PVC & CPVC

Fittings & Valves

Thermoplastic Flow Solutions

®

Chemtrol

®

Chemtrol® is a brand of

www.chemtrol.com

®

Thermoplastic Flow Solutions

®

Our high quality line of thermoplastic valves, fittings, and

pipe are the reason you can count on Chemtrol to fit your

industrial flow-control applications.

Chemtrol

Proven

dependability.

Chemtrol flow-control

products are unsurpassed in

performance and longevity.

With more than 60 years of

experience in industrial

thermoplastics, Chemtrol

offers dependable products

that work in the most

demanding environments.

Innovative

technology.

Great ideas flow from

Chemtrol in PVC, CPVC, PP,

and PVDF products for a

wide range of flow-control

applications.

Technical service

and sales support.

Our technical specialists

are some of the best in the

business. As part of your

team, they provide expert

advice, solve problems, and

assist you every step of the

wa y.

Our distributors, sales

professionals, and service

representatives offer ideas,

answer questions, and put

their knowledge to work

for you.

Education and

training.

We help you learn about the

benefits of thermoplastics

through excellent programs:

classes and seminars specific

to your industry, presented

at our manufacturing facility,

or product and application-

specific seminars conducted

in the field. Our high-quality

product and technical

manuals are available on

request, and a full listing of

Chemtrol products is provided

on our web site,

www.chemtrol.com

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

2

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

®

Table of Contents

www.chemtrol.com

Introduction 4

Introduction to Chemtrol

Materials 5

Chemical Resistance 5

Product Line 6

Product Guide 8

Ball Valves

®

PVC & CPVC Tru-Bloc

PVC & CPVC Tru-Bloc

Model D Ball Valves 9

®

Model C Ball Valves 10

PVC & CPVC Vented (Bleach) Ball Valves 11

PVC & CPVC 3-Way Ball Valves 12

PVC Compact Economy Ball Valves 14

Butterfly Valves

PVC & CPVC Butterfly Valves, Model C 15

PVC & CPVC Butterfly Valves, Model B 16

Ball Check Valves

PVC & CPVC True Union Ball Check Valves 17

Angle & Globe Valves

PVC Angle and Y-Pattern Globe Valves 18

Lab Valves

TM

PVC Chemcock

and Calibrated-Needle Valves 19

Valve Accessories 20

PVC Schedule 80 Fittings 24

CPVC Schedule 80 Fittings 34

Reference Data 43

Standards 53

Product Specifications 54

Warranty 59

Copies of the Chemtrol publications are available for download on www.chemtrol.com.

Kynar® is a registered trademark of Arkema Inc.

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

3

®

Introduction

Introduction to Chemtrol

With more than 60 years of experience in industrial

thermoplastics, Chemtrol offers dependable products that

work in the most demanding environments.

The premium line of quality Chemtrol

corrosion-resistant, and maintenance-free – saving you time

and money.

For specific recommendations of chemical compatibility, see

the Chem-Guide. For engineering data related to plastic piping

system design and installation and maintenance instructions,

see the Chemtrol Thermoplastic Piping Technical Manual.

All Chemtrol publications are available for download on

www.chemtrol.com in PDF format.

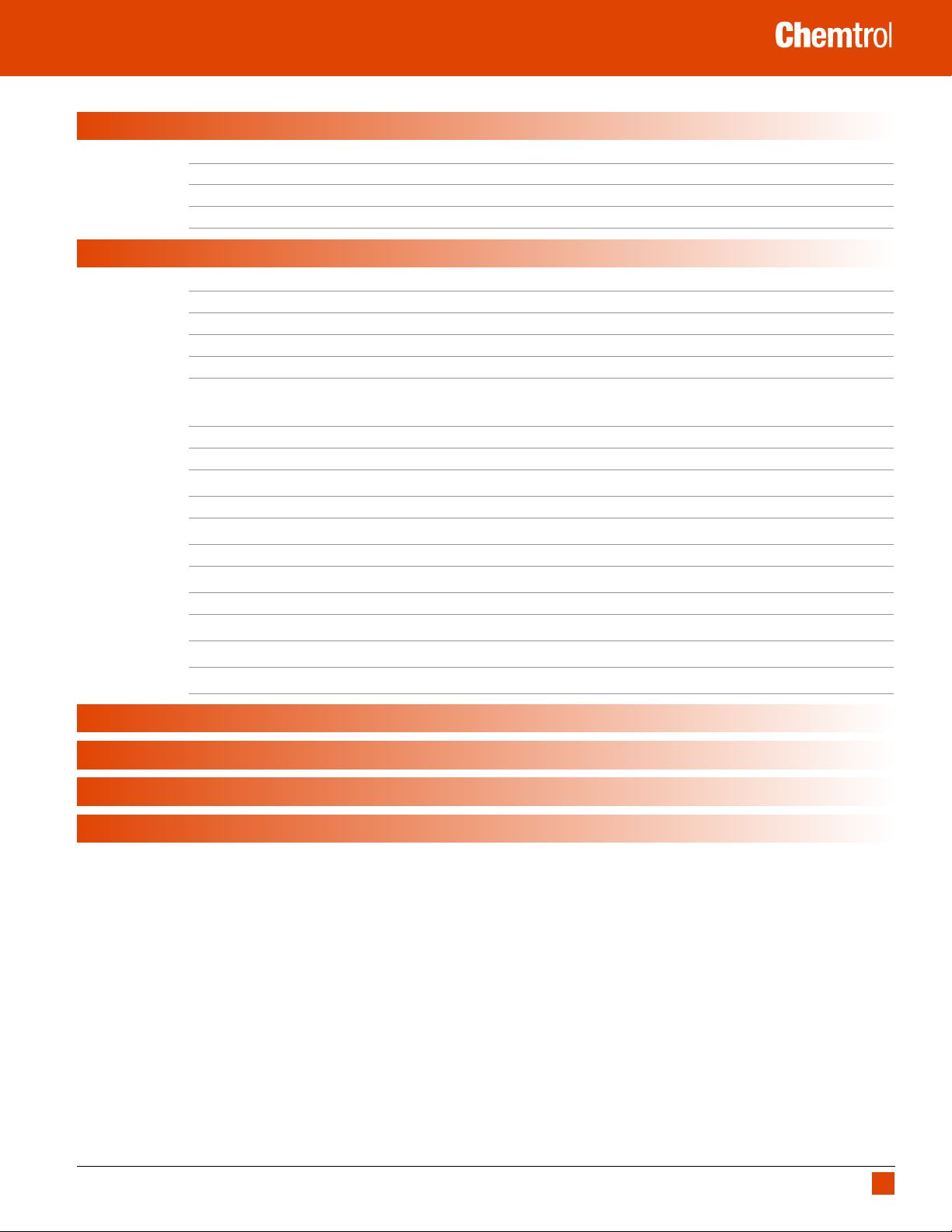

True Union Ball Valves

®

valves are lightweight,

True Union

www.chemtrol.com

True Union 3-Way

True Union Flanged

The True Union feature, a Chemtrol introduction, an exclusive Chemtrol

introduction, so revolutionized the industrial plastic valve industry that it

has become the standard followed by all major manufacturers. The purpose

of the design is to permit the valve cartridge, i.e., the body containing all

operational components, to be easily lifted from the piping system for

servicing/replacement when the union nuts are backed off. Easy repair/

replacement, interchangeability, distribution availability, technical service,

and reliable quality are the synergistic rationale many plants and original

equipment manufacturers have embraced while standardizing on Chemtrol

True Union Ball and Check Valves.

The laying length of the body and the heavy-duty modified-acme threads

in the union connections to the body have not changed in the four distinct

models’ 40-year history of the valve. This permits fouled valve replacement

with a new body cartridge, which will fit the old union nuts. No change in

piping length is required.

The distinctive orange handle indicates “open/close” and direction of flow

at a distance. And molded-in arrows on top of the handle dictate rotational

direction to personnel for easy operation within 90° stops. For applications

requiring handle removal, the D-ring stem flats indicate "open/close" and a

molded-in arrow on top of the stem indicates flow direction.

The Evolution of Chemtrol

As a result of continuous testing and improvements since the inception of

the True Union Ball Valve, three distinct model changes have occurred. The

original True Union Model A design had a seat-carrier that slid into the

smooth bore of the valve body, held in place by the external nut and end

connector. Tightening the external nut adjusted the compression of the PTFE

seat onto the ball.

The first major evolution to the True Union Ball Valve, Model B, introduced

the Tru-Bloc concept, a functional safety feature. With this design a

separate threaded retainer locked the seat-carrier into the body and

prevented the seat-carrier from being extruded out of the valve body when

the external nut was removed. This change is intended to prevent pressure

on the other side of the valve from ejecting the internal components and

fluid medium out of the open valve end and to further prevent possible

injury to persons or property.

®

Ball Valves

®

The Model C seat-carrier design was modified to include an external thread

which mated into the valve body threads, eliminating the separate retainer.

This modification also eliminated the adjustment of the seat-carrier by the

external nut and end connector, resulting in a sealing envelope that was

independent of external forces. An energized O-ring was added under the

PTFE seat that provided automatic adjustment to compensate for seat wear.

This design modification continued the Tru-Bloc feature, preventing the seat

carrier from being extruded out of the valve body when the external valve

nut was removed.

Manufactured in PVC and CPVC through 2", the current Model D ball

valve’s seat-carrier internal threads and the external union nut threads

were strengthened to provide an increased pressure rating of 250 psi at

73°F and improved the pressure ratings at higher temperatures. The end

connector design was modified to provide wrench flats. The union nut

OD was changed to provide improved gripping for strap wrenches. The

Model D design continued the sealing envelope that was independent of

external forces with an energized O-ring under the PTFE seat that provided

automatic adjustment to compensate for seat wear. The Tru-Bloc® feature

was also retained.

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

4

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

®

Introduction

Materials

PVC

(Polyvinyl Chloride) PVC conforming to ASTM D1784, Classification 12454, formerly

designated Type I, Grade 1, is the most frequently specified of all thermoplastic piping

materials. It has been used successfully for more than 55 years in such diverse areas as

chemical processing, industrial plating, chemical drainage, fresh and wastewater treatment,

chilled and tower cooling water, deionized water manufacture and distribution, and irrigation

sprinkler systems. PVC is characterized by high physical properties and resistance to chemical

attack by strong acids and other oxidizers, alkalis, salt solutions, some organic chemical

solutions, and many other chemicals. However, it is attacked by non-ionic surfactants,

some vegetable oils (e.g., peanut), and many organic chemicals such as polar solvents (e.g.,

ketones), aromatics (i.e., benzene ring structure), and chlorinated hydrocarbons. The maximum

service temperature of PVC is 140°F. With a design stress of 2,000 psi at 73°F, the long-term

hydrostatic strength of PVC is as high as any of the major thermoplastic materials being used

for solid piping systems. PVC is joined by solvent cementing, threading, or flanging.

CPVC (Corzan®)

(Chlorinated Polyvinyl Chloride) CPVC conforming to ASTM D1784, Classification

23447, is a resin created by the post-chlorination of a PVC polymer. The material’s resistance

to chemical attack is almost identical to that of PVC. And the physical properties of CPVC

are very similar to those of PVC at 73°F, but the additional chlorine in the CPVC polymer

extends its maximum service temperature to 210°F. For example, the design stress for CPVC

is 2,000 psi at 73°F, identical to that of PVC. But its strength is only reduced to 500 psi at

180°F, as compared to 440 psi for PVC at 140°F. For more than 35 years, CPVC has proven to

be an excellent material for hot corrosive liquids, hot and cold water distribution, and similar

applications above the useful temperature range for PVC. CPVC may even be chosen over PVC

in the 110°F to 140°F temperature range because its higher strength-at-temperature, requiring

less frequent piping supports, can translate to a more favorable overall installed cost than

PVC. CPVC is joined by solvent cementing, threading, or flanging.

PVDF (Kynar®)

(Polyvinylidene Fluoride) PVDF homopolymer conforming to ASTM D3222, Type I,

Grade 2, is a tough, abrasion-resistant fluorocarbon material that has a design stress of

1,360 psi at 73°F and a maximum service temperature of 280°F. It has versatile chemical

resistance to salts, strong acids, dilute bases, and many organic solvents, such as the

aromatics (i.e., benzene ring structure), the aliphatics (i.e., paraffin, olefin, and acetylene

hydrocarbons), and the chlorinated groups. And PVDF is ideally suited for handling wet or dry

chlorine, bromine, and other halogens. However strong bases and some organic chemicals

such as polar solvents (e.g., ketones) and esters attack it. No other solid thermoplastic

piping material can approach the combined strength, working temperature, and chemical

resistance characteristics of PVDF. It is joined by the thermo-sealing socket fusion process,

threading, or flanging.

PVDF, absent of any color pigment, is transparent to ultraviolet light. So while PVDF is one

of the few plastic materials that is not degraded by UV radiation, exposure of the fluid

medium inside a piping system to direct sunlight can frequently adversely affect its stability.

Therefore, all PVDF piping components that Chemtrol produces for general chemical service,

contain an FDA-approved red pigment to mask the penetration of UV rays.

®

Natural Kynar

of metallic ions and foreign organic compounds. And since the resin does not require

processing or other external additives to aid manufacturing or long-term stability, the hardpolish surface of components will remain intact, so that piping systems will not release

particulate to the fluid medium. Further, there will be no surface micropores to encourage

biological growth. Natural Kynar

and chemical services, such as electronics, pharmaceuticals, and processed foods and

beverages.

PVDF Type I (polymerized in emulsion) homopolymer is notably free

®

PVDF systems are intended for ultra high pure water

www.chemtrol.com

PP

(Polypropylene) PP as specified by ASTM D4101, is a member of the polyolefin family

of pure hydrocarbon plastics. Although PP has half the strength of PVC and CPVC, with a

design stress of 1,000 psi at 73°F, it may have the most versatile chemical resistance of

the thermoplastic materials identified as the sentinels of industrial piping. Consider the

fact that there are no known solvents for PP. As a result, it has been the material of choice

for drainage of mixed industrial chemicals for over 40 years. As pressure piping, PP has no

peers for concentrated acetic acid or hydroxides. It is also suitable for milder solutions of

most acids, alkalis, salts, and many organic chemicals, including solvents. The nemeses

for PP are strong oxidizers, such as the hypochlorites and higher concentrations of sulfuric,

nitric, and hydrofluoric acids. They are Environmental Stress Cracking (ESC) agents for PP,

meaning that time-to-failure is a function of the combined variables of concentration and

temperature of the fluid and stress. Although PP is not recommended for some organic

chemicals, such as polar and chlorinated solvents and the aromatics, the concern is

permeation through rather than catastrophic damage of the molecular chain.

Black PP used in Chemtrol products is formulated with a minimum 2.5% carbon black. The

plastic pipe industry recognizes PP formulated with this level of carbon black as suitable for

long-term outdoor service.

®

Chem-Pure

because of its extremely low content of metals, organic compounds other than naturally

pure propylene, and free ions. No pigments or other adulterants (natural) are added to

the plastic resin. Chem-Pure

Chem-Pure systems are intended as an economic alternative to the ultra high purity PVDF

systems typically found in the highly sophisticated electronic semi-conductor industry.

Natural PP utilized to produce Chemtrol® piping products was selected

®

systems are intended for high purity chemicals or DI water.

FKM

(Fluoroelastomer) FKM is compatible with a broad spectrum of chemicals. Because

of this extensive chemical compatibility, spanning wide ranges of concentration and

temperature, FKM has gained wide acceptance as a material of construction for valve

o-rings and seats. These fluoroelastomers can be used in most applications involving

mineral acids (with the exception of HCl), salt solutions, chlorinated hydrocarbons, and

petroleum oils. FKM is not recommended for most strong alkali solutions.

EPDM

(Ethylene-propylene-diene monomer) EPDM is a terpolymer elastomer that has good

abrasion and tear resistance and offers excellent chemical resistance to a variety of salt,

acidic, and organic chemical solutions. It is the best material for most alkali solutions and

hydrochloric acid, but is not recommended for applications involving petroleum oils or

most strong acids.

PTFE

(Polytetrafluoroethylene) PTFE has outstanding resistance to chemical attack by most

chemicals and solvents. PTFE has a temperature rating of -200°F to +500°F. It is a selflubricating material used as a seat and/or bearing material in most Chemtrol

®

valves.

Chemical Resistance

While thermoplastic piping systems are useful in general water service because they are

light-weight, easy to install, and cost-effective, they excel in corrosive environments, such

as water and wastewater treatment, food and pharmaceuticals, chemical processing,

mining, power plants, oil refineries and more. Choosing the proper material for corrosive

fluids can be handled by consulting the NIBCO Chem-Guide and understanding the effect

that temperature will have upon plastic materials’ strength.

Chemical resistance is the ability for a particular plastic material to maintain properties in

contact with a chemical. To ensure comprehensive chemical compatibility, a piping system

must take into consideration the chemical resistance of all system components, including,

but not limited to, plastic components, solvent cements or thread pastes (if applicable),

elastomeric seals, all valve components and lubricants. Testing under field conditions may

be the best way to ensure selected materials will work in a particular application.

Kynar® is a registered trademark of Arkema Inc.

®

is a registered trademark of The Lubrizol Corporation.

Corzan

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

5

®

Introduction

Typical Applications

Joining Methods

Max. Service Temperature

Polyvinyl

Chloride (PVC)

Chemical processing, industrial plating, chilled

water distribution, chemical drainage, and

irrigation systems

Solvent cementing, threading, or flanging

140° F/60° C

www.chemtrol.com

Chlorinated

Polyvinyl Chloride

®

(Corzan

Systems for hot corrosive liquids, hot and cold

water distribution, chemical processing, industrial

plating, deionized water lines, chemical drainage,

waste water treatment systems, and similar

applications above the temperature range of PVC

210° F/99° C

CPVC)

Fittings Schedule 80

Large diameter

Valves Tru-Bloc

Tru-Bloc

Butterfly valves*

Multiport valves*

Specialty valves

®

/True Union

ball valves*

®

/True Union

ball check valves

Socket– 1/4" through 12"

Threaded– 1/4" through 4"

10" and 12" couplings, tees, 90° and 45° elbows,

reducer bushings, and Van Stone flanges

1/2" through 6" socket, threaded, and flanged

connections

1/2" through 4" with socket, threaded, or

flanged ends

EPDM and FKM liner 2" through 10" Model C

True Union 3-way/3-position; 1/2" through 2"

with socket, threaded, or flanged ends

Angle and Y pattern: 1/4" through 1" threaded

Needle and Chemcock

TM

: 1/4" threaded

Socket– 1/4" through 12"

Threaded– 1/4" through 4"

10" and 12" couplings, tees, 90° and

45° elbows, reducer bushings

1/2" through 6" socket, threaded, and flanged

connections

1/2" through 4" with socket, threaded, or

flanged ends

EPDM and FKM liner 2" through 10" Model C, 3"

only Model B

True Union 3-way/3-position; 1/2" through 2"

with socket, threaded, or flanged ends

Pipe

*For pneumatic or electric actuation.

Refer to Chemtrol Technical Manuals for pressure ratings at various temperatures.

Kynar® is a registered trademark of Arkema Inc.

®

is a registered trademark of The Lubrizol Corporation.

Corzan

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

6

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

www.chemtrol.com

®

Polypropylene

(PP)

Black Polypropylene:

Clean chemical processes,

hot corrosive liquids,

industrial plating, waste

treatment systems

180° F/82° C 180° F/82° C

IPS socket type–

1/2" through 6"

Threaded–

1/2" through 4"

Natural Polypropylene:

Deionized water systems,

clean chemical processes,

pharmaceutical operations,

food processing

Socket heat fusion, threading, or flanging

IPS socket type–

1/2" through 4"

Threaded–

1/2" through 4"

Polyvinylidene Fluoride

®

(Kynar

Red Kynar

Protects fluid medium from

UV exposure, is an excellent

material for general

industrial applications,

especially outdoor

installations.

280° F/138° C

IPS socket type–

1/2" through 6"

Threaded–

1/2" through 2"

PVDF)

®

PVDF:

®

Natural Kynar

(unpigmented) PVDF:

Ideal for industries

such as electronics,

pharmaceuticals,

and processed foods

or beverages.

280° F/138° C

IPS socket type–

1/2" through 6"

Threaded–

1/2" through 2"

1/2" through 4" with

socket, threaded, or

flanged ends

1/2" through 4" with socket,

threaded, or flanged ends

1/2" through 6" schedule 80 wall thicknesses

1/2" through 4" with

socket ends

1/2" through 2" with

socket ends

1/2" through 4" with

socket, threaded, or

flanged ends

1/2" through 4" with socket,

threaded, or flanged ends

1/2" through 6" schedule 80 wall thicknesses

1/2" through 4" with

socket, threaded, or

flanged ends

1/2" through 4" with socket,

threaded, or flanged ends

Kynar® is a registered trademark of Arkema Inc.

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

7

®

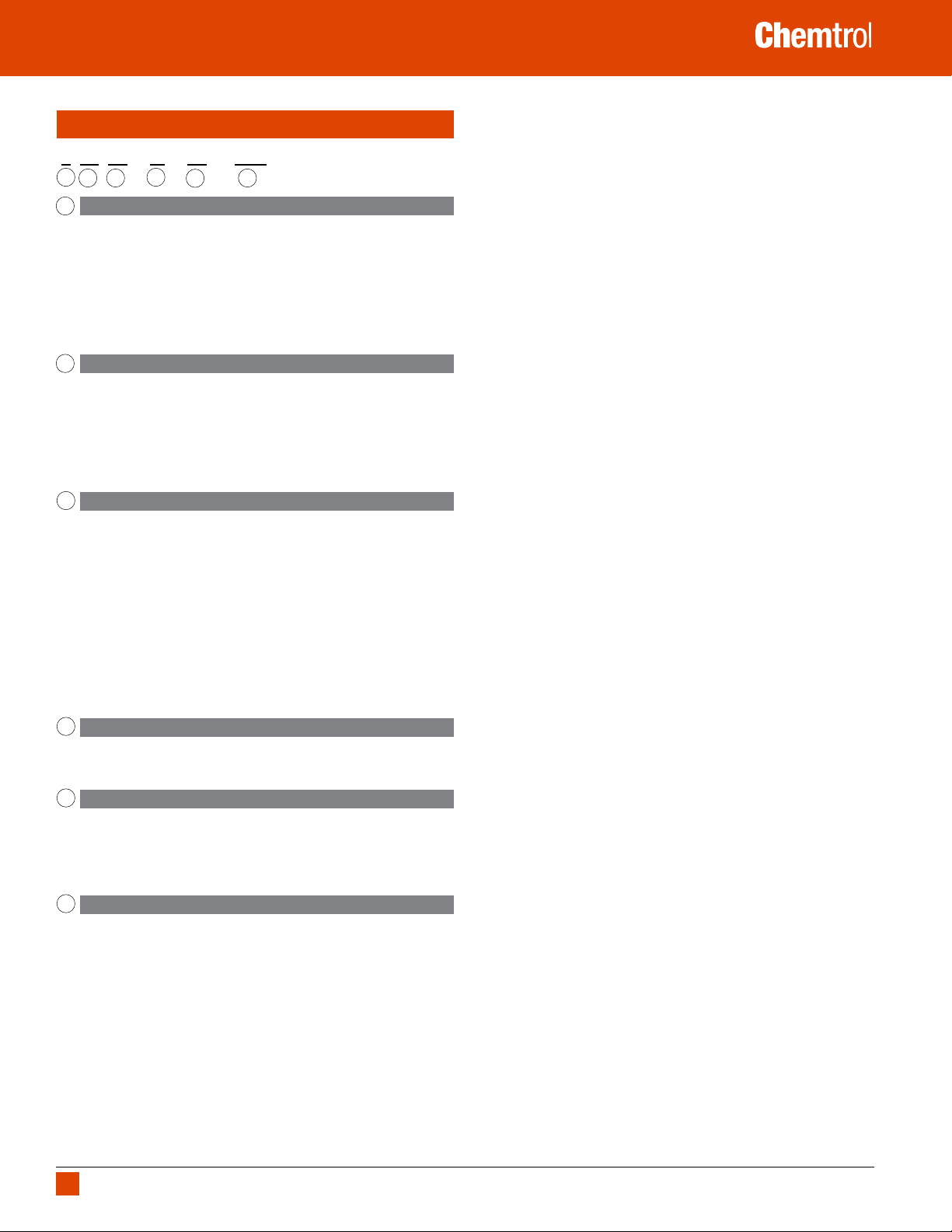

Product Guide – Valves

Key to Chemtrol Valve Figure Number System

X XX XX - X - XX - SIZE

1 2 3 4 5 6

1 End Configurations

S Socket

F Flanged

T Threaded (female)

M Threaded (male)

A Hose x Male Threaded

W Wafer Style Butterfly

U Universal (socket and threaded)

2 Body Material

45 PVC Schedule 80

51 CPVC Schedule 80

61 Black Polypropylene (PP)

62 Chem-Pure® Natural Polypropylene (PP)

65 Red Kynar® PVDF

66 Natural Kynar® PVDF

3 Types of Valves

AC Angle

BC Ball Check

BF Butterfly (Model B)

BG Butterfly (Model C)

CC ChemcockTM

CN Needle

D2 Diverter (3-Way, 2-Position)

FV Ball Foot

M3 Multiport (3-Way, 3 Position)

TB Tru-Bloc® True Union Ball Valve

YP Y-Pattern

www.chemtrol.com

4 O-Ring Material

E EPDM

V FKM

5 Operating Mechanisms

NO None

LH Lever Handle, Manual

RH Round Safety Handle, Manual

GO Gear Operator, Manual

6 Size

State Valve Size

Kynar® is a registered trademark of Arkema Inc.

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

8

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

®

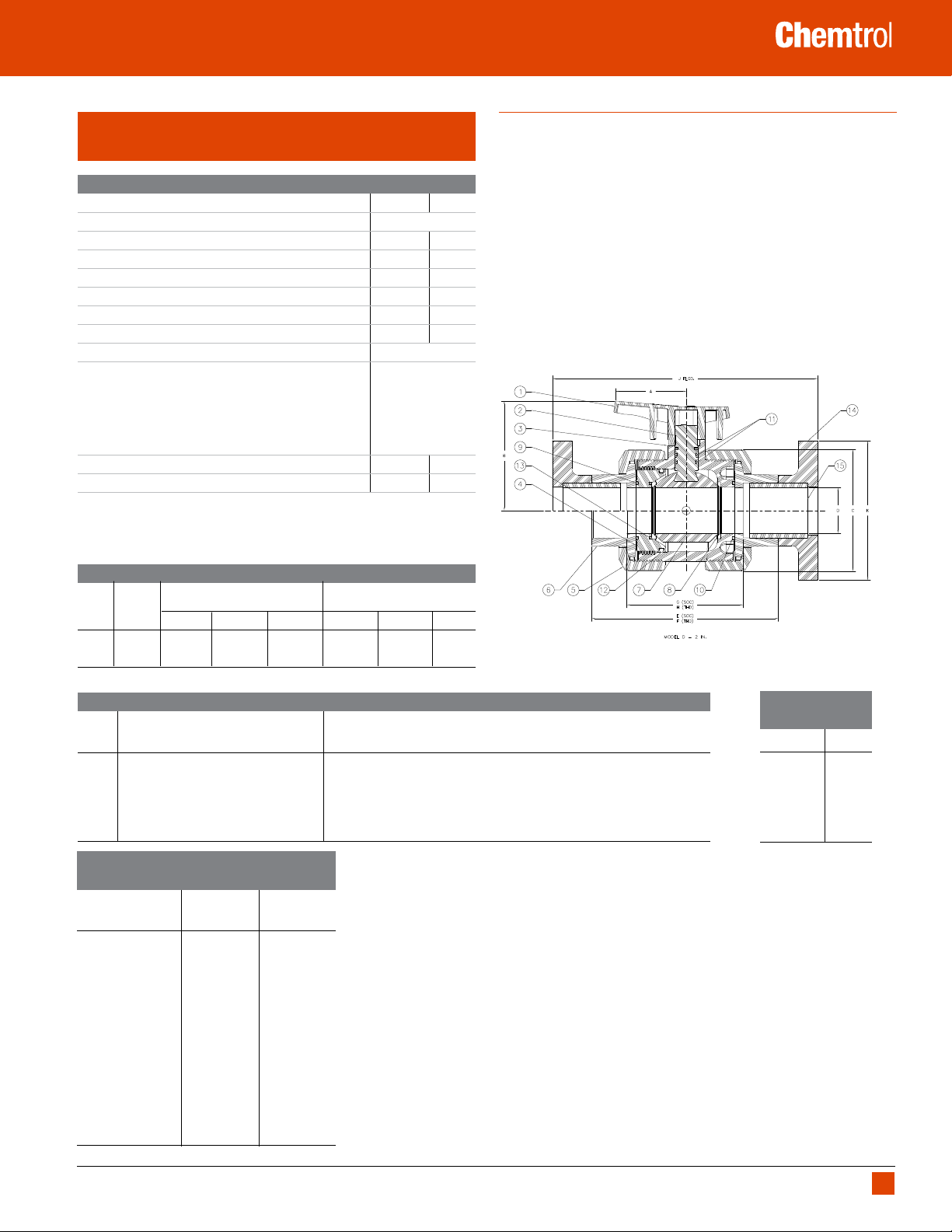

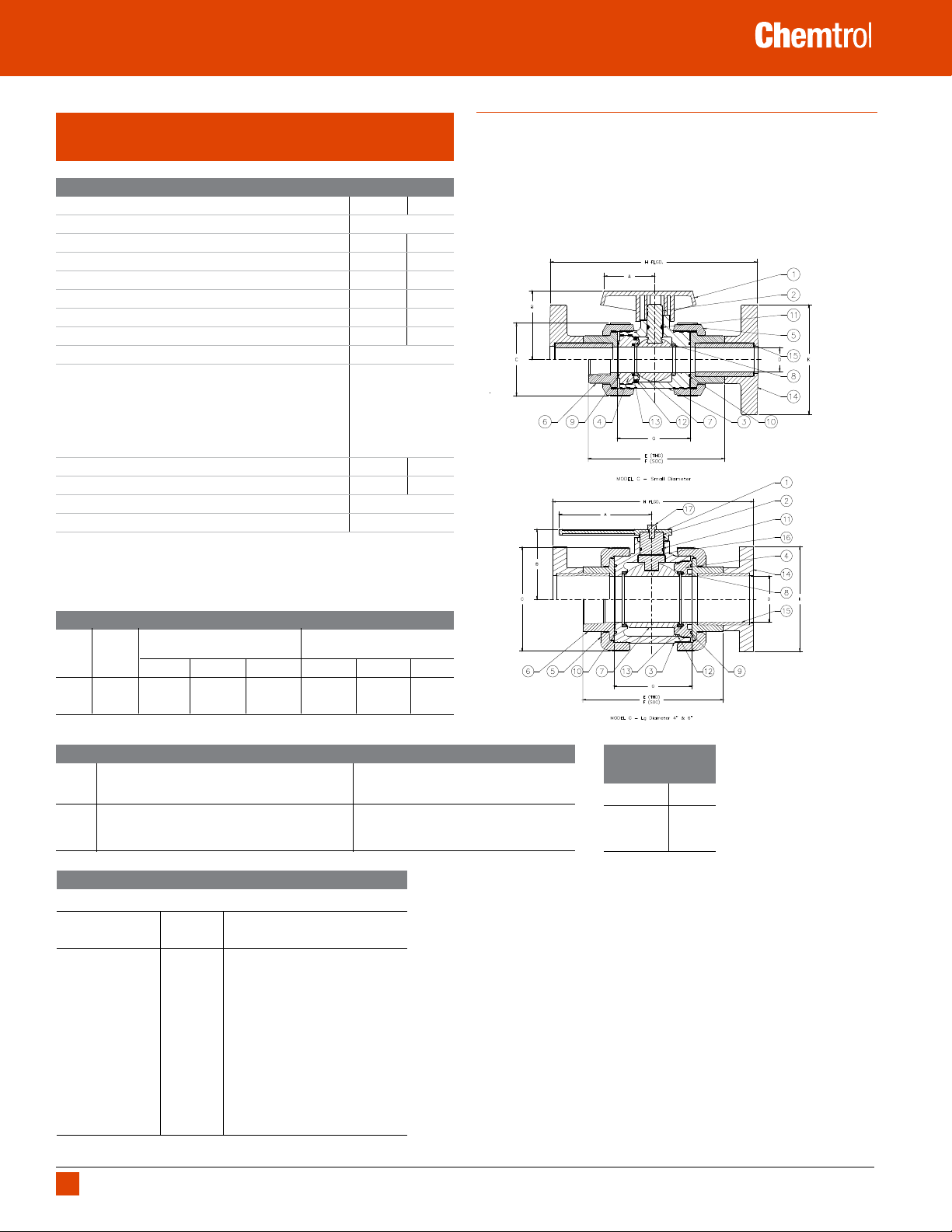

Product Guide – Ball Valves

PVC and CPVC Tru-Bloc® True Union Ball Valve,

Model D

Construction Materials

1

Components

1. Handle Orange PVC

2. Stem PVC CPVC

3. Body PVC CPVC

4. Seat-Carrier PVC CPVC

5. Union Nut PVC CPVC

6. End Connector PVC CPVC

7. Ball PVC CPVC

8. Seat

9. O-Ring

10. O-Ring

11. O-Ring

12. O-Ring

13. O-Ring

14. Flange – 2 ea. Socket-End PVC CPVC

15. Plain-End Nipple; 2 ea. Spg x Spg PVC CPVC

1 All components except valve bodies are available as replacement parts.

2 Each replacement PTFE seat kit contains two seats.

3 Each replacement O-ring kit contains all the O-rings required to refurbish a particular size True

Union Ball or Check Valve (regardless of model or style), or a minimum of two pipe unions.

PVC CPVC

2

; (2 ea.) PTFE

3

– Seat-Carrier; End Seal

3

– Body; End Seal

3

– Stem; OD Seal FKM or EPDM

3

– Seat-Carrier; OD Seal

3

– Seat-Carrier; Seat Energizer

www.chemtrol.com

Features

• Rated at 250 psi with non-shock water service at 73°F

• Corzan® HP CPVC rated at 130 psi at 180°F, see chart in Reference

Data section for maximum service temperature.

• Retains laying length of previous models, full interchangeable

cartridge, nuts and end connectors

• Designed, with an energizer O-ring beneath the PTFE seat, Model D

and C valves automatically adjust for seat wear.

• Full-port design produces minimum flow restriction with the lowest

possible pressure-drop

• Improved union nut grip style and flats on end connectors

• Universal product includes socket and threaded end connections

• Ergonomic handle with built-in carrier wrench

• Valves are manufactured and assembled without exposure to silicone

compounds. Silicone-free lubricant is used to assemble all ball valves.

Chemtrol Figure Number

Elasto-

Valve meric

Style Trim Soc. Thd. Flgd. Soc. Thd.

U/TB FKM U45TB-V* U45TB-V* F45TB-V U51TB-V* U51TB-V* F51TB-V

T

EPDM U45TB-E* U45TB-E* F45TB-E U51TB-E* U51TB-E* F51TB-E

* As original equipment, 1/2" - 2" True Union Tru-Bloc valve models are supplied with universal connectors (i.e., a set of both socket and thread end connectors).

Dimensions–Weights–Flow Coefficients

Valve A

1

B C D K E F G H J PVC Approx.2 CPVC Approx.

Size Flgd. Soc. Thd. Soc. Thd. Flgd. Wt. Lbs. Wt. Lbs.

1/2 2.07 2.16 1.82 .50 3.50 4.20 4.10 2.42 2.44 6.30 0.350 0.370

3/4 2.74 2.90 2.36 .75 3.88 5.02 4.62 3.02 3.05 7.34 0.690 0.730

1 2.74 3.07 2.73 1.00 4.26 5.47 5.32 3.22 3.40 8.17 0.960 1.000

1 1/4 2.62 3.91 4.07 1.25 4.62 6.53 6.07 4.01 4.06 9.41 2.155 2.255

1 1/2 2.62 3.91 4.07 1.50 5.00 6.89 6.23 4.10 4.18 10.05 2.190 2.315

2 3.12 4.71 5.23 2.00 6.00 8.04 7.39 5.01 5.19 11.44 4.410 4.670

Maximum Non-Shock Pressure Ratings (psi)

vs. Temperaturets

"Operating

PVC CPVC

1 Handle is not symmetrical about centerline. Dimensions shown represent the

longest operational radius. The handle position is correctly shown for the

1/2" - 3" True Union valve style.

2 Weight for 1/2" - 2" TU figures includes both sets of end connectors.

values computed for basic valve laying lengths (G).

3 C

V

Flgd.

Fluid Flow

2

Coefficient

Valve Size C

1/2 6.4

3/4 38.7

1 58.2

1 1/4 61.7

1 1/2 117.4

2 178.4

Temperature(F)" PVC CPVC

73 250 250

80 250 250

90 240 250

100 180 250

110 140 225

120 115 180

130 80 160

140 60 140

150 NR 115

160 NR 95

170 NR 80

180 NR 70

190 NR 60

200 NR 50

210 NR NR

Corzan® is a registered trademark of The Lubrizol Corporation.

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

3

TU

V

9

®

Product Guide – Ball Valves

PVC and CPVC Tru-Bloc® True Union Ball Valve,

Model C

Construction Materials

1

Components

1. Handle

2. Stem PVC CPVC

3. Body PVC CPVC

4. Seat-Carrier PVC CPVC

5. Union Nut PVC CPVC

6. End Connector PVC CPVC

7. Ball PVC CPVC

8. Seat

9. O-Ring

10. O-Ring

11. O-Ring

12. O-Ring

13. O-Ring

14. Flange – 2 ea. Socket-End PVC CPVC

15. Plain-End Nipple; 2 ea. Spg x Spg PVC CPVC

16. Stem; Friction Washer (4" & 6" Only) PTFE

17. Handle Bolt (4" & 6" Only) PVC

1 All components except valve bodies are available as replacement parts.

2 Each replacement PTFE seat kit contains two seats.

3 Each replacement O-ring kit contains all the O-rings required to refurbish a particular size True

Union Ball or Check Valve (regardless of model or style), or a minimum of two pipe unions.

PVC CPVC

Orange PVC

2

; (2 ea.) PTFE

3

– Seat-Carrier; End Seal

3

– Body; End Seal

3

– Stem; OD Seal FKM or EPDM

3

– Seat-Carrier; OD Seal

3

– Seat-Carrier; Seat Energizer

www.chemtrol.com

Features

• Rated at 150 psi with non-shock water service at 73 °F.

• Designed with an energizer O-ring beneath the PTFE seat, Model D and C

valves automatically adjust for seat wear.

• Full-port design produces minimum flow restriction with the lowest

possible pressure-drop. 6" ball valve is reduced port.

• Valves are manufactured and assembled without exposure to silicone

compounds. Silicone-free lubricant is used to assemble all ball valves.

Chemtrol Figure Number

Elasto-

Valve meric

Style Trim Soc. Thd.

U/TB FKM S45TB-V T45TB-V F45TB-V S51TB-V T51TB-V F51TB-V

T

EPDM S45TB-E T45TB-E F45TB-E S51TB-E T51TB-E F51TB-E

* Thread end connections are not available for 6" valves.

PVC CPVC

* Flgd. Soc. Thd.*

Flgd.

Dimensions–Weights–Flow Coefficients

Valve A

1

B C D N P E F G H Approx.

Size Thd. Soc. Soc. Flgd. Wt. Lbs.

3 4.00 5.59 7.18 3.00 7.42 7.50 10.39 10.39 6.58 14.63 11.25

4 8.00 6.05 8.78 4.00 8.52 9.00 12.22 12.22 7.66 17.63 17.68

4

8.00 6.05 8.78 4.00 11.90 11.05 NA 30.22 24.16 24.08 29.25

6

Maximum Non-Shock Pressure Ratings (psi) vs. Temperature

"Maximum Operating Pressure (psi) vs. Temperature"

"Operating

Temperature (F)" PVC CPVC

100 150 150

110 135 140

1 Handle is not symmetrical about center line. Dimensions shown represent the longest operational radius.

The handle position is correctly shown for the 3" True Union valve style, but the position must be rotated

180° from that shown for the 4" - 6" True Unions.

2 Weight includes socket end connections only for 3" - 6" sizes. The material represented is PVC in all cases.

values computed for basic valve laying lengths (G).

3 C

V

4 The 6" ball valve is a Venturi design derived from the 4" valve: a 4" end connector and a 6"

coupling are connected by a 6" x 4" Venturied reducer, with a union nut captured within the

assembly. Threaded end connection not available.

120 110 130

130 75 120

140 50 110

150 N.R. 100

160 N.R. 90

170 N.R. 80

180 N.R. 70

190 N.R. 60

200 N.R. 50

250 N.R. N.R.

280 N.R. N.R.

N.R. - Not recommended

Fluid Flow

2

Coefficient

Valve Size C

3

TU

V

3 1348

4 2602

4

6

2602

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

10

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

®

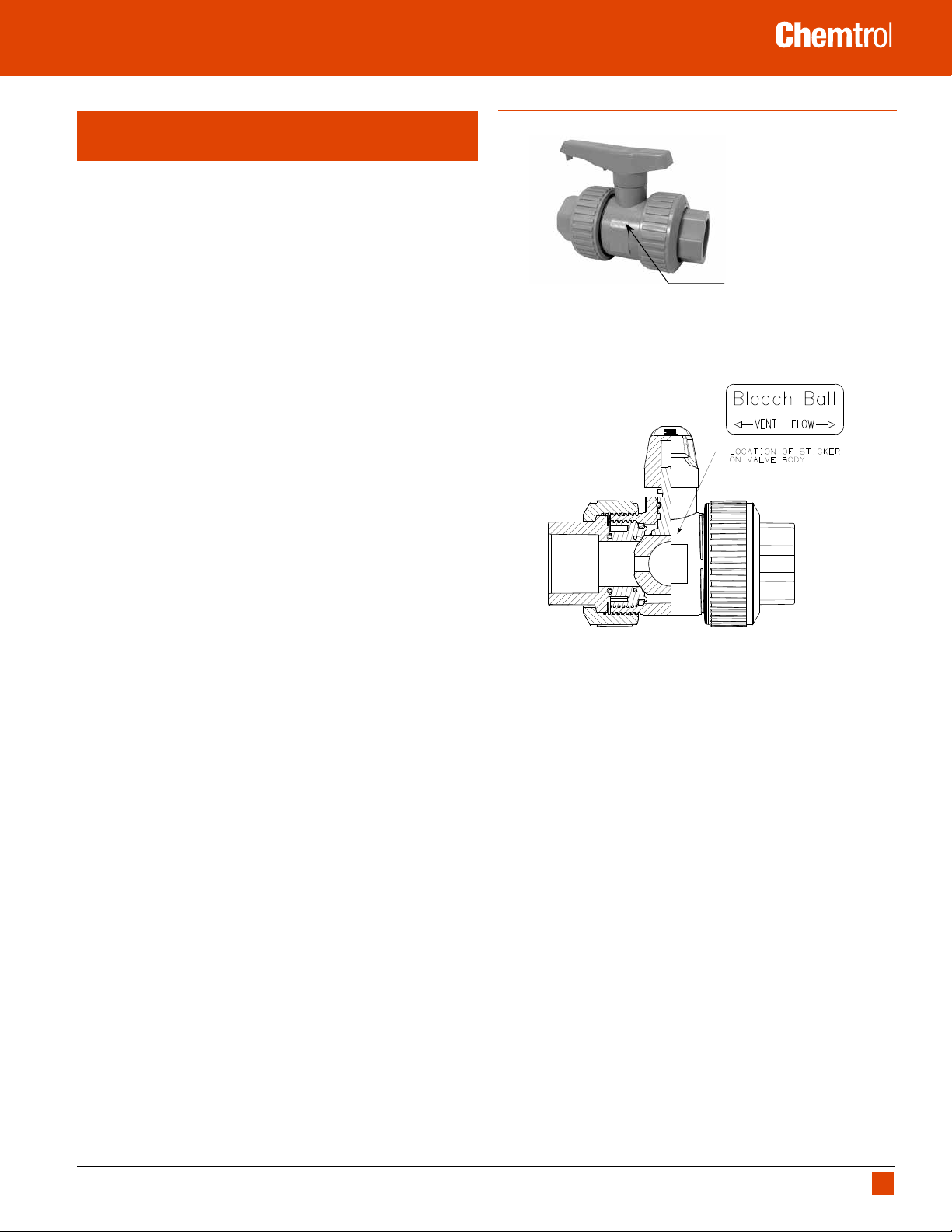

Product Guide – Ball Valves

PVC and CPVC Tru-Bloc® True Union Vented

(Bleach) Ball Valve, Model D

The Problem

Sodium hypochlorite, used in water treatment, aquatic centers, and paper

and textile applications, can become trapped in the body cavity of a closed

ball valve and create conditions that may result in damage to the valve or

system as a result of unstable chemical decomposition.

The Chemtrol Solution

The Vented Ball Valve is a special factory modification to a PVC or CPVC

True Union Ball Valve that effectively vents sodium hypochlorite out-gassing

to the pressure port. In addition, the inner valve surfaces are kept constantly

wetted to ensure problem-free use of the ball valves in bleach transfer and

injection applications.

Background

In the search for a safer alternative to chlorine vacuum gas injection, fresh

and wastewater treatment, paper and textile plants, and aquatic centers are

converting to the use of sodium hypochlorite as a disinfectant or bleaching

agent. A high pH level characterizes commercial bleach, which consists of

a nominal 15% solution of sodium hypochlorite along with approximately

1-2% of sodium hydroxide to act as a chemical stabilizer. Known as a

good oxidizer, the solution has been found to cause stress cracking in

polyethylene and polypropylene materials. And metallic materials react,

causing rapid decomposition of the “hypo.” However, PVC and CPVC, with

fluorocarbon rubber (FKM) seals, have been successfully used for years to

handle this aggressive chemical solution.

www.chemtrol.com

Permanent Bleach

And Vent/Flow

Directional Marking

Some system design considerations are important, though. Heat, time, and

positive ions are enemies of bleach stability. When a ball valve is closed in

periods of inactivity, the bleach will decompose over time liberating oxygen

gas. The decomposition rate is increased by heat absorbed from sun shining

on exposed piping, or by reaction heat resulting from debris trapped in a ball

valve body between the ball and its seats. Gas pressure may slowly build in

the closed valve cavity, or quite rapidly in the reactive case. Such conditions

may result in damage to the valve or system.

Also, evaporation of sodium hypochlorite in the ball cavity can lead to the

formation of crystalline residue that eventually embeds in the PTFE seats of

a ball valve and significantly raises the turning torque due to excessive wear

on the ball by fouled seats. Such conditions may result in a broken valve

stem, frozen valve ball, or other damage to the valve or system.

The Chemtrol

hypochlorite transfer and injection applications. Our unique factoryassembled bleach ball valve has effectively eliminated the problems

associated with these uses. By ensuring that all inner surfaces of the valve

are kept constantly wetted and vented to the upstream side when the valve

is in the closed position, we have eliminated the conditions required for gas

accumulation and caustic crystallization in the body cavity.

®

Vented Ball Valve offers a viable solution for sodium

Kynar® is a registered trademark of Arkema Inc.

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

11

®

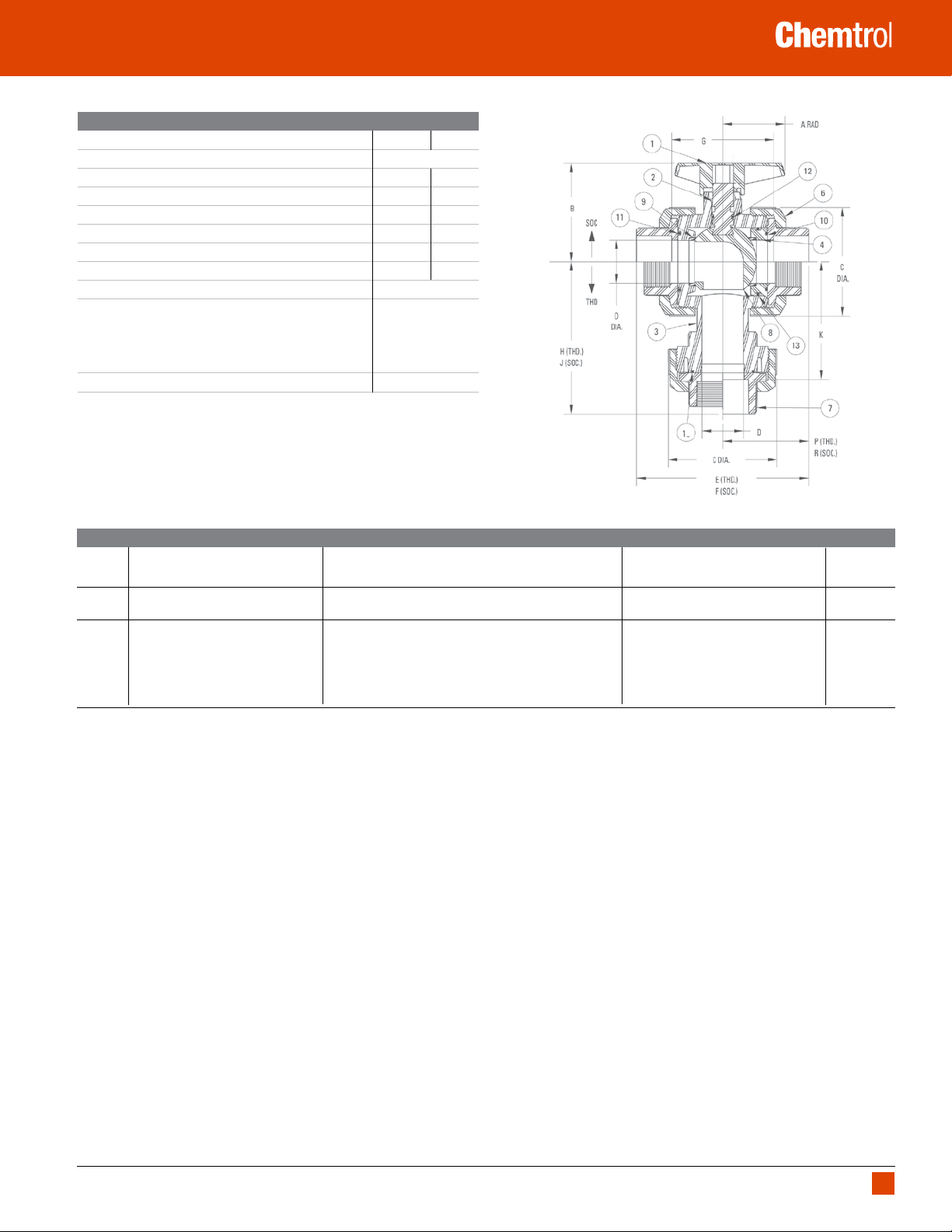

Product Guide – Ball Valves

PVC and CPVC 3-Way Ball Valves, True Union

3-Position (Multiport) and 2-Position (Diverter)

The Chemtrol True Union Multiport Valve is a 3-Way/3 Position

Ball Valve

It is ideally suited for applications where flow direction and on/off controls

are needed. When the handle is rotated 180°, the three (3) positions of on,

off and on may direct flow from the branch center-inlet to one side run-outlet

(at the 0° stop position), then to shut-off (at the 90° position), and then to the

opposite side run-outlet (at the 180° stop position). The multiport may also

be used to alternately direct flow from either of the side run-inlet ports to the

branch center-outlet port, with shut-off at the mid-position (when handle is

perpendicular to the body). Cross-contamination of the two inlet streams is

prevented by all intermediate positions between the 180° stops.

www.chemtrol.com

Features

• Rated at 150 psi with non-shock water service at 73°F

•

• ADJ externally molded onto the body to indicate the seat carrier end

• Valves are manufactured and assembled without exposure to silicone

• Full port design produces minimum flow restriction with the lowest

externally molded onto the body to indicate the fixed end

FLOW

containing a PTFE seat.

of the valve. Adjustment of this union nut can compensate for wear of PTFE

seats, with no production loss to remove valve for internal adjustment.

compounds.

possible pressure drop for 90° porting.

The Chemtrol True Union Diverter Valve is a 3-Way/3 Position

Ball Valve

It is used for applications where a quarter-turn will achieve diversion of flow,

but shut-off control is not required. When the handle is rotated 90°, the two

positions of on and on may direct flow from the branch center-inlet to one

side run-outlet (at the 0° stop position). and then the opposite side run-outlet

(at the 90° stop position). The diverter may also be used to alternately divert

flow either of the side run-inlet ports to the branch center-inlet port. The

internal porting of the diverter makes no provision for shut-off. Therefore,

the valve can be used for proportional mixing at all intermediate positions

between the 90° stops.

Maximum Operating Pressure (psi)

vs. Temperature

"Operating

Temperature (F)" PVC CPVC

100 150 150

110 135 140

120 110 130

130 75 120

140 50 110

150 N.R. 100

160 N.R. 90

170 N.R. 80

180 N.R. 70

190 N.R. 60

200 N.R. 50

250 N.R. N.R.

280 N.R. N.R.

N.R. - Not recommended

Chemtrol Figure Numbers

Valve Style Trim Soc. Thd. Soc. Thd.

1/2” – 2” Multiport FKM S45M3-V T45M3-V S51M3-V T51M3-V

(3-Way/3-Position) EPDM S45M3-E T45M3-E S51M3-E T51M3-E

1/2” – 2” Diverter FKM S45D2-V T45D2-V S51D2-V T51D2-V

(3-Way/3-Position) EPDM S45D2-E T45D2-E S51D2-E T51D2-E

Elastomeric PVC CPVC

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

12

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

4

®

Product Guide – Ball Valves

Construction Materials

1

Components

1. Handle

2. Stem PVC CPVC

3. Body PVC CPVC

4. Seat-Carrier PVC CPVC

6. Union Nut PVC CPVC

7. End Connector PVC CPVC

8. Ball PVC CPVC

9. Seat

10. O-Ring

11. O-Ring

12. O-Ring

13. O-Ring

14. O-Ring

1 All components except valve bodies are available as replacement parts.

2 Each replacement PTFE seat kit contains two seats.

3 Each replacement O-ring kit contains all the O-rings required to refurbish a particular size True

Union Ball or Check Valve (regardless of model or style), or a minimum of two pipe unions.

PVC CPVC

2

; (2 ea.) PTFE

3

– Seat-Carrier; End Seal

3

– Body; End Seal

3

– Stem; OD Seal FKM or EPDM

3

– Seat-Carrier; OD Seal

3

– Branch Union; End Seal FKM or EPDM

www.chemtrol.com

Dimensions–Weights–Flow Coefficients

Fluid Flow

Soc. & Thd Figures Socket Figures Threaded Figures Coefficient

Valve Approx.

Size A

1

B C D F G J K R Wt. Lbs. E H P Wt. Lbs C

2

Approx.2

V

3

1/2 2.07 1.94 2.00 0.50 4.19 2.41 3.56 2.69 2.13 0.64 4.00 3.50 2.06 0.60 8

3/4 2.74 2.50 2.44 0.75 5.00 2.97 4.19 3.19 2.50 1.15 4.63 4.00 2.31 1.05 19

1 2.74 2.69 2.86 1.00 5.50 3.22 4.63 3.50 2.75 1.59 5.18 4.44 2.63 1.50 36

1 1/4 2.62 3.74 4.08 1.25 6.47 3.94 5.88 4.63 3.25 3.43 6.10 5.63 3.06 3.24 55

1 1/2 2.62 3.74 4.08 1.25 6.76 3.98 6.00 4.63 3.38 3.62 6.15 5.63 3.06 3.37 55

2 3.12 4.25 5.25 2.00 8.01 4.98 7.08 5.63 3.96 7.02 7.35 6.81 3.62 6.25 149

1 Handle is not symmetrical about stem centerline. Dimension shown represents the longest

operational radius.

2 Weights shown for socket figures are CPVC models. Weights for threaded figures are PVC models.

3 Cv values were computed using equivalent cylinder length for 90° turn with full bore.

* 1 1/2" valve has conventional port on center outlet.

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

13

®

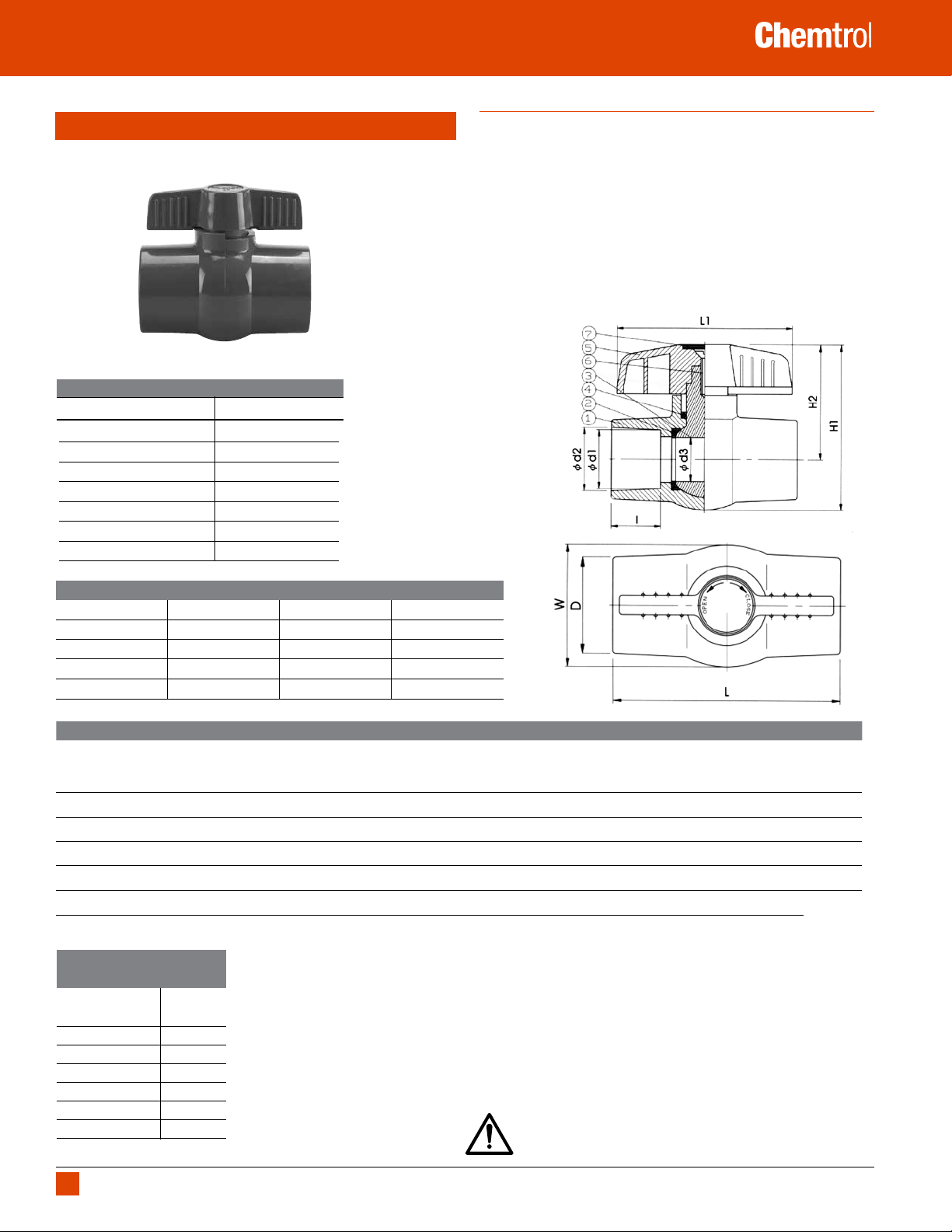

Product Guide – Ball Valves

PVC Compact Economy Ball Valve

150 psi at 73°F water–non-shock

Construction Materials

Part Specification

1. Body PVC

2. Seat Seal (2) PTFE

3. Ball PVC

4. O-Ring EPDM, FKM

5. Handle ABS

6. Bolt Zinc-Plated Steel

7. Cap ABS

www.chemtrol.com

Features

• For water distribution in industrial, residential, commercial and

agricultural applications.

• Multiple industrial uses

• Durable one-piece molded body

• Excellent flow characteristics

• Socket and threaded end connections per ASTM D2467 for

Schedule 80 PVC pipe fittings

• NPT threads per ASME B1.20.1

• Rated for 150 psi water service at 73°F and 50 psi service at 140°F

• Convenient 1/4 turn operation

• Meets NSF/ANSI 14 standard

Chemtrol Figure Numbers

Material O-Rings Ends (1/2" - 2")

PVC EPDM Soc. S45CE-E

PVC EPDM Thd. T45CE-E

PVC FKM Soc. S45CE-V

PVC FKM Thd. T45CE-E

DIMENSIONS—WEIGHTS—QUANTITIES

Size

In. mm Thd./In. (NPT) d1 d2 d3 D L L1 I H1 H2 W Weight/lbs.

Fluid Flow

Coefficient

1/2 15 14 0.84 0.85 0.55 1.18 3.27 2.76 0.87 2.44 1.69 1.50 0.18 8.84

3/4 20 14 1.05 1.06 0.79 1.50 3.74 3.46 1.00 3.07 2.13 1.93 0.18 —

1 25 11.5 1.31 1.32 0.98 1.77 4.17 3.94 1.12 3.66 2.56 2.24 0.49 25.24

11/4 32 11.5 1.65 1.67 1.18 2.13 4.48 3.94 1.25 3.86 2.64 2.48 0.64 38.53

11/2 40 11.5 1.89 1.91 1.42 2.44 5.12 4.29 1.38 4.53 3.07 2.95 0.94

2 50 11.5 2.39 2.39 1.83 3.03 5.79 5.28 1.50 5.31 3.50 3.62 1.50

Maximum Operating Pressure

(psi) vs. Temperature

"Operating

Temperature (F)" PVC

100 150

110 135

120 110

130 75

140 50

150 N.R.

N.R. - Not recommended

WARNING: This product can expose you to chemicals including

styrene, which is known to the State of California to cause cancer.

For more information go to www.P65Warnings.ca.gov.

Cv

51.28

96.67

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

14

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

®

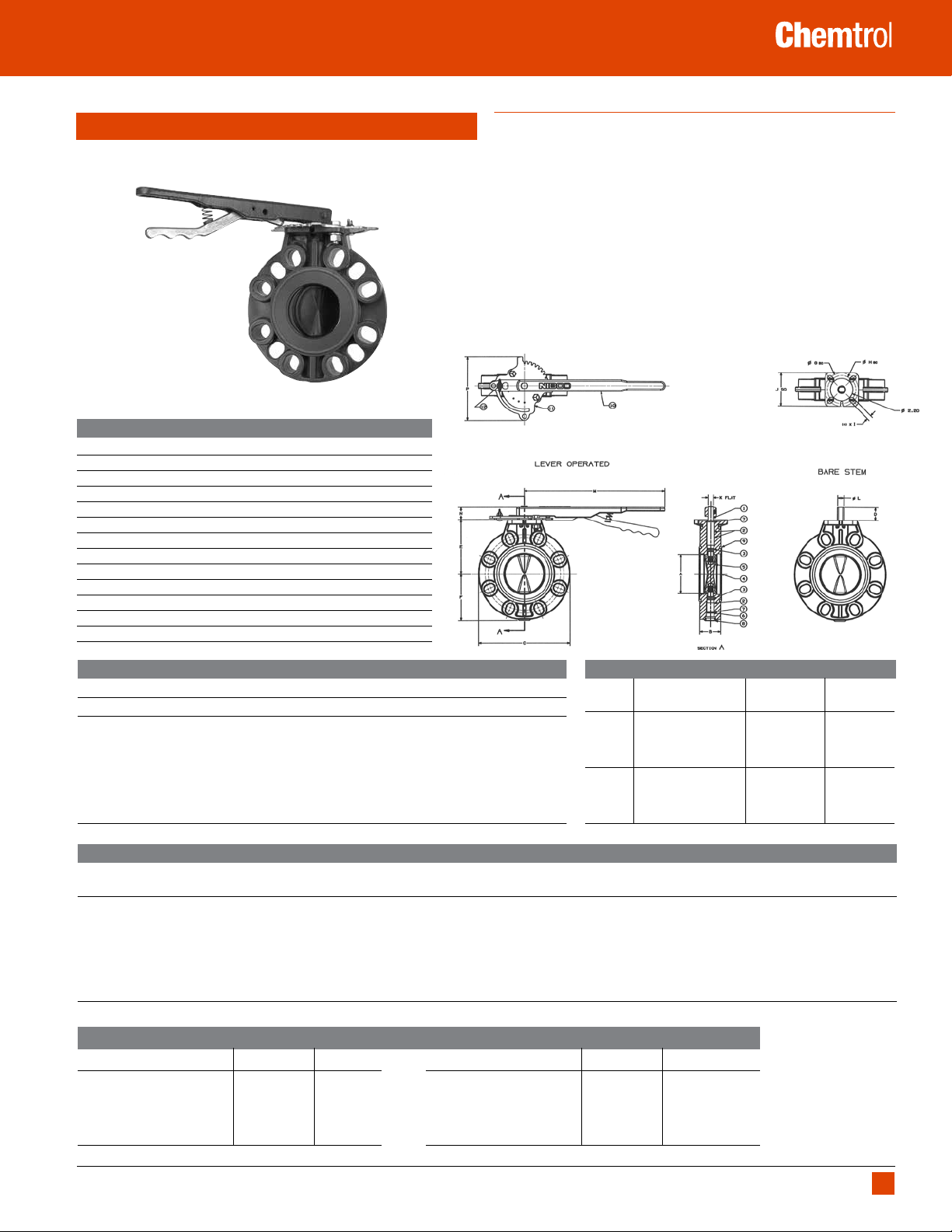

Product Guide – Butterfly Valves

PVC and CPVC Butterfly Valves, Model C

Construction Materials

Part Material

1. Upper Stem 416 Stainless Steel

2. Bushings (3) Stainless Steel backed PTFE

3. O-Ring Stem Seal (2) EPDM or FKM

4. Body CPVC or PVC

5. Disk EPDM or FKM Encapsulated Ductile Iron

6. Lower Stem 416 Stainless Steel

7. Retaining Ring (2) 304 Stainless Steel

8. Plug LDPE (Polyethylene)

9. Face o-ring (2) EPDM or FKM

10. Handle w/Lever Malleable Iron with Epoxy Coating

11. Throttle Plate Zinc Plated Steel

12. Position Lock Zinc Plated Steel

www.chemtrol.com

Features

• Rated at 150 psi with non-shock service at 73°F

• Bolt hole pattern compatible with Class 150 ASME B16.5; BS 1560 class 150;

DN 200 ISO 2084 PN 10; and DN 200 DIN EN 1092 PN 10

• Built-in O-ring face-seals require no gaskets between mating flanges.

• A hole in the lever handle provides a blockage point for trigger lock

operation, thus, locking the valve in the off position or any of the 9

increments of opening (10° each).

• Black graphite and fluorocarbon lubricant is used to assemble Model C

butterfly valves.

• NIBCO electric and pneumatic actuation available.

• Valves with CPVC and/or FKM launching soon. Contact NIBCO Technical

Services for currently available sizes and materials.

Cv TABLE MODEL C BUTTERFLY VALVE GPM/1.0 PSI ∆P

VALVE DEGREE OPEN

SIZE NPS 10° 20° 30° 40° 50° 60° 70° 80° 90° FULL

2 0 0 3.2 13.2 26.2 44.4 67.5 80 82.7

2.5 0 0 5.5 20.4 35.5 63.4 101 161.8 183.5

3 0 0.7 13.8 36.8 58.7 95.7 154 280.2 312

4 0 0.9 24.3 68.6 128 208.5 338.5 535.3 585.6

6 0 27.7 124.2 220.9 340.1 580.7 854.7 1226.3 1357.8

8 2.8 87 209.8 372.6 648.1 1013.1 1484.1 2353.4 2860

10 6 87.6 340 679 1068.9 1719.2 2724.8 4349.9 5013

Chemtrol Figure Numbers

Seat Operating

Material Mechanism PVC CPVC

EPDM No Operator W45BG-E-0 W51BG-E-0

With Lever Handle

With Gear Operator W45BG-E-5 W51BG-E-5

FKM No Operator W45BG-V-0 W51BG-V-0

With Lever Handle

With Gear Operator W45BG-V-5 W51BG-V-5

1

10" is available with lever handle

1

W45BG-E-3 W51BG-E-3

1

W45BG-V-3 W51BG-V-3

Dimensions–Weights

Valve Handle Approx.1

Size A B C D E F G H I J K L M N P Wt./Lbs.

2 1.93 1.69 6.38 1.37 3.94 3.27 3.25 2.75 0.44 3.25 0.37 0.50 10.50 1.19 6.19

2 1/2 2.44 1.81 7.16 1.28 4.13 3.67 3.25 2.75 0.44 3.25 0.37 0.50 10.50 1.19 6.19

3 2.86 1.81 7.72 1.21 4.41 3.96 3.25 2.75 0.44 3.25 0.37 0.50 10.50 1.19 6.19

4 3.83 2.06 8.98 1.26 5.30 4.56 3.25 2.75 0.44 3.25 0.50 0.66 10.50 1.19 6.19

6 5.75 2.20 11.21 1.28 7.09 5.73 3.25 2.75 0.44 3.25 0.56 0.78 13.75 1.23 6.19

8 7.73 2.36 13.60 1.36 7.99 6.95 3.25 2.75 0.44 3.25 0.56 0.78 13.75 1.23 6.19

10 9.56 2.68 16.44 1.34 9.84 8.34 5.00 4.01 0.56 4.75 0.75 1.06 Gear Operator Only

1

Operator not included in weight. Weight is for PVC.

Maximum Operating Pressure (psi) vs. Temperature

"Operating Temperature (F)" PVC CPVC

100 150 150

110 135 140

120 110 130

130 75 120

140 50 110

N.R. - Not recommended

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

"Operating Temperature (F)" PVC CPVC

150 N.R. 100

160 N.R. 90

170 N.R. 80

180 N.R. 70

190 N.R. N.R.

15

®

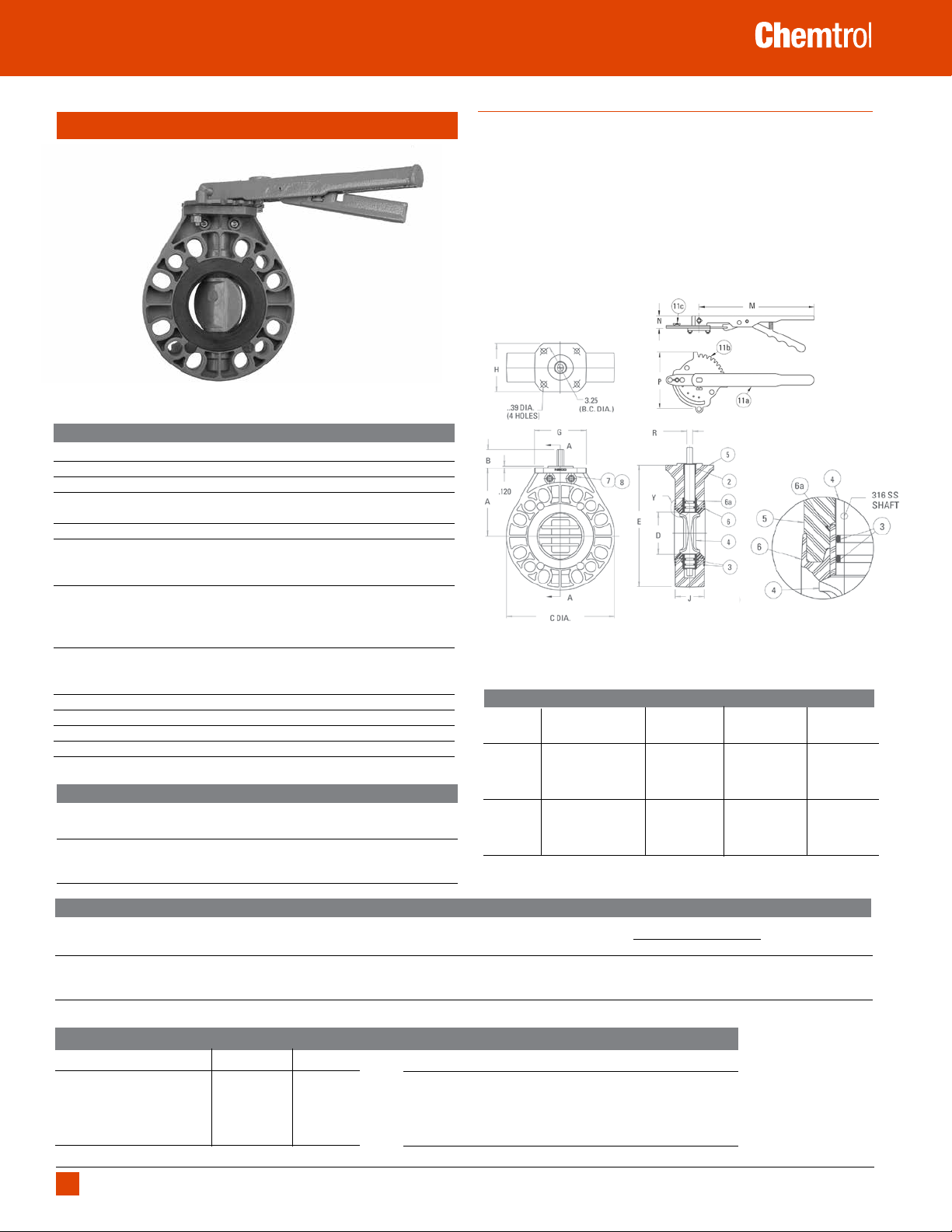

Product Guide – Butterfly Valves

CPVC and PVC Butterfly Valves, Model B

Section A–A

Construction Materials

Part Material

2. Top Bearing Glass-Filled PTFE

3. O-Ring Seal (4 required) FKM or EPDM

4. Disk/Stem PVC

Insert-Molded

5. Body (2 required – mirror image) 3" - CPVC

6. Seat/Boot FKM or EPDM w/ GF-PTFE Upper &

Lower Bearing-Bushings

Insert-Molded

7. Cap Screws; 3" Valve (6) ea. 1/4"-20 x 7/8" Long Zinc Coated

4" Valve (6) ea. 5/16"-18 x 1" Long Zinc Coated

6" Valve (6) ea. 5/16"-18 x 1-1/2" Long & (2) ea.

5/16"-18 x 1" Long Zinc Coated

8. Hex Nuts; 3" Valve (6) ea. 1/4"-20 Zinc Coated

4" Valve (6) ea. 5/16"-18 Zinc Coated

6" Valve (8) ea. 5/16"-18 Zinc Coated

9. Lever Handle Assembly

Handle w/Lever Lock Malleable Iron

Throttling Plate Zinc Plated Steel

Position Lock Zinc Plated Steel

1 Body, disk/stem, and throttle plate for 3" size are available in CPVC only.

Cv Table

Degrees Open

Size 10° 20° 30° 40° 50° 60° 70° 80° 90°

3 4.3 16 35 62 94 135 180 235 290

4 8.6 34 76 137 215 310 420 550 690

6 17.5 67 200 265 410 580 790 1040 1340

1

w/ 316 Stainless Hex Shaft

1

; 4" & 6" - PVC

www.chemtrol.com

Features

• Rated at 150 psi with non-shock service at 73°F (6" size 115 psi)

• Mates between ASME B16.5, Class 150; ISO 2084 PN 10, DN 80; and DIN EN

1092, PN 10, DN 80. Both 4-bolt and 8-bolt patterns are in 3" size.

• PVC overmolded 316 stainless hex shaft not exposed to the liquid

• Top bearing, as well as the upper and lower bushings, are glass-filled

PTFE for ease of operation and maximum service life.

• Seat/boot design eliminates need for gaskets between mating flanges.

• Silicone-free lubricant is used to assemble Model B butterfly valves.

NIBCO

CHEMTROL

Chemtrol Figure Numbers

Seat Operating

3" (CPVC)

Material Mechanism Figure No. Figure No. Figure No.

EPDM No Operator W51BF-E-NO W45BF-E-NO W45BF-E-NO

1

With Lever

Handle W51BF-E-LH W45BF-E-LH W45BF-E-LH

With Gear Operator NA W45BF-E-GO W45BF-E-GO

1

No Operator W51BF-V-NO W45BF-V-NO W45BF-V-NO

FKM

With Lever1 Handle W51BF-V-LH W45BF-V-LH W45BF-V-LH

With Gear Operator NA W45BF-V-GO W45BF-V-GO

1 Includes throttle plate and hardware.

2 Body and disk/stem for 3" size are available in CPVC only.

2

4" (PVC) 6" (PVC)

Model-B Butterfly Valve Dimensions–Weights

Handle Approx.

Valve Size A B C D E J G H R M N P Wt./Lbs.

3 4.75 1.26 7.00 3.06 8.50 2.00 3.62 3.38 .37 10.50 1.01 6.19 3.25

4 6.13 1.22 9.00 4.00 10.63 2.22 3.62 3.38 .50 10.50 1.01 6.19 6.00

6 7.50 1.62 11.00 5.97 13.00 2.77 3.76 3.50 .56 13.75 1.01 6.19 12.00

1 Operator not included in weight.

Maximum Operating Pressure (psi) vs. Temperature

"Operating Temperature (F)" PVC CPVC

100 150 150

110 135 140

120 110 130

130 75 120

140 50 110

N.R. - Not recommended

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

16

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

"Operating Temperature (F)" PVC CPVC

150 N.R. 100

160 N.R. 90

170 N.R. 80

180 N.R. 70

190 N.R. N.R.

1

®

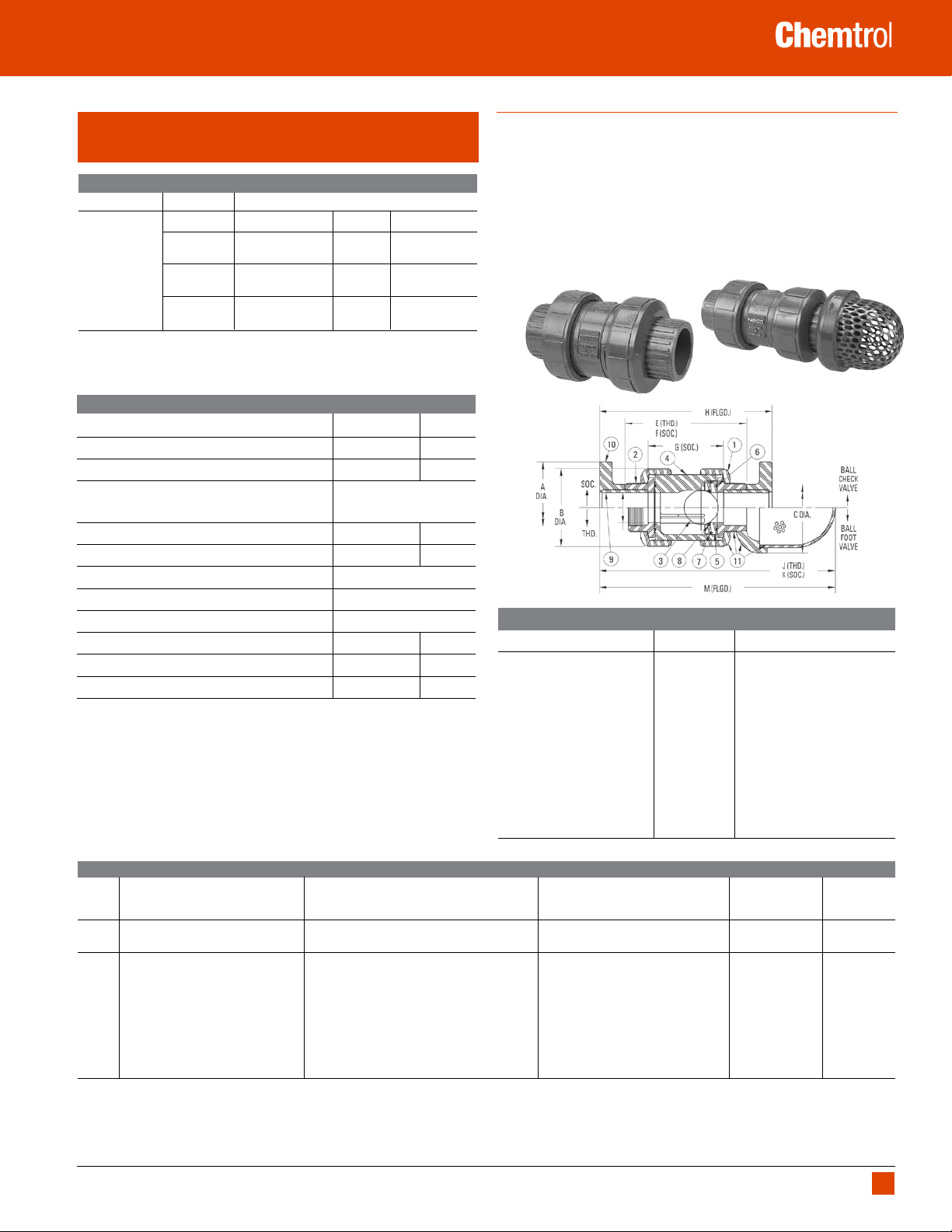

Product Guide – Ball Check Valves

PVC and CPVC True Union Ball Check, Foot, and

Vent Valves

Chemtrol Figure Numbers

Type Valve End Conn Elastomeric Trim Materials

PVC CPVC

Soc.

EPDM U45BC-E1 U51BC-E1

Ball Check Valve

EPDM U45BC-E1 U51BC-E1

Flgd. FKM F45BC-V F51BC-V

EPDM F45BC-E F51BC-E

1

1/2"–2" PVC and CPVC TU ball check figures are supplied with universal connection components

(i.e., a set of both socket and threaded end connectors). For 3" and 4" sizes of PVC and CPVC

BC valves, replace U in the figure no. with S or T for socket or threaded units respectively.

FKM U45BC-V1 U51BC-V1

Thd. FKM U45BC-V1 U51BC-V1

Features

• Rated at 150 psi with non-shock service at 73°F.

• Gravity ball check may be converted for air or gas venting by replacement

of standard ball with natural polypropylene floater ball. Then install valve

upside down for fluid to lift ball into seat.

• For foot valve, replace inlet end connection with a foot valve screen

housing assembly.

• Free oscillation of ball in guide ribs facilitates full port flow with minimum

turbulence and chatter.

• Equally effective in checking back flows from head pressure on the

discharge or suction sides of pump.

www.chemtrol.com

Construction Materials

Components

1

PVC CPVC

1. Union Nut PVC CPVC

2. End Connector PVC CPVC

3.Ball PVC CPVC

4. Body

– Standard for Check or Foot Valve

– Floater Ball for Vent Valve

1

2

Natural PP Floater Ball

PVC CPVC

5. C.V. Seat-Carrier PVC CPVC

3

6. O-ring

7. O-ring

8. O-ring

9. Plain End Pipe Nipple for Flanged Valve PVC CPVC

10. Flange–Socket for Flanged Valve PVC CPVC

11. Foot Valve Screen Housing Assembly

1 All components except valve bodies are available as replacement parts.

2 Gravity ball check valves are converted to vent valves by replacing the standard ball with a

3 Each replacement O-ring kit contains all the O-rings required to refurbish any True Union Check

4 Gravity ball check valves are converted to foot valves by replacing the union nut and end

Body & Carrier; End Seal FKM or EPDM

3

Seat-Carrier, OD Seal FKM or EPDM

3

Seat Seal FKM or EPDM

4

floater ball and inverting the valve at installation–with seat up.

or Ball Valve (regardless of model or style), or a minimum of two pipe unions.

connector on the receiving end – seat end – of the body with an F.V. screen housing assembly.

PVC CPVC

Maximum Operating Pressure (psi) vs. Temperature

"Operating Temperature (F)" PVC CPVC

100 150 150

110 135 140

120 110 130

130 75 120

140 50 110

150 N.R. 100

160 N.R. 90

170 N.R. 80

180 N.R. 70

190 N.R. 60

200 N.R. 50

250 N.R. N.R.

280 N.R. N.R.

N.R. - Not recommended

Dimensions1–Weights3–Fluid Flow Coefficients

Ball Check/Foot Ball Check Valve Ball Foot Valve Seating Head Fluid Flow

Ft – H

2

Valve E F G H Approx.

J K M Approx.3

0 Coefficient

2

Size A B C D Thd. Soc. Soc. Flgd. Wt. Lbs. Thd. Soc. Flgd. Wt. Lbs Vert. Horiz. C

1/2 3.50 1.98 2.63 0.50 3.94 4.13 2.36 6.27 0.42 6.13 6.19 7.25 0.23 6 7 5

3/4 3.88 2.44 2.63 0.75 4.65 5.02 3.00 7.38 0.72 6.88 7.13 8.25 0.29 6 7 10

1 4.26 2.83 3.63 1.00 5.08 5.40 3.12 7.99 1.05 8.13 8.25 9.63 0.37 4 5 19

1 1/4 4.62 4.08 5.50 1.25 6.38 6.75 4.22 9.65 2.46 11.13 11.25 12.75 1.34 4 5 37

1 1/2 5.00 4.08 5.50 1.50 6.38 6.99 4.21 10.18 2.62 11.13 11.50 13.13 1.34 4 5 56

2 6.00 5.23 5.50 2.00 7.36 8.02 4.99 11.45 4.76 11.75 12.13 13.75 1.88 4 5 101

3 7.50 7.17 5.50 3.00 9.98 9.98 6.17 14.22 9.21 13.38 13.38 15.63 3.00 3 4 251

4

4

9.00 7.17 5.50 3.00 20.76 20.76 16.20 16.14 14.18 18.50 18.50 16.25 3.00 3 4 251

1 Foot valve screen housing assemblies are available for the field conversion of PVC and CPVC TU ball check valves in sizes 1/2" - 4".

2 Weights shown for ball valve figures are PVC threaded models. For an approximation of CPVC check valve weights, the PVC weight may be multiplied by factor of 1.123. Weights shown for foot valves

are actually those for PVC F.V. screen housing assemblies. So, the weight for a CPVC F.V. screen housing assy. may be found by multiplying the PVC weight by the 1.123 factor. These must be added to

check valve weight for full foot valve weight.

values are based on the basic valve laying length (G).

3 C

v

4 The 4" PVC and CPVC check valves are fabricated by solvent cementing either reducing flanges or reducing couplings onto the ends of a 3" valve with plain-end nipples.

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

3

V

17

®

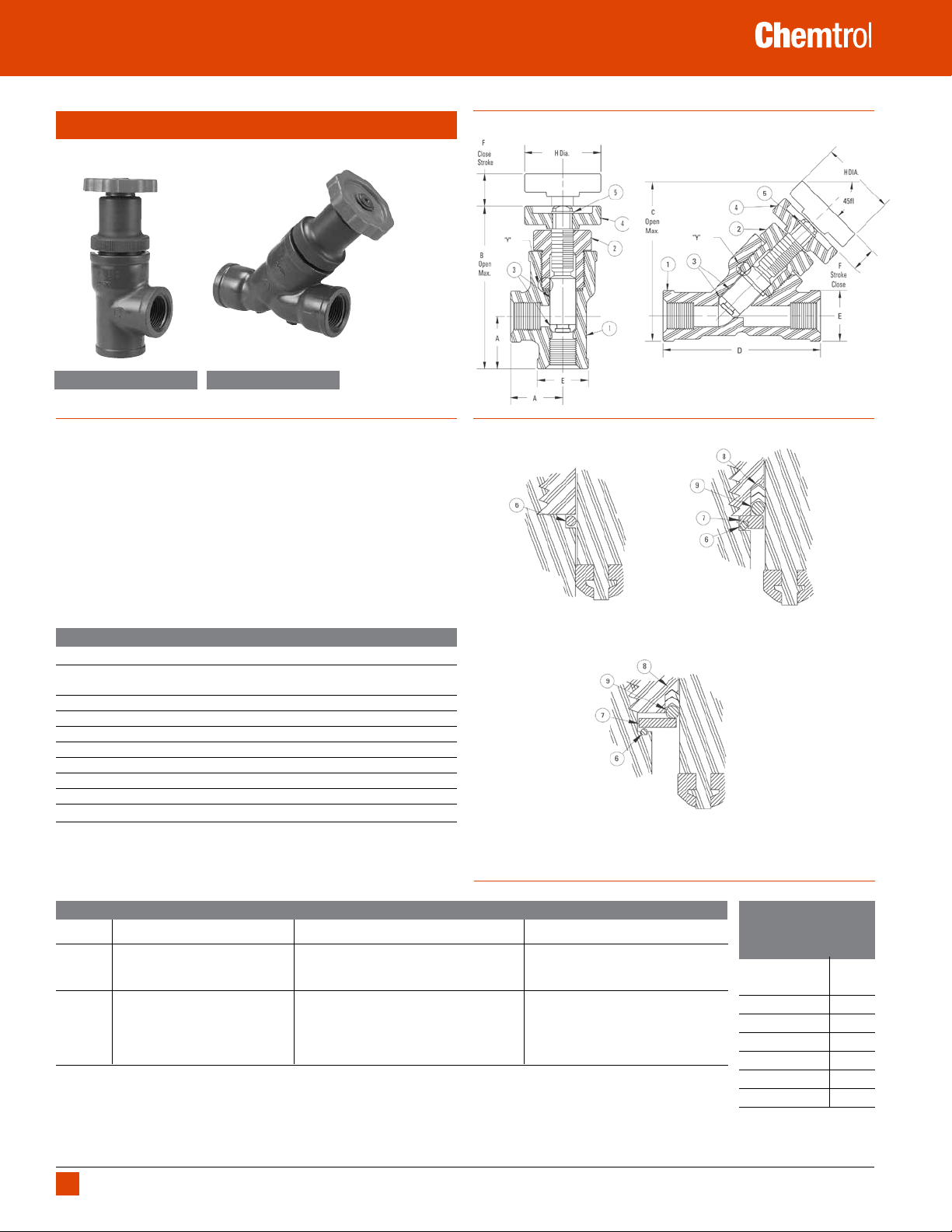

Product Guide – Angle & Globe Valves

PVC Angle and Y-Pattern Globe Valves

Both styles

Chemtrol Figure No.

T45AC-V

Chemtrol Figure No.

T45YP-V

Features

• Rated at 150 psi with non-shock service at 73°F

• Y-pattern style has a minimal pressure-drop when compared with a

conventional upright style globe valve

• Malleable glass reinforced PTFE seat disk ensures long-lasting positive

sealing.

• Stub acme thread on stem provides rapid open-close operation.

• Liquid or slurry never touches stem threads.

• Can be used for both on-off and throttling control of fluid flow.

• Easy in-line maintenance.

available with

threaded end

connections only.

www.chemtrol.com

Construction Materials

Detail “Y” Enlarged View

1/4” Size Valve

Detail “Y” Enlarged View

1/2” & 3/4” Size Valve

Part Material

1. Body – Angle PVC

– or Y-Pattern PVC

2. Bonnet PVC

3. Stem Assembly PVC w/ Glass Filled PTFE Seat Disk

4. Handle PVC

5. Snap Ring Retainer Zinc Plated Steel

6. O-Ring – Body Seal FKM

7. Energizer Back-Up Washer

8. CV Stem Seal (2 required)

9. O-Ring – Stem Seal Energizer

1 Items not required for 1/4" valve.

1

PVC

1

PTFE

1

FKM

Detail “Y” Enlarged View

1” Size Valve

Valve Dimensions – Weights – Flow Coefficients

Common Dimensions Angle Valve

1

Y-Pattern Valve

1

Hub Close Handle Center- Open Flow Approx. End- Open Flow Approx.

Valve Dia. Stroke Dia. To-Face Max. Coef. Weight To-End Max. Coef. Weight

Size E F H A B C

2

Lbs. D C C

v

2

Lbs.

v

1/4 0.88 .44 1.32 0.88 3.56 1.1 0.11 2.75 2.75 3.1 0.12

1/2 1.25 .75 2.19 1.31 5.38 5.4 0.28 3.50 4.63 17.7 0.30

3/4 1.50 .94 2.19 1.41 6.50 9.9 0.47 4.25 5.56 32.5 0.53

1 1.75 1.19 2.19 1.88 7.88 15.8 0.69 5.00 6.31 49.3 0.73

1 Available with threaded end connections only.

measured with valves completely open.

2 C

V

Maximum Operating

Pressure (psi) vs.

Temperature

"Operating

Temperature (F)" PVC

100 150

110 135

120 110

130 75

140 50

150 N.R.

N.R. - Not recommended

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

18

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

®

Product Guide – Lab Valves

PVC ChemcockTM and Calibrated Needle Lab Valves

Chemtrol Figure No.

A45CC-V 1/4" Hose x 1/4" MPT

M45CC-V 1/4" MPT x 1/4" MPT

Features

• Rated at 150 psi with non-shock service at 73°F

• Its (4.8) calculated fluid flow coefficient (Cv) is based on the laying length

being equivalent to 1/4" Schedule 80 pipe.

• Easily adaptable to any type of connection.

• Opens and closes with only a quarter turn.

• Replaceable FKM O-ring seats and seals.

• Corrosion-resistant all thermoplastic PVC construction.

• No sticking or galling.

• Full port design.

www.chemtrol.com

Approx. Weight 0.06 lbs.

Construction Materials

Part Material

1. Handle PVC

2. Ball/Stem PVC

3. Body End – Hose PVC

or Thread PVC

4. Body Half – Stem Side PVC

5. O-Ring – Body Seal FKM

6. O-Ring – Ball Seats (2) FKM

7. O-Ring – Stem Seal FKM

8. Handle Screw Cadmium Plated Steel

Chemtrol Figure No.

T45CN-V 1/4" FPT x 1/4" FPT

Features

• Rated at 150 psi with non-shock service at 73°F

• Precise flow measurement.

Approx. Weight 0.13 lbs.

• Positive stop for safe operation.

• PTFE seat prevents wear on needle.

• Accurately adjust the flow by observing the knob handle exposing

numerals molded on the valve body

Knob Position GPM @ Constant 50 PSI

8 .85

7 1.41

6 1.79

5 2.15

4 2.42

3 3.15

2 4.40

Construction Materials

Part Material

1. Adjustment Knob PVC

2. Stem Assembly PVC w/PTFE Seat Seal

& FKM Stem Seal

3. Body PVC

4. Retainer Washer PVC

5. Snap Ring Stainless Steel

6. Screw Stainless Steel

Maximum Operating

Pressure (psi) vs.

Temperature

"Operating

Temperature (F)" PVC

100 150

110 135

120 110

130 75

140 50

150 N.R.

N.R. - Not recommended

1 4.50

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

19

®

Product Guide – Valve Accessories

www.chemtrol.com

Alternative Manual Operators

Part Numbers For Alternative Manual Operators

Accessory Use Valve Size

1/2 3/4 & 1 1 1/4 &1 1/2 2 2 1/2 3 4 6 8

2" Sq. Nut

Stem Adapter PVC for TB Ball Valves 21630007 21630009 21630011 21630012 — 21630014 21630016 21630016 —

PVC for HV Ball Valves 21630007 21630009 21630011 21630011 — — — — —

Round Safety PVC for TB Ball Valves 81616007 81616009 81621011 81621012 — — — — —

Handle PVC for HV Ball Valves 81616007 81616009 81621011 81621011 — — — — —

2" Square Nut Stem Adapter–Permits operation of a valve with a standard

utility (AWWA) wrench. The most common application is for valves located in

an underground valve box. The square nut for ball valves is made from PVC. It

snaps onto the stem and locks into the slot for turning-stops of a ball valve of any

material, in place of its standard handle.

Round Safety Handle–Design prevents accidental operation of low-torque

ball valve by snagging the lever handle with personal clothing or equipment.

Suitable for PVC and CPVC Tru-Bloc

®

True Union Ball Valves, Model D.

Standoff Stem Extensions for Ball Valves–Provide handle clearance, with the

integrity of turning-stops, for insulating, panel-mounting, or shallow submerged

applications. These extensions are made of solid PVC, and are short; so top support is

not required. Although priced in increments of 1" standoff, between handle and stem,

they can be supplied in exact lengths if specified when ordered. And, if the extension is

to be installed on a valve of material other than PVC or CPVC, that must also be specified

when ordering.

PVC Standoff Stem Extensions For Ball Valve

Valve Size

Length

Of Ext. 1/2 3/4 & 1 1 1/4 2 3 4 & 6

& 1 1/2

1" Long 21618007 21618009 — — — —

2" Long 21617150 21617175 21617214 21617226 21617069 21617076

3" Long 21617151 21617177 21617216 21617229 21617249 21617078

4" Long 21617153 21617179 21617218 21617231 21617251 21617257

6" Long 21617157 21617183 21617222 21617235 21617252 21617260

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

20

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

®

Product Guide – Valve Accessories

www.chemtrol.com

Valve Lockout Devices

Part Numbers for Valve Lockout Devices

Type Lockout

Device Mounted 1/2 3/4 1 1 1/4 1 1/2 2 2 1/2 3 4 6 8

BV Handle and Locking Ring Kit Field 81644007 81644008 81644009 81644011 81644011 81644012

PP Lockout Cover for Ball Valve Field 70060210 70060210 70060210 70060211 70060211 70060211 — 70060212 — — —

Ball Valve-Mounted Lockout Kit Field 70050007 70050008 70050009 70050011 70050011 70050012 — 70050014 70050016 70050016 —

W/ Std. Plastic Handle Factory 70050107 70050108 70050109 70050111 70050111 70050112 — 70050114 70050116 70050116 —

Ball Valve-Mounted Lockout Kit Field 70080007 70080008 70080009 70080011 70080011 — — — — — —

W/ Lever Handle and Index Plate Factory 70080107 70080108 70080109 70080111 70080111 — — — — — —

Meet OSHA Standard 29 CFR 1910.147; The Control of Hazardous Energy (Lockout/

Tagout). The range in complexity and cost of these devices generally reflects the

various usage requirements of frequency, permanency, and multiples of function. The

gang hasp, for multi-discipline locking, is shown for the purpose of illustration only. It

is not available with any of the devices.

TB Ball Valve Handle and Locking Ring Kit

The locking ring surrounds the valve body for permanent attachment to the valve.

When the lock device is removed from the handle and retaining arm of the ring,

the ring arm simply hangs beneath the valve. This single function kit is effective for

valve-off lockout only or may be added to other Tru-Bloc

Location

Valve Size

®

valves of any material.

— — — — —

Ball Valve Lockout Cover

This two-piece molded polypropylene split clamshell closure, which is hinged to

fasten around the common handles of Tru-Bloc valves, is a simple provision for

maintenance or operations lockout. The cover can be locked with the handle in the

on, off, or any throttling position, but when the cover is locked the handle position,

relating ball posture, is not visible. One of three cover sizes is usually transported

to the point of use, because a cover is not easily attached to the valve when it is

unlocked.

TB Ball Valve-Mounted Lockout Kit w/Standard Plastic Handle

This all-plastic kit, permanently mounted on a valve, may be locked in the on or off

valve position. Whether locked or unlocked, the distinguishing handle position is

clearly visible at all times, including throttling postures.

TB Ball Valve-Mounted Lockout Kit w/ Lever Handle and Index Plate

This kit consists of a lever-lock handle and index plate, adapted to fit a ball valve

mount. It provides for locking the valve in the off position or any of the 9 increments

of opening (10° each), including the full on position. The handle position, aligned

with the fully on ball posture, is visible at all times.

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

21

®

Product Guide – Fittings

PVC Schedule 80

www.chemtrol.com

Couplings 24

Adapters 25

Elbows 26

Tees 27

Plugs 28

Caps 28

Bushings 29

Class 150 Flanges 30

Unions 32

Metal Transition Unions 33

Corzan® CPVC Schedule 80

Couplings 34

Adapters 35

Elbows 35

Tees 36

Plugs 37

Caps 38

Bushings 38

Class 150 Flanges 40

Unions 42

Corzan® is a registered trademark of The Lubrizol Corporation.

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

22

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

®

Product Guide – PVC Schedule 80

Fitting Terms and Abbreviations Schedule 80 only

FPT Female Pipe Thread

CL Close

MPT Male Pipe Thread

S Female Socket

SH Short

SPG Male End (Spigot)

Dimensions and Standards

Universal Part No. Chemtrol Part No.

(Discontinued)

XX XX - XXX XX XXX XXX

1 2 4 1 2 4

Material and Product Type

1 1 1

Product Universal Chemtrol Chemtrol

Line Part Number Part Number Figure Number

PVC Sch. 80 8 01 45

CPVC Sch. 80 18 05 51

PP Black Sch. 80. 28 07 61

Chempure PP Sch. 80 78 10 62

PVDF Red Sch. 80 38 58 65

NPVDF Natural Sch. 80 48 06 66

Fitting Description

2 2 2 3

Fitting & End Universal Chemtrol Chemtrol Figure No.

Connection Part No. Part No. Fitting Connection(s)

Tee-Socket 01 013 00 Blank

Tee-Socket x Thread 02 015 12 Blank

Tee-Thread 05 014 12 3-3

90° ELL-Socket 06 001 07 Blank

90° ELL-Socket x Thread 07 003 07 3

90° ELL-Thread 08 002 07 3-3

90° Street ELL-Male 10 219 07 4

Thread x Socket

90° Street ELL-Male 12 213 07 3-4

Thread x Thread

45° ELL-Socket 17 007 06 Blank

45° ELL-Thread 19 008 06 3-3

Coupling-Socket 29 025 01 Blank

Coupling-Thread 30 026 01 3-3

Adapter Coupling-Socket 35 027 03 Blank

x Thread

Male Adapter-Male 36 217 04 Blank

Thread x Socket

Reducing Bushing-Socket 37 049 18 Blank

Reducing Bushing- 38 051 18 3

Spigot x Thread

Reducing Bushing-Thread 39 050 18 3-4

Cap-Socket 47 031 17 Blank

Cap-Thread 48 032 17 3

Plug-Spigot 49 042 16 Blank

Plug-Thread 50 043 16 4

Flange-Socket 51 045 51 Blank

Flange-Thread 52 044 51 3

Flange-Blind 53 046 19 Blank

Van Stone Flange-Socket 54 069 51 A

Union-Socket 97 028 33 Blank

Union-Thread 98 029 33 3-3

Nipple-Thread x Thread 61 053 29 Blank

www.chemtrol.com

Chemtrol Figure

XX XX - X - X - SIZE

1 2 3 4

Size Description

4 4 4

Universal Chemtrol Chemtrol

Size Part Number Part Number Figure Number

1/4 002 004

1/2 005 007

3/4 007 008

1 010 009

1 1/4 012 010

1 1/2 015 011

2 020 012

2 1/2 025 013

3 030 014

4 040 016

6 060 018

8 080 019

10 100 020

12 120 021

1/2 x 1/4 072 027

3/4 x 1/4 098 029

3/4 x 1/2 101 031

1 x 1/4 128 032

1 x 1/2 130 034

1 x 3/4 131 035

1 1/4 x 1/2 166 038

1 1/4 x 3/4 167 039

1 1/4 x 1 168 040 Simply State Size

1 1/2 x 1/2 209 043

1 1/2 x 3/4 210 044

1 1/2 x 1 211 045

1 1/2 x 1 1/4 212 046

2 x 1/2 247 049

2 x 3/4 248 050

2 x 1 249 051

2 x 1 1/4 250 052

2 x 1 1/2 251 053

2 1/2 x 1/2 287 056

2 1/2 x 3/4 288 057

2 1/2 x 1 289 058

2 1/2 x 1 1/4 290 059

2 1/2 x 1 1/2 291 060

2 1/2 x 2 292 061

3 x 1 335 066

3 x 1 1/4 336 067

3 x 1 1/2 337 068

3 x 2 338 069

3 x 2 1/2 339 069

4 x 2 420 076

4 x 2 1/2 421 077

4 x 3 422 078

6 x 2 528 082

6 x 3 530 084

6 x 4 532 085

8 x 6 585 088

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

23

®

Product Guide – PVC Schedule 80

Couplings

Chemtrol

Fig. No.

4501 Socket Coupling (S x S)

Nominal Universal Approx. Dim.

Size Part No. Lbs./Ea. N

1/4 829-002 0.05 0.12

1/2 829-005 0.09 0.25

3/4 829-007 0.13 0.25

1 829-010 0.14 0.25

1 1/4 829-012 0.22 0.25

1 1/2 829-015 0.29 0.25

2 829-020 0.42 0.25

2 1/2 829-025 0.68 0.20

3 829-030 1.05 0.19

4 829-040 1.83 0.19

6 829-060 3.56 0.25

8 829-080 8.69 0.25

10 829-100 13.88 0.38

12 829-120 22.69 0.50

4501-R Reducing Socket Coupling (S x S)

Nominal Universal Approx. Dim.

Size Part No. Lbs./Ea. N

3/4 x 1/2 829-101 0.12 0.44

1 x 1/2 829-130 0.18 0.67

1 x 3/4 829-131 0.19 0.55

1 1/4 x 3/4 829-167 0.26 0.72

1 1/4 x 1 829-168 0.27 0.60

1 1/2 x 1/2 829-209 0.31 0.81

1 1/2 x 3/4 829-210 0.31 0.76

1 1/2 x 1 829-211 0.33 0.63

1 1/2 x 1 1/4 829-212 0.35 0.51

2 x 1 829-249 0.44 0.75

2 x 1 1/2 829-251 0.50 0.50

3 x 2 829-338 1.00 1.24

4 x 2 829-420 1.59 1.59

4 x 3 829-422 1.88 1.20

Other Reducing Couplings are produced by solvent cementing appropriate Reducer Bushings into

Socket Couplings. They may be ordered as factory fabrications or may be assembled in the field.

www.chemtrol.com

Chemtrol

Fig. No.

4501-3-3 Thread Coupling (FPT x FPT)

Nominal Universal Approx. Dim.

Size Part No. Lbs./Ea. L

1/4 830-002 0.06 1.41

1/2 830-005 0.09 2.03

3/4 830-007 0.14 2.28

1 830-010 0.23 2.53

1 1/4 830-012 0.33 2.78

1 1/2 830-015 0.41 3.03

2 830-020 0.60 3.28

2 1/2 830-025 0.86 3.76

3 830-030 1.22 4.00

4 830-040 2.13 4.75

4501-3-3-R Reducing Thread Coupling (FPT x FPT)

Nominal Universal Approx. Dim.

Size Part No. Lbs./Ea. L

3/4 x 1/2 830-101 0.14 2.34

1 x 1/2 830-130 0.20 2.70

1 x 3/4 830-131 0.18 2.70

1 1/4 x 3/4 830-167 0.29 3.00

1 1/4 x 1 830-168 0.31 3.00

1 1/2 x 3/4 830-210 0.35 3.16

1 1/2 x 1 830-211 0.38 3.16

1 1/2 x 1 1/4 830-212 0.40 3.16

2 x 1 830-249 0.50 3.40

2 x 1 1/2 830-251 0.56 3.40

3 x 2 830-338 1.15 4.66

4 x 2 830-420 1.79 5.38

4 x 3 830-422 2.11 5.38

Other Reducing Couplings are produced by solvent cementing appropriate Reducer Bushings

into Socket Couplings. They may be ordered as factory fabrications or may be assembled in

the field.

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

24

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

®

Product Guide – PVC Schedule 80

Adapters

Chemtrol

Fig. No.

4503 Female Adapter Coupling (S x FPT)

Nominal Universal Approx. Dim.

Size Part No. Lbs./Ea. O

1/4 835-002 0.04 0.77

1/2 835-005 0.09 1.14

3/4 835-007 0.14 1.27

1 835-010 0.21 1.39

1 1/4 835-012 0.30 1.52

1 1/2 835-015 0.38 1.64

2 835-020 0.56 1.77

2 1/2 835-025 0.77 1.98

3 835-030 1.15 2.10

4 835-040 1.95 2.47

www.chemtrol.com

Chemtrol

Fig. No.

4550 Tank Adapter (Tank x FPT)

Nominal Universal Approx. Dim. Dim. Dim

Size Part No. Lbs./Ea. A B C

1/2 0.20 2.00 2.75 1.38

3/4 Use 0.35 2.38 2.88 1.63

1 Figure 0.40 2.56 2.88 1.88

1 1/4 No. & 0.55 3.25 3.00 2.63

1 1/2 Nom. 0.65 3.25 3.00 2.63

2 Size 1.15 4.38 3.25 3.25

3

Note: Gasket is EPDM and nut is self-tightening left hand thread.

2.10 6.00 3.63 4.50

4504 Male Adapter (S x MPT)

Nominal Universal Approx. Dim.

Size Part No. Lbs./Ea. O

1/2 836-005 0.04 0.94

3/4 836-007 0.06 0.97

1 836-010 0.10 1.15

1 1/4 836-012 0.14 1.12

1 1/2 836-015 0.19 1.12

2 836-020 0.27 1.20

2 1/2 836-025 0.50 1.89

3 836-030 0.79 1.99

4 836-040 1.30 2.09

M

For complete technical information and more, refer

to our website at www.chemtrol.com.

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

25

®

Product Guide – PVC Schedule 80

Elbows

Chemtrol

Fig. No.

4507 Socket 90° Elbow (S x S)

Nominal Universal Approx. Dim.

Size Part No. Lbs./Ea. G

1/4 806-002 0.01 0.33

1/2 806-005 0.11 0.52

3/4 806-007 0.16 0.69

1 806-010 0.21 0.75

1 1/4 806-012 0.25 0.92

1 1/2 806-015 0.38 1.06

2 806-020 0.57 1.27

2 1/2 806-025 1.16 1.53

3 806-030 1.50 1.84

4 806-040 3.08 2.34

6 806-060 8.03 3.50

8 806-080 15.25 4.56

10 806-100 27.70 5.75

12 806-120 43.90 6.89

11

www.chemtrol.com

Chemtrol

Fig. No.

4507-3-3 Thread 90° Elbow (FPT x FPT)

Nominal Universal Approx. Dim.

Size Part No. Lbs./Ea. H

1/4 808-002 0.04 0.97

1/2 808-005 0.12 1.41

3/4 808-007 0.18 1.71

1 808-010 0.28 1.89

1 1/4 808-012 0.42 2.18

1 1/2 808-015 0.55 2.45

2 808-020 0.82 2.78

2 1/2 808-025 1.25 3.31

3 808-030 1.90 3.74

4 808-040 3.62 4.62

4506 Socket 45° Elbow (S x S)

4507-3 Socket x Thread 90° Elbow (S x FPT)

Nominal Universal Approx. Dim. Dim.

Size Part No. Lbs./Ea. G

1/2 807-005 0.12 0.52 1.41

3/4 807-007 0.17 0.69 1.71

1 807-010 0.28 0.75 1.89

1 1/4 807-012 0.33 0.92 2.18

1 1/2 807-015 0.55 1.06 2.45

2 807-020 0.82 1.27 2.78

H

4507-12/4506-12 Flanged ELLs

Flanged fitting center-to-face dimensions may be found on page 32. When

ordering, specify the figure number and the nominal size (e.g., 2" Schedule 80

PVC flanged 90° Elbow–4507-12 2")

Nominal Universal Approx. Dim.

Size Part No. Lbs./Ea. J

1/4 817-002 0.03 0.18

1/2 817-005 0.04 0.26

3/4 817-007 0.14 0.33

1 817-010 0.15 0.37

1 1/4 817-012 0.24 0.43

1 1/2 817-015 0.31 0.47

2 817-020 0.48 0.61

2 1/2 817-025 0.93 0.68

3 817-030 1.23 0.78

4 817-040 2.46 1.02

6 817-060 6.21 1.75

8 817-080 13.03 2.22

10 817-100 19.70 2.61

12 817-120 32.70 3.08

WARNING: DO NOT USE OR TEST THE PRODUCTS IN THIS CATALOG WITH COMPRESSED AIR OR OTHER GASES. Revision 1/2/2018

26

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY OR DAMAGE TO PROPERTY.

®

Product Guide – PVC Schedule 80

Chemtrol

Fig. No.

4506-3-3 Thread 45° Elbow (FPT x FPT)

Nominal Universal Approx. Dim.

Size Part No. Lbs./Ea. K

1/4 819-002 0.04 0.82

1/2 819-005 0.11 1.15

3/4 819-007 0.13 1.35

1 819-010 0.25 1.51

1 1/4 819-012 0.35 1.70

1 1/2 819-015 0.48 1.86

2 819-020 0.71 2.13

2 1/2 819-025 1.03 2.46

3 819-030 1.53 2.69

4 819-040 2.52 3.30

Tees

4511 Socket Tee (S x S x S)

www.chemtrol.com

Chemtrol

Fig. No.

4511-12 Flanged Tee

Flanged fitting center-to-face dimensions may be found on page 32. When

ordering, specify the figure number and the nominal size (e.g., 2" Schedule 80

PVC flanged tee–4511-12 2")

4511-R Reducing Socket Tee (S x S x S)

Nominal Universal Approx. Dim. Dim. Dim.

Size Part No. Lbs./Ea. G G I

3/4 x 3/4 x 1/2 801-101 0.18 0.52 0.52 0.62

1 x 1 x 1/2 801-130 0.24 0.53 0.53 0.73

1 x 1 x 3/4 801-131 0.26 0.63 0.63 0.74

1 1/2 x 1 1/2 x 3/4 801-210 0.48 0.67 0.67 1.05

1 1/2 x 1 1/2 x 1 801-211 0.52 0.77 0.77 1.04

2 x 2 x 1/2 801-247 0.61 0.61 0.61 1.30