the handset battery before attempting to change the fire unit battery.

Remote handset battery

1 x 9V block

(Quality alkaline recommended)

Receiver batteries

4 x 1.5V “AA”

(Quality alkaline recommended)

The battery compartment should be placed in an accessible area so that the

batteries can be changed without the need to open the door.

Suggested areas - under the appliance for appliances able to be accessed or for

appliances such as the Alpine or Shipton the battery compartment should be

placed out the back of the appliance.

Ensure to follow direction of the batteries (indicated in the compartment).

Check the connections are secure before replacing the box back in the appliance.

Page 64

63

Cleaning

Cleaning should only be carried out when the fire is turned off and cold.

This appliance contains no asbestos.

Cleaning paintwork

Use a clean soft dry brush to remove dirt and debris from the appliance.

If the appliance has ingrained dirt use soapy water to dampen a soft cloth and use

to clean.

Cleaning Glass

The glass in your stove is specially formulated to withstand very high temperatures.

The products of combustion can cause white deposits to appear.

It is advised to remove the residue during a service.

NOTE - The longer it stays on the harder it is to remove.

Use a suitable cleaner such as 'White Off', ‘Brasso’ or a metal polish.

IMPORTANT – Do not use abrasive materials to remove the residue from the glass

as it could etch the glass and make future cleaning harder.

Fuel bed components

For opening the door please read instructions on page 43.

Wear suitable safety equipment when cleaning the products inside the appliance.

It is advised to wear protective gloves and a dust mask conforming to EN

149:2001+A1:2009 FFP3 (available from most DIY shops) when cleaning the logs

and embers.

It is necessary to clean the fire if debris or soot deposits have accumulated on the

logs. A soft brush is advised to clean the logs and burner unit.

The ceramic parts are fragile; care must to be taken when handling this product.

Warning – Do not change the fuel bed layout or the quantity of material

When placing the logs it is important to carefully follow the layout in this manual

see pages 36-38, the layout has been set to give the best performance and flame

picture of the appliance any deviation may cause poor combustion.

The addition of further ceramic components are strictly prohibited, any extra parts

supplied are spares for future use.

Ceramic components should last around 2 years in normal use at which time is

recommended that they are replaced.

Replacements can be bought from any Chesney’s stockists. State the model

number (found on the gas fire data plate).

Always ask for genuine Chesney’s parts.

This appliance is manufactured by -

Chesney’s Limited

194 – 200 Battersea Park Road,

London, SW11 4ND

Tel: 020 7627 1410 Fax: 020 7622 1078

Page 65

64

14. Installer check list

Flue checklist

PASS

FAIL

Flue Size

Flow test

Spillage test

Gas checklist

PASS

FAIL

Soundness

Standing Pressure

Working Pressure

Ventilation

PASS

FAIL

Ventilation requirements for appliance

15. Dealer and Installer Information

Dealer and Installer Information

Dealer

Installation Company

Contact No.

Gas Safe Registered Engineer

Date of Purchase

Contact No.

Model No.

Gas Safe Register No.

Serial No.

Date of Installation

Gas Type

16. Annual Service Record

Page 66

65

Annual service record

Year 1

Gas Safe Registered Engineer

Contact No.

Gas Safe Register No.

Date of Service

Annual service record

Year 2

Gas Safe Registered Engineer

Contact No.

Gas Safe Register No.

Date of Service

Annual service record

Year 3

Gas Safe Registered Engineer

Contact No.

Gas Safe Register No.

Date of Service

Annual service record

Year 4

Gas Safe Registered Engineer

Contact No.

Gas Safe Register No.

Date of Service

Annual service record

Year 5

Gas Safe Registered Engineer

Contact No.

Gas Safe Register No.

Date of Service

Annual service record

Year 6

Gas Safe Registered Engineer

Contact No.

Gas Safe Register No.

Date of Service

The following information supplied in this manual is correct at the time of publish;

Date of last manual update 26 Feb 2013. V6.

Loading...

Loading...