Page 1

Chem-Wik Rosin

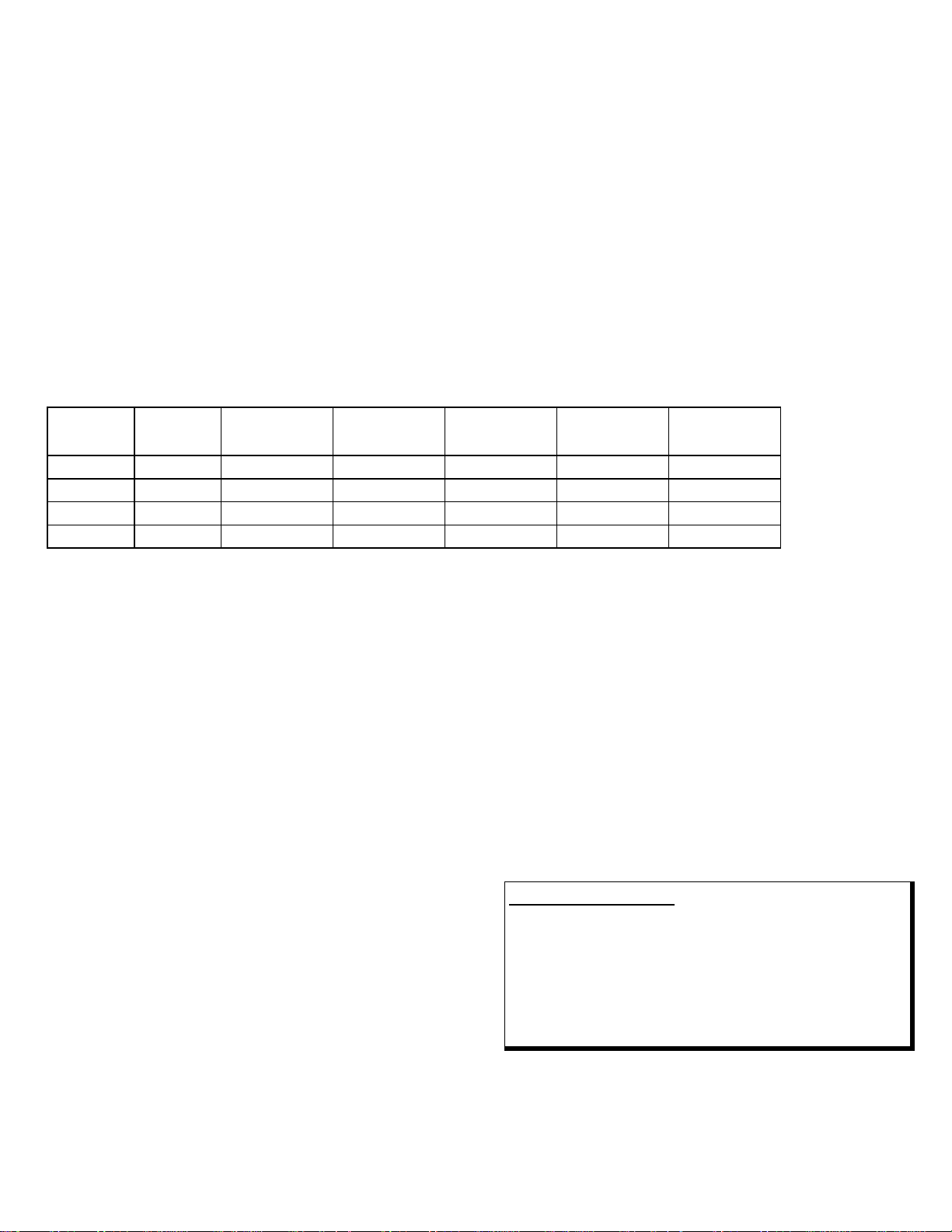

Part #

Size

Inches

Size

Metric

2-5L

.030”

.76mm

5-5L

.050”

1.27mm

7-5L

.075”

1.91mm

10-5L

.100”

2.54mm

TDS # CWik

CHEMTRONICS

Technical Data Sheet

Chem-Wik Rosin

PRODUCT DESCRIPTION

Chem-Wik Rosin is especially designed for

today’s heat sensitive ele ctronic components.

The lighter mass, pure copper braid

construction allows for better thermal

conductivity, even at low temperatures.

Chem-Wik

faster than conventional desoldering braids.

This design minimizes overheating and

requires less “contact” pressure for greater

operator control. All sizes are coated with a

Type “R” organic flux system .

Requires little or no post solder cleaning

No corrosive residues

Optimized we ave design for faster

wicking and heat transfer

Halide free

Minimal risk of heat da mage to

components and circuit boa rds

TYPICAL APPLICATIONS

Chem-Wik

removes solder fr om:

Thru-hole Components

Surface Mount Device Pads

BGA Pads

Micro Circuits

Terminals

Lugs and Posts

Identification Script

Rosin responds as much as 50%

Rosin desoldering braid safely

TYPICAL PRODUCT DATA AND

PHYSICAL PROPERTIES

Flux Type: Grade WW, Type “R”

Clean-up Required: No

Military Specifications: MIL-F-14256F

Shelf Life – 2 years from manufacturer

date

STATIC DISSIPATIVE PACKAGING

Static Dissipative packaging is available on

all 5 foot bobbins. The static dissipative

bobbins qualify as electrostatic discharge

protective per DOD Standard 1686 and DOD

Handbook 263. Meets the static delay rate

provision of MIL-B-81705C.

Page 2

Color

5 ft.

25 ft.

50 ft.

100 ft.

500 ft.

.030”

White

2-5L

2-25L

2-50L

2-100L

2-500L

.050”

Yellow

5-5L

5-25L

5-50L

5-100L

5-500L

.075”

Green

7-5L

7-25L

7-50L

7-100L

7-500L

.100”

Blue

10-5L

10-25L

10-50L

10-100L

10-500L

USAGE INSTRUCTIONS

For industrial use only.

Read MSDS care fully prior to use.

1) Choose a Chem-Wik desoldering braid

width equal to or slightly larger than the

pad or connection.

2) Choose a solder iron tip equal to or slightly

smaller than the pad or connection.

3) Set temperature of iron between 600-750°F

4) Place wick on solder joint and place tip of hot

iron on top of wick

AVAILABILITY

5) As solder becomes molten, the color of the

wick will change from copper to silver.

6) Remove wick and iron from solder joint

simultaneously once color change has stopped.

7) The component lead is now clean and free

from solder.

8) Clip and discard the used portion of the wick.

Width

Code

Bobbin

Spool

Chem-WikRosin is designed to meet

or exceed the following stand ards:

MIL-F-14256F, Type R

MIL-STD-2000A

MIL-B-81705C

NASA NHB5300.4(3A)

NASA SP-5002

NASA NPC200-4

IPC SF-818

DOD Handbook 263

DOD Standard 1686

BELLCORE TR-NWT-00078

TECHNICAL & APPLICATION

ASSISTANCE

Chemtronics provides a technical hotline to

answer your technical and application related

questions. The toll free number is:

1-800-TECH-401.

Spool

NOTE:

This information is believed to be accurate. It is

intended for professional end users having the skills

to evaluate and use the data properly.

CHEMTRONICS does no t guarantee t he accuracy of

the data and assumes no liability in connection with

damages incurred while using it.

CHEMTRONICS

8125 COBB CENTER DRIVE

KENNESAW, GA 30152

1-770-424-4888 REV. D (08/13)

Spool

Spool

DISTRIBUTED BY:

Loading...

Loading...