Cherry Semiconductor CS5166HGDWR16, CS5166HGDW16 Datasheet

Features

■

V

2

TM

Control Topology

■

Dual N-Channel Design

■

125ns Controller Transient Response

■

Excess of 1Mhz Operation

■

5-bit DAC with 1% Tolerance

■

Power-Good Output with Internal

Delay

■

Adjustable Hiccup Mode Over

Current Protection

■

Complete Pentium

®

II System

Requires just 21 Components

■

5V and 12V Operation using either

Dual or Single Supplies

■

Adaptive Voltage Positioning

■

Remote Sense Capability

■

Current Sharing Capability

■

V

CC

Monitor

■

Overvoltage Protection (OVP)

■

Programmable Soft Start

■

200ns PWM Blanking

■

65ns FET Non-Overlap

■

40ns Gate Rise and Fall Times

(3.3nF load)

Package Options

CS5166H

5-Bit Synchronous CPU Controller

with Power-Good and Current Limit

CS5166H

Description

The CS5166H is a synchronous

dual NFET Buck Regulator

Controller. It is designed to power the core logic of the latest high

performance CPUs. It uses the

V

2

TM

control method to achieve

the fastest possible transient

response and best overall regulation. It incorporates many additional features required to ensure

the proper operation and protection of the CPU and power system. The CS5166H provides the

industry’s most highly integrated solution, minimizing external

component count, total solution

size, and cost.

The CS5166H is specifically

designed to power Intel’s

Pentium

®

II processor and

includes the following features:

5-bit DAC with 1% tolerance,

Power-Good output, adjustable

hiccup mode over-current protection, V

CC

monitor, Soft Start,

adaptive voltage positioning,

over-voltage protection, remote

sense and current sharing capability.

The CS5166H will operate over a

4.15 to 20V range using either

single or dual input voltage and

is available in a 16 lead wide

body surface mount package.

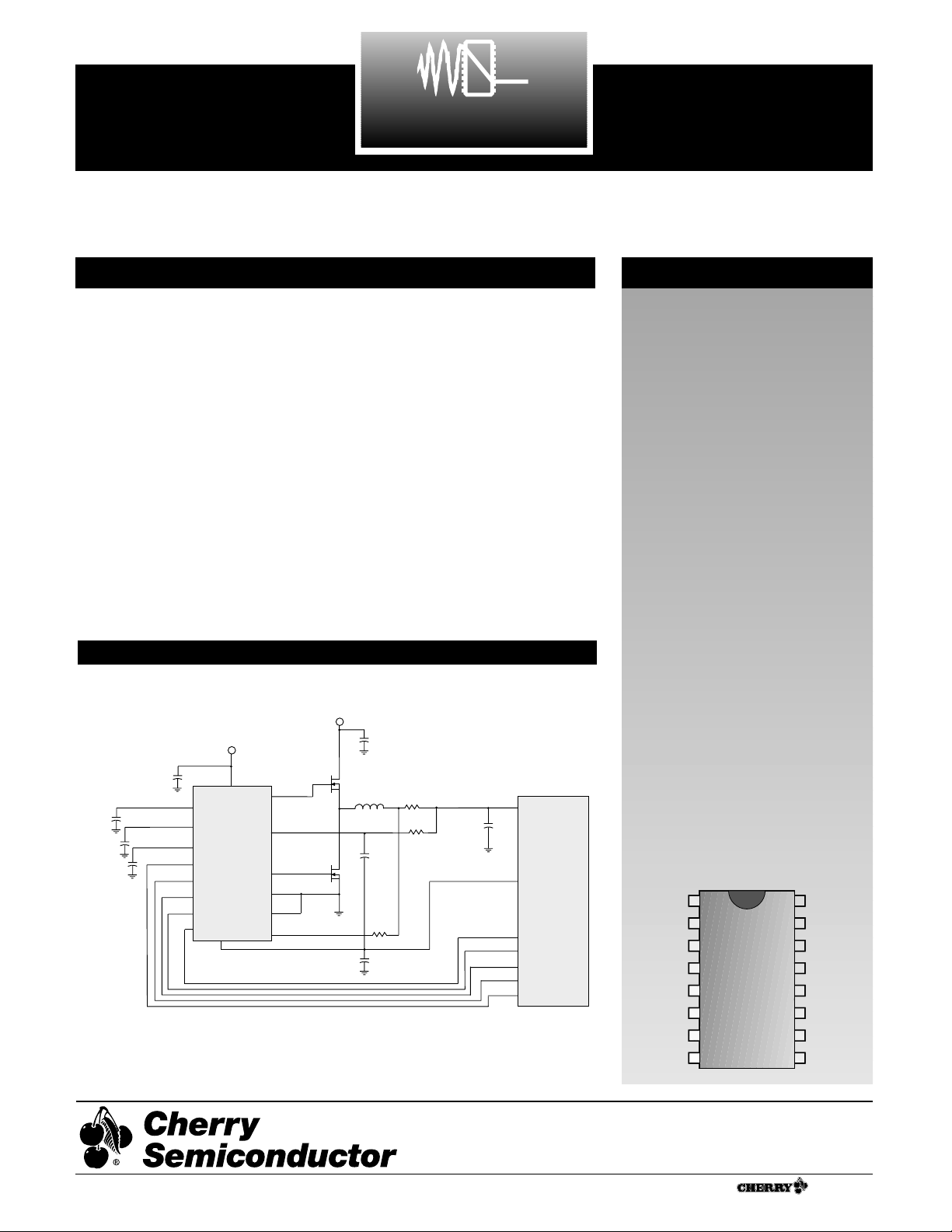

Application Diagram

16 Lead SO WIDE

V

ID0

V

ID1

V

ID2

V

ID3

I

SENSE

C

OFF

SS

V

ID4

V

FB

COMP

LGnd

PWRGD

GATE(L)

PGnd

GATE(H)

V

CC

Pentium is a registered trademark of Intel Corporation.

5V to 2.8V @ 14.2A for 300MHz Pentium® II

1

V2is a trademark of Switch Power, Inc.

Rev. 6/28/99

Cherry Semiconductor Corporation

2000 South County Trail, East Greenwich, RI 02818

Tel: (401)885-3600 Fax: (401)885-5786

Email: info@cherry-semi.com

Web Site: www.cherry-semi.com

A Company

®

12V

1µF

C

OFF

330pF

0.1µF

0.1µF

SS

COMP

V

ID0

V

ID1

V

ID2

V

ID3

V

ID4

V

CS5166H

PWRGD

CC

GATE(H)

I

SENSE

GATE(L)

PGnd

LGnd

V

FB

5V

1200µF/10V x 3

1.2µH

3.0mΩ

1200µF

510

10V x 5

V

V

V

V

V

ID4

ID3

ID2

ID1

ID0

Pentium® II

System

0.1µF

PWRGD

3.3K

1000pF

1

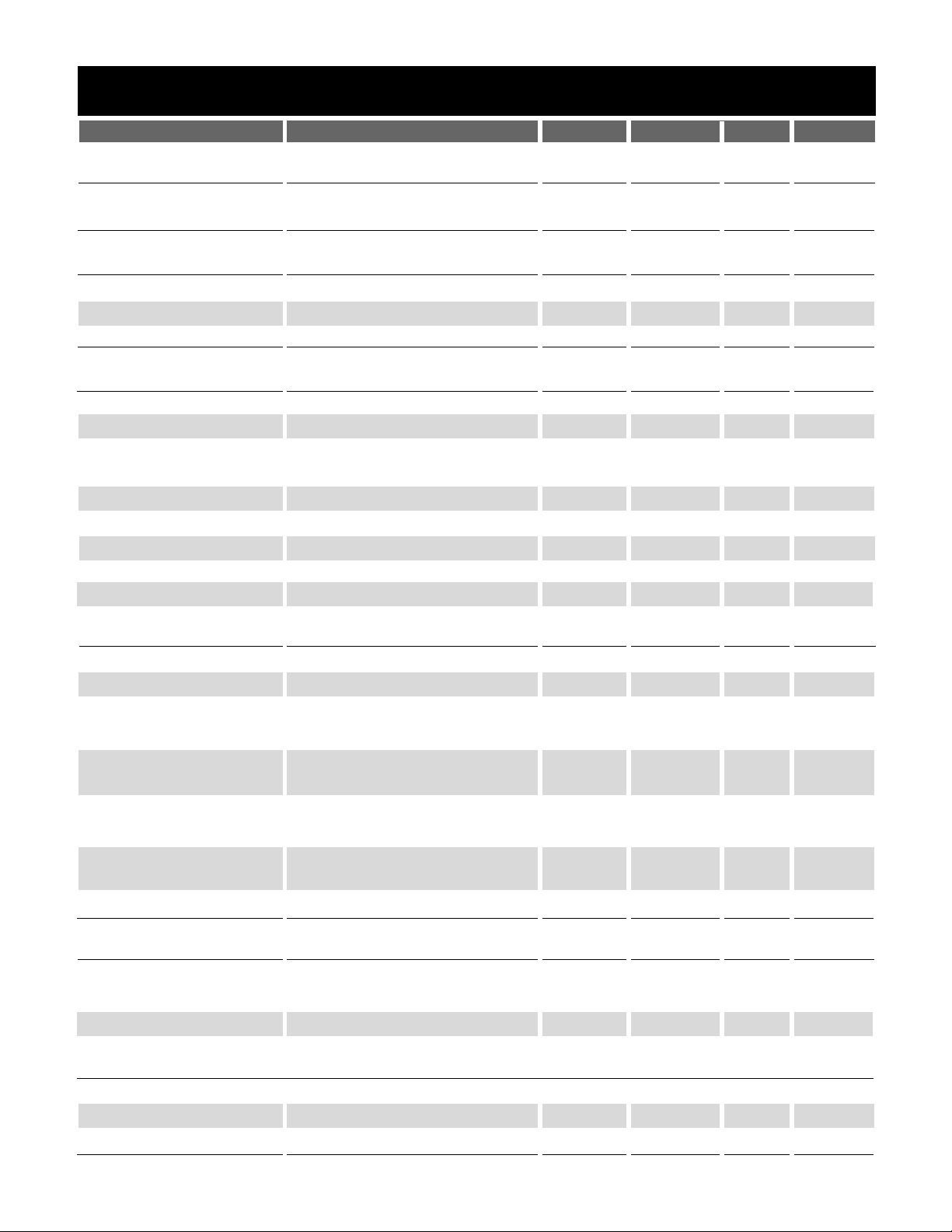

Absolute Maximum Ratings

Pin Symbol Pin Name

V

MAX

V

MIN

I

SOURCE

I

SINK

2

PACKAGE PIN # PIN SYMBOL FUNCTION

Package Pin Description

CS5166H

V

CC

IC Power Input 20V -0.3V N/A 1.5A Peak 200mA DC

SS Soft Start Capacitor 6V -0.3V 200µA 10µA

COMP Compensation Capacitor 6V -0.3V 10mA 1mA

V

FB

Voltage Feedback and Current 6V -0.3V 1mA 1mA

Sense Comparator Input

C

OFF

Off-Time Capacitor 6V -0.3V 1mA 50mA

V

ID0-4

Voltage ID DAC Inputs 6V -0.3V 1mA 10µA

GATE(H) High-Side FET Driver 20V -0.3V 1.5A Peak 1.5A Peak

200mA DC 200mA DC

GATE(L) Low-Side FET Driver 20V -0.3V 1.5A Peak 1.5A Peak

200mA DC 200mA DC

I

SENSE

Current Sense Comparator Input 6V -0.3V 1mA 1mA

PWRGD Power-Good Output 6V -0.3V 10µA 30mA

PGnd Power Ground 0V 0V 1.5A Peak N/A

200mA DC

LGnd Logic Ground 0V 0V 100mA N/A

1,2,3,4,6 V

IDO

– V

ID4

Voltage ID DAC inputs. These pins are internally pulled up to 5V if left

open. V

ID4

selects the DAC range. When V

ID4

is high (logic one), the

Error Amp reference range is 2.125V to 3.525V with 100mV increments.

When V

ID4

is low (logic zero), the Error amp reference voltage is 1.325V

to 2.075V with 50mV increments.

5 SS Soft Start Pin. A capacitor from this pin to LGnd sets the Soft Start and

fault timing.

7C

OFF

Off-Time Capacitor Pin. A capacitor from this pin to LGnd sets both the

normal and extended off time.

8I

SENSE

Current Sense Comparator Inverting Input

9VCCInput Power Supply Pin.

10 GATE(H) High Side Switch FET driver pin.

11 PGnd High Current ground for the GATE(H) and GATE(L) pins.

12 GATE(L) Low Side Synchronous FET driver pin.

13 PWRGD Power-Good Output. Open collector output drives low when VFBis out

of regulation.

14 LGnd Reference ground. All control circuits are referenced to this pin.

15 COMP Error Amp output. PWM Comparator reference input. A capacitor to

LGnd provides Error Amp compensation.

16 V

FB

Error Amp, PWM Comparator feedback input, Current Sense

Comparator Non-Inverting input, and PWRGD comparator input.

Operating Junction Temperature, T

J

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0° to 150°C

Lead Temperature Soldering:

Reflow (SMD styles only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 Sec max. above 183˚C, 230˚C Peak

Storage Temperature Range, TS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -65 to 150˚C

CS5166H

3

Electrical Characteristics: 0˚C < TA< 70˚C; 0˚C < TJ< 125˚C; 8V < VCC< 20V; 2.0V DAC Code (V

ID4

= V

ID3

= V

ID2

=

V

ID1

=0, V

ID0

= 1), C

GATE(H

) = C

GATE(L)

= 3.3nF, C

OFF

= 330pF, CSS= 0.1µF; Unless otherwise stated.

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

■ VCCSupply Current

Operating 1V<V

FB<VDAC

(Max On-Time),

No Loads on GATE(H) and GATE(L) 12 20 mA

■ V

CC

Monitor

Start Threshold GATE(H) Switching 3.75 3.95 4.15 V

Stop Threshold GATE(H) not switching 3.65 3.87 4.05 V

Hysteresis Start – Stop 80 mV

■ Error Amplifier

V

FB

Bias Current VFB= 0V 0.1 1.0 µA

COMP Source Current COMP = 1.2V to 3.6V; V

FB

= 1.9V 15 30 60 µA

COMP CLAMP Voltage V

FB

= 1.9V, Adjust COMP voltage 0.85 1.0 1.15 V

for Comp current = 60µA

COMP Clamp Current COMP = 0V 0.4 1.0 1.6 mA

COMP Sink Current V

COMP

=1.2V; VFB=2.2V; VSS> 2.5V 180 400 800 µA

Open Loop Gain Note 1 50 60 dB

Unity Gain Bandwidth Note 1 0.5 2 MHz

PSRR @ 1kHZ Note 1 60 85 dB

■ GATE(H) and GATE(L)

High Voltage at 100mA Measure V

CC

–GATE 1.2 2.0 V

Low Voltage at 100mA Measure GATE 1.0 1.5 V

Rise Time 1.6V < GATE < (V

CC

– 2.5V), 40 80 ns

8V < V

CC

< 14V

Fall Time (V

CC

– 2.5V) >GATE > 1.6V, 40 80 ns

8V < V

CC

< 14V

GATE(H) to GATE(L) Delay GATE(H)<2V, GATE(L)>2V

8V < V

CC

< 14V 30 65 100 ns

GATE(L) to GATE(H) Delay GATE(L)<2V, GATE(H)>2V

8V < V

CC

< 14V 30 65 100 ns

GATE pull-down Resistance to PGnd (Note 1) 20 50 115 kΩ

■ Over Current Detection

Current limit voltage V

FB

= 0V to 3.5V 55 76 130 mV

8V < V

CC

< 12V + 10%

I

SENSE

Bias Current I

SENSE

= 2.8V 13 30 50 µA

■ Fault Protection

SS Charge Time V

FB

= 3V, V

ISENSE

= 2.8V 1.6 3.3 5.0 ms

SS Pulse Period V

FB

= 3V, V

ISENSE

= 2.8V 25 100 200 ms

SS Duty Cycle (Charge Time/Period) × 100 1.0 3.3 6.0 %

CS5166H

4

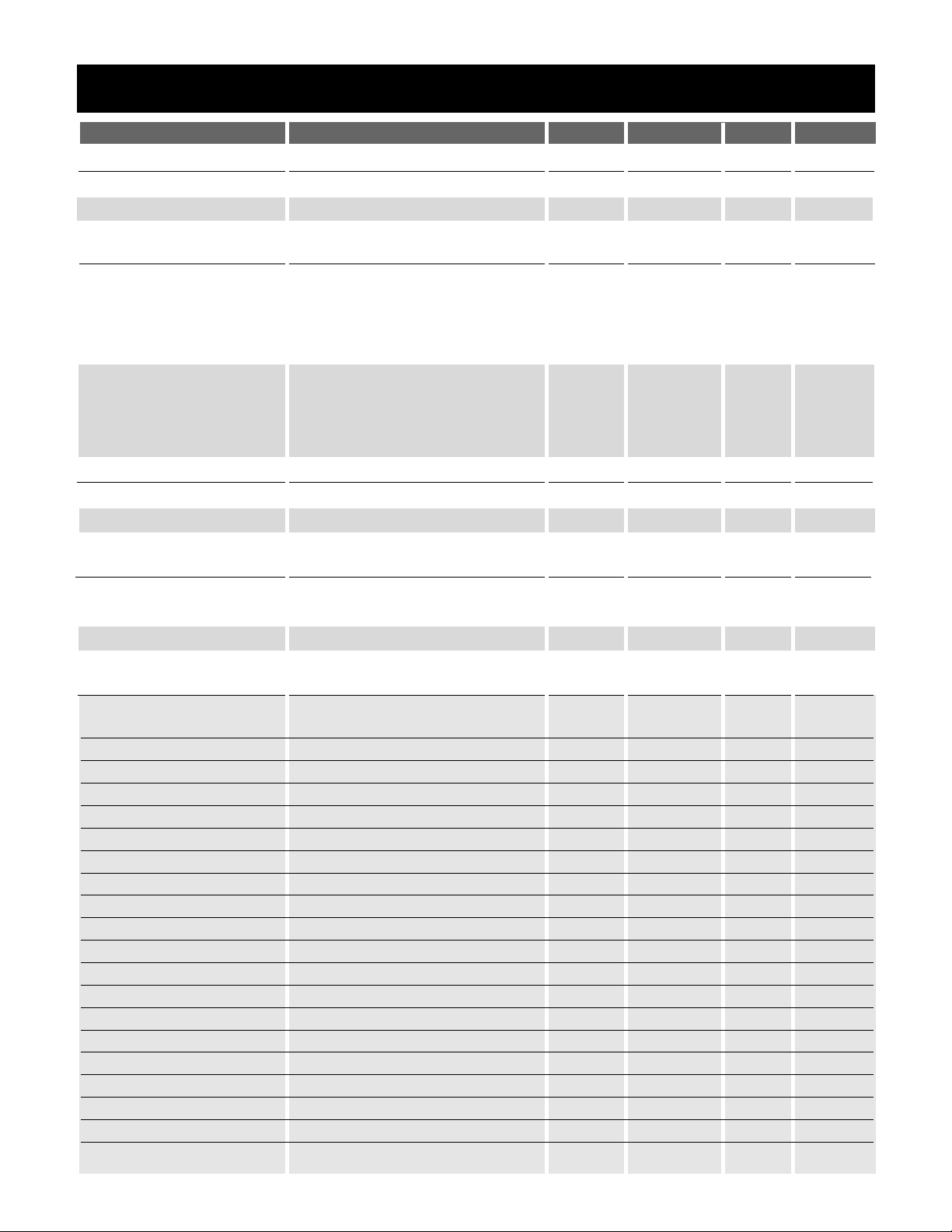

Electrical Characteristics: 0˚C < TA< 70˚C; 0˚C < TJ< 125˚C; 8V < VCC< 20V; 2.0V DAC Code (V

ID4

= V

ID3

= V

ID2

=

V

ID1

=0, V

ID0

= 1), C

GATE(H

) = C

GATE(L)

= 3.3nF, C

OFF

= 330pF, CSS= 0.1µF; Unless otherwise stated.

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

■ Fault Protection continued

SS Comp Clamp Voltage VFB= 2.7V, VSS= 0V 0.50 0.95 1.10 V

V

FB

Low Comparator Increase VFBtill normal off-time 0.9 1.0 1.1 V

■ PWM Comparator

Transient Response V

FB

= 1.2V to 5V 500ns after GATE(H) 115 175 ns

(after Blanking time) to

GATE(H) = (V

CC

– 1V)

to 1V, 8V < V

CC

< 14V

Minimum Pulse Width Drive V

FB

1.2V to 5V upon GATE(H) 100 200 300 ns

(Blanking Time) rising edge (> V

CC

– 1V), measure

GATE(H) pulse width,

8V < V

CC

< 14V

■ C

OFF

Normal Off-Time VFB= 2.7V 1.0 1.6 2.3 µs

Extended Off-Time V

SS

= VFB= 0V 5.0 8.0 12.0 µs

■ Time-Out Timer

Time-Out Time V

FB

= 2.7V, Measure GATE(H) 10 30 50 µs

Pulse Width

Fault Duty Cycle V

FB

= 0V 30 50 70 %

■ Voltage Identification DAC

Accuracy

(all codes except 11111) Measure V

FB

= COMP, (C

OFF

= Gnd) -1.0 1.0 %

V

ID4VID3VID2VID1VID0

25˚C ≤ TJ ≤ 125˚C, VCC= 12V

1 0 0 0 0 3.489 3.525 3.560 V

1 0 0 0 1 3.390 3.425 3.459 V

1 0 0 1 0 3.291 3.325 3.358 V

1 0 0 1 1 3.192 3.225 3.257 V

1 0 1 0 0 3.093 3.125 3.156 V

1 0 1 0 1 2.994 3.025 3.055 V

1 0 1 1 0 2.895 2.925 2.954 V

1 0 1 1 1 2.796 2.825 2.853 V

1 1 0 0 0 2.697 2.725 2.752 V

1 1 0 0 1 2.598 2.625 2.651 V

1 1 0 1 0 2.499 2.525 2.550 V

1 1 0 1 1 2.400 2.425 2.449 V

1 1 1 0 0 2.301 2.325 2.348 V

1 1 1 0 1 2.202 2.225 2.247 V

1 1 1 1 0 2.103 2.125 2.146 V

0 0 0 0 0 2.054 2.075 2.095 V

0 0 0 0 1 2.004 2.025 2.045 V

0 0 0 1 0 1.955 1.975 1.994 V

0 0 0 1 1 1.905 1.925 1.944 V

CS5166H

5

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

THRESHOLD ACCURACY

LOWER THRESHOLD UPPER THRESHOLD

MIN TYP MAX MIN TYP MAX UNITS

% of Nominal VIDCode -12 -8.5 -5 5 8.5 12 %

■ DAC CODE

V

ID4VID3VID2VID1VID0

1 0 0 0 0 3.102 3.225 3.348 3.701 3.824 3.948 V

1 0 0 0 1 3.014 3.133 3.253 3.596 3.716 3.836 V

1 0 0 1 0 2.926 3.042 3.158 3.491 3.607 3.724 V

1 0 0 1 1 2.838 2.950 3.063 3.386 3.499 3.612 V

1 0 1 0 0 2.750 2.859 2.968 3.281 3.390 3.500 V

1 0 1 0 1 2.662 2.767 2.873 3.176 3.282 3.388 V

1 0 1 1 0 2.574 2.676 2.778 3.071 3.173 3.276 V

1 0 1 1 1 2.486 2.584 2.683 2.966 3.065 3.164 V

1 1 0 0 0 2.398 2.493 2.588 2.861 2.956 3.052 V

1 1 0 0 1 2.310 2.401 2.493 2.756 2.848 2.940 V

1 1 0 1 0 2.222 2.310 2.398 2.651 2.739 2.828 V

Electrical Characteristics: 0˚C < TA< 70˚C; 0˚C < TJ< 125˚C; 8V < VCC< 20V; 2.0V DAC Code (V

ID4

= V

ID3

= V

ID2

=

V

ID1

=0, V

ID0

= 1), C

GATE(H

) = C

GATE(L)

= 3.3nF, C

OFF

= 330pF, CSS= 0.1µF; Unless otherwise stated.

Accuracy (all codes except 11111) Measure VFB= COMP, (C

OFF

= Gnd) -1.0 1.0 %

V

ID4VID3VID2VID1VID0

0 0 1 0 0 1.856 1.875 1.893 V

0 0 1 0 1 1.806 1.825 1.843 V

0 0 1 1 0 1.757 1.775 1.792 V

0 0 1 1 1 1.707 1.725 1.742 V

0 1 0 0 0 1.658 1.675 1.691 V

0 1 0 0 1 1.608 1.625 1.641 V

0 1 0 1 0 1.559 1.575 1.590 V

0 1 0 1 1 1.509 1.525 1.540 V

0 1 1 0 0 1.460 1.475 1.489 V

0 1 1 0 1 1.410 1.425 1.439 V

0 1 1 1 0 1.361 1.375 1.388 V

0 1 1 1 1 1.311 1.325 1.338 V

1 1 1 1 1 1.219 1.247 1.269 V

Input Threshold V

ID4

, V

ID3

, V

ID2

, V

ID1

, V

ID0

1.0 1.25 2.4 V

Input Pull-up Resistance V

ID4

, V

ID3

, V

ID2

, V

ID1

, V

ID0

25 50 100 kΩ

Input Pull-up Voltage 4.85 5.00 5.15 V

■ Power-Good Output

Low to High Delay V

FB

= (0.8 × V

DAC

) to V

DAC

30 65 110 µs

High to Low Delay V

FB

= V

DAC

to (0.8 × V

DAC

) 30 75 120 µs

Output Low Voltage V

FB

= 2.4V, I

PWRGD

= 500µA 0.2 0.3 V

Sink Current Limit V

FB

= 2.4V, PWRGD = 1V 0.5 4.0 15.0 mA

THRESHOLD ACCURACY

LOWER THRESHOLD UPPER THRESHOLD

MIN TYP MAX MIN TYP MAX UNITS

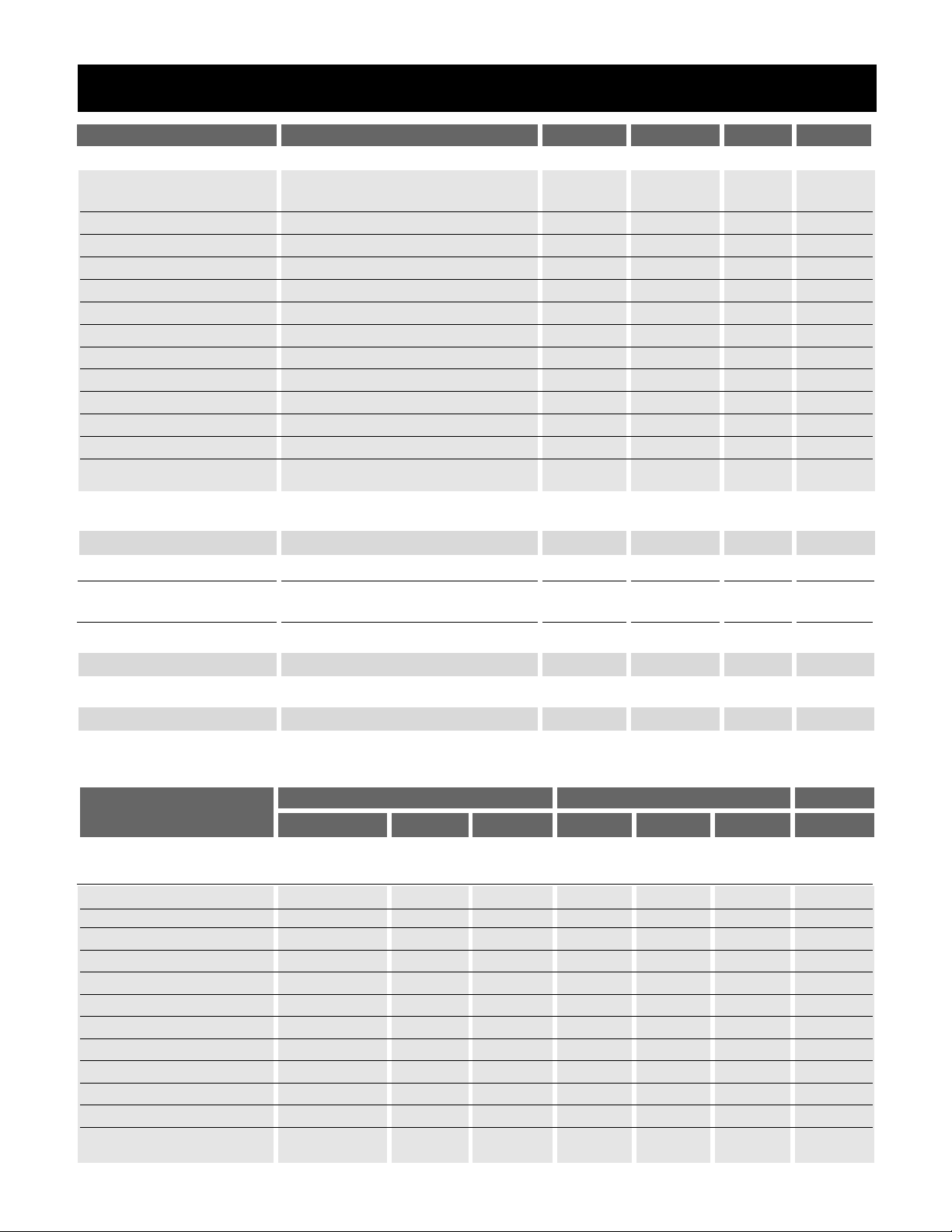

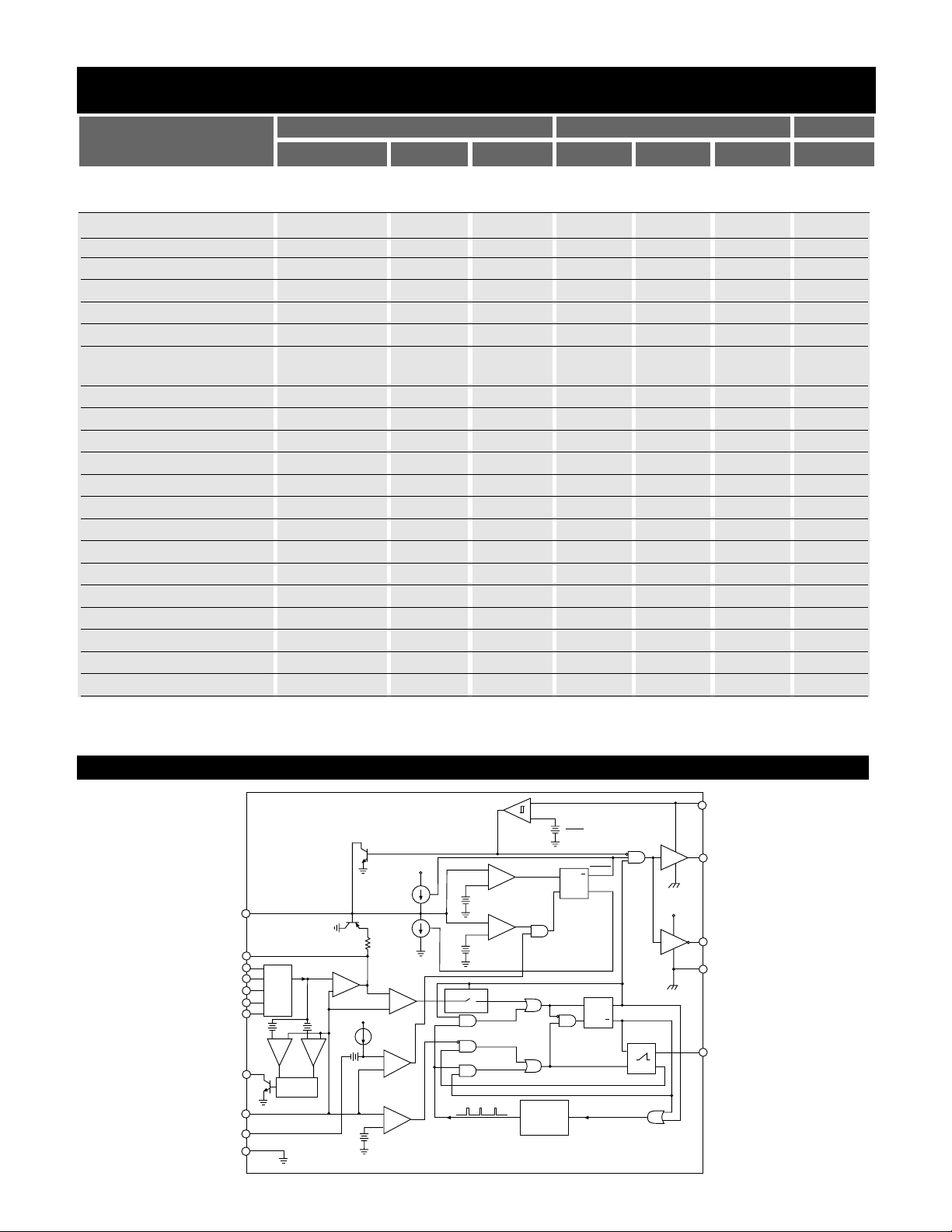

Block Diagram

6

CS5166H

Electrical Characteristics: 0˚C < TA< 70˚C; 0˚C < TJ< 125˚C; 8V < VCC< 20V; 2.0V DAC Code (V

ID4

= V

ID3

= V

ID2

=

V

ID1

=0, V

ID0

= 1), C

GATE(H

) = C

GATE(L)

= 3.3nF, C

OFF

= 330pF, CSS= 0.1µF; Unless otherwise stated.

% of Nominal V

ID

Code -12 -8.5 -5 5 8.5 12 %

■ DAC CODE

V

ID4VID3VID2VID1VID0

1 1 0 1 1 2.134 2.218 2.303 2.546 2.631 2.716 V

1 1 1 0 0 2.046 2.127 2.208 2.441 2.522 2.604 V

1 1 1 0 1 1.958 2.035 2.113 2.336 2.414 2.492 V

1 1 1 1 0 1.870 1.944 2.018 2.231 2.305 2.380 V

0 0 0 0 0 1.826 1.898 1.971 2.178 2.251 2.324 V

0 0 0 0 1 1.782 1.8520 1.923 2.126 2.197 2.268 V

0 0 0 1 0 1.738 1.807 1.876 2.073 2.142 2.212 V

0 0 0 1 1 1.694 1.761 1.828 2.021 2.088 2.156 V

0 0 1 0 0 1.650 1.715 1.781 1.968 2.034 2.100 V

0 0 1 0 1 1.606 1.669 1.733 1.916 1.980 2.044 V

0 0 1 1 0 1.562 1.624 1.686 1.863 1.925 1.988 V

0 0 1 1 1 1.518 1.578 1.638 1.811 1.871 1.932 V

0 1 0 0 0 1.474 1.532 1.591 1.758 1.817 1.876 V

0 1 0 0 1 1.430 1.486 1.543 1.706 1.763 1.820 V

0 1 0 1 0 1.386 1.441 1.496 1.653 1.708 1.764 V

0 1 0 1 1 1.342 1.395 1.448 1.601 1.654 1.708 V

0 1 1 0 0 1.298 1.349 1.401 1.548 1.600 1.652 V

0 1 1 0 1 1.254 1.303 1.353 1.496 1.546 1.596 V

0 1 1 1 0 1.210 1.258 1.306 1.443 1.491 1.540 V

0 1 1 1 1 1.166 1.212 1.258 1.391 1.437 1.484 V

1 1 1 1 1 1.094 1.138 1.181 1.306 1.349 1.393 V

Note 1: Guaranteed by design, not 100% tested in production

5V

60µA

COMP

V

V

V

V

V

PWRGD

V

I

SENSE

LGnd

SS

5 BIT

DAC

+8.5%

-+-

65µS

Delay

ERROR AMPLIFIER

+

-

+

76mV

ID0

ID1

ID2

ID3

ID4

-8.5%

FB

2µA

PWM

COMPARATOR

-

+

V

CC

30µA

-

+

I

SENSE

COMPARATOR

-

+

VFB LOW COMPARATOR

1V

2.5V

VCC Monitor

PWM Comp

Blanking

0.7V

Extended

-

+

+

-

Maximum

On-Time

Timeout

Normal

Off-Time

Off-Time

Timeout

-

+

SS Low

Comparator

SS High

Comparator

Time Out

Timer

3.95V

3.87V

R

S

FAULT

Latch

Off-Time

Timeout

FAULT

Q

FAULT

Q

Q

R

S

Q

PWM

Latch

Edge Triggered

GATE(H) = ON

GATE(H) = OFF

C

OFF

One Shot

R

S

Q

V

CC

V

GATE(H)

PGnd

V

CC

V

GATE(L)

PGnd

C

OFF

CS5166H

7

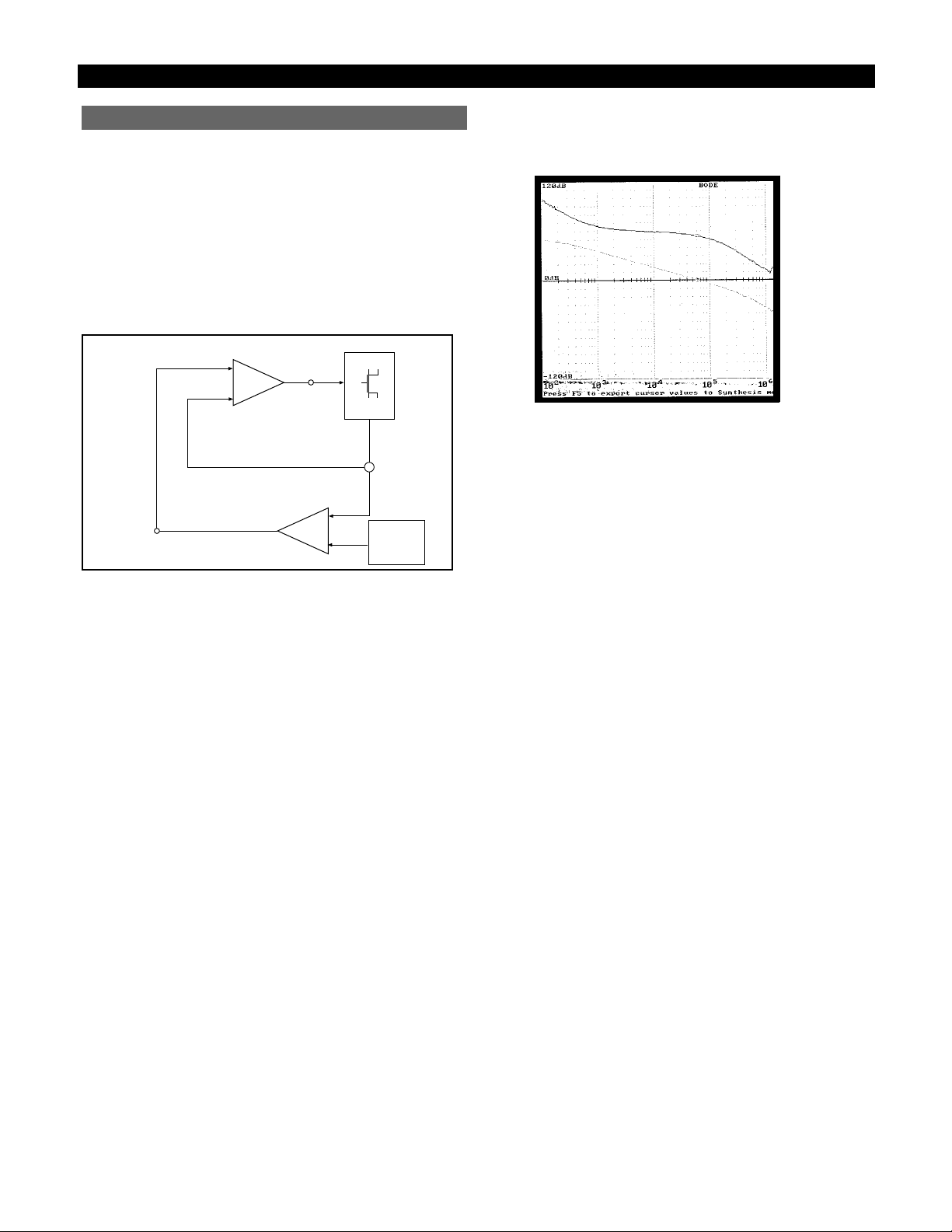

V

2

TM

Control Method

The V

2

TM

method of control uses a ramp signal that is generated by the ESR of the output capacitors. This ramp is

proportional to the AC current through the main inductor

and is offset by the value of the DC output voltage. This

control scheme inherently compensates for variation in

either line or load conditions, since the ramp signal is generated from the output voltage itself. This control scheme

differs from traditional techniques such as voltage mode,

which generates an artificial ramp, and current mode,

which generates a ramp from inductor current.

Figure 1: V

2

TM

Control Diagram.

The V

2

TM

control method is illustrated in Figure 1. The output voltage is used to generate both the error signal and

the ramp signal. Since the ramp signal is simply the output

voltage, it is affected by any change in the output regardless of the origin of that change. The ramp signal also contains the DC portion of the output voltage, which allows

the control circuit to drive the main switch to 0% or 100%

duty cycle as required.

A change in line voltage changes the current ramp in the

inductor, affecting the ramp signal, which causes the V

2

TM

control scheme to compensate the duty cycle. Since the

change in inductor current modifies the ramp signal, as in

current mode control, the V

2

TM

control scheme has the same

advantages in line transient response.

A change in load current will have an affect on the output

voltage, altering the ramp signal. A load step immediately

changes the state of the comparator output, which controls

the main switch. Load transient response is determined

only by the comparator response time and the transition

speed of the main switch. The reaction time to an output

load step has no relation to the crossover frequency of the

error signal loop, as in traditional control methods.

The error signal loop can have a low crossover frequency,

since transient response is handled by the ramp signal

loop. The main purpose of this ‘slow’ feedback loop is to

provide DC accuracy. Noise immunity is significantly

improved, since the error amplifier bandwidth can be

rolled off at a low frequency. Enhanced noise immunity

improves remote sensing of the output voltage, since the

noise associated with long feedback traces can be effectively filtered.

The Bode plot in Figure 2 shows the gain and phase margin

of the CS5166H single pole feedback loop and demonstrates the overall stability of the CS5166H-based regulator.

Figure 2: Feedback loop Bode Plot.

Line and load regulation are drastically improved because

there are two independent voltage loops. A voltage mode

controller relies on a change in the error signal to compensate for a deviation in either line or load voltage. This

change in the error signal causes the output voltage to

change corresponding to the gain of the error amplifier,

which is normally specified as line and load regulation.

A current mode controller maintains fixed error signal

under deviation in the line voltage, since the slope of the

ramp signal changes, but still relies on a change in the error

signal for a deviation in load. The V

2

TM

method of control

maintains a fixed error signal for both line and load variation, since the ramp signal is affected by both line and load.

Constant Off-Time

To maximize transient response, the CS5166H uses a

Constant Off-Time method to control the rate of output

pulses. During normal operation, the Off-Time of the high

side switch is terminated after a fixed period, set by the

C

OFF

capacitor. To maintain regulation, the V

2

TM

Control

Loop varies switch On-Time. The PWM comparator monitors the output voltage ramp, and terminates the switch

On-Time.

Constant Off-Time provides a number of advantages.

Switch duty Cycle can be adjusted from 0 to 100% on a

pulse-by pulse basis when responding to transient conditions. Both 0% and 100% Duty Cycle operation can be

maintained for extended periods of time in response to

Load or Line transients. PWM Slope Compensation to

avoid sub-harmonic oscillations at high duty cycles is

avoided.

Switch On-Time is limited by an internal 30µs (typical)

timer, minimizing stress to the Power Components

Programmable Output

The CS-5166H is designed to provide two methods for programming the output voltage of the power supply. A five

bit on board digital to analog converter (DAC) is used to

program the output voltage within two different ranges.

Theory Of Operation

Application Information

COMP

PWM

Comparator

+

C

–

Ramp Signal

Error

Signal

Error

Amplifier

GATE(H)

GATE(L)

E

V

FB

–

+

Reference

Voltage

.1µF

10K

Open Loop

49.63

BW

62.3 KHz

Phase margin

81.9

Loading...

Loading...