Page 1

OPERATIONS MANUAL

SCC3500XRD

SCM2500XRD

Streaming Current Monitor &

Streaming Current Controller

with Dura-Trac

R 4 8/2/06 RA

™

Remote Sensor

Page 2

Page 3

TABLE OF CONTENTS

Section Title Page

IMPORTANT INSTRUCTIONS .......................................................................... 4

WARRANTY INFORMATION............................................................................. 5

1.0 GENERAL INFORMATION................................................................................ 6

1.1 Description of Operation ............................................................................ 6

1.2 Selecting Proper Sample Point .................................................................. 6

1.3 Process Control Procedures ...................................................................... 8

1.4 System Components ................................................................................. 9

1.5 Technical Specifications ............................................................................ 10

2.0 MOUNTING AND INSTALLATION..................................................................... 12

2.1 Mounting Location ..................................................................................... 12

2.2 Power Requirement ................................................................................... 12

2.3 Signal Wiring ........................................................................................ 14

2.4 Sample Connection ................................................................................... 15

2.5 Sensor Flush Options ................................................................................ 16

2.5.1 Dura-Trac with Flush ....................................................................... 16

2.5.2 Sensor Maintenance Module ........................................................... 17

3.0 OPERATION ........................................................................................ 19

3.1 Monitor/Controller User Interface............................................................... 19

3.2 SCM2500XRD Readout, Menus and Controls ........................................... 20

3.2.1 SCM2500XRD Main Screen ........................................................... 20

3.2.2 SCM2500XRD Setup Menu (1)........................................................ 21

3.2.3 SCM2500XRD Setup Menu (2)........................................................ 22

3.2.4 SCM2500XRD Alarm Status Menu .................................................. 23

3.2.5 SCM2500XRD Flush Control Menu ................................................. 24

3.3 SCC3500XRD Readout, Menus, and Controls........................................... 24

3.3.1 SCC3500XRD Main Screen ............................................................ 24

3.3.2 SCC3500XRD Setup Menus............................................................ 25

3.3.3 SCC3500XRD Alarm Status Menu .................................................. 26

3.3.4 SCC3500XRD Pump Control (1) Menu............................................ 27

3.3.5 SCC3500XRD Pump Control (2) Menu............................................ 29

3.3.6 SCC3500XRD Flow Control (3) Menu.............................................. 29

3.3.7 SCC3500XRD Flush Control Menu.................................................. 31

3.4 System operation....................................................................................... 33

3.5 Treatment Optimization Procedure ............................................................ 34

3.6 Manual Control Using Controller ................................................................ 35

3.7 Automatic Control ...................................................................................... 35

3.8 Automatic Control Setup............................................................................ 38

3.9 Flow Control ........................................................................................ 38

3.10 Tuning Constant Specifications ................................................................. 39

4.0 GENERAL GUIDELINES ................................................................................... 41

4.1 Streaming Current Value Response Factors.............................................. 41

4.2 Fundamental Streaming Current Knowledge ............................................. 42

Page 2

Page 4

TABLE OF CONTENTS (Continued)

Section Title Page

5.0 TROUBLESHOOTING GUIDES......................................................................... 45

6.0 MAINTENANCE PROCEDURES ....................................................................... 47

6.1 Replacement Procedures .......................................................................... 47

6.2 Cleaning Procedures ................................................................................. 47

6.3 Replacement Parts .................................................................................... 48

6.4 Ordering Information.................................................................................. 50

7.0 Mechanical Specifications............................................................................... 53

LIST OF FIGURES

Figure Title Page

1 Streaming Current Profile ................................................................................. 7

2 System Components ........................................................................................ 9

3 Monitor/Controller Power Wiring ....................................................................... 12

4 Dura-Trac Sensor Power Wiring ....................................................................... 13

5 Dura-TRAC II Sensor Power Wiring.................................................................. 13

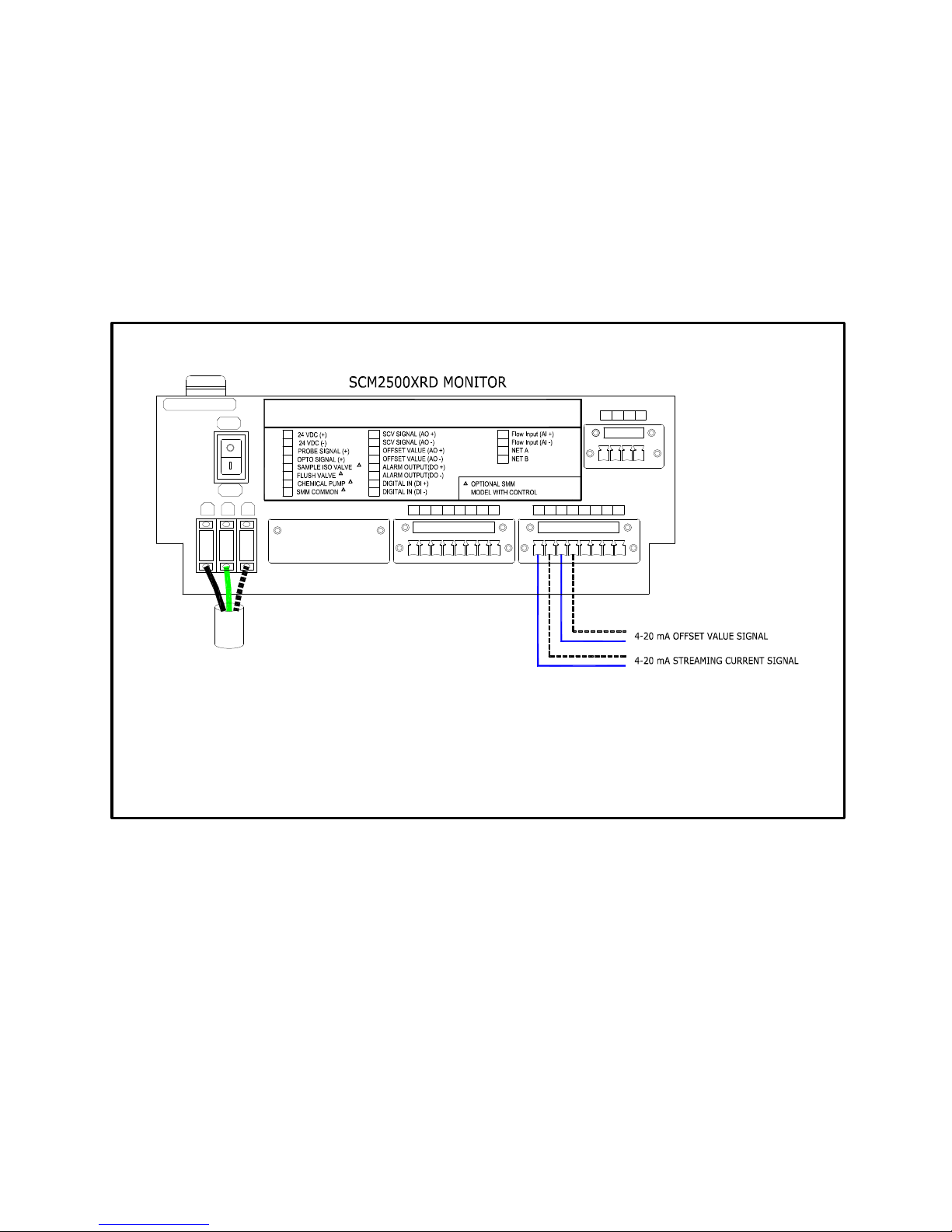

6 Signal Wires Interconnection Diagram.............................................................. 14

7 Dura-TRAC Sensor Sample Connection ........................................................... 15

8 Dura-TRAC II Sensor Sample Connection ........................................................ 16

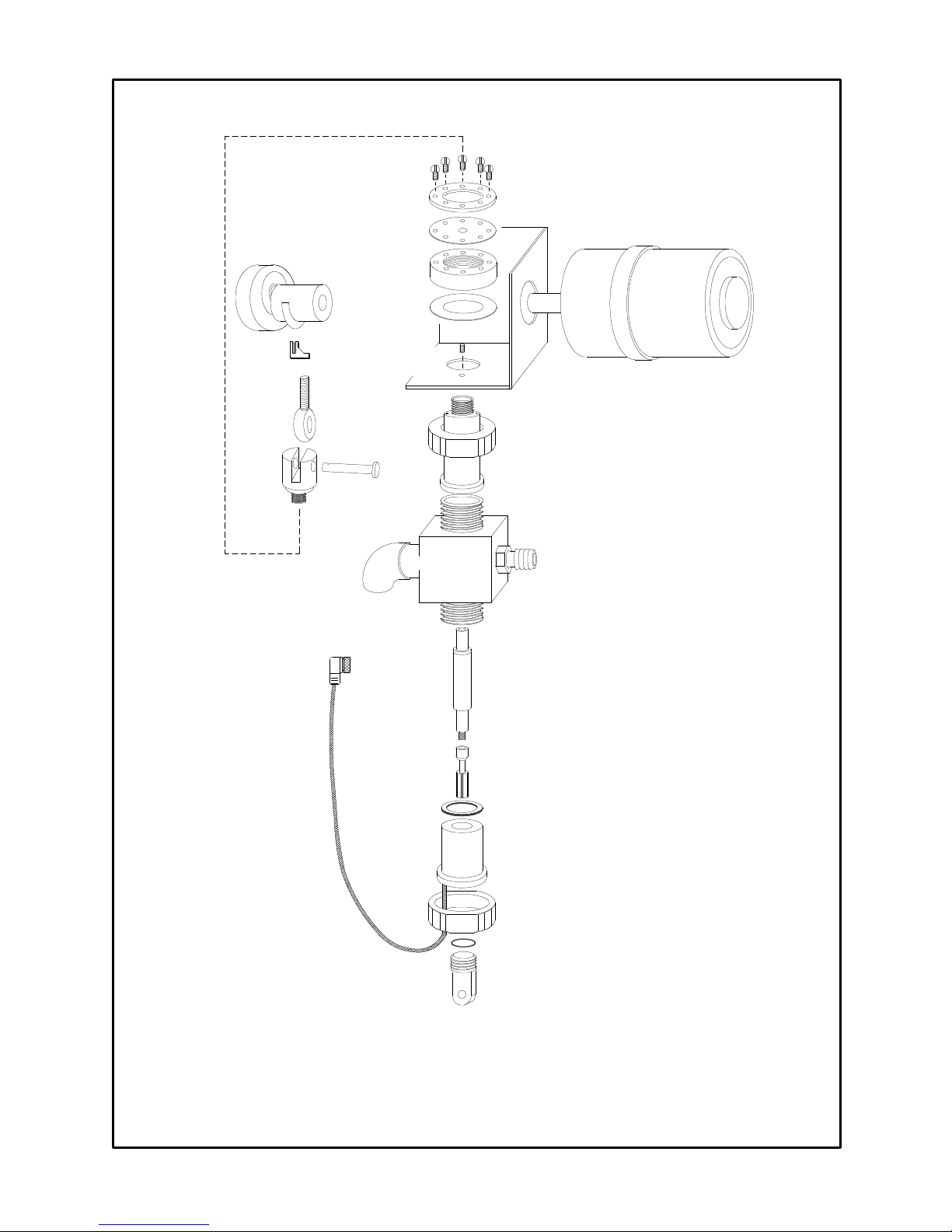

9 Dura-TRAC Sensor with Flush.......................................................................... 17

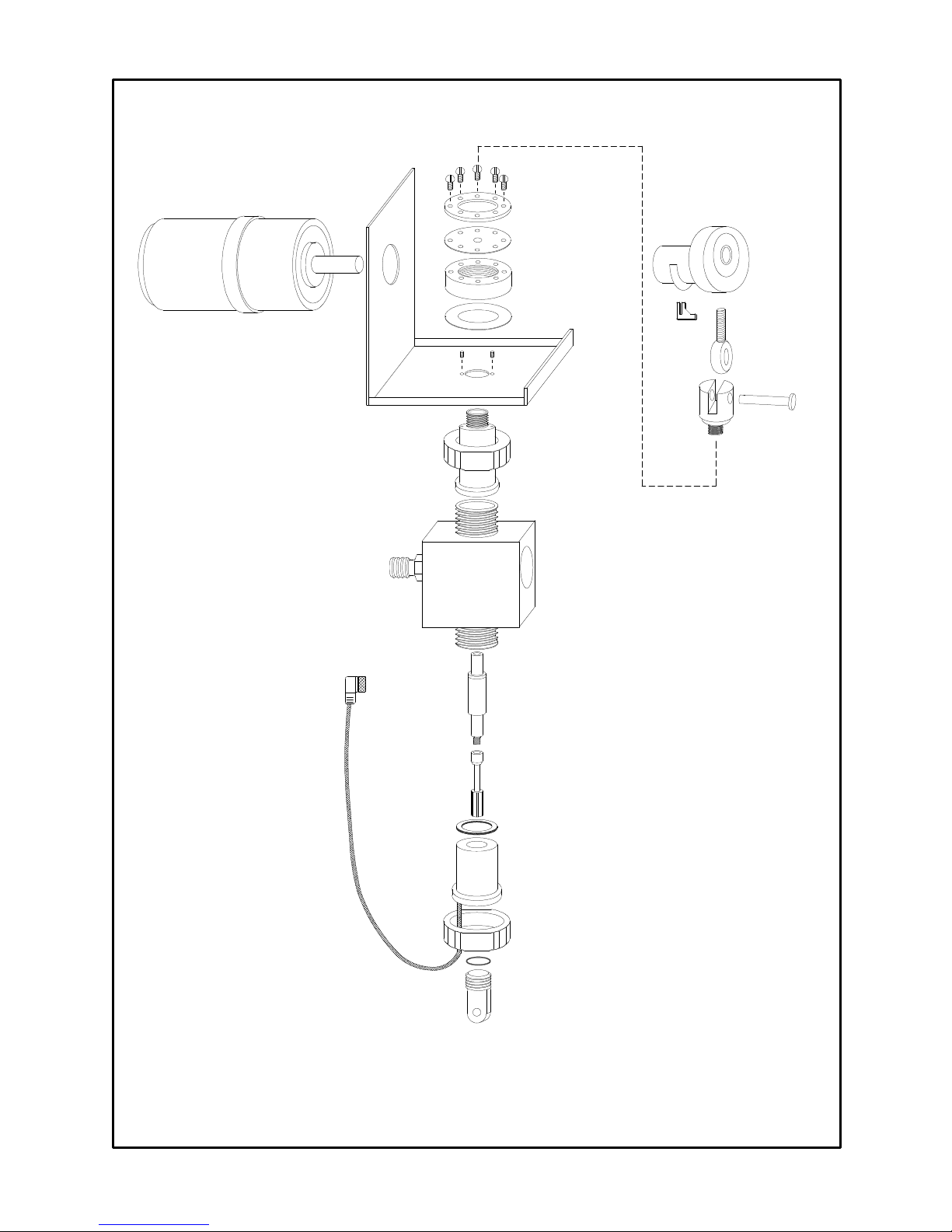

10 SMM Tubing Connections to Dura-Trac II Sensor............................................. 18

11 Automatic Flush Timing Diagram ...................................................................... 33

12 Dura-Trac Sensor Parts Identification ............................................................... 49

13 Dura-Trac II Sensor Parts Identification ............................................................ 50

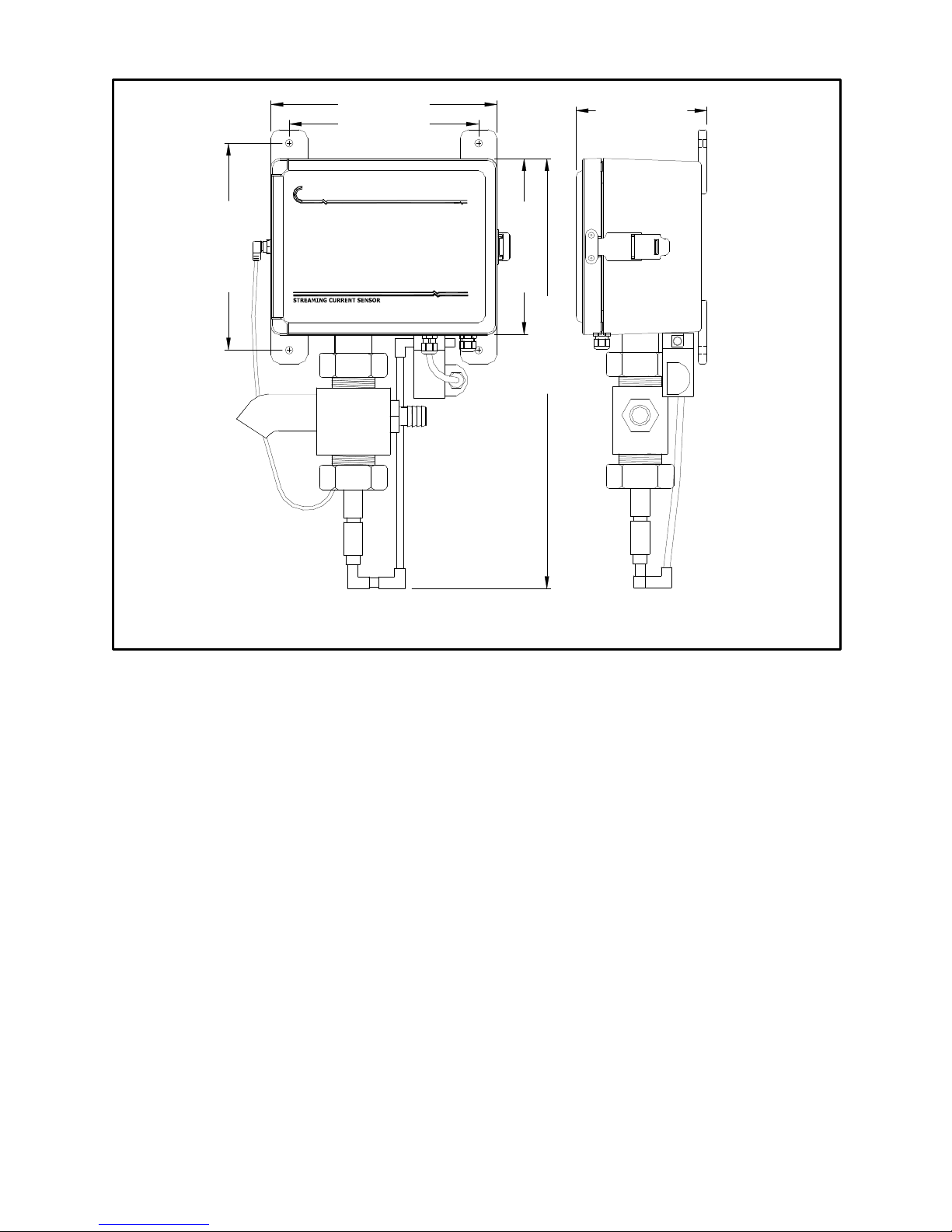

14 Streaming Current Monitor/Controller Dimensions ............................................ 53

15 Dura-Trac Sensor Dimensions.......................................................................... 54

16 Dura-Trac II Sensor with SMM Dimensions....................................................... 54

17 Dura-Trac Sensor with Flush Dimensions ......................................................... 55

18 Dura-Trac II Sensor Dimensions....................................................................... 56

19 SMM Dimensions ........................................................................................ 56

Chemtrac Systems, Inc.

Page 3

Page 5

IMPORTANT INSTRUCTIONS

When using this instrument, basic safety precautions shall always be followed to

reduce the risk of fire, electrical shocks and injury to persons, including the

following:

R Before attempting to unpack, set up, or operate this instrument, please

read this entire manual.

R Make certain the unit is disconnected from the power source before

attempting to service or remove any component.

R Follow all warnings and marked on the instrument.

R Failure to follow these precautions could result in personal injury or

damage to the equipment.

R Do not attempt to disassemble the unit.

R Water must not be allowed to enter the housing of the unit.

R Close and fasten the covers of the unit prior to any external cleaning to

prevent water ingress.

R Do not drop or jar the unit.

R Do not modify any internal electrical wiring or electronics.

R Use a mild non-abrasive cleanser when cleaning the outer cover of the

unit.

SAFETY PRECAUTIONS

In order to provide maximum user safety this instrument was designed with all electrical

circuitry enclosed within a protective non-conductive housing. The label below will be

visible at any location where high voltage is present.

Chemtrac Systems, Inc.

Page 4

Page 6

WARRANTY INFORMATION

Chemtrac® Systems, Inc. warrants its equipment to be free from defects in

material and workmanship for a period of one (1) year from date of shipment to

the original purchaser. Upon receipt of written notice from purchaser, seller shall

repair or replace the equipment (at option of Chemtrac® Systems, Inc.).

Chemtrac® Systems, Inc. assumes no responsibility for equipment damage or

failure caused by:

1. Improper installation, operation, or maintenance of equipment.

2. Abnormal wear and tear on moving parts caused by some processes.

3. Acts of nature (i.e. lightning, etc.)

This warranty represents the exclusive remedy of damage or failure of

equipment. In no event shall Chemtrac® Systems, Inc. be liable for any special,

incidental, or consequential damage such as loss of production or profits.

Should you experience trouble with the equipment, please contact:

Chemtrac Systems, Inc

6991 Peachtree Industrial Blvd., Building 600

Norcross, GA 30092

Phone: 1-800-442-8722 (Inside US only), 770-449-6233

Fax: 770-447-0889

Email: chemtrac@chemtrac.com

Website: www.chemtrac.com

Chemtrac Systems, Inc.

Page 5

Page 7

SECTION 1.0 GENERAL INFORMATION

1.1 DESCRIPTION OF OPERATION

The Streaming Current Monitor/Controller includes a remote sensor module placed at

the desired sample point, and a Monitor/Controller module. The monitor is a chargemeasuring device. The charge that it measures is the net ionic and colloidal surface

charge (positive and negative) in the sample being tested. Streaming current is related

to zeta potential, however, they are not the same value.

The treated water sample flows into the sample cell where it is drawn into the bore

during the upstroke of the piston cycle and is expelled from the bore on the piston down

stroke. Particles contained in the water are temporarily immobilized on the piston and

cylinder surfaces. As the water is moved back and forth by the piston, charges

surrounding these particles (+ and -) are moved downstream to the electrodes. This

movement of like charges causes an alternating current to be generated, defined as

"streaming current." A signal gain selector, accessed through the menu screen, is used

to select the best signal amplification. The signal amplification should be set where a

normal change in dosage results in a desired deviation in streaming current (normally 30

units). The displayed streaming current value (SCV) should be considered as a relative

reading due to amplification of the primary signal.

The streaming current amplitude and polarity is a function of sampling location in the

treatment process. It is important to understand why the streaming current varies at

different points in the system to properly interpret the readings, therefore, Section 1.2

should be read very carefully.

1.2 SELECTING PROPER SAMPLE POINT

The sample must be taken at a point where uniform distribution and mixing of coagulant

is obtained for all flow rate conditions, and at a point that allows for a quick response to

chemical feed changes as measured by the monitor (i.e. after the rapid mixer or static

mixer, and before the slow mixer or flocculation basin). The lag time, or the amount of

time it takes the water to travel from the point of chemical addition to the sensor, should

be no greater than 3 minutes (30 seconds to 1.5 minutes are typical lag times). If

uniform distribution and mixing is not being obtained at a selected sample point, the

streaming current reading will oscillate. If the chemical is not being properly mixed

(indicated by an oscillating monitor reading), the sample point needs to be moved

further downstream away from the mixing device to allow the chemical more time to mix

in with the water. Under rare circumstances, moving the sample point further

downstream in order to obtain a more stable reading may result in a lag time longer than

3 minutes. Steps should be taken to improve chemical mixing under these conditions.

When possible, avoid sampling from places where sludge, grit, etc., will be drawn into

the sensor sample cell. Sample lines must be sized to provide velocities that will

prevent floc/sludge accumulation. Keep sample lines as short as possible to minimize

delay in response time.

Figure 1, Streaming Current Profile, normally observed in a typical water plant. When

coagulant is added to raw water, the charge neutralization process begins immediately.

The time required for this neutralization process to go to completion is primarily a

function of mixing, time, raw water characteristics, type of coagulant, and to a lesser

Chemtrac Systems, Inc.

Page 6

Page 8

degree, temperature. Untreated raw water has a net negative charge. Cationic

coagulant charges, (alum, polymer, etc.) can produce a net positive streaming current

early in the system. As shown on the graph, this current becomes less positive as

negative charges react with the coagulant. At the settling basin outlet, the streaming

current value can return to nearly the same as raw water. If raw water flow or sample

flow rate is increased, the total time for the sample to travel from point of coagulation

injection to the cell is decreased. This may cause a change in monitor reading (in the

positive direction), even though the coagulant dosage (PPM) remains constant.

Conversely, if raw water or sample flow rate is decreased, streaming current readings

may go more negative. Plants that have a shifting set point caused by wide swings in

raw water flows can minimize this effect by moving the sample point further

downstream, lengthening sample line, or adding a detention pot. It is important to

maintain the sample flow at +/- 10% of the rate initially set.

Based upon the above discussion, the proper sample point for a specific plant depends

upon the following conditions:

1. Point or points of coagulant feed.

2. Mixing efficiency of raw water and coagulant.

3. Magnitude of raw water flow swings.

4. Type and quantity of coagulants used.

Chemtrac Systems, Inc.

FIGURE 1. Streaming Current Profile

Page 7

Page 9

1.3 PROCESS CONTROL PROCEDURES

Model SCC3500XRD Only

In order for the monitor to be used for automatically controlling the coagulant feed

(alum, polymer, ferric chloride), the following guidelines must be followed:

1. The coagulant must be thoroughly mixed with the raw water by the time the

sample is taken.

2. “Lag time” (i.e., the time it takes for the monitor to see a change in coagulant

feed) should be no greater than 5 minutes.

3. Variability in sample flow rates should be no greater than +/- 10 % of the initial

rate.

4. Coagulant pumps must be kept in good mechanical condition to respond quickly

and accurately to process changes.

5. Raw water quality should be in a stable condition (turbidity, pH, color, etc. should

not change rapidly or widely) when setting up the system.

The monitor should be operated a few days in manual control to observe how it

responds to normal process operation. Recording streaming current changes on a strip

chart recorder is very helpful in anticipating factors that may have to be dealt with when

automatic control is started. This period, if using the monitor with a recorder for

monitoring, is also a good time to determine the optimum coagulant dosage and

establish the operating “setpoint”. This enables the system to be put on automatic

control very simply.

Chemtrac Systems, Inc.

Page 8

Page 10

1.4 SYSTEM COMPONENTS

The SCM2500XRD and SCC3500XRD system include the following:

q Monitor/Controller

q Dura-Trac Remote Sensor

q Dura-Trac Remote Sensor with Flush (Optional)

q Dura-Trac II Remote Sensor (Optional)

q Sensor Maintenance Module (Optional)

Figure 2 illustrates system components.

MONITOR/CONTROLLER

SCC3500XRD

Power

Service

Diag.

Alarm

CHEMTRAC

SYSTEMS, INC.

SEMSOR MAINTENANCE MODULE

DURA-TRAC SENSOR OR DURA-TRAC SENSOR WITH FLUSH

CHEMTRAC

SYSTEMS, INC.

PATENTED MADE IN U.S.A.

DURA-TRAC

TM

CHEMTRAC

SYSTEMS, INC.

PATENTED MADE IN U.S.A.

DURA-TRAC

TM

DURA-TRAC II SENSOR

Chemtrac Systems, Inc.

CHEMTRAC

SYSTEMS, INC.

TM

PATENTED MADE IN U.S.A.

DURA-TRAC II

FIGURE 2. System Components

Page 9

OPERATOR

MANUAL

Page 11

1.5 TECHNICAL SPECIFICATIONS

MONITOR/CONTROLLER

Power ...................................... 85-264 VAC, 47–63 Hz

Current Load ........................... 110 VAC @ 0.5A Max

220 VAC @ 0.25A Max

User Interface.......................... Backlit Liquid Crystal Display, Menu Driven Functions,

Keypad Interface

SCV Readout .......................... -1000 to +1000

Resolution ............................... Streaming Current Units

Signal Gain.............................. User Adjustable 1X to 20X

Zero Offset .............................. Automatic, Full Scale All Ranges

Accuracy ................................. 0.5% of Full Scale

Response Time ....................... 1 Second

SCV Output Signal .................. Standard 4-20 mA (300 ohm Load)

Optional 0-10 VDC

Alarm Output ........................... 24 VDC (Solid State Relay Optional) and Auditable

Alarm for Sensor Status, High/Low Streaming Current

Value and High/Low Pump Output - SC3500XRD Only

Digital Input ............................ Dry Contacts

Enclosure Type ....................... NEMA 250 Type 4X, Reinforced Fiberglass

Enclosure Size ........................ 9.2”W, 11.2”H, 6.3”D (234mm W, 285mm H, 161mm D)

Mounting Holes ....................... 11.25”W, 7.4”H (286mm W, 188mm H)

Weight..................................... 6 Pounds (2.72 kg)

Control Output Alarms............. Adjustable High/Low Alarms

Operating Temperature ........... 32° F to 120° F (0° C to 49° C)

Following Parameter are for SCC3500XRD Only

PID Tuning Parameters........... Proportional Gain: Range 0-1000

Integral Time: Range 0-1000

PID Rate: Range 1-20

SmartTrac PID Control ............ SCC3500XRD Only

Analog Input ............................ 4-20 mA

Control Output Signal .............. 4 – 20 mA (300 Ohm Load) or 0 – 10 VDC

Control Output Limits............... Adjustable High/Low Limits

Dura-Trac REMOTE SENSOR

Power ...................................... 115 VAC, 60 Hz (standard)

230 VAC, 50 Hz (optional)

Sample Flow Rate ................... 5.0 GPM

Sample Cell Type .................... External Receiver, High Flow

Probe Type.............................. Quick Replacement Cartridge

Water Sample Connections..... Inlet: 3/4” O.D. Barb Type, Outlet: 1” O.D.

Materials Contacting Sample... Delrin, Nylon, Neoprene Viton, PVC, Stainless Steel

Chemtrac Systems, Inc.

Page 10

Page 12

Dura-Trac REMOTE SENSOR (Continue)

Output Wiring .......................... 4 Conductors Twisted Shielded Pair, 20 AWG

(6 Conductors Twisted Shielded Pair with Flush Option)

Enclosure Type ....................... NEMA 250 Type 4X, Reinforced Fiberglass

Enclosure Size ........................ 11.2”W, 9.2”H, 6.3”D (285mm W, 234mm H, 161mm D)

Mounting Holes ....................... 7.4” W, 11.25” H (188mm W, 286mm H)

Overall Height with Sensor ...... 14.7’’ (373mm)

Weight..................................... 10 Pounds (4.5 kg)

Operating Temperature ........... 32° F to 120° F (0° C to 49° C)

Dura-Trac WITH FLUSH (OPTION):

Flush Water Connections ........ ¼’’ Quick Connect Tube Fitting, Adaptable

Flush Water Pressure…. ......... 35 to 80 PSI

Overall Height with Sensor ...... 17.6’’ (447mm)

Dura-Trac II REMOTE SENSOR

Power ...................................... 115 VAC, 60 Hz (standard)

230 VAC, 50 Hz (optional)

Sample Flow Rate ................... 10 GPM

Sample Cell Type .................... External Receiver, High Flow

Probe Type.............................. Quick Replacement Cartridge

Water Sample Connections..... Inlet: 3/4” O.D. Barb Type, Outlet: 1-1/2” O.D.

Materials Contacting Sample... Delrin, Nylon, Neoprene Viton, PVC, Stainless Steel

Output Wiring .......................... 4 Conductors Twisted Shielded Pair, 20 AWG

(6 Conductors Twisted Shielded Pair with Flush Option)

Enclosure Type ....................... NEMA 250 Type 4X, Reinforced Fiberglass

Enclosure Size ........................ 11.2”W, 9.2”H, 6.3”D (285mm W, 234 mm H, 161mm D)

Overall Height with Sensor ...... 18.8’’ (477mm) without SMM Option

21.8’’ (554mm) with SMM Option

Mounting Holes ....................... 9.7”W x 10.5”H (247mm W x 266mm H)

Weight..................................... 15 Pounds (6.8 kg)

Operating Temperature ........... 32° F to 120° F (0° C to 49° C)

SENSOR MAINTENANCE MODULE (OPTIONAL)

Power ...................................... 24 VDC (Supplied From Monitor)

Flush Water Connections ........ ¼’’ Quick Connect, Adaptable

Flush Water Inlet PSI .............. 35 to 80 PSI

Chemical Injection Pump......... 1,000 mL/min (Max)

Outlet Connection.................... ¼’’ Quick Connect, Semi Rigid Tubing

Enclosure Type ....................... NEMA 250 Type 4X, Reinforced Fiberglass

Module Size ............................ 11.2”W, 9.2”H, 6.3”D (285mm W, 234 mm H, 161mm D)

Mounting Holes ....................... 9.7”W x 10.5”H (247mm W x 266mm H)

Weight..................................... 6 Pounds (2.72 kg)

Chemtrac Systems, Inc.

Page 11

Page 13

SECTION 2.0 MOUNTING AND INSTALLATION

2.1 MOUNTING LOCATION

The sensor can be located several hundred feet from the monitor. The sensor must be

mounted in a vertical position with the sample flowing into the inlet (3/4” barb fitting) and

exiting from the outlet (PVC elbow). Typically, the sensor is mounted as closely as

possible to the sampling point. Minimizing sample line lengths provides quicker

response to process changes. Sample may be obtained by using a sample pump,

tapping off a pressurized line, or using gravity feed system to get sample to the sensor.

The sample flow rate should not exceed 5.0 GPM for Dura-Trac sensor and 10.0 GPM

for Dura-Trac II sensor. Draining to atmosphere (unobstructed) is required; a

closed pipe (pressurized) drain is not recommended.

The Monitor/Controller module should be installed in a location, which will allow regular

viewing of the display as well as easy access to the front panel menu keys. See

Mounting Dimension Diagrams at end of Manual.

2.2 POWER REQUIREMENT

Electrical power should be connected in the following order

R Insert the ground wire into the middle terminal labeled “G”.

R Insert the hot wire into the left terminal labeled “L”.

R Insert the neutral wire into the right terminal labeled “N”.

For safety and proper operation, the monitor must be properly grounded through their

power cord. In cases where potential noise sources could affect the performance of the

equipment, a "surge suppressor" must be installed with the unit. The following drawings

show power terminal connections for models SCM2500XRD and SCC3500XRD

monitors, and Dura-Trac or Dura-Trac II Sensor.

Figures 3 thru 5 illustrate power-wiring connections to Monitor/Controller, Dura-Trac,

and Dura-Trac II Sensors.

FUSE: AGC-1.5A

Chemtrac Systems, Inc.

FUSE

WARNING TURN POWER OFF BEFORE MAKING ANY WIRE CONNECTIONS

TO AVOID DAMAGING THE ELECTRONIC CIRCUIT.

OFF

ON

G

L N

L

N

GND

POWER CORD

SMM | Sensor

*

*

*

*

*

1

432 65

FIELD WIRING TERMINALS

8 9 1311 12 1514 16

7

10

181719 20

FIGURE 3. Monitor/Controller Power Wiring

Page 12

Page 14

6543

1

2

119 10 1287

Opto (W)

Opto (O)

+24 Vdc

Opto (B)

+ Probe

Vdc Gnd

Cond.

High

- Probe

Shield

Signal

Opto

L1

N

FIGURE 4. Dura-Trac Sensor Power Wiring

543

1

2

6 119 10 1287

Opto (W)

Opto (O)

+24 Vdc

Vdc Gnd

Opto (B)

Cond.

+ Probe

High

- Probe

Shield

Signal

Opto

L1

N

FIGURE 5. Dura-TRAC II Sensor Power Wiring

Chemtrac Systems, Inc.

Page 13

Page 15

2.3 SIGNAL WIRING

The Dura-Trac and Dura-Trac II Sensors transmit the sensing signal to

Monitor/Controller by a multi conductor wires, see Figure 7 for signal wires

interconnection diagram. Twisted shielded cable should be used. The cable should be

enclosed in conduit for maximum protection against damage or electrical interference.

Do not run cable in same conduit with any other wiring.

R Make sure the monitor’s power switch is turn to off position before making any

signal wiring connections.

FUSE

FUSE: AGC-1.5A

OFF

ON

GL N

WARNING TURN POWER OFF BEFORE MAKING ANY WIRE CONNECTIONS

TO AVOID DAMAGING THE ELECTRONIC CIRCUIT.

1

2

3

4

5

6

7

SMM | Sensor

8

CAUTIONS

1817 19 20

9

10

11

12

13

14

15

16

*

*

*

*

1

32 4

17

18

19

*

8657

920121110

16151413

L

N

GND

(BLACK)

(RED)

(WHITE)

(BLUE)

1

+24 Vdc

Vdc Gnd

Signal +

Signal -

5432

Shield

6 87 9

+ Probe

- Probe

Opto (O)

Opto (B)

10

Opto (W)

(BLACK)

(BROWN)

(RED)

(WHITE)

64 5321 12111087 9

CHEMICAL PUMP

FLUSH VALVE

SAMPLE ISO VALVE

24 VDC COMMON

FIGURE 6. Signal Wires Interconnection Diagram

Chemtrac Systems, Inc.

Page 14

Page 16

2.4 SAMPLE CONNECTION

Sample shall be connected to the sample cell inlet side. A 3/4" barbed fitting connection

is provided for hose connection. The PVC elbow opposite the inlet is the outlet. The

outlet sample must flow to an open drain (sample receiver). The cell cannot operate

properly if pressurized. Do not replace either fitting with any other type of fitting.

Start treated water sample through the cell at a rate of between 1 to 5 GPM. Make sure

the outlet is free of obstructions. Continuous reliability of the sample flow is essential.

Interruption of the sample flow will result in erroneous readings on the

Monitor/Controller. For Controller model SCC3500XRD operating in AUTO mode, loss

of flow to the Dura-Trac sensor will result in improper coagulant dosing. A suitable flow

alarm is recommended for maximum reliability.

On the SCC3500XRD, the pump control output of the controller must be set in the

MANUAL mode if the sensor is flushed or cleaned or if power to the sensor is

interrupted for any reason. The controller can be placed back in AUTO once power

and sample flow is restored. For system with Dura-Trac with flush with Sensor

Maintenance Module (SMM), during Automatic Flushing cycles, the pump control

output signal is maintained at a constant value (see Flush Menu).

IMPORTANT

PATENTED MADE IN U.S.A.

SAMPLE OUTLET

PVC Drain

Funnel

4" Cup

DURA-TRAC

TM

SAMPLE INLET

3/4" BARB FITTING

FIGURE 7. Dura-TRAC Sensor Sample Connection

Chemtrac Systems, Inc.

2" Line

Page 15

Page 17

CHEMTRAC

SYSTEMS, INC.

DURA-TRAC II

PATENTED MADE IN U.S.A.

SAMPLE INLET

3/4" BARB FITTING

FIGURE 8. Dura-TRAC II Sensor Sample Connection

2.5 SENSOR FLUSH OPTIONS

The SCM2500XRD and SCC3500XRD are available with one of two options for

automatic sensor flushing/cleaning. The first option is the Dura-Trac with flush and is

composed of a valve mounted onto the Dura-Trac sensor, which is connected to flush

water. The second option is the SMM and is composed of a flush valve, sample

isolation valve, and chemical injection pump. The Dura-Trac with flush is recommended

for Drinking Water applications where high turbidity is often experienced. The SMM is

recommended for Waste Water applications. These options are only supplied if

specified at the time of purchase. The line of monitors offered by Chemtrac® can be

upgraded to include one of these two options. To upgrade to the Dura-Trac with either

options, the Dura-Trac sensor will need to be returned to the factory.

Potable water or the best quality plant water available shall be used for the flush water

supply. If potable water is used for flush water, a backflow prevention device should be

installed on the flush water line to prevent contamination of the potable water source.

The flush water needs to maintain a pressure of 35 PSI min to 80 PSI max.

2.5.1 Dura-Trac with Flush

Connect the male NPT end of the ¼’’ MNPT to ¼’’ Quick Connect Tube adapter fitting

(supplied with the unit) to the flush water supply. Connect a sufficient length of ¼’’

Teflon tubing between the flush water supply (¼’’ Quick Connect Tube adapter fitting)

and the valve’s ¼” quick connect fitting (see Figure 10 on the next page). The flush

valve’s outlet should already be connected to the probe flush assembly. The third valve

outlet (located on the bottom of the valve and pointed towards the ground) is the drain

outlet. Run this outlet to an appropriate drain using ¼’’ semi-rigid tubing. A manual

control valve should be installed on the flush water line in close proximity of the unit so

TM

SAMPLE OUTLET

45 DEGREE ELBOW

4" Cup

2" Line

PVC Drain

Funnel

Chemtrac Systems, Inc.

Page 16

Page 18

that the flush water may be shut off during sensor maintenance. Do not open flush

water supply valve until all connections have been made.

CHEMTRAC

SYSTEMS, INC.

PATENTED MADE IN U.S.A.

25 PSI

CHECK

VALVE

FIGURE 9. Dura-TRAC Sensor with Flush

2.5.2 Sensor Maintenance Module

Figure 11 show tubing connections between SMM and Dura-Trac II sensor. The semirigid Teflon tubing is supplied with the unit.

u Connect an appropriate length of ¼’’ semi-rigid Teflon tubing between the

PINCH VALVE outlet quick connect fitting on the SMM and the PINCH VALVE

assembly quick connect fitting.

DURA-TRAC

TM

FLUSH WATER

CONNECTION

1/8" NPT TO 1/4"

COMPRESSION

FLUSH VALVE

v Connect the male NPT end of the ¼’’ MNPT to ¼’’ Quick Connect Tube adapter

fitting to the flush water supply. Connect a sufficient length of ¼’’ Teflon tubing

between the flush water supply (1/4’’ Quick Connect Tube adapter fitting) and

the SMM’s flush water inlet ¼’’ quick connect fitting. A manual control valve

should be installed on the flush water line in close proximity of the unit so that the

flush water may be shut off during sensor maintenance. Do not open flush water

supply valve until all connections have been made.

w Connect an appropriate length of ¼’’ semi-rigid Teflon tubing between the

PROBE FLUSH outlet quick-connect fitting on the SMM and the PROBE FLUSH

assembly quick connect fitting on the Dura-Trac II Sensor.

x Connect an appropriate length ¼’’ semi-rigid Teflon tubing between the

“Chemical Rinse” PUMP INLET quick connect fitting on the SMM and the

chemical carboy.

Chemtrac Systems, Inc.

Page 17

Page 19

y Connect an appropriate length ¼’’ semi-rigid Teflon tubing between the

“Chemical Rinse” PUMP OUTLET quick connect fitting on the SMM and the and

the Dura-Trac II chemical injection port.

The SMM has a drain port on the bottom of the unit. If the drain port needs to be

extended, connect an appropriate length of ¼’’ semi-rigid Teflon tubing between the

SMM Drain quick-connect fitting to the nearest drain.

During the automatic flush/cleaning cycle, the chemical pump injects a cleaning solution

into the sensor. This cleaning solution prevents the buildup of fouling agents, which can

overtime affect the sensitivity and response of the instrument. Periodic checks of the

chemical carboy should be made to ensure the chemical storage tank is at least 1/4 full.

CAUTIONS

R Acid concentration shall not exceed 15% concentration.

SENSOR

MAINTENANCE

MODULE

(SMM)

CHEMTRAC

SYSTEMS, INC.

PATENTED MADE IN U.S.A.

PINCH VALVE

TM

DURA-TRAC II

25 PSI

CHECK

VALVE

DURA-TRAC II

SENSOR

CARBOY

TANK

FIGURE 11. SMM Tubing Connections to Dura-Trac II Sensor

Chemtrac Systems, Inc.

Page 18

Page 20

SECTION 3.0 OPERATION

3.1 MONITOR/CONTROLLER USER INTERFACE

The Monitor/Controller is equipped with user interface keys, LED indicators, and audible

beeps. The interface keys are up (p), down (q), left (t), right (u), and function keys.

There are four LED lights to the left of the graphical display. These are:

The Monitor/Controller provides the user with an audible beep feedback every time a

button is pressed.

The menu navigation of the Monitor/Controller is by using buttons at the front panel.

The following steps explain general menu navigations.

t = LEFT key

q Power –Green LED that illuminates when there is power to the unit.

q Service - Yellow LED displays the status of the electronics.

q Diag. – Green LED that blinks to give a diagnostic status of the remote sensor.

u

== RRIIGGHHTT kkeeyy

u

When this LED stops blinking, the remote sensor diagnostic alarm is in alarm

condition.

q Alarm – Red LED that illuminates when the Monitor/Controller is in alarm condition.

1. From the MAIN screen, pressing any function key will gain access to other

menu screens.

2. At the menu screen, on the far left hand side of the text there is a text cursor (})

that indicates the active line on the menu. By pressing the p or q key, the text

cursor will move to a different menu text line.

3. To modify the parameter setting on the active menu text, first press the u key

to gain access to the parameter and then press the p or q key to scroll

through the parameter range. By holding down the p or q key, the number will

increased or decreased with larger unit changes.

4. When finished making the parameter change, press t key to store the value.

At this point, the new parameter has not been saved. After all parameters

modification are completed, press the SAVE function key to accept the change

or press the MAIN function key to discard the changes.

p = UP key

q = DOWN key

Graphically define function

keys. Acsess by pressing on

button directly below.

Chemtrac Systems, Inc.

Page 19

Page 21

3.2 SCM2500XRD READOUT, MENUS, AND CONTROLS

The menu system for the SCM2500XRD is simple to navigate, below you will find the

different screens accessible through the function keys (SETUP, ALARM, and FLUSH):

3.2.1 SCM2500XRD Main Screen

The MAIN screen on the SCM2500XRD is the screen used under normal operation of

the instrument. From this screen, all other features and menus can be accessed. The

menu screen shows with Flush option.

v

u

u

w

x

y

Definitions

Streaming Current Value (SCV) ranges from –1000 to +1000

u

Gain, signal amplification factor, adjustable from 1X to 20X

v

Next Flushing Cycle (optional): If the unit include sensor flush feature, the

w

menu display the time when the next flush will occur in days, hours, and minutes.

x

Offset: OUT Offset condition OUT, actual SCV is display

Offset Value: -1000 to +1000

Zero Offset Conditions

Offset: IN Offset condition IN, adjusted SCV is displayed and the actual

SCV value will be display to the right of OUT.

The Offset function is used to automatically zero the current reading. Once an

optimum chemical dosage has been obtained, the user can null the reading so

that the setpoint becomes referenced to zero for easier interpretation (see Setup

Screen Menu).

Function Keys – There are four main menu selections across the bottom for the

y

four buttons below. The four menus are:

SETUP – SCV Setup Menu

ALARM – Alarms Status

FLUSH – Sensor Flush Control Menu

Pressing one of these keys directly below these menu selections accesses the

functions within that menu.

Chemtrac Systems, Inc.

Page 20

Page 22

3.2.2 SCM2500XRD Setup Menu (1)

From the MAIN screen, press SETUP function key, the SETUP screen will display.

Within the SETUP screen menu, the GAIN, OFFSET, and SCV ALARMS settings can

be modified.

u

v

w

x

y

z {

“

Definitions

u Sensor Gain: Signal amplification factor, adjustable from 1X to 20X. The gain

should be adjusted so that a regular change in dosage results in a noticeable

deviation (e.g. 20 to 30 units). To select the proper gain setting let the reading

stabilize for 10 minutes and record the reading. Make a normal dosage change

and then allow another 5 to 10 minutes for the reading to fully stabilize. If the

reading did not change noticeably, simply increase the gain setting and repeat

testing. If the reading changed, but did so by more than 50 units, it is suggested

to decrease the gain setting. Ideal change in Streaming Current for a normal

dosage change is anywhere between 20 to 50 units. If the reading seems

unstable when flow, dosage, NTU, and PH are stable, then check to ensure the

probe is clean and that the sensor is getting a well mixed sample.

v

w

Offset Mode: Offset mode can be changed to IN or OUT. Changing the Offset

mode to from “OUT” to “IN” will automatically zero or null the current Streaming

Current reading. For example, if the current reading was –150 and the Zero

Offset was changed to “IN”, then the adjusted Streaming Current value is

displayed on the Main Screen would be zero. The reading will not stay exactly at

zero since the reading is always slightly changing as a result of slight changes in

charge. The Offset value will display at the line below. On the Main Display, the

raw Streaming Current value (with offset) will be displayed to the right of the

Zero Offset: IN. The different between the Streaming Current value and the raw

is the offset value. To disengage the Offset, simply change the Offset mode to

“OUT” and the true Streaming Current Reading will be displayed.

Offset Value: The Offset value indicates the amount of offset that has been

applied to the reading in order to offset the reading to zero. So that, at any time

the operator can see what the offset value is and if anyone has changed it from a

previous offset. To disengage the offset, simply change the Offset Mode to

“OUT” and the true Streaming Current Reading will be displayed. This is also

the method used to re-zero the reading if the current offset no longer

corresponds to optimum coagulant feed. To re-zero the reading when Offset

mode is “IN”, increased or decreased the Offset Value then press Enter to

SAVE.

Chemtrac Systems, Inc.

Page 21

Page 23

SCV Lo (Low) Alarm - This is the streaming current low value alarm

x

(-1000 to +1000). This alarm should be set so that it correlates to a reading

which indicates an under dosage of chemical. Once properly set, if there is an

under dosage (or total loss) of chemical feed, the streaming current value will

drop below this alarm threshold and the alarm will be activated (meaning that the

Main Display will show “Alarm: On” and the Alarm Output will be engaged. Once

the streaming current value returns above the alarm threshold, the Alarm will

deactivate.

SCV Hi (High) Alarm - This is the streaming current high value alarm

y

(-1000 to +1000).and works the same way as the SCV Low alarm except this

alarm value should be set to correlate to a reading which indicates an over

dosage of chemical.

z

SCV AO Scale – The analog output’s scaling of the streaming current value can

be set for +/-1000, +/-750, +/-500, or +/-250. This setting allows the analog

output to change based on different scale settings.

{ MAIN Function Key – Pressing this key will ignore any setting modifications on

this screen and brings up the MAIN screen.

SAVE Function Key – Pressing this key will save current setting modifications

|

and brings up the MAIN screen.

3.2.3 SCM2500XRD Setup Menu (2)

From the SETUP MENU (1), continue pressing the down arrow key until SETUP MENU

(2) menu screen display. SETUP MENU (2) menu screen is a continuation of the

SETUP MENU (1) menu screen.

u v

Definitions

u

SCV Filter: The filter function activate rolling average of the Streaming Current

value over time. The SCV filter can be set to OFF, 30, 60, 90, or 120 seconds.

The default setting is OFF.

Chemtrac Systems, Inc.

Page 22

Page 24

3.2.4 SCM2500XRD Alarm Status Menu

From the MAIN screen, press ALARM function key, the ALARM STATUS screen will

display. Within the ALARM STATUS menu you can view which Alarm has been

triggered, as well as, turn the Monitor/Controller’s audible alarm feature on and off.

u

v

w

x

y

Definitions:

u Diagnostic: Display sensor diagnostic alarm condition. When the sensor is in

diagnostic alarm, it will show ALARM, the green LED (Diag.) will also stop

blinking, and the Streaming Current value will show “---“. Most likely cause for a

diagnostic alarm is that the motor in the

sensor is not turning. Check to ensure the

motor is turning. If the motor is turning,

ensure the blade of crank is passing cleanly

through the opto-switch. If the blade is

rubbing against the opto-switch, make an

adjustment by loosening the setscrew of the

crank and sliding it over so that the blade

lines up in the middle of the opto-switch. If the blade was rubbing, it will be

necessary to use compressed air to remove any debris (dust) that may be

blocking the optics of the opto-switch. Finally, check the interconnect wiring if no

other cause can be found for the diagnostic alarm. A loose connection or a

terminal that is screwed down on the insulation of the wire instead of the wire

itself can cause the diagnostic alarm to activate.

v

w

x

y

z

SCV Lo (Low): The SCV Lo Alarm indicates that the SCV fall below the SCV Lo

Alarm threshold.

SCV Hi (Low): The SCV Hi Alarm indicates that the SCV rises above the SCV

Hi Alarm threshold.

Dry Contact: Digital input status (normally open) indicates the state of digital

input. When digital input is close, the ALARM condition will display.

MAIN Function Key – Pressing this key will bring up the MAIN screen.

Audible Alarm Indication – The Monitor/Controller is equipped with audible

alarm feature. The audible alarm will beep and the red LED light will come on

when any alarm condition occurred. The Ù symbol will appear when the audible

alarm is enabled, see Special Function Key’s definition below to activate and

deactivate the audible alarm. There are two audible alarm sound lever; high and

low. When the audible alarm is enabled and alarm condition occurs, high-level

beep will be generated. The method of acknowledging the alarm is to press the

ALARM function from the MAIN screen, the alarm beep will switch to low level. If

any new alarms occur, the high-level beep will be generated to notify the user of

the new alarm.

z

z

{

{

Chemtrac Systems, Inc.

Page 23

Page 25

{

When any alarm is triggered, a +24 Vdc signal will be present on the Monitor’s digital

alarm output terminals. This signal can be connected to a SCADA/DCS system to alert

the operators to an Alarm condition. In lieu of a +24VDC signal, an optional solid state

relay output is available (must be specified with order).

After being properly adjusted by the operator to match up with the upper and lower SCV

readings that typically correlate to the acceptable window of process performance, the

Hi and Lo Alarms alert the operator as to whether the SCV has exceeded acceptable

limits. A Lo Alarm signify an underfeed of chemical (even possible loss of chemical

feed) and a Hi Alarm signify an overfeed.

3.2.5 SCM2500SRD Flush Control Menu

This flush feature is an option that is available for the SCM2500XRD, see Section 3.3.7

for detail description.

3.3 SCC3500XRD READOUT, MENUS, AND CONTROLS

The menu system for the SCC3500XRD is simple to navigate; below you will find the

different screens accessible through the function keys (SETUP, ALARM, FLUSH, and

CTRL). The menu screen shows with Flush option.

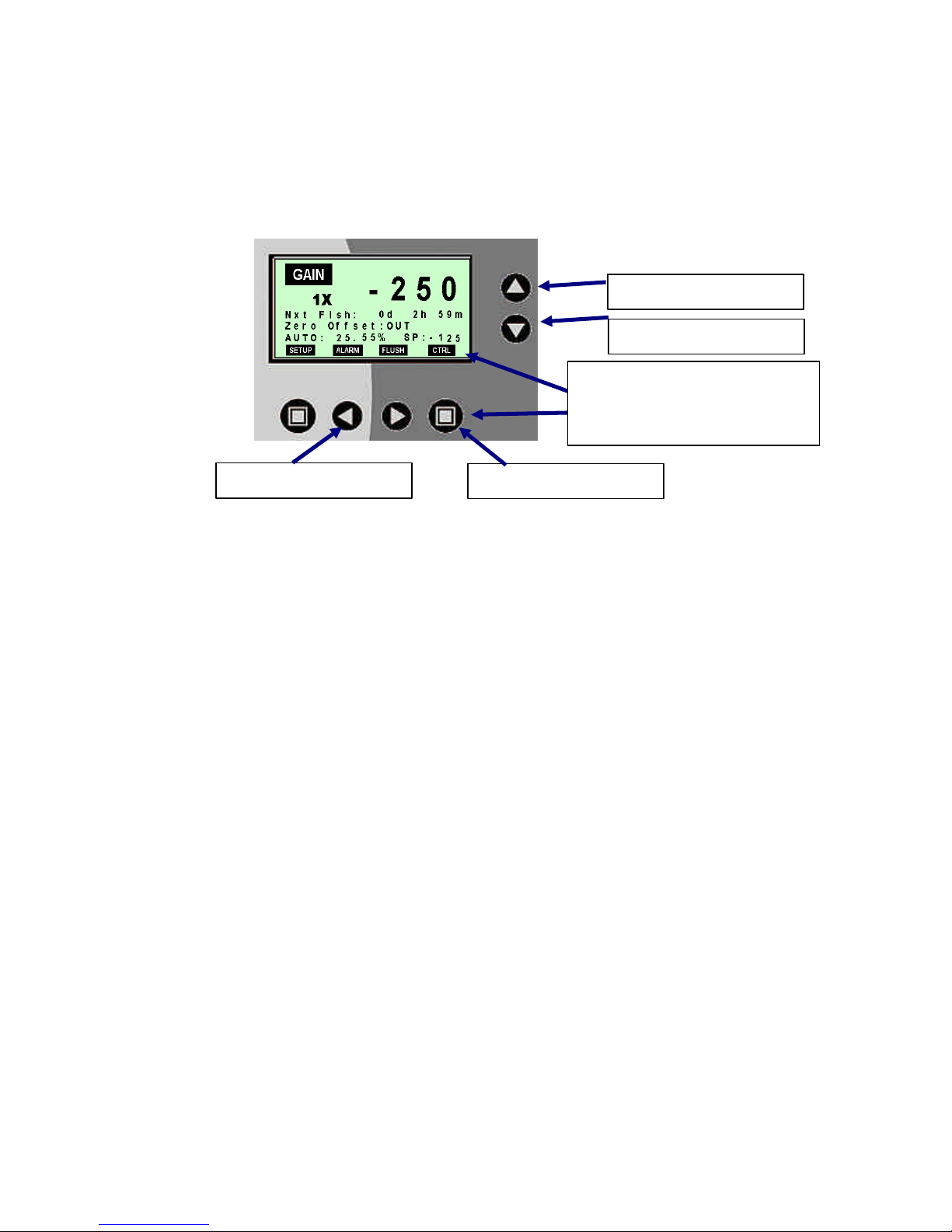

3.3.1 SCC3500 Main Screen

Special Function Key – The audible alarm can be toggled ON and OFF by

pressing both q and p keys. The Ù symbol will only appear when the audible

alarm is enabled. Once the audible alarm is disabled, the only way to enable is

to toggle with this Special Function key.

u

u

u

v

w {

{

{

x

y

z

Definitions

Streaming Current Value (SCV) ranges from –1000 to +1000

u

Gain, signal amplification factor, adjustable from 1X to 20X

v

Next Flushing Cycle (optional): If the unit include sensor flush feature, the

w

menu display the time when the next flush will occur in days, hours, and minutes.

x

Offset: OUT Offset condition OUT, actual SCV is display

Offset Value: -1000 to +1000

Zero Offset Conditions

Offset: IN Offset condition IN, adjusted SCV is displayed and the actual

SCV value will be display to the right of OUT.

Chemtrac Systems, Inc.

Page 24

Page 26

The Offset function is used to automatically zero the current reading. Once an

optimum chemical dosage has been obtained, the user can null the reading so

that the setpoint becomes referenced to zero for easier interpretation (see Setup

Screen Menu).

Coagulant Pump Control Mode

y

Mode: AUTO or MAN

PID Control Output: 0-100.00%

SP (Setpoint): SCV control setpoint (-1000 to +1000)

z

SETUP – SCV Setup Menu

ALARM – Alarms Status

FLUSH – Sensor Flush Control Menu

CTRL – Coagulant Pump Control and Flow Based Control Menu

Function Keys – There are four main menu selections across the bottom for the

four buttons below. The four menus are:

Pressing one of the keys directly below these menu selections accesses the

functions within that menu.

{ Special Function Key – For the coagulant pump control mode, the control mode

can be toggled between AUTO and MAN by pressing both q and p keys at the

same time. When AUTO is present, the instrument is operating in automatic

mode, sending a control signal to the coagulant pump. When MAN is present,

the instrument is operating in manual mode, sending a control signal to the

coagulant pump, which corresponds, to the manual value. The manual control

value can be changed by the operator by pressing the p or q key, see Section

3.7 for more detail.

3.3.2 SCC3500XRD Setup Menus

From the MAIN screen, press SETUP function key, the SETUP screen will display.

Within the SETUP screen menu, the GAIN, OFFSET, SCV ALARMS, and SCV Filter

settings can be modified. The SETUP Menus are the same for SCM2500XRD and

SCC3500XRD see Sections 3.2.2 and 3.2.3 for detail descriptions.

Chemtrac Systems, Inc.

Page 25

Page 27

3.3.3 SCC3500XRD Alarm Status Menu

From the MAIN screen, press ALARM function key, the ALARM STATUS screen will

display. Within the ALARM STATUS menu you can view which Alarm has been

triggered, as well as, turn the Monitor/Controller’s audible alarm feature on and off.

u |

v }

w

x

y

z

{

Definitions:

u Diagnostic: Display sensor diagnostic alarm condition. When the sensor is in

diagnostic alarm, it will show ALARM, the green LED (Diag.) will also stop

blinking, and the Streaming Current value will show “---“. Most likely cause for a

diagnostic alarm is that the motor in the sensor is not turning. Check to ensure

the motor is turning. If the motor is turning, ensure the blade of crank is passing

cleanly through the opto-switch. If the blade is rubbing against the opto-switch,

make an adjustment by loosening the setscrew of the crank and sliding it over so

that the blade lines up in the middle of the opto-switch. If the blade was rubbing,

it will be necessary to use compressed air to remove any debris (dust) that may

be blocking the optics of the opto-switch. Finally, check the interconnect wiring if

no other cause can be found for the diagnostic alarm. A loose connection or a

terminal that is screwed down on the insulation of the wire instead of the wire

itself can cause the diagnostic alarm to activate.

v

w

x

y

z

{

|

SCV Lo (Low): The SCV Lo Alarm indicates that the SCV fall below the SCV Lo

Alarm threshold.

SCV Hi (Low): The SCV Hi Alarm indicates that the SCV rises above the SCV

Hi Alarm threshold.

Pump Output Lo (Low): The Pump Output Lo Alarm indicates that the pump

output has exceeded the lower Alarm threshold.

Pump Output Hi (High): The Pump Output Hi Alarm indicates that the pump

output has exceeded the upper Alarm threshold.

Dry Contact: Digital input status (normally open) indicates the state of digital

input. When digital input is close, the ALARM condition will display.

MAIN Function Key – Pressing this key will bring up the MAIN screen.

Audible Alarm Indication – The Monitor/Controller is equipped with audible

alarm feature. The audible alarm will beep and the red LED light will come on

when any alarm condition occurred. The Ù symbol will appear when the audible

alarm is enabled, see Special Function Key’s definition below to activate and

deactivate the audible alarm. There are two audible alarm sound lever; high and

low. When the audible alarm is enabled and alarm condition occurs, high-level

beep will be generated. The method of acknowledging the alarm is to press the

|

|

}

}

Chemtrac Systems, Inc.

Page 26

Page 28

ALARM function from the MAIN screen, the alarm beep will switch to low level. If

any new alarms occur, the high-level beep will be generated to notify the user of

the new alarm.

}

Special Function Key – The audible alarm can be toggled ON and OFF by

pressing both q and p keys. The Ù symbol will only appear when the audible

alarm is enabled. Once the audible alarm is disabled, the only way to enable is

to toggle with this Special Function key.

When any alarm is triggered, a +24 Vdc signal will be present on the Monitor’s

alarm terminals 13 (+) and 14 (-). This signal can be connected to a

SCADA/DCS system to alert the operators to an Alarm condition. In lieu of a

+24VDC signal, an optional solid-state relay output is available (must be

specified with order).

After being properly adjusted by the operator to match up with the upper and

lower Streaming Current readings that typically correlate to the acceptable

window of process performance, the Streaming Current Value (SCV) Hi and Lo

Alarms alert the operator as to whether the streaming current value has

exceeded acceptable limits. A Lo Alarm will signify an underfeed of chemical

(even possible loss of chemical feed) and a Hi Alarm will signify an overfeed.

3.3.4 SCC3500XRD Pump Control (1) Menu

From the MAIN screen, press CTRL function key, the PUMP CONTROL (1) Menu

screen will display. There are PUMP CONTROL (1), PUMP CONTROL (2), and FLOW

CONTROL (3) menus under CTRL function key. Use up or down arrow key to navigate

between menus. Within the PUMP CONTROL (1) Menu screen, the PID tuning

parameters can be adjusted.

u

v

w

x |

y

z

{

Definitions

u Pump Ctrl: The Controller’s pump output control has two mode of operation;

AUTO or Manual. In AUTO mode, the pump output percent will increased or

decreased automatically in response to deviations from the setpoint. In MAN

mode, the pump output percent can be increased or decreased manually by

setting the Man Output. The two mode can be toggle by pressing the p or q

key.

v Man Output: In MAN mode, the pump output percent % can be increased or

decreased by pressing the p or q key. The Man Output value can be changed

from 0 to 100% at 0.1% increment. This parameter is saved in non-volatile

memory. When running in Automatic mode, the Man Output setting is ignored.

However, when switching from AUTO to MAN, it is important to understand that

the Pump Output value will be changing from the value it was in MAN mode.

Chemtrac Systems, Inc.

Page 27

Page 29

Therefore, it is recommended to change the Man Output value to match the

AUTO pump output value prior to switching mode. Failing to do so can result in

a significant change in the pump output when switching from AUTO to MAN

control.

w SCV Setpoint: The SCV setpoint is the SCV value that the controller is

programmed to maintain when in AUTO mode. The SCV setpoint value can be

changed from -1000 to +1000 at one unit increment by pressing the p or q key,

see Section 3.7 for determine the optimum setting. To determine the setpoint,

the operator must first adjust the chemical feed manually until an optimum

dosage is reached. Once the optimum dosage has been reached, the operator

simply records the Streaming Current Value seen on the display and enters this

as the Setpoint value. It is important that the correct polarity (+/-) be entered

when programming the setpoint.

x Proportion Band: The Proportional Band setting determines the level of

response, or amount of change to the pump output, when the SCV deviates from

the setpoint. The Proportional Band value can be changed from 1 to 1000 at 1

unit increment by pressing the p or q key, see Section 3.7 for determine the

optimum setting.

y Integral Time: The Integral Time setting determines how much adjustment is

made to the pump output while the SCV is away from the setpoint. The Integral

Time value can be changed from 1 to 1000 at 1 unit increment by pressing the

p or q key, see Section 3.7 for determining the optimum setting.

z PID Rate: The PID Rate function serves to improve the controller’s response

when higher Proportional Band and Integral Time settings appear to be too

responsive for the application. The PID Rate setting is usually left at 1 for most

applications since proper setting of Proportional Band and Integral Time are

capable of providing proper response. Higher PID Rate settings will serve to

buffer the responsiveness of the controller. The PID Rate setting should not

exceed 10. The PID Rate value can be changed from 1 to 20 at 1 unit increment

by pressing the p or q key, see Section 3.7 for determining the optimum

setting.

{ MAIN Function Key: Pressing this key will ignore any setting modifications on

this screen and brings up the MAIN screen.

| SAVE Function Key: Pressing this key will save current setting modifications

and brings up the MAIN screen.

Chemtrac Systems, Inc.

Page 28

Page 30

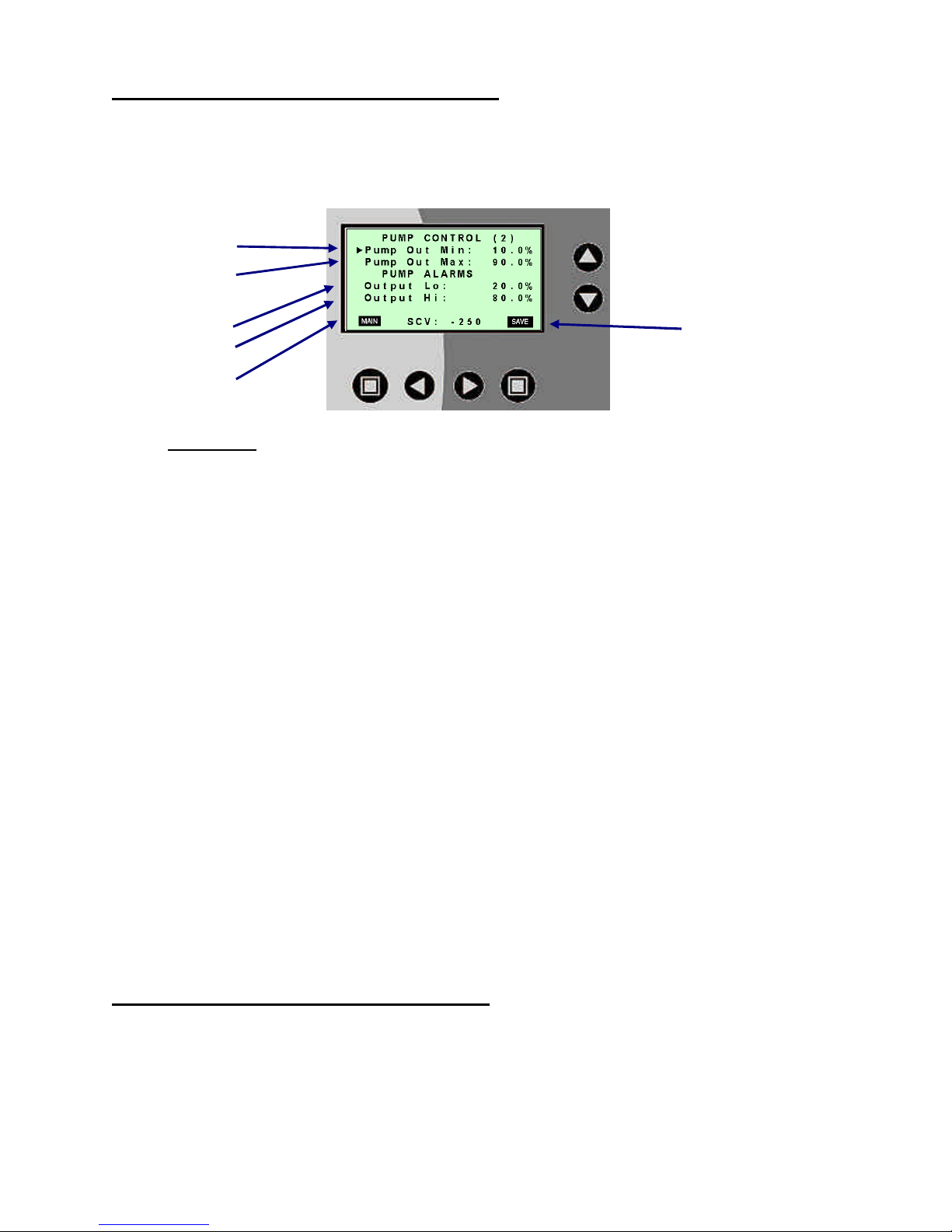

3.3.5 SCC3500XRD Pump Control (2) Menu

From the PUMP CONTROL (1) menu screen, continue pressing the down arrow key

until PUMP CONTROL (2) menu screen display. PUMP CONTROL (2) menu screen is

a continuation of the Pump Control (1) menu screen.

u

v

w z

x

y

Definitions

u Pump Out Min: The pump output limit define the minimum value of the pump

control output signal. The minimum percent (%) value can be increased or

decreased by pressing the p or q key. The minimum percent (%) value can be

changed from 0 to 100% at 0.1% increment.

v Pump Out Max: The pump output limit define the maximum value of the pump

control output signal. The maximum percent (%) value can be increased or

decreased by pressing the p or q key. The maximum percent (%) value can be

changed from 0 to 100% at 0.1% increment.

w Output Lo: The pump output limit define the low alarm value of the pump

control output signal. The low alarm percent (%) value can be increased or

decreased by pressing the p or q key. The low alarm percent (%) value can be

changed from 0 to 100% at 0.1% increment. When the pump control output

signal fall below the low alarm value, alarm condition will occur.

x Output Hi: The pump output limit define the high alarm value of the pump

control output signal. The low alarm percent (%) value can be increased or

decreased by pressing the p or q key. The high alarm percent (%) value can

be changed from 0 to 100% at 0.1% increment. When the pump control output

signal rise above the high alarm value, alarm condition will occur.

y MAIN Function Key: Pressing this key will ignore any setting modifications on

this screen and brings up the MAIN screen.

z SAVE Function Key: Pressing this key will save current setting modifications

and brings up the MAIN screen.

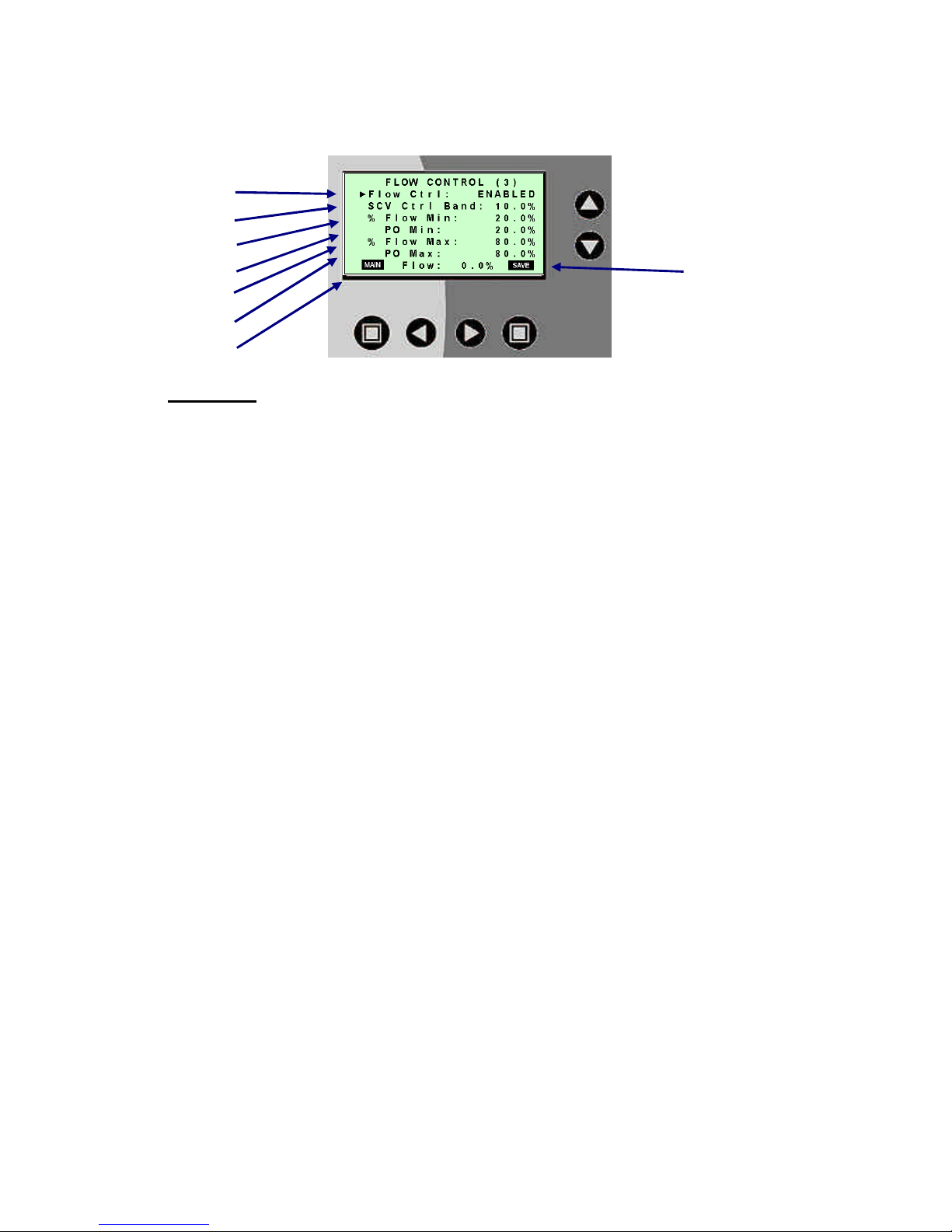

3.3.6 SCC3500XRD Flow Control (3) Menu

From the PUMP CONTROL (2) menu screen, continue pressing the down arrow key

until FLOW CONTROL (3) menu screen display. FLOW CONTROL (3) menu screen is

a continuation of the Pump Control (2) menu screen.

When ENABLED, the FLOW CONTROL function allows the user to control the chemical

feed based on the process FLOW rate and the Streaming Current Value PID control

Chemtrac Systems, Inc.

Page 29

Page 31

output. The flow control is a proportional pump output control base on the process flow

rate. The proportional pump output control is set by using the four parameters; Flow

Min, Pump Output Min, Flow Max, and Pump Output Max.

u

v

w

x |

y

z

{

Definitions

u Flow Ctrl: The flow control modes are ENABLED or DISABLED. When the

flow control is ENABLED, pump output percent % will increased or decreased

automatically in response to process flow changes and SCV deviation from the

setpoint. When the flow control is DISABLED, the pump output percent will

increased or decreased automatically in response PID loop control only. By

pressing either p or q key to switch between ENABLED or DISABLED control

mode.

v

w

x

y

z

{

SCV Control Band: When flow control is ENABLED, the proportional pump

output flow control will be adjusted (up and down) by the PID loop control. SCV

control band value (percent) set up how much the pump output control will be

effected by the PID loop control. For example, the SCV control band is set to

5% and the proportional pump output flow control is at 55%, the PID loop control

can adjust the pump output control up to 60% maximum and down to 50%

minimum. The SCV control band percent (%) value can be increased or

decreased by pressing the p or q key. The SCV control band percent (%)

value can be changed from 0 to 100% at 0.1% increment.

Flow Min: Minimum process flow in percent set for the produce the minimum

pump control output for the parameter below (Pump Output Min). The percent

(%) value can be increased or decreased by pressing the p or q key. The

percent (%) value can be changed from 0 to 100% at 0.1% increment.

Pump Output Min: Pump control output for the minimum process flow set

above (Flow Min). The percent (%) value can be increased or decreased by

pressing the p or q key. The percent (%) value can be changed from 0 to

100% at 0.1% increment.

Flow Max: Maximum process flow in percent set to produce the maximum

pump control output for the parameter below (Pump Output Max). The percent

(%) value can be increased or decreased by pressing the p or q key. The

percent (%) value can be changed from 0 to 100% at 0.1% increment.

Pump Output Max: Pump control output for the maximum process flow set

above (Flow Max). The percent (%) value can be increased or decreased by

pressing the p or q key. The percent (%) value can be changed from 0 to

100% at 0.1% increment.

MAIN Function Key: Pressing this key will ignore any setting modifications on

this screen and brings up the MAIN screen.

Chemtrac Systems, Inc.

Page 30

Page 32

|

SAVE Function Key: Pressing this key will save current setting modifications

and brings up the MAIN screen.

3.3.7 SCC3500XRD Flush Control Menu

From the MAIN screen, press FLUSH function key, the FLUSH CTRL MENU screen will

display. The goal of the sensor flush is to minimize the need for operator involvement

for maintenance purposes. This feature greatly enhances the reliable operation of the

Streaming Current Monitor. Within the FLUSH CTRL MENU screen, the flush

parameter settings can be modified.

Sensor Flush is only available with the optional Sensor Maintenance Module or the

Dura-Trac Flush feature.

u

v

w

x }

y

z

{ |

Definitions

u

v

w

Auto Flush: The SMM or Dura-Trac with Flush runs an automatic

flushing/cleaning sequence and will continue to flush according to the flush

parameter settings. The Auto Flush can be set to ENABLED or DISABLED.

When it is in ENABLED mode, the Monitor/Controller will begin flushing

based on Flush time value setting. When it is in DISABLED mode, the

flushing will be de-activated.

Flush Time: The flush time period setting determines how often the flushing

will take place when the Auto Flush is set to ENABLED. There are two

parameters on this menu line that can be modified; number (1 to 99 at 1 unit

increment) and number’s unit (DAY, HRS, or MIN). To modify the first

parameter setting (number), press the u key to gain access to the parameter

and then press the p or q key to scroll through the parameter range. To

modify the next parameter setting (number’s unit), press the u key to gain

access to the parameter and then press the p or q key to scroll through the

parameter range. When finish, press the t twice to get to the next menu

line.

Flush Period: The flush period setting determines the duration of water

flush to the sensor. With each flushing sequence, there are actually two

flushes performed. One at the beginning of the flush cycle (before the wash)

and one after the wash. The Flush setting determines the duration of each of

these flushes. So that, if Flush is set for 30 sec., the actual total time of flush

duration will be 60 seconds (30 seconds for each flush). The value can be

increased or decreased by pressing the p or q key. The value can be

changed from 1 to 99 at 1 second increment.

Chemtrac Systems, Inc.

Page 31

Page 33

x

y

z

{

|

}

Figure 11 shows the timing diagram of the Sensor Flush.

Chemical Period: The Chemical period setting determines the duration of

the chemical pump on time. It is recommended to use default value of 8

seconds. Excessively long chemical period (or too highly of a concentrated

chemical like Acid) can damage the probe. The value can be increased or

decreased by pressing the p or q key. The value can be changed from 1

to 20 at 1second increment.

Wash Period: The Wash period setting is only applicable for the SMM. For

the Dura-Trac with flush option, this setting should be left at 30 sec. The

Wash Period setting determines the duration of the sensor’s chemical

washing. Harder to remove scale or deposits will require longer Wash times.

It is recommended to only use a Wash duration that is no longer than

required to remove scale/deposits. Excessively long Wash durations (or too

highly of a concentrated chemical like Acid) can damage the probe. The

value can be increased or decreased by pressing the p or q key. The value

can be changed from 1 to 99 at 1second increment.

Hold Period: The Hold period setting determines how long the monitor’s

output will be held stable (or frozen at last output value before the flush) after

the flushing is finished. Flushing will cause the actual monitor reading to

fluctuate, thus it would adversely affect an automatic chemical feed control

program running through a Supervisory Control and Data Acquisition

(SCADA) or Distributed Control Systems (DCS). For this reason, the Hold

feature has been provided and must be properly set to avoid the flushing

sequence from interfering with Automatic Chemical feed control. The Output

of the monitor is automatically held stable during the flush, however, the

operator must determine the Hold duration after the flush is finished. To

determine the proper Hold setting, record the streaming current value before

the flush starts and then time how long it takes for the monitor to reach the

previously recorded reading after the flush is completed (this must be done

while the monitor is online with treated water passing through the sensor).

The simplest way of doing this will be to record the reading and then change

the Man. Flush from “Off” to “On” as this will activate the flush sequence. If it

takes 30 seconds for the reading to stabilize to the previously recorded

reading, then set the Hold setting for 1 minute. If it takes 50 seconds, then it

is recommended to set the Hold for 2 minutes. The value can be increased

or decreased by pressing the p or q key. The value can be changed from 1

to 99 at 1 minute increment.

MAIN Function Key: Pressing this key will ignore any setting modifications

on this screen and brings up the MAIN screen.

FLUSH Function Key: Pressing this key will activate a one-time manual

flush. This can be done at anytime regardless of the Auto Flush mode.

SAVE Function Key – Pressing this key will save current setting

modifications and brings up the MAIN screen.

Chemtrac Systems, Inc.

Page 32

Page 34

PUMP OUTPUT HOLD

SAMPLE ISOLATION

SENSOR FLUSH

AND RINSE

CHEMICAL PUMP

ON

OFF

ON

OFF

ON

OFF

ON

OFF

HOLD PERIOD

RINSEFLUSH

WASH PERIOD

TIME (SECONDS)

FIGURE 11. Automatic Flush Timing Diagram

NOTES

R Sample Isolation and Chemical Wash is only available with the optional SMM.

The Dura-Trac with flush option does not include the sample isolation or chemical

pump feature; however, there will still be a delay between sensor flush and rinse.

3.4 SYSTEM OPERATION

After sample flow is established and power has been applied to the sensor and

streaming current monitor, allow 10-15 minutes or longer for the reading to stabilize.

Stable conditions differ from plant to plant. The reading may fluctuate 10 to 20 units,

even under stable conditions due to the chemical not being thoroughly mixed. If

readings fluctuate widely, refer to Troubleshooting Guide. The monitor’s reading may

be negative, zero, or positive. The monitor is simply indicating the streaming current

value of the sample. In most applications, the reading will be slightly negative (anionic).

After the reading has had ample time to stabilize, adjust the chemical dosage in normal

increments to test the response of the monitor. For model SCC3500XRD, enter the

Control menu to manually adjust chemical feed. For each dosage change, the reading

should respond by changing 20 to 50 SCV units. If the response is less than 20 units,

increase the gain. Likewise, if the response is greater than 50 units, it is recommended

to decrease the gain (especially if the monitor is to be used for automatic chemical feed

control).

Next, a test should be performed to determine the Raw SCV reading. This will help

determine the LO SCV Alarm setting and give a better understanding of instrument

response. To determine the Raw SCV reading, shut off sample flow to the sensor and

turn the outlet fitting up. Pour a sample of raw untreated water into the sensor and allow

the reading to stabilize and then record the reading. This reading should serve as an

absolute alarm value, which if measured by the monitor will indicate a loss of chemical

feed. It is recommended to set the Lo SCV Alarm value (see Alarm setup menu)

between the Raw SCV measurement and the setpoint value. Further testing will help to

Chemtrac Systems, Inc.

Page 33

Page 35

determine the best ideal alarm value. The HI Alarm value should be set above the

setpoint value and at a point where testing shows an unacceptable amount of overfeed.

After verifying proper response, the next step should be to optimize the process to

establish a SCV setpoint. The SCV setpoint can then be zero’d, or offset, so that the

setpoint will be adjusted to a reading of zero (0). This is done by entering the Setup

menu and changing the Offset mode to “IN”. Offsetting the SCV is not necessary for

normal monitor operation as it is only provided so that an easier reference of zero can

be used for monitoring changes in the process. For example, if the true SCV setpoint

reading was –150, and the user offset that reading to equal zero (0), if chemical dosage

was decreased the reading may go from 0 to –50. If the reading had not been zero’d,

then the true SCV would have gone from –150 to –200 (a –50 unit change). Once the

setpoint has been zero’d, it is easier to determine whether chemical is being under or

overdosed since going negative (anionic) from 0 would be an under-dose and going

positive (cationic) would be an overdose. A setpoint of zero (0) is also easier for

multiple operators (night and day shift) to remember. Since the setpoint will change

seasonally, adjusting the setpoint so that it equals zero (0) helps to avoid confusion.

A common mistake made with the monitor’s offset function is that it has been used to rezero the reading as it drifts from the previously offset reading of zero. Once the process

has been optimized and the Streaming Current Value has been zero’d at that point, it is

no longer necessary or correct to re-zero the reading. If the reading changes from the

setpoint of zero (or the true SCV setpoint if the offset is out), the chemical dosage

should be adjusted to bring the reading back to the setpoint and not the offset function.

Eventually, a new setpoint might need to be established due to seasonal changes or

large excursions in turbidity, but under normal conditions, the setpoint should not be

changed on a daily or even weekly basis. It is recommended to use the monitor for a

few weeks in the Offset Out mode to become familiar with the operation and response

of the unit.

3.5 TREATMENT OPTIMIZATION PROCEDURE

The treatment optimization process should be done slowly and stepwise. Assuming that

the plant is producing acceptable water with present chemical dosages, trim

approximately 10%, wait for the reading to stabilize, and record the reading as the

setpoint. You may need to change GAIN setting to increase magnitude of response. If

the settled and finished water quality is still acceptable at the reduced dosages, trim

another increment, wait for the reading to stabilize, and record the reading as the new

setpoint. Continue this process, being sure to wait long enough each time to see the full

effect of the chemical feed changes on the process (i.e. settled water turbidity,

appearance of floc). In between these dosage changes it will be necessary to maintain

the setpoint. Failure to maintain the setpoint while trying to reach a lower dosage level

could result in under dosing the chemical if turbidity starts to increase. By maintaining

the setpoint, the chemical dosage is kept in check with process changes (i.e. turbidity,

flow rates).

If the Offset function is being used, re-zero the monitor reading as described in section

3.3 after each reduction in chemical feed. If a cationic coagulant is being used, the

streaming current value will become more negative with each reduction in dosage. The

"optimum setpoint" is obtained when a minimum dosage of coagulant is being fed and

produces desired results for the particular treatment process. This setpoint will remain

very close to the same reading even when raw water turbidities increase or decrease.

Simply adjust the coagulant dosage to maintain this setpoint reading on the monitor.

Chemtrac Systems, Inc.

Page 34

Page 36

This procedure may need to be repeated on a monthly to seasonal basis to ensure the

setpoint remains representative of optimum process performance.

NOTE - If automatic control is used, refer to Section 3.7 on Automatic Control.

3.6 MANUAL CONTROL USING CONTROLLER

Only available on model SCC3500XRD.

Make electrical connections between Streaming Current Controller and the chemical

feed pump. The AUTO or Manual control mode is indicated on the MAIN screen. To

switch between AUTO or Manual control mode can be done by pressing both p and q

keys from the MAIN screen. Once in Manual control mode, the pump control output

percentage can be increased or decreased by pressing the p or q key.

The AUTO or Manual control mode can also be change from the Pump Control (1)

menu. Once Pump Control (1) menu is display, move the text cursor on the far left hand

side of the screen (}) to “Pump Ctrl:” then press u the control text will blink. The

control mode can be set by pressing the pressing p or q key, this will toggle between

AUTO and MAN mode. Set the controller to MAN. Once completed, press t key then

press p or q key to get to next parameters on that screen. Next press q key to “Man

Output:” then press u the control number will blink. The percent (%) number will blink,

the manual chemical feed control value output can now be increased or decreased the

by pressing p or q key to the desire manual control value. When completed, press t

key to get to other parameters on that screen. The SAVE Function Key must be

pressed to save current setting modifications and brings up the MAIN screen.

3.7 AUTOMATIC CONTROL

Only available on model SCC3500XRD.

Automatically controlling the treatment process with the Streaming Current Controller