Chemtrol 255, 235, 250, 230 Instruction Manual

MAN255/04B

$ 10.00

INSTRUCTION MANUAL

CHEMTROL® 255 PPM/pH Controller

CHEMTROL® 250 ORP/pH Controller

(v. 4.0 and up)

(v. 4.5 and up)

TOLL FREE 800-621-2279

PHONE 805-683-8833

FAX 805-683-1893

EMAIL support@sbcontrol.com

A Division of SANTA BARBARA CONTROL SYSTEMS

5375 Overpass Road, Santa Barbara CA 93111

TECHNICAL SUPPORT

MAN255/04B

IMPORTANT SAFETY INSTRUCTIONS

Mandated by ITS Testing Laboratories, Inc

1. READ AND FOLLOW ALL INSTRUCTIONS

2. WARNING - To reduce the risk of injury, do not permit children to use this product unless they are closely supervised

at all times.

3. WARNING - Risk of Electric Shock. Connect only to a grounding type receptacle protected by a ground-fault circuit

interrupter (GFCI). Contact a qualified electrician if you cannot verify that the receptacle is protected by a GFCI. (Only

required for cord-connected units.)

4. Do not bury cord. Locate cord to minimize abuse from lawn mowers, hedge trimmers, and other equipment. (Only

required for cord-connected units.)

5. WARNING - To reduce the risk of electric shock, replace damaged cord immediately. (Only required for cordconnected units.)

6. WARNING - To reduce the risk of electric shock, do not use extension cord to connect unit to electric supply; provide a

properly located outlet. (Only required for cord-connected units.)

7. SAVE THESE INSTRUCTIONS.

WARRANTY

This CHEMTROL® Electronic Controller Model ________S/N _____________________________________ is warranted by SANTA

BARBARA CONTROL SYSTEMS (SBCS) to be free from defects in manufacturing and workmanship for a period of FIVE (5) YEARS from

the date of purchase for the electronic module and ONE (1) YEAR for all other components. SBCS will repair or replace, at its option, any

defective part during the warranty period. Labor, shipping or incidental expenses are specifically excluded from this warranty. For warranty

coverage, defective parts should be returned immediately to your CHEMTROL

purchase receipt and a detailed description of the malfunction.

Dealer or to our factory postpaid with a copy of your

TABLE OF CONTENTS

TECHNICAL SUPPORT...........................................................1

WARRANTY.............................................................................2

TABLE OF CONTENTS ...........................................................2

INTRODUCTION......................................................................3

FREE CHLORINE ......................................................3

ORP CONTROL (Models 230/250) ............................3

PPM CONTROL (Models 235/255) ............................3

WATER CHEMISTRY ................................................3

INPUTS AND OUTPUTS ...........................................3

INSTALLATION........................................................................4

LOCATION.................................................................4

SENSOR INSTALLATION .........................................4

MAIN LINE INSTALLATION.......................................4

BYPASS LINE INSTALLATION .................................5

SENSOR CELL ..........................................................5

WATER FLOW...........................................................5

ELECTRICAL ...........................................................................6

VOLTAGE ..................................................................6

PPM BATTERY (Models 235/255) .............................6

REMOTE ALARM ......................................................6

FLOW SWITCH .........................................................6

SETUP MENU..........................................................................6

ACID/BASE FEED .....................................................6

SANITIZER/pH INTERLOCK .....................................6

SAFETY FLOW SWITCH...........................................6

TERMINAL BLOCK WIRING....................................................6

CHEMICAL FEEDERS .............................................................7

CHEMICAL FEED PUMPS ........................................7

EROSION FEEDER ...................................................7

OPERATION ............................................................................7

PPM SENSOR CONDITIONING (Models 235/255) ...7

SENSOR CALIBRATION ...........................................7

GAIN FACTOR (Models 235/255)..............................7

CONTROL SETPOINTS ............................................ 7

OVERFEED SAFETY TIMERS.................................. 7

OUT-OF-RANGE ALARMS .......................................8

FEED MODE .............................................................8

PROPORTIONAL FEED............................................ 8

CONTROLLER RESET .............................................8

STARTUP ................................................................................8

DEFAULT PARAMETERS.........................................8

AUTOMATIC CONTROL ...........................................8

MAINTENANCE ....................................................................... 9

GENERAL MAINTENANCE....................................... 9

EFFECT OF CYANURIC ACID.................................. 9

PPM SENSOR TESTING (Models 235/255).............. 9

PPM BATTERY (Models 235/255)............................. 9

NO PPM SENSOR CLEANING (Models 235/255)..... 9

ORP AND pH SENSOR TESTING ............................9

ORP AND pH SENSOR CLEANING.......................... 9

SENSOR REPLACEMENT........................................9

SENSOR STORAGE ................................................. 9

WINTERIZING ........................................................... 9

PORTABLE TESTER.............................................................10

ORP SENSOR TESTING ........................................10

pH SENSOR TESTING ........................................... 10

ORP AND pH SIMULATION .................................... 10

TROUBLESHOOTING ........................................................... 11

TABLE OF FIGURES............................................................. 11

PARTS LIST .......................................................................... 12

OPTIONS...............................................................................12

SPECIFICATIONS .................................................................12

MAN250/04 Page 3

INTRODUCTION

The CHEMTROL® 250 Series Controllers are microprocessorbased digital controllers designed to monitor and control the

sanitizer and pH levels in swimming pools, spas, cooling towers

and industrial applications.

The controllers are available with three types of sensors for

measurement of water acidity (pH) and of sanitizer level in either

PPM (parts per million or milligrams/liter) or ORP in millivolts.

This manual covers new versions (4.0 and up) of five models:

• CHEMTROL

• CHEMTROL

• CHEMTROL

• CHEMTROL

• CHEMTROL

FREE CHLORINE

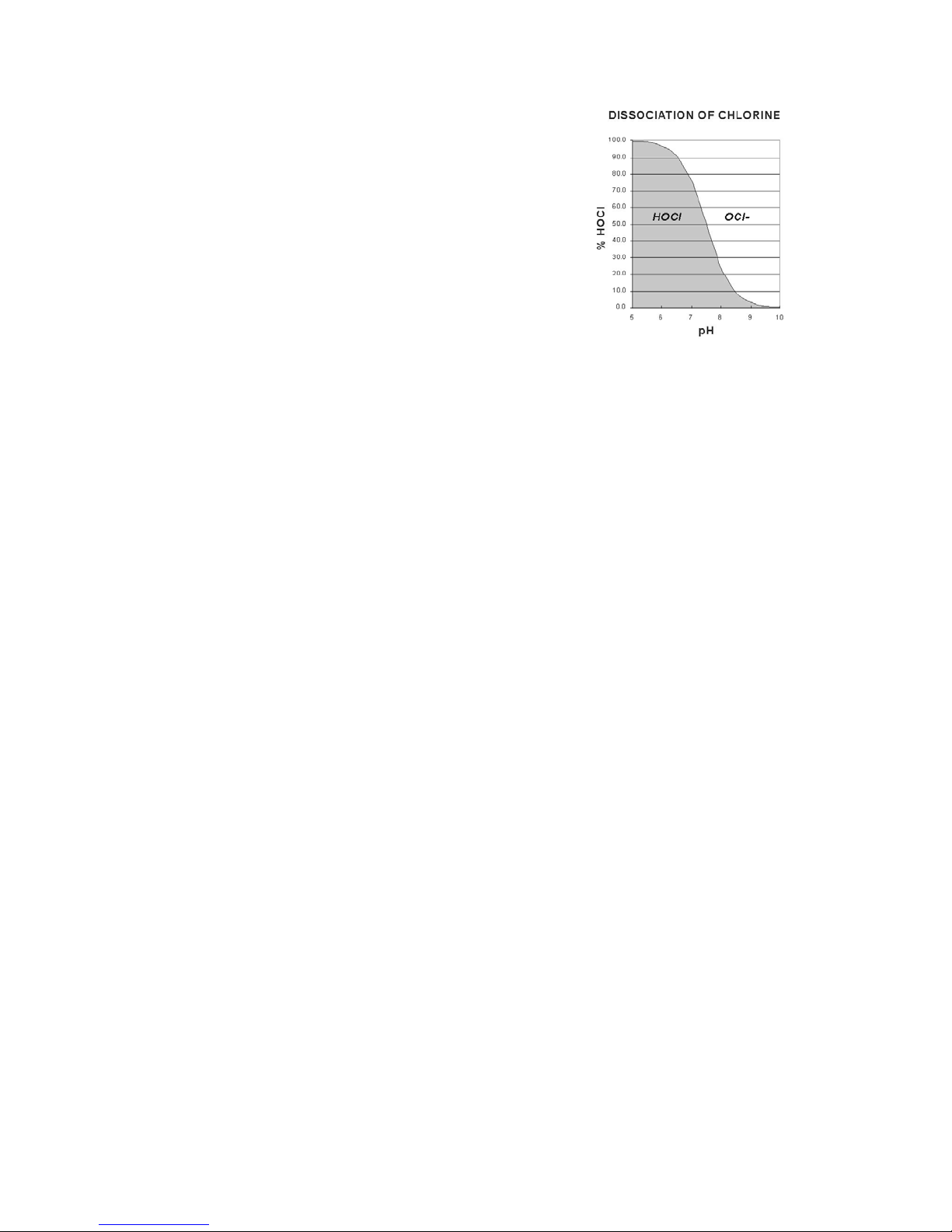

As shown on Figure 1, Free Chlorine in water is in equilibrium

under two forms:

• Molecular HOCl, a strong sanitizer and oxidizer,

• Ionized OCl-, a weak sanitizer and oxidizer.

At a pH of 7.5, the two forms are in equal proportions of 50%

each. At lower pH values, HOCl predominates. At higher pH

values, OCl- is dominant.

ORP CONTROL (Models 230/250)

The ORP sensor shows the voltage (in mV) produced by

oxidizers in water.

It responds to strong oxidizers, such as HOCl and its bromine

equivalent HOBr. It also responds to other strong oxidizers that

are used in water treatment, such as Ozone (O3) or Potassium

Monopersulfate (KSO3).

Because HOCl is the primary oxidizer, the signal of the ORP

sensor decreases with increasing pH values.

®

255 PPM/pH Controller,

®

250 ORP/pH Controller,

®

240 pH Controller,

®

235 PPM Controller.

®

230 ORP Controller.

Figure 1 - Equilibrium of Free Chlorine

The Free Chlorine display does not vary up to a pH of 7.8.

The PPM setpoint default value on the controller is 1.0 ppm,

which is recommended to kill germs and bacteria and maintain

good water quality. It can be adjusted to meet local conditions

and Health Department requirements.

WATER CHEMISTRY

Before starting automatic control, test the water chemistry to

make sure that the pH, Cyanuric Acid and Total Dissolved Solids

are within the ranges recommended by the National Spa and Pool

Institute (NSPI).

The pH should be adjusted manually within 7.4 to 7.6. If it is

below 7.0 or above 8.0, the controller will show an alarm condition

and prevent feeding (programmable option).

To stabilize chlorine against solar UV radiation, a cyanuric acid

level of 20 to 25 ppm is ideal. However, this level can be quickly

exceeded with stabilized chlorine (dichlor or trichlor). Note that

many Health Department codes do not allow stabilizer levels

above 100 ppm. If above 100 ppm, this results in chlorine lock

that shows as low ORP readings even with high chlorine levels.

It is not specific to chlorine or bromine and responds to other

oxidizers.

The chlorine or bromine concentration required to generate a

desired ORP value varies with pH and overall water quality,

particularly Total Dissolved Solids (TDS) concentration, organic

load and cyanuric stabilizer concentration.

The ORP setpoint default value on the controller is 700 mV,

which is recommended to kill germs and bacteria and maintain

good water quality.

PPM CONTROL (Models 235/255)

The PPM sensor is specific to Free Chlorine only.

The controller displays the concentration of Total Free Chlorine

(HOCl + OCl-) in PPM (parts per million or milligrams/liter). It

does not respond to Bromine and/or oxidizers.

The Total Dissolved Solid (TDS) level should be below 2,000

ppm. If higher, the water is full of organic and inorganic

impurities and should be dumped and replaced partially or

completely.

For effective pH control, the Total Alkalinity should be between

80 to 120 ppm. If too low, the pH will bounce and be hard to

control. If too high, the pH will be hard to change.

INPUTS AND OUTPUTS

Depending on the model number, the inputs include one or two

sensors:

• a PPM sensor to monitor free chlorine concentration,

• an ORP sensor to monitor ORP or Redox,

• a pH sensor and a safety flow switch (optional).

The outputs are two relays for sanitizer and pH feed - acid or

base - plus a relay for an optional remote alarm or telephone

dialer.

MAN250/04 Page 4

INSTALLATION

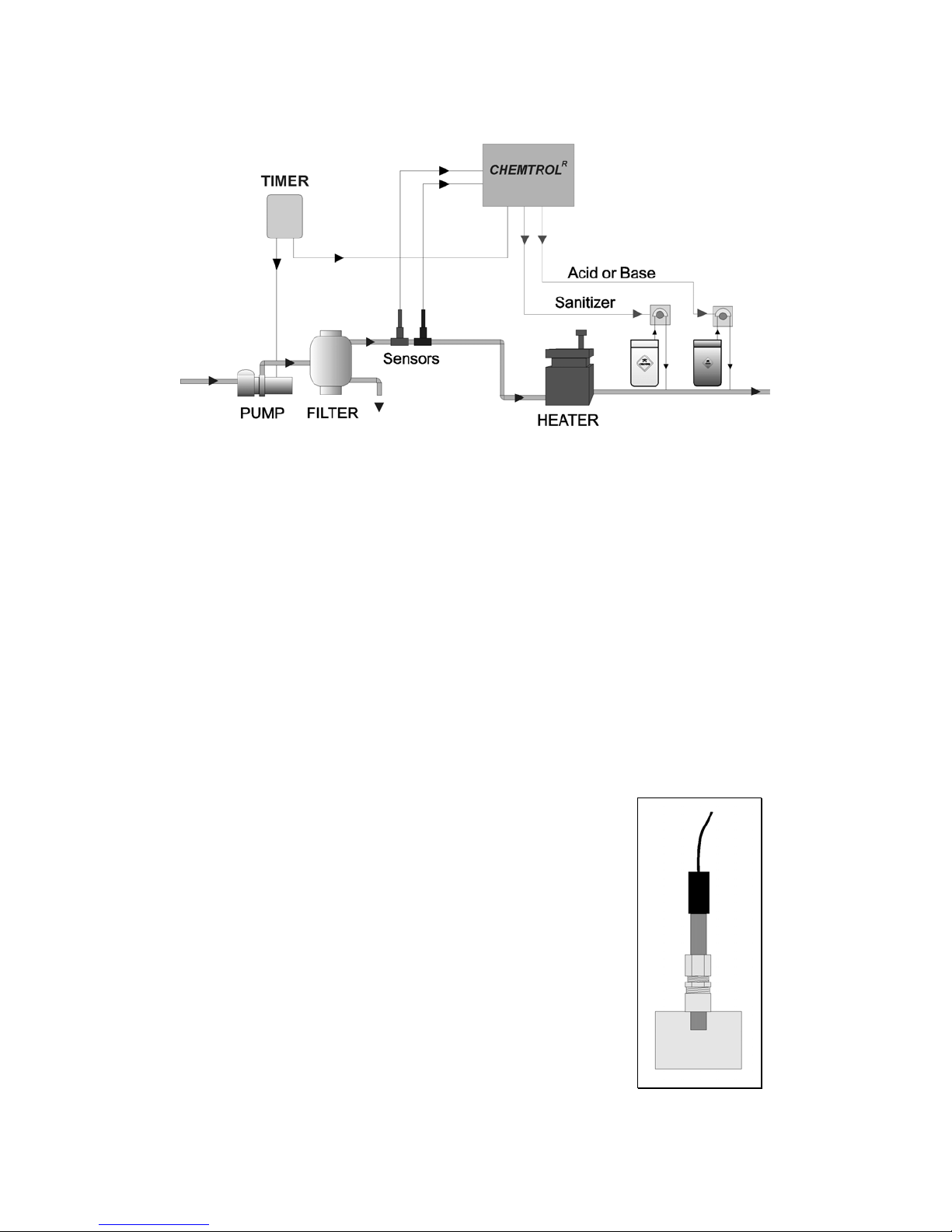

Figure 2 - Installation with Sensors on Main Line

LOCATION

Mount the controller cabinet as shown in Figure 2 on a wall in a

secure location:

• more than 10' (3 m) away from the water edge to

comply with electrical code requirements,

• if possible, not more than 10' (3 m) of the main

recirculation line or of the bypass line. The sensors

come with standard 10-foot (3-m) cables. If needed,

you can order 25 or 50-ft BNC extension cables from

your dealer.

• not exposed to direct sunlight,

• easily accessible to maintenance personnel,

• if possible in a separate room, or in a well- ventilated

room as far away as possible from corrosive chemicals

and storage tanks,

• at a safe distance from power transformers, pump

motors or high voltage power lines

• safe from unauthorized access or vandalism.

SENSOR INSTALLATION

Save the sensor caps for storage or shipping of the sensors.

When in storage or shipping, add salt water in the cap to keep the

sensors from drying out. During winter, store the sensors above

freezing temperature.

MAIN LINE INSTALLATION

On smaller installations (2 “ pipe diameter), the sensors can be

mounted directly on the main recirculation line (Figure 2).

Use only the 2x2x1/2 in. SST reducing tees without reducers

(Figure 3). Do not install the sensors near an elbow or a

constriction where there might be excessive turbulence.

Install the tees after the pump and filter. Insert the sensor tip

down so that the tip is about 1/4 inch (1 cm) in the water. The

sensors should be readily accessible for servicing but not

exposed to physical damage.

Tighten the compression fitting by hand only to avoid breaking the

internal glass tube in the sensors. Do not use a wrench!

The sensors can be mounted three different ways:

• directly on the main recirculation line (Figure 2) (2 in.

pipe only),

• on a 1/2 in. bypass line as shown Figure 3,

• even better, in a sensor cell mounted on the bypass line

(Figure 5).

Figure 3 - Sensor in PVC Tee

Loading...

Loading...