Page 1

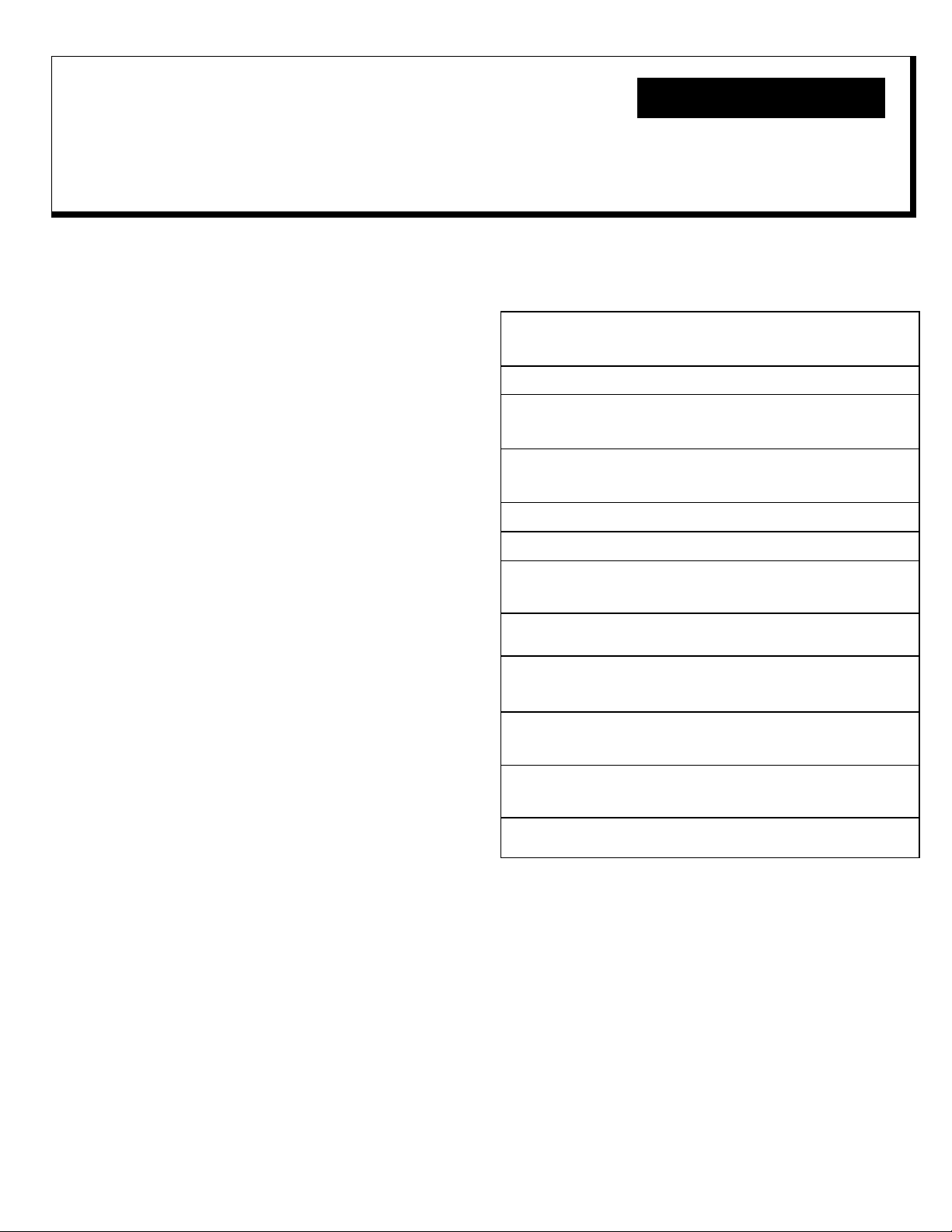

of Cured Coatings (-59°C to 132°C)

Tack Free Time 30 min.

(@ 80% R.H.) 8 Hours @ 170°F (77°C)

(Water=1) @ 68°F (Liquid Only)

Viscosity (cps @ 77°F) 70± 5 cps

Flash Point (TCC) 30°F

(ohm/cm)

Index (CTI) (PLC of 2)

Expansion (in/in/°C)

(1 mil/ft2) CTAR-12 20.2

2 years

TDS # CTAR

CHEMTRONICS

Technical Data Sheet

Konform AR

PRODUCT DESCRIPTION

Konform AR is ide al f or pr oviding

insulation a gainst high -voltage a rcing a nd

corona shor ts. T his extremely effective

acrylic c onformal c oating pr ovides a hard,

durable pr otective ba rrier a gainst hum idity,

salt, corrosive vapors and fungus for printed

circuit board and e lectronic a ssemblies.

Konform

AR r esin m eets MIL-I-46058C,

Type AR.

Clear transparent coating

Excellent dielectric strength

Helps prevent arcing and shorts

Increases life of electronic assemblies

Will not discolor over time under normal

use

Contains a UV indicator for thorough

Quality Control inspection

UL Recognized, File E76307

TYPICAL APPLICATIONS

Konform

AR is ideal for applications in:

Aerospace

Data Communications

Instrumentation

Automotive Manufacturing

Marine Manufacturing

Process Control

TYPICAL PRODUCT DATA AND

PHYSICAL PROPERTIES

Usable Temp. Range -75°F to 270°F

Curing Conditions 24 Hours @ 77°F (25°C)

Specific Gravity 0.93

Volume Resistivity 1 x 1014

Dielectric Breakdown (volts/mil) 8300

Comparative Tracking 250

Coefficient of Thermal 5 x 10-5

Coverage CTAR-1 254.0

Shelflife

COMPATIBILITY

Konform

AR is ge nerally c ompatible w ith

most materials f ound on pr inted c ircuit

boards. A s w ith a ny c hemical pr oduct,

product/component compatibility m ust be

determined on a non-critical a rea pr ior to

use.

Page 2

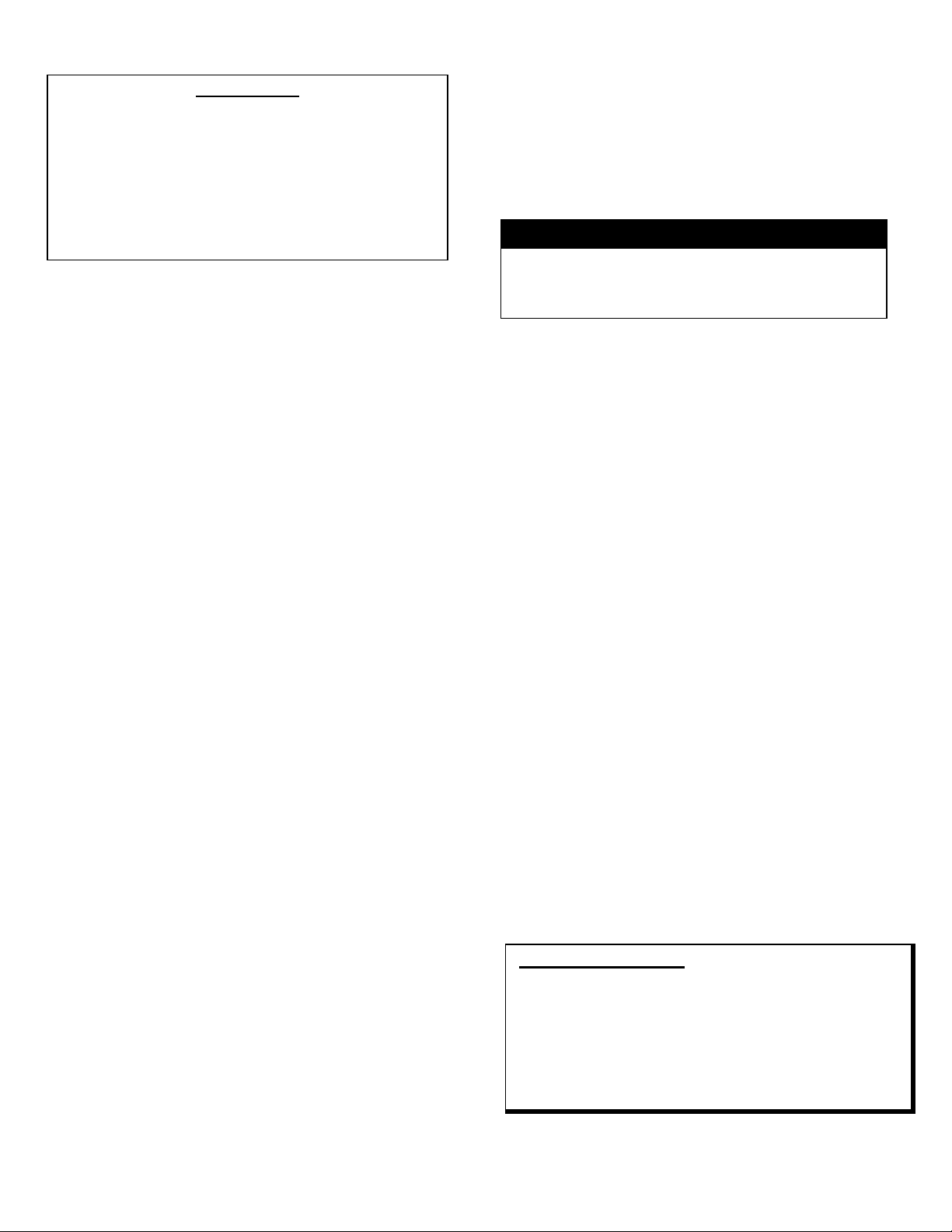

Performance

Moisture Resistance

Good

Removability

Excellent

Ease of Repair

Excellent

Flexibility

Fair

Adhesion

Excellent

Abrasion Resistance

Excellent

Solvent Resistance

Fair

CFC

0.0%

VOC

88.9%

HCFC

0.0%

HFC

0.0%

Cl. Solv.

0.0%

ODP

0.00

USAGE INSTRUCTIONS

For industrial use only.

Read MSDS carefully prior to use.

Before a pplying K onform AR conformal c oatings,

clean c ircuit boa rds t o r emove c ontamination a nd

allow t o dr y. C leaning m ay be performed with

Chemtronics Flux-Off products.

SPRAY AP PLICATION: A pply t op to bot tom,

allowing coating to flow evenly around components.

Rotate PCB 9 0° and repeat application. R otate and

apply coating two additional times, then allow board

to c ure. I f a dditional t hickness is desired, apply

additional c oatings. W hen us ing l iquid spray w ith

automatic di spensing e quipment, a djustments may

be required in application rate and viscosity.

DIP AP PLICATION: Using automatic e quipment

or ha nd i mmersion t echnique, s lowly i mmerse PCB

into the coating and remove slowly. Use an average

rate of a pproximately 1 f oot pe r m inute. A fter

allowing the board to cure, process may be repeated

to achieve desired thickness.

BRUSH AP PLICATIONS: E venly a pply c oating

to areas desired at t hickness r equired. A llow t ime

for curing before r eapplying t o ach ieve a t hick

coating. U se C hemask to pr otect c omponents

during conformal coating process.

REMOVAL: After a pplication, c ured K onform

AR m ay be r emoved by s oaking in Chemtronics

Electro-Wash Two Step.

AVAILABILITY

CTAR-12 11.5 oz. Aerosol

CTAR-1 1 Gallon Liquid

ENVIRONMENTAL IMPACT DATA

(For Aerosol Product)

ENVIRONMENTAL IMPACT DATA

CFC, HCFC, CL. SOLV., V OC, and H FC numbers

shown a re t he content by weight. O zone de pletion

potential ( ODP) i s d etermined i n acco rdance w ith the

Montreal Protocol and U.S. Clean Air Act of 1990.

TECHNICAL & APPLICATION ASSISTANCE

Chemtronics provides a t echnical hot line t o answer

your t echnical a nd a pplication r elated que stions.

The toll free number is: 1-800-TECH-401.

NOTE: This information is believed to be accurate. It

is intended for professional end users having the skills to

evaluate and u se t he d ata p roperly. C HEMTRONICS

does not guarantee the accuracy of the data and assumes

no liability in connection w ith da mages i ncurred w hile

using it.

DISTRIBUTED BY:

Loading...

Loading...