Chemtrol PC6000, PC3000 Instruction Manual

MANUALPC-2012

© SBCS 2012

i

INSTRUCTION MANUAL

CHEMTROL® PC PROGRAMMABLE

WATER TREATMENT CONTROLLERS

WARRANTY

This CHEMTROL® Controller S/N _________________ is warranted by SANTA BARBARA CONTROL SYSTEMS (SBCS) to be free

from defects in manufacturing and workmanship for a period of FIVE (5) YEARS from the date of purchase for the printed circuit boards

and ONE (1) YEAR for all other components. SBCS will repair or replace at its option any defective part during the warranty period.

Labor, shipping or incidental expenses are specifically excluded from this warranty. For warranty coverage, defective parts should be

returned immediately to your CHEMTROL® Dealer or to our factory postpaid with a copy of your purchase receipt and a description of

the malfunction.

TECHNICAL SUPPORT

US/CANADA

OTHER COUNTRIES

AUSTRALIA

EMAIL

support@chemtrol.com.au

800-621-2279

805-683-8833

1-300-585-820

MANUALPC-2012

ORP AUTO

Calibrate mV 750

Setpoint mV 700

Alarm Low mV 650

Alarm High mV 850

Time Limit min 30

Run Time 10 125

Last Shock 05/01/98

SANITIZER OFF

Calibrate ppm 1.5

Setpoint ppm 1.5

Alarm Low ppm 0.3

Alarm High ppm 3.0

Time Limit min 30

Run Time 10 125

Last Shock 00/00/00

CONTROL TYPE

OFF

Manual

Automatic

Timer

CALIBRATION

1 Point (Zero)

2 Point (Slope)

3 Point (Curve)

ALARM OPTIONS

Feed Lockout YES

Buzzer YES

SHOCK & SAVER

Shock Treatment

Chemical Saver

ON/OFF

Proportional

4-20 mA

Cycle ON 0.1

Cycle OFF 1.0

Deadband

Deadband

Progressive Zone

Top Limit

Bottom Limit

pH AUTO

Calibrate 7.5

Setpoint 7.5

Alarm Low 7.0

Alarm High 8.0

Time Limit min 30

Run Time 10 25

Probe Clean AUTO

CLEAN ON OFF

Mo 19:00 19:05

Tu 00:00 00:00

We 19:00 19:05

Th 00:00 00:00

Fr 00:00 00:00

Sa 19:00 19:05

Su 00:00 00:00

TDS AUTO

Calibrate ppm 1650

Setpoint ppm 2000

Alarm Low ppm 50

Alarm High ppm 2500

Time Limit min 30

Run Time 10 25

Select Scale

Cell Constant 1

TDS Factor 0.5

HEATER AUTO

Calibrate F 82

Setpoint F 82

Alarm Low F 70

Alarm High F 85

Time Limit min 30

Run Time 15 60

Energy Saver AUTO

Heating

Cooling

Acid Feed

Base Feed

Both

Oxidizer

Reducer

Both

ENERGY SAVER

Mo 19:00 06:00

Tu 19:00 06:00

We 19:00 06:00

Th 19:00 06:00

Fr 19:00 06:00

Sa 19:00 06:00

Su 19:00 06:00

PUMP AUTO

P influent psi 25

P effluent psi 20

Flow Rate gp m 800

Alarm low gp m 500

Flow Total Mga 2.20

Heater Delaymi n 20

Water Level AUTO

PUMP ON OFF

Mo 05:00 20:00

Tu 05:00 20:00

We 05:00 20:00

Th 05:00 20:00

Fr 05:00 20:00

Sa 05:00 20:00

Su 05:00 20:00

PRESSURE ALARMS

Low psi + 10

High psi + 50

FLOWMETER FACTOR

Pulses/ga: 6.705

FILTER AUTO

Backwash Date 8/10

Start Time 15:30

Filter Time (min)10.0

Advance (min) 1.0

Number of Filters 5

Pump shutdownYES

Pump Override YES

CONFIGURATION

Initial Setup

Operations

Reports

Communications

Time Interval

P Differential

Time or Pressure

Time & Pressure

Flow rate

Volume of water

Volume or Pressure

Volume & Pressure

Number of Filters5

Priority Valve YES

PUMP Override YES

Stop Time between

valves (sec) 10

COMMUNICATIONS

Phone

Unit ID

Alarm calling YES

INITIAL SETUP

Language

Units

Password

Clock Set

Readings

Data Logging

Model Options

MODEL OPTIONS

ORP Yes

SANITIZER Yes

p H Yes

CONDUCTIVITY Yes

HEATER Yes

PUMP Yes

FILTER Yes

PHONE NUMBERS

1: ______________

2: ______________

3: ______________

4: ______________

5: ______________

6: ______________

SATURATION

Alkalinity 150

Hardness 300

pH 7.5

Temperature 80

Langelier Limits

Langelier Index

Condition OK

OPERATIONS

Audio Alarms YES

Bypass Line YES

Saturation OK

Print Reports

Reset

Battery

Probe Monitor YES

Complete Reset

Partial Reset

ORP

SANITIZER

pH

CONDUCTIVITY

HEATER

PUMP

FILTER

LANGUAGE

English

French

Spanish

UNITS

U.S.

Metric

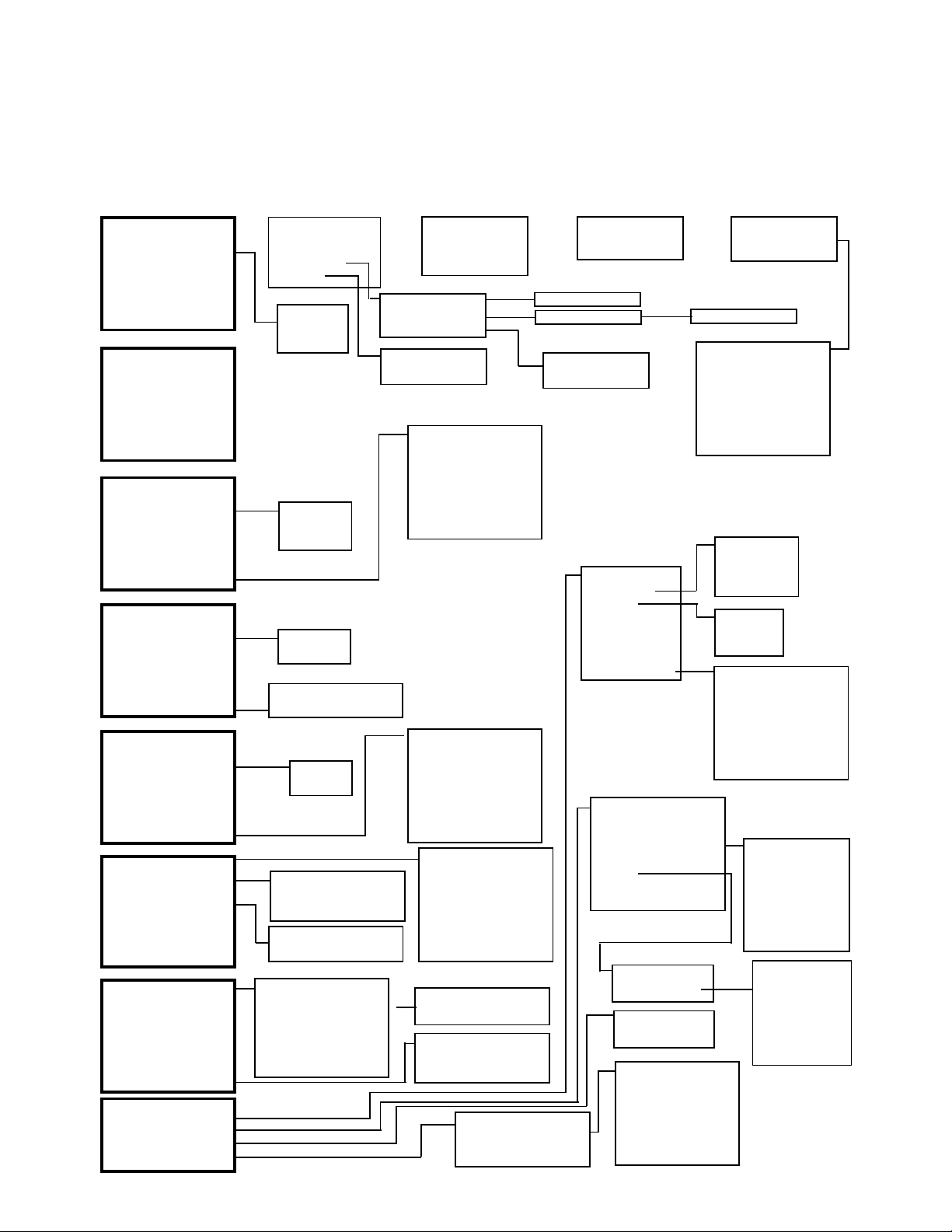

MENU TREE CHEMTROL

(R)

PC CONTROLLERS

Decrease

Increase

SHOCK AUTO

Date 05/08/98

Cycle (days) 7

Time ON pH 18:00

Level pH 7.8

Time ON shock 21:00

Level ORP 820

Time OFF 21:30

View data log

Print Reports

ii

MENU TREE

MANUALPC-2012

1. READ AND FOLLOW ALL INSTRUCTIONS

2. WARNING - To reduce the risk of injury, do not permit children to use this product unless they are closely

supervised at all times.

3. A wire connector is provided on this unit to connect a minimum No. 8 AWG solid copper conductor between

this unit and any metal equipment, metal enclosures or electrical equipment, metal water pipe or conduit within 5

feet of this unit.

4. DANGER - Risk of injury.

a) Replace damaged cord immediately.

b) Do not bury cord.

c) Connect to a grounded, grounding type receptacle only.

5. WARNING - This product must be connected to a power source equipped with a ground-fault circuit interrupter

(GFCI). The GFCI must be tested before each use. With the product operating, open the service door. If the

product stops operating, this merely indicates that the door is equipped with an electrical interlock. Next, push the

test button on the GFCI and close the service door. The product should not operate. Now open the service door,

push the reset button on the GFCI and close the service door. The product should now operate normally. If the

product fails to operate in this manner, there is a ground current flowing indicating the possibility of an electric

shock. Disconnect the power until the fault has been identified and corrected.

8. DANGER - Risk of electric shock. Install at least 5 feet (1.5 m) from inside wall of tub or spa using nonmetallic

plumbing.

7. DANGER - Risk of electric shock. Do not permit any electric appliance, such as a light, telephone, radio, or

television, within 5 feet (1.5 m) of a spa or hot tub.

8. WARNING - To reduce the risk of injury:

a) The water in a spa should never exceed 40 ºC (104 ºF). Water temperatures between 38 ºC (100 ºF) and

40 ºC (104 ºF) are considered safe for a healthy adult. Lower water temperatures are recommended for

young children and when spa use exceeds 10 minutes.

b) Since excessive water temperatures have a high potential for causing fetal damage during early months of

pregnancy, pregnant or possibly pregnant women should limit spa water temperatures to 38 ºC (100 ºF).

c) Before entering a spa or hot tub, the user should measure the water temperature with an accurate

thermometer since the tolerance of water temperature-regulating devices varies.

d) The use of alcohol, drugs or medication before or during spa or hot tub use may lead to unconsciousness

with the possibility of drowning.

e) Persons suffering from obesity or with a medical history of heart disease, low or high blood pressure,

circulatory system problems or diabetes should consult a physician before using a spa.

f) Persons using medication should consult a physician before using a spa or hot tub since some medication

may induce drowsiness while other medications may affect heart rate, blood pressures and circulation.

iii

IMPORTANT SAFETY INSTRUCTIONS

Specified by ITS Testing Services for Swimming Pools and Spas

9. SAVE THESE INSTRUCTIONS

MANUALPC-2012

TABLE OF CONTENTS

MENU TREE ...................................................................II

IMPORTANT SAFETY INSTRUCTIONS .......................II

IMPORTANT SAFETY INSTRUCTIONS ......................III

TABLE OF CONTENTS ............................................... IV

LIST OF FIGURES .........................................................3

CHAPTER I - INTRODUCTION ......................................1

Water Maintenance ...........................................................1

Reference Manuals........................................................1

CONTROLLER FEATURES.................................................2

New Features....................................................................2

Models...............................................................................2

Automated Water Treatment .............................................2

Control Functions ..............................................................2

Free Chlorine.................................................................3

Free Chlorine control .....................................................3

ORP control ...................................................................3

Probe Failure Analysis ......................................................3

CONTROL PANEL ...............................................................4

LCD Display Screen ..........................................................4

Display Readings ..............................................................4

Data Entry Keyboard ......... E

Remote Communications ..................................................4

PROGRAM MENUS .............................................................5

Initial Screens....................................................................5

Display Screens ................................................................5

Main Menus and Submenus..............................................5

Alarm Displays .................. Error! Bookmark not defined.

CHAPTER II - INSTALLATION ......................................6

SAFETY NOTICE .................................................................6

UNPACKING........................................................................6

INSTALLATION REPORT....................................................6

TECHNICAL SUPPORT.......................................................6

PRINCIPLE OF INSTALLATION..........................................6

CONTROLLER CABINET ....................................................6

LOCATION...........................................................................6

ELECTRICAL .......................................................................8

Electrical Codes ................................................................8

AC Power Input .................................................................8

Grounding (GFI) ................................................................8

Main Power Interlock.........................................................8

Panel Interlock ..................................................................8

PC Boards.........................................................................8

Power Board .....................................................................8

115V/230V Power Transformer ........E

defined.

Relay Jumpers (PC7000) ..................................................8

rror! Bookmark not defined.

rror! Bookmark not

iv

Relays and Fuses ............. E

Remote Alarm ................................................................... 9

Mother Board ....................................................................9

Sensor Connections.......................................................... 9

Buzzer............................................................................... 9

Display Brightness ............................................................9

Backup Battery................................................................ 11

Remote Communications................................................ 11

Multiple Serial Connections (Option)............................... 11

4-20 mA Converter Boards .............................................12

Field Installation .............................................................. 12

4-20 mA Connections ..................................................... 12

PPM Sensor Board .........................................................12

PLUMBING ........................................................................13

Installation of Sensors..................................................... 13

In-line Installation (2" Pipe) ............................................. 13

Flow Cell Assembly......................................................... 13

Sensor Cell Cabinet (Option) .......................................... 13

Water Flow...................................................................... 14

Paddle Wheel Rotary Flow Switch .................................. 14

PPM SENSORS ................................................................. 15

PPM Sensor Flow Cell .................................................... 15

PPM Sensor Installation.................................................. 15

ORP AND PH SENSORS....................................................16

Properties........................................................................ 16

Packaging .......................................................................16

Sensor cables .................................................................16

Electrical Interference .....................................................16

Storage and Winterizing.................................................. 17

Sensor Warranties ..........................................................17

TEMPERATURE SENSOR ................................................ 17

CONDUCTIVITY SENSOR.................................................17

FLOW SENSOR.................................................................18

Flow Sensor Location ..................................................... 18

Flow Sensor Saddles ...................................................... 18

Flow Sensor Connections ............................................... 18

PRESSURE TRANSDUCERS ........................................... 19

Transducer Connections ................................................. 19

WATER LEVEL SENSOR .................................................. 19

Installation....................................................................... 19

Maintenance ................................................................... 19

Figure 28 - Optical Level Sensor..................................... 19

CHEMICAL FEEDERS....................................................... 20

WARNING: Tank Sizing .................................................. 20

Chemical Feed Pumps.................................................... 20

Carbonic Acid (CO2) Valve ............................................. 20

Gas Chlorinator............................................................... 20

Erosion Feeders.............................................................. 20

Back Diffusion ................................................................. 20

FILTER BACKWASH......................................................... 21

Main Pump Shutoff ......................................................... 21

Single Filter Backwash.................................................... 21

Multiple Filter Backwash .................................................21

Backwash Stager ............................................................ 21

Electrical Valves.............................................................. 21

Hydraulic Valves .............................................................21

Pneumatic Valves ...........................................................21

rror! Bookmark not defined.

CHAPTER III - STARTUP ............................................ 22

MANUALPC-2012 Page 1

CONTROLLER STARTUP .................................................22

Initial Reset .....................................................................22

Configuration Menu .........................................................22

Alarm Buzzer...................................................................22

Bypass Line.....................................................................22

Battery Check..................................................................22

PPM Board Initialization ..................................................22

CHEMICAL CONTROL ......................................................22

Initial Activation of Sensors .............................................22

Bypass Line Test.............................................................22

Water Chemistry Adjustment...........................................22

Water Sampling...............................................................22

pH Calibration .................................................................22

pH Feed (Acid or Base)...................................................23

pH Setpoint .....................................................................23

ORP Calibration ..............................................................23

ORP Setpoint ..................................................................23

Sanitizer Calibration ........................................................23

Time Limits......................................................................23

Shock Treatment .............................................................23

Chemical Saver...............................................................23

WATER SATURATION ......................................................23

CHAPTER IV - CONTROLLER OPERATION..............24

Access.............................................................................24

Default Setup ..................................................................24

8 - CONFIGURATION MAIN MENU ...................................24

8.1 - INITIAL SETUP SUBMENU ....................................25

8.1.1 - Language..........................................................25

8.1.2 - Units .................................................................25

8.1.3 - Code Number ...................................................25

8.1.4 - Clock ................................................................26

8.1.5 - Readings ..........................................................26

8.1.6 - Data Logging ....................................................26

8.1.7 - Model Options ..................................................26

8.2 - OPERATIONS SUBMENU......................................27

8.2.1 - Audio Alarms ....................................................27

8.2.2 - Bypass Line ......................................................27

8.2.3 - Langelier Saturation Index................................27

8.2.4 - Reset ................................................................28

8.2.5 - Backup Battery .................................................28

8.2.6 - Probe Monitor ...................................................28

8.3 - REPORT SUBMENU ..............................................28

8.3.1 - View Data Log ..................................................28

8.3.2 - Print Reports.....................................................29

On-Site Printing ...........................................................29

On-Site Download........................................................29

8.4 - COMMUNICATIONS SUBMENU............................30

8.4.1 - Phone Numbers................................................30

8.4.2 - Unit Identification ..............................................30

8.4.3 - Alarm Calling ....................................................30

8.4.4 - 4-20 mA Output ................................................30

1 - ORP MENU....................................................................31

Operation.....................................................................31

1.1 - Control Mode...........................................................31

1.2 - Display and Calibration ...........................................31

1.3 - Setpoint...................................................................31

1.4 - Low Alarm ...............................................................31

1.5 – High Alarm .............................................................32

1.6 - Time Limit ...............................................................32

1.7 - Run Time ................................................................32

1.8 - Last Shock ..............................................................32

1.8.1 - Shock Treatment ..............................................32

1.8.2 - Deshock............................................................32

1.8.3 - Chemical Saver ................................................32

2 - SANITIZER MENU ........................................................ 33

Input Selection ................................................................33

Free Chlorine Control...................................................... 33

Calculated PPM Readings .............................................. 33

2.1 - Display and Calibration ........................................... 33

Free Chlorine Calibration............................................. 33

Calculated PPM Calibration......................................... 33

2.3 - Setpoint...................................................................34

2.4 - Low Alarm............................................................... 34

2.5 - High Alarm .............................................................. 34

2.6 - Time Limit ...............................................................34

2.7 - Run Time ................................................................34

2.8 - Last Shock .............................................................. 34

2.8.1 - Superchlorination .............................................34

2.8.2 - Deshock ...........................................................34

2.8.3 - Chemical Saver ................................................ 34

3 - PH MENU.......................................................................35

Operation ........................................................................35

3.1- Control Mode ...........................................................35

3.2 - Display and Calibration ........................................... 35

3.3 - Setpoint...................................................................35

3.4 - Low Alarm............................................................... 36

3.5 - High Alarm .............................................................. 36

3.6 - Time Limit ...............................................................36

3.7 - Run Time ................................................................36

3.8 - Probe Clean............................................................ 36

4 - CONDUCTIVITY MENU ................................................ 37

Conductivity and TDS .....................................................37

Conductivity or TDS Displays.......................................... 37

4.1- Control Mode ...........................................................37

4.2 - Display and Calibration ........................................... 37

4.3 - Setpoint...................................................................37

4.4 - Low Alarm............................................................... 37

4.5 - High Alarm .............................................................. 37

4.6 - Time Limit ...............................................................38

4.7 - Run Time ................................................................38

4.8 - Select Scale............................................................ 38

4.8.1 - Scale Selection................................................. 38

4.8.2 - Cell Constant....................................................38

4.8.3 - TDS Factor....................................................... 38

5 - TEMPERATURE MENU ................................................ 39

Operation ........................................................................39

5.1 - Control Mode ..........................................................39

5.2 - Display and Calibration ........................................... 39

5.3 - Setpoint...................................................................39

5.4 - Low Alarm............................................................... 39

5.5 - High Alarm .............................................................. 39

5.6 - Time Limit ...............................................................39

5.7 - Run Time ................................................................39

5.8 - Energy Saver .......................................................... 39

6- PUMP MENU.................................................................. 40

Operation ........................................................................40

6.1- Control Mode ...........................................................40

6.2 - Influent Pressure..................................................... 41

Pressure Alarms.......................................................... 41

Calibration ...................................................................41

6.3 - Effluent Pressure ....................................................41

Differential Pressure ....................................................... 41

6.4 - Flow Rate.................. E

6.5 - Flow Total ................. Error! Bookmark not defined.

6.6 - Heater Delay (Cooldown Safety) ...........................43

6.7 - Water Level Control ................................................ 43

7 - FILTER MAIN MENU..................................................... 44

Filter Backwash............................................................... 44

7.1 - Automatic Backwash............................................... 44

7.1.2 - Pressure Differential.........................................45

rror! Bookmark not defined.

MANUALPC-2012 Page 2

7.1.3 - Time or Pressure Differential ............................45

7.1.4 - Time and Pressure Differential .........................45

7.1.5 – Flow Rate.........................................................45

7.1.6 – Volume of Water ..............................................46

7.1.7 – Volume or Pressure Differential .......................46

7.1.8 - Volume and Pressure Differential .....................46

Safety Shutoff ..............................................................46

7.6 - Priority Valve ...........................................................46

7.7 - Pump Shutdown......................................................46

7.8 - Pump Override ........................................................46

CONTROL SUBMENUS.....................................................47

Features ..........................................................................47

X.1 - Control Type ...........................................................47

X.0.1 - Deadband.........................................................47

X.0.2 - Progressive Zone .............................................47

X.1.3 - Automatic Control.............................................48

X.1.4 - Timer Control ...................................................48

CALIBRATION SUBMENUS..............................................49

X.2 - Calibration Options .................................................49

X.2.1 - One-Point Calibration.......................................49

X.2.2 - Two-Point Calibration.......................................49

X.2.3 - Three-Point Calibration ....................................49

SHOCK AND SAVINGS SUBMENUS ................................50

X.8 - Treatment Selection................................................50

X.8.1 - Shock Treatment Program ...............................50

X.8.2 - Deshock Program ............................................50

X.8.3 - Chemical Saver Program .................................50

Limit Timers (Overfeed Safety) ....................................... 57

Timer Settings .............................................................57

PERIODIC MAINTENANCE............................................... 57

Water Testing.................................................................. 57

Shock Treatment............................................................. 57

Precautions ................................................................. 57

PORTABLE TESTER......................................................... 58

ORP SENSOR TESTING................................................ 58

pH SENSOR TESTING................................................... 58

ORP AND pH SIMULATION ........................................... 58

CONDUCTIVITY AND TEMPERATURE.........................58

TROUBLESHOOTING ................................................. 59

PARTS, ACCESSORIES AND UPGRADES ............... 60

INDEX ........................................................................... 62

CHAPTER V - COMMUNICATIONS ............................51

CHEMCOM

MODEM CONNECTIONS ..........................................................52

COMPUTER SOFTWARE INSTALLATION.....................................52

REMOTE OPERATION .............................................................52

Secondary Units..............................................................52

Duplex Operation ............................................................52

DATA COLLECTION ................................................................53

AUTOMATIC SCANNING ..........................................................53

Direct Scanning...............................................................53

Data Log Download.........................................................54

DATA DISPLAY ......................................................................54

Text Data Display ............................................................54

Graphic Data Display ......................................................54

PROGRAM .....................................................51

™

CHAPTER VI - MAINTENANCE...................................55

CONTROLLER MAINTENANCE........................................55

Regular Maintenance ......................................................55

The Acid Test ..................................................................55

Sensor Cleaning..............................................................55

PPM Sensor: ...............................................................55

ORP and pH Sensors: .................................................55

Conductivity Sensor.....................................................55

PPM Sensor Storage.......................................................55

ORP and pH Sensor Storage ..........................................55

Sensor Winterizing ..........................................................55

Battery Replacement.......................................................55

Software Upgrade ...........................................................55

CHEMICAL MAINTENANCE..............................................56

Overview .........................................................................56

pH Control .......................................................................56

ORP and Sanitizer Control ..............................................56

MANUALPC-2012 Page 3

LIST OF FIGURES

Figure 1 - Models Comparision Chart.......................................2

Figure 2 - Equilibrium of Free Chlorine.....................................3

Figure 3 - Control Panel and Main Screen ...............................4

Figure 4 - Remote Computer....................................................4

Figure 5 – Installation Schematics............................................7

Figure 6 - Mother Board ........... Error! Bookmark not defined.

Figure 9 - Power Board ............ Error! Bookmark not defined.

Figure 10 - Multiplex Connections ..........................................11

Figure 11 - Installation of Optional Boards .............................12

Figure 12 - 4-20 mA Converter Board ....................................12

Figure 13 - Sensor Installation................................................13

Figure 14 - Flow cell Assembly .

Figure 15 - Sensor Cell Cabinet (Option)............................13

Figure 16 - PPM Sensor Flow Cell .........................................15

Figure 17 - PPM Sensor Package ..........................................15

Figure 18 - ORP and pH Sensors...........................................16

Figure 19 - Temperature Sensor ...........................................17

Figure 20 - Conductivity Sensor .............................................17

Figure 21 - Flow Sensor Installation .......................................18

Figure 22 - Model 2536 Flow Sensor .....................................18

Figure 23 - Model 2540 Flow Sensor .....................................18

Figure 24 - Saddle for FS2536 ...............................................18

Figure 25 - Saddle for FS 2540 ..............................................18

Figure 26 - Pressure Transducer............................................19

..........................................13

Figure 27 - Optical Level Sensor............................................ 19

Figure 28 - Optical Beam Path ............................................... 19

Figure 29 - Water Level Assembly ......................................... 19

Figure 30 - Erosion Feeder Control........................................ 20

Figure 31 - Single Filter Backwash......................................... 21

Figure 32 - Multiple Filter Backwash ...................................... 21

Figure 33 - On-screen Data Log............................................. 28

Figure 34 - Proportional Feed Rate........................................ 48

Figure 35 - CHEMCOM™ Program Menu.............................. 51

Figure 36 - CHEMCOM™ System Setup ............................... 51

Figure 37 - CHEMCOM™ Facility Menu ................................ 51

Figure 38 - CHEMCOM™ Facility Selection ..........................52

Figure 39 - CHEMCOM™ Secondary Units ........................... 52

Figure 40 - CHEMCOM™ Remote Operation Screen............ 52

Figure 41 - CHEMCOM™ Automatic Scanning .....................53

Figure 42 - CHEMCOM™ Scan Facilities ............................. 53

Figure 43 - CHEMCOM™ Manual Scanning.......................... 53

Figure 44 - CHEMCOM™ Recent Scans ............................... 53

Figure 45 - CHEMCOM™ Data Display ................................. 54

Figure 46 - CHEMCOM™ Text Data Display ......................... 54

Figure 47 - CHEMCOM™ Graphic Data Display....................54

Figure 48 - PORTA-PROBETM Portable Tester......................58

Figure 49 - pH / mV Scale...................................................... 58

MANUALPC-2012 Page 1

PLATE COUNT

CHAPTER I - INTRODUCTION

Congratulations on your selection of a CHEMTROL® PC

Programmable Controller for your water treatment.

CHEMTROL® Automation uses advanced electronic sensing

technology to monitor and control the most control critical

parameters in water, such as sanitizer activity, pH,

temperature, conductivity or total dissolved solids (TDS).

These are all essential for maintaining safe and enjoyable

water.

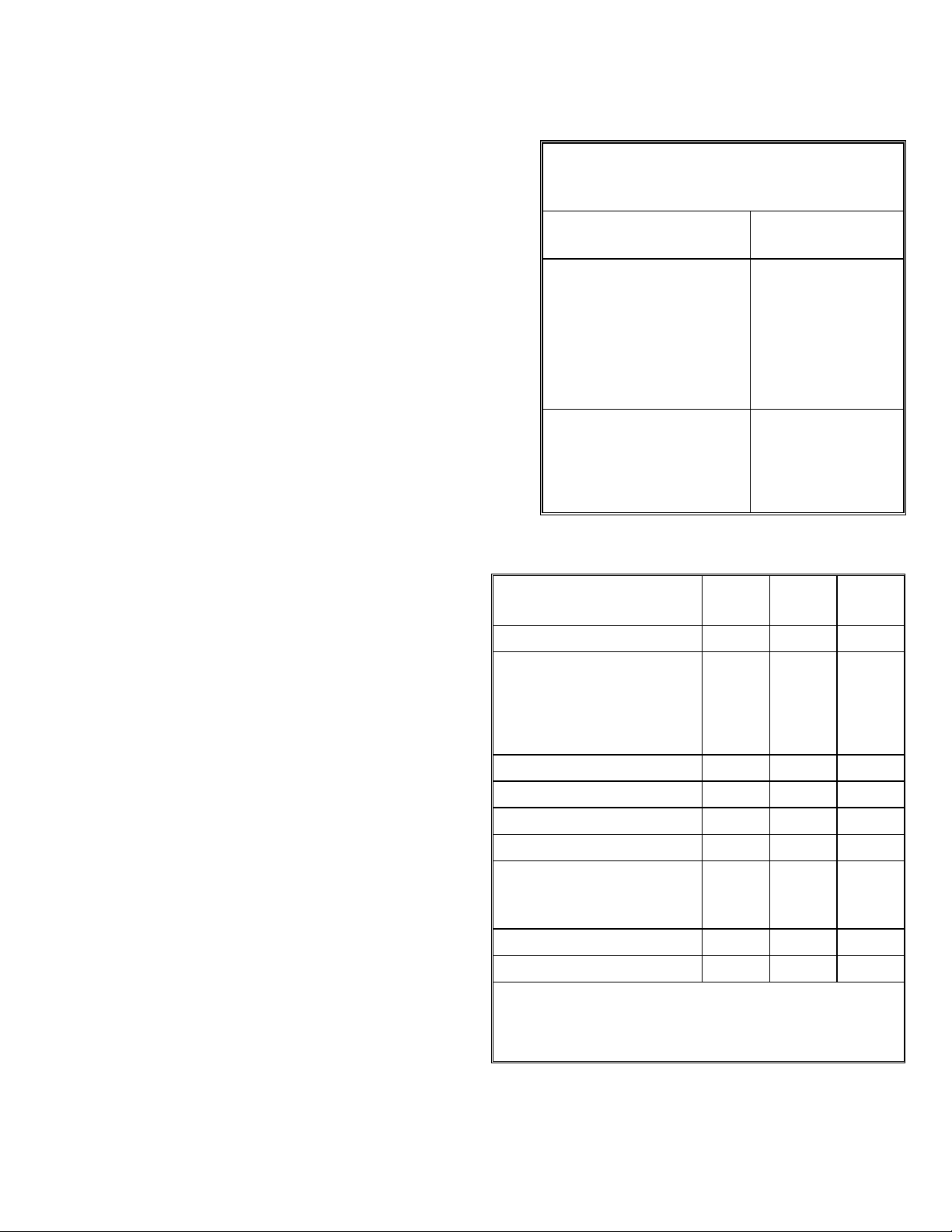

Water Maintenance

The primary purpose of water maintenance is to maintain clean

water that meets the bacteriological and physiological

requirements of state and local Health Departments, as shown,

for example, in the table for the State of California.

Equally important is the protection of the equipment from the

aggressiveness of water and its constituents.

The guidelines adopted by the National Spa and Pool Institute

(NSPI), as shown in the second table.

For chemical automation, we recommend:

- Adequate filtration with a maximum turnover rate of six

hours for a pool or 30 minutes for a spa,

- Proper water balance with a pH between 7.4 and 7.6,

alkalinity between 80 and 120 ppm (mg/l) and Langelier

Saturation Index between 0 and 0.3,

- Minimum Free Chlorine level of 1.0 ppm (mg/l) ,

- Oxidation-Reduction Potential (ORP) above 650 mV,

- Total Dissolved Solids (TDS) less than 1,500 ppm (mg/l).

- If required, stabilization not exceeding a cyanuric acid

level above 40 ppm (mg/l),

CHEMTROL® PC controllers are designed to automate and

facilitate the attainment of these goals.

Reference Manuals

For more information on water treatment, see the Maintenance

section in this Instruction Manual or refer to one of the

following reference manuals:

- “Basic Pool and Spa Technology”

National Spa and Pool Institute (NSPI)

- “Pool/Spa Operators Handbook”

National Swimming Pool Foundation(NSPF)

- “Aquatic Facility Operator Manual

National Recreation and Park Association (NRPA).

1986 CALIFORNIA HEALTH CODE

for Swimming Pools

CLARITY

STANDARD

at 35o, per ml

TOTAL COLIFORM COUNT

per 100 ml

Main drain to be

visible from deck.

Less than 200

Bacteria

Less than 2.2

organisms

No eye or skin

PHYSIOLOGICAL QUALITY

irritation.

No objectionable

physiological effect.

TEST

MIN IDEAL MAX

pH 7.2 7.5 7.6

FREE CL, ppm

Non-stabilized

Stabilized

Spa

1

1.5

2

1.5

2

3

COMBINED CL, ppm 0 0 0.2

BROMINE, ppm 2 3 4

OZONE, ppm 0.01 - 1

ORP, mV 650 750 -

CYANURIC ACID, ppm

Outdoor Pool Indoor Pool

Spa

30 0

0

40 0

0

TOTAL ALKALINITY, ppm 100 125 150

TDS, ppm 300 1000 3000

Based on Standards for Public Pools and Spas.

Published in 1988 by the

NATIONAL SPA AND POOL INSTITUTE

2

3

5

100 0

100

MANUALPC-2012 CHAPTER I – INTRODUCTION Page 2

CONTROLLER FEATURES

CHEMTROL® PC Controllers are microprocessor-based

programmable controllers designed for automatic control of

water chemistry, water balance and filtration in swimming

pools, spas, cooling towers and industrial applications.

New Features

This manual introduces two new features:

- On-screen data display, available on all models,

- New solid state PPM sensor for Free Chlorine, available

with PC5000 and PC7000 controllers.

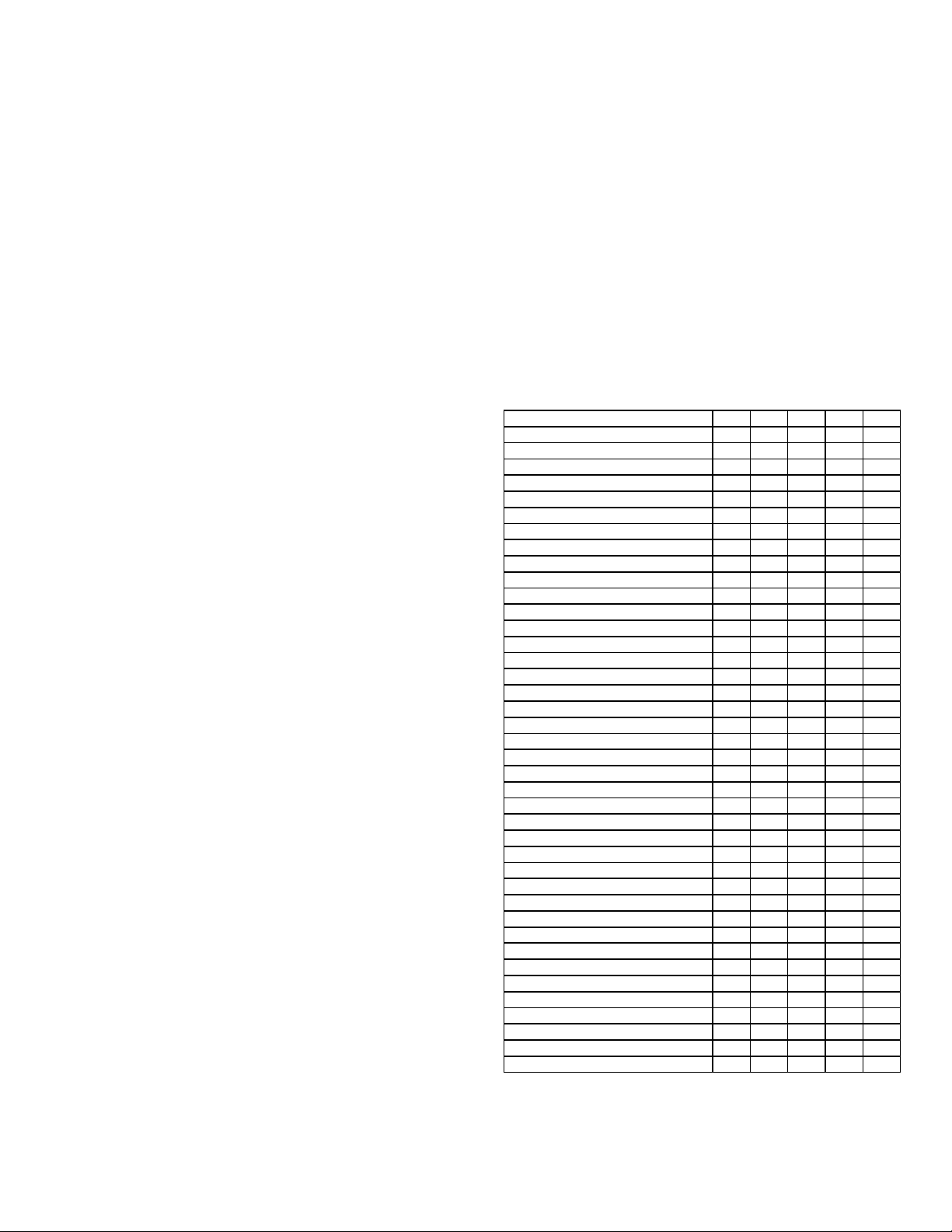

Models

Five different, yet very similar, CHEMTROL® controller models

are covered in this manual: PC2100, PC3000/PC5000, and

PC6000/PC7000. The latter 4 models use similar hardware

and thus are referred to as PC3000 Product Line.

Please refer to Figure 1 showing the standard features and

available options for each model. Note that these models have

few differences and can do mostly all the same functions

based on how they’re equipped. While PC2100 lacks level and

filtration control capability for example, PC5000/PC7000 only

have Free Chlorine control included when compared to their

otherwise identical counterparts PC3000/PC6000, respectively.

Automated Water Treatment

CHEMTROL® PC controllers are advanced automation

systems for water maintenance. Designed around a

sophisticated microprocessor, the controllers display userfriendly menus and submenus on an easy-to-read LCD (Liquid

Crystal Display) screen. All the displays and adjustments are

accessible from menu screens that are laid out in a logical and

intuitive order. They can in fact be used without reference to

the instruction manual.

All sensing devices are connected to the central control

module. That makes it possible to monitor the status of all

operational parameters at a glance. Also, in case of

malfunction or alarm, the operator is immediately alerted.

A 24-hour clock/calendar shows the date and time on the main

screen.

Control Functions

The following display and control functions are:

- Oxidation-Reduction Potential (ORP or Redox) in

millivolts with programmable oxidizer feed, superoxidation

and chemical savings program,

- Sanitizer Concentration in parts per million (ppm) or

milligrams per liter (mg/l) with programmable sanitizer feed,

superchlorination and chemical savings program,

- pH from 0 to 14 with capability for acid and base feed,

- Conductivity in microsiemens/cm or Total Dissolved

Solids (TDS) in ppm or mg/l with capability for programmed

dumping and replacement of water and for addition of three

different chemical additives, such as inhibitor, different

biocides or probe cleaner.

- Heater Control with temperature display in Fahrenheit or

Celsius, programmable heater control, and energy savings

program.

- Water Recirculation with automatic programming or manual

control of main pump, plus display of flowrate in gallons per

minute (gpm) or liters per minute (l/m) and cumulative flow in

Millions of Gallons (Mga) or cubic meters (m3),

- Water Balance and Saturation Condition derived from the

Langelier Saturation Index and showing water balance

conditions as either OK, corrosive or scaling.

- Filtration with display of inlet and outlet pressures and

programmable filter backwashing (PC6000/PC7000 only)

based on choice of time, inlet pressure, pressure differential

or combinations of the above.

OPTIONS PC2100 PC3000 PC5000 PC6000 PC7000

Free Chlorine Control / PPM sensor ● ● √ ● √

ORP Control/ Sensor √ √ √ √ √

pH Control/ Sensor √ √ √ √ √

PPM Display √ √ √ √ √

TDS/ Conductivity Control ● ● ● √ √

Water Level Control – ● ● √ √

Heater Control ● √ √ √ √

Shock Program √ √ √ √ √

Chemical Saver Program √ √ √ √ √

Langlier Saturation Index Display √ √ √ √ √

Safteytimers √ √ √ √ √

Energy Saver Program √ √ √ √ √

Adjustable Setpoints √ √ √ √ √

Proportional Feed √ √ √ √ √

Automatic Data Logging √ √ √ √ √

Influent/ Effluent Pressures ● ● ● √ √

Main Pump Control and Flow Rate ● ● ● √ √

Automated Filter Backwash – ● ● √ √

Remote Computer Operation ● ● ● √ √

Telephone Voice Communications ● ● ● √ √

Recirculation Pump Control ● – ● √ √

Remote Alarm √ √ √ √ √

Autodialer for Alarm Callout ● ● ● ● ●

Sensor Cell Cabinet ● ● ● √ √

Flow Cell Assembly ● √ √ √ √

Safety Flowswitch √ √ √ √ √

4-20mA Data Output ● ● ● ● ●

4-20mA Control ● ● ● ● ●

Ethernet/ Internet w/ Chemcon Software ● ● ● ● ●

RS-485 Direct Computer Operation ● ● ● ● ●

RS-232 for direct download ● √ √ √ √

USB Data Port √ – – – –

SD Card Reader for Firmware Updates √ – – – –

Modbus ● ● ● ● ●

Priority Valve Control - ● ● √ √

Interlock √ √ √ √ √

Waste Pit and Surge Pit Alarms – – – – –

Multiple Backwash Programs – – ● √ √

Full Screen Menus √ √ √ √ √

Compatible w/ all common Sanitizers and A.C.T. Program √ √ √ √ √

5 Year Electronics Warranty √ √ √ √ √

√ Standard Feature ● Optional Add-On – Not Available

Figure 1 - Models Comparision Chart

MANUALPC-2012 CHAPTER I – INTRODUCTION Page 3

Sanitizer Control

CHEMTROL® PC controllers offer two choices for sanitizer

control:

- Direct chlorine control using a membrane solid state

sensor for Free Chlorine (standard on PC5000/PC7000

and available on PC2100/PC3000/PC6000)

- Oxidation-Reduction Potential control for chlorine or

bromine using an ORP sensor with a platinum ring

(available on all PC controllers).

Free Chlorine

When chlorine in any form is introduced in water it forms

Hypochlorous Acid HOCl, which is called Free Chlorine and is

an excellent bactericide.

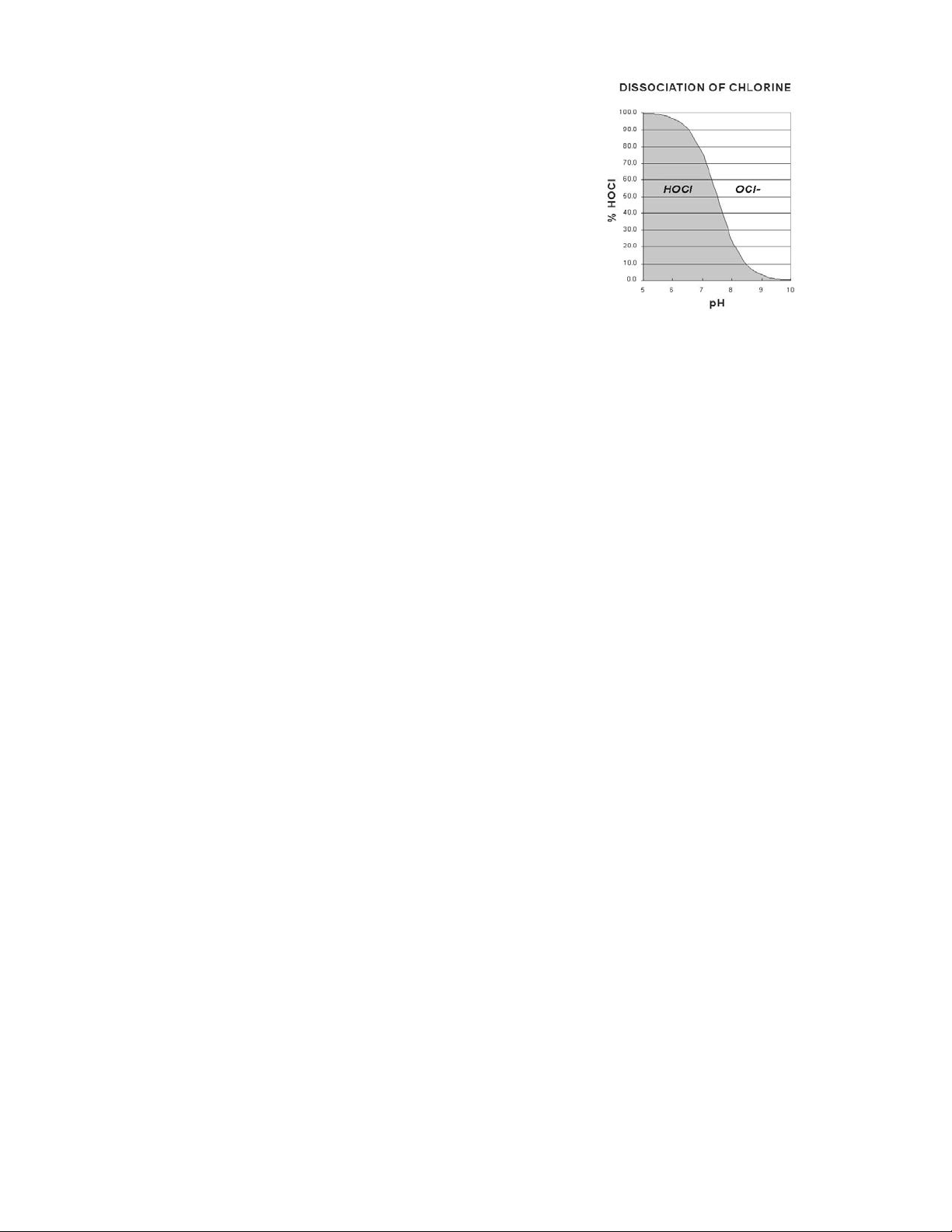

As shown in Figure 2, HOCl is a weak acid. It dissociates to

produce an hypochlorite ion OCl- and a hydrogen ion H+:

HOCl ========= OCl- + H+

Free chlorine in water is therefore always present in two forms:

- Hypochlorous acid HOCl, which is Fast Acting Free

Chlorine, and

- Hypochlorous ion OCl-, which is a much slower acting

sanitizer.

Note in that same figure that the concentration of HOCl

decreases very rapidly with increasing pH in the range of 7 to

8. At a pH of 7.5, it is equally divided between HOCl and OCL-

.

Free Chlorine control

CHEMTROL® PC5000/PC7000 include true Free Chlorine

control using a solid state sensor with a selective membrane

for Free Chlorine.

The controller displays the concentration of Total Free Chlorine

(HOCl + OCl-) in PPM (parts per million or milligrams/liter). It

does not respond to Bromine and it is not affected by oxidizers.

The Free Chlorine display does not vary with pH.

The PPM setpoint default value on the controller is 1.0 ppm,

which is recommended to kill germs and bacteria and maintain

good water quality. It can be adjusted to meet local conditions

and Health Department requirements.

ORP control

The oxidizing activity of the sanitizer (chlorine or bromine) can

be monitored with a special electrode for Oxidation-Reduction

Potential, called ORP or Redox.

ORP does not measure sanitizer concentration but only the

activity of the more active forms: HOCl or HOBr. As shown in

Figure 2, their concentration varies with pH. Therefore, for

ORP control, it is important to maintain a constant pH in the

water.

Figure 2 - Equilibrium of Free Chlorine

ORP readings are measured in millivolts (mV). They are

valuable because they provide an excellent index of

bacteriological water quality.

In 1971, the third edition of the "International Standards for

Drinking Water Quality" of the WORLD HEALTH

ORGANIZATION (WHO) stated:

"A redox potential of 650 mV (measured between platinum

and calomel electrodes) will cause almost instantaneous

inactivation of even high concentrations of virus. Such a

potential can be obtained with even a low concentration of

free chlorine but only with an extremely high concentration

of combined chlorine."

In 1985, a study of thirty commercial spas by the OREGON

DEPARTMENT OF HEALTH also confirmed 650 mV to be the

minimum value required to prevent growth of germs and

bacteria. Public pools and spas in many European countries

are required by law to maintain an ORP level of 750 mV or

more.

In the US, the 1988 revision of the Standards for Public Spas

published by the NATIONAL SPA AND POOL INSTITUTE

(NSPI) states:

"When chlorine or bromine is used as a primary

disinfectant, ORP can be used as a supplemental

measurement of proper sanitizer activity. The

recommended minimum is 650 mV with no ideal and no

maximum. The use of ORP testing does not eliminate the

need for testing the sanitizer level with standard test kits".

Probe Failure Analysis

All CHEMTROL® PC controllers include the exclusive safety

feature called Probe Failure Analysis.

With this proprietary technology (US Patent No. 5,895,565),

the controller continuously monitors and tests the dynamic

response of the ORP and pH sensors (see page 28). This

important feature allows early detection of probe failure,

thereby avoiding the dangerous out-of-range conditions that

can develop with other controllers that alert the operator only

after a failure has actually occured. This could result in serious

damage and liability.

MANUALPC-2012 CHAPTER I – INTRODUCTION Page 4

CONTROL PANEL

LCD Display Screen

The operator interacts with the controller using the LCD display

screen and the 16-key data entry keypad on the front panel of

the controller, both shown in Error! Reference source not

found.. Newer controllers come equipped with touch screens.

The display shows different screens each consisting of up to

eight lines of text. Each data line can be highlighted using the

UP and DOWN arrow keys to navigate to its submenu using

the LEFT and RIGHT arrow keys.

A line flashes to alert the operator if an alarm condition for that

specific data is met.

For models that do not come equipped with all functions

available, only the applicable screens and menus are shown.

The LCD display screen features backlight illumination for

better viewing at night and in dark areas. To protect the

display, the backlight turns off automatically after a short time

and on again as soon as a key is pressed.

The brightness of the LCD display screen is adjusted at the

factory before shipping. If required, it can be re-adjusted at

any time with a potentiometer on the Mother Board (R16 for

PC2100 or R39 for PC3000 product line).

Display Readings

As shown on the Display Screen (Error! Reference source

not found.), the operator can check all operating parameters

at a glance.

Line 1 shows an ORP reading of 750 mV with the feed pump

in Automatic feed mode (A) and running (>)

Line 2 shows a Sanitizer level of 1.5 ppm with the feed mode

OFF (X)

Line 3 shows a pH reading of 7.5 with the Acid feed mode in

Automatic (A) and the pump not running (no >)

Line 4 shows the Total Dissolved Solids (TDS) at 801 ppm

and bleed valve control OFF (X)

Line 5 shows a Temperature reading of 82 F with the heater

control on Automatic (A)

Line 6 shows Flow Rates of 1.5 and 800 gpm in the Bypass

line and Main line and the Pump in Manual mode (M)

Line 7 shows an Influent Pressure of 25 psi, an Effluent

Pressure of 20 psi and the backwash program in

Automatic mode (A)

Line 8 shows the Date and Time and an indication that the

water saturation condition is OK. The line is

highlighted to give access to the Configuration Menu

Figure 3 - Control Panel and Main Screen

emote Communications

R

CHEMTROL® controller features remote operation by

computer (Figure 4).

Unlike less advanced controllers, the CHEMTROL® PC

operates in true duplex mode with full access to all menus and

submenus.

This means that any change on the controller screen is

immediately reproduced on the remote computer screen.

Similarly, any operation that is performed on the remote

computer screen is reproduced immediately on the controller.

Both the controller as well as your computer have the same

available commands and interface. This facilitates operator

training and allows instant verification and adjustment of all

control parameters anywhere from any remote computer. To

prevent unauthorized access, the controller could be

programmed with different authorization level password

protection.

Please see Chapter V – Communications on the CHEMTROL®

communication software CHEMCOM

Figure 4 - Remote

Computer

TM and how it works.

MANUALPC-2012 CHAPTER I – INTRODUCTION Page 5

WELCOME TO

>ORP

650

mV A

>ORP

710

mV A

PROGRAM MENUS

Initial Screens

When power is applied to the controller, CHEMTROL® PC

displays the Welcome Screen shown on the right. It includes

the firmware version of the operating software installed on the

controller and the factory’s Technical Support phone numbers.

Canada has the same toll-free support numbers as the USA.

These screens can also be accessed at any time from the

Main Display Screen by pressing the LEFT ARROW key.

Display Screens

The Welcome Screen is followed by the main menu showing

the main functions of the controller and their conditions.

The adjustable operational information are shown from left to

right as follows:

1. Operational status arrow indicating outlet activation,

2. Function identification: ORP, SANITIZER, pH,

CONDUCTIVITY, TEMPERATURE, PUMP and FILTER,

3. Function/Sensor readings,

4. Units of measurement (US or metric),

5. Function operational mode:

A: Automatic control,

M: Manual operation,

T: Timer control,

X: OFF.

Main Menus and Submenus

As shown on the Menu Tree included in the manual, there are

several submenus that are accessed directly from the Main

Screen; one for each operating function, and one for system

configuration.

Navigation through the menus is done with the four arrow keys

located on the front panel keypad. To access any menu or

submenu, use the UP and DOWN ARROW keys to highlight

the desired function and press the RIGHT ARROW key. To

exit from any submenu or screen, press the LEFT ARROW

key.

Alarm Displays

Probe failure, out-of-range and overfeed conditions are

indicated on the main screen and submenues with flashing

lines. For probe failure, the display flashes “Probe” on the

corresponding line.

If the display shows an out-of-range or overfeed alarm

condition, press the DOWN ARROW key to the flashing line

and enter that function’s submenu with the RIGHT ARROW

key to determine the cause of alarm.

CHEMTROL® 6000

Version 2.16

TECHNICAL SUPPORT

USA 800-621-2279

PHONE 805-683-8833

FAX 805-683-1893

Welcome Screen

SANITIZER 1.0 ppm X

>ACID 7.5 pH A

COND 2000 uS X

TEMP 82 F A

>PUMP 200 gpm A

FILTER 25 / 20 psi X

08/10/11 5:30 LSI OK

PC5000/7000 Main Display

SANITIZER 1.4 ppm X

>pH 6.7 pH A

COND 1730 uS X

TEMP 79 F A

FLOW 2 4 gpm X

06/03/12 12:47 OK

PC2100 Main Display

MANUALPC-2010 CHAPTER II – INSTALLATION Page 6

CHAPTER II - INSTALLATION

SAFETY NOTICE

See important safety information on the first page of the

manual.

UNPACKING

Immediately upon receipt of your shipment, check the shipping

carton carefully for damage and report any damage directly to

the shipping company. Please report any shortage

immediately to the factory.

Before opening the carton, check the outside label and verify

the model number, voltage, tee size and feed mode. Unpack

the carton carefully and accounting for any of small parts such

as PVC fittings.

The controller carton should include the following:

- Controller Cabinet,

- Sensors as required for selected model,

- Instruction Manual and Warranty Card,

- Installation Report to be mailed back to factory upon

completion of installation,

- Bypass Line Assembly (Optional).

INSTALLATION REPORT

he Installation Report is a triplicate form designed to assure

T

warranty coverage, technical updates and factory support.

1. White copy: to mail back to factory.

2. Pink copy: to Facilities Manager.

3. Yellow copy: to Qualified Dealer.

Upon completion of installation, it must be filled out and signed

by the Qualified Dealer and by the facilities manager.

TECHNICAL SUPPORT

lease take your time to read this detailed Instruction Manual

P

to insure proper installation and operation. If you need further

technical assistance, you can contact your Qualified

CHEMTROL® Representative, call our Technical Department

toll free at 800-621-2279 or e-mail us at

chemtrol@sbcontrol.com.

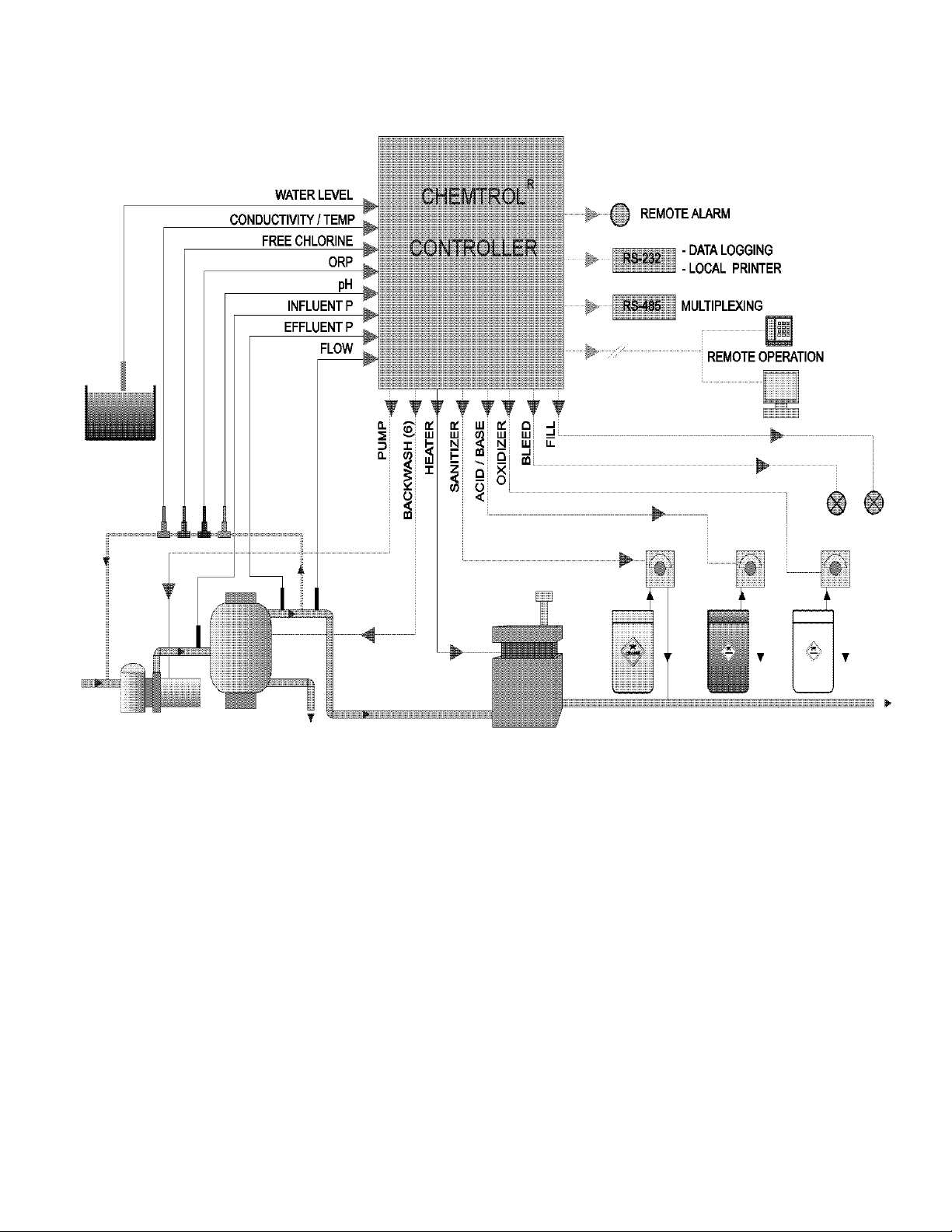

PRINCIPLE OF INSTALLATION

C

HEMTROL® PC constitutes an integrated command center

for complete monitoring and control of all water treatment

operations, including chemistry, filtration, heating recirculation

pump and water level.

All information provided by the sensors is processed by the

microprocessor on the Mother Board and displayed on the

Main display screen. Command signals are then sent to the

different control outputs on the Power Board (see

ELECTRICAL below).

The schematic of installation in Figure 5 shows the principle of

installation with all options installed. Figure 11 show the details

of installation for the bypass line and sensor cell assembly.

CONTROLLER CABINET

HEMTROL® PC controllers are contained in a rain proof and

C

splash proof NEMA Type 3 cabinets.

For ease of installation, there are two external mounting ears

on the top of the cabinet.

All the electronic and electrical components are mounted

inside the cabinet on two separate PC Boards, the Mother

Board and the Power Board. Outlets are provided on the

bottom of the cabinet for ½" conduits connectors.

LOCATION

ount the cabinet on a wall in a secure location:

M

- More than 10' (3 m) away from the water edge to comply

with electrical code requirements,

- Within 10' (3 m) of the main recirculation line or of the

bypass line - unless special extension cables are used for

the sensors (see Sensor Cables),

- Not exposed to direct sunlight as the LCD display screen will

darken at high temperature,

- Easily accessible to maintenance personnel,

- If possible, in a separate or well-ventilated room as far away

as possible from corrosive chemicals and storage tanks,

- At a safe distance from power transformers, pump motors or

high voltage power lines,

- Safe from unauthorized access or vandalism

MANUALPC-2010 CHAPTER II – INSTALLATION Page 7

Figure 5 – Installation Schematics

MANUALPC-2010 CHAPTER II – INSTALLATION Page 8

ELECTRICAL

Electrical Codes

INSTALLATION MUST FOLLOW

ALL APPLICABLE ELECTRICAL CODES

The controller is available in either hard-wiring or plug-in

configurations. Make sure to use the proper type of wiring

according to the local electrical code, usually the same as for

the chemical feeders.

The internal wiring and labeling for the Power Board of the

controller (Error! Reference source not found.) are as

follows:

RELAYS POWER IN

GREEN GROUND GND GND

BLACK HOT NO1 L1

WHITE NEUTRAL NO2 L2

AC Power Input

The CHEMTROL® PC is a dual-voltage controller with a

voltage selector switch located inside the cabinet on the Power

Board. Before connecting the unit to an external power supply,

make sure that the voltage selector switch is set to the proper

AC power input: 115 V or 230 V.

CAUTION: Damage resulting from improper voltage

selection is not covered by manufacturer

warranty.

Grounding (GFI)

grounding lug is provided on the right side of the cabinet. It

A

is important to connect it to a proper earth ground to prevent

dangerous current leakage and electrical shock. Ground Fault

Interruption (GFI) protection is also strongly recommended for

all installations.

Main Power Interlock

To prevent accidental chemical feeding, the controller and the

chemical feeders should always be interlocked (i.e. wired in

parallel) with the manual switch for the main pump. This

prevents feeding chemicals when there is no water flow in the

recirculation line.

Panel Interlock

For safety of operation, a panel interlock switch is mounted

inside the cabinet to shut off all internal power when the control

panel is open.

DO NOT ATTEMPT TO DEFEAT ITS PURPOSE !!!

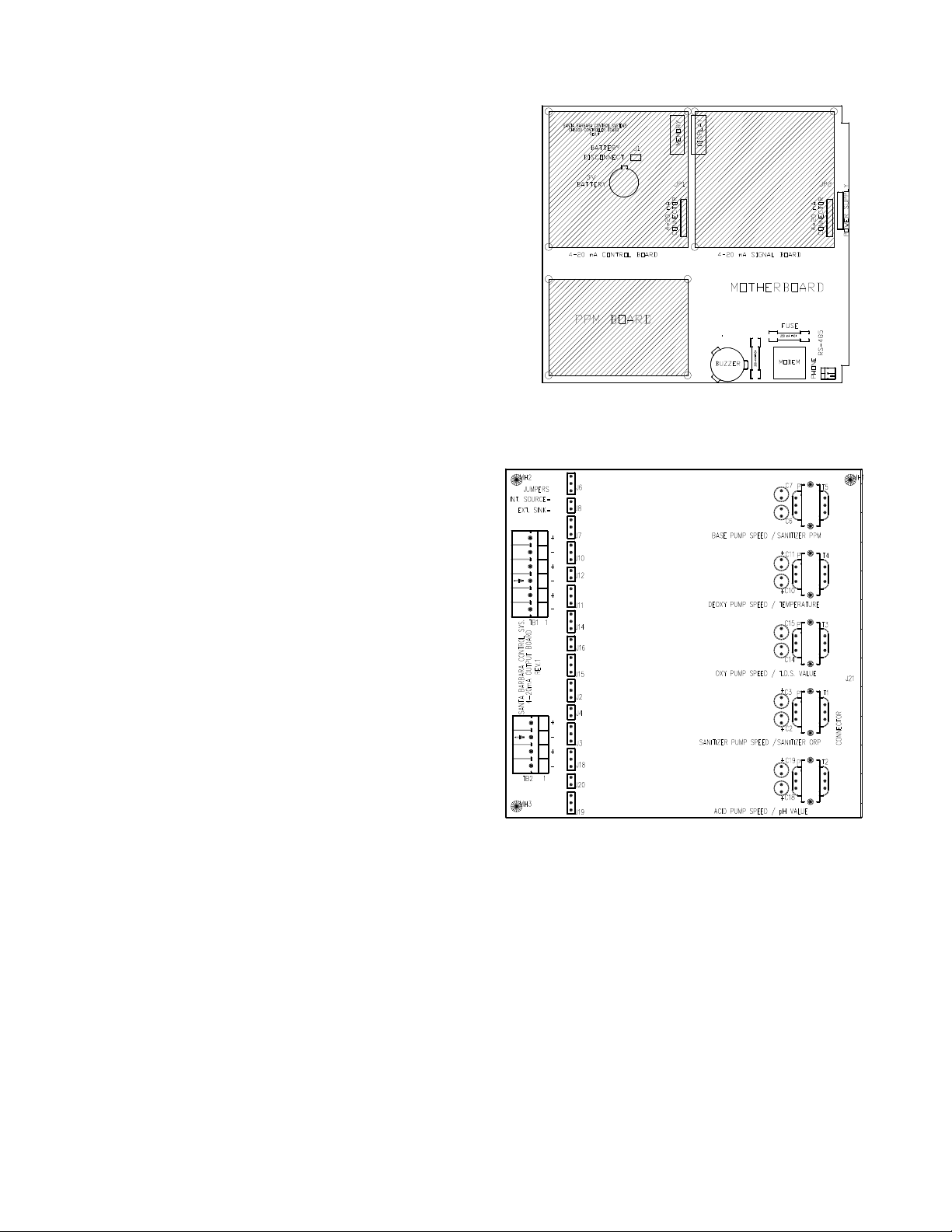

PC Boards

CHEMTROL® PC controllers use two PC boards connected

together with a ribbon connector.:

1) A Mother Board behind the front panel containing the

software, memories, main processor and operating

electronics,

.

2) A Power Board in the back of the cabinet containing the

power input and all output relays.

The components on the two boards are labeled with their

respective identifiers and/or descriptions.

The PC boards are protected with a 1A fuse located on the

Power board. If the fuse has to be replaced, make sure to use

a 1A fuse only. The use of a larger fuse may cause irreparable

damage to the electronic boards.

Power Board

CHEMTROL® PCs are equipped with a switchable dual

voltage power transformer for 115v or 230v, and is mounted on

the Power Board inside the cabinet.

Always verify that the switch is set to the correct voltage.

Connecting the controller to higher voltage than its settings

may cause damage to the electronics that is not covered by

the manufacturer’s warranty.

Jumpers, Relays and Fuses

Jumpers on the Power Board determine the connections for

the output relays and should only be changed by a Qualified

CHEMTROL® dealer.

All output relays are fused on the Normally Open (NO) and

Normally Closed (NC) sides. Both the Hot and the Neutral

sides are fused with 5A Slow Blow fuses.

Make sure not to overload the relays. Chemical feed pumps

normally draw less than 5A. If a pump draws more than 5A, it

will need a motor starter or a magnetic switch.

Relays on your Power Board are found only for the specific

options your PC is configured for.

Fuses for the Power Supply are AGC-1 Fast Blow. The two

fuses for the dialup modem if present are 250mA Fast Blow. All

other fuses for relay outputs are 5A Slow Blow.

The Mother Board is mounted directly behind the face panel of

the controller and contains all the low voltage circuitry including

the microprocessor and program chips, the LCD display and

the keyboard pad. It is also used to connect all the sensor

inputs.

MANUALPC-2010 CHAPTER II – INSTALLATION Page 9

Remote Alarm

The remote alarm is a 5A DPDT relay located on the upper

right corner of the Power Board. The remote alarm relay can

be set for dry or hot contacts, or for any external signal.

To avoid damaging the Power Board, make sure to use the

right type of contacts. Call your dealer or the factory if you are

not sure.

With hot contacts, the controller powers the alarm with 110 or

230V, depending on the setting of the input voltage of the

controller (see preceding page). Connect the leads to the

alarm to the Normally Open contacts (NO1 and NO2) on the

terminal strip located next to the alarm relay.

For an external power source, wire the input power to the

terminals marked NC1 and NC2. Wire the remote alarm to the

normally open contact (NO1 and NO2). The alarm voltage will

be the same as the external power source.

Mother Board

he Mother Board is mounted directly behind the face panel of

T

the controller and contains all the low voltage circuitry including

the microprocessor and program chips, the LCD display and

the keyboard pad. It is also used to connect all the sensor

inputs.

The key electronic components are the microprocessor and the

programmable chips for Program, Display and Memory. The

program chips are located in the center at the very top of the

board. They can be replaced for upgrading of the software

program, which should be done only by an experienced

technician.

Sensor Connections

ll sensor connections are on the Terminal Barrier strips on the

A

Mother Board, as shown on Error! Reference source not

found.. The pH and ORP sensors are connected externally to

the bulkhead BNC connectors on the left side of the cabinet.

The temperature sensor has two leads, black and red. The

combined conductivity/temperature sensor has four leads:

white, green, red and black. Connect all leads as shown on

the Mother Board schematic (Error! Reference source not

found.).

The color coding for the connections are as follows.

TB1 - Level control sensor and

blade-type flow switch (PC3) or high alarm sensor (PC6)

5 = Low White wire from level sensor

4 = Ground

3 = Flow switch NO f/s wire or white wire high alarm

2 = Ground Black wires

1 = +5vdc Red wires from level sensors

TB2 - Pressure transducer

4 = In White wire from influent transducer

3 = Out White wire from effluent transducer

2 = Ground Black wire

1 = 24vdc Red wire from transducers

TB3 - Bypass line flow pulser

3 = +5VDC Red wire

2 = Signal White wire

1 = Ground Black wire

TB4 - Main flow pulser (Signet)

3 = + Black

2 = Signal Red

1 = Ground Shield

TB5 - Temp & TDS, pH, ORP

8 = TDS Black

7 = TDS Red

6 = Temperature White Red

5 = Temperature Green Black

4 = pH Shield

3 = pH Signal

2 = ORP Shield

1 = ORP Signal

TB6 - RS-485 Communications

Connect to A and B only, for multiple serial installations,

using Host/Slave configurations (see Remote

Communications below).

TB7 - RS-232 Communications

5 = Green

4 = Brown

3 = Black

2 = White

1 = Red

Buzzer

The buzzer is located near the bottom of the Mother Board, as

shown on Error! Reference source not found.. It can be

turned on for specific alarm conditions through the software

program or for all alarms using the Audio Alarm Submenu

8.2.1 (see page 27).

Display Brightness

MANUALPC-2010 CHAPTER II – INSTALLATION Page 10

The brightness of the display can be adjusted with the

potentiometer marked R-39 that is located in the center of the

Mother Board (Error! Reference source not found.).

MANUALPC-2010 CHAPTER II – INSTALLATION Page 11

Backup Battery

The 3V Backup Battery is located on the left side of the Mother

Board (Error! Reference source not found.). It is used to

maintain the memory settings in case of loss of AC power.

This battery is designed to last for several years in normal

operation.

Under normal conditions, the controller will operate without

battery power. However, the clock and other memory settings

will have to be restored in case of complete power shutdown.

Replace the battery if the voltage falls below 2.6 V. The

voltage is displayed in Configuration Menu / Battery Submenu.

Remote Communications

he Remote Communications option connects the modem with

T

a standard US-type, 6-position RJ12 phone jack located on the

center right hand side of the Mother Board (Error! Reference

source not found.).

If possible, connect the controller to a direct outside telephone

line dedicated for remote operation. If the line is also used for

voice communications, users should wait for at least three

rings to allow the modem to answer a call.

The modem is a combination Data/Fax/Voice multimedia

device registered by the Federal Communications Commission

(FCC), Number B46USA-22429-MN-E.

MODEM SPECIFICATIONS

FCC Registration Number

B46USA-22429-MN-E

The Ring Equivalency Number (REN) is 0.2 A. Most telephone

companies require that the sum of all devices connected to a

telephone line do not exceed 5. If a problem arises as a result

of operating this equipment, you may have to provide

information about this modem to the Phone Company or to the

FCC. If the equipment causes disruption to the telephone

network, the Phone Company may disconnect your service.

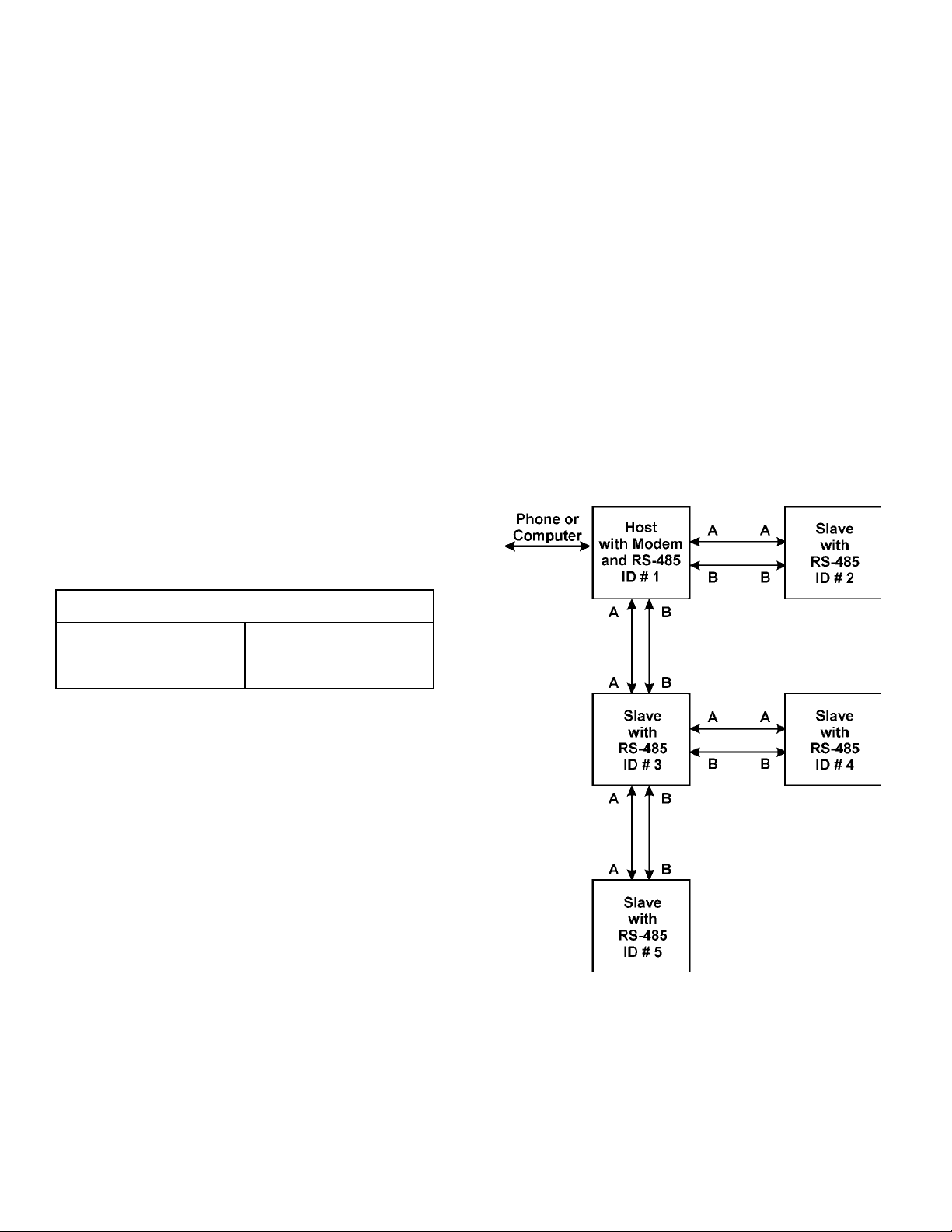

Multiple Serial Connections (Option)

Up to thirty (30) CHEMTROL® PC controllers can be

multiplexed to a single phone line or a single computer line by

using a network consisting of a host and several slaves. The

connections are made through RS485 Serial Ports (Option

RS485).

Different models of CHEMTROL® PC controllers can be mixed

and matched in a network. Each controller has its own ID

number. This number is set up through software in the

Communications Submenu 8.3.1 (see Page 30)

Ring Equivalency Number

(REN) 0.2 A

As shown in Figure 6, the host controller includes a modem

and an RS485 connection (Option REM). It is connected to the

telephone line by modem or to a computer equipped with an

RS485 communication card. The slave units need only an

RS485 connection (no modem needed) and an internal ID

number.

Any controller can be set up at any time as either host or slave

by orienting the jumper JP9 as marked on the motherboard

(Error! Reference source not found.).

The slave units must be located within 3,000 feet of the host

controller and connected with two Category 5 wires (one pair).

The RS485 terminal has four terminals, only two of which,

marked A and B, are used. Each unit must be wired A to A

and B to B for proper communications. The slave units can be

connected directly to the host unit or through any other slave

units.

CAUTION: Do not wire the connections marked 24 VDC or

GND on the RS485 terminal. This could cause

serious damage to the terminal.

Figure 6 - Multiplex Connections

MANUALPC-2010 CHAPTER II – INSTALLATION Page 12

4-20 mA Converter Boards

The 4-20 mA Converter Boards are two optional piggyback

boards. They convert the digital outputs of the controller

(sensor or control outputs) into analog signals that can be used

by analog monitoring and control equipment.

The two boards are identical and are normally installed at the

factory on the motherboard before shipping, as shown in

(Figure 7). The location on the motherboard determines the

function, i.e. sensor signal or control outputs. Either one of the

boards or both can be installed, depending on requirements.

If the boards are installed properly, the controller software

automatically shows the 4-20 mA menu line in the Submenu

8.3 - Communications.

Field Installation

or field installation, turn off all power to the controller.

F

Position the converter board on top of the motherboard as

shown on Figure 7. Press the electrical connector J21 into the

socket of the motherboard marked JP1 (or JP2 depending on

option) and the three plastic standoffs fittings into the three

corresponding holes on the motherboard.

4-20 mA Connections

Figure 8 shows the connections for each Converter Board.

Determine the type of signal required by the host system.

There are two types of signals used in 4-20mA

communications, Internal source or external sink. Each

communication channel has four sets of jumpers that must be

shunted to the proper setting. (Please note that the factory

settings are generally for internal source).

The 4-20mA output signals from the board are located on the

terminal boards marked TB1 and TB2. Each channel has a +

and - indication corresponding to the markings on the board.

The 4-20mA Signal Board has five communication channels for

pH, ORP, TDS, temperature and PPM readouts. Each analog

signal requires two wires for connection to the central

monitoring system.

The 4-20mA Control Board also has five pump control

channels for acid, sanitizer, oxidizer, deoxidizer and base feed.

Each analog control signal requires two wires for connection to

the corresponding pump.

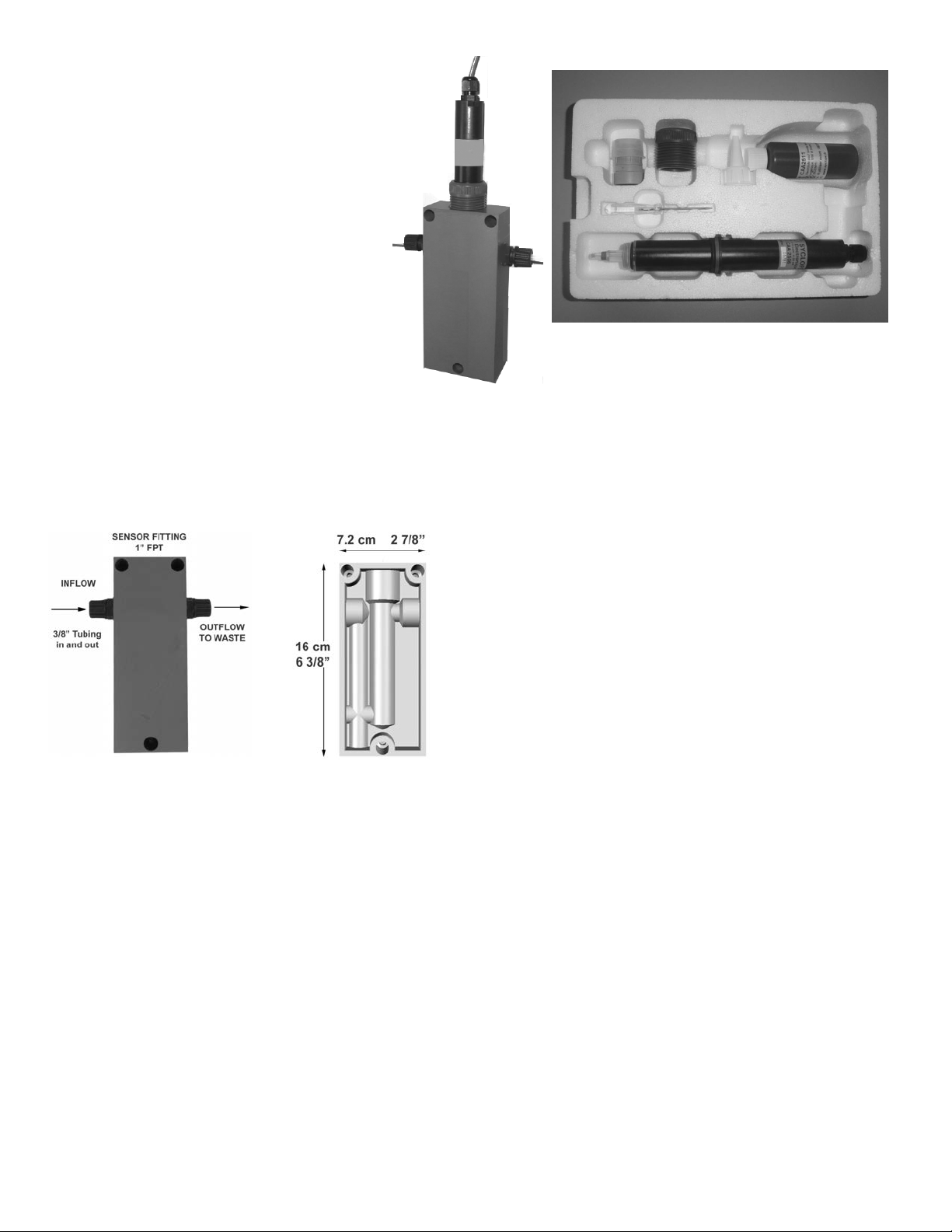

PPM Sensor Board

For new controllers, the PPM sensor board is already installed

on the lower left quadrant of the motherboard, as shown in

Error! Reference source not found..

For upgrades and retrofits, the PC board can be easily

installed on the motherboard.

At the bottom of the keypad between S15 / S16 locate the

jumper marked JP3. Insert the black pin receptacle on the

back of the PPM board into the JP3 pin connector. The two

plastic standoffs located on opposite sides of the pin

receptacle will snap into the two holes on the motherboard to

secure it.

Figure 7 - Installation of Optional Boards

Figure 8 - 4-20 mA Converter Board

MANUALPC-2010 CHAPTER II – INSTALLATION Page 13

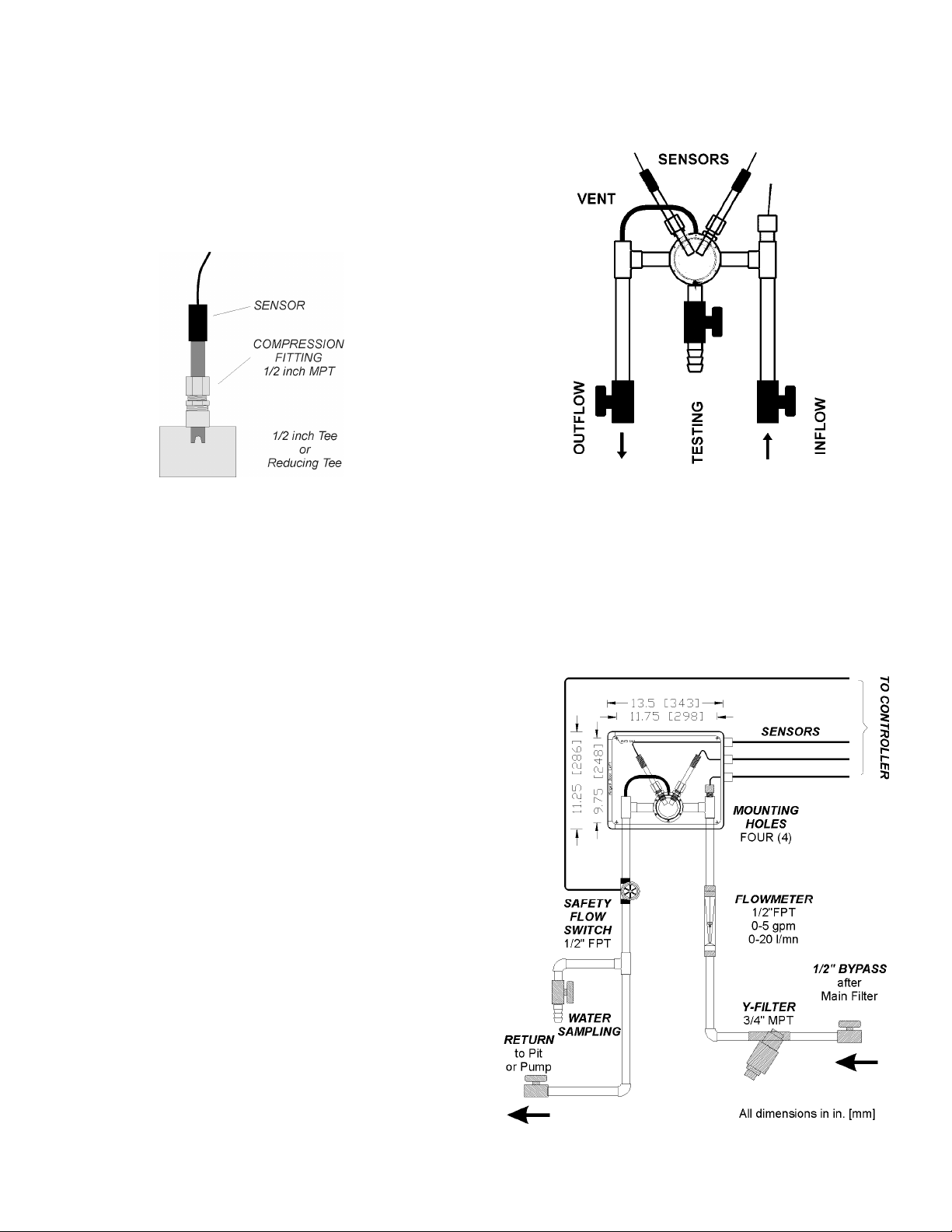

PLUMBING

This section covers the installation of the sensors and the

connection of the chemical feeders or control valves.

All chemical injection should be done on the return line, i.e.

downstream of the sensors and pool equipment, as explained

in the Chemical Feeders section.

Installation of Sensors

Figure 9 - Sensor Installation

The CHEMTROL® PC controllers use up to nine different

sensors for measurement of water chemistry, temperature,

flow rate, pressure and water level:

- amperometric sensor for Free Chlorine,

- potentiometric sensors for pH and ORP,

- thermistor for temperature,

- conductivity sensor for Total Dissolved Solids,

- Hall effect pulse generator for flow rate,

- piezoelectric sensors for influent and effluent pressures,

- electro-optical water level sensor.

The first five sensors measure water chemistry (Free Chlorine,

ORP, pH, conductivity and temperature). These can be

mounted directly on a 2-inch main recirculation line using PVC

reducing tees Figure 9). On larger diameter lines, they must

be mounted on a ½-inch bypass line - using a Sensor Cell

Cabinet (Figure 11).

In-line Installation (2" Pipe)

n smaller installations (2 “ pipe diameter), the sensors can be

O

mounted directly on the main recirculation line between the

strainer and the pump (Figure 9).

Use only 2x2x½ in. SST reducing tees without reducers. Do

not install the sensors near an elbow or a constriction where

there might be excessive turbulence.

Install the tees on the suction side of the pump and make sure

that the tip of the sensor is oriented downward - as shown in

Figure 9 - to avoid formation of air pockets near the tip. The

sensors should be readily accessible for servicing but not

exposed to physical damage.

After inserting the sensor, be careful not to overtighten the

compression fitting as it can crush the small glass tube inside

the sensor. Make it finger tight (no wrench).

Flow Cell Assembly

Figure 10 - Flow cell Assembly

For ease of installation and maintenance, the sensors should

be mounted on the Flow Cell Assembly, as show above. It

includes a sensor cell with an air vent and a clear cover, two

compression fittings for the ORP and pH sensors, a water

sampling tap and two ball valves for controlling the water flow

in and out.

Sensor Cell Cabinet (Option)

Figure 11 - Sensor Cell Cabinet (Option)

MANUALPC-2010 CHAPTER II – INSTALLATION Page 14

For even greater ease of installation and maintenance, the

components of the bypass line assembly can be supplied in a

pre-plumbed Sensor Cell Cabinet (also called Wet Box). The

Flow Cell Assembly is mounted in a fiberglass cabinet

containing the sensor cell assembly. Also included is a Y-filter,

a flowmeter and a paddle wheel safety flow switch. Install on a

½" bypass line, as shown in Figure 11,

Make sure that the Sensor Cell Cabinet is located within 2' (60

cm) of the controller cabinet or order sensor extension cables

(see Sensor Cables). See wiring instructions in the